Patents

Literature

120results about How to "Does not affect the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

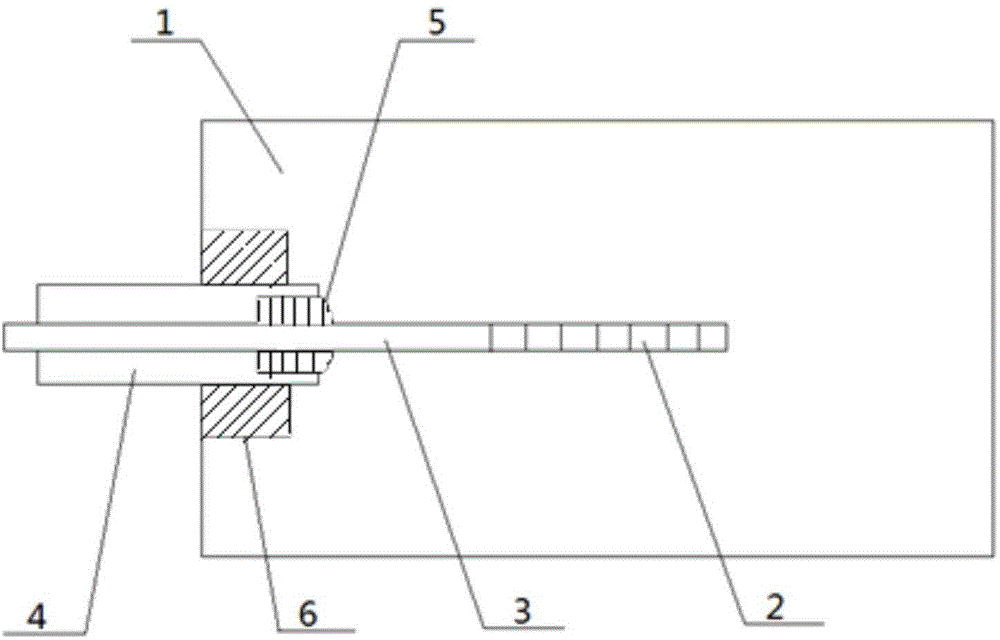

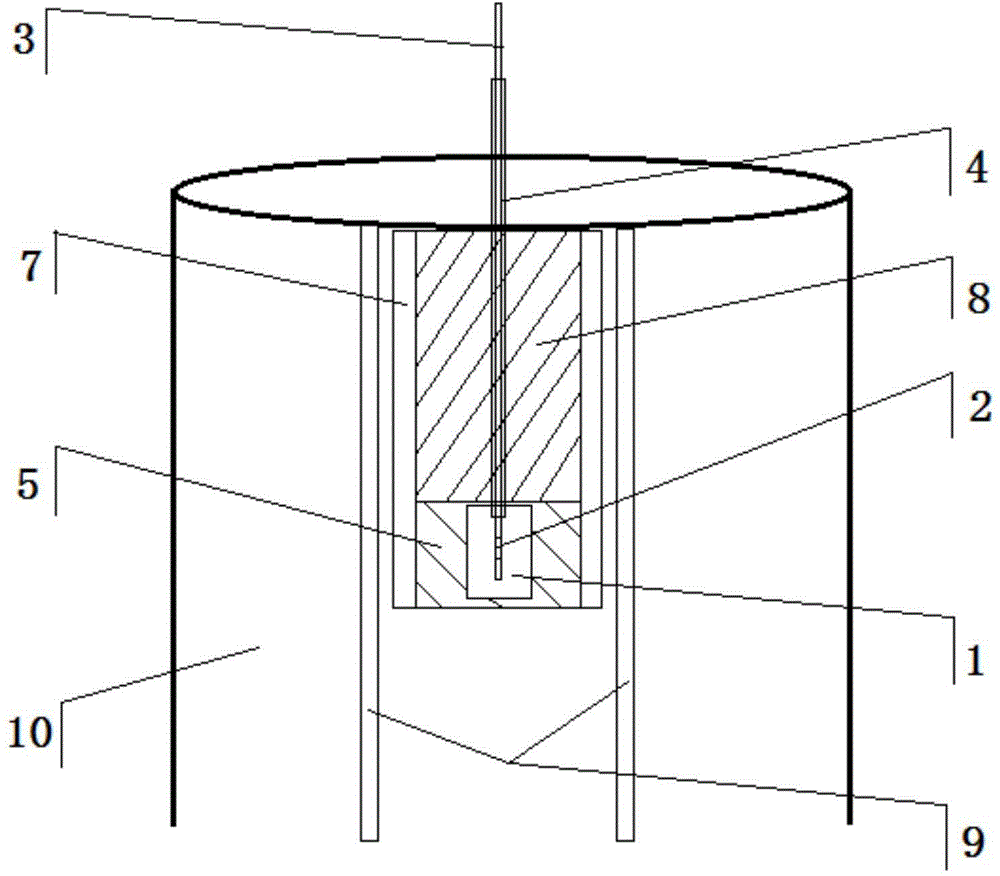

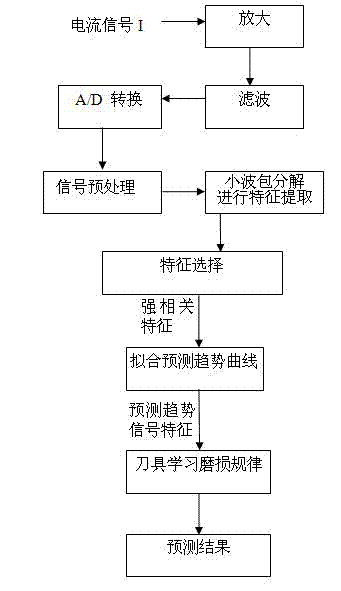

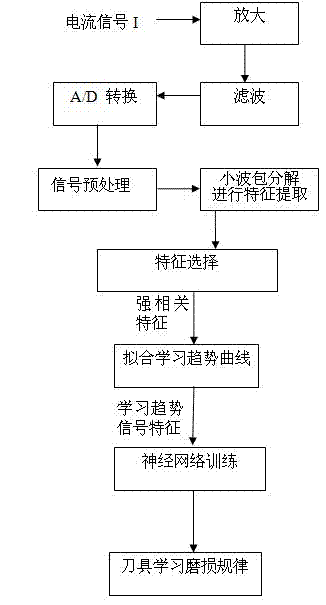

Numerical control machine tool wear monitoring method

InactiveCN102091972AHigh precisionReal-time monitoring of tool wearMeasurement/indication equipmentsNumerical control systemWavelet packet decomposition

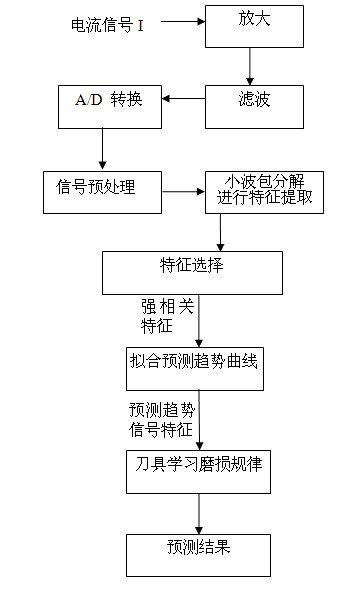

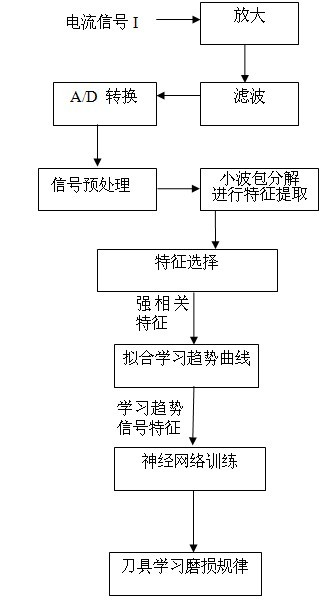

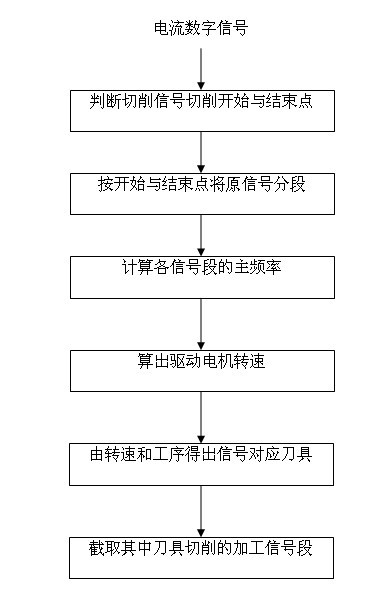

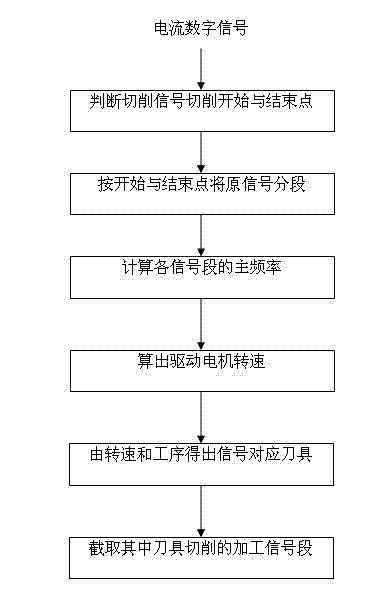

The invention belongs to the field of numerical control machine tool wear measurement, and discloses a numerical control machine tool wear monitoring method. In the method, servo drive motor current signals of a numerical control machine can reflect the change of a cutting load along with the tool wear; the acquired servo drive current signals are analyzed; the signals are decomposed in a frequency domain by a wavelet packet decomposition technology, and time-frequency domain characteristics of the signals in each frequency domain range are obtained and a plurality of characteristics stronglycorrelated to the tool wear are automatically selected; the tool wear process is learned through a neural network and a tool wear rule is obtained; in reverse, the tool wear characteristics are obtained in real time and are matched with the tool wear rule obtained through learning so as to monitor the tool wear state. The method solves a problem that the conventional tool wear monitoring method cannot realize online real-time monitoring, the servo drive signals of the numerical control machine are utilized, the integration with a numerical control system is easy to realize, the monitoring cost is reduced and the monitoring accuracy is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH +1

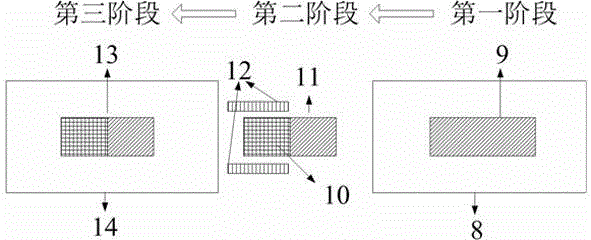

Hot stamping method for performance gradient distribution of high-strength steel parts

ActiveCN104668326AEasy to industrializeReduce difficultyQuenching devicesHot stampingUltimate tensile strength

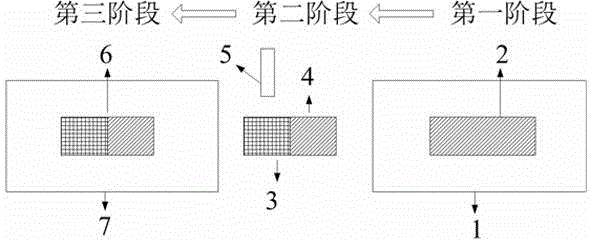

The invention relates to a hot stamping method for performance gradient distribution of high-strength steel parts. The hot stamping method comprises the following steps: locally and quickly cooling homogenized sheets heated to reach austenitization to a certain temperature (cooling to be below Ms point within 1 to 30s) and quenching; feeding the sheets with non-uniform temperature into another furnace for heating at the temperature of 600 to 1,000DEG C for 0.5 to 10min; after heating, obtaining structures in a low-strength area, namely ferrites, tempered martensiteas and austenites of certain amounts, and obtaining microstructures in the high-strength area, which are still complete austenitizing structures; transferring the sheets with different microstructures into a die with cooling water for stamping, and finally obtaining hot stamping forming parts with different mechanical properties.

Owner:东营广大金科机器人有限公司

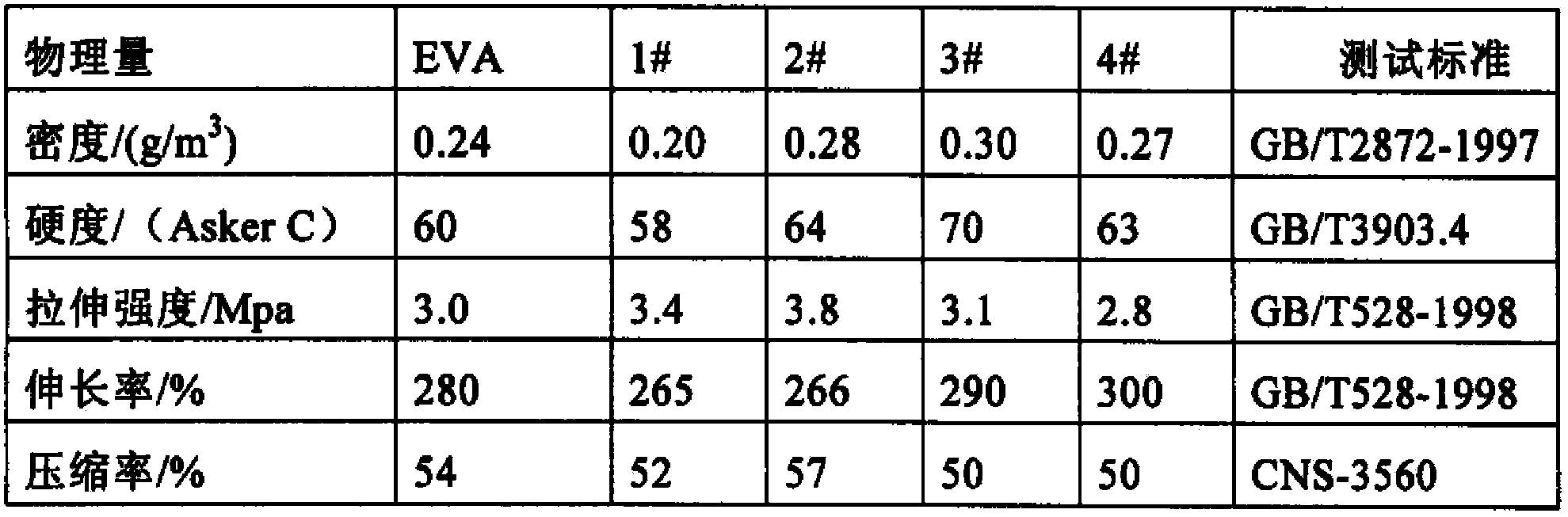

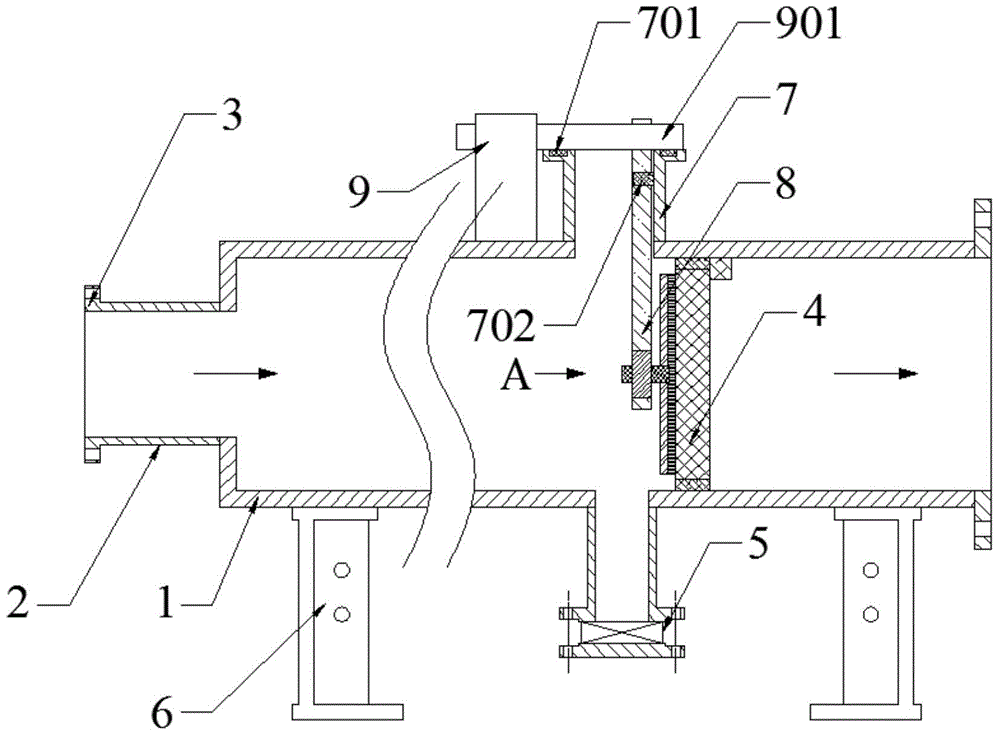

EVA foam material and preparation method thereof

The invention relates to an EVA (ethylene / vinyl acetate) foam material and a preparation method thereof. The foaming material comprises the following components in parts by weight: 100 of EVA, 2-10 of a foaming agent, 0.5-5 of a foaming promoter, 0.05-1 of a bridging agent, 5-30 of a filler, 0.5-5 of a deodorant, and 0.5-5 of a lubricant. The preparation method includes: mixing the raw materials uniformly, then drying the mixture in an oven at 60-80DEG C for 6-12h to obtain a dried mixture, subjecting the dried mixture to mixing injection molding to obtain an EVA sheet, cutting the EVA sheet, then putting the cut EVA sheet into a flat vulcanizing machine to undergo die-filling hot pressing, then performing automatic pressure release, and cooling the die, thus obtaining the EVA foam material. Compared with the prior art, the deodorant integrating absorption and reaction is adopted by the invention and added to EVA and various additives. With very good dispersibility, the deodorant reacts with an ammonia radical through a chelating mechanism and strongly adsorbs ammonia so as to effectively remove the ammonia radical and ammonia, and can destroy the formation conditions of formamide before its formation and has no influence to the properties of production products. Thus, the EVA foam material has wide application.

