Patents

Literature

76 results about "Self-separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aircraft self-separation is the capability of an aircraft maintaining acceptably safe separation from other aircraft without following instructions or guidance from a referee agent for this purpose, such as air traffic control. In its simplest forms, it can be described by the concept of see and avoid, in the case of human-piloted aircraft, or sense and avoid, in the case of non-human piloted aircraft (such as UAVs). However, because of several factors such as weather, instrument flight rules and air traffic complexity, the Self-separation capability involves other elements and aspects such as rules of the air, communication technologies and protocols, air traffic management and others.

Automated flight control system for unmanned aerial vehicles

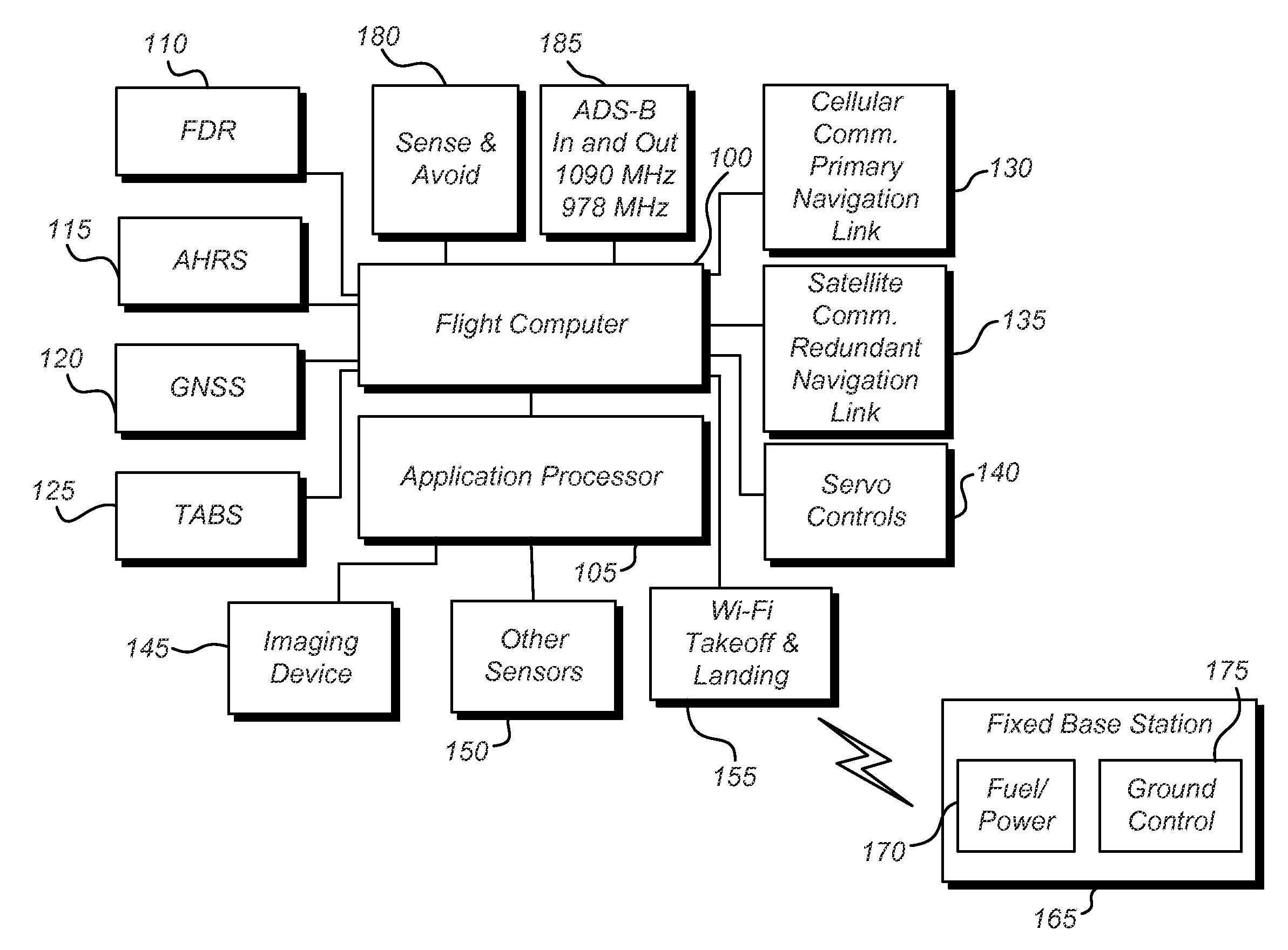

InactiveUS20160070261A1Avoid collisionRegistering/indicating working of vehiclesUnmanned aerial vehiclesAttitude and heading reference systemFlight computer

An automated flight control system for an unmanned aerial vehicle (UAV), comprising a flight computer for managing functions related to a flight of the UAV, an application processor for managing functions on the UAV not related to flight, a flight data recorder to record data related to a flight of the UAV, an attitude and heading reference system, a global navigation satellite system receiver, a self-separation module for communicating with another aircraft for the purpose of avoiding a collision, and a wireless communications module for communicating with the remote system, wherein the automated flight control system is capable of receiving operational instructions via the wireless communications module from the remote system.

Owner:APPAREO SYST

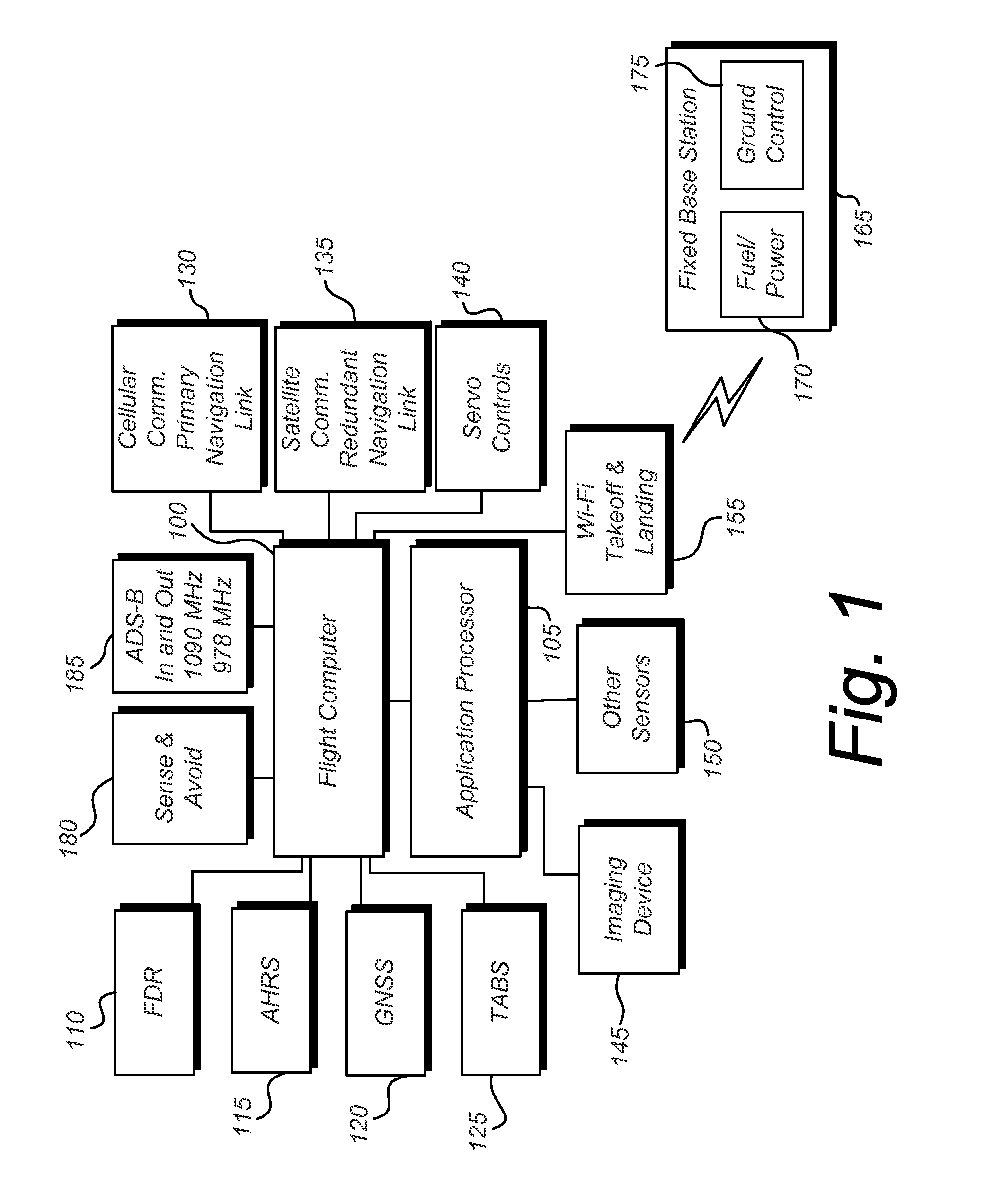

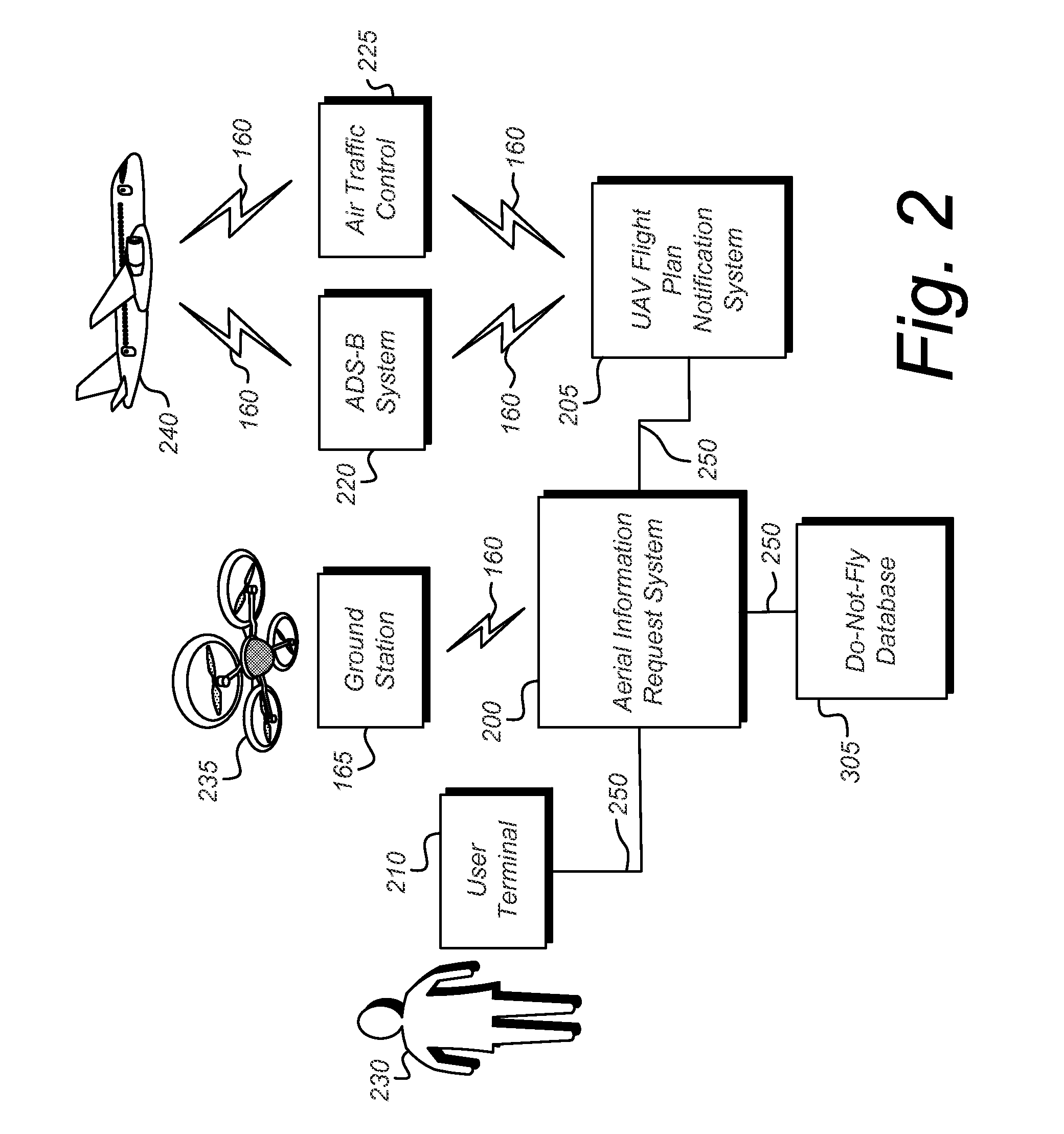

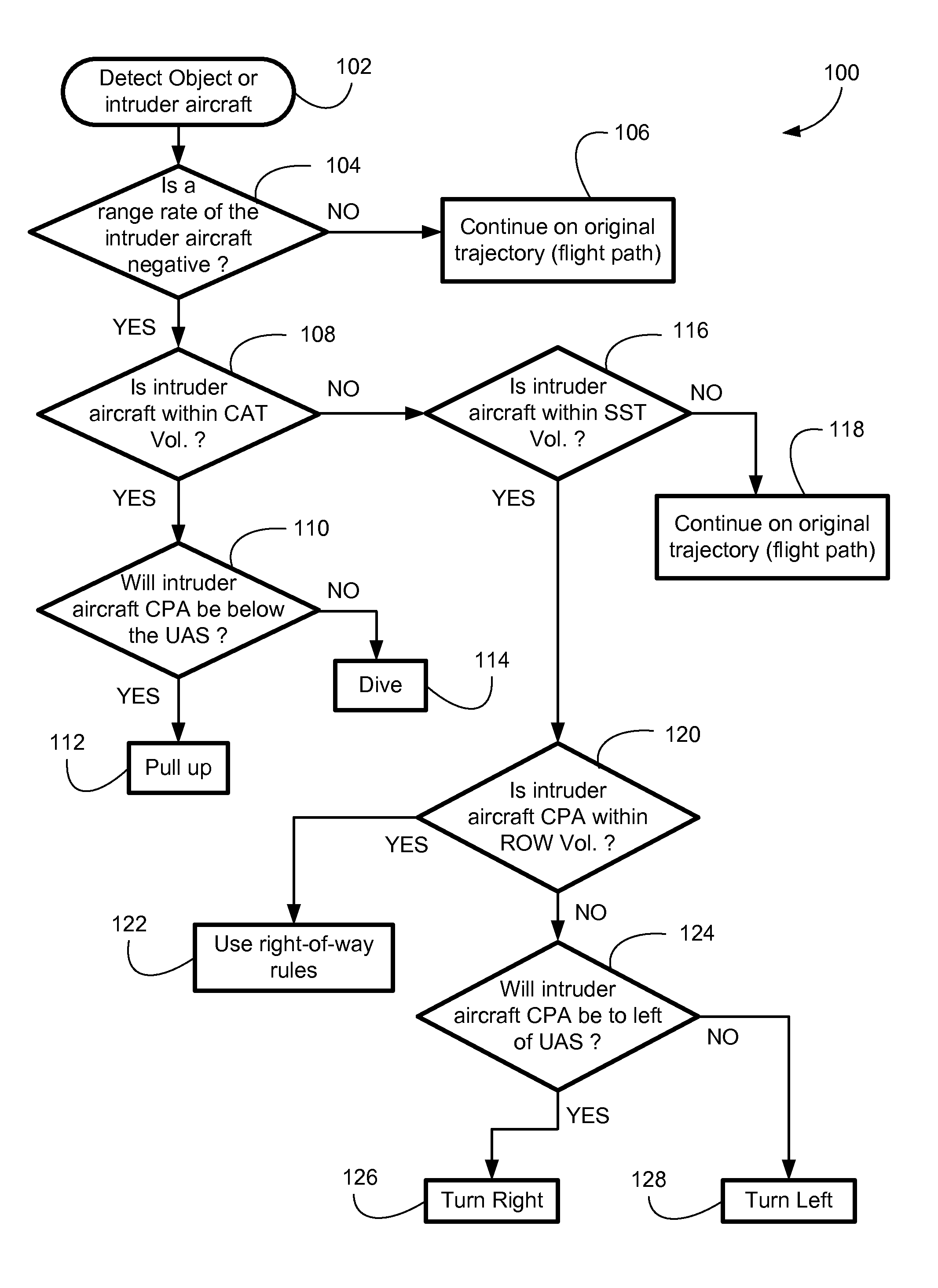

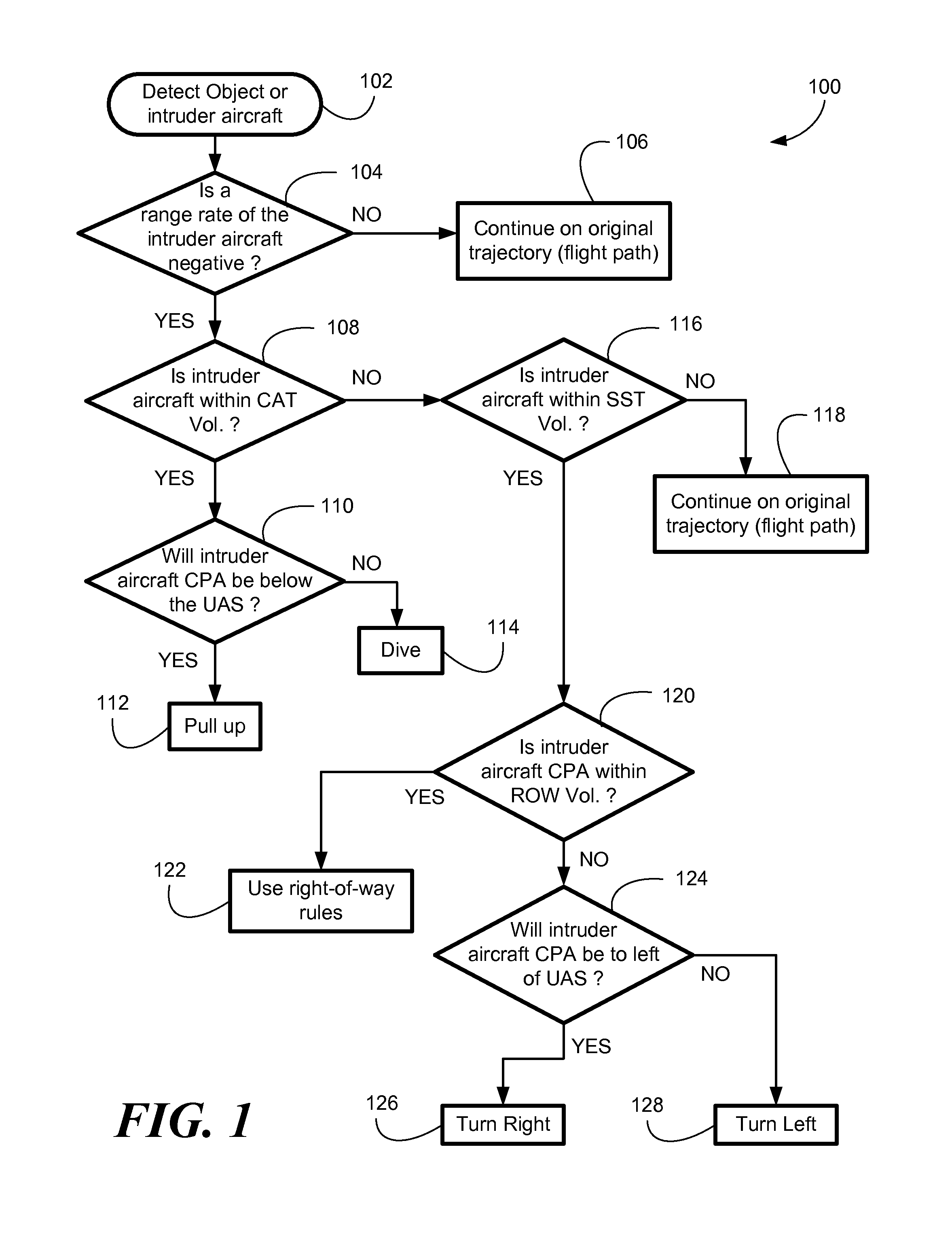

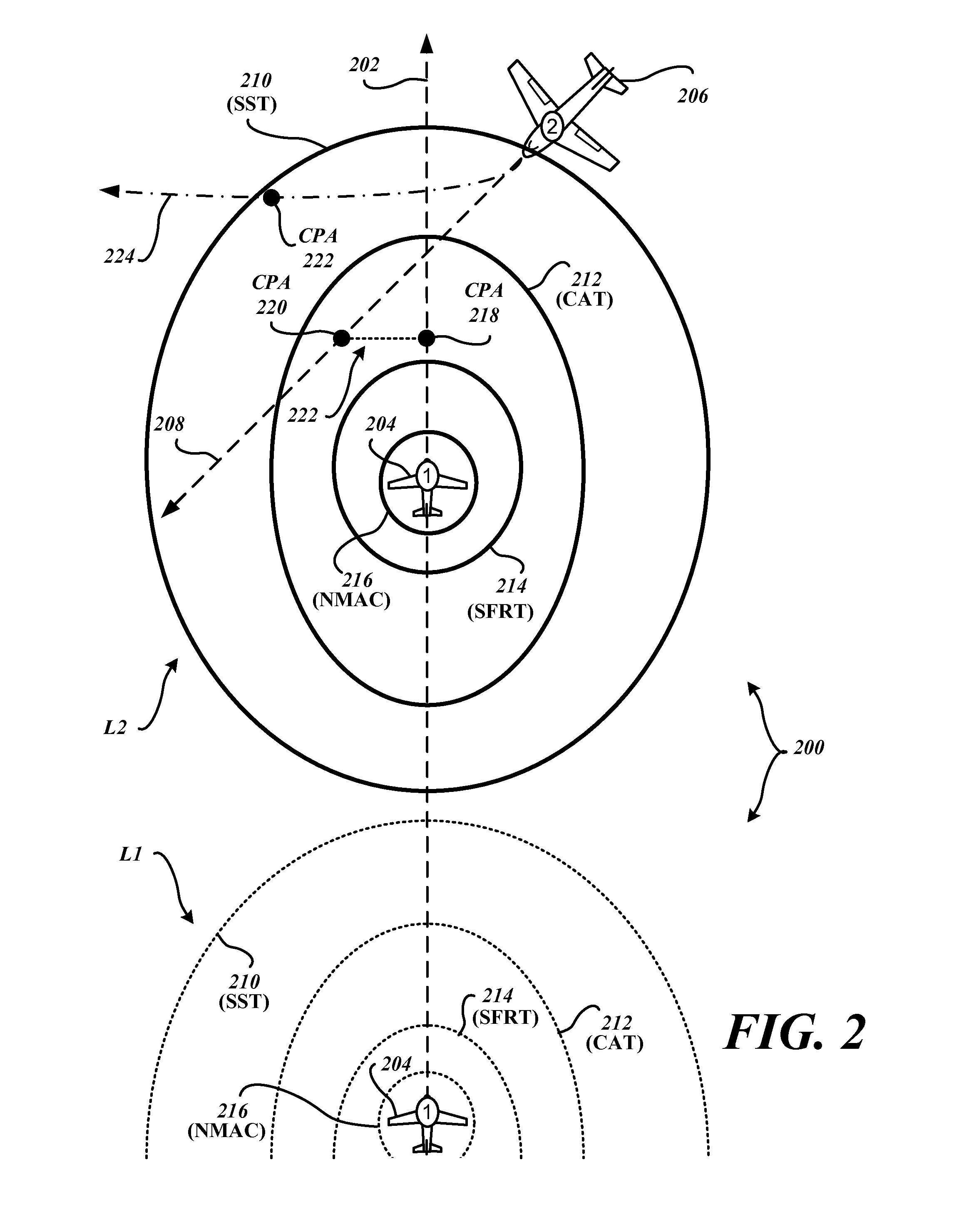

Systems and methods for unmanned aircraft system collision avoidance

ActiveUS20140249738A1Process safetyAnti-collision systemsPosition fixationCurrent velocityHandling system

