Self-separation type reel sprinkler with sprinkler wagon

一种喷头车、自分离的技术,应用在气候变化适应、园艺、植物学设备和方法等方向,能够解决额外功耗、功能单一、操作复杂等问题,达到便于自动回收、使用范围广、防止原地打滑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

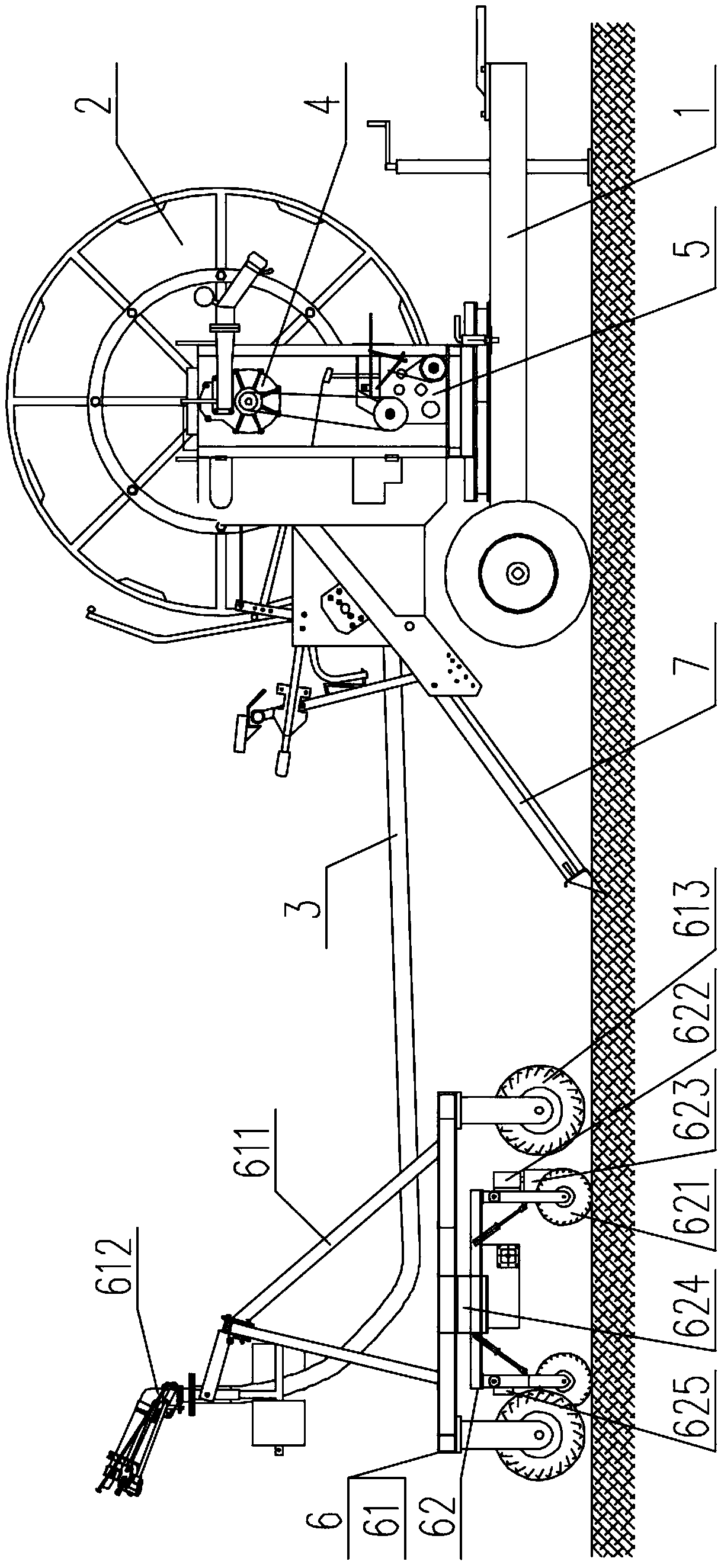

[0026] Such as figure 1 As shown, the sprinkler car self-separating reel sprinkler irrigation machine includes a chassis 1, a reel 2, a PE pipe 3, a water turbine box 4, a reel drive gearbox 5 and a sprinkler car 6.

[0027] The reel 2 , the water turbine case 4 and the reel drive gearbox 5 are all installed on the underframe 1 .

[0028] The PE pipe 3 is wound on the reel 2, and the input end of the PE pipe 3 is connected with the water supply plug of the pressure water source through the water turbine box 4.