Owner:HEFEI GENIUS NEW MATERIALS

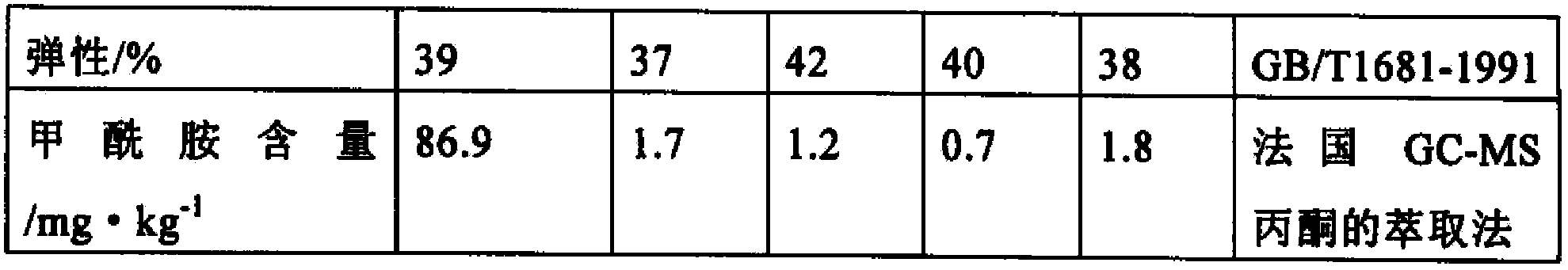

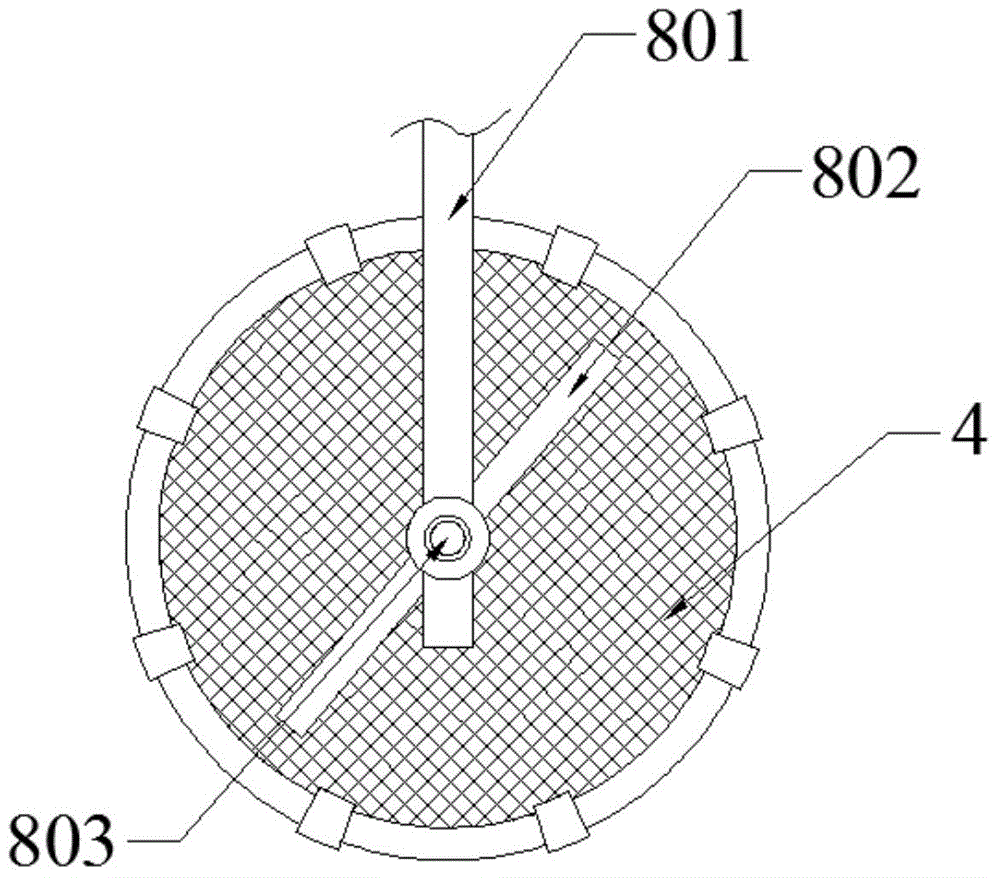

Self-cleaning horizontal type dirt remover

InactiveCN104436822ASimple structureImprove cleaning efficiencyStationary filtering element filtersMotor driveEngineering

The invention provides a self-cleaning horizontal type dirt remover and belongs to the technical field of chemical equipment. The self-cleaning horizontal type dirt remover also comprises a cleaning assembly, wherein the cleaning assembly comprises a cleaning brush, a rotary motor for driving the cleaning brush and a supporting rod for fixing and supporting the rotary motor; the cleaning brush is attached on the side surface of a filtering net towards the inlet end of a body, and is fixedly connected with an output shaft of the rotary motor. The rotary motor drives the cleaning brush to rotate in the vertical surface. The self-cleaning horizontal type dirt remover provided by the invention has the advantages that the structure is simple; due to the arranged cleaning assembly, the filtering net can be cleaned without stoppage, so that the cleaning efficiency is high, no influence on the production process is caused, the frequency of whole maintenance and clearing of the dirt remover is reduced, the production frequency is improved and convenience is brought for use of equipment in the dirt-removing process.

Owner:TIANJIN ZECHANG CHEM EQUIP MFG

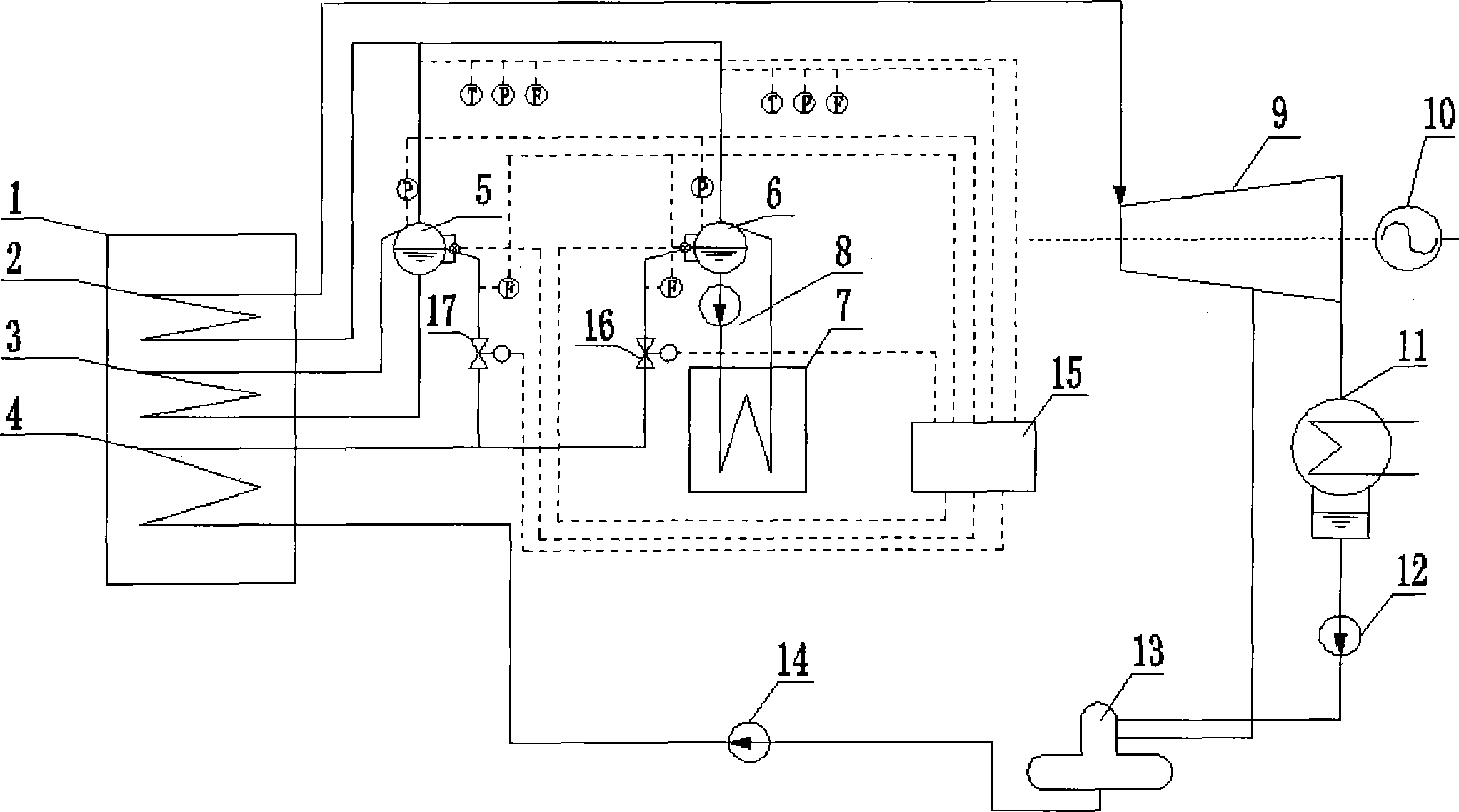

Heating furnace flue gas and steam waste heat recycling and power generating system and power generating method

InactiveCN103291390ARealize combined evaporation waste heat power generationDoes not affect the production processEnergy industrySteam engine plantsSuperheaterEvaporator

The invention provides a heating furnace flue gas and steam waste heat recycling and power generating system and a power generating method. The system comprises a flue gas waste heat boiler system, a heating furnace vaporization cooling system, a turbine generator unit system, a condensation water return supply system and a combined control system. The flue gas waste heat boiler system comprises an economizer, an evaporator and a superheater. Water of the vaporization cooling system is supplied by the economizer of a heating furnace, and generated saturated steam enters the superheater of the heating furnace. According to operation characteristics of the heating furnace, the flue gas and vaporized cooling steam of the heating furnace are explored and used together, so that flue gas and steam combined evaporation waste heat power generation is achieved. Waste heat of the flue gas is used, the waste heat of the vaporized cooling saturated steam is also used, meanwhile stability of the system is well guaranteed, and waste heat utilization is achieved to the largest extent.

Owner:华效资源有限公司

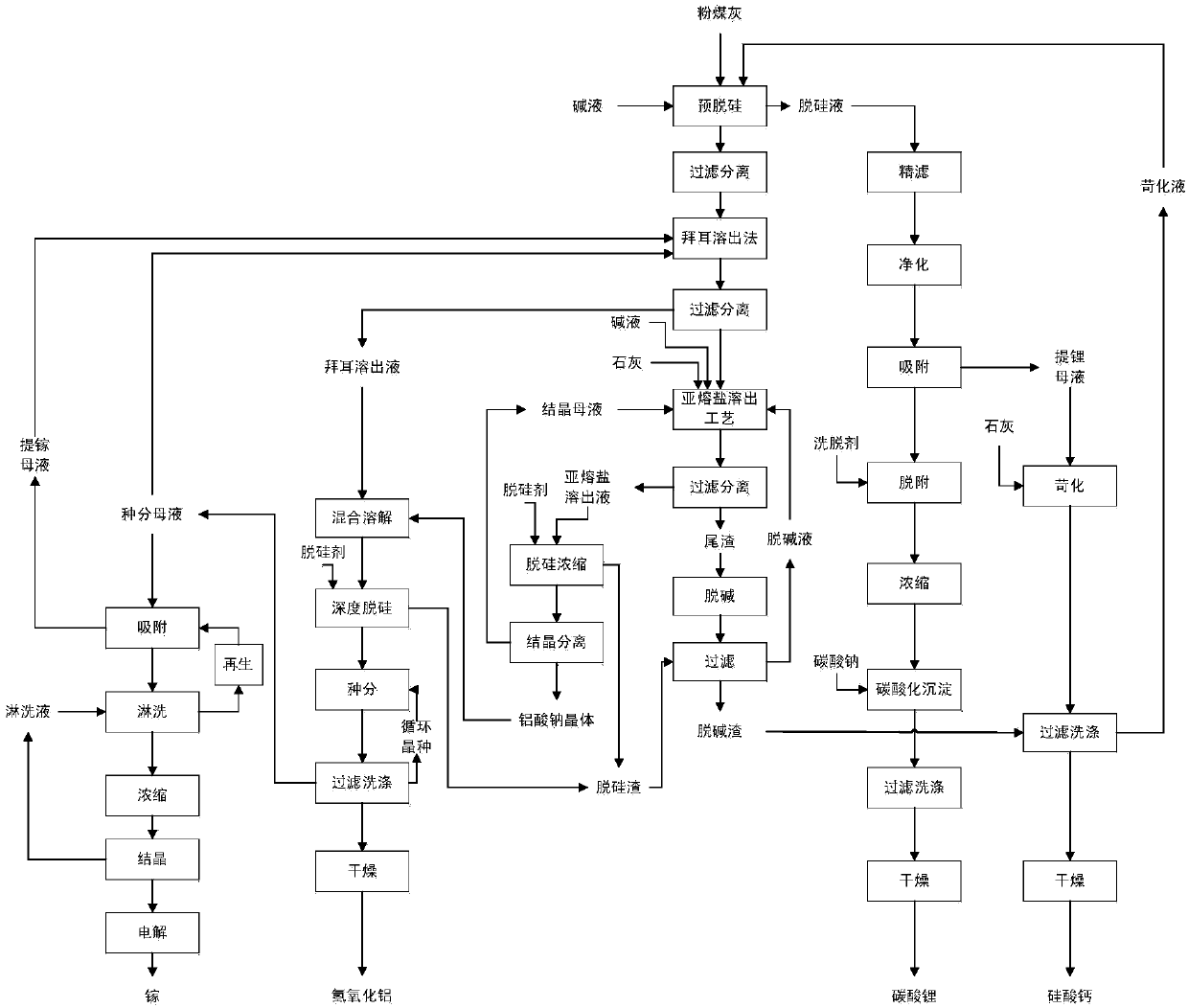

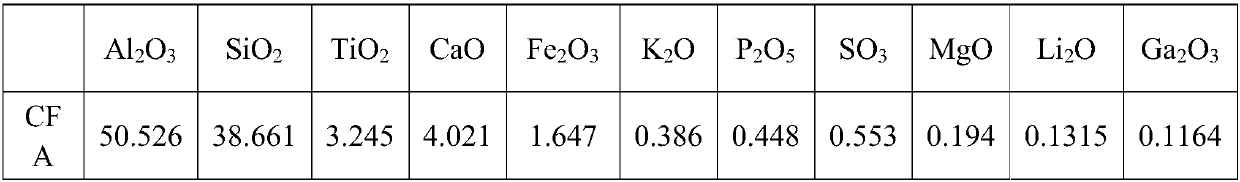

Extraction method for cooperating with aluminum-silicon-lithium-gallium combination method in coal ash

ActiveCN107758714ARealize wet productionHigh extraction rateAlkaline-earth metal silicatesProcess efficiency improvementCalcium silicateElectrolysis

The invention discloses an extraction method for cooperating with an aluminum-silicon-lithium-gallium combination method in coal ash. The method comprises the steps of aluminum oxide extraction, wherein pre-desiliconization, dissolving-out through a Bayer method, dissolving-out of sub-molten salt, crystallization and separation, desilicication and seed precipitation are conducted; gallium extraction, wherein adsorption, drip washing, concentration and electrolysis are conducted; lithium extraction, wherein purification, adsorption, desorption, concentration and carbonation sedimentation; preparation of calcium silicate products, wherein causticization of desilicication liquid and dealkalization of desilicication residue are conducted. According to the extraction method, aluminum, silicon,lithium and gallium elements in the coal ash are comprehensively extracted through a whole-wet method, substep and stairstep comprehensive utilization of aluminum, silicon, lithium and gallium is achieved, energy consumption is low, the technological process is simple, the extraction rate of aluminum, lithium and gallium is high, the additional value of solid waste is effectively improved, and themethod is a good comprehensive utilization technology for processing the coal ash through a whole-alkali method and is suitable for industrialization popularization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

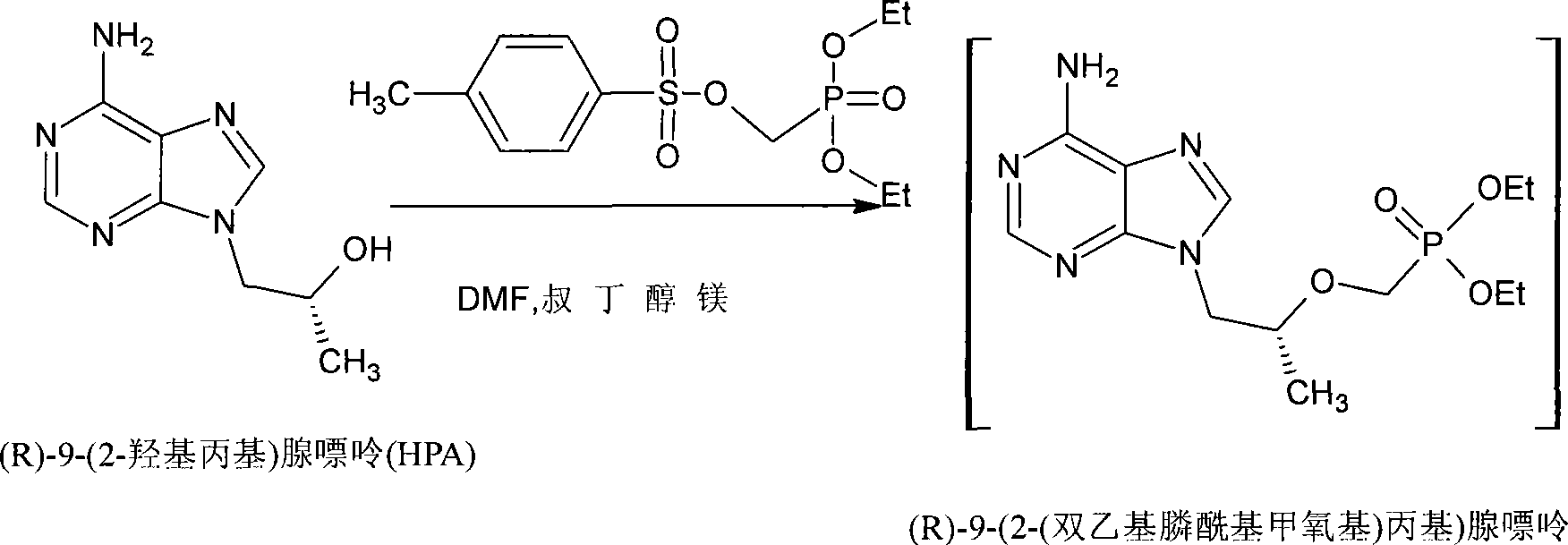

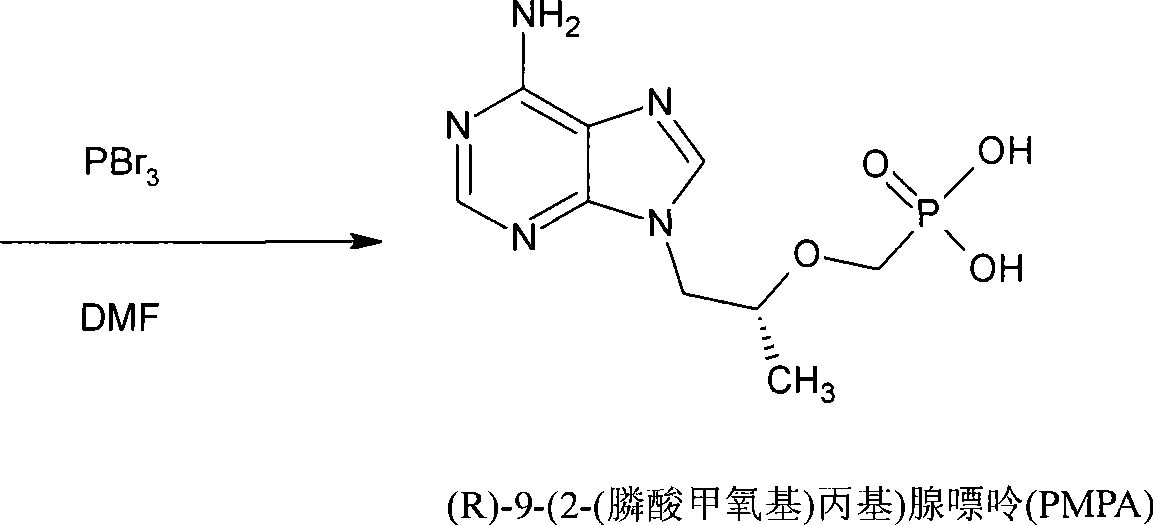

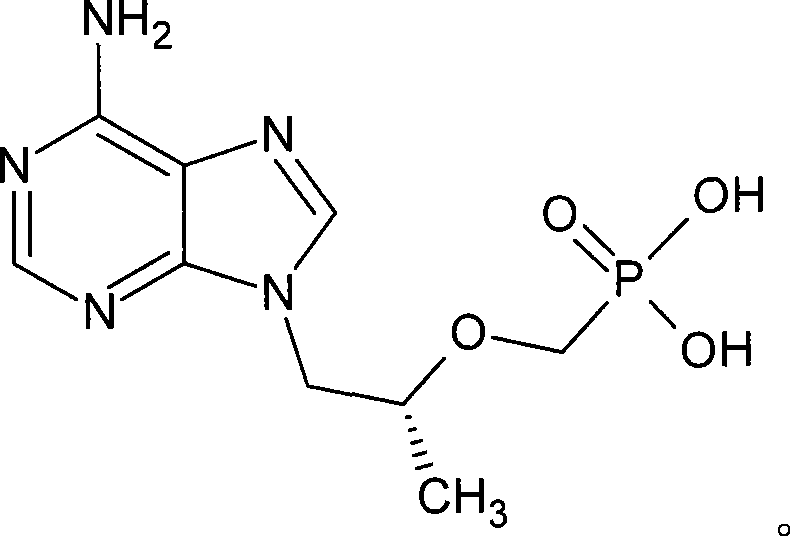

Method for synthesizing (R)-9-(2-phosphate methoxy propyl)adenine

InactiveCN101418017ALow priceNo environmental pollutionGroup 5/15 element organic compoundsAntiviralsEthyl phosphateChemistry

The invention discloses a method for synthesizing (R)-9-(2-phosphonomethoxypropyl) adenine. The method comprises the following steps: (R)-9-(2- hydroxypropyl) adenine and methyl phosphono diethyl p-toluenesulfonate are taken as raw materials to synthesize (R)-9-(2-( diethylphosphono) methoxypropyl) adenine and then diethyl is removed to give the (R)-9-(2-phosphonomethoxypropyl)adenine. The method has the advantages of readily available raw materials, low price, no pollution to environment, high yield of reactions, simple process and suitability for mass production.