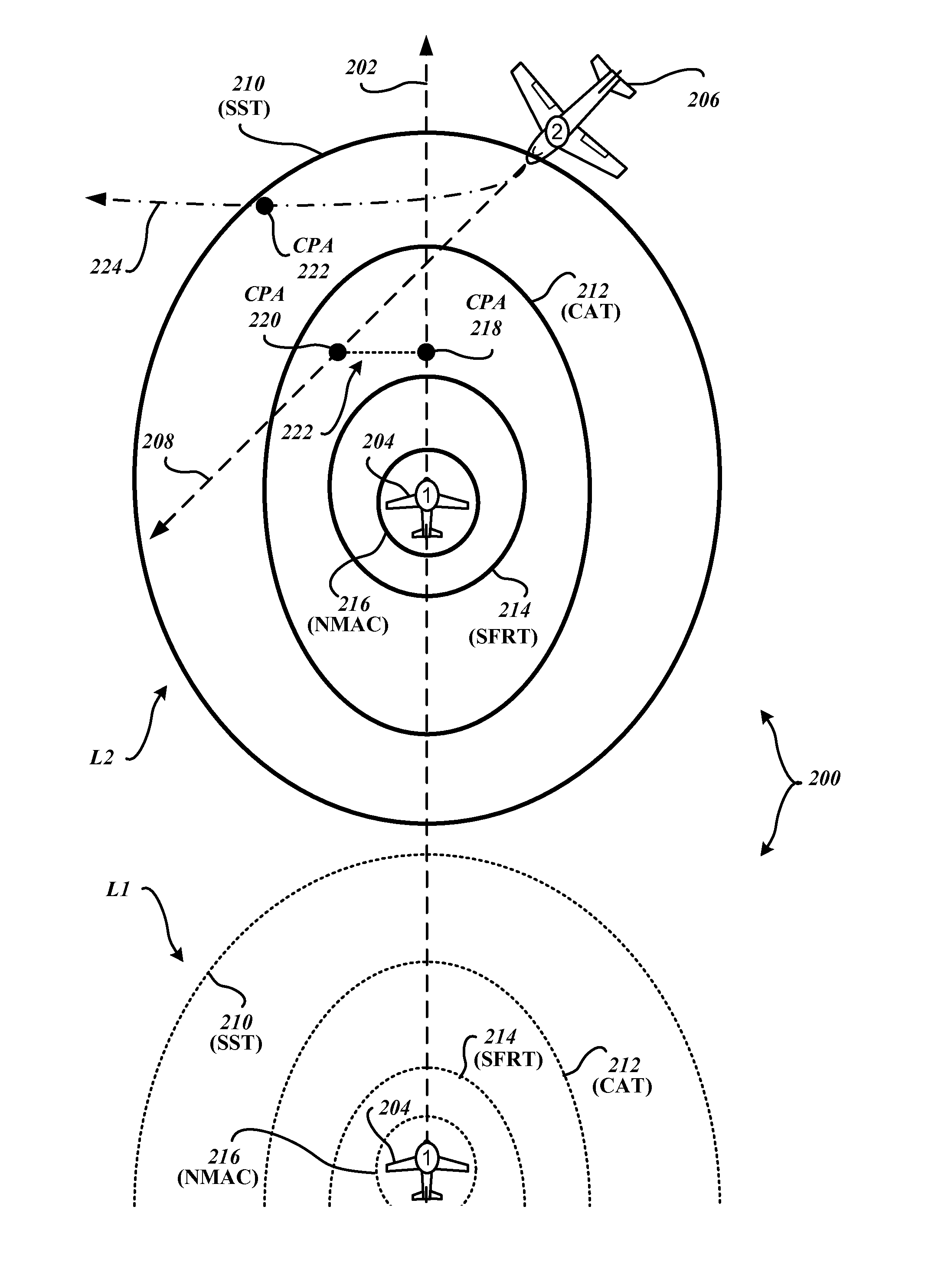

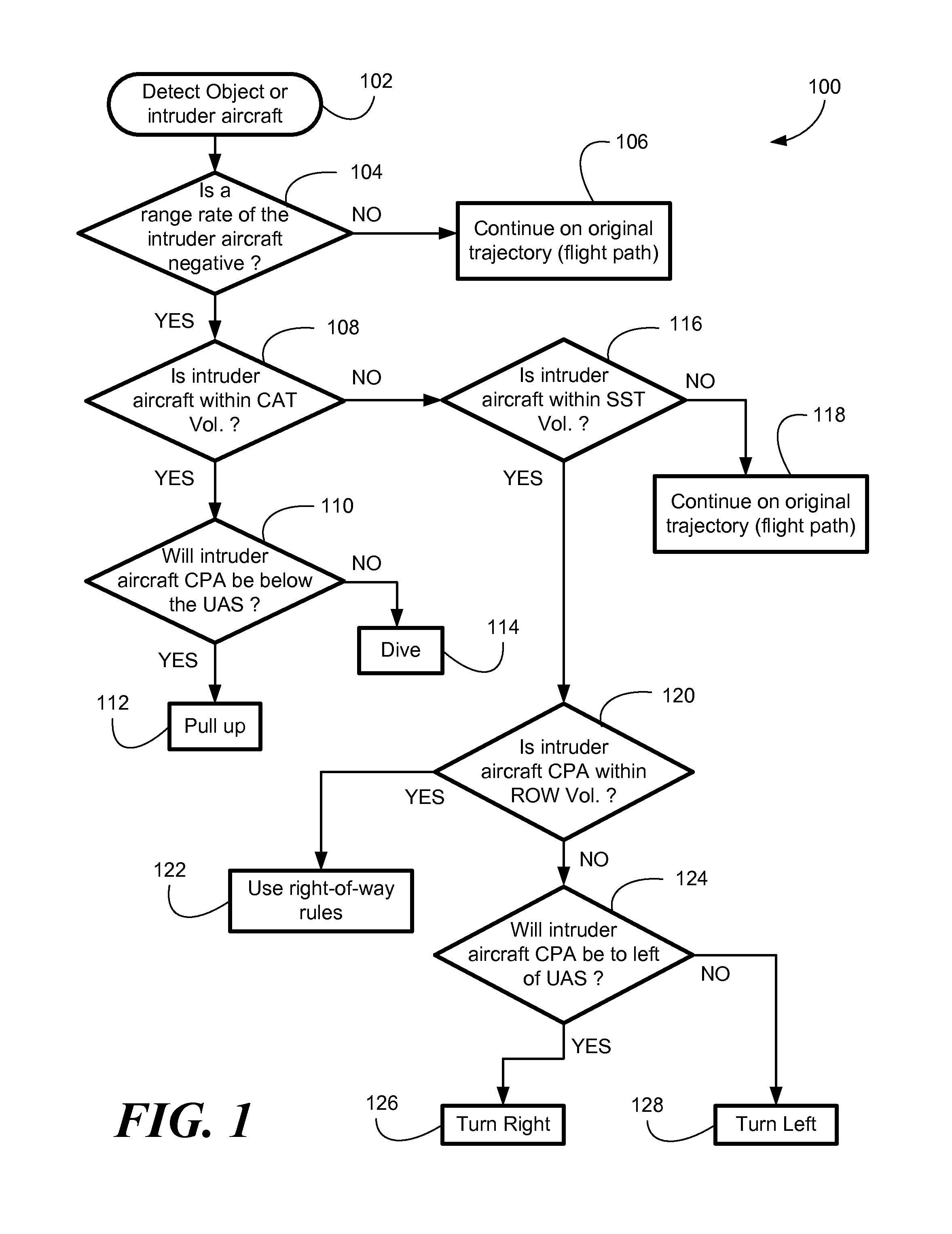

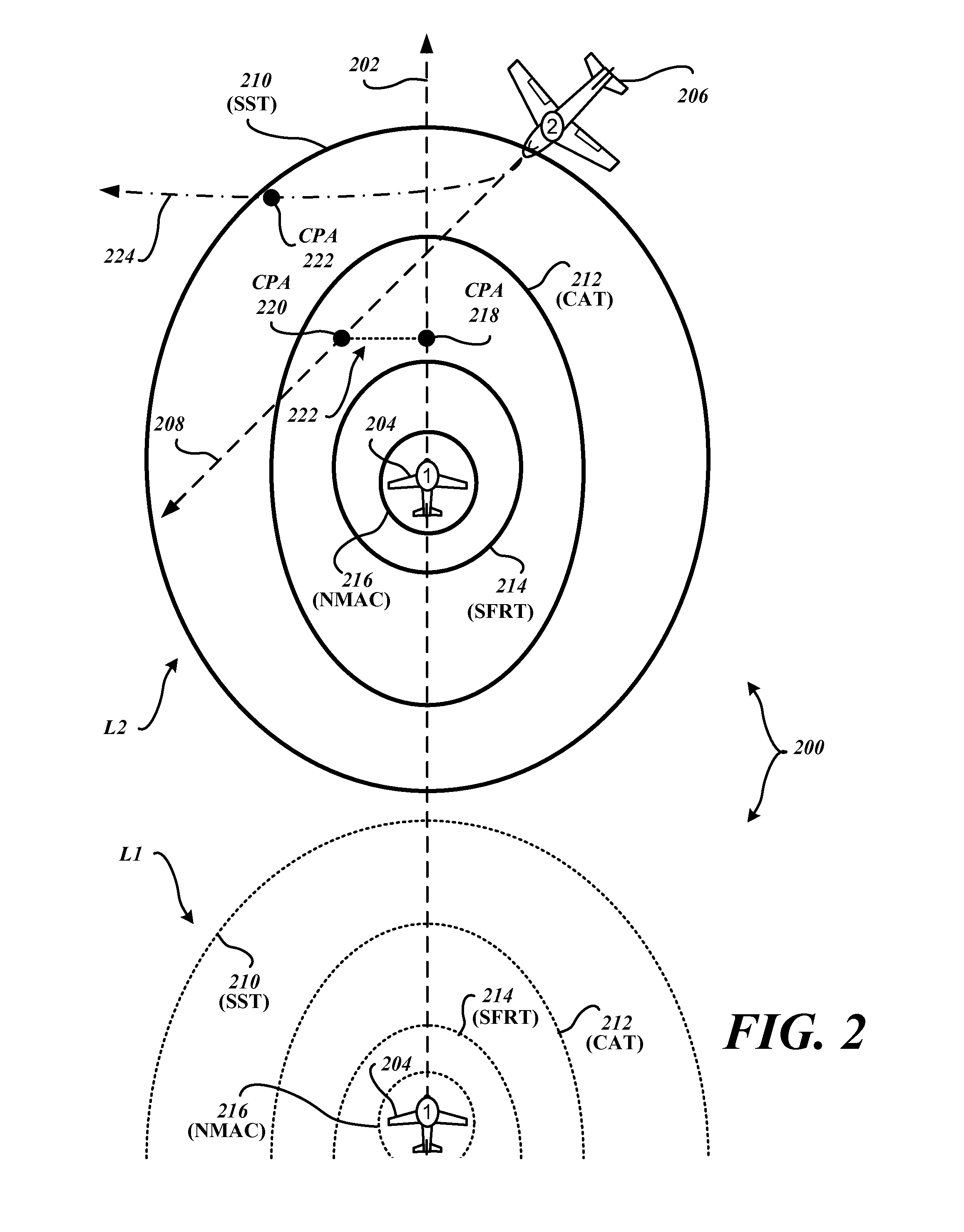

Systems and methods are operable maintain a proscribed Self Separation distance between an unmanned aircraft system (UAS) and an object. In an example system, consecutive intruder aircraft locations relative to corresponding locations of a self aircraft are determined, wherein the determining is based on current velocities of the intruder aircraft and the self aircraft, and wherein the determining is based on current flight paths of the intruder aircraft and the self aircraft. At least one evasive maneuver for the self aircraft is computed using a processing system based on the determined consecutive intruder aircraft locations relative to the corresponding locations of the self aircraft.

Owner:HONEYWELL INT INC

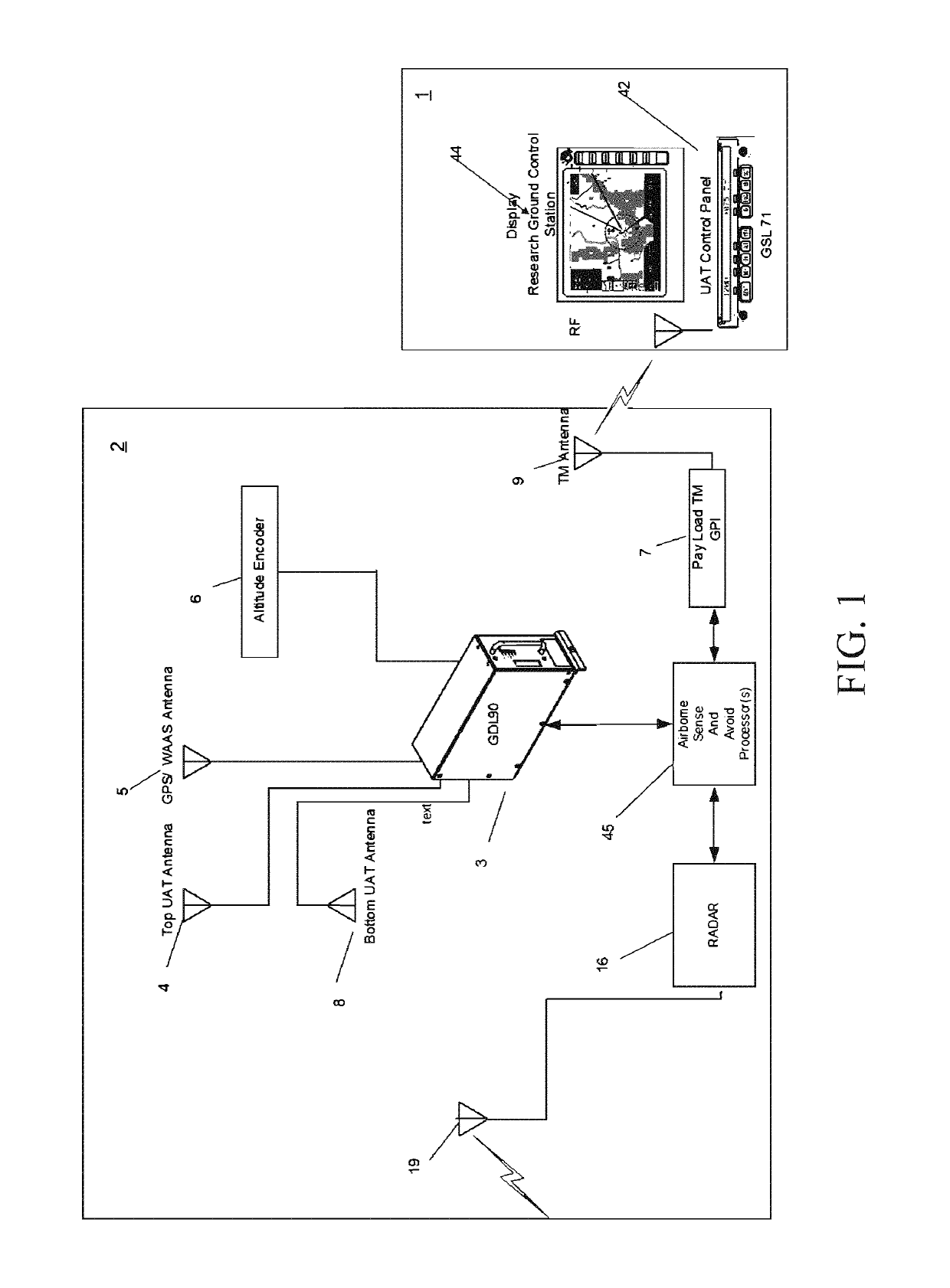

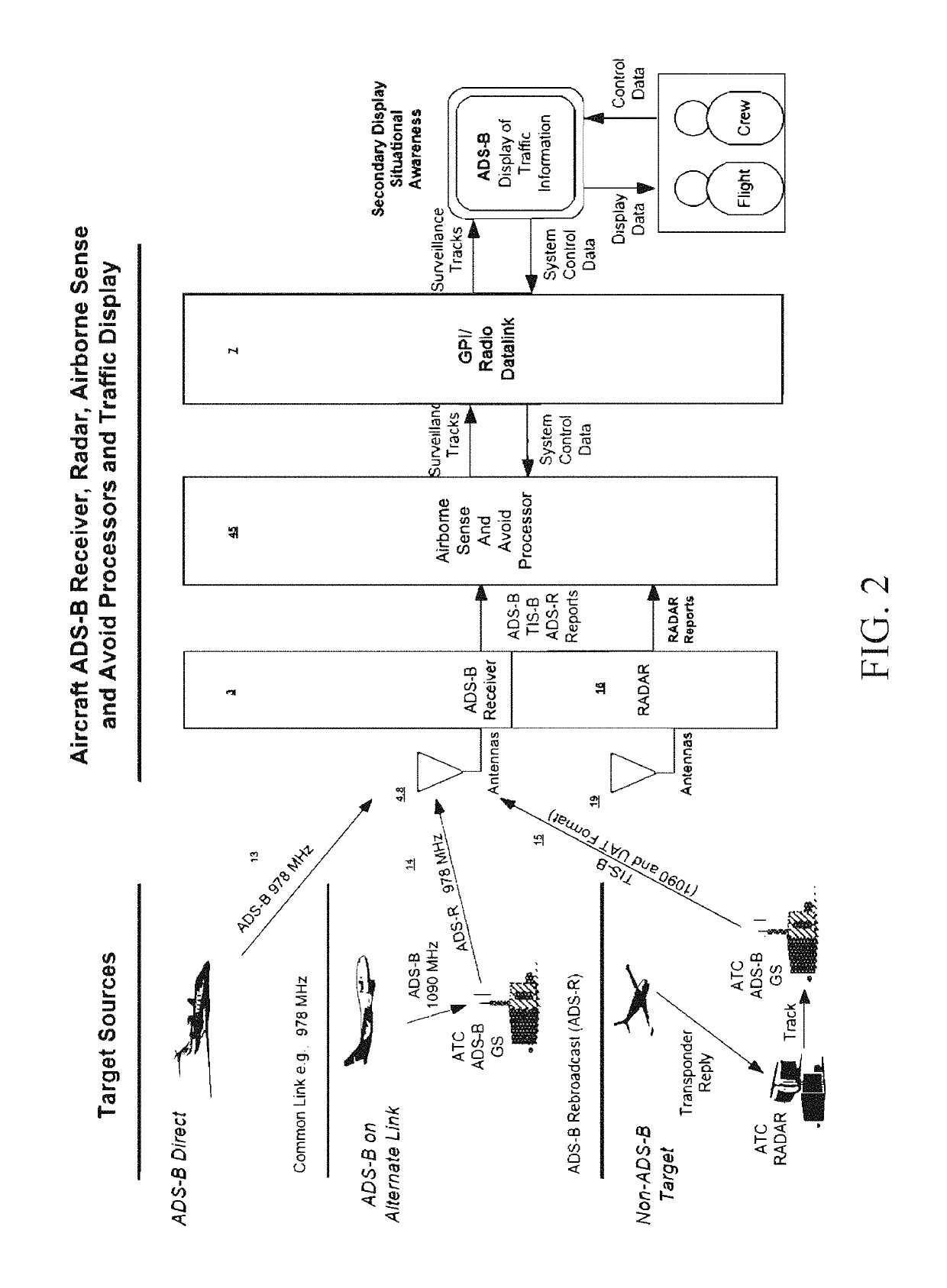

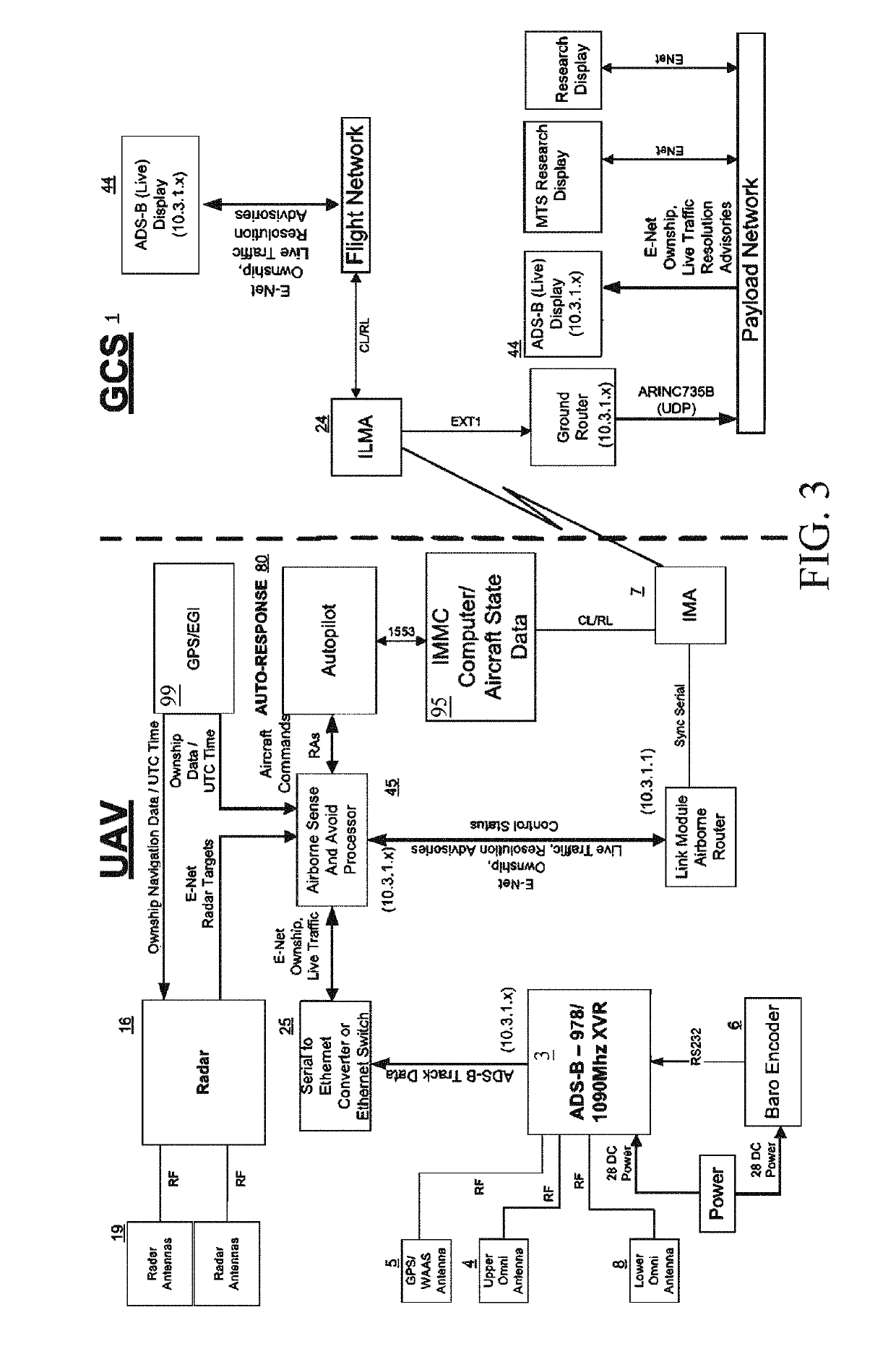

Automatic dependent surveillance broadcast (ADS-B) system with radar for ownship and traffic situational awareness

ActiveUS10302759B1Enhanced ownship situational awarenessEnhanced Situational AwarenessSatellite radio beaconingRadio wave reradiation/reflectionRadarVisual perception

The present invention proposes an automatic dependent surveillance broadcast (ADS-B) architecture and process, in which priority aircraft and ADS-B IN and radar traffic information are included in the transmission of data through the telemetry communications to a remote ground control station. The present invention further proposes methods for displaying general aviation traffic information in three and / or four dimension trajectories using an industry standard Earth browser for increased situation awareness and enhanced visual acquisition of traffic for conflict detection. The present invention enable the applications of enhanced visual acquisition of traffic, traffic alerts, and en-route and terminal surveillance used to augment pilot situational awareness through ADS-B IN display and information in three or four dimensions for self-separation awareness.

