Self-separation method and device for spatial error of superprecise revolution reference

A space error and error separation technology, which is applied in the field of self-separation of ultra-precision rotary reference space error, can solve the problems of increased axial size, increased error links, and inability to separate space rotation errors of cylindricity measuring instruments, etc., to achieve shortened axial Size, Simplified Error Separation Device and Effect of Error Separation Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

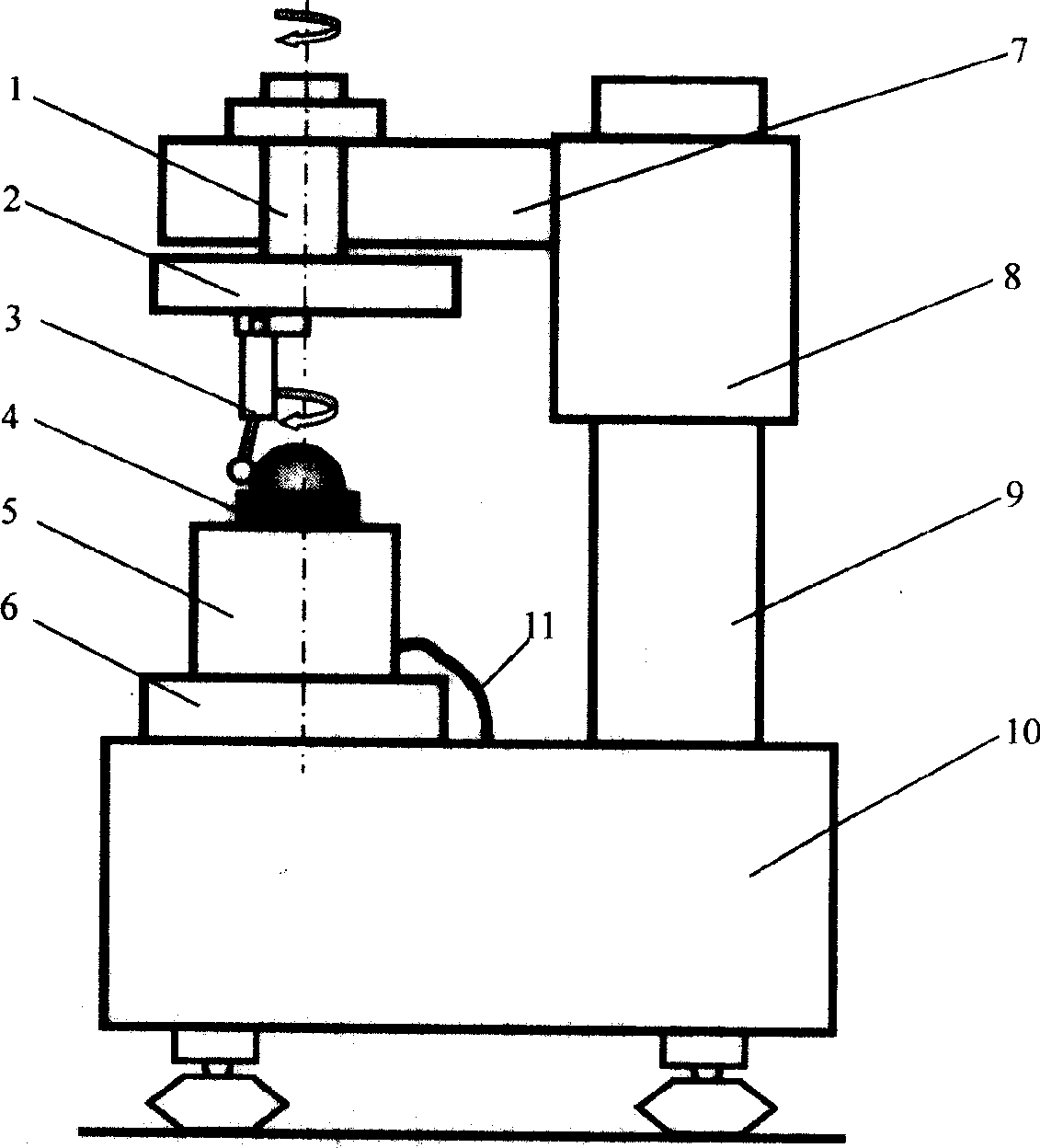

[0035] The structure and working principle of the ultra-precision rotary reference space error self-separation device of the present invention are described in detail in combination with the embodiments and accompanying drawings as follows:

[0036] Schematic diagram of the structure of an embodiment of the ultra-precision rotary reference space error self-separation device of the present invention. Such as Figure 7 As shown, it includes: a circular profile measurement sensor 3, a measured cylinder 4, a rotary table 13, an error separation turntable 14, the B end of the air bearing shaft system of the error separation turntable, an indexing angle (small angle) generating system 20, and an instrument Rotary spindle 15, indexing angle (small angle) detection system 25 (commonly used reflective sector grating and combined photoelectric receiver), conductive slip ring 17, motor drive system 18, angle measuring encoder 19, base 10, closing force Generator 23, threaded PZT 24 etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com