Owner:AURISCO PHARMACEUTICAL CO LTD

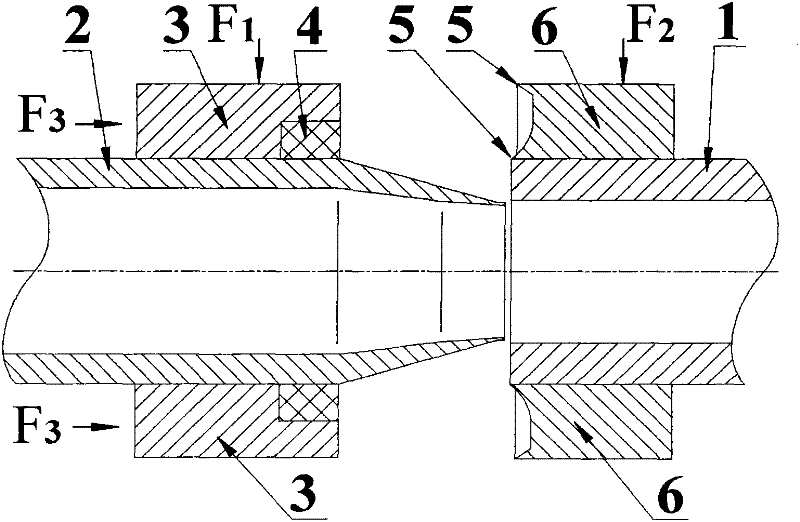

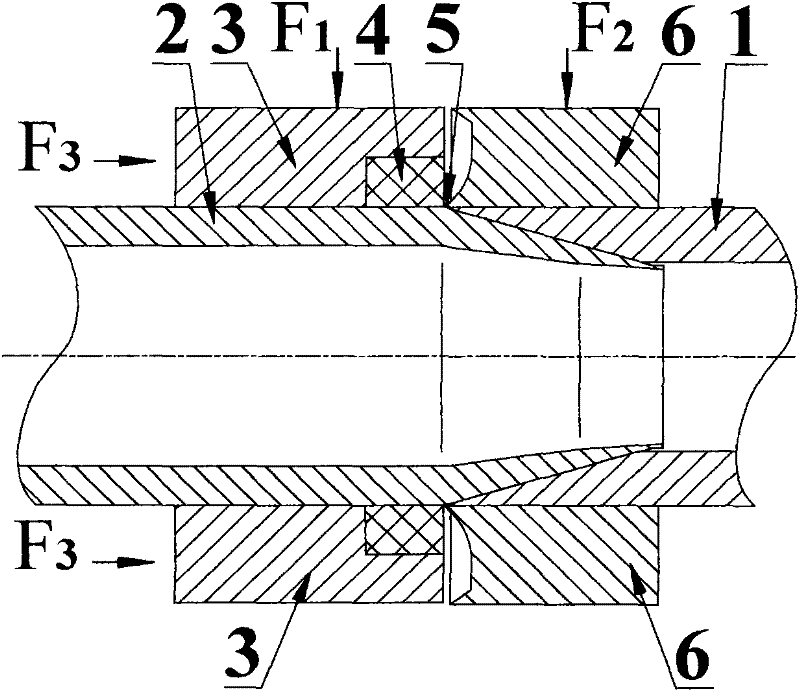

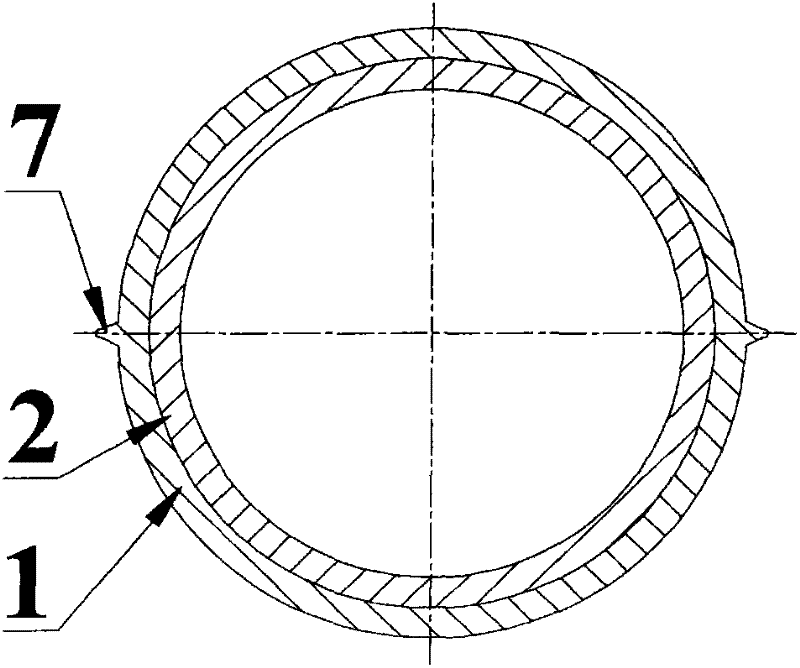

Special welding fixture for copper aluminum tube and welding method and copper aluminum welded tube utilizing the same

InactiveCN102513684AReduce wearExtended service lifeResistance welding apparatusUltimate tensile strengthCushion

The invention discloses a special welding fixture for a copper aluminum tube, which comprises a grinding and cutting clamping mould capable of being used for welding positive and negative electrodes, and a sole plate clamping mould; the grinding and cutting clamping mould is divided into an upper mould and a lower mould, the upper mould and the lower mould are of symmetrical structures, and the upper mould and the lower mould respectively comprise clamping main bodies on the back segments thereof and grinding and cutting cutters on the front ends thereof; the sole plate clamping mould is divided into an upper mould and a lower mould, and a rigid cushion block is arranged on the front end of a position touching a tubular product of the sole plate clamping mould. A copper aluminum welded tube produced by the special welding fixture for copper aluminum tube comprises a copper tube with a bell mouth-shaped front end and an aluminum tube, the front end of the copper tube is stretched into the inner wall of the aluminum tube, and reinforcement ribs with fin-shaped structures formed by molten aluminum are arranged on the outer wall of the aluminum tube. The special welding fixture disclosed by the invention has the advantages of guaranteeing a smooth welding surface, saving the working procedure, reducing the demand on production field, greatly improving the production efficiency, reducing the production cost, guaranteeing a more smooth production process, effectively relieving the fixture attrition, prolonging the service life of the grinding tool, improving the strength of the key combination position, and enhancing the qualified rate and quality of the products.

Owner:左铁军 +1

Prestressed concrete pipe pile anticorrosion joint

InactiveCN102199919AImprove construction efficiencyExtended service lifeBulkheads/pilesFlangePrestressed concrete

The invention discloses a prestressed concrete pipe pile anticorrosion joint, which is characterized by comprising an end plate and a connection flange, wherein, the connection flange is provided with a rib frame; the end plate is provided with a plurality of screw holes; and the connection flange is also provided with a plurality of bolt interpenetration positions corresponding to the screw holes. By adopting the anticorrosion joint provided by the invention, the influence of the friction extrusion process of geological environments on anticorrosion measures in construction can be avoided, the service life of the pipe pile foundation is effectively prolonged, and the safety of the engineering is ensured; and meanwhile, the performances, such as shear resistance and bending resistance and the like of a pipe pile connection structure at the joint are ensured, the connection is stable and firm, and the quality and the safety in construction and using process of the pipe pile are ensured.

Owner:GUANGDONG SANHE PILE CO LTD

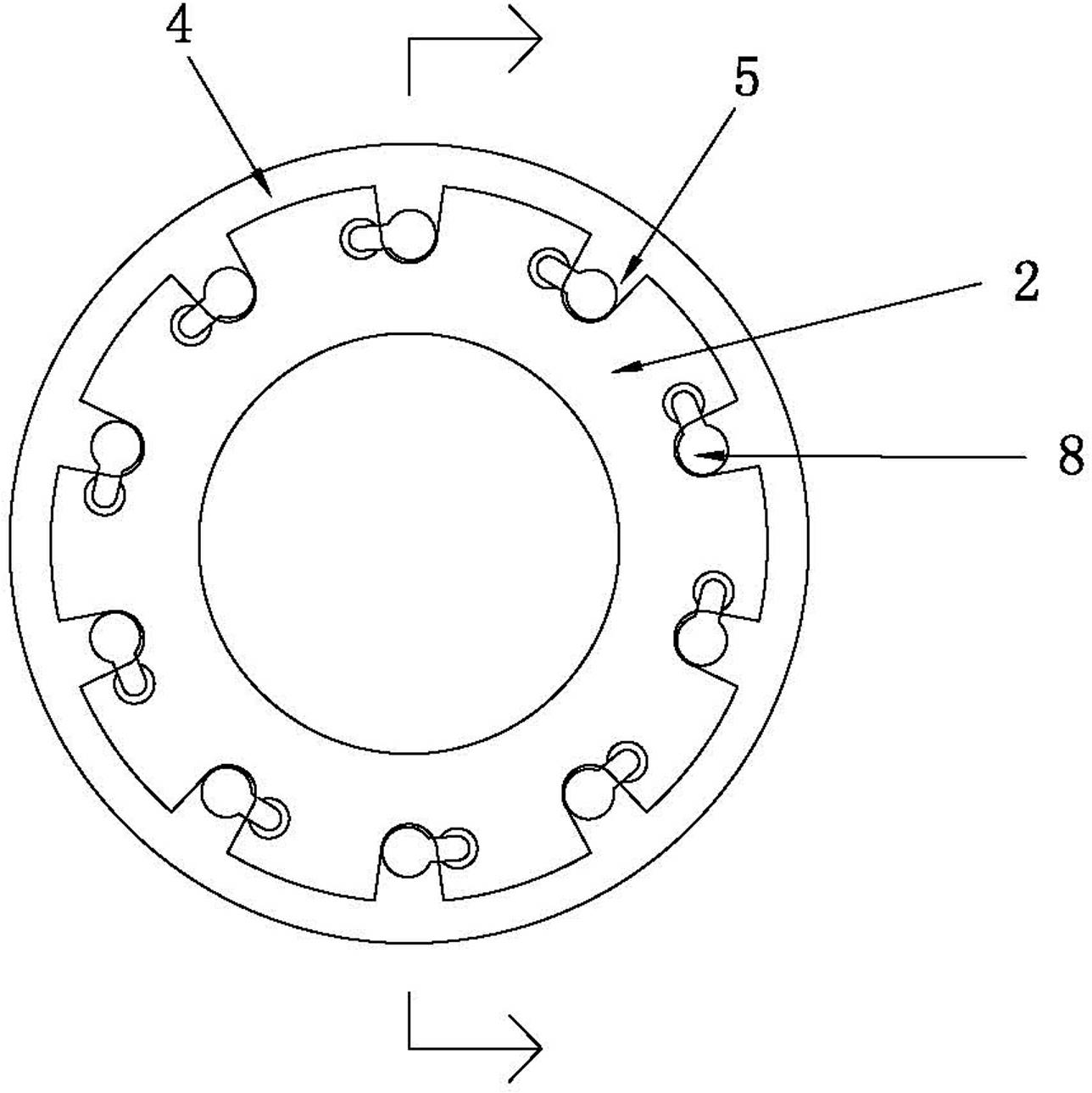

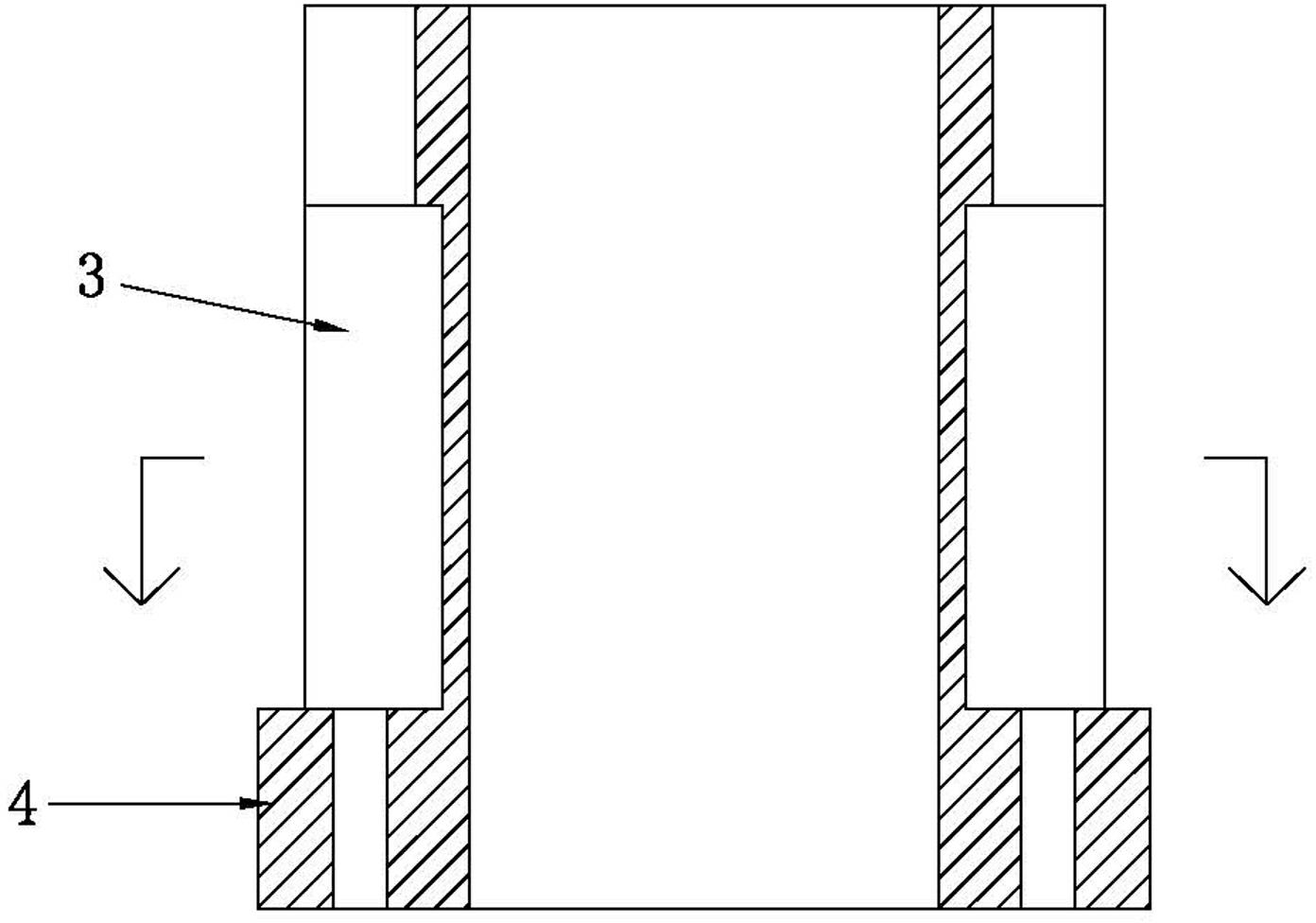

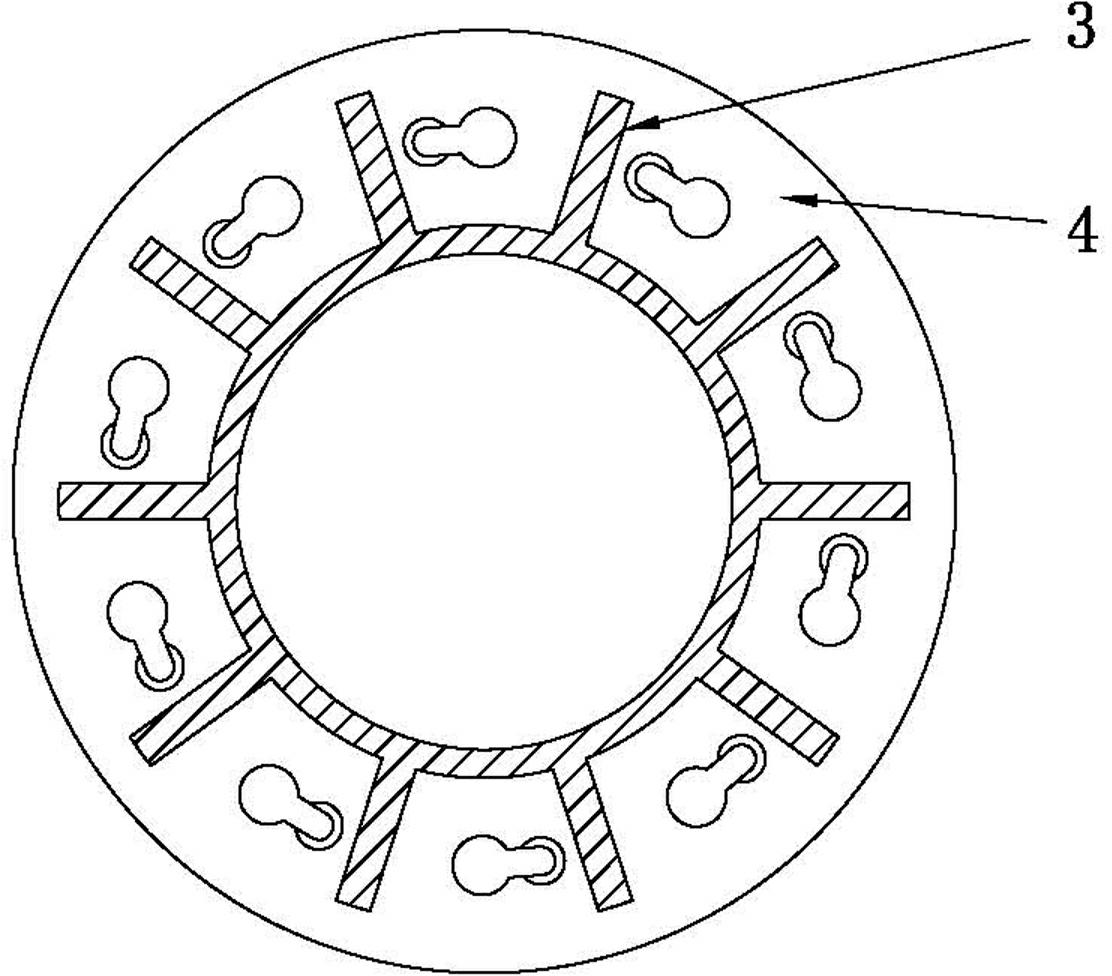

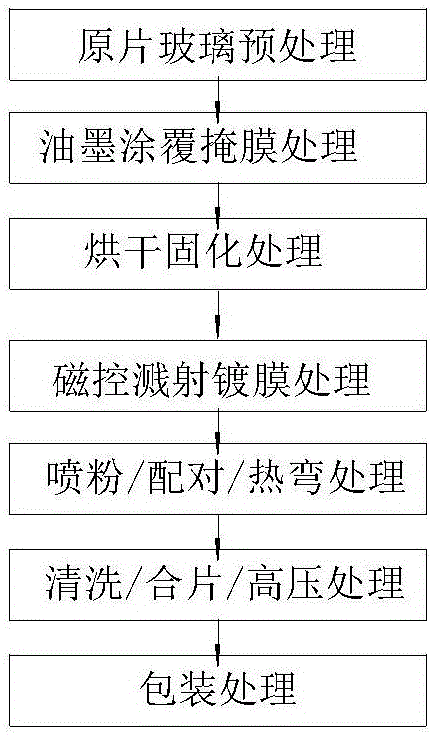

Method of removing film from edge of coated glass

The invention discloses a method of removing a film from edge of coated glass. The method at least comprises the following steps: 1) carrying out mask coating treatment on a region, without needing to coat the film, of glass to be coated by adopting low-temperature thermal decomposition ink; 2) carrying out drying and solidification treatment on the glass to be coated, which is treated in the first step; 3) carrying out magnetron sputtering coating treatment on the glass to be coated, which is obtained in the second step; and 4) carrying out powder spraying, matching, hot bending, cleaning, laminating, high pressure and packaging treatments on the glass obtained in the third step. A coated glass product prepared by the film removing method is beautiful in side boundary and reliable in quality and is suitable for edge film removing process of automobile glass.