Owner:UNITED STATES AS REPRESENTED BY THE ADMINISTATOR OF NASA

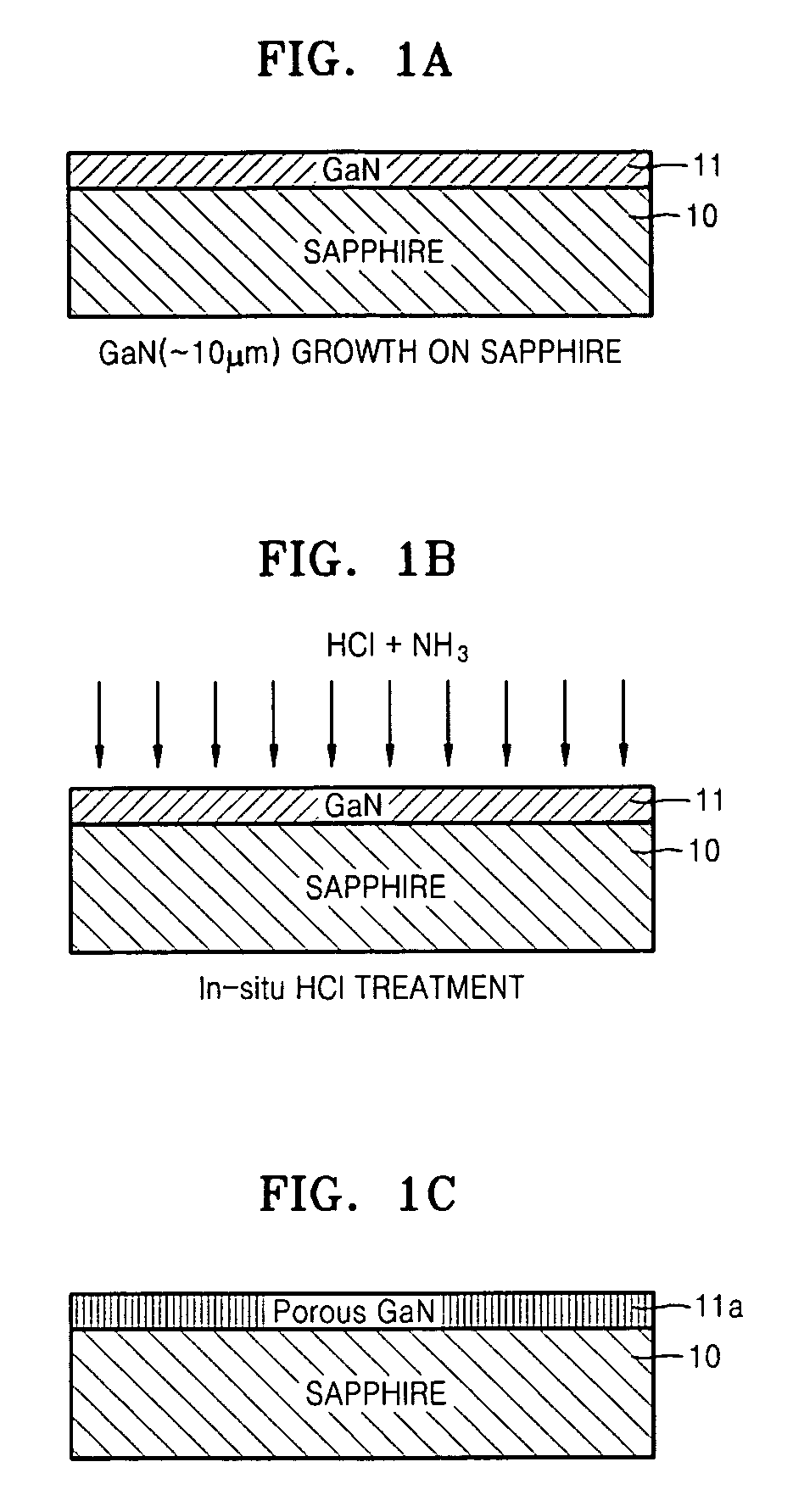

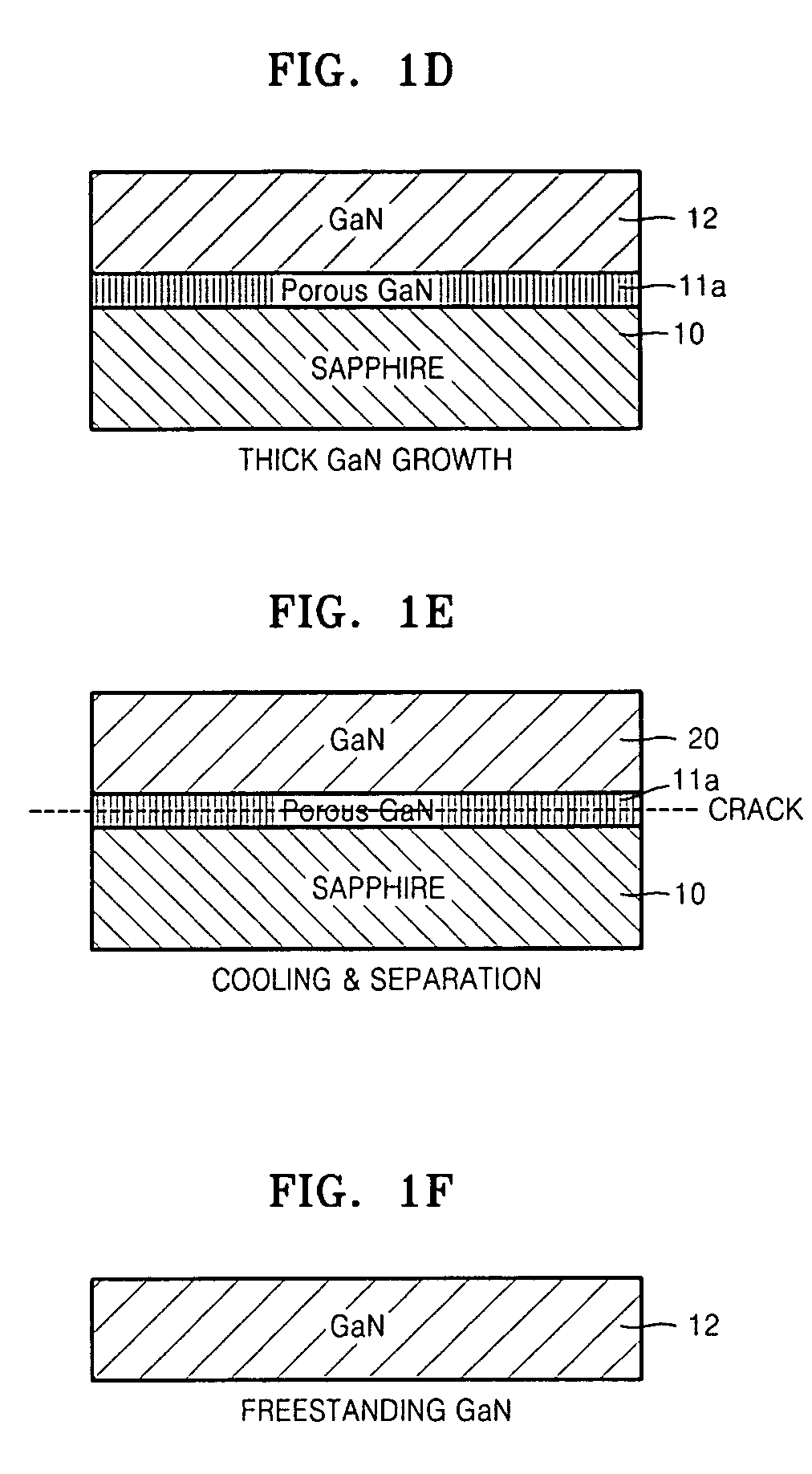

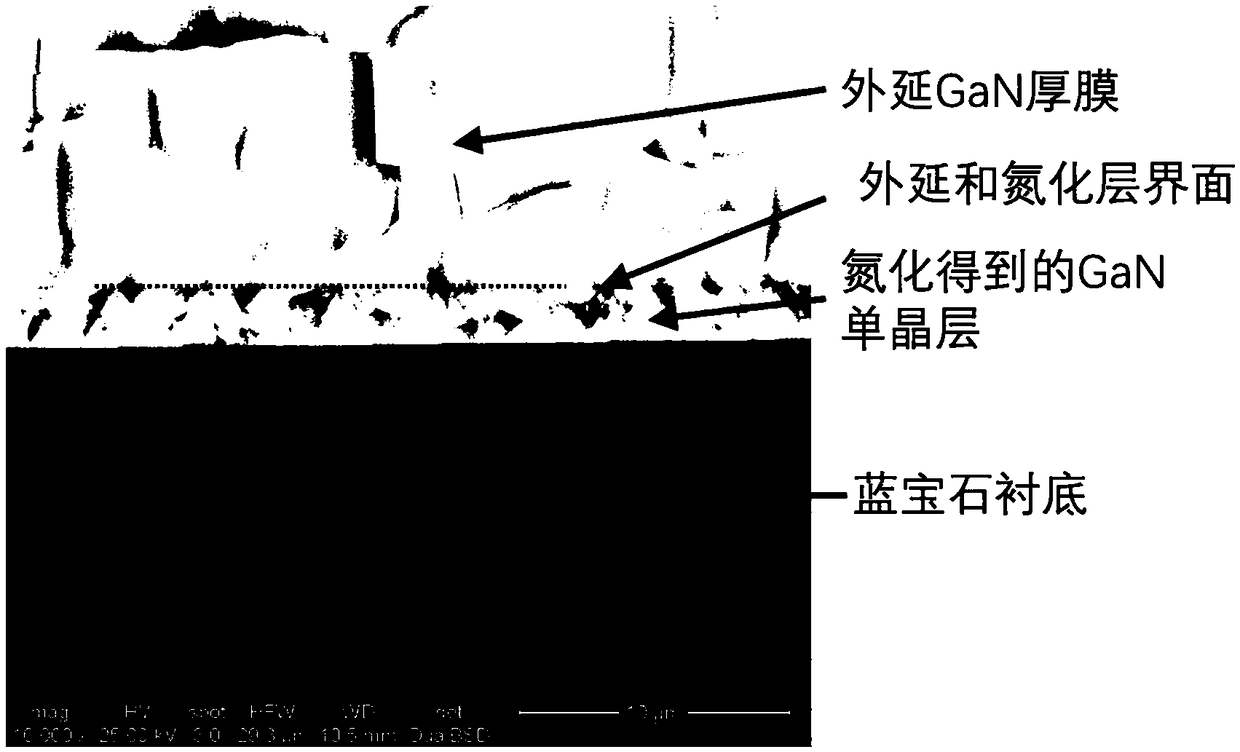

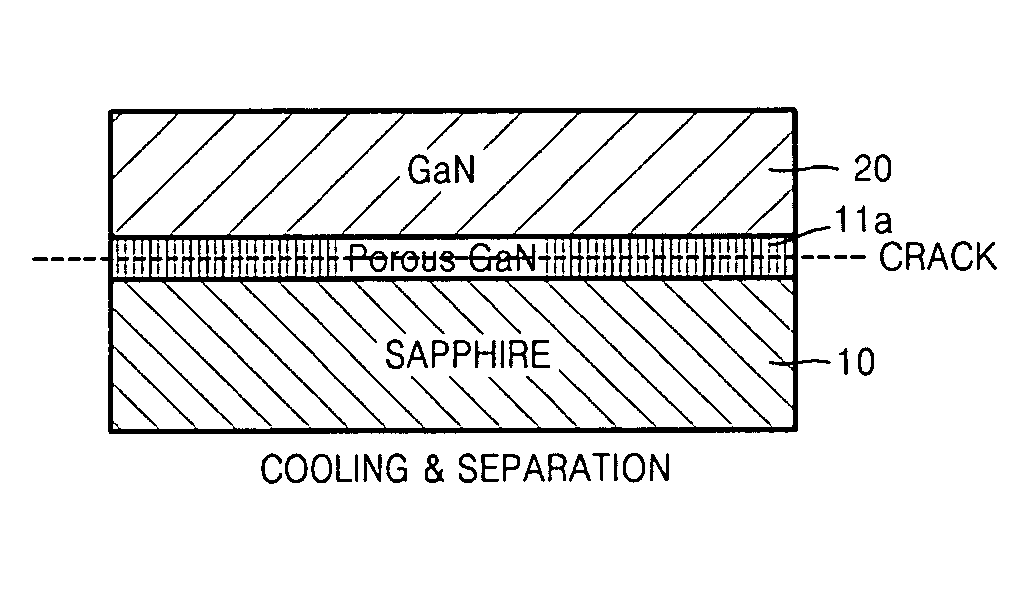

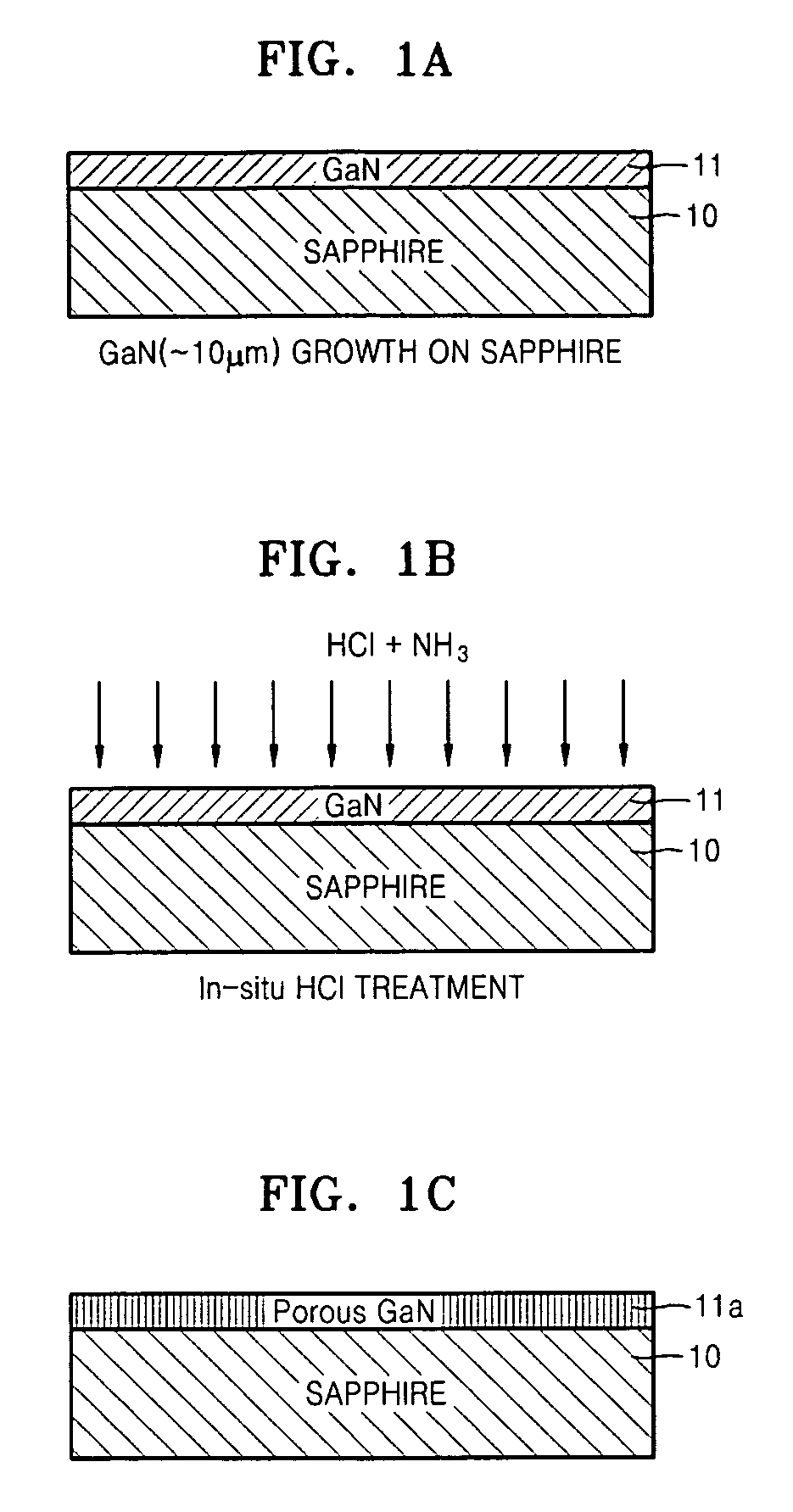

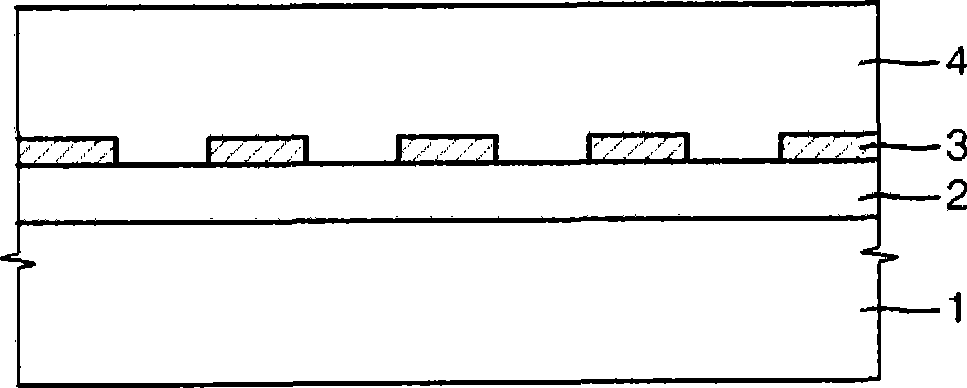

Method of fabricating GaN substrate

InactiveUS20070082465A1Improve production yieldSimple and low-costPolycrystalline material growthAfter-treatment detailsManufacturing cost reductionGallium nitride

A method of fabricating a freestanding gallium nitride (GaN) substrate includes: preparing a GaN substrate within a reactor; supplying HCl and NH3 gases into the reactor to treat the surface of the GaN substrate and forming a porous GaN layer; forming a GaN crystal growth layer on the porous GaN layer; and cooling the GaN substrate on which the GaN crystal growth layer has been formed and separating the GaN crystal growth layer from the substrate. According to the fabrication method, the entire process including forming a porous GaN layer and a thick GaN layer is performed in-situ within a single reactor. The method is significantly simplified compared to a conventional fabrication method. The fabrication method enables the entire process to be performed in one chamber while allowing GaN surface treatment and growth to be performed using HVPE process gases, thus resulting in a significant reduction in manufacturing costs. The fabrication method also allows self-separation of thick GaN without cracking, thus achieving a short process time and a high manufacturing yield.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

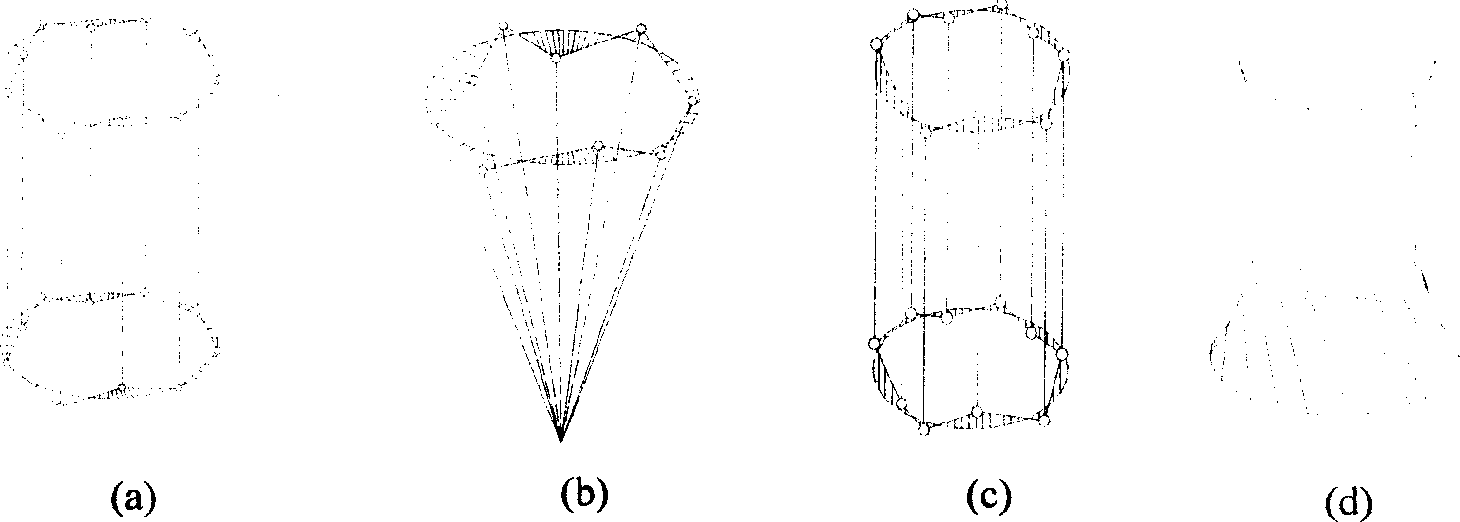

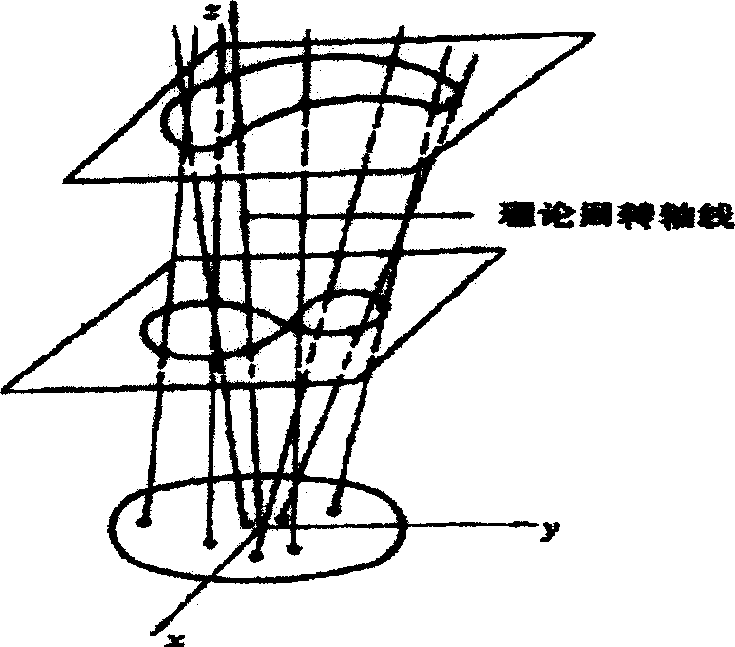

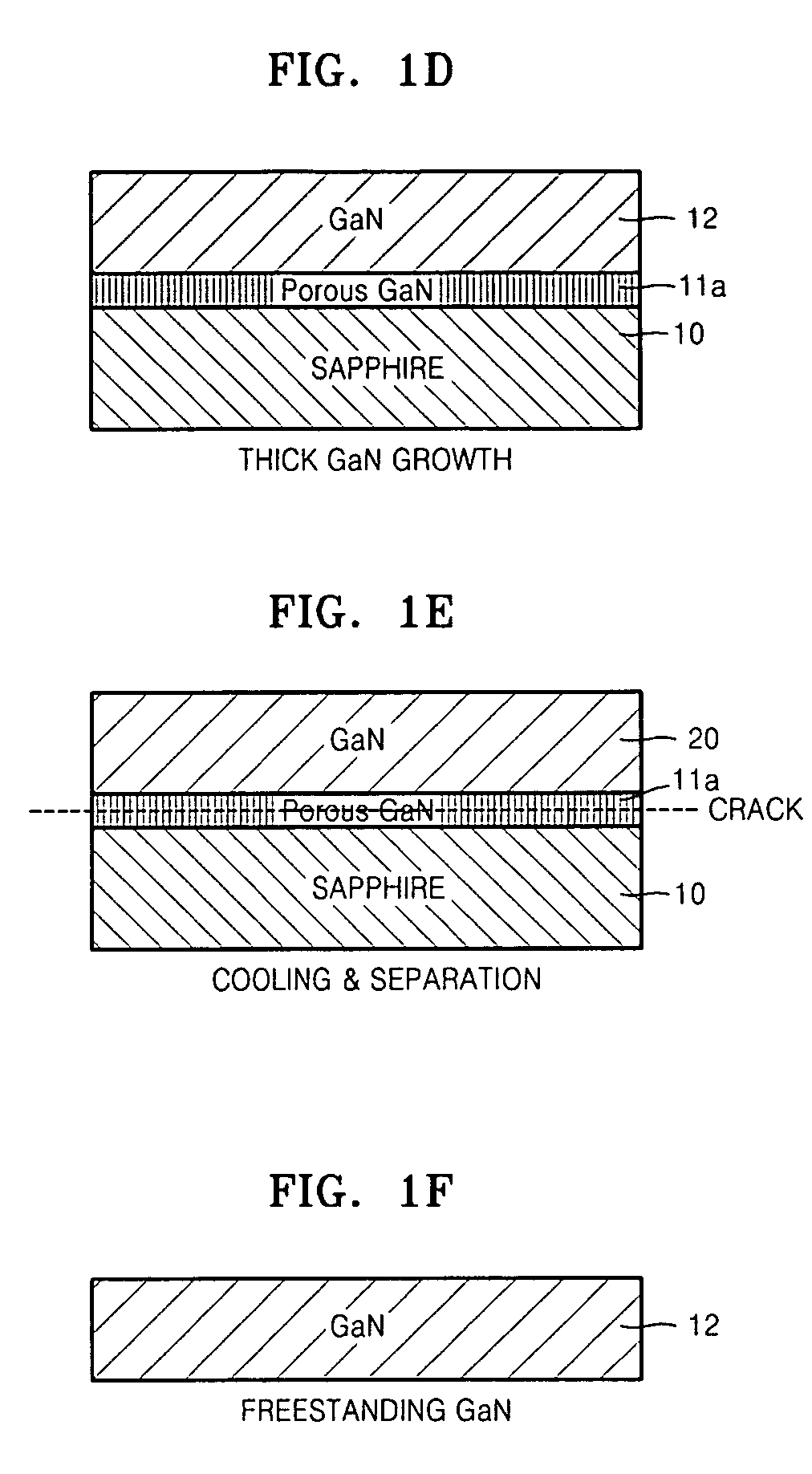

Self-separation method and device for spatial error of superprecise revolution reference

ActiveCN1527022AGood effectReduce axial sizeMechanical counters/curvatures measurementsMotion errorComputer science

The present invention belongs to the field of precise instrument manufacture and measurement technology, and is especially self-separation method and device for spatial error of super-precise revolution reference. The method of Z-direction section-by-section separation of super-precise revolution reference spatial motion error can meet the requirement of high precision cylindricity instrument to reduce spatial revolution error. The self-separation device for spatial error of super-precise revolution reference is developed by means of integrating roundness error separating system and cylindricity instrument revolution main shaft system. The bench revolving single-transposition small-angle error separation method is adopted in realizing the section-by-section separation of spatial revolution motion error of cylindricity instrument revolution main shaft, so as to reach the aim of reducing the effect of the spatial revolution motion error on measurement result.

Owner:HARBIN INST OF TECH

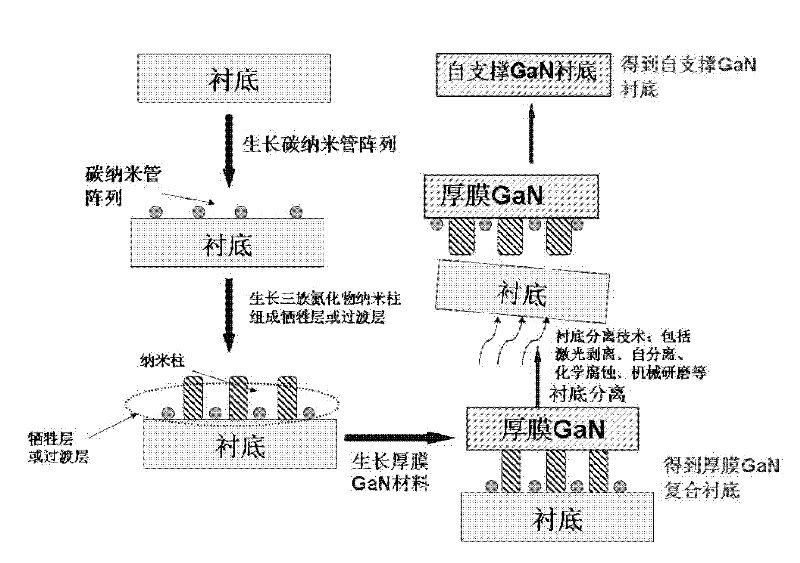

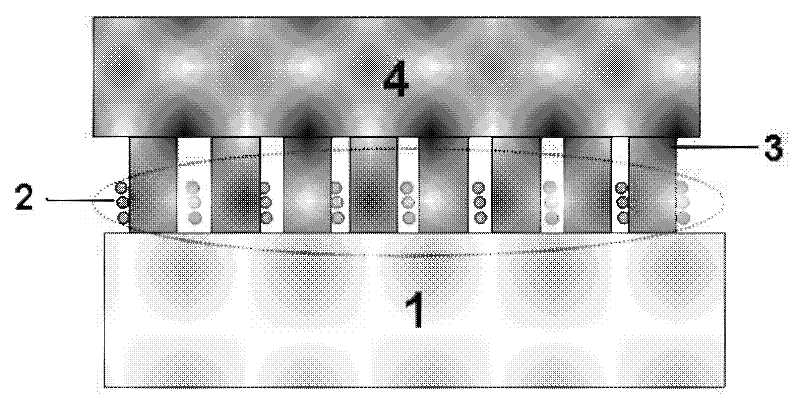

Preparation method of GaN substrate

InactiveCN102201332AImprove crystal qualityEasy to manufacturePolycrystalline material growthLaser detailsCarbon nanotubeProcess conditions

The invention provides a preparation method of a GaN substrate, belonging to the field of preparation of photoelectronic devices. The key points of the preparation method different from the prior art are as follows: a transition layer formed by carbon nano tubes and GaN, InGaN, AlGaN, AlN or InN nano columns is formed on the epitaxial growth surface of a substrate (such as Si, sapphire and SiC and the like), then a thick film GaN grows, the thick-film GaN substrate is obtained or a self-support GaN substrate is obtained by a substrate removing process or a self-separation process. In the invention, the preparation method is simple, the process condition is easily controlled, the price is low, different substrates can be selected and multiple substrate separating technologies also can be supported.

