Polymer melt mixing tower

A technology of melt mixing and mixing tower, which is applied in the field of textile and chemical fiber spinning, and can solve problems such as unfavorable production, influence of properties and spinning properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

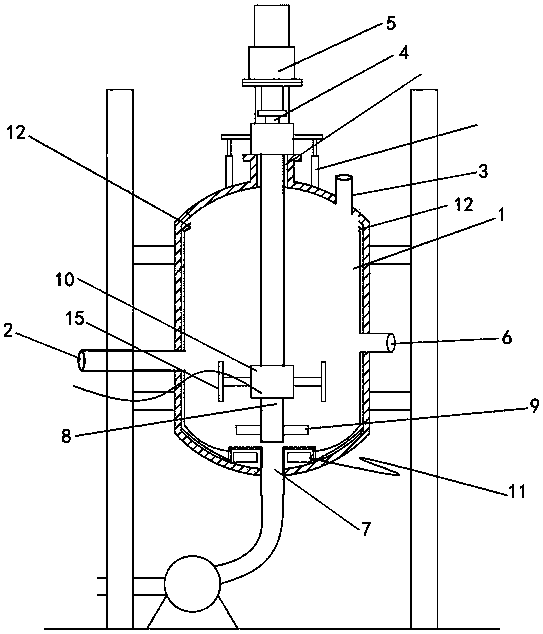

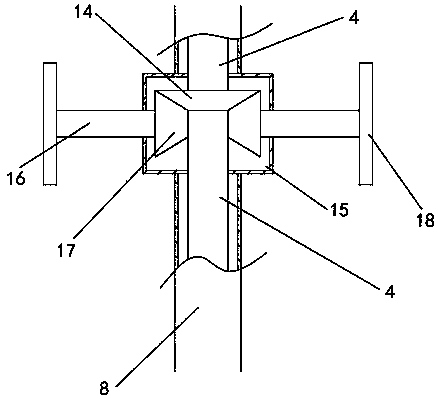

[0024] A polymer melt mixing tower, comprising a mixing tower 1 and a stirring shaft 4, the mixing tower has a multi-layer composite structure shell, the side bottom of the mixing tower 1 is provided with several polymer melt feeding ports 2; the mixing tower The top of the mixing tower 1 is arc-shaped, and the side of the arc-shaped top of the mixing tower 1 is also provided with a monomer suction device inlet 3, and the top of the arc-shaped top of the mixing tower 1 is provided with a shaft for the stirring shaft 4 to pass through. Through the hole, one end of the stirring shaft 4 goes deep into the mixing tower 1, and the other end is connected with the motor 5; the bottom of the mixing tower 1 is also arc-shaped, and the side of the arc-shaped bottom of the mixing tower 1 is provided with a detection inlet 6. There is a discharge port 7 at the top of the arc-shaped bottom of the mixing tower, and the discharge port 7 is connected with a discharge pump and a discharge pipe;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com