Owner:信义超薄玻璃(东莞)有限公司

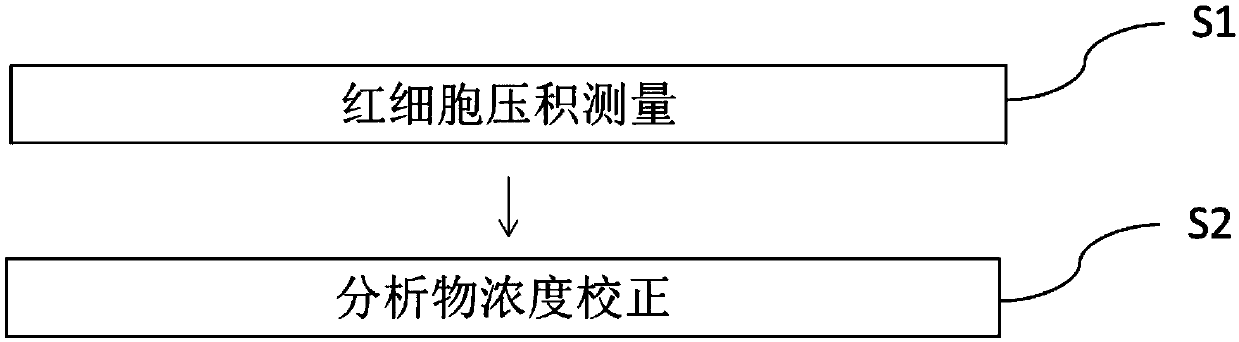

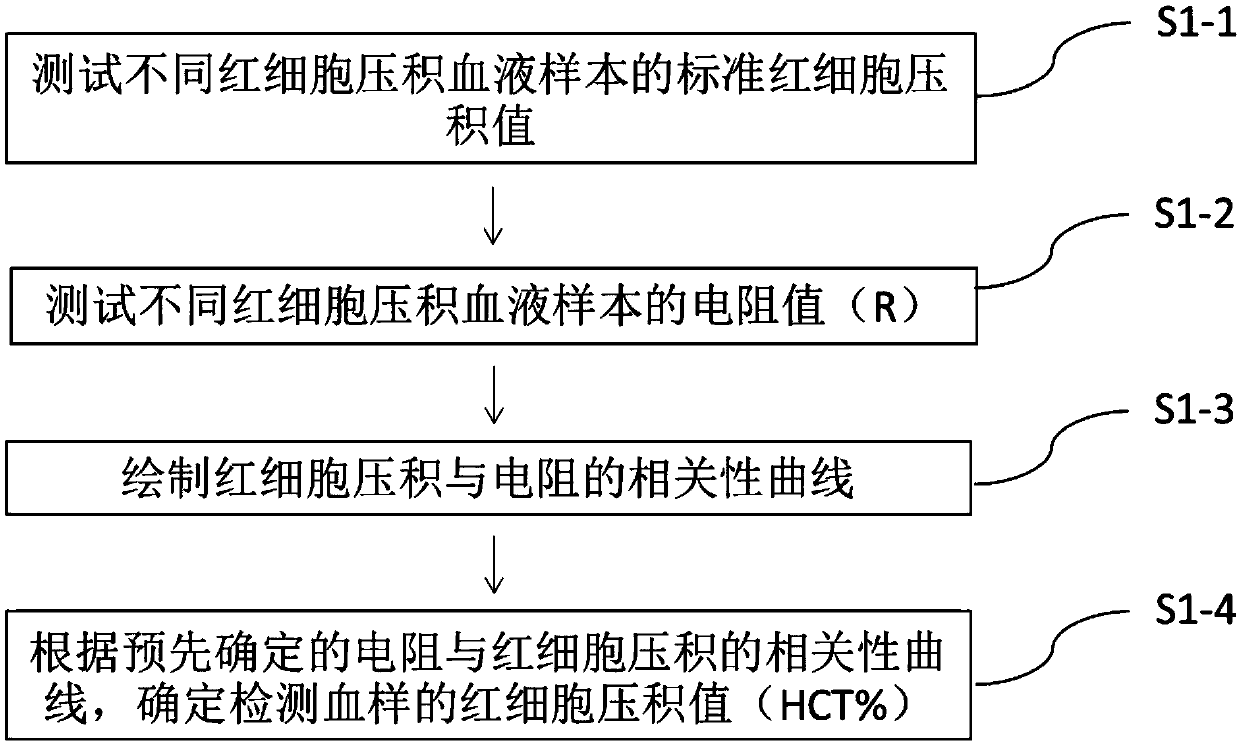

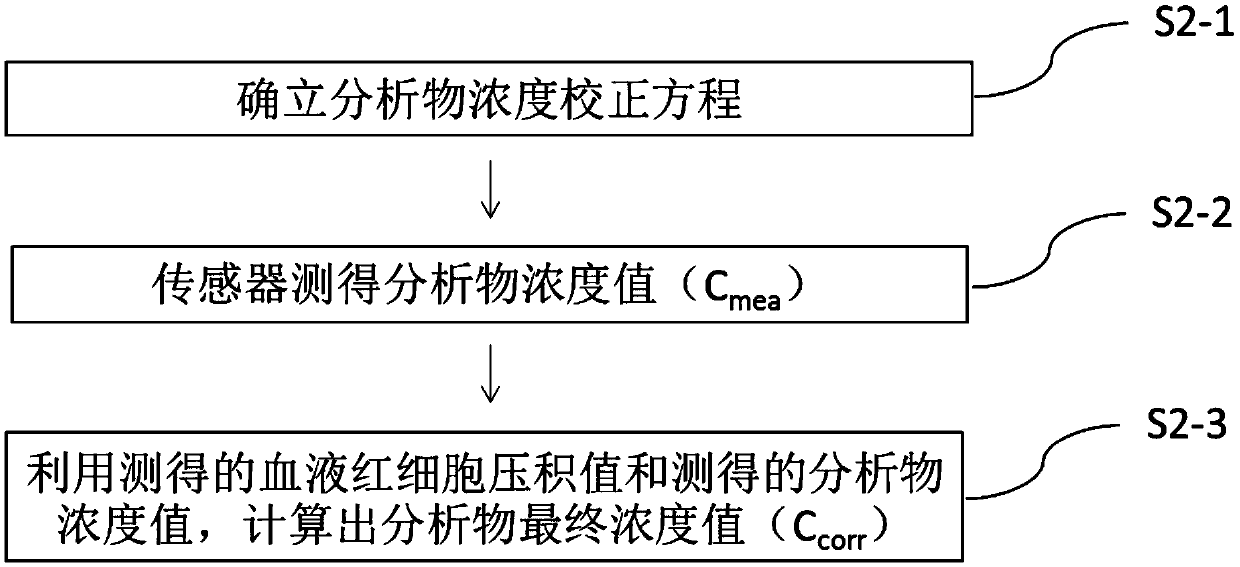

Method for measuring and correcting hematocrit (HCT) in electrochemical biosensor

InactiveCN108680622AEliminates effects of concentration determinationDoes not affect the production processSedimentation analysisMaterial electrochemical variablesElectrochemical biosensorAnalyte

The invention provides a method for measuring and correcting hematocrit (HCT) in an electrochemical biosensor. According to the method, analyte content to be determined is corrected by utilizing a determined HCT value, so as to eliminate influences, caused by the HCT, on the determination of the analyte content. The method comprises the steps of measuring the HCT and correcting analyte concentration. The method for measuring the HCT comprises the following steps: firstly, acquiring resistance value (R) of different HCT blood samples; manufacturing a relativity curve between the HCT and the blood resistance (R); then determining HCT value (HCT percent) of the blood samples according to the pre-determined relativity curve between the resistance and the HCT. The method for correcting the analyte concentration comprises the following steps: establishing a correction equation; measuring the analyte concentration and calculating final concentration value of analyte (Ccorr) by utilizing the measured HCT value (HCT percent) and measured analyte concentration value (Cmea).

Owner:北京乐普诊断科技股份有限公司

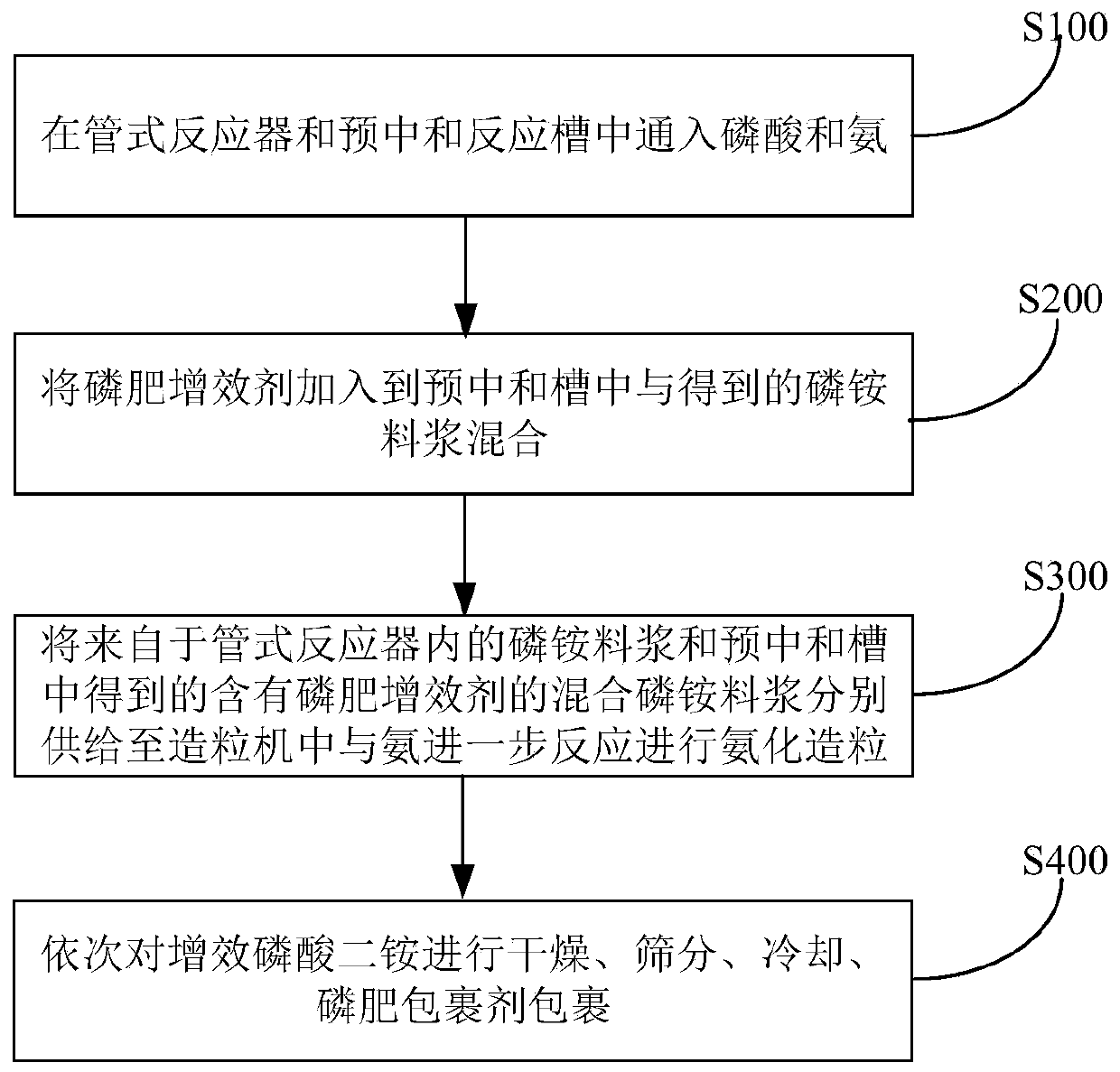

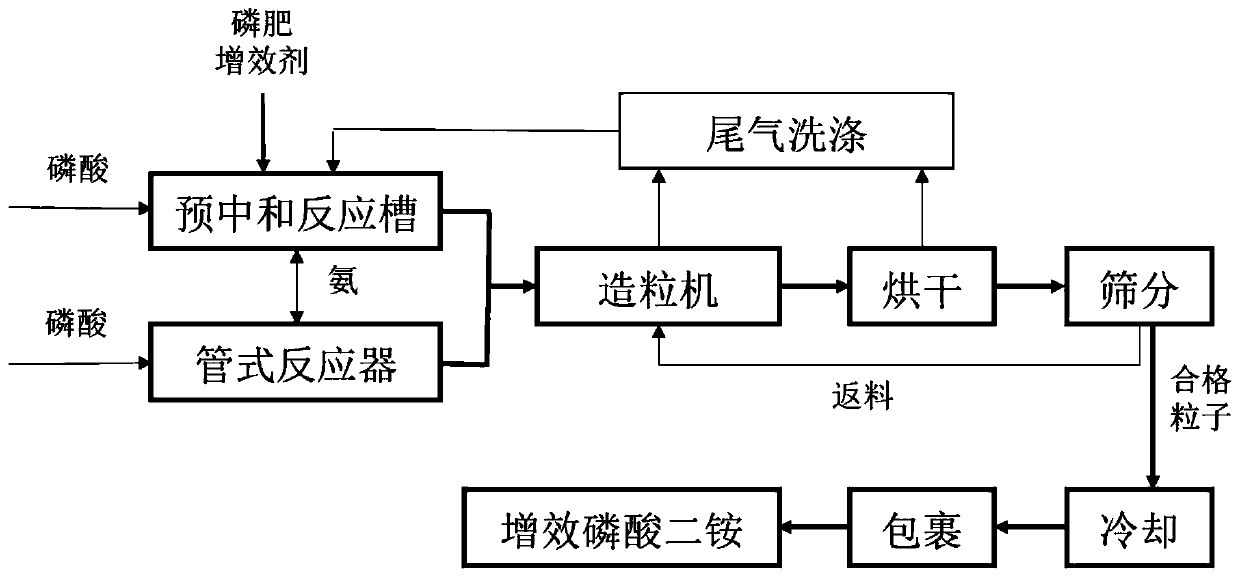

Preparation process of efficient humic acid diammonium phosphate

InactiveCN102086140ADoes not affect the existing production processDoes not affect the production processAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiammonium phosphateSlurry

The invention discloses a preparation process of efficient humic acid diammonium phosphate, which belongs to the field of novel fertilizers and in particular relates to a production process for preparing an efficient humic acid diammonium phosphate product through modifying diammonium phosphate in the traditional method. The preparation process comprises the following steps of: (1) utilizing 30-50wt% of humic acid ammonium containing water soluble humic acid as an activating agent, and adding the powder or paste humic acid ammonium to a returning charge according to 10-20wt% of adding amount in the returning charge part of the course of producing diammonium phosphate by adopting the traditional method; and (2) uniformly mixing the diammonium phosphate returning charge containing the added humic acid ammonium, then adding the diammonium phosphate returning charge into a cylinder for pelletizing, pelletizing and aminating the diammonium phosphate returning charge together with pre-neutralizing slurry, and drying. The preparation process of the efficient humic acid diammonium phosphate has the advantages that because the humic acid ammonium containing high water soluble humic acid is added in the returning charge part in the production process of the diammonium phosphate by utilizing the traditional method, the physiological activity of the humic acid is not destroyed, the traditional production process of the diammonium phosphate is not affected, the production cost of the diammonium phosphate can be effectively reduced, and the obtained efficient humic acid diammonium phosphate has excellent agricultural effect and ecological effect.

