Anti-adhesion screw extruder

A screw extruder, anti-adhesion technology, applied in textiles and papermaking, complete sets of equipment for the production of artificial threads, feeding solution to the spinneret, etc., can solve dead corners that are difficult to clean, the inner wall is completely smooth, time and cost consumption And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

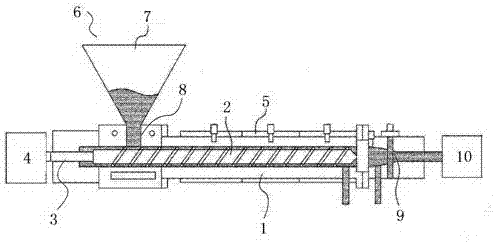

[0027] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0028]An anti-adhesion screw extruder, comprising an extruding tube 1, an extruding screw 2 is arranged in the extruding tube 1, a screw shaft 3 is arranged in the extruding screw 2, and a driving device 4 is also arranged, the The output end of the driving device 4 is connected to the input end of the screw shaft 3 through the drive shaft; the outer wall of the extruded tube 1 is provided with a melt constant temperature device 5 in turn, and a heating wire is arranged in the melt constant temperature device 5; The extruded tube includes a feeding zone, a melting zone and a homogenizing zone. Vent holes are arranged on the top outer wall of the extruding tube in the melting zone, and a feeding device 6 is arranged on the extruding tube in the feeding zone. The feeding device includes a feed hopper 7, the bottom end of the feed hopper is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com