Owner:北京燕园中镓半导体工程研发中心有限公司

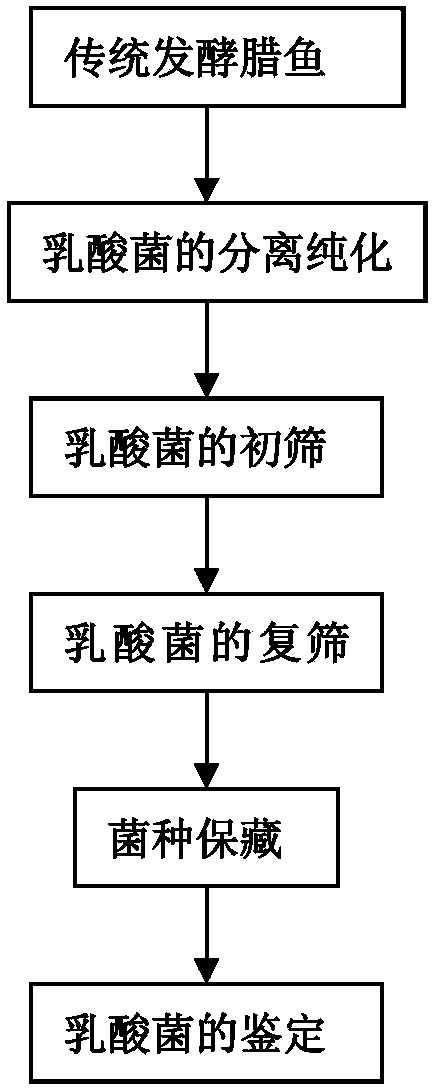

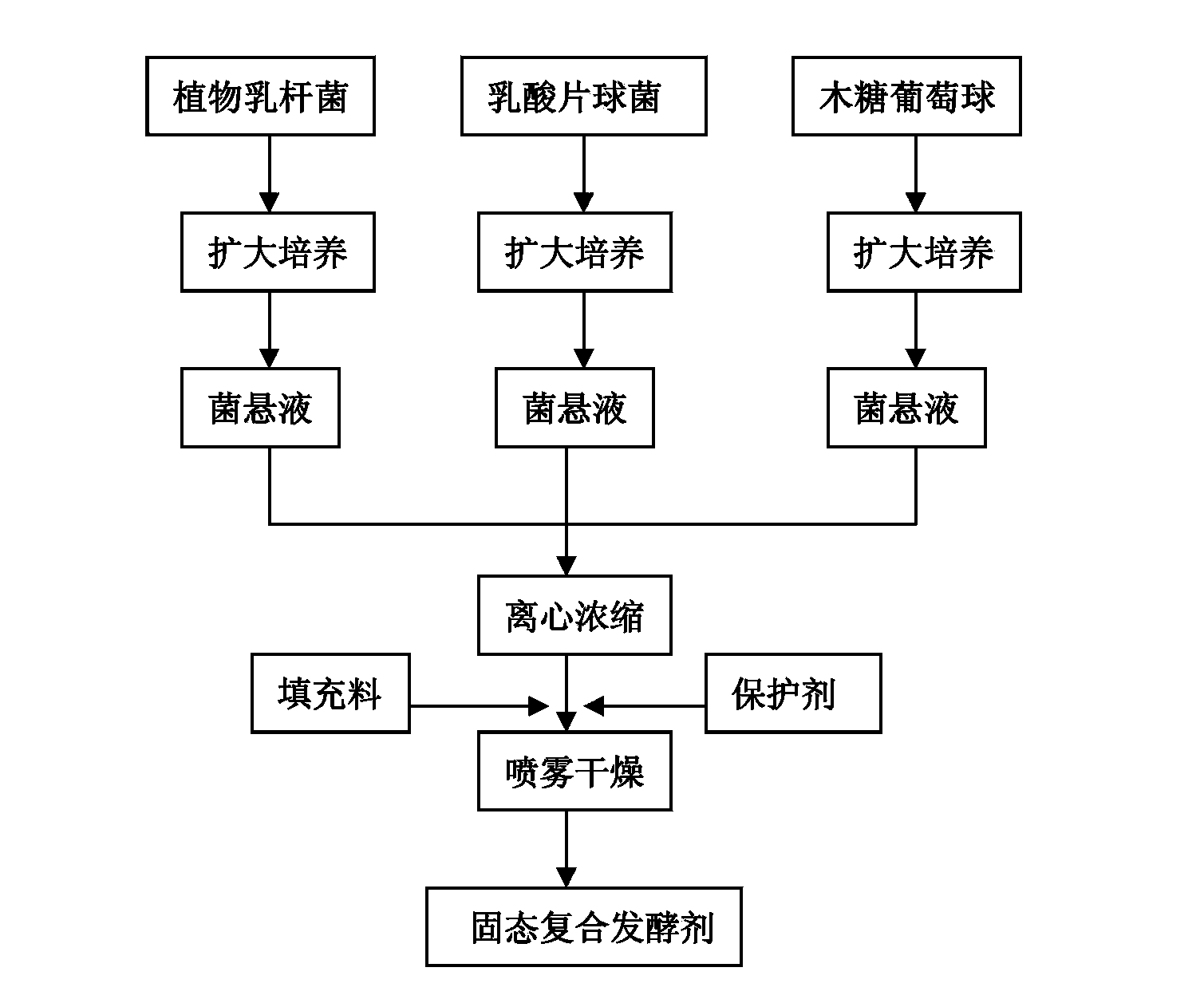

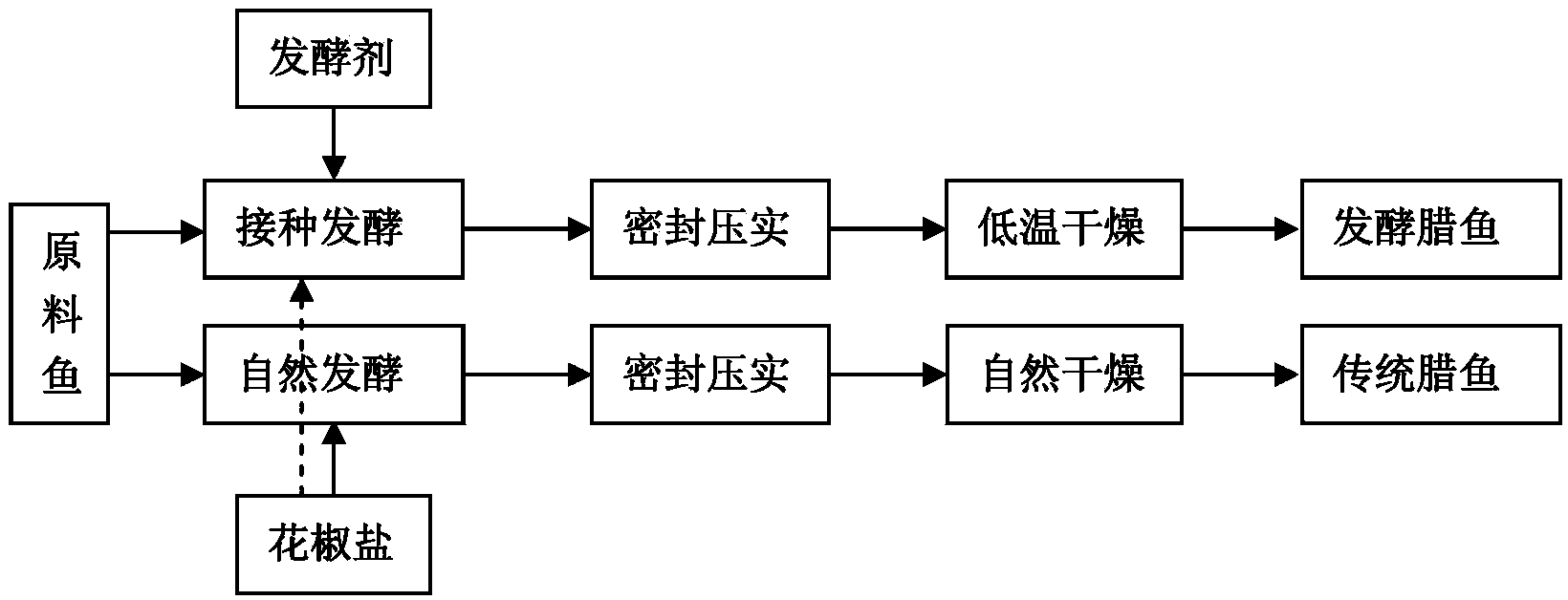

Lactobacillus plantarum for freshwater fish fermentation product and application thereof

InactiveCN103421704AAchieving enhanced fermentationShort fermentation timeBacteriaMicroorganism based processesMicroorganismAquatic product

The invention belongs to the technical field of agricultural microorganisms and aquatic product processing, and particularly relates to a compound starter for lactobacillus plantarum and application thereof, wherein the compound starter is used as a microbial starter, is especially suitable for freshwater fish fermentation, and is composed of lactobacillus, pediococcus acidilactici and staphylococcus xylosus. A lactic acid bacterium, namely lactobacillus plantarum, suitable for freshwater fish fermentation is obtained through self separation and screening, and the preservation number in the China center for typical culture collection is CCTCC NO: M2012396. The compound microbial starter is prepared from lactobacillus plantarum, pediococcus acidilactici and staphylococcus xylosus, is suitable for fish product fermentation and particularly suitable for the application to preserved fish fermentation, has a sound fermenting property, has typical fermentation fragrance, and facilitates industrial production.

Owner:HUAZHONG AGRI UNIV +1

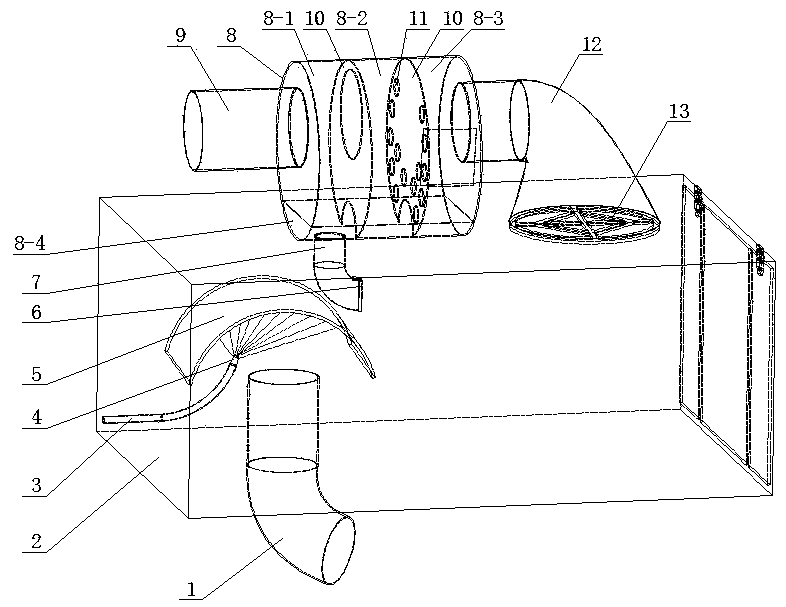

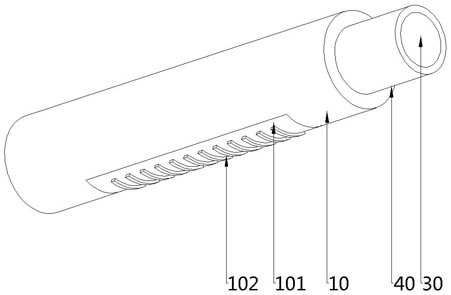

Self-separation type wet dust and gas separator of sweeper

ActiveCN103711096AIncrease storage capacityReduce kinetic energyCombination devicesRoad cleaningSprayerMechanical equipment

The invention relates to the technical field of sweeping mechanical equipment, in particular to a self-separation type wet dust and gas separator of a sweeper. The self-separation type wet dust and gas separator comprises a garbage can, an arc guide plate is connected in the garbage can, a garbage guide pipe is arranged on the garbage can in a penetrating mode, a dust falling sprayer pipe is arranged on the garbage can in a penetrating mode, and one end of the dust falling sprayer pipe is connected with a water nozzle. A separating box is arranged on the garbage can, two filtering plates are arranged in the separating box, airflow ventilation openings are formed in the two filtering plates respectively, and the airflow ventilation openings in the two filtering plates are arranged in a staggered mode. One end of the separating box is connected with the garbage can through an air pipe, a filtering net is arranged in the air pipe, the other end of the separating box is connected with a fan air suction pipe, the lower portion of the end, connected with the fan air suction pipe, of the separating box is connected with an automatic wet garbage outlet, the other end of the automatic wet garbage outlet is arranged in the garbage can, and a check valve is connected on the automatic wet garbage outlet. The self-separation type wet dust and gas separator replaces an original filtering net, work is reliable, the storage capacity of the garbage can is large, and manufacturing and using cost can be greatly lowered.

Owner:NANTONG MINGNUO ELECTRIC TECH CO LTD

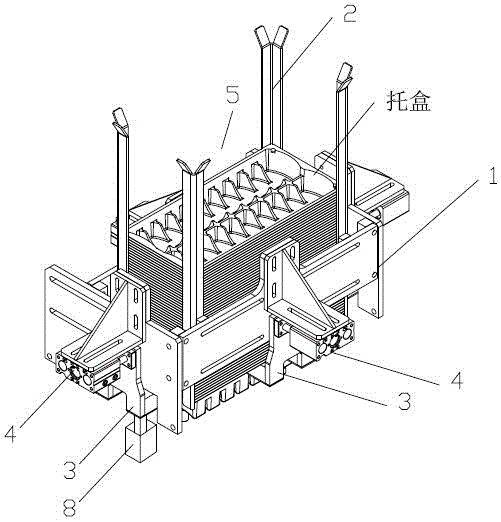

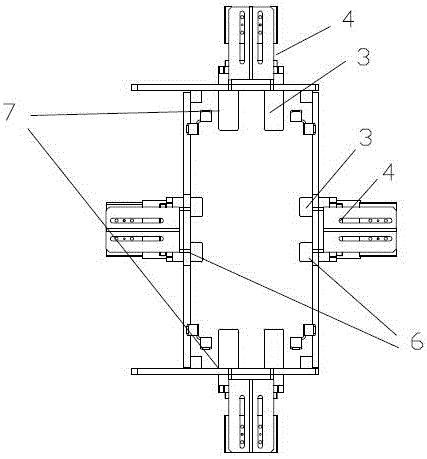

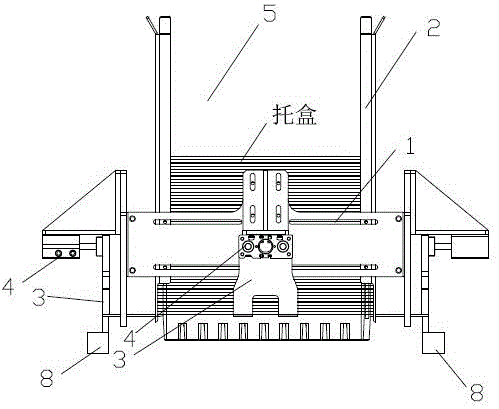

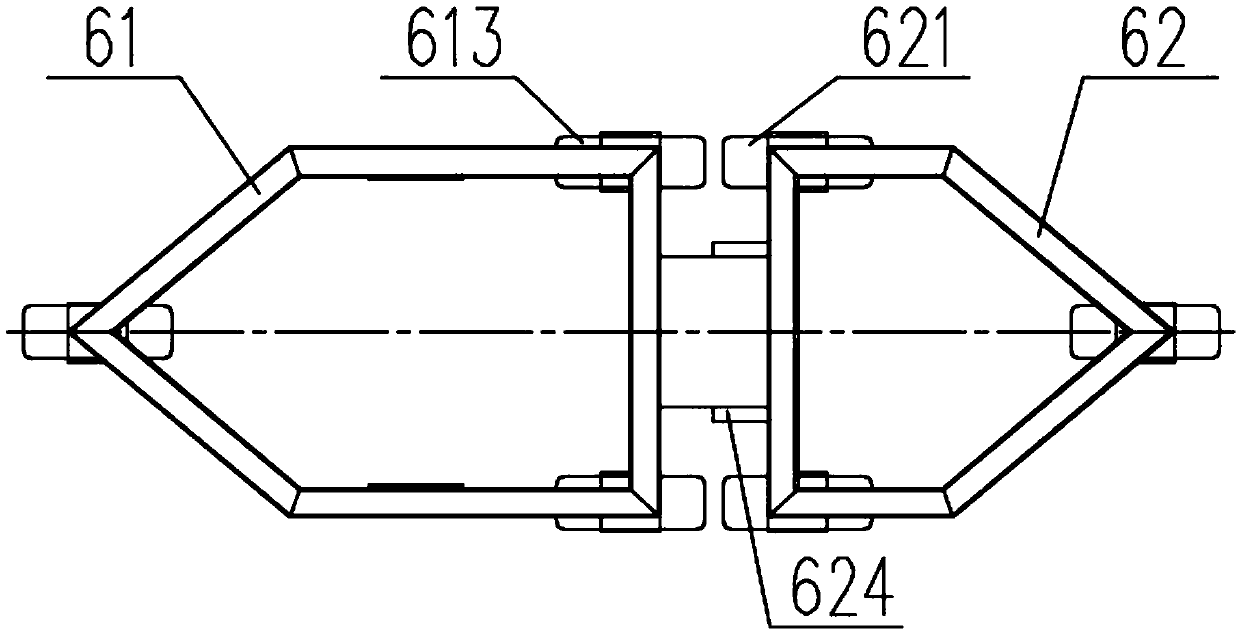

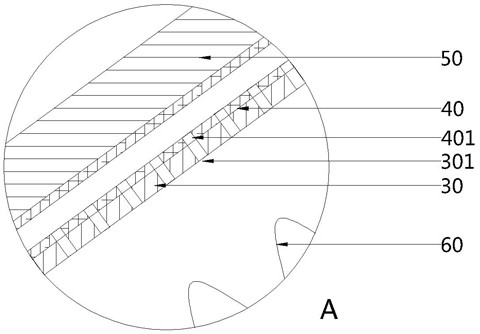

Self-separation type box lowering mechanism of box packing machine

ActiveCN106006055ARealize automatic unboxingStable supportConveyorsDe-stacking articlesReciprocating motionEngineering

The invention relates to the field of product processing mechanical equipment, in particular to a self-separation type box lowering mechanism of a box packing machine. The self-separation type box lowering mechanism comprises a fixed frame. A plurality of protecting plates used for fixing the positions of supporting boxes are installed in the fixed frame. A fork plate is arranged between every two adjacent protecting plates. The protecting plates gather together to form a supporting box storage space used for storing the supporting boxes. The first set of fork plates and the second set of fork plates conduct transverse reciprocating motion in the horizontal direction alternately. The first set of fork plates and the second set of fork plates conduct longitudinal reciprocating motion in the vertical direction alternately. The fork plates are connected with horizontal driving mechanisms and vertical driving mechanisms. According to the self-separation type box lowering mechanism, the first set of fork plates and the second set of fork plates conduct transverse reciprocating motion in the horizontal direction alternately and conduct longitudinal reciprocating motion in the vertical direction alternately, the box lowering mechanism is different from other existing mechanisms in the box lowering process through the characteristic of alternate motion, and the supporting boxes tightly attached to one another can be separated more effectively.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