Owner:YUNNAN CHEM RES INST

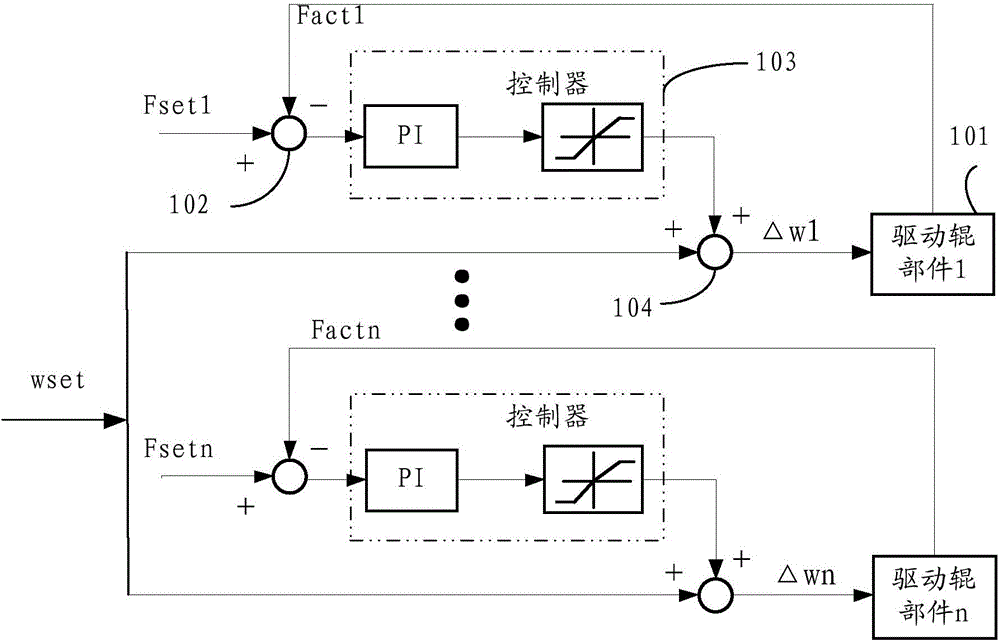

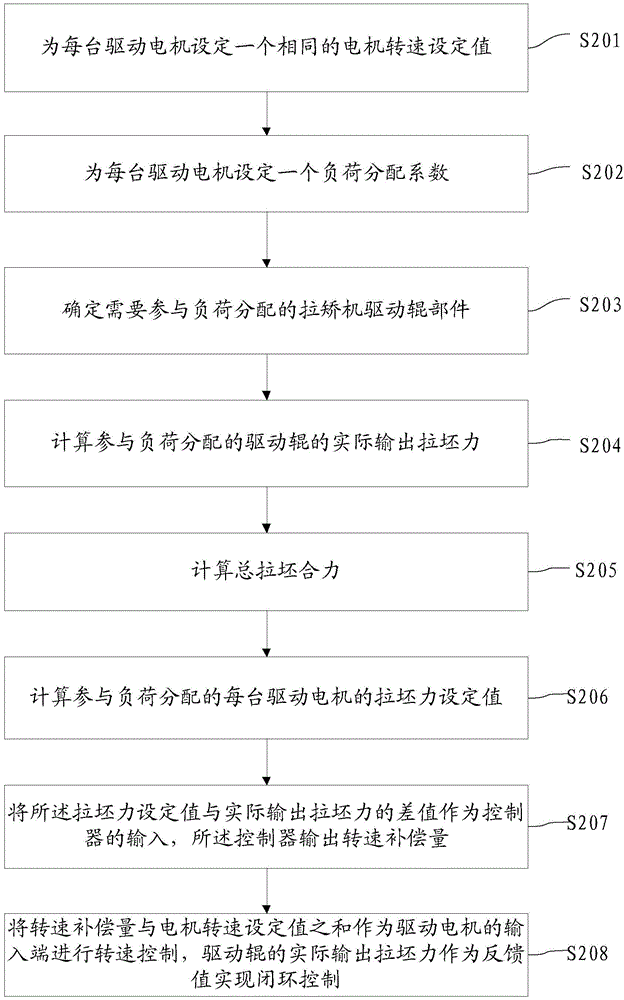

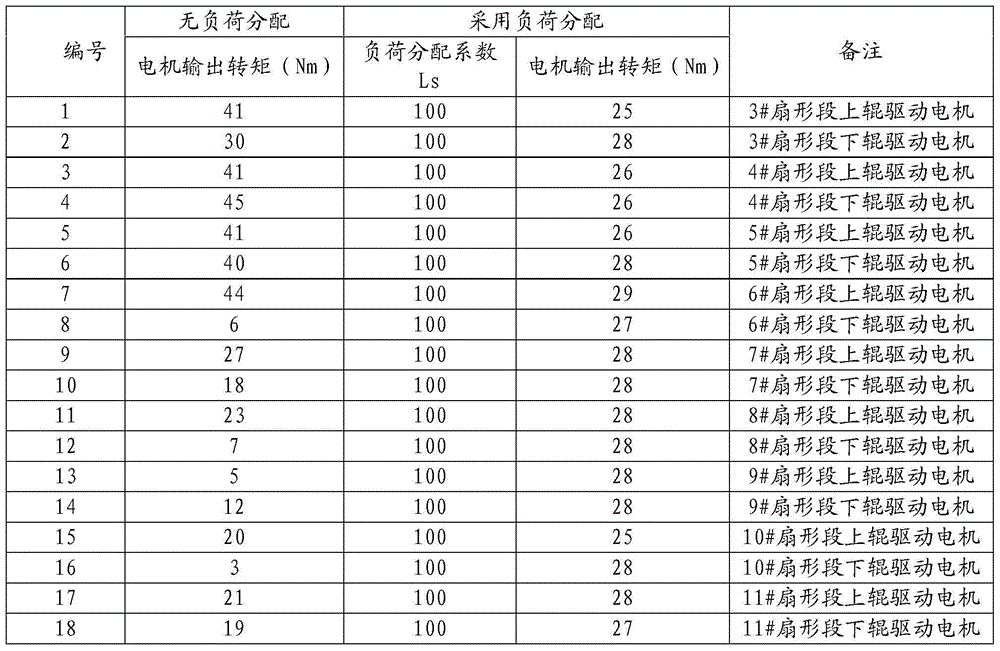

Continuous-casting withdrawal and straightening unit system and load distributing method

ActiveCN104001886AEliminate the no-load phenomenonImprove working conditionAutomatic controlClosed loop

The invention discloses the technical field of continuous-casting equipment, and provides a continuous-casting withdrawal and straightening unit system and a load distributing method. The method comprises the steps that the same motor rotating speed set value is set for all driving motors; a load distributing coefficient is set for each driving motor; withdrawal and straightening unit driving roller components needing to participate in load distribution are determined; actual output throwing force of driving rollers participating in load distribution is calculated; the total throwing resultant force is calculated; the throwing force set value of each driving motor participating in load distribution is calculated; a controller outputs the rotating speed compensation dosage; the sum of the rotating speed compensation dosage and the motor rotating speed set value is used as the input ends of the driving motors for rotating speed control, and the actual output throwing force of the driving rollers is used as feedback values to achieve closed-loop control. The load distributing coefficients are introduced to achieve free distribution of withdrawal and straightening unit total loads in withdrawal and straightening units, automatic control over the throwing force is achieved through closed-loop adjustment, and meanwhile according to the method, the pull speed changes can not be caused, and the production technology is not affected.

Owner:WISDRI ENG & RES INC LTD

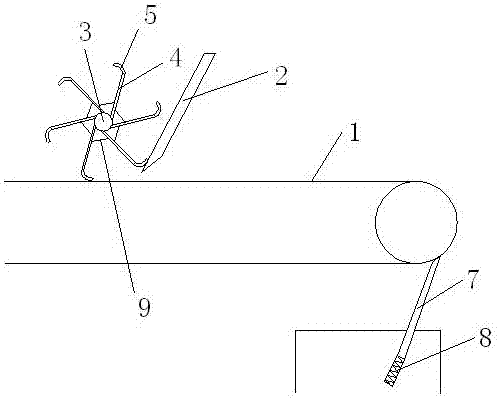

Material screening belt conveyor

InactiveCN107377182ADoes not affect the production processNo cloggingCleaning using toolsGrain treatmentsEngineeringLarge particle

The invention discloses a material screening belt conveyor. The material screening belt conveyor comprises a conveying belt, at least one classification screening device is arranged above the conveying belt, the classification screening device comprises a baffle plates arranged in an inclined mode, a rotating shaft is arranged on one side of the baffle plates, scraping plates are uniformly arranged on the rotating shaft at intervals, bent scraping teeth are arranged on the end parts of the scraping plates, and a material discharging channel is formed below one end of the rotating shaft. According to the material screening belt conveyor, a sorting and screening device is additionally arranged in the belt conveying process, large particles in the materials are screened out, meanwhile, the materials conveyed on the belt are pushed and flattened, and therefore the stability and the continuity of material feeding are ensured.

Owner:NANTONG LIYUANHENG MACHINERY

Polypropylene composite material and preparation method thereof

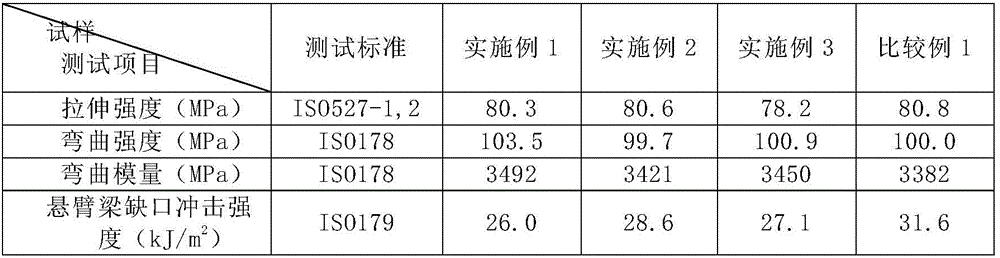

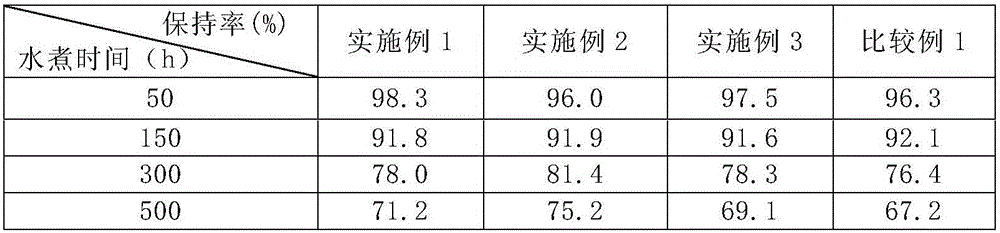

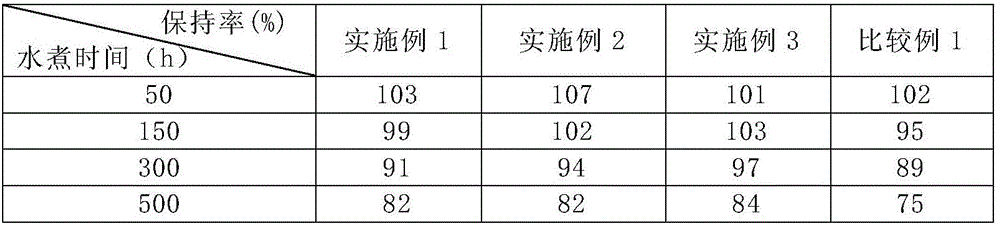

InactiveCN106220997AGood mechanical propertiesLong-lasting hydrolysis resistancePolypropylene compositesPolymer science

The invention belongs to the field of high molecular materials, and relates to a polypropylene composite material and a preparation method thereof. The polypropylene composite material provided by the invention comprises 10 to 90 weight parts of long fiber reinforced polypropylene master batches and 90 to 10 weight parts of modified polypropylene granules, wherein the modified polypropylene granules contain fluorine-containing polymers. The invention also provides a preparation method of the polypropylene composite material. In the polypropylene composite material, the fluorine-containing polymers are added into the modified polypropylene granules, so that the interface bonding between the fiber and the polypropylene in the long fiber reinforced polypropylene master batches cannot be influenced; the mechanical property of the long fiber reinforced polypropylene composite material injection molded product is not influenced. In addition, the fluorine-containing polymers achieve the effect of reducing the surface energy of the long fiber reinforced polypropylene composite material, so that the water permeability is retarded; the hydrolysis resistance performance is improved.

Owner:ZHEJIANG GOLDENSEA ENVIRONMENT TECH

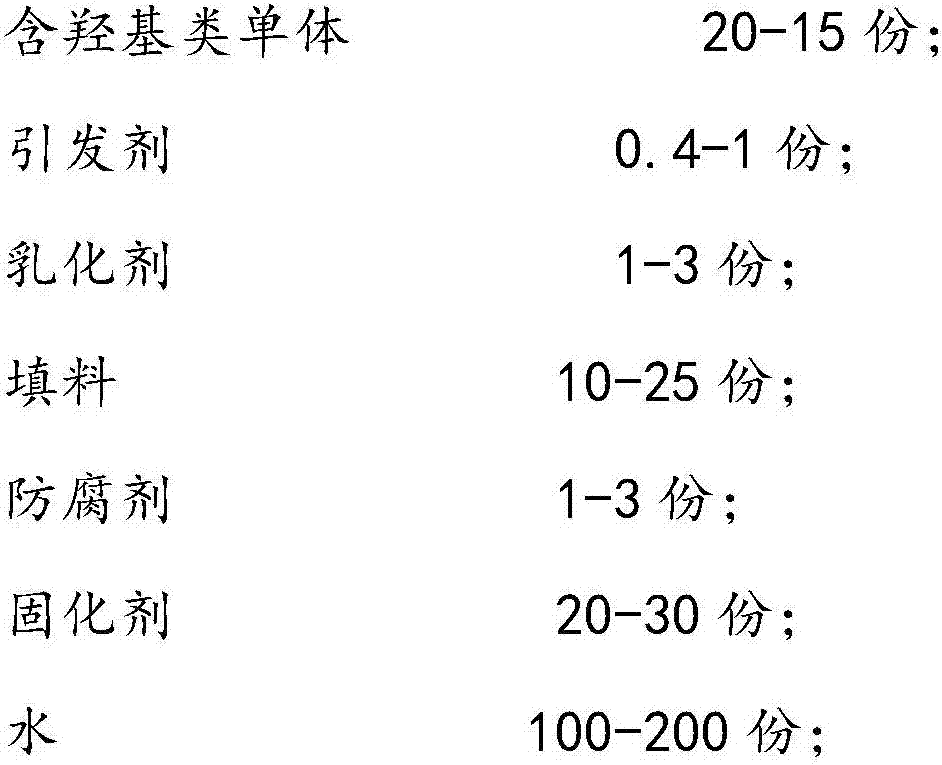

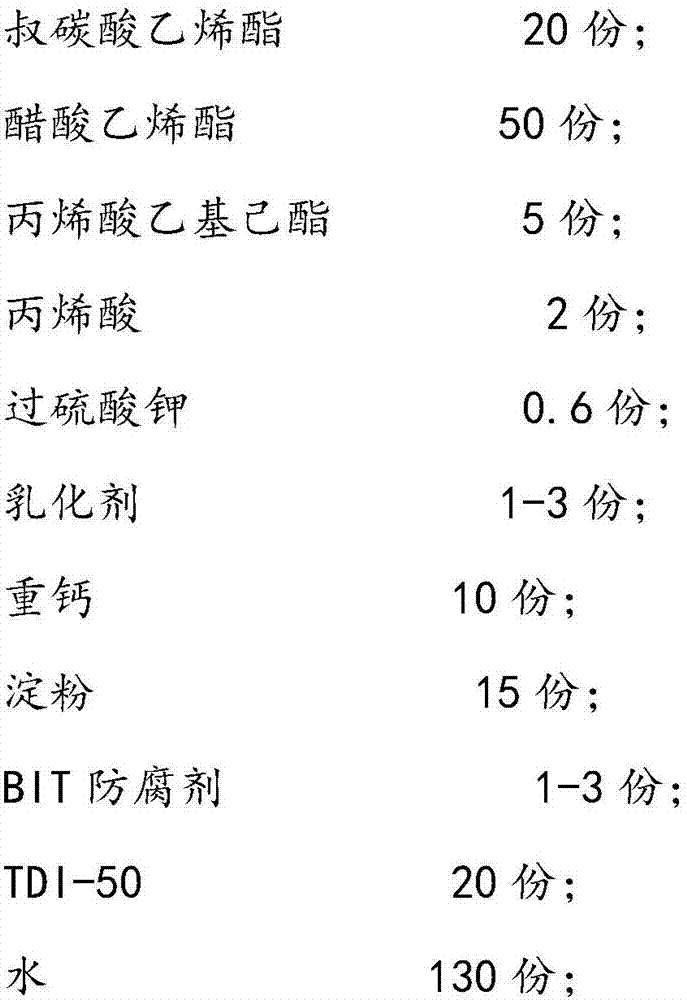

Zero-formaldehyde wood adhesive and preparation method thereof

InactiveCN106995676ASolve the problem of formaldehyde pollutionGood adhesion and water resistancePolyureas/polyurethane adhesivesFunctional monomerEmulsion

The invention discloses a zero-formaldehyde wood adhesive and a preparation method thereof, and belongs to the technical field of adhesive preparation. The zero-formaldehyde wood adhesive is prepared by taking vinyl acetate monomer, acrylic acid monomer, hydroxyl-containing functional monomer, an emulsifying agent, an initiator and the like as raw materials to prepare copolymer emulsion with a semi-continuous process, adding a small amount of filler, preservative, curing agent and the like in the emulsion, and stirring and mixing, the adhesive has the advantages of strong initial adhesion, good film forming property, excellent water resistance, zero formaldehyde and the like, and can be widely applied to manufacturing and production of artificial boards such as plywood, core-boards, shaving boards and density boards.

Owner:孙小力

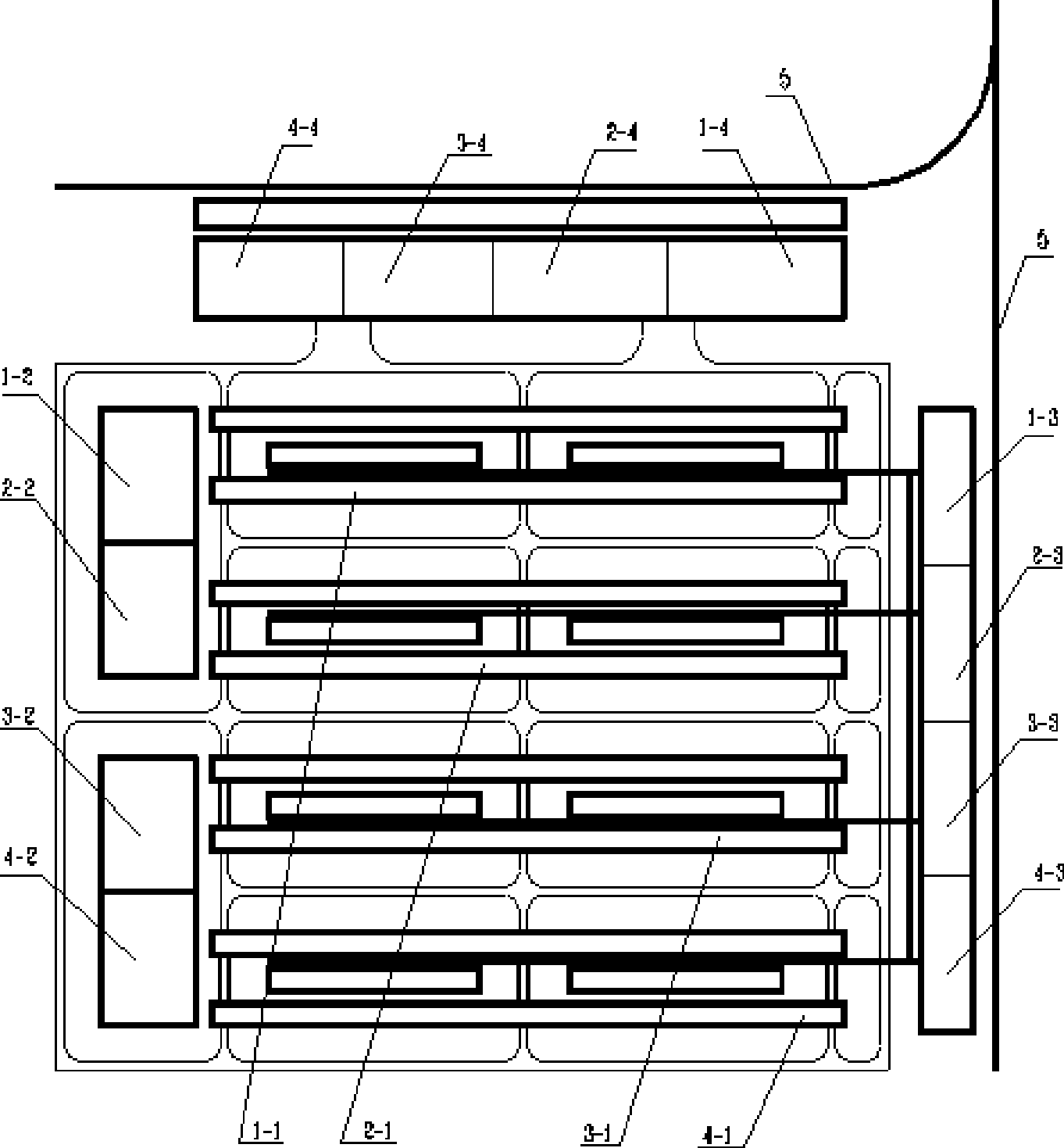

Electrolytic aluminum plant collocation form of series layout

The invention discloses a series layout configuration form for an electrolytic aluminum plant, which is characterized in that according to productivity requirements planned by the electrolytic aluminum plant, production scale is divided into a plurality of production series, and the design is completed once and the construction is carried out step by step; according to production nature and functions, main production facilities of each production series are divided into an electrolytic production area, a power supplying and transforming rectification area, an alumina discharging and storage as well as conveying area, a cast and storage area and other functional areas, wherein the alumina discharging and storage as well as conveying area and the cast and storage area are close to a railway transportation system. Compared with the prior art, the configuration form can reduce the occupied area of the electrolytic aluminum plant, save engineering pipeline cost, and reduce energy consumption. In addition, the construction of an expansion project in subsequent period has little interference on a production system in early period, thereby facilitating the production and construction.

