Polymer melt metering pump

A kind of polymer and metering pump technology, which is applied in the direction of feeding solution to the spinneret, etc., can solve the problems of unfavorable production, impact, and completely smooth inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with specific embodiments and drawings.

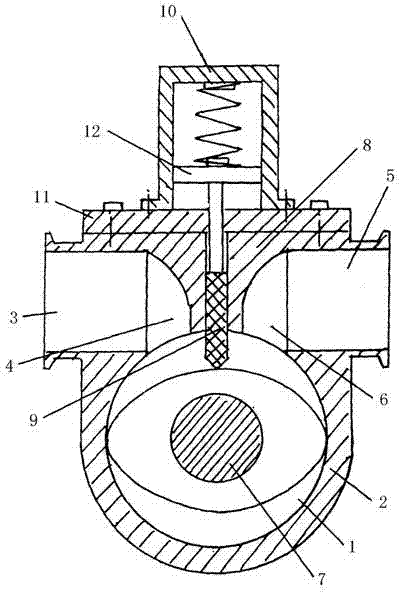

[0033] A polymer melt metering pump includes a pump body 2 with a pump cavity 1 and inlet and outlet ports. The inlet port 3 communicates with the pump cavity 1 through the inlet cavity 4, and the outlet port 5 passes through the outlet cavity. 6 is in communication with the pump cavity 1; a power device is fixed on the pump body 2; a rotor 7 arranged in the pump cavity 1 and rotatably supported on the pump body 2, the rotor 7 and According to the transmission connection of the power unit, the upper part and the middle part of the pump body 2 is provided with a material cavity separation groove 8 communicating with the inlet and outlet cavities, and the material cavity separation groove 8 is provided for opposite feeding , The barrier slider 9 separated by the discharge chamber, the barrier slider 9 moves up and down in the material chamber separation groove 8 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com