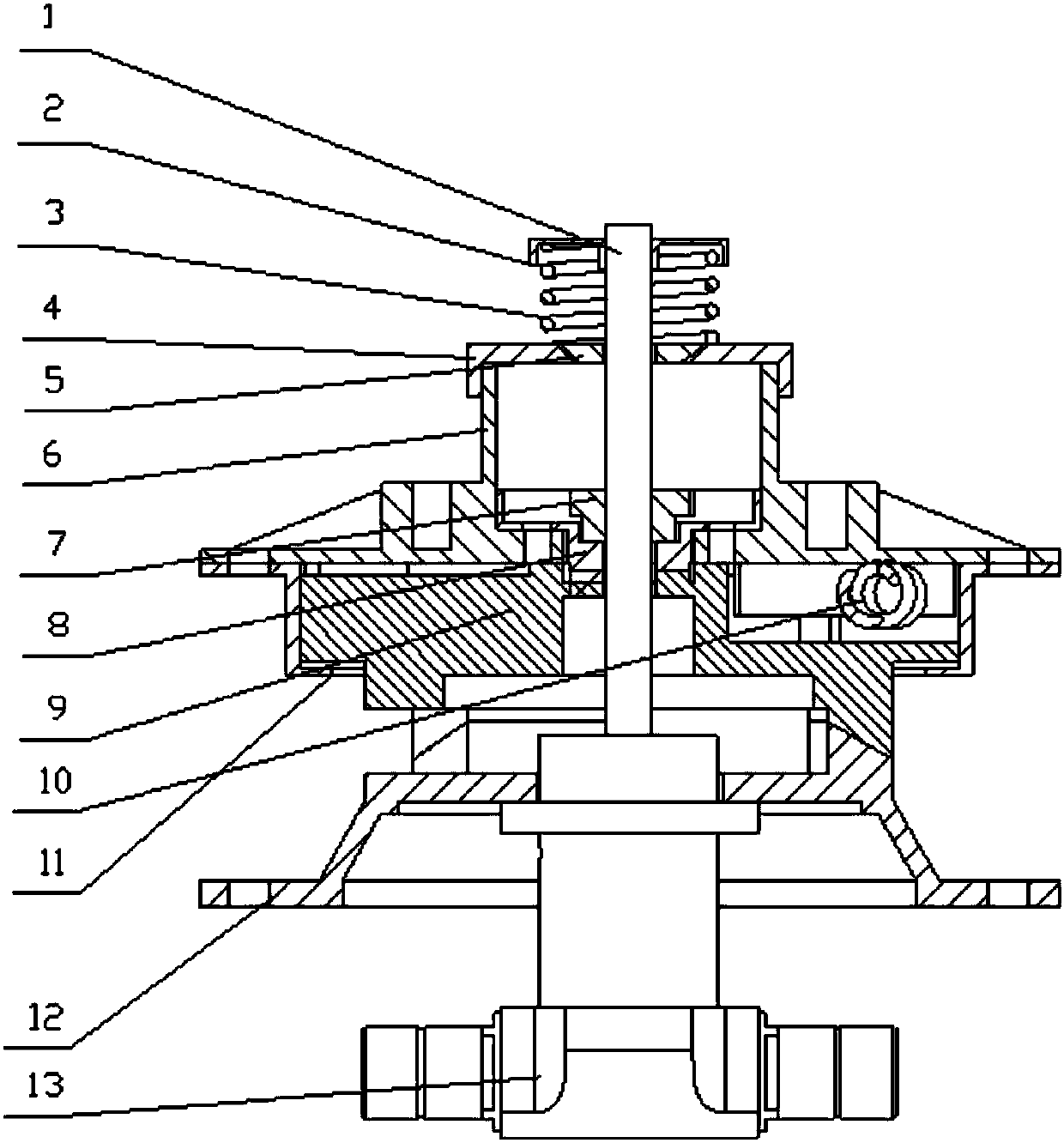

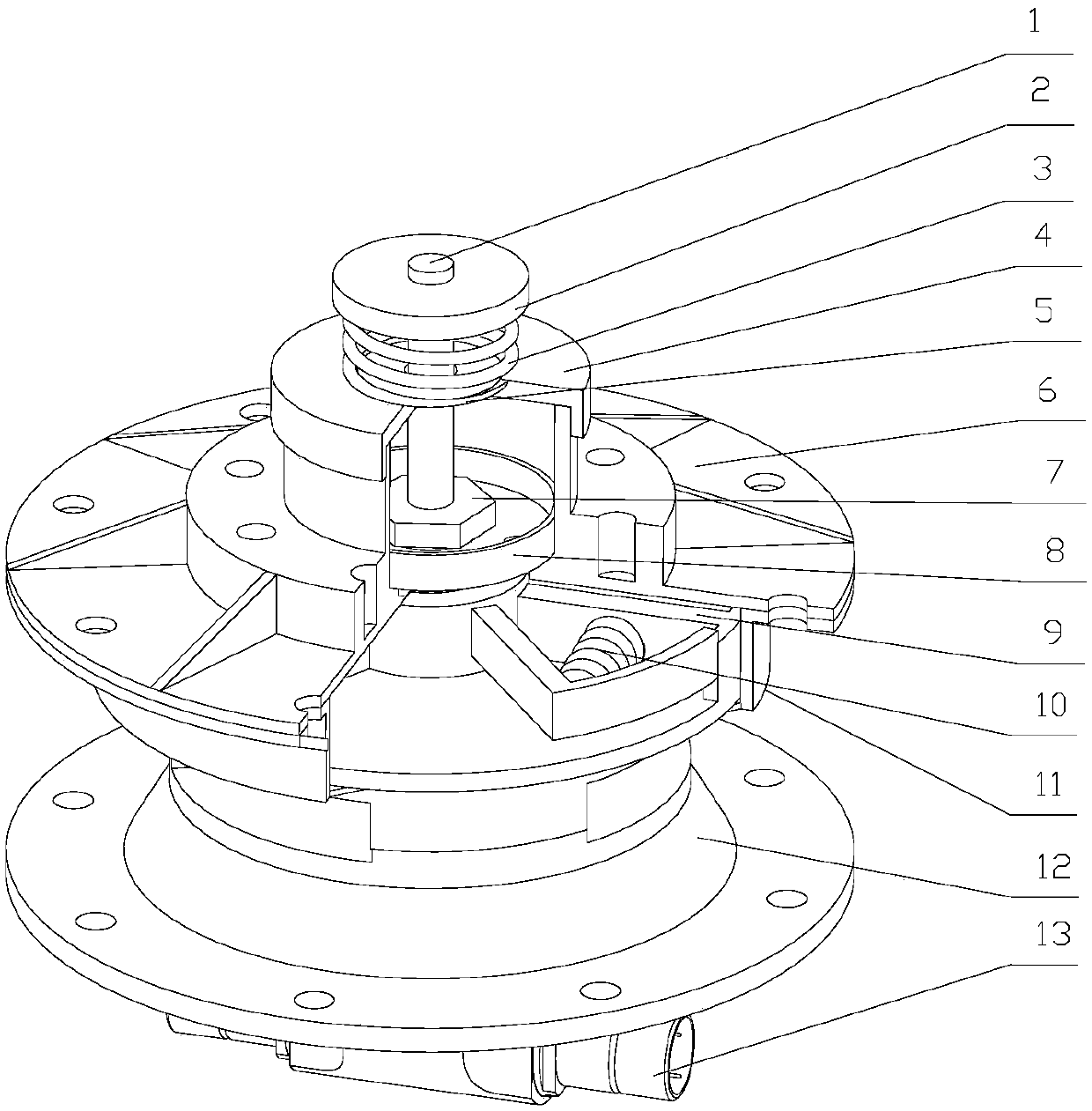

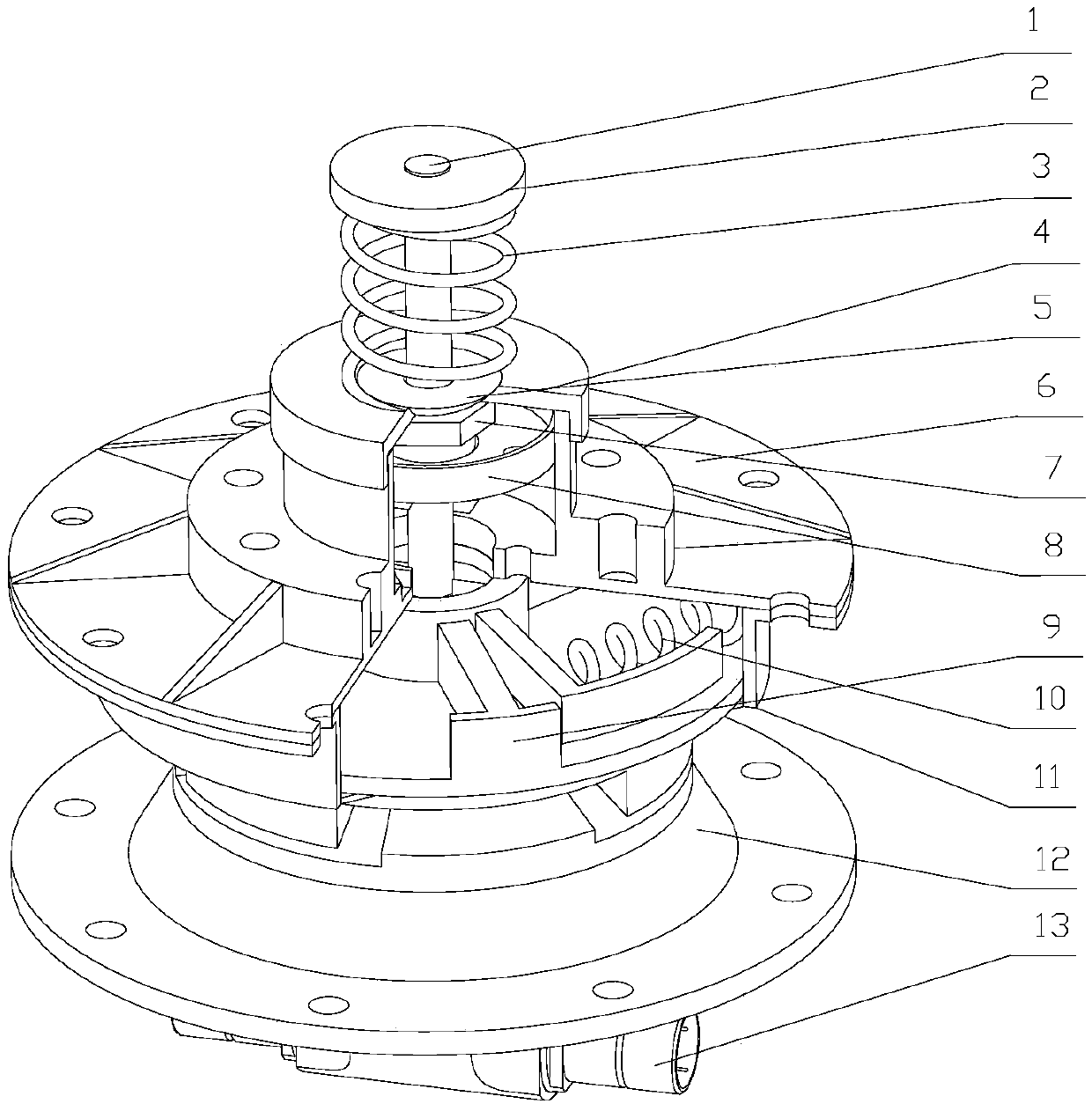

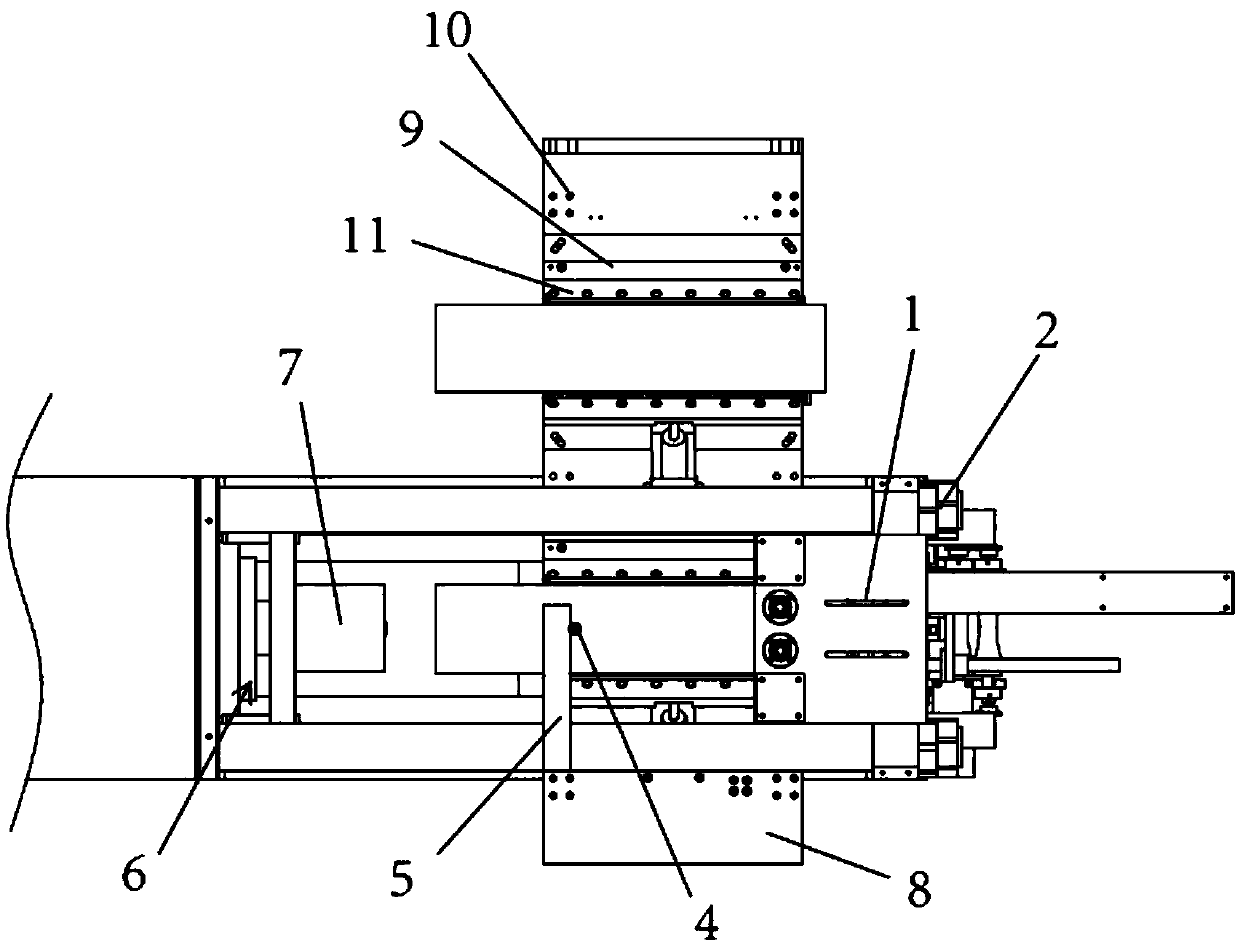

Rotary low-impact self-separation pressing and releasing device

ActiveCN107839906AAvoid damageImprove carrying capacityCosmonautic vehiclesCosmonautic component separationPetalEngineering

The invention discloses a rotary low-impact self-separation pressing and releasing device. The upper end of a compressing rod compresses a separation spring onto an upper end cover through a compressing cap, the compressing rod sequentially penetrates through the upper end cover, an upper base, a limiting block and a rotating lock petal, the lower end of the compressing rod is fixedly connected with a separation nut, and the separation nut is fixedly connected with a lower base; a compressing nut is fixed onto the compressing rod and used for limiting rotating motion of the locking petal through a limiting block; an unlocking spring is installed between a stop dog of the rotating lock petal and a stop dog of the upper base, when the device is locked, the separation spring and the unlockingspring are in a pre-compressed state, and tapered teeth at the bottom of the rotating lock petal is occlusive in an over against mode. By means of the rotary low-impact self-separation pressing and releasing device, connected objects at the two ends can be connected and separated and do not move relatively during separation.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

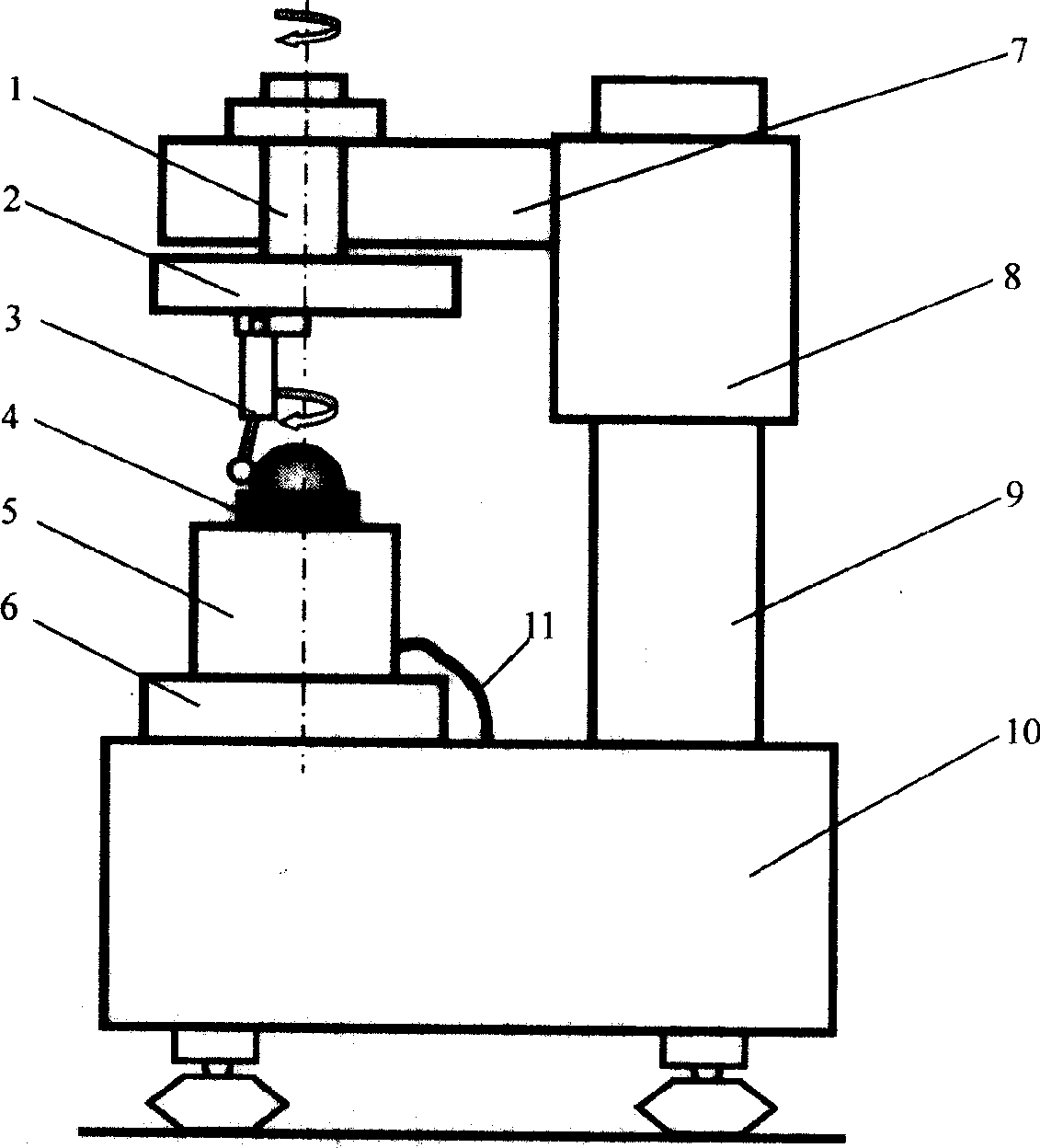

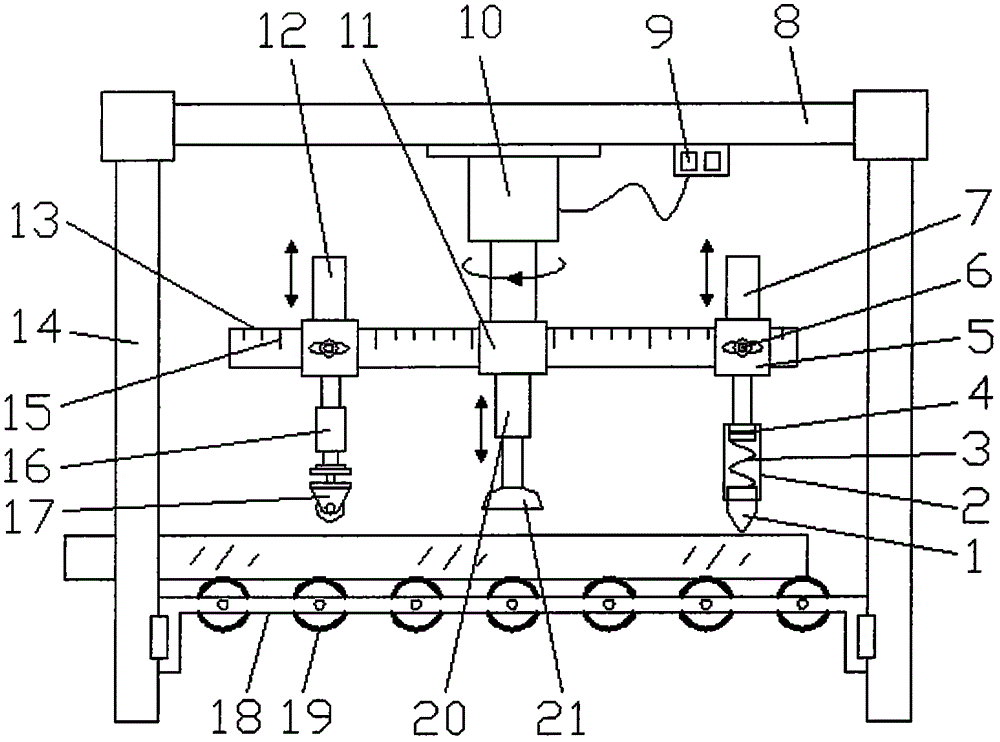

Self-separation and buffering type round glass cutting machine

InactiveCN104860523AAvoid breakingPrevent movementGlass severing apparatusPulp and paper industryStructural stability

The invention discloses a self-separation and buffering type round glass cutting machine. The machine comprises a rack, wherein a cross beam is transversely arranged at the top of the rack; a rotary motor is fixed to the lower side of the middle of the cross beam; a fixed sleeve is fixed to an end part of an output shaft of the rotary motor; a horizontal rod transversely penetrates through the fixed sleeve; an air cylinder I is vertically arranged on a side surface of a sliding sleeve on the right side of the horizontal rod, a sleeve is fixed to the bottom end of the air cylinder I, and a pressure sensor, a spring and a cutter are sequentially arranged in the sleeve; an air cylinder II is vertically arranged on a side surface of a sliding sleeve on the left side of the horizontal rod, and the bottom end of the air cylinder II is connected with a universal wheel through an elastic telescopic rod; an air cylinder III is fixed at the bottom of the fixed sleeve, and a suction cup is fixed at the bottom end of the air cylinder III. The machine is high in structural stability and convenient to adjust; glass can be automatically separated and taken out after round glass cutting operation, the operation difficulty is reduced for workers, and the work efficiency is improved.

Owner:何小平

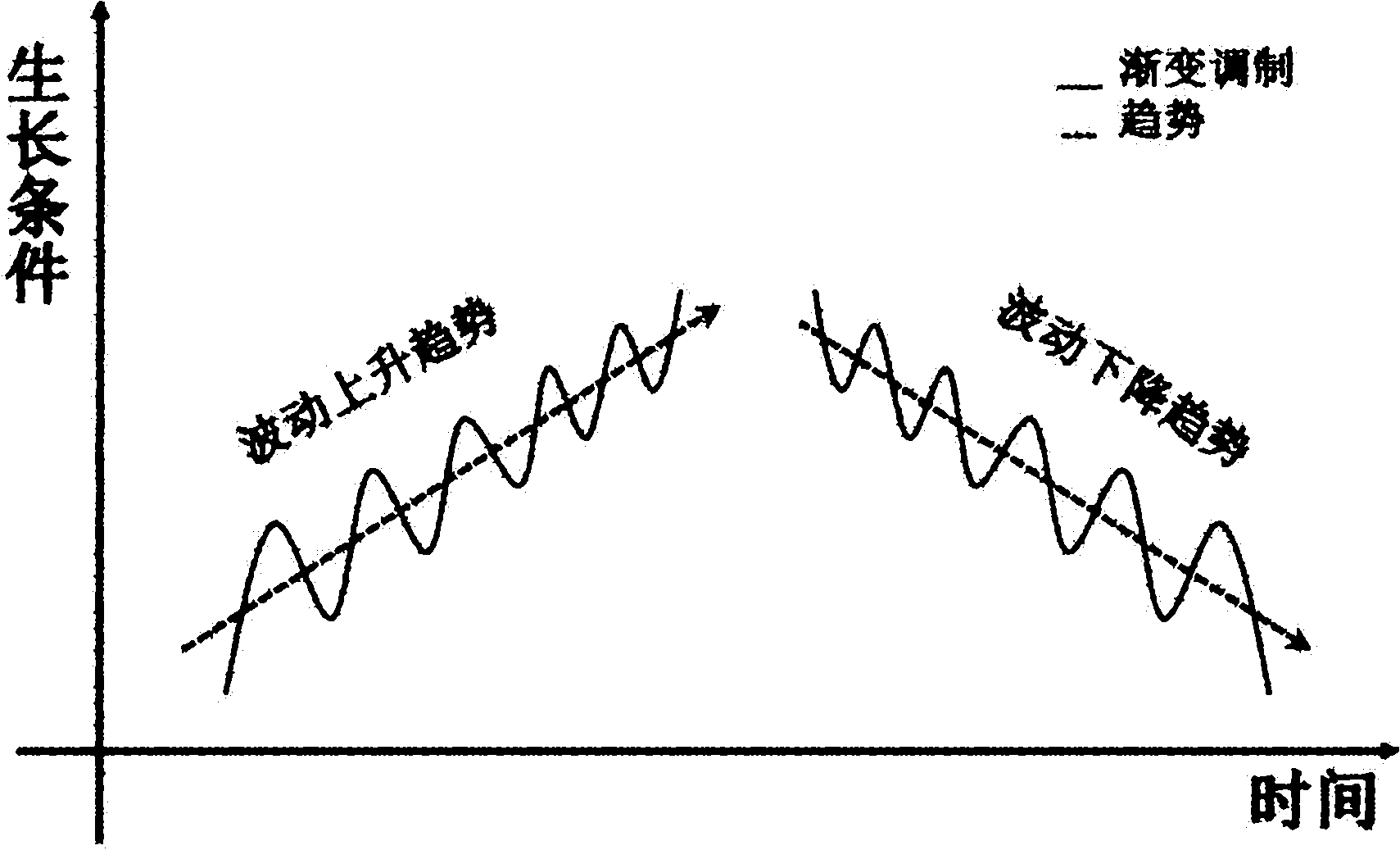

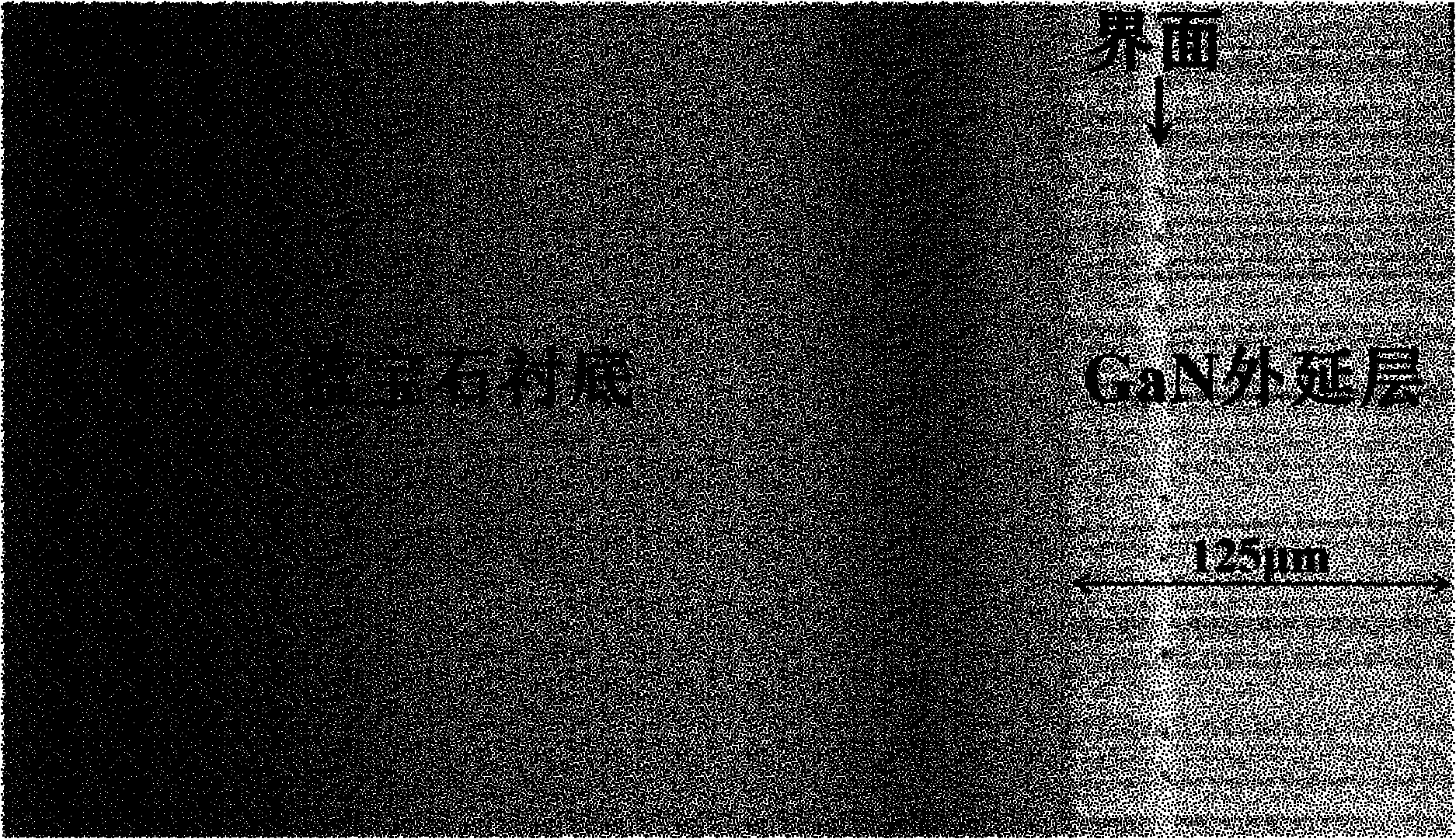

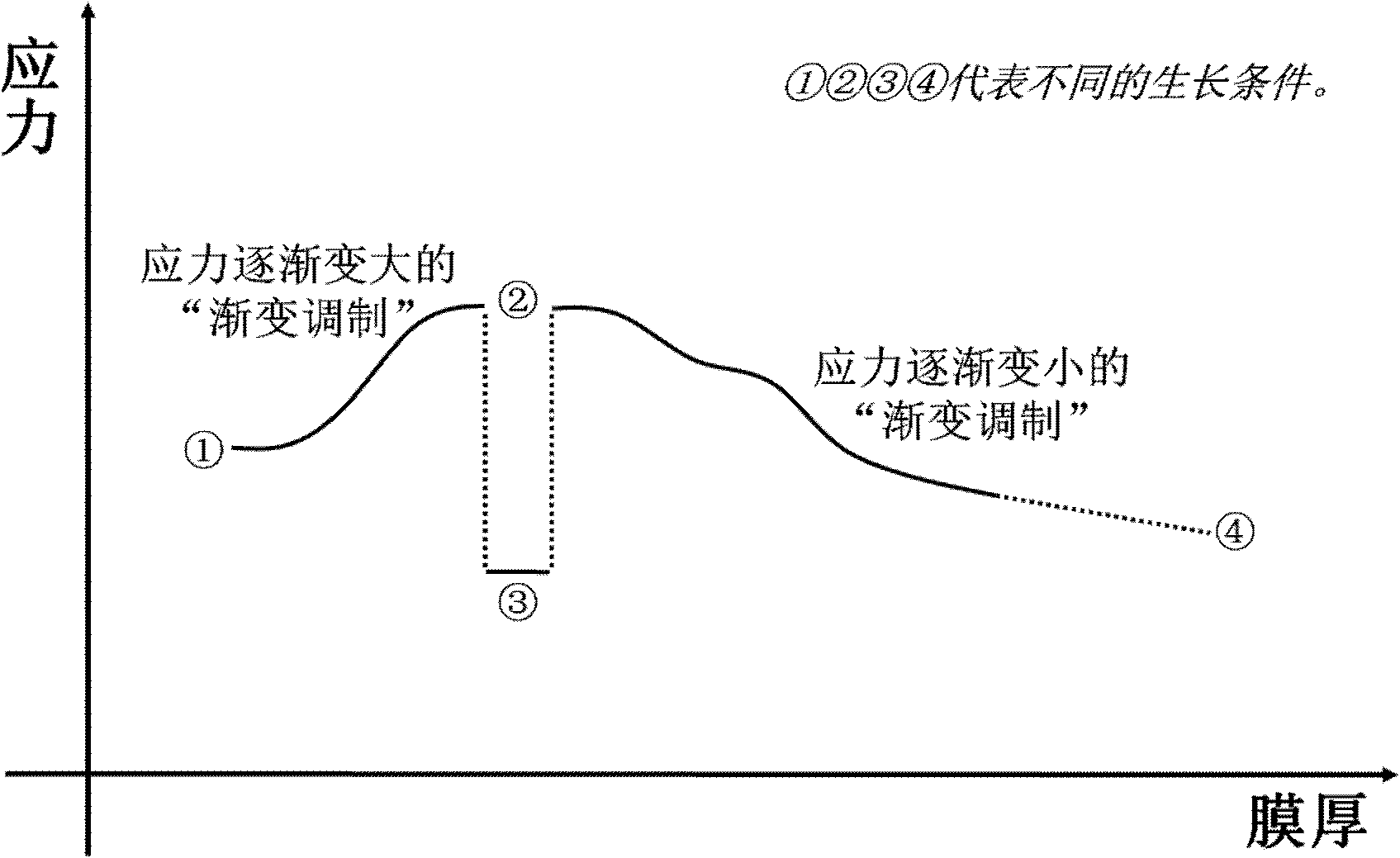

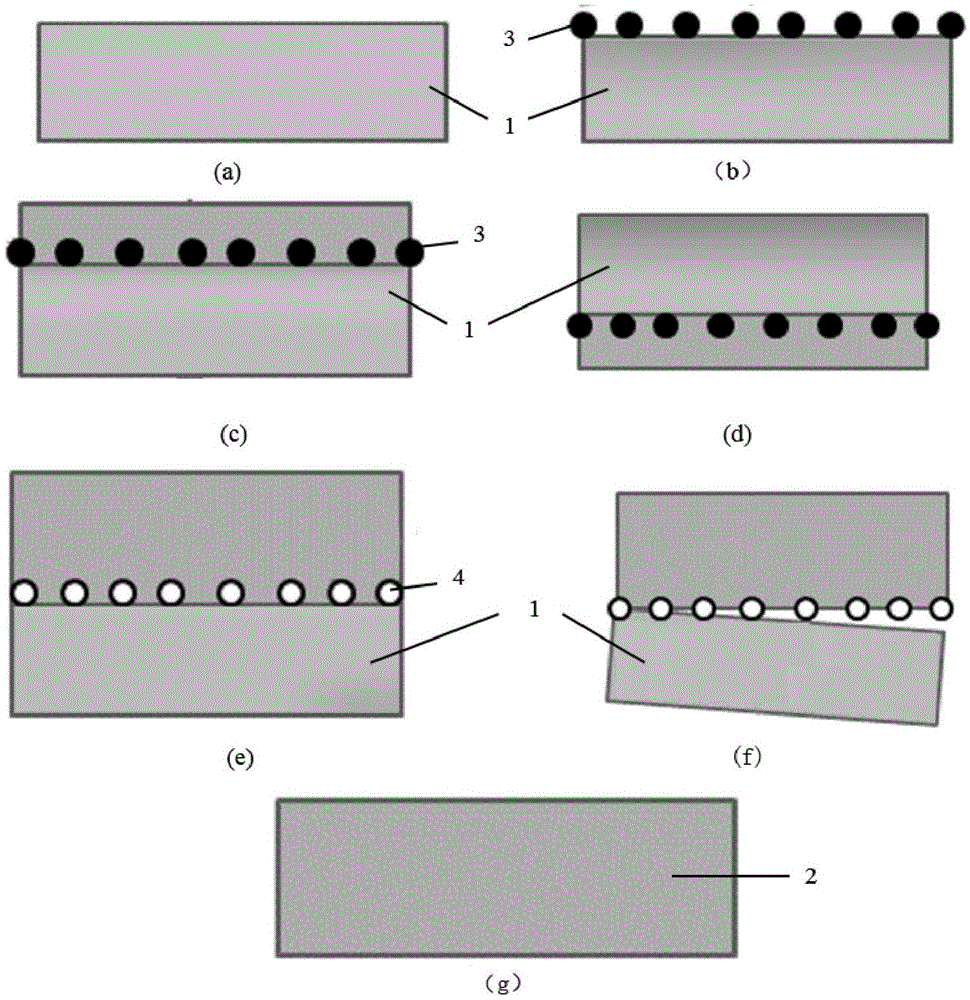

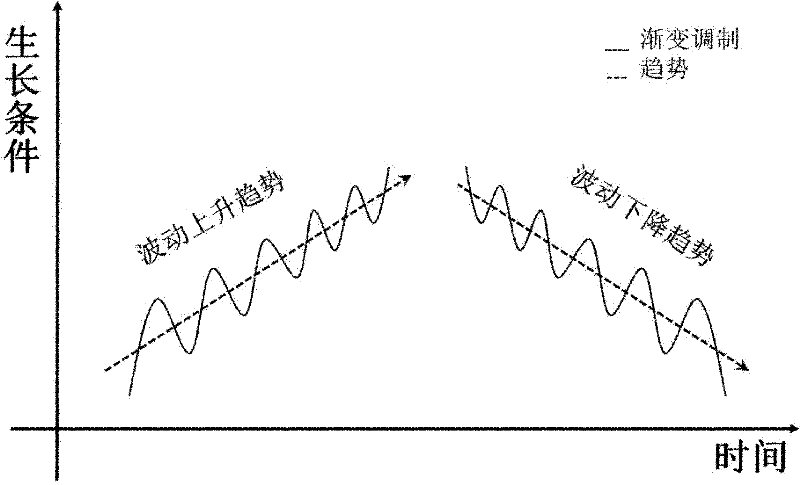

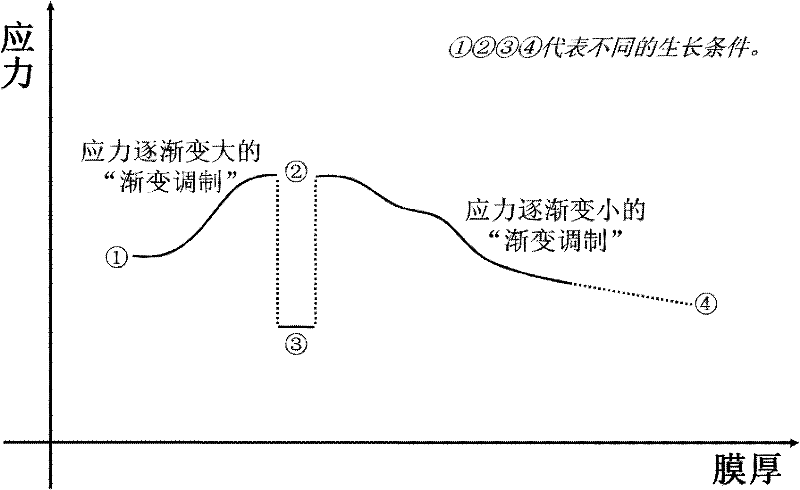

Epitaxial material stress control-based GaN thick film self-separation method

InactiveCN101962804ASimple processUniversally applicablePolycrystalline material growthFrom chemically reactive gasesEpitaxial materialProcess conditions

The invention discloses an epitaxial material stress control-based GaN thick film self-separation method, which comprises the following steps of: pretreating a substrate material; growing an epitaxial material on the substrate, gradually modulating process conditions to ensure that the stress of the epitaxial material is gradually concentrated to a preset self-separation position; when the thickness of the epitaxial material reaches the preset self-separation position, and performing jumping modulation on the process conditions to ensure that the stress is jumped at the preset position; gradually modulating the process conditions again to ensure that the stress of the epitaxial material is gradually released along with the increase of the thickness, namely the stress is reversely concentrated to the preset position; and finishing the epitaxial growth, and gradually reducing temperature to make stress difference on the two sides of the preset self-separation position further amplified so as to realize the self-separation of the monocrystalline thick film at the preset position. The method can effectively control the integral distribution of the stress in the epitaxial material and well realize the self-separation of the epitaxial material on the basis of ensuring the quality of the epitaxial material.