Owner:GUIYANG AL-MG DESIGN & RES INST

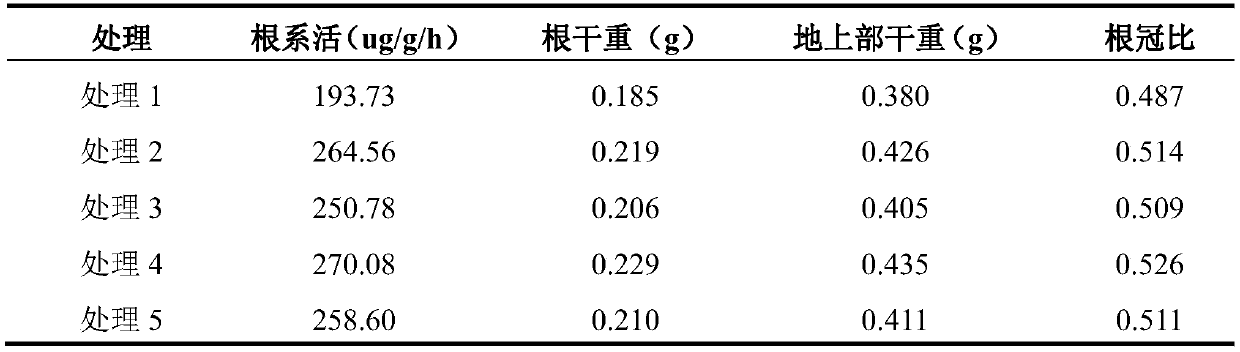

Phosphorus fertilizer synergist, synergistic diammonium phosphate containing phosphorus fertilizer synergist , and method for preparing synergistic diammonium phosphate

InactiveCN111004065AIncrease Phosphorus ActivityPromote root growth of cropsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiammonium phosphateHumic acid

The invention discloses a phosphorus fertilizer synergist, synergistic diammonium phosphate containing the phosphorus fertilizer synergist, and a method for preparing the synergistic diammonium phosphate, wherein 100 parts by weight of the phosphorus fertilizer synergists comprise, by weight, 10-15 parts of humic acid, 5-15 parts of polyglutamic acid, 2-5 parts of carboxymethyl chitosan, 2.5-6 parts of the EDTA chelated trace elements, and 0.5-2 parts of the sodium methylene bis-naphthalene sulfonate. According to the invention, after the phosphorus fertilizer synergist is mixed with a phosphorus fertilizer, the fixation of the phosphorus fertilizer by soil can be remarkably reduced, the phosphorus activity is improved, crop root growth is promoted, and trace elements in the soil are activated and supplemented.

Owner:中化农业(临沂)研发中心有限公司

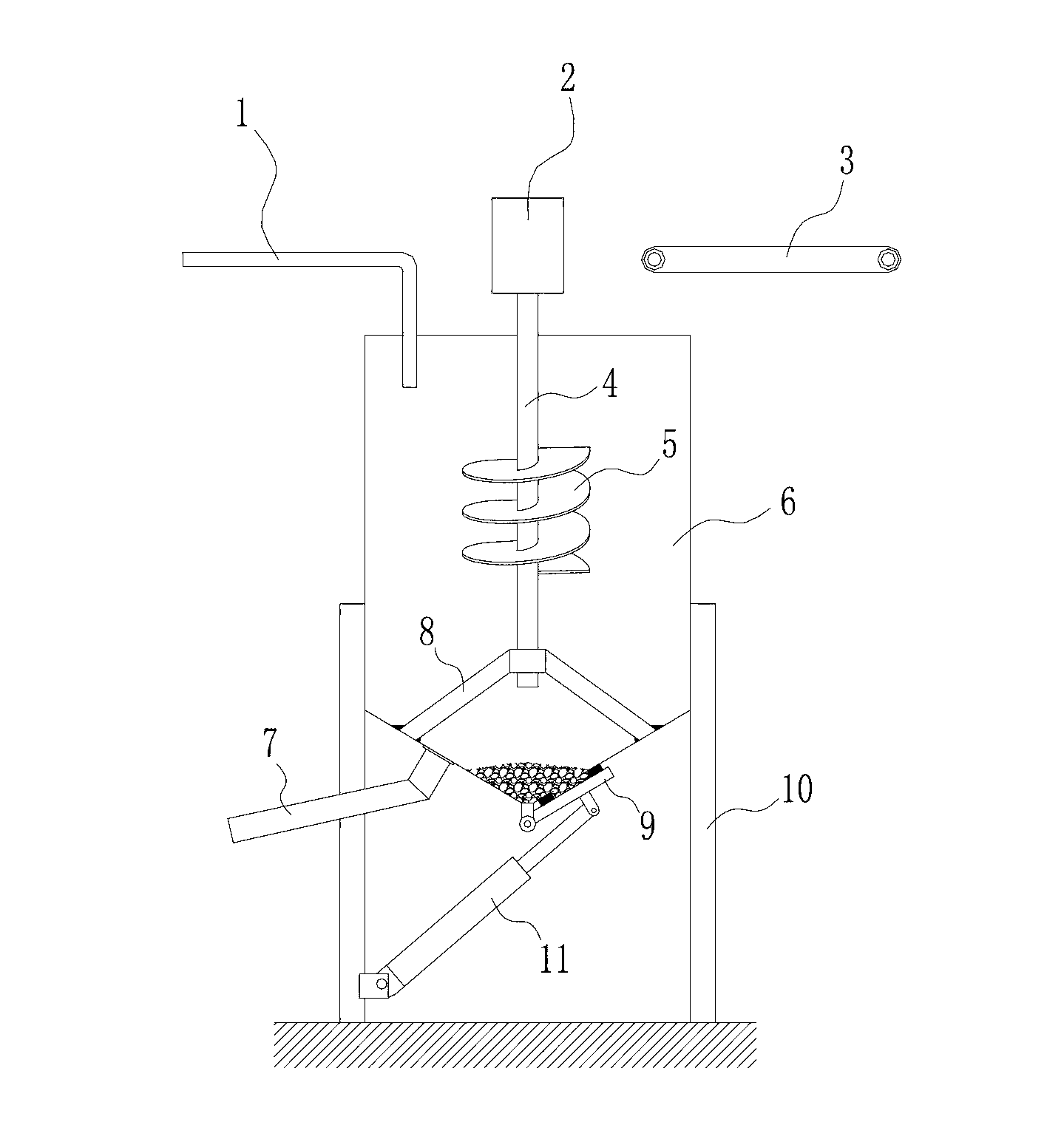

Impurity removal agitator tank

InactiveCN103231450AAvoid personal injuryDoes not affect the production processRotary stirring mixersMixing methodsHydraulic cylinderBiochemical engineering

The invention belongs to the technical field of agitation equipment, and particularly relates to an agitator tank with an impurity removal function. The agitator tank comprises a tank body, a driving machine, an agitating shaft connected with the driving machine and an agitating blade positioned on the agitating shaft, wherein a shaft sleeve is further sleeved at the bottom end of the agitating shaft; a plurality of supporting bodies are arranged between the shaft sleeve and the inner wall of the tank body; the tank body is supported by a plurality of upright posts and the bottom of the tank body is inverted-cone-shaped; an impurity outlet is arranged on the side wall of the inverted-cone-shaped bottom; the agitator tank further comprises a buckle cover buckled on the impurity outlet, wherein the edge of the buckle cover is hinged with the bottom of the tank body, and a connecting lug plate is further arranged on the buckle cover; the agitator tank further comprises a hydraulic cylinder, wherein the end of a piston rod of the hydraulic cylinder is hinged with the connecting lug plate; and a discharging pipeline is further arranged at the bottom of the tank body, and the height of a connecting part of the discharging pipeline and the tank body is larger than that of the impurity outlet. According to the impurity removal agitator tank disclosed by the invention, the bottom of the tank body is arranged to be inverted-cone-shaped and the impurity outlet and the buckle cover are arranged, so that large grained impurity in size can be precipitated and merged and is convenient to take out.

Owner:TIANJIN FUYUAN BUILDING MATERIALS CO LTD

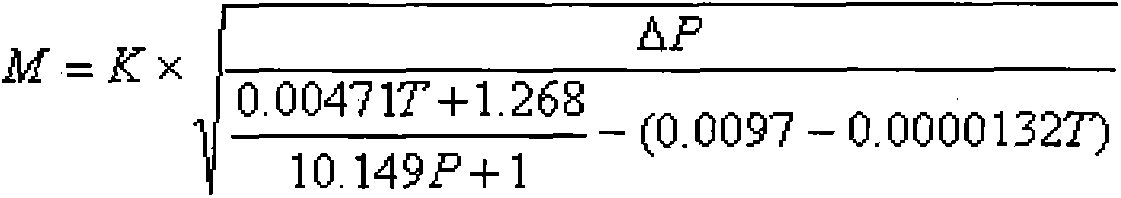

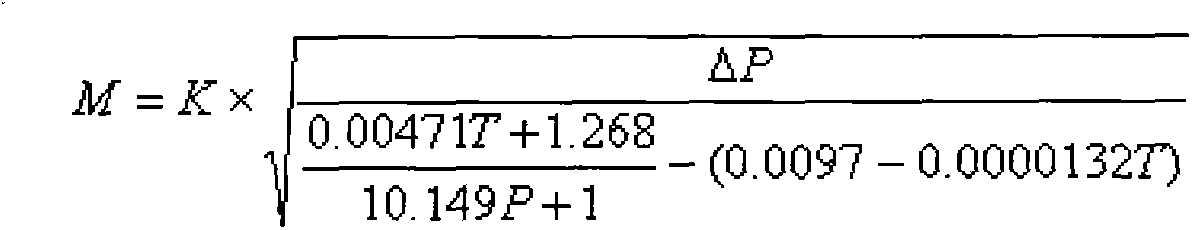

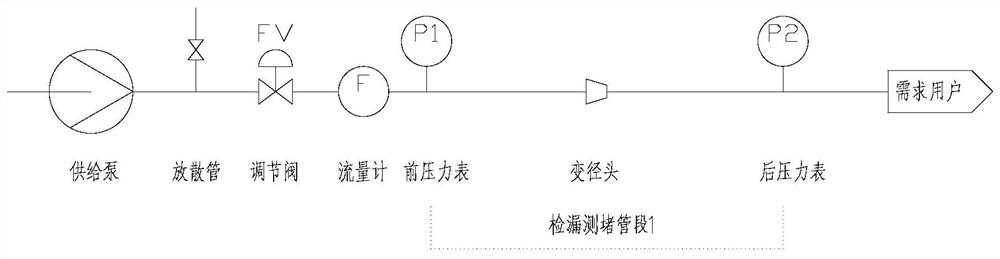

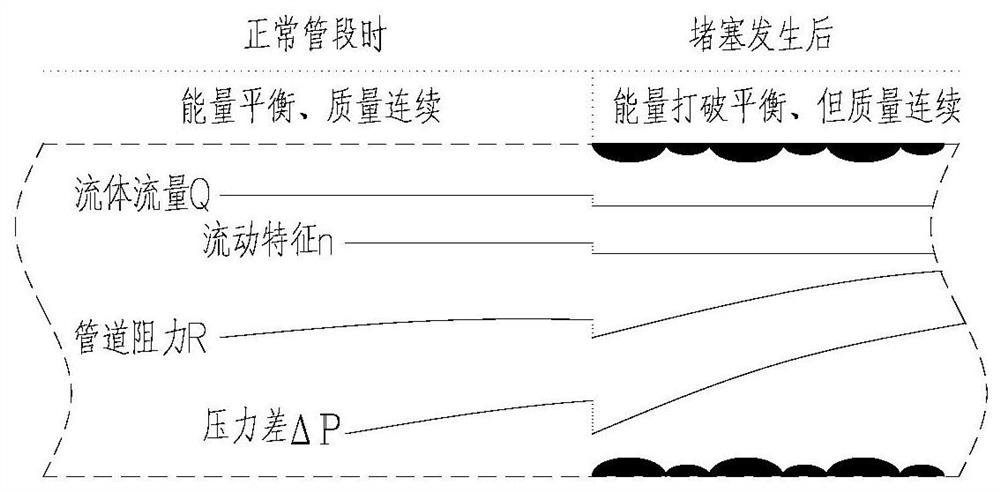

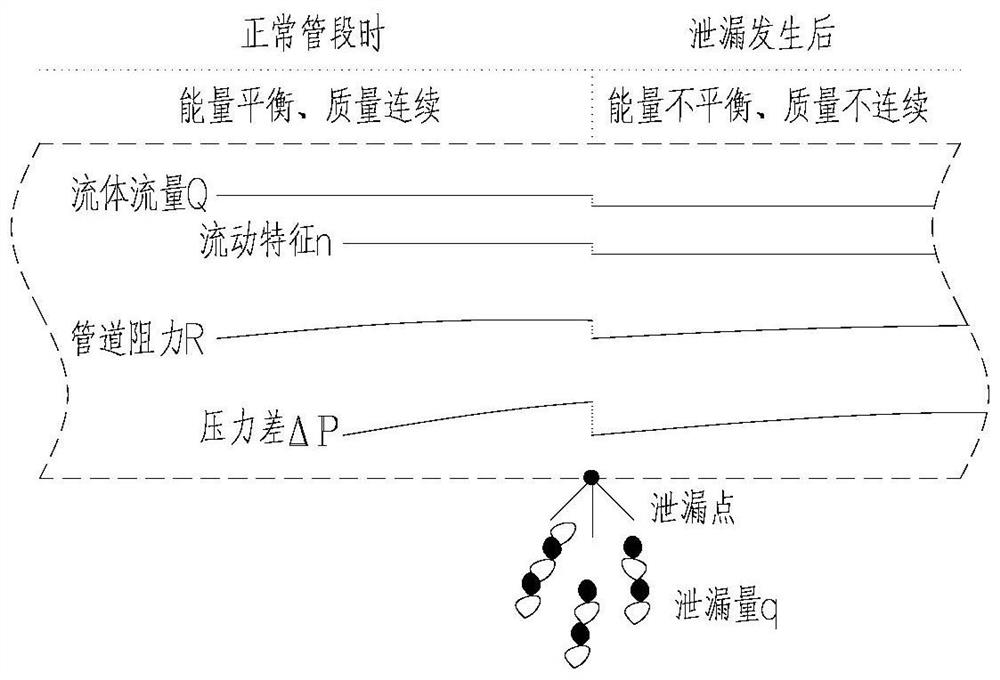

Fault detection method and system for fluid pipeline

ActiveCN111853553ASimple leak detectionLeak detection easyPipeline systemsReference sampleControl engineering

The invention provides a fault detection method and system for a fluid pipeline. The problems that a leakage and blockage detection method in the prior art cannot be applied to any pipeline and is nothigh in precision are solved. The method comprises the following steps of mapping the mutual constraint relation between the pipeline and fluid according to energy balance of the fluid in the pipeline, the flow of the fluid in the pipeline and the pressure difference value between the front end and the rear end of a pipeline section on the specified leakage and blockage detection pipe section; continuously obtaining a pipeline stroke resistance value R and a fluidity characteristic coefficient n through a machine self-learning mode as a normal reference sample; once the stroke resistance value R and the fluidity characteristic coefficient n change, determining that the pipeline is in an abnormal state; and capturing the time and the degree of quantitative change of the stroke resistance Rand the fluidity characteristic coefficient n, and identifying that the pipe section is in a quality change fault state of blockage or leakage. Through the machine self-learning mode, original parameters such as pipeline erection condition, section surface shape, clear viscous medium type and fast and slow flow speed do not need to be observed, and the application range is wide.

Owner:CISDI INFORMATION TECH CO LTD

Method for detecting roughness of etched side walls through capacitance changes

InactiveCN104089572AAvoid complex designDoes not affect the production processElectric/magnetic roughness/irregularity measurementsCapacitanceMature technology

The invention discloses a method for detecting roughness of etched side walls through capacitance changes. The technical process is added before the etching process is carried out on a functional area only, and design complexity of functional devices is prevented from being increased. The roughness of the side walls of the functional area is reflected through the capacitance changes of detection areas, errors caused by small sizes are reduced, operations such as fracture surfaces causing damage to the devices are avoided, and nondestructive detection on etched structures is achieved. The number of the detection areas is determined through sizes and varieties of etched windows of the functional area, the purpose of more accurately detecting the roughness of the etched side walls under different conditions is achieved, and meanwhile the roughness of the etched side walls under the different etching conditions can be detected in one step. The technical process is simple, mature technologies are adopted in the process, technical difficulty is low, implementation is easy and convenient, and operation is easy.