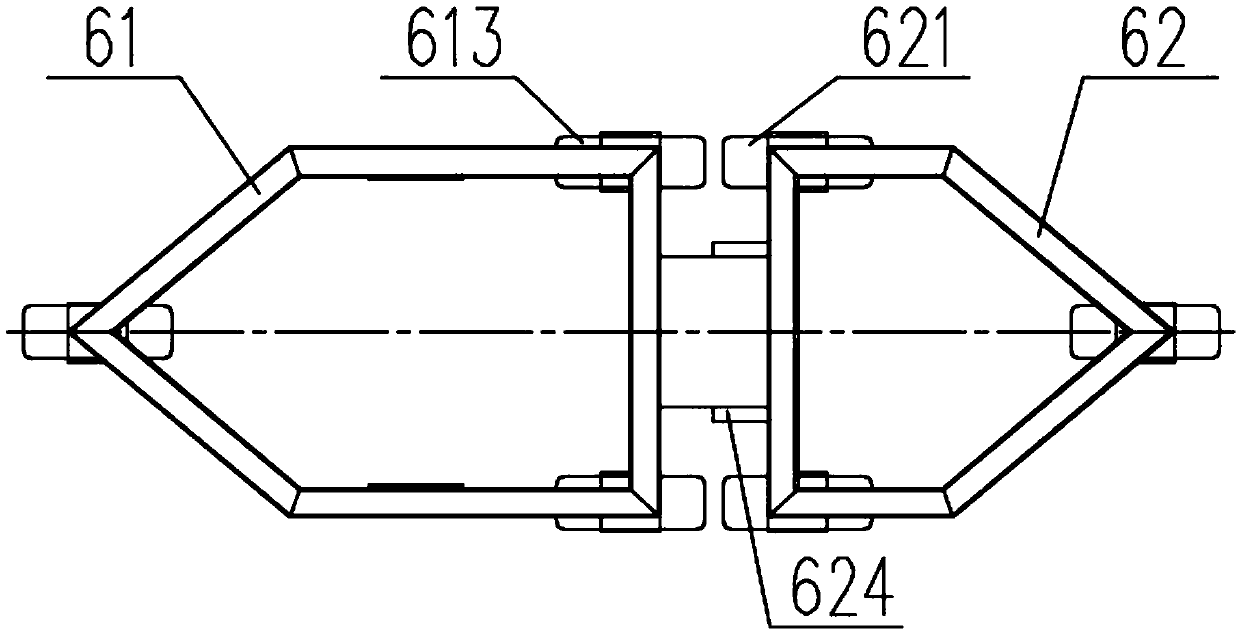

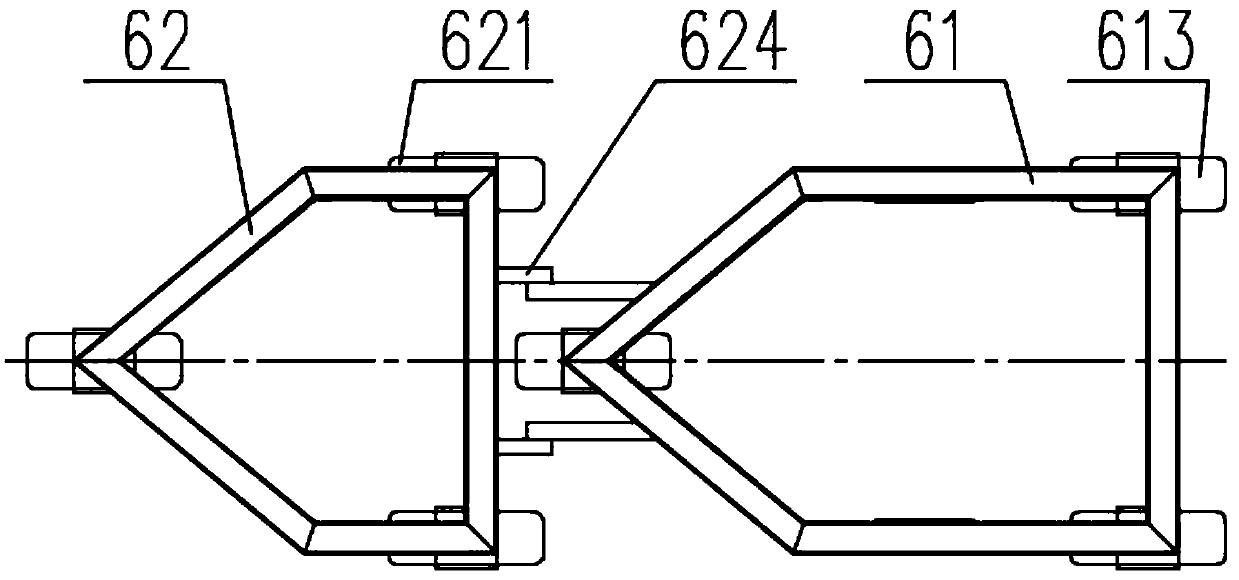

[0029] The nozzle vehicle 6 includes a main vehicle body 61 and an auxiliary vehicle body 62 connected and installed with the main vehicle body 61;

[0030] The main vehicle body 61 is provided with a nozzle frame 611 and a nozzle 612, the nozzle 612 is fixedly installed on the nozzle frame 611, and the lower part of the main vehicle body 61 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com