Owner:PEKING UNIV

Systems and methods for unmanned aircraft system collision avoidance

ActiveUS8965679B2Analogue computers for vehiclesDirection finders using radio wavesCurrent velocityFlight vehicle

Systems and methods are operable maintain a proscribed Self Separation distance between an unmanned aircraft system (UAS) and an object. In an example system, consecutive intruder aircraft locations relative to corresponding locations of a self aircraft are determined, wherein the determining is based on current velocities of the intruder aircraft and the self aircraft, and wherein the determining is based on current flight paths of the intruder aircraft and the self aircraft. At least one evasive maneuver for the self aircraft is computed using a processing system based on the determined consecutive intruder aircraft locations relative to the corresponding locations of the self aircraft.

Owner:HONEYWELL INT INC

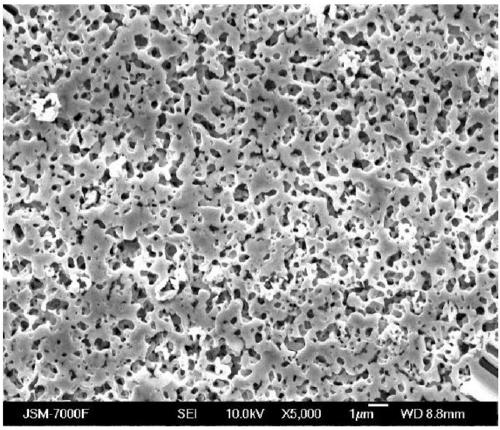

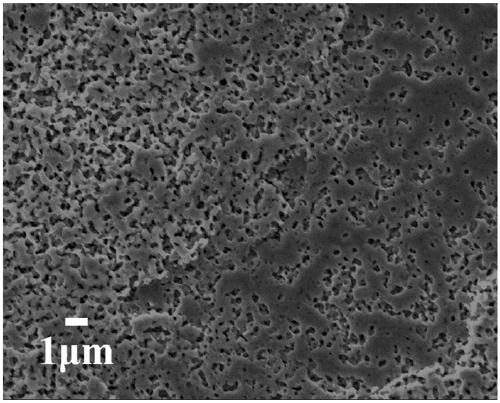

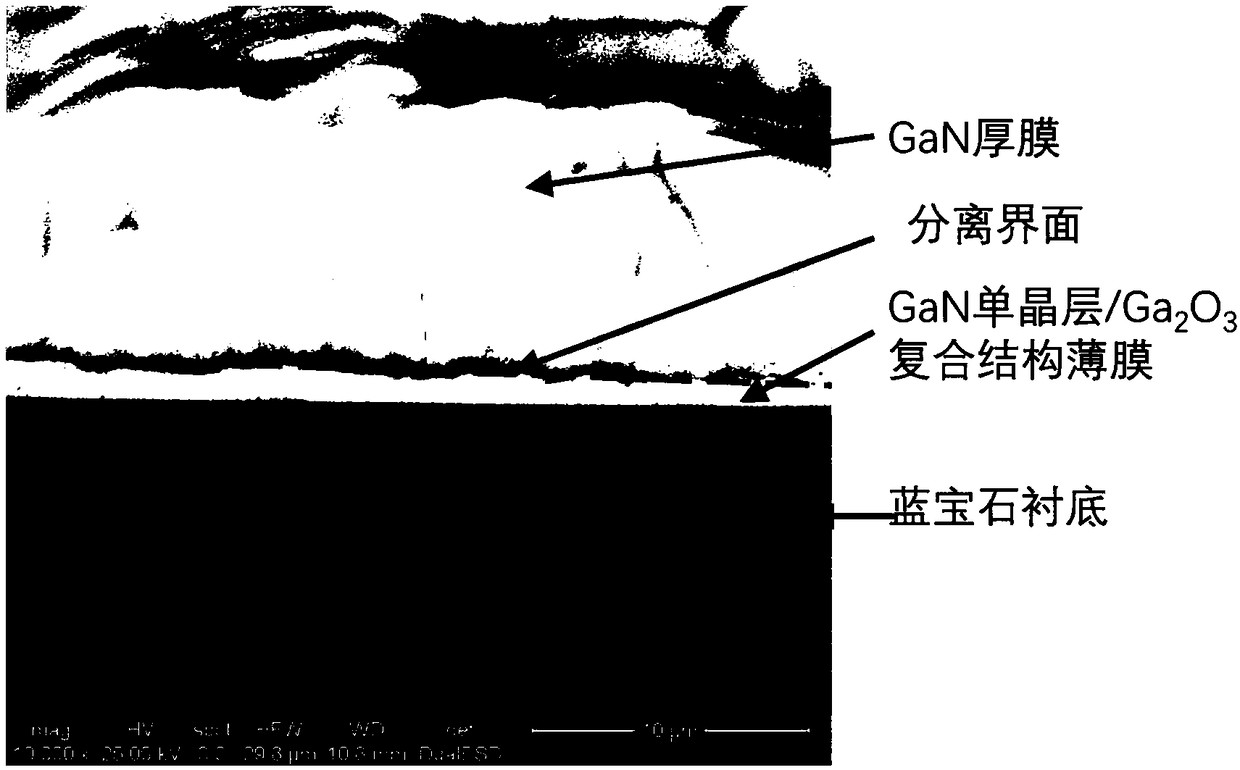

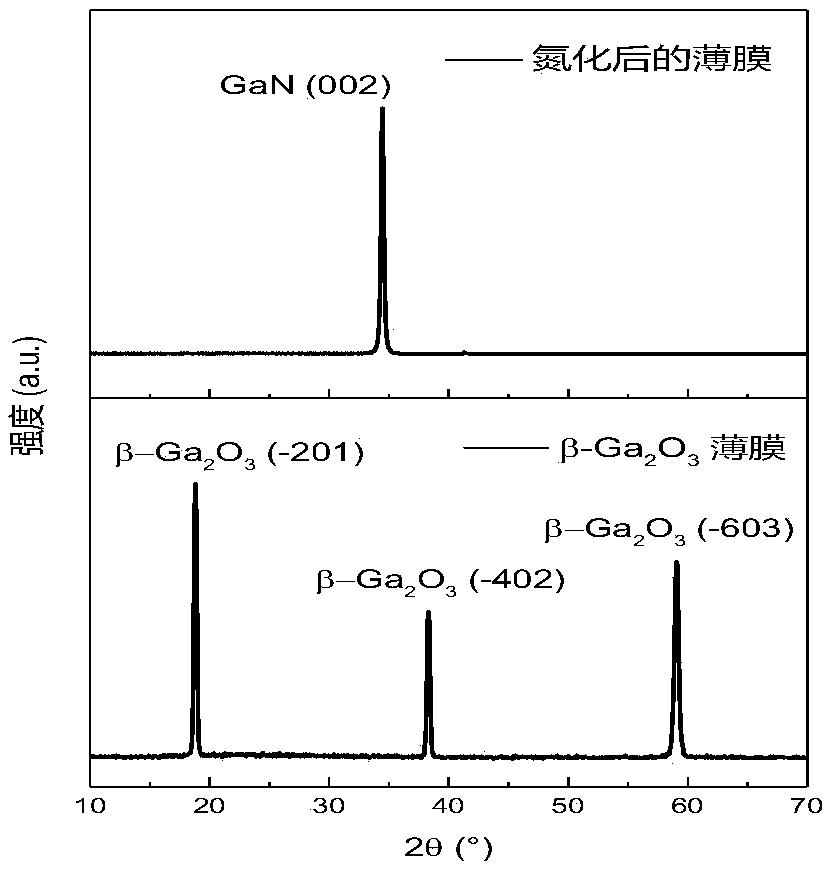

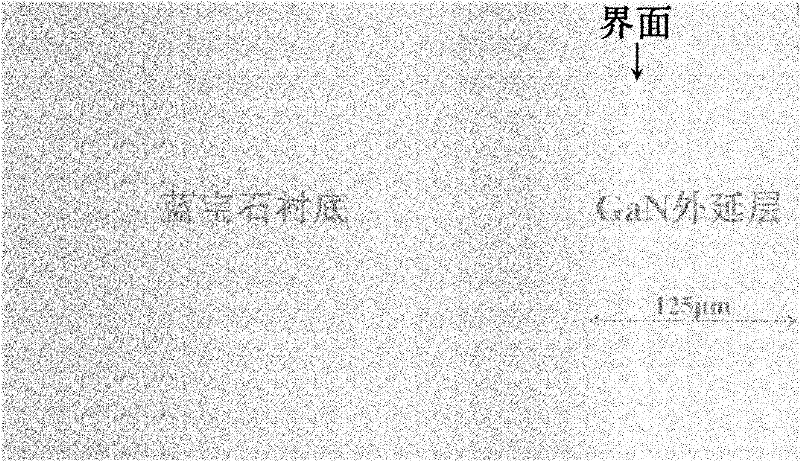

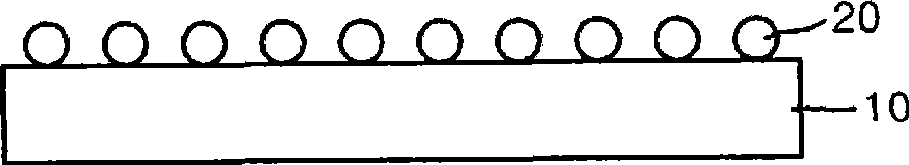

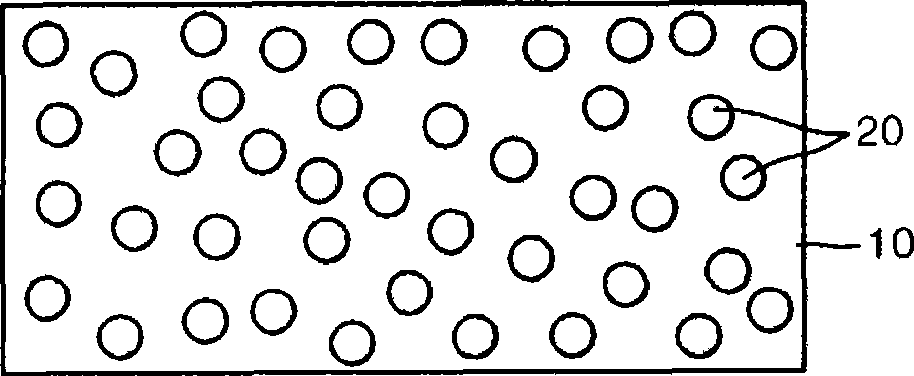

Self-separation method for preparing self-supporting GaN substrate

InactiveCN109023516AIncrease stressSustained DiffusionPolycrystalline material growthFrom chemically reactive gasesRoom temperatureGallium nitride

The invention discloses a self-separation method for preparing a self-supporting GaN substrate, which includes steps of: 1) on a sapphire substrate, growing a uniformly-distributed Ga2O3 film, whereinthickness range of the film is 0.1-1 [mu]m; 2) in an ammonia atmosphere, performing complete nitridation to the film, thus forming a porous GaN film in latticed distribution; 3) on the porous GaN film, performing halide vapor phase epitaxy growth of a GaN thick film, thus forming a low stress and high quality GaN thick film; 4) after the epitaxy is completed, cooling the material to room temperature, so that the epitaxy GaN thick film is automatically separated from the sapphire substrate, thus obtaining the self-supporting GaN substrate.

Owner:NANJING UNIV

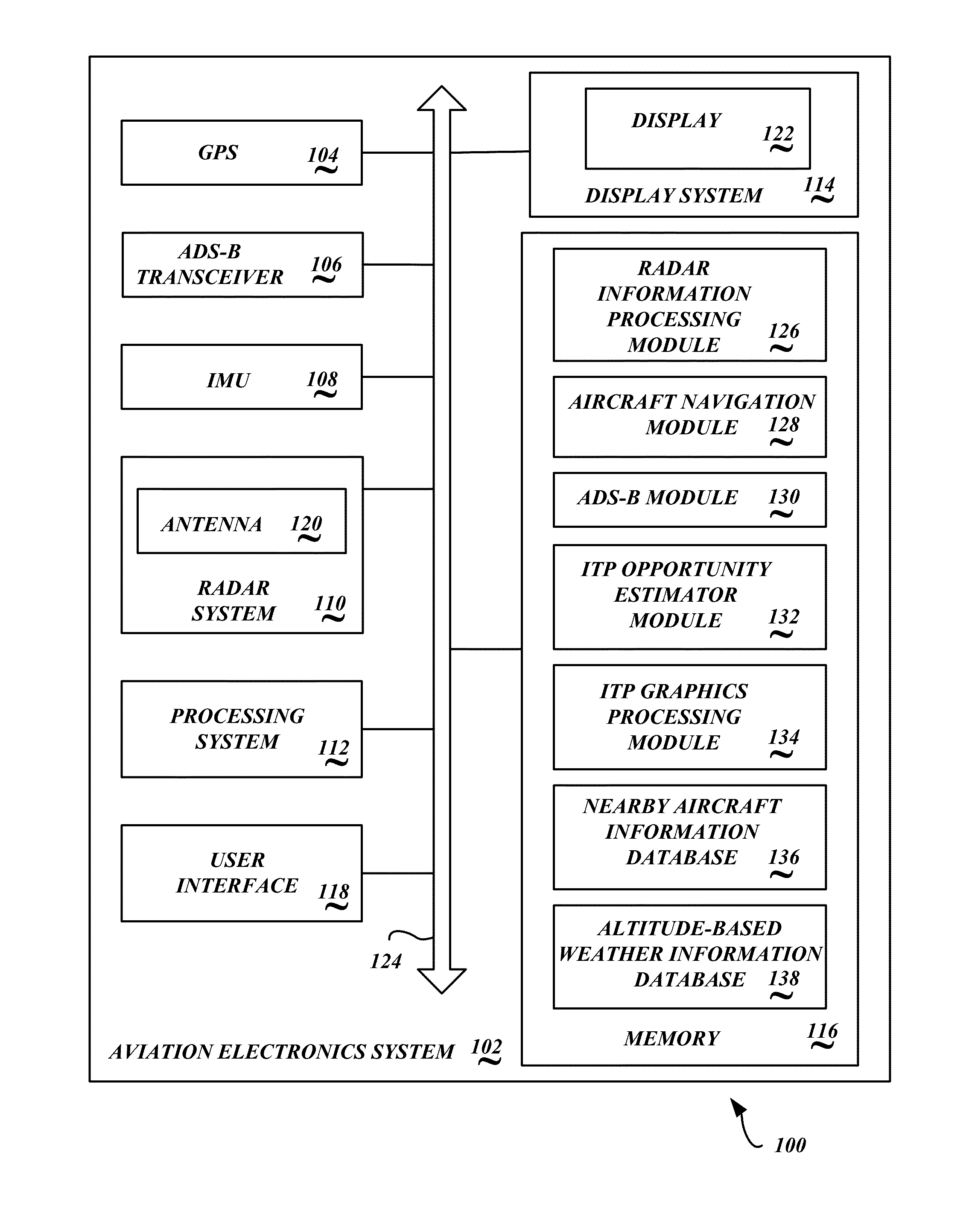

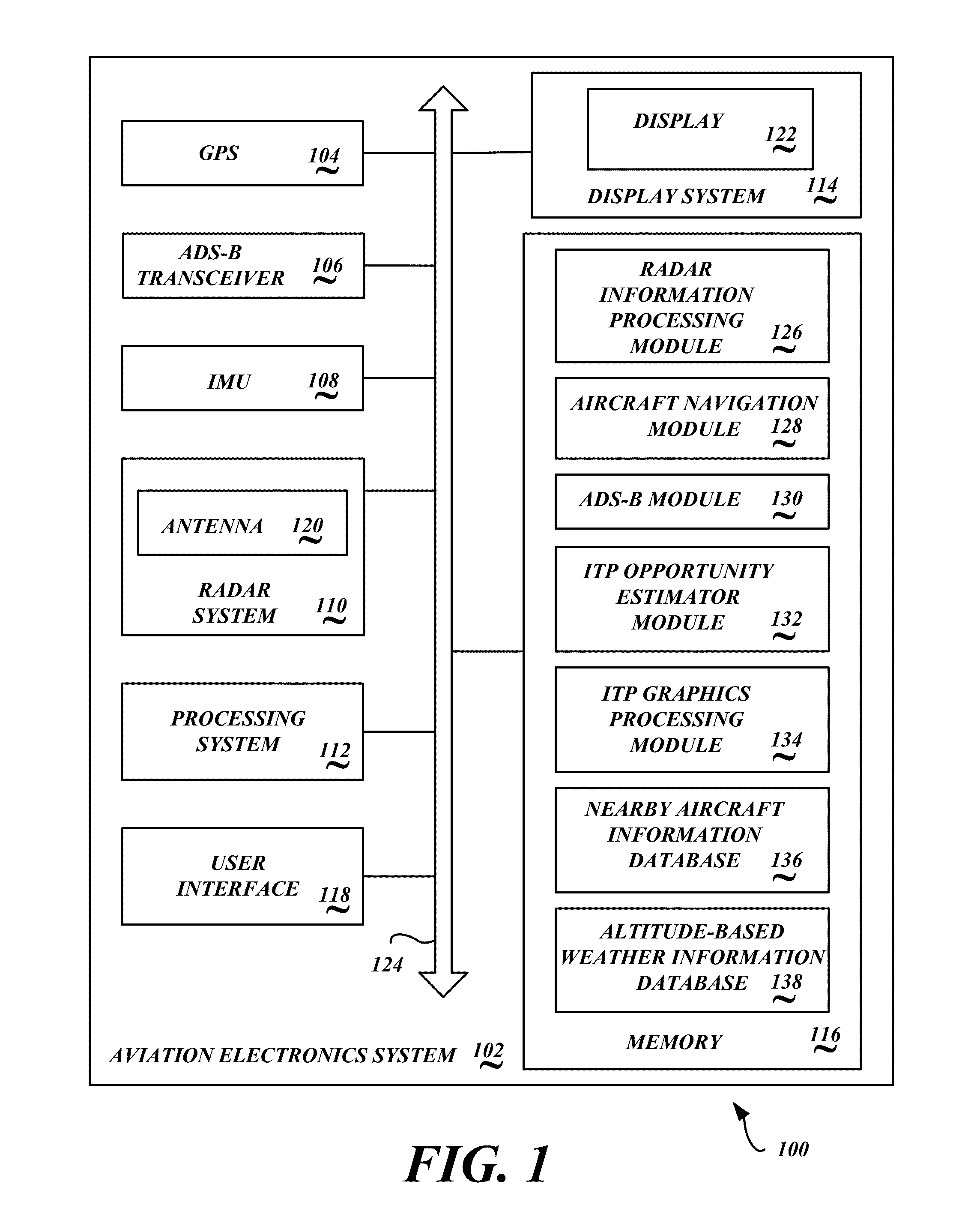

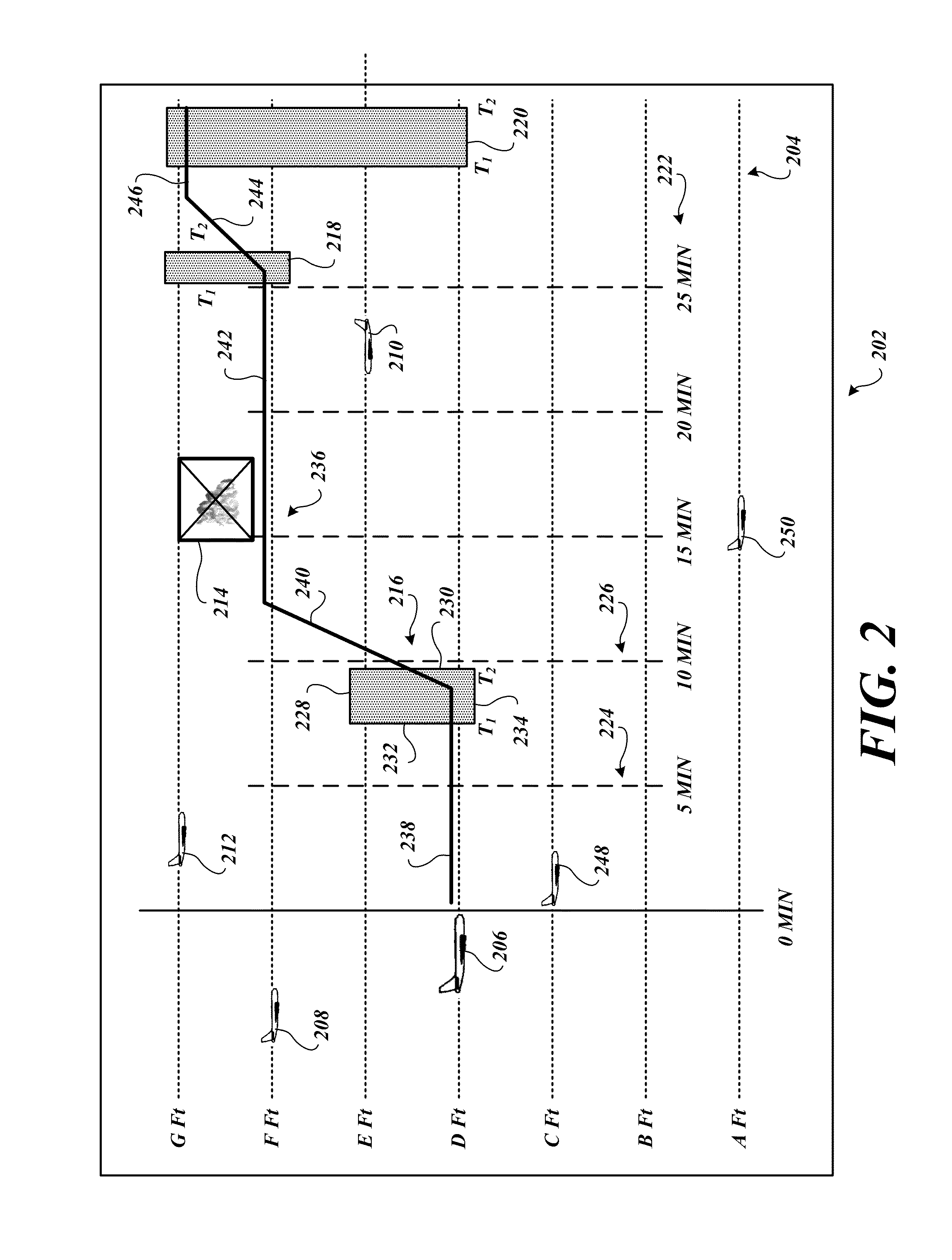

Systems and methods for in-trail opportunity window estimator

Systems and methods are operable to identify and indicate opportunities for an In-Trail procedure (ITP) aircraft to make an ITP altitude change. An exemplary embodiment receives information corresponding to a desired ITP altitude for the ITP aircraft and a projected window period; estimates at least one ITP maneuver opportunity window based on the estimated location of each of the plurality of other aircraft and based on a current airspeed and a current altitude of the ITP aircraft; generates a screen shot that presents an ITP maneuver opportunity window icon, wherein the ITP maneuver opportunity window icon graphically indicates the soonest time and the latest time that the ITP aircraft may initiate the ITP maneuver, and wherein the ITP maneuver opportunity window icon indicates an altitude change made by the ITP aircraft will maintain minimum safe self-separation distances from the plurality of other aircraft during the ITP maneuver.