Owner:PEKING UNIV +1

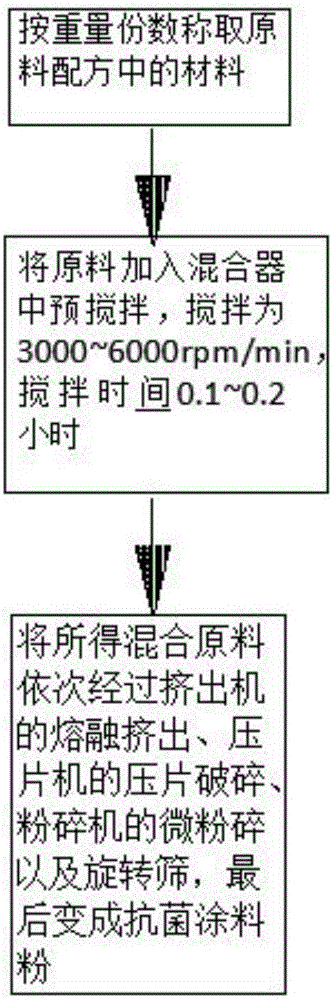

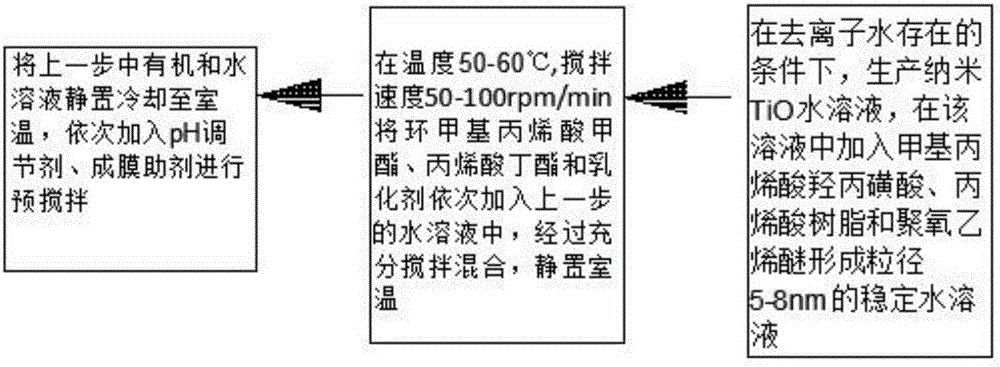

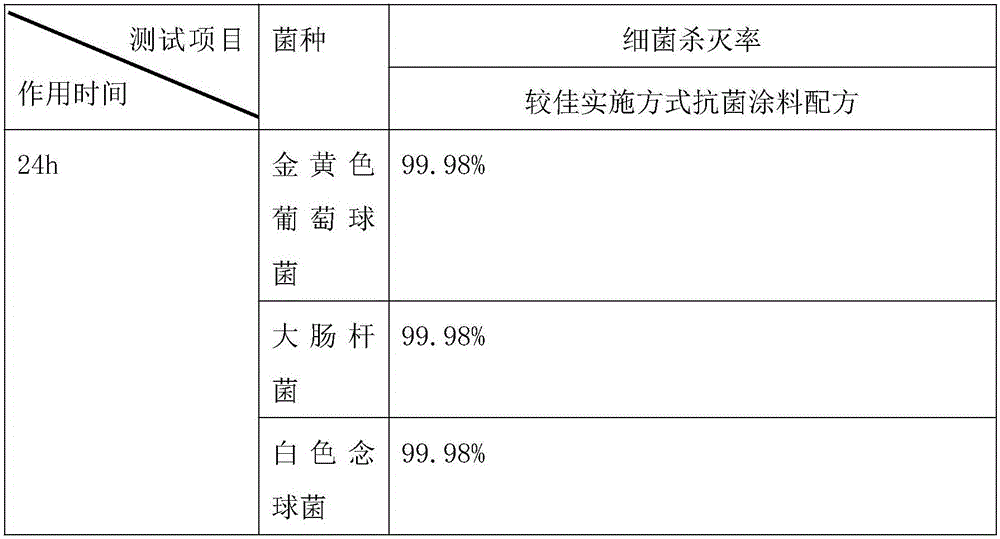

Production method of antibacterial coating, antibacterial coating and ventilated antibacterial film containing antibacterial coating

InactiveCN105925103AImprove the production processSimple production methodAntifouling/underwater paintsSynthetic resin layered productsMethacrylateAcrylic resin

The invention provides a production method of an antibacterial coating, the antibacterial coating and a ventilated antibacterial film containing the antibacterial coating. The production method comprises the following steps: S1: weighing materials in a raw material formula in parts by weight; S2: adding cyclomethyl methacrylate, butyl acrylate, nano TiO, methacrylic acid hydroxylpropyl sulfonic acid, acrylic resin, polyoxyethylene ether, an emulsifying agent, de-ionized water, a pH regulator and a film-forming addition agent into a mixer and pre-stirring, wherein the stirring speed is 3000rpm / min to 6000rpm / min and the stirring time is 0.1h to 0.2h; S3: fusing and extruding the mixed raw materials obtained by the step S2 through an extruder, tabletting and crushing through a tabletting machine, micro-crushing by a crusher and screening in a rotary manner in sequence to finally obtain antibacterial coating powder. The production method of the antibacterial coating, provided by the invention, is finished through three steps; the production process method is simple and the production method is simple; the production time is short and the production efficiency is greatly improved.

Owner:江苏科德宝建筑节能科技有限公司

Optical fiber Bragg grating temperature sensor for measuring temperature of dry type air-core reactor and application method of optical fiber Bragg grating temperature sensor

ActiveCN104634477ASimple structureEliminate the effects ofThermometers using physical/chemical changesEpoxyGrating

The invention relates to an optical fiber Bragg grating temperature sensor for measuring temperature of a dry type air-core reactor and an application method of the optical fiber Bragg grating temperature sensor, and belongs to the technical field of photoelectron measurement. The tail part of an optical fiber Bragg grating is connected with an optical fiber; the lead-out optical fiber penetrates out from a polytetrafluoroethylene sleeve and is adhered and fixed by epoxy resin, so as to play a role in protecting the optical fiber; a rectangular gap is formed in the middle of the left end of a polytetrafluoroethylene plate; a transverse round hole is drilled in the gap, and is used for planting the optical fiber Bragg grating; the optical fiber Bragg grating is in a cantilever beam structure in the round hole, fills the rectangular gap by a polytetrafluoroethylene material after being planted, and is integrally encapsulated into a rectangular structure together with the polytetrafluoroethylene plate; the temperature change of the dry type air-core reactor is calculated according to the relational expression delta lambdaB is equal to KT multiplied by deltaT of a displacement value of a center wavelength of the optical fiber Bragg grating and the outer encapsulation temperature of a lead of the reactor. The optical fiber Bragg grating temperature sensor is suitable for temperature detection in a strong electromagnetic field environment, and is high in anti-corrosion capability and very small in size.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST +1

Numerical control machine tool wear monitoring method

InactiveCN102091972BEasy to installHigh precisionMeasurement/indication equipmentsEngineeringControl theory

The invention belongs to the field of numerical control machine tool wear measurement, and discloses a numerical control machine tool wear monitoring method. In the method, servo drive motor current signals of a numerical control machine can reflect the change of a cutting load along with the tool wear; the acquired servo drive current signals are analyzed; the signals are decomposed in a frequency domain by a wavelet packet decomposition technology, and time-frequency domain characteristics of the signals in each frequency domain range are obtained and a plurality of characteristics stronglycorrelated to the tool wear are automatically selected; the tool wear process is learned through a neural network and a tool wear rule is obtained; in reverse, the tool wear characteristics are obtained in real time and are matched with the tool wear rule obtained through learning so as to monitor the tool wear state. The method solves a problem that the conventional tool wear monitoring method cannot realize online real-time monitoring, the servo drive signals of the numerical control machine are utilized, the integration with a numerical control system is easy to realize, the monitoring cost is reduced and the monitoring accuracy is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH +1

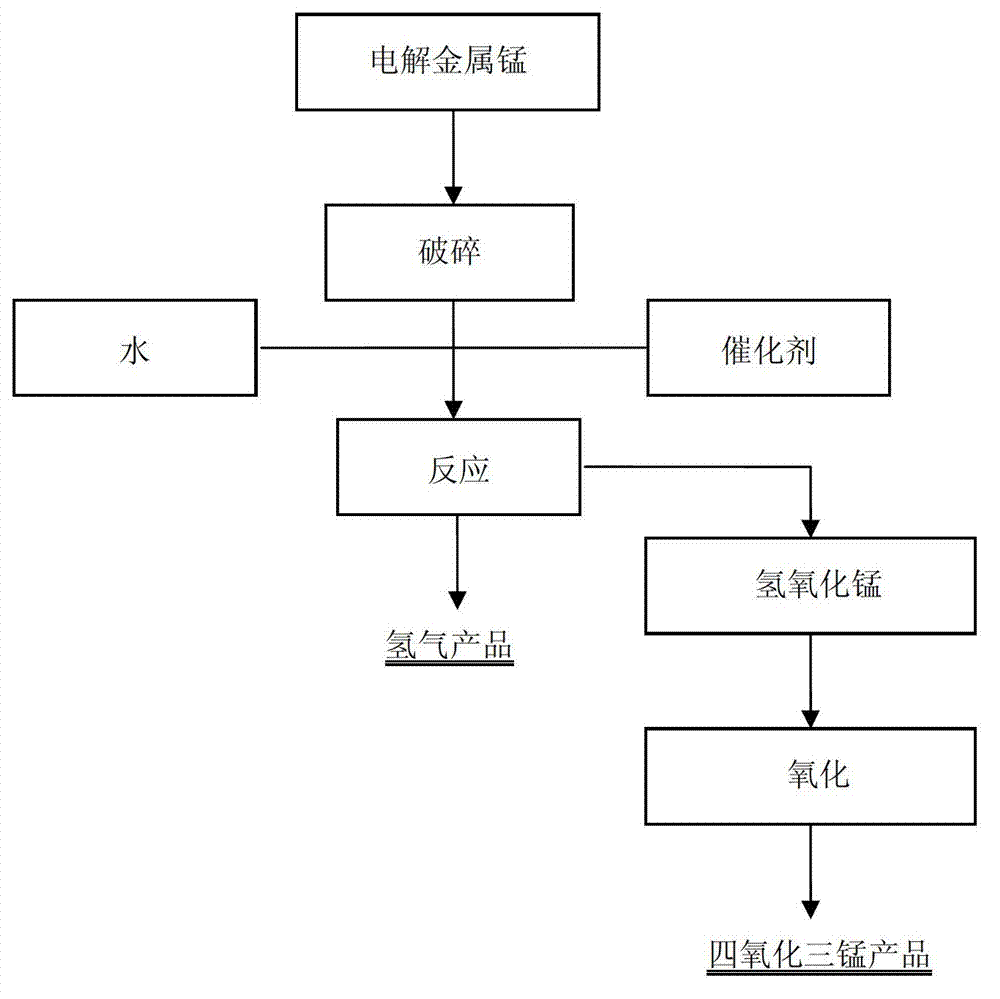

Method for preparing hydrogen in process of producing trimanganese tetroxide from electrolytic manganese metal

InactiveCN103241711ADoes not affect the production processSolve the safety hazards of flammable and explosiveHydrogen productionManganese oxides/hydroxidesElectrolysisReaction temperature

The invention relates to a method for preparing hydrogen in process of producing manganous-manganic oxide through electrolytic manganese metal and belongs to the field of chemical metallurgy. The preparation method comprises the following steps: crushing the electrolytic manganese metal in the process of producing the manganous-manganic oxide by taking the electrolytic manganese metal as a raw material, reacting the electrolytic manganese metal with water to generate manganese hydroxide under specific conditions under the catalytic action of a catalyst, and releasing the hydrogen, wherein the specific reaction conditions in the process of preparing the hydrogen are that the crushing particle size of the electrolytic manganese metal is less than 150 microns, the addition amount of the catalyst is 5-15g of catalyst added into each 1000g of electrolytic manganese metal, the reaction temperature is controlled to be 40-90 DEG C, and the PH value of the reaction process is controlled to be 6-12. The manganese hydroxide generated through the reaction is prepared into a manganous-manganic oxide product through other oxidation processes, and the hydrogen concentration of the hydrogen released from the reaction can reach 80-90 percent, and the hydrogen becomes a final gas product. The added catalysts are ammonium chloride, ammonium sulfate, hydrochloric acid, manganese chloride and oxalic acid and also comprise two or more catalysts.

Owner:湖南特种金属材料有限责任公司宁乡分公司

Refining agent for atmosphere protected electro-slag re-melting

The invention provides a refining agent for atmosphere protected electro-slag re-melting. The refining agent comprises aluminum metal, calcium metal and electro-slag, wherein the specific gravity of the refining agent is greater than that of molten slag and smaller than that of molten alloy. The refining agent for the atmosphere protected electro-slag re-melting can be used for refining various products suitable for electro-slag re-melting process treatment such as carbon steel, alloy constructional steel, bearing steel, die steel, high-speed steel, stainless steel, heat resistant steel, ultrahigh-strength steel, high-temperature alloy, precision alloy, anticorrosive alloy, electric heating alloy and the like. The refining agent can effectively reduce the content of impurity elements such as O, S, P and the like of an alloy product on the premise that the conventional atmosphere protected electro-slag re-melting production process is not affected, can reduce nonmetallic inclusion content of the alloy and does not introduce new impurity elements, so as to improve the metallurgical quality of the alloy product.

Owner:CENT IRON & STEEL RES INST

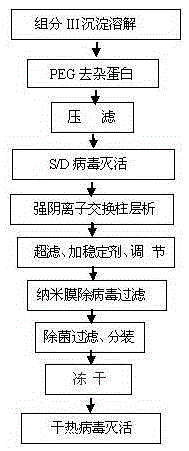

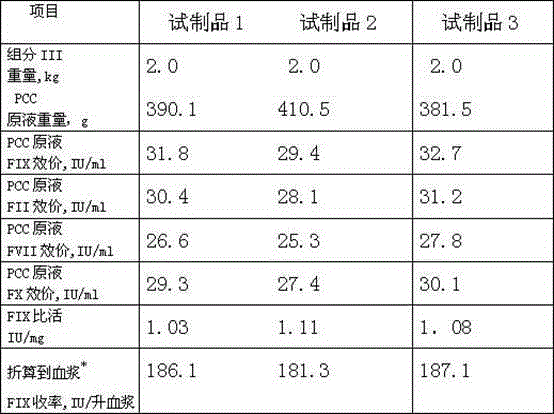

Method for preparing human prothrombin complex from Cohn blood plasma component III

InactiveCN105326859ASimple processGood economic benefitsPeptide/protein ingredientsDigestive systemUltrafiltrationStrong anion exchange

The invention discloses a method for preparing a human prothrombin complex from a Cohn blood plasma component III. The method comprises the following steps: 1, dissolving the Cohn blood plasma component III; 2, sedimenting polyethylene glycol (PEG), and removing impure protein; 3, conducting S / D viral inactivation; 4, conducting strong anion-exchange column chromatography; 5, conducting ultrafiltration dialysis and concentration; 6, adding a stabilizing agent, and conducting adjustment; 7, conducting virus-removal filtration through nanofilms; 8, conducting sterilization, filtration and subpackage; 9, conducting freeze-drying; 10, conducting dry-heat viral inactivation. According to the method, efficient strong anion-exchange column chromatography is adopted, traditional batch processing gel adsorption is replaced, labor intensity of operation is greatly lowered, cross contamination problems caused by a batch processing method are avoided, meanwhile, in the whole production process, three steps of viral inactivation and removal measures are adopted for products, and the method has the advantages that the flow is brief and simple, the production cycle is short, operation is easy to conduct, and the products are safe and reliable to use.