Owner:HONEYWELL INT INC

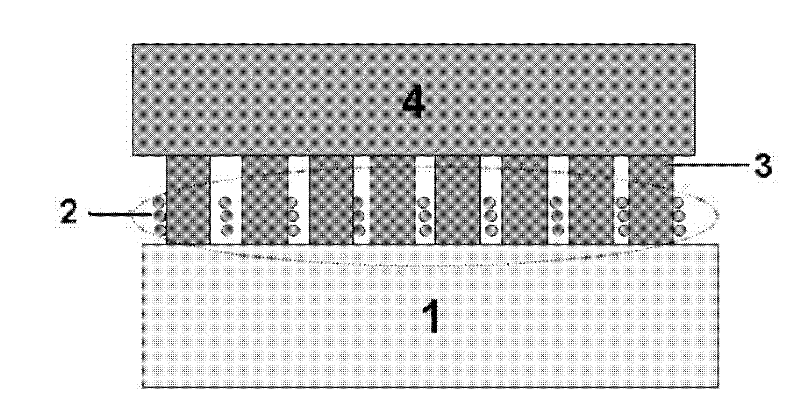

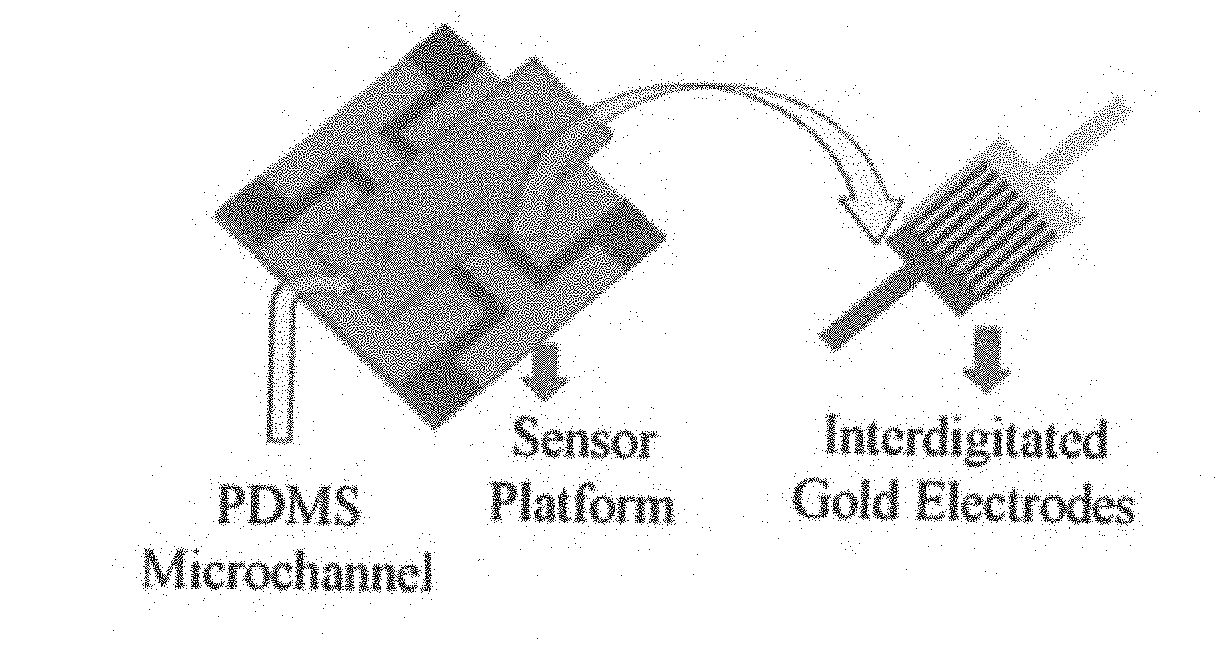

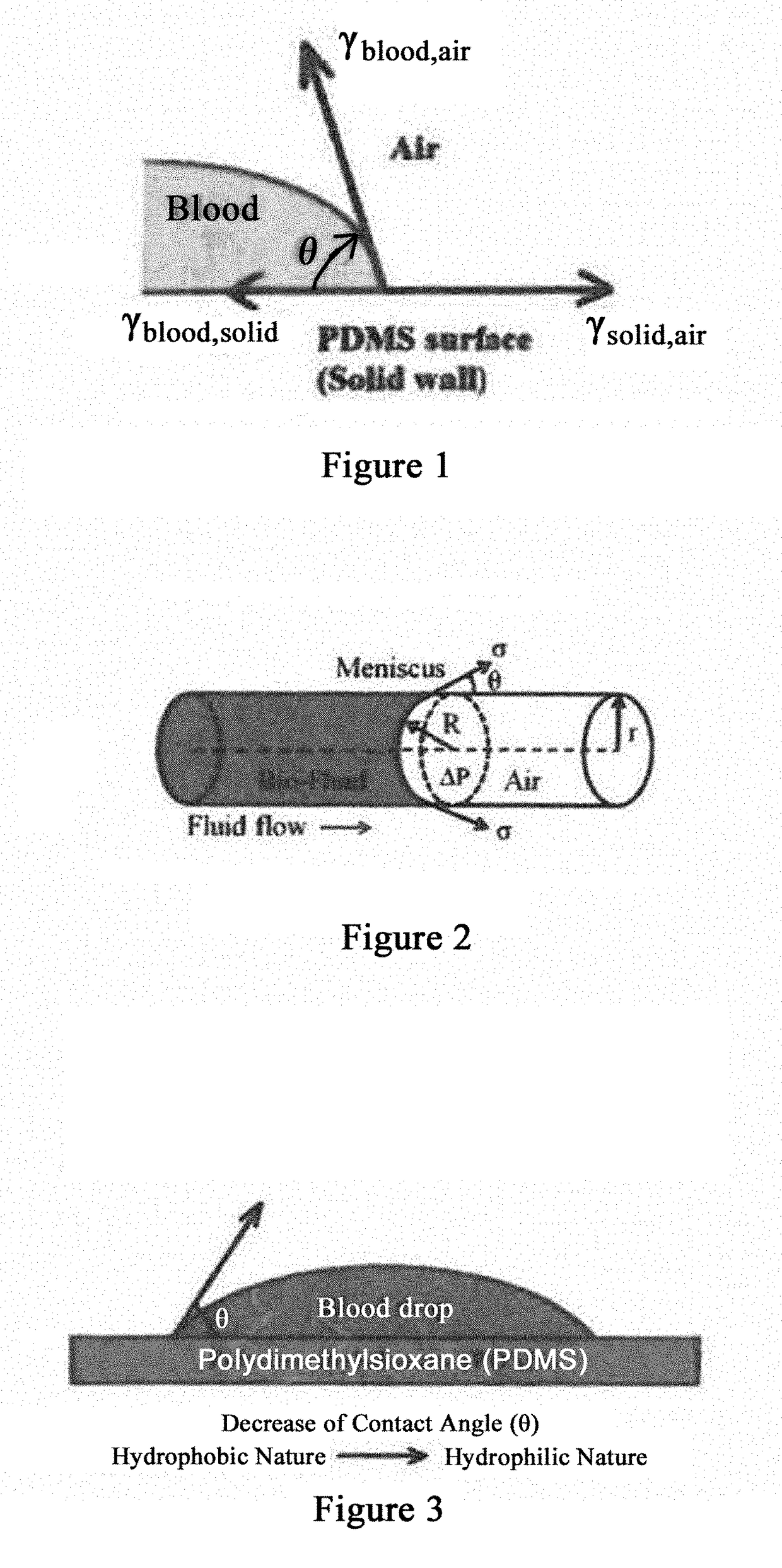

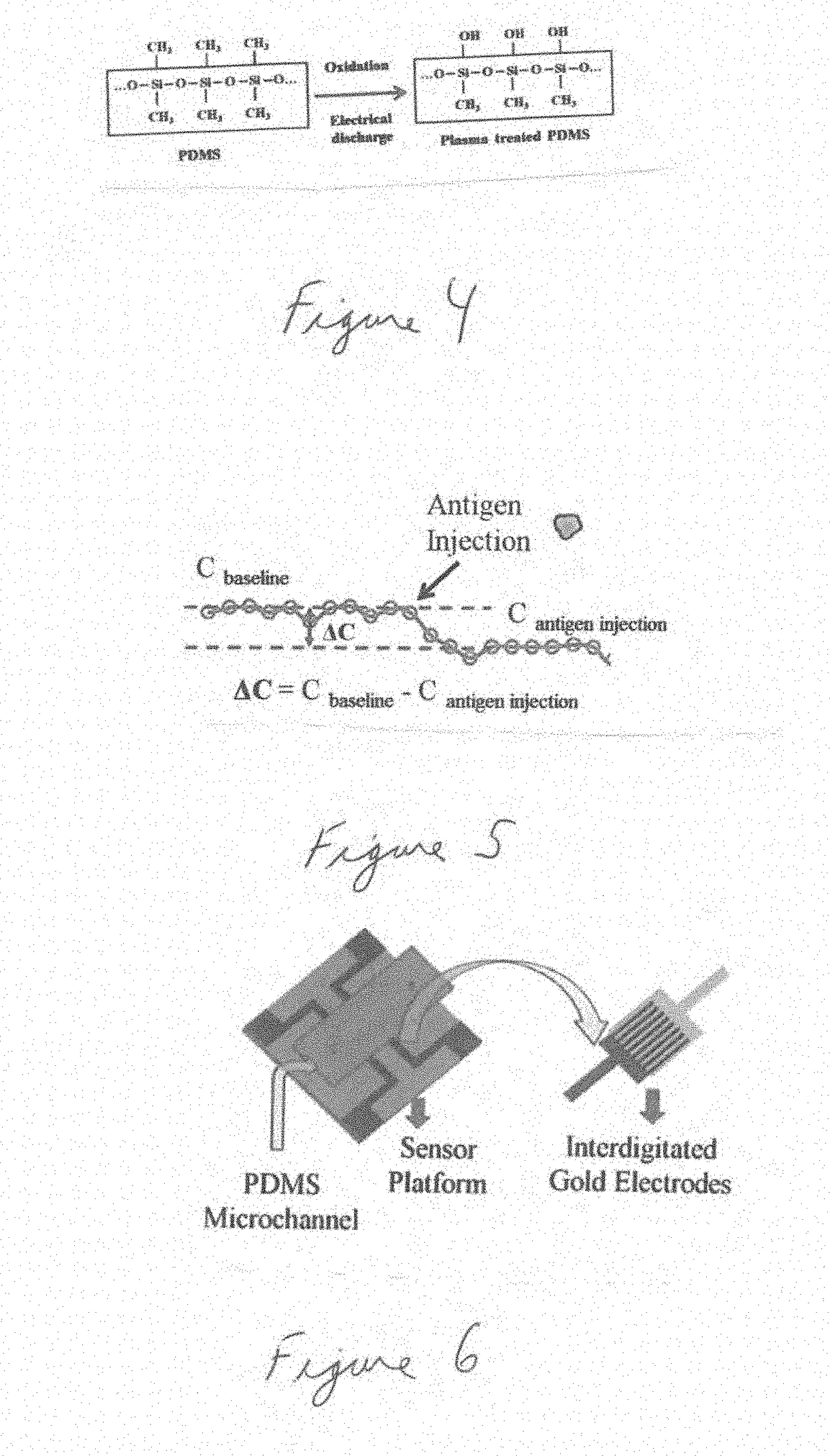

Biomarker detection and self-separation of serum during capillary flow

ActiveUS20180128823A1Reduce effortReduce man powerBiological material analysisLaboratory glasswaresAntigenCapacitance

Molecularly Imprinted Polymers (MIPs) are utilized to detect diseases and minimize false negative / positive scenarios. MIPs are implemented on a nano-electric circuit in a biochip where interactions of MIPs and an Antigen / Antibody (AG / AB) are detected, and disease specific biomarkers diagnosed. Biomarker detection is achieved with interdigitated gold electrodes in a biochip's microchannel. Capacitance changes due to biomarker interaction with AG / AB electrode coating diagnose diseases in a microfluidic environment. Biofluid passes through the microchannel and exposed to the nanocircuit to generate a capacitance difference and diagnose any specific disease in the biofluid sample. Blood capillary flow in a microchannel curved section experience centrifugal forces that separate liquid from solid. Various blood densities and segments experience different centrifugal effects while flowing through the curved section so serum is separated from various solid matter without using external devices.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Method of fabricating GaN substrate

InactiveUS8349076B2Simple and low-costImprove production yieldPolycrystalline material growthAfter-treatment detailsManufacturing cost reductionGallium nitride

A method of fabricating a freestanding gallium nitride (GaN) substrate includes: preparing a GaN substrate within a reactor; supplying HCl and NH3 gases into the reactor to treat the surface of the GaN substrate and forming a porous GaN layer; forming a GaN crystal growth layer on the porous GaN layer; and cooling the GaN substrate on which the GaN crystal growth layer has been formed and separating the GaN crystal growth layer from the substrate. According to the fabrication method, the entire process including forming a porous GaN layer and a thick GaN layer is performed in-situ within a single reactor. The method is significantly simplified compared to a conventional fabrication method. The fabrication method enables the entire process to be performed in one chamber while allowing GaN surface treatment and growth to be performed using HVPE process gases, thus resulting in a significant reduction in manufacturing costs. The fabrication method also allows self-separation of thick GaN without cracking, thus achieving a short process time and a high manufacturing yield.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

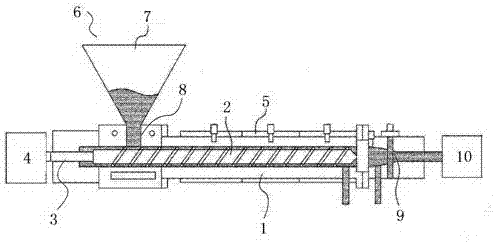

Melt electrostatic spinning device

InactiveCN107604450AReduce direct contactAchieve anti-adhesion effectFilament/thread formingElectrospinningEngineering

A melt electrostatic spinning device comprises a spinning nozzle, a spinning nozzle suite, a nozzle sleeve, a plunger, a counterweight disk, a heating device, a temperature sensor and an elastic sealing ring. Concave-convex anti-adhesion structures are arranged on the surfaces of all parts, making contact with a molten polymer, of a melt electrostatic spinning assembly so that the anti-adhesion effect of polymer melt in the spinning assembly can be achieved. According to the action mechanism of the concave-convex anti-adhesion structures, the concave-convex anti-adhesion structures comprise concave parts and convex parts, the convex parts are higher than the surfaces of the parts, and the direct contact between the high-viscosity polymer melt and the surfaces of the parts is reduced by utilizing the supporting action between points; besides, a gas suspension effect is formed under the action of the high-temperature high-pressure melt, and self-separation type adhesion prevention is achieved.

Owner:TONGXIANG YIZHIJIANNENG INFORMATION TECH

Self-separation method for preparation of GaN substrate

InactiveCN109023515AReduce stressQuality improvementPolycrystalline material growthFrom chemically reactive gasesComposite filmSurface layer

The invention discloses a self-separation method for preparation of a GaN substrate, which includes steps of: 1) on a sapphire substrate, growing a uniformly-distributed Ga2O3 film, wherein thicknessrange of the film is 1-5 [mu]m; 2) in an ammonia atmosphere, performing partial nitridation to the surface layer of the film, thus forming a GaN / Ga2O3 composite film in a porous latticed distributionstructure; 3) on the composite film, performing halide vapor phase epitaxy growth of a GaN thick film, thus forming a low stress and high quality GaN thick film; 4) after the epitaxy is completed, cooling the material to room temperature, so that the epitaxy GaN thick film is automatically separated from the substrate, thus obtaining the self-supporting GaN substrate.

Owner:NANJING UNIV

Preparation method of GaN substrate

ActiveCN106298443AGood removal effectEasy to manufactureSemiconductor/solid-state device manufacturingSemiconductor devicesNanopillarDecomposition

The invention discloses a preparation method of a GaN substrate, wherein the preparation method belongs to the field of optoelectronic device preparation. According to the preparation method, a GaN film, an InGaN film, an AlGaN film, an AlN film or an InN film or nanometer columns are epitaxially grown on a sapphire substrate on which carbon nanotubes are laid for forming a transition layer; a carbon nanotube laying range exceeds the edge of the substrate by 200 mu m-1 mm; then a composite substrate is arranged below laser for bearing irradiation; the carbon nanotubes which exceed the edge of the substrate facilitate gradual decomposition of the carbon nanotubes or GaN under laser radiation from the edge to the central part and discharging of generated gas; holes (with diameters of 200-800nm) remain at occupation positions of the carbon nanotubes; and finally a thick GaN film is grown, thereby obtaining a thick GaN film substrate or obtaining a self-supporting GaN substrate through a substrate removing process or a self-separation process. The preparation method of the GaN substrate has advantages of simple operation, easy control of technological conditions, low price and high convenience in large-scale batch production. Different substrates can be selected. Furthermore the preparation method supports a plurality of substrate separation processes.

Owner:PEKING UNIV

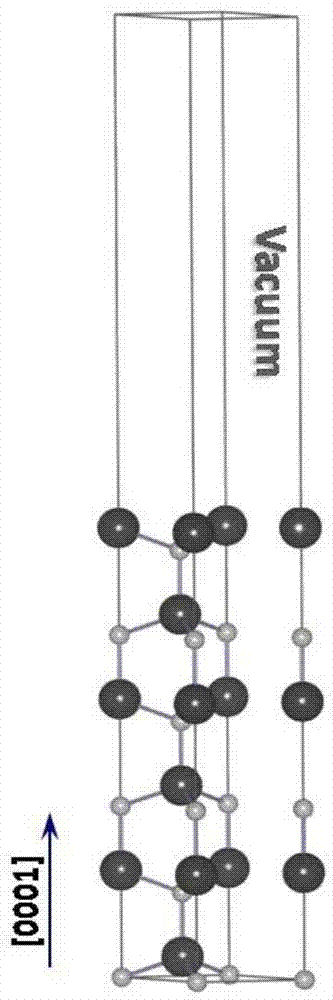

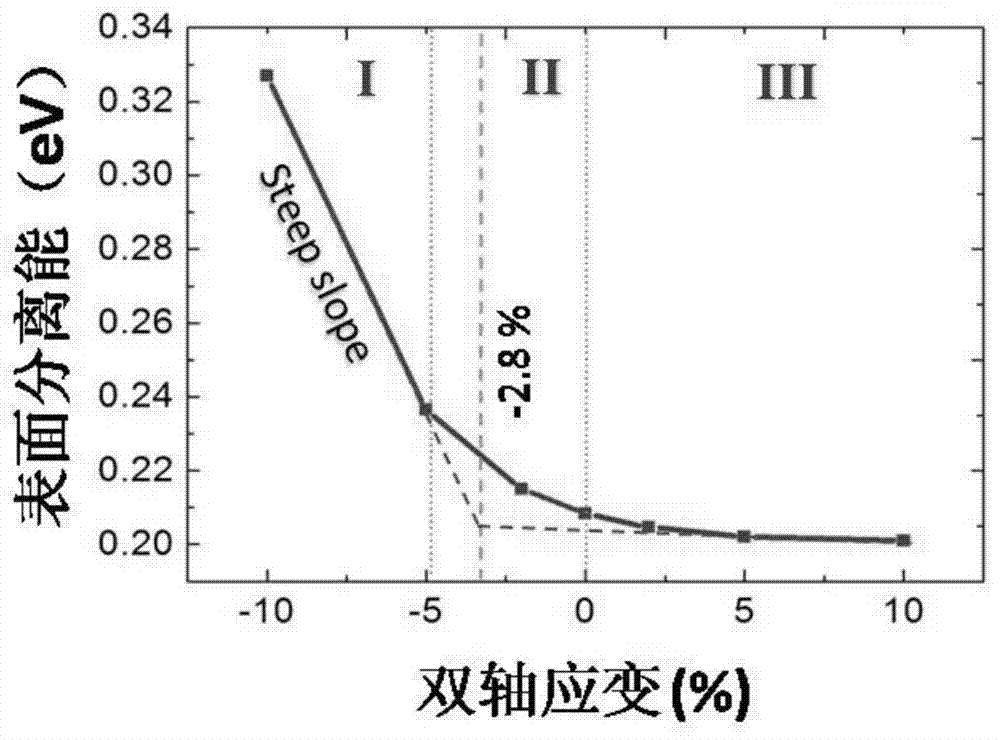

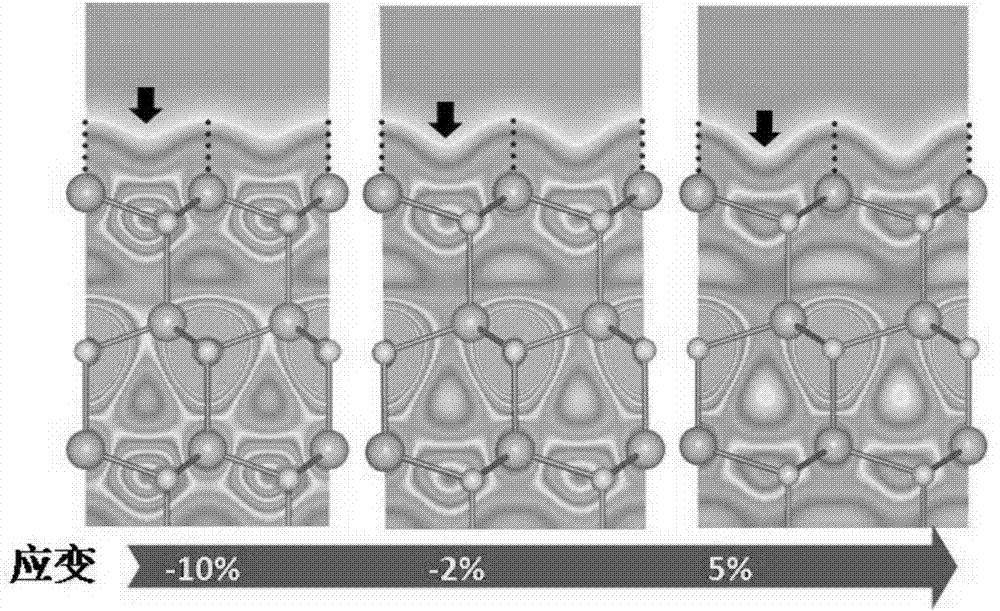

Method for separating nitride self-supporting substrate by utilizing stress gradient

InactiveCN103943467ASelf-separation phenomenonSimple methodPolycrystalline material growthSemiconductor/solid-state device manufacturingGrowth parameterFirst principle

The invention provides a method for separating a nitride self-supporting substrate by utilizing stress gradient and relates to a nitride based photoelectric device. The method for separating the nitride self-supporting substrate by utilizing the stress gradient comprises the steps of 1 performing on first-principle theory method analog computation of GaN layer crystal; 2 performing sapphire substrate pre-treatment before sample preparation; 3 enabling a GaN buffer layer to grow; 4 preparing GaN epitaxial growth. By utilizing relation of separation energy and stress, special treatment is performed in a GaN epitaxial layer grown by adopting an HVPE method, and the stress gradient distribution is adjusted by effectively controlling the thickness of the GaN epitaxial layer, so that a self separation phenomenon of the GaN epitaxial layer with the critical thickness is achieved. An in-situ GaN self separation technology is achieved by regulating and controlling epitaxial growth parameters, GaN self separation can be finished while HVPE growth, and the method is simple, easy to operate and good in practicability.

Owner:XIAMEN UNIV

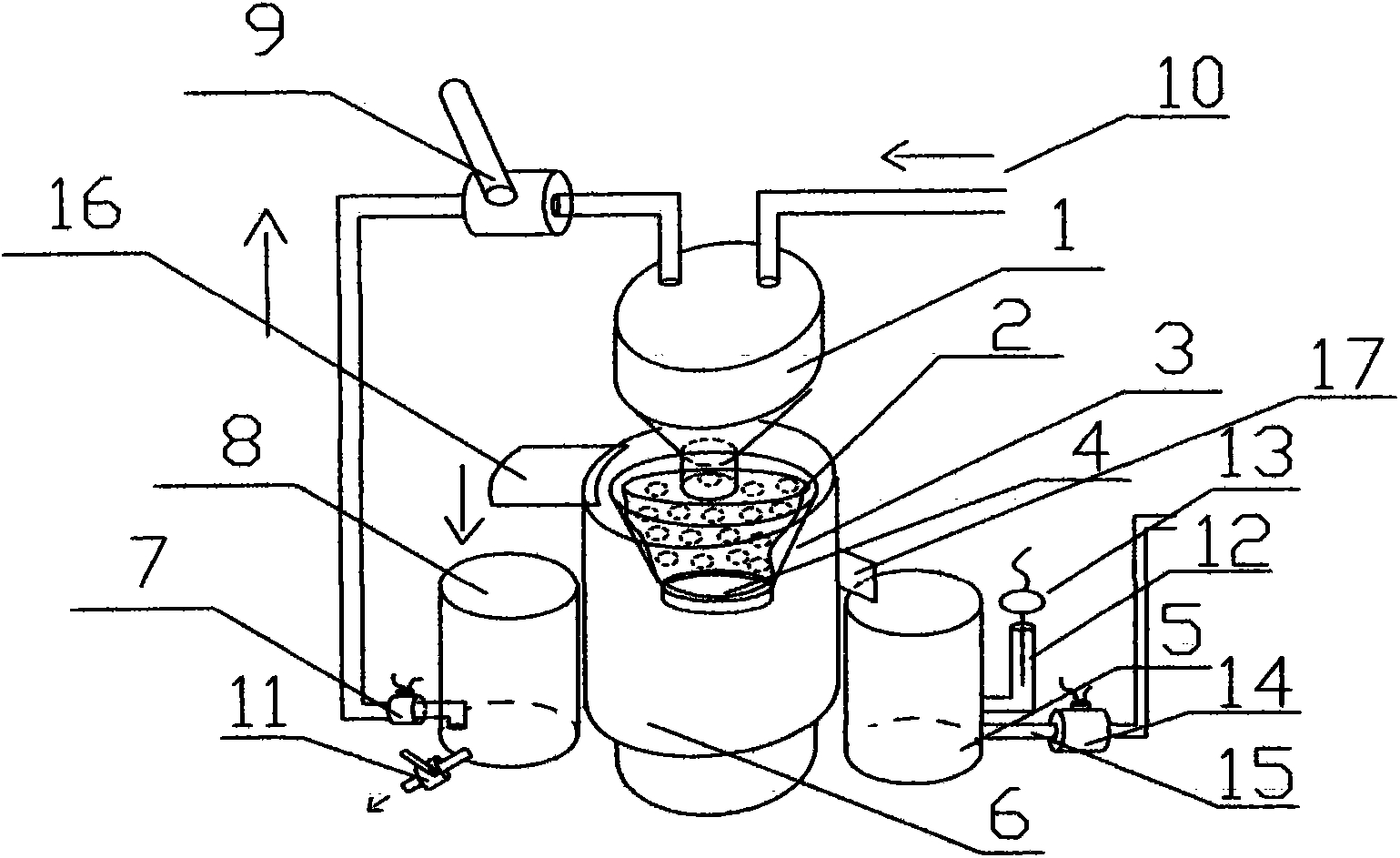

Cooked soybean milk filtering device

InactiveCN103843910ALow costTurn slowlyBeverage vesselsMilk substitutesHigh concentrationEngineering

The invention discloses a cooked soybean milk filtering device which is characterized in that a mechanism of a slurry residue self-separation machine is used for a cooked soybean milk filtering device; the rotating mechanism (6) is provided with a filter screen (2) and a feedback pump (7), wherein the rotating mechanism (6) rotates at high speed, the cooked soybean milk is filtered by utilizing the centrifugal force of the rotating mechanism (6), the feedback pump (7) pumps bean dregs and soybean milk in a container (8) into a hopper (1) for circulating filtering; the cooked soybean milk filtering device has the characteristics of being simple in structure, low in production cost and quick and practical, can filter high-concentration cooked soybean milk, is high in filtering efficiency and saves fuel.

Owner:杨安林

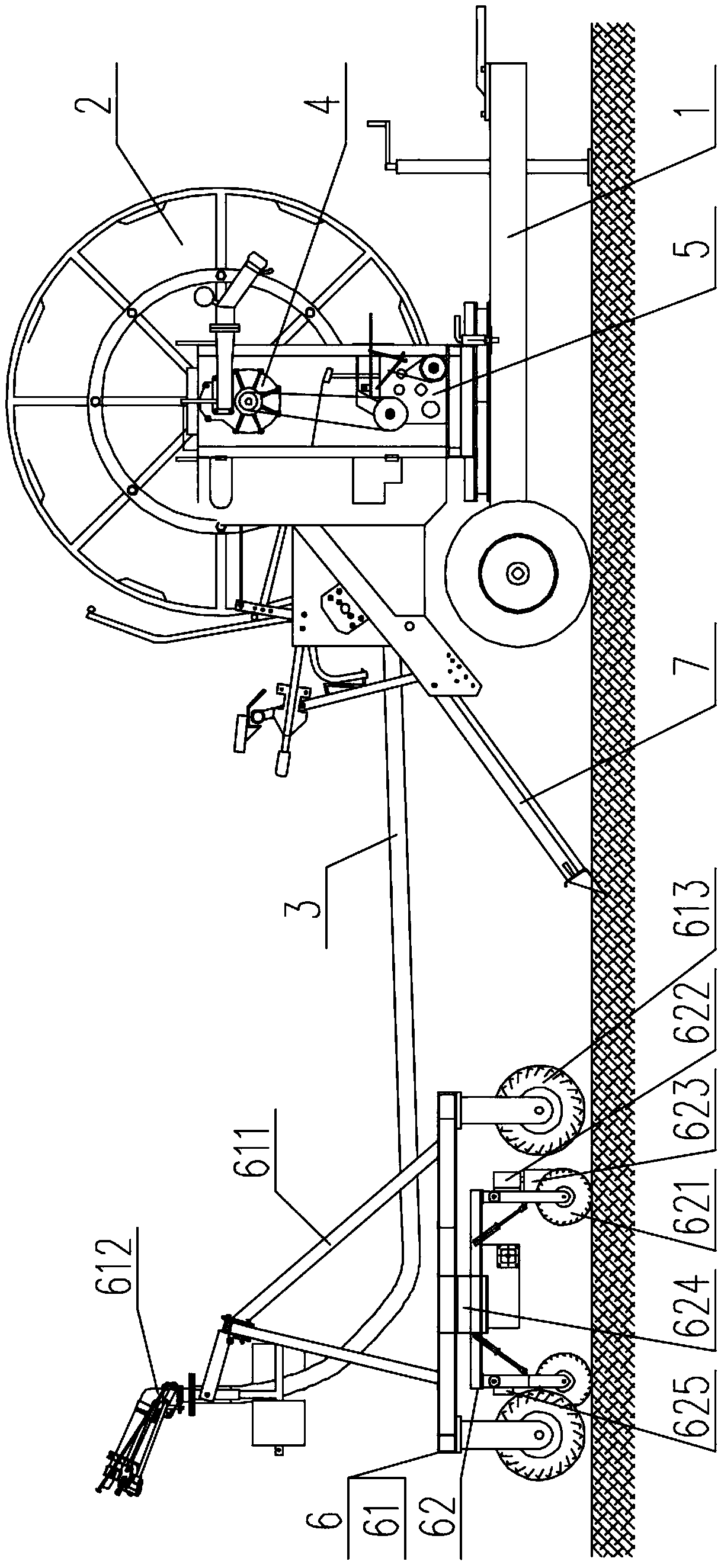

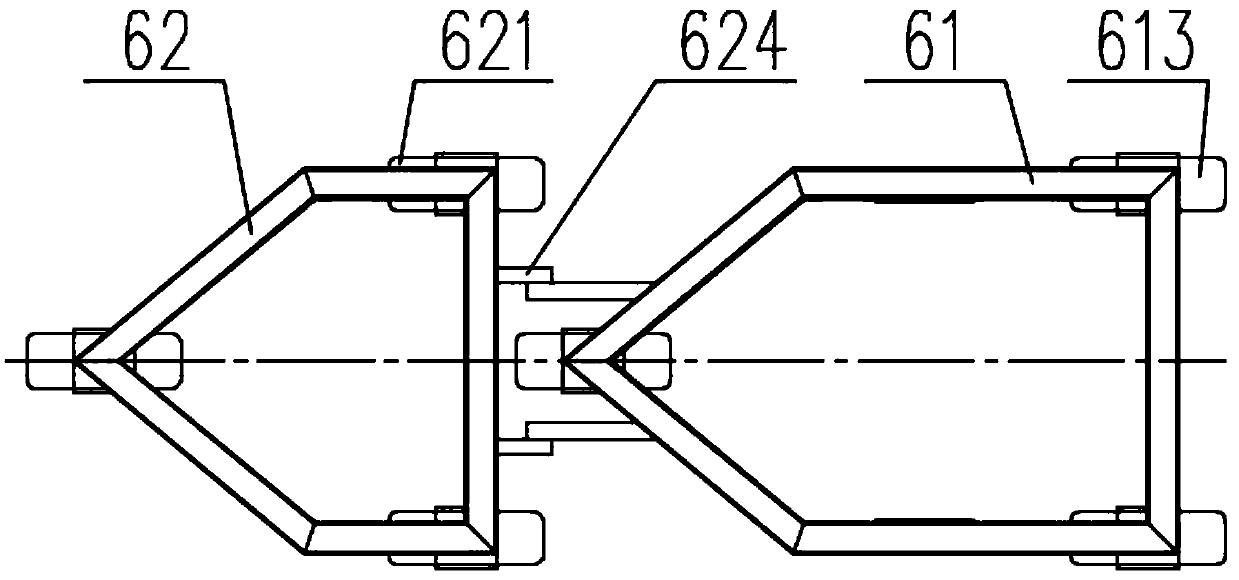

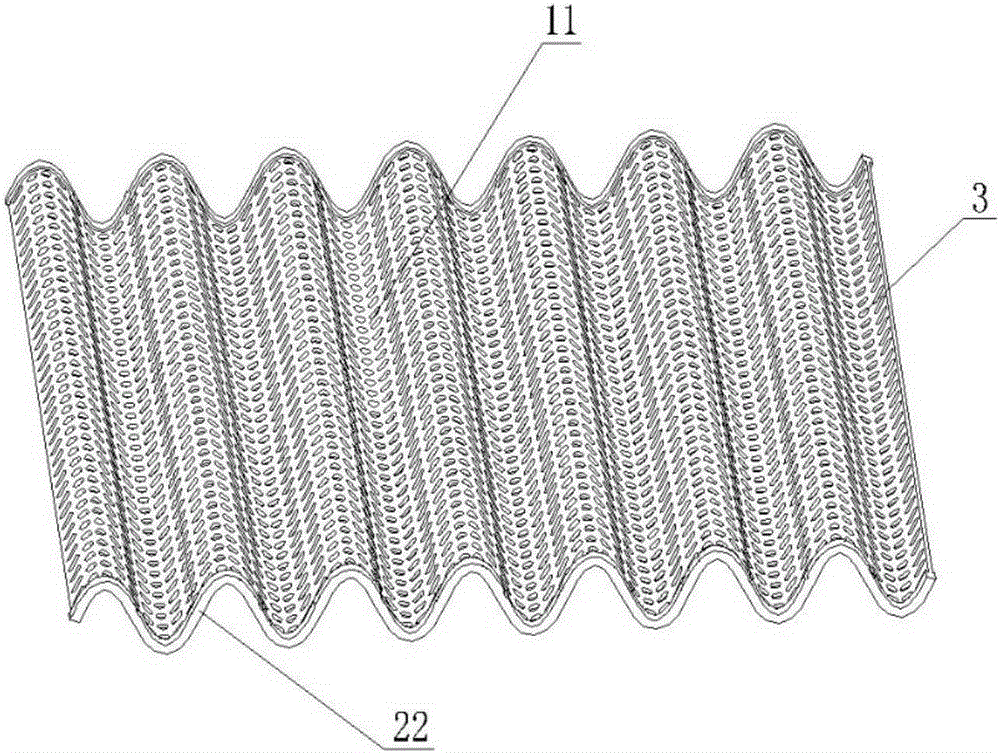

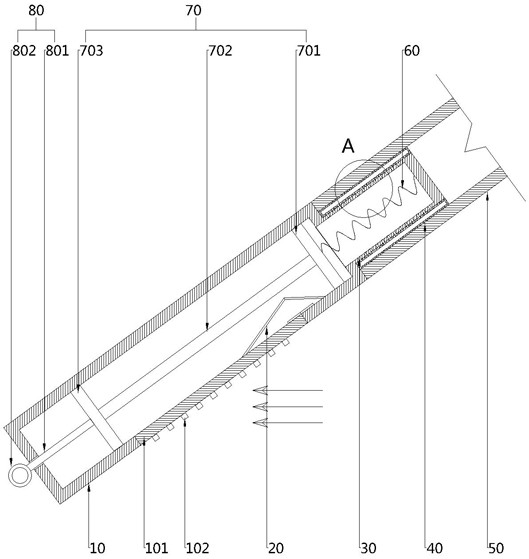

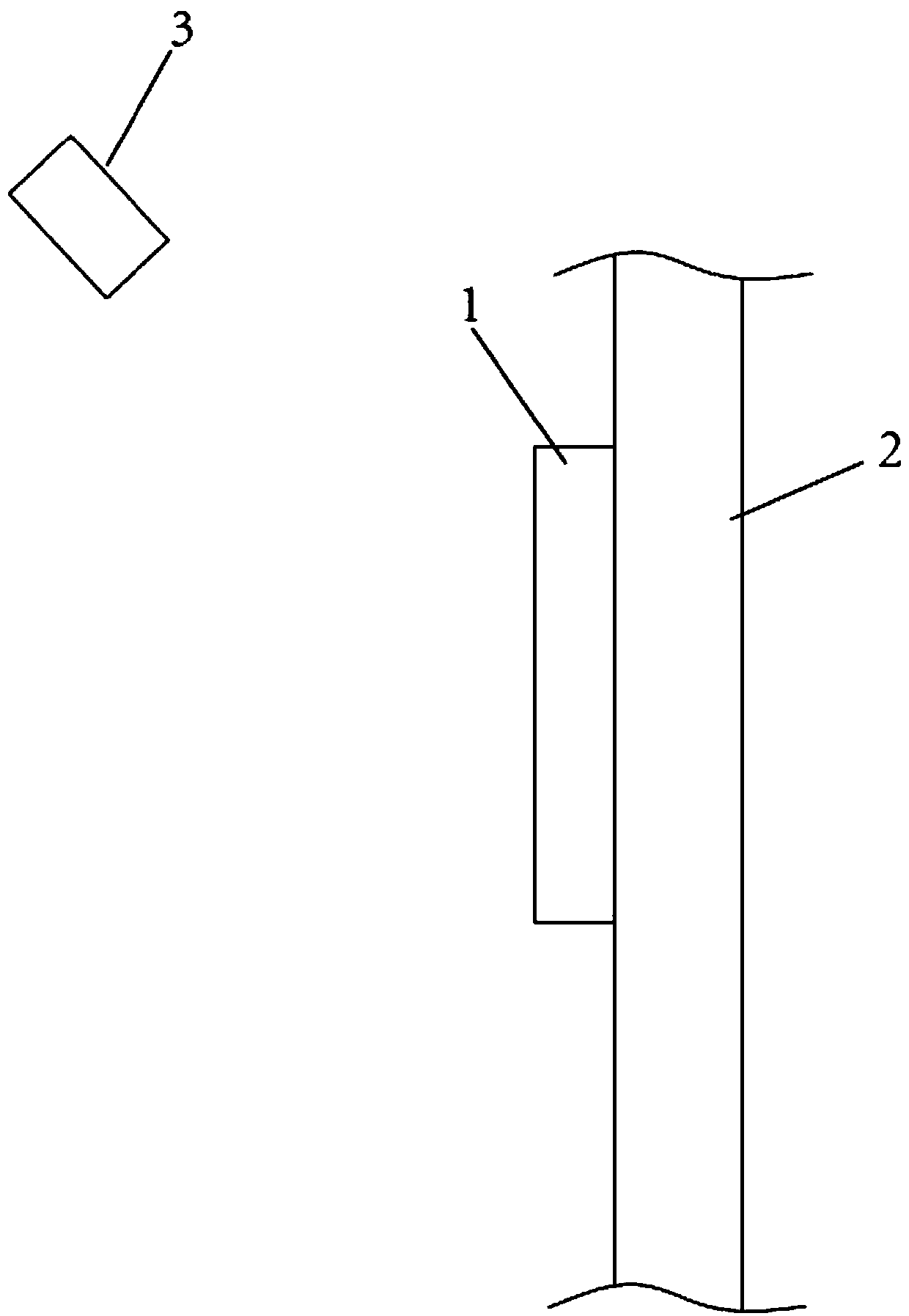

Self-separation type reel sprinkler with sprinkler wagon

ActiveCN109601344AReduce resistanceFacilitate automatic recyclingClimate change adaptationWatering devicesWater turbineSteering control

The invention discloses a self-separation type reel sprinkler with a sprinkler wagon. The self-separation type reel sprinkler comprises a chassis (1), a reel (2), a PE pipe (3), a water turbine box (4), a reel drive speed changing box (5) and the sprinkler wagon (6), wherein the sprinkler wagon comprises a main wagon body (61) and an auxiliary wagon body (62); a sprinkler rack (611), a sprinkler (612) and main wagon body supporting wheels (613) are arranged on the main wagon body; auxiliary wagon body wagon wheels (621), a power source (622), a sprinkler drive speed changing box (623), a wagonbody locking device (624), a steering control device (625), a counter weight and an electric control box are installed on the auxiliary wagon body, and the auxiliary wagon body is connected with themain wagon body through the wagon body locking device. According to the self-separation type reel sprinkler with the sprinkler wagon, the change for the own weight of the sprinkler wagon is realized through the self-separation of the main wagon body and the auxiliary wagon body, and the reduction for the rewinding resistance of the PE pipe can be realized under the premise that enough road grabbing capacity is generated by the sprinkle wagon to pull the PE pipe to walk automatically.

Owner:JIANGSU HUAYUAN IRRIGATION & DRAINAGE

Epitaxial material stress control-based GaN thick film self-separation method

InactiveCN101962804BSimple processUniversally applicablePolycrystalline material growthFrom chemically reactive gasesEpitaxial materialProcess conditions

The invention discloses an epitaxial material stress control-based GaN thick film self-separation method, which comprises the following steps of: pretreating a substrate material; growing an epitaxial material on the substrate, gradually modulating process conditions to ensure that the stress of the epitaxial material is gradually concentrated to a preset self-separation position; when the thickness of the epitaxial material reaches the preset self-separation position, and performing jumping modulation on the process conditions to ensure that the stress is jumped at the preset position; gradually modulating the process conditions again to ensure that the stress of the epitaxial material is gradually released along with the increase of the thickness, namely the stress is reversely concentrated to the preset position; and finishing the epitaxial growth, and gradually reducing temperature to make stress difference on the two sides of the preset self-separation position further amplified so as to realize the self-separation of the monocrystalline thick film at the preset position. The method can effectively control the integral distribution of the stress in the epitaxial material and well realize the self-separation of the epitaxial material on the basis of ensuring the quality of the epitaxial material.

Owner:PEKING UNIV

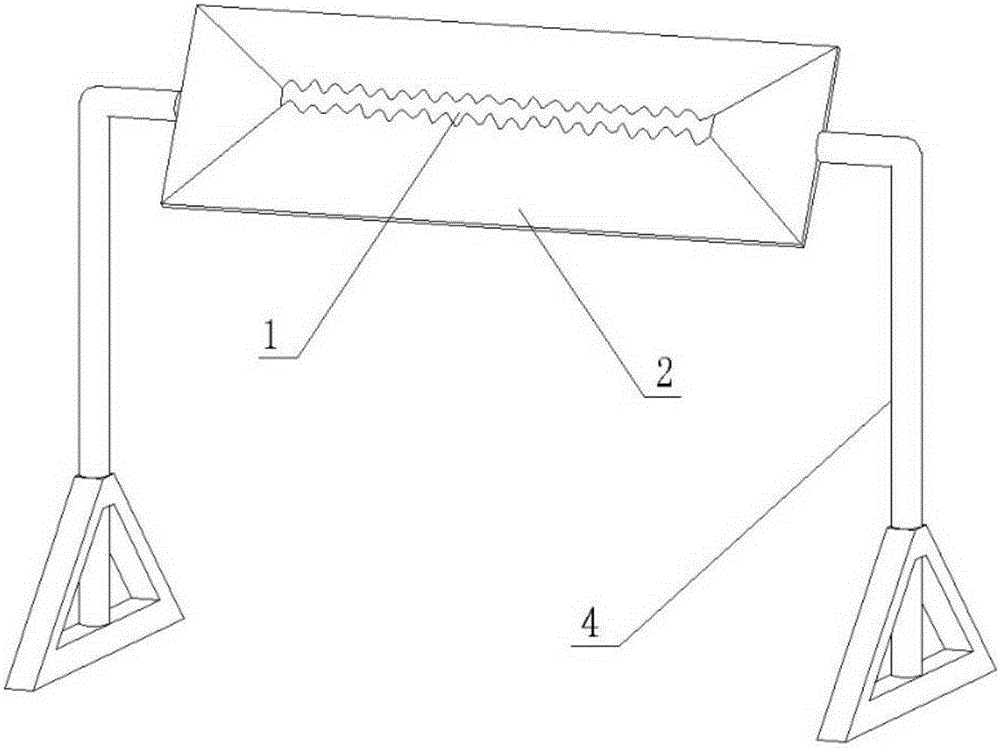

An automatic mounting and rapid cocoon harvesting device

ActiveCN105230578AAchieve self-separationReduce labor intensityAnimal husbandryWave shapeEngineering

Owner:高伟

Anti-adhesion screw extruder

InactiveCN107447262AAchieve anti-adhesion effectReduce direct contactSpinning head liquid feederArtificial thread manufacturing machinesEngineeringHigh pressure

An anti-adhesion screw extruder of the present invention comprises an extruding tube, an extruding screw is arranged in the extruding tube, a screw shaft is arranged in the extruding screw, and the spinning assembly is in contact with the molten polymer Concave-convex anti-adhesion structures are provided on the surface of the parts, which can realize the anti-adhesion effect of polymer melt in the spinning assembly; the mechanism of the concave-convex anti-adhesion mechanism is: the concave-convex anti-adhesion structure includes concave parts and convex Part, the raised part is set higher than the surface of the part, using the support between points to reduce the direct contact between the high-viscosity polymer melt and the surface of the part, and forms a gas suspension under the action of the high-temperature and high-pressure melt Function, play a self-separating anti-adhesion.

Owner:陈慧忠

Method for preparing compound semiconductor substrate

ActiveCN101436531AReduce dislocation generationQuality improvementSemiconductor/solid-state device manufacturingDislocationSelf-separation

Owner:硅得荣株式会社

Self-separation protective sleeve for airspeed tube of civil aircraft

ActiveCN113866451AGuaranteed to workAchieve separationAircraft componentsSpeed/acceleration/shock instrument detailsCivil aviationMechanical engineering

The invention provides a self-separation protective sleeve for an airspeed tube of a civil aircraft, and belongs to the technical field of aircraft protection devices. The self-separation protective sleeve comprises a pipeline, a first elastic piece, an extension head, a clamping part and a driving part; an air inlet is formed in the side wall of the pipeline, a spoiler is movably arranged in the air inlet, one end of the first elastic piece is connected with the inner wall of the pipeline, the other end of the extension head is connected with the spoiler and used for providing elastic support for the spoiler, the extension head is fixedly installed at one end of the pipeline and used for being inserted into an airspeed tube, the clamping part is arranged on the outer side of the extension head and used for fixing the extension head into the airspeed tube, and the driving part is movably arranged in the pipeline. Compared with the prior art, the self-separation protective sleeve has the advantages that in the takeoff process of an airplane, automatic separation between the airspeed tube protective sleeve and the airspeed tube can be achieved, potential safety hazards caused by manual negligence are eliminated, and normal work of the airspeed tube is guaranteed.

Owner:北京航源众诚动力科技有限公司

Self-separation peeling equipment

InactiveCN107598293AEffective self-separation effectImprove automation performanceEngineeringSelf-separation

Owner:TAICANG BEST MECHANICAL EQUIP

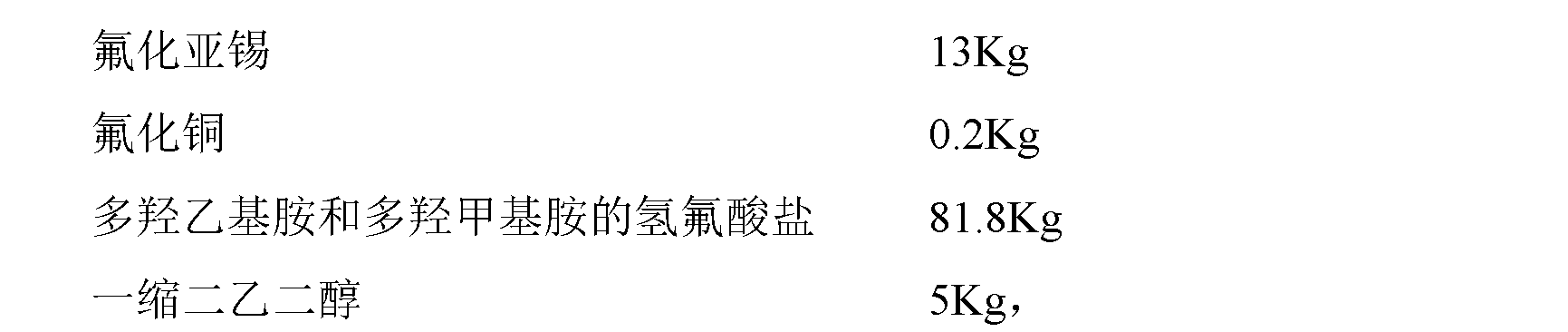

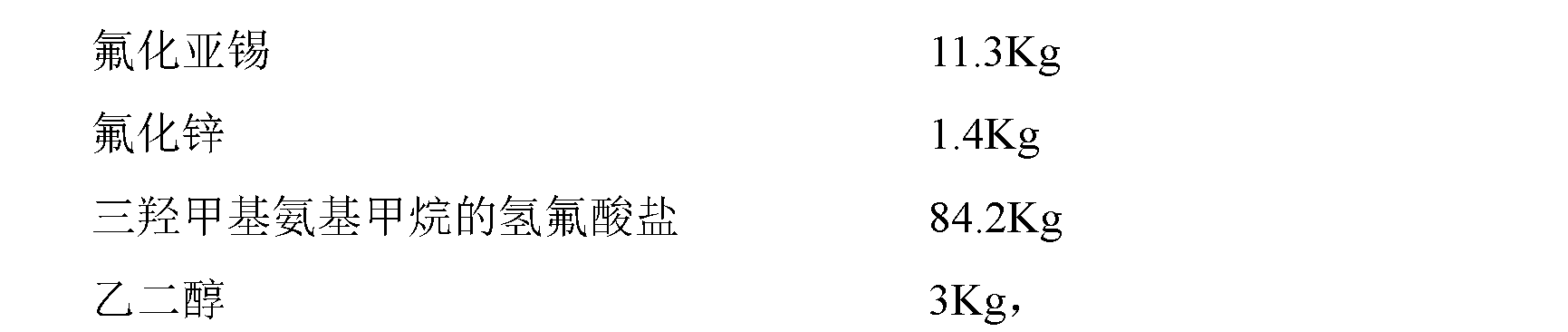

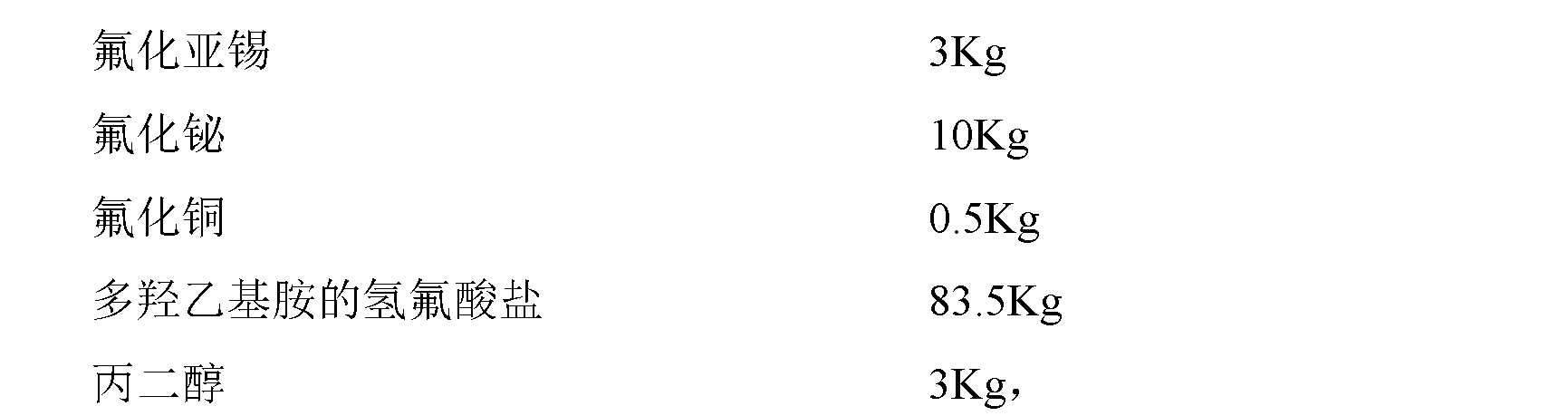

Self-separation fluxing agent of hot tinning and tin alloy and preparation method thereof

ActiveCN103182612AAct as a carrierAvoid problemsWelding/cutting media/materialsSoldering mediaTinningActive agent

The invention relates to a self-separation fluxing agent of hot tinning and a tin alloy and a preparation method thereof. The self-separation fluxing agent comprises the following raw materials by weight percentage of 10-15% of a heavy metal fluoride active agent, 80-87% of polyhydroxy ethylene diamine and 3-5% of an alcohol solvent. According to the self-separation fluxing agent provided by the invention, the borofluoride with poor activity is abandoned and a perfluorinated compound with higher activity as an active agent is adopted, meanwhile, the hydrofluoride of polyhydroxy methyl organic amine with the high activity is utilized as a matrix in a matching manner so as to enable the perfluorinated compound to be fully dissolved, the matrix has a carrier action, and a scaling powder does not fully contain an inactive filling.

Owner:烟台博瑞锡业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com