Owner:上海洲跃生物科技有限公司

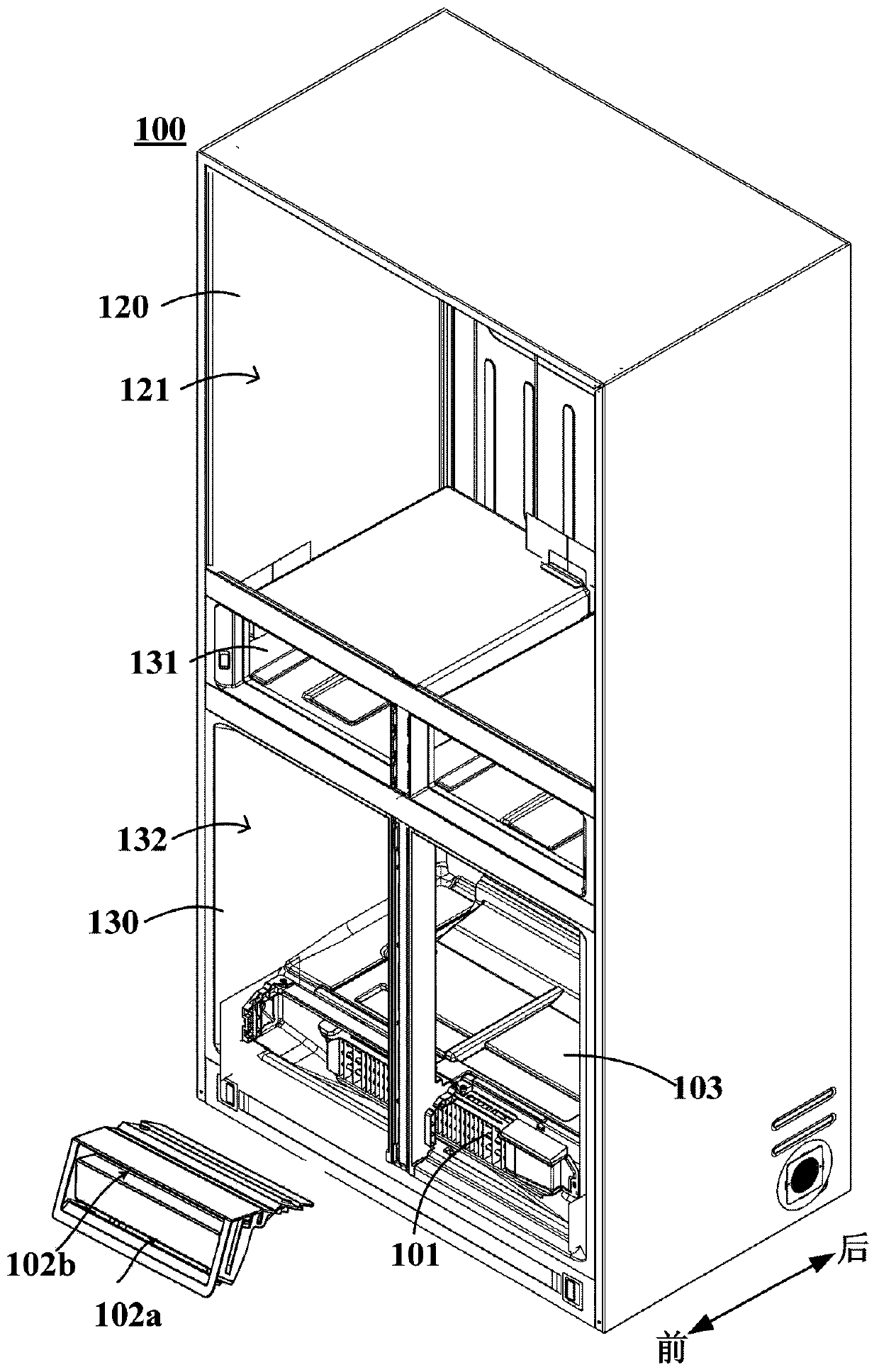

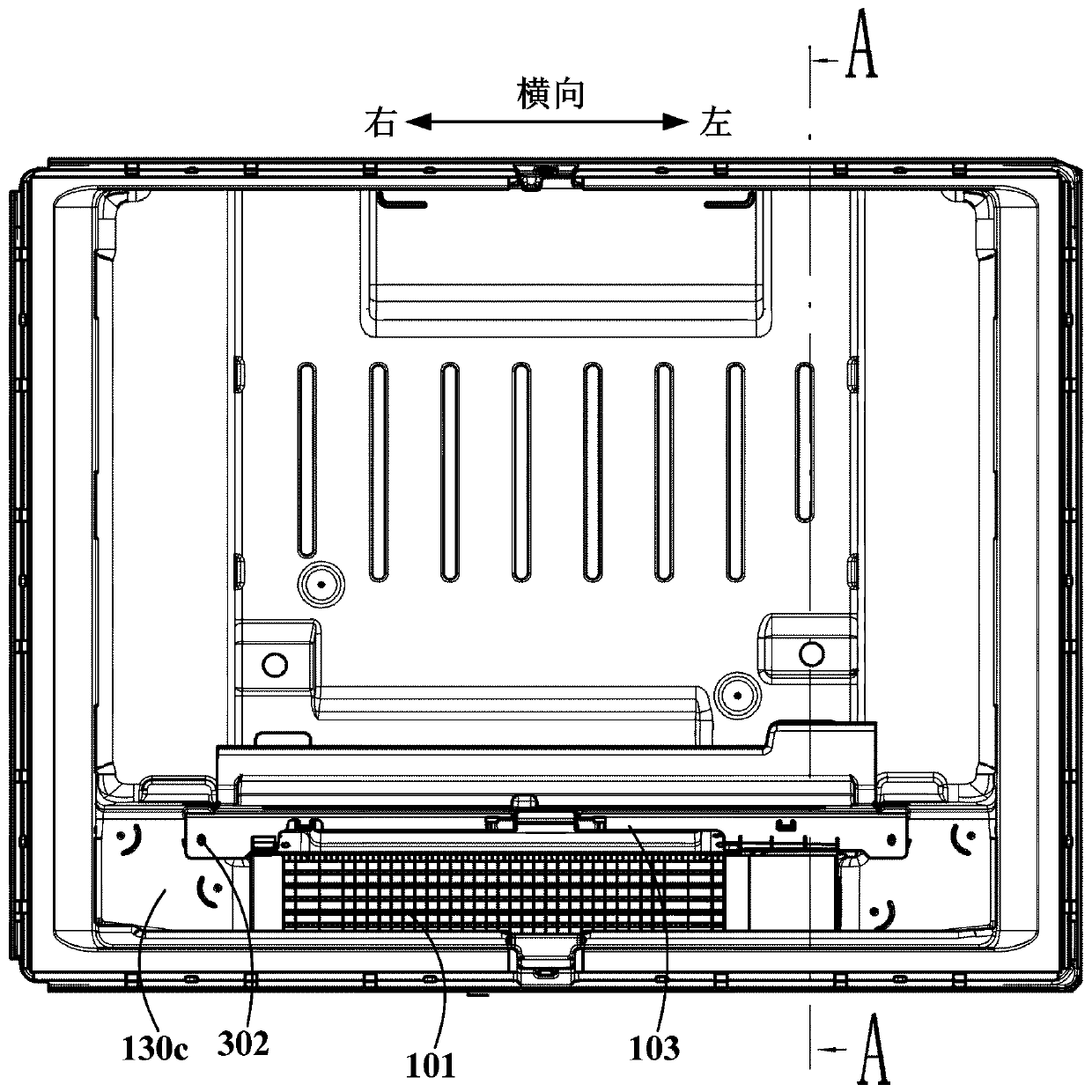

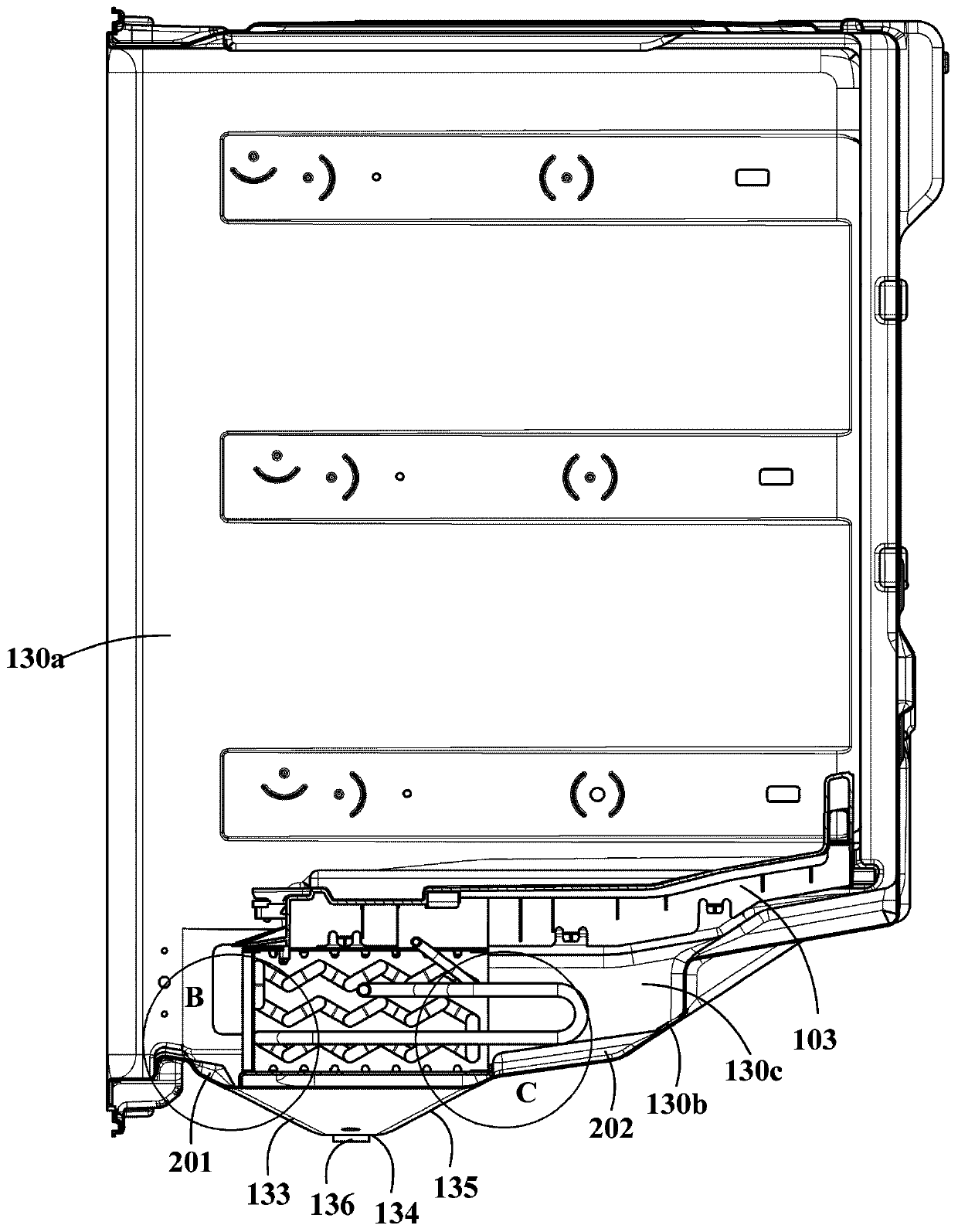

Refrigerator with improved evaporator mounting structure

ActiveCN110579071AImprove user experienceRealize front and rear limitEvaporators/condensersCooling fluid circulationEngineeringLower face

The invention provides a refrigerator. The refrigerator comprises a box body, a top cover and an evaporator. The box body comprises a storage inner container located on the lowest portion. The top cover is arranged to divide the storage inner container into a storage space located on the upper face and a cooling space located on the lower face. The evaporator is arranged in the cooling space and configured to cool airflow entering the cooling space in order to form cooling airflow. The evaporator is put on the bottom wall of the storage inner container, wherein limiting structures are formed on the portions, in front of and behind the evaporator, of the bottom wall separately, and therefore the evaporator is limited front and back. The space on the lowest portion of the refrigerator is thecooling space, the height of the storage space located above the cooling space is increased, and therefore the use experience of a user is improved; and the evaporator is arranged to be put on the bottom wall of the storage inner container, the limiting structures are formed on the portions, in front of and behind the evaporator, of the bottom wall separately, and therefore the evaporator is limited front and back.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

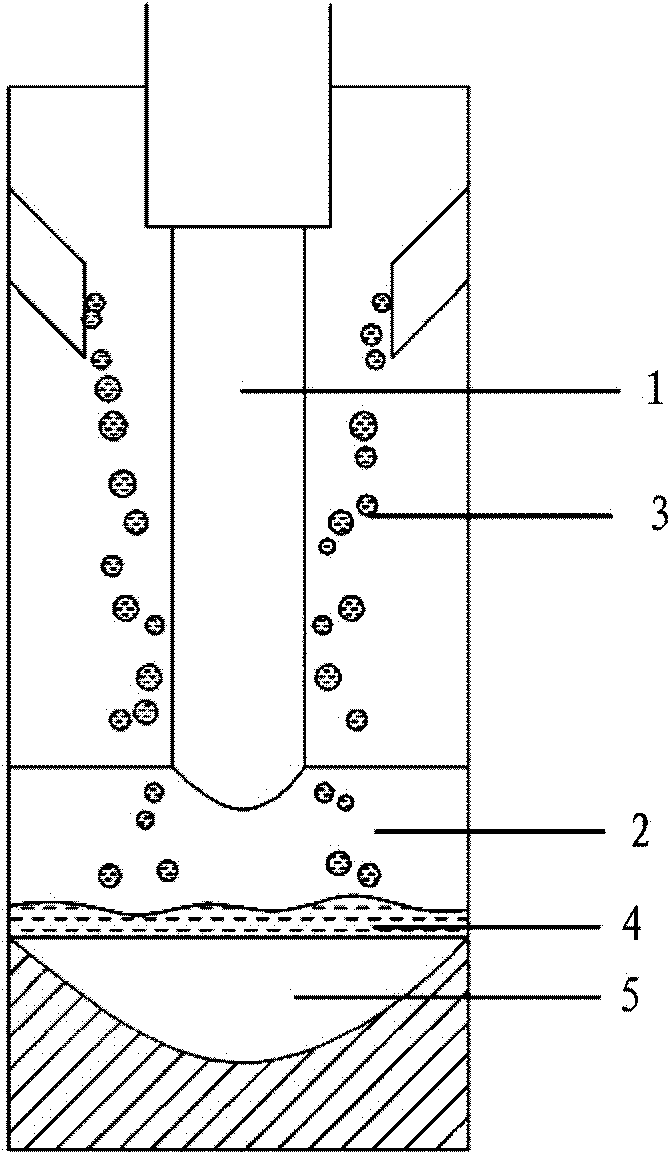

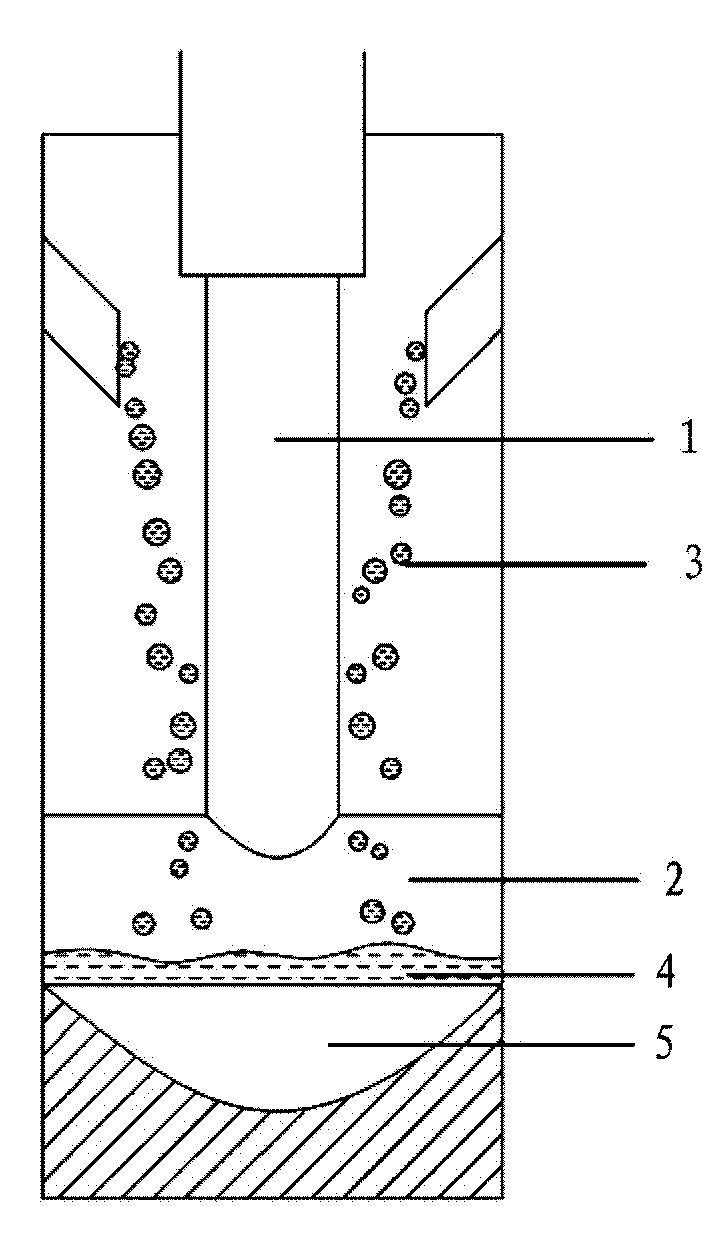

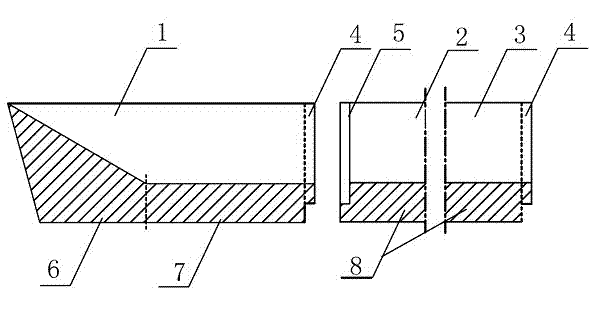

Accident swing groove device

The invention comprises an accident swing groove device, comprising a straight punched groove and one or more groups of flow guide grooves, wherein the straight punched groove comprises an adapting part internally arranged on the bottom of the groove body of the straight punched groove, and a backflow part; the backflow part is a cube comprising an upper plane which is parallel to the plane of the bottom of the groove body; the adapting part is a cube comprising an inclined plane which is inclined relative to the plane of the bottom of the groove body, connected with the top of the groove body of the straight punched groove via the straight line of the highest point of the inclined plane, and connected with the upper plane of the backflow part via the straight line of the lowest point of the inclined plane; and the flow guide groove is an integrated structure which is divided into two parts, namely, a first flow guide groove and a second flow guide groove. According to the invention, the spattering of molten steel can be reduced, and the safety factor of the use of the accident swing groove device can be increased; the overall structure is formed by connecting a plurality of sections, and simple and convenient in detachment and connection steps; and a spare flow guide groove can be replaced on line during production and use processes, without influence on the production progress.

Owner:JIANGSU YONGGANG GROUP CO LTD

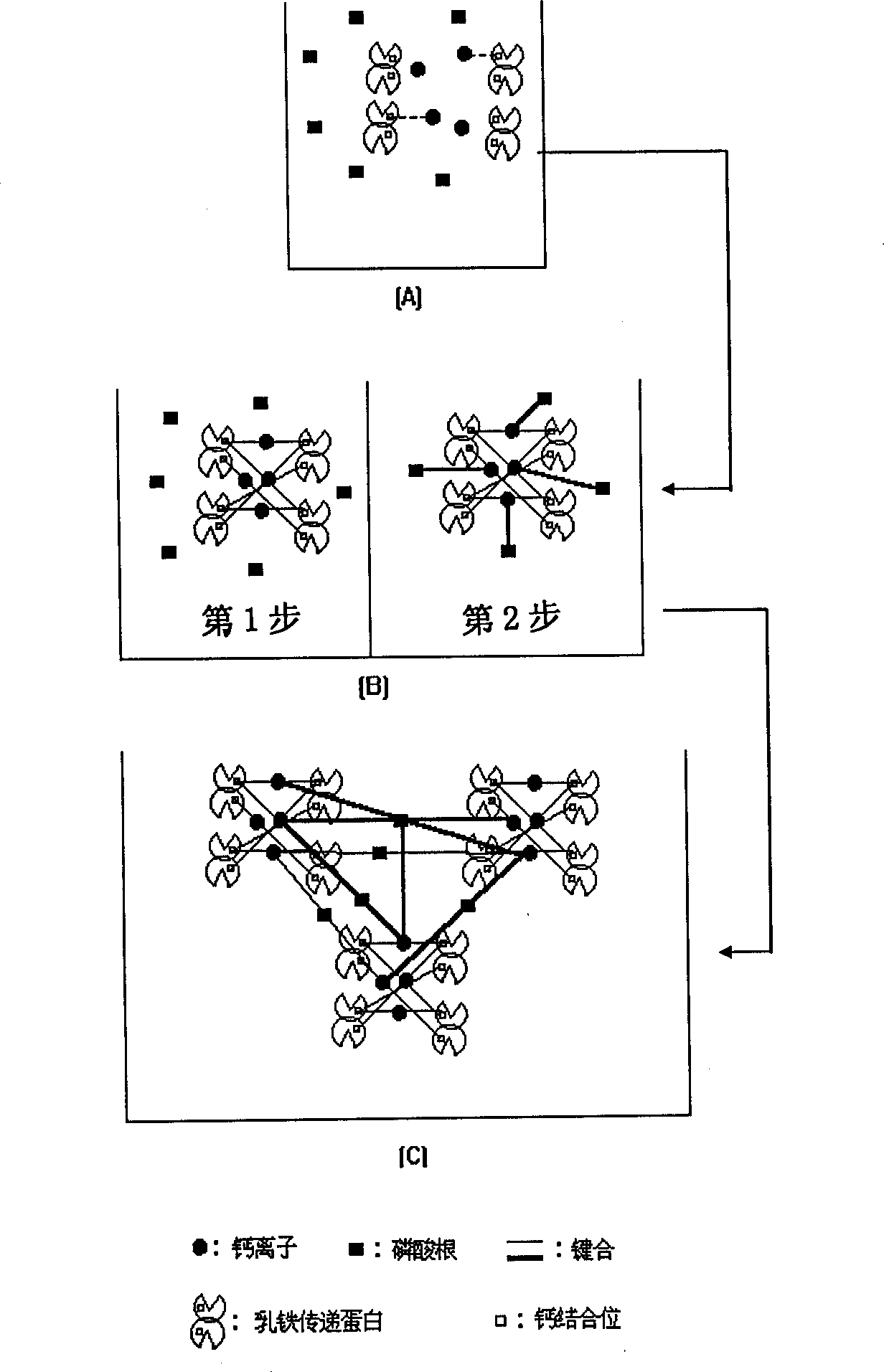

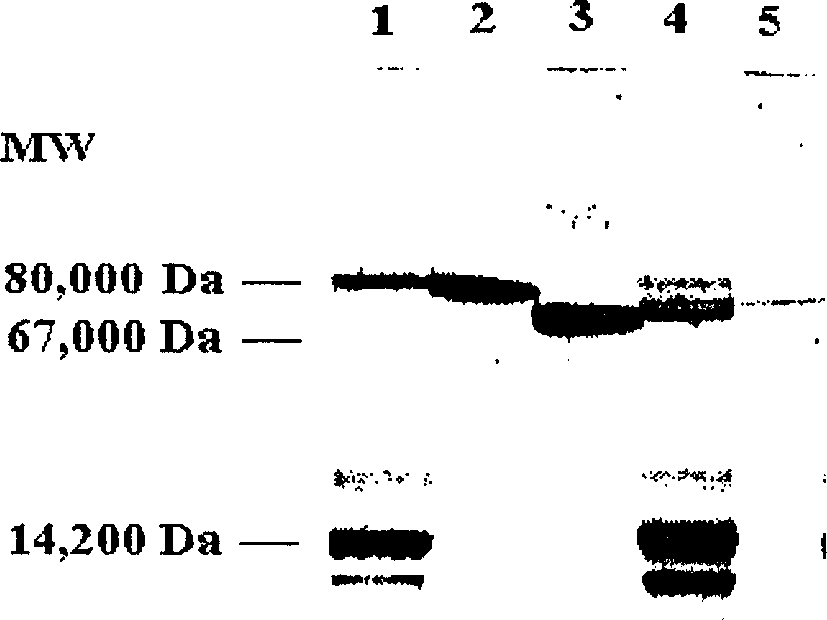

Method of separating lactotransferrin from whey liquid

InactiveCN1375504AReduce the amount of operationLess investmentTransferrinsPeptide preparation methodsFreeze-dryingUltrafiltration

The method for separating lactoferritransfer protein from whey liquor includes: 1. adopting noe-step calcium phosphate affinity precipitation method to selectively preprecipitate and separate micro amount of lactoferritransfer protein from whey liquor to obtain its precipitate powder; 2. extracting said precipitate powder by using buffer solution or salt water to obtain extract containing lactoferritransfer protein; 3. separating said extract liquor by using ultrafiltration membrane whose molecular weight trapping value is 5000 daltons, concentrating, spraying or freeze-drying to obtain its powder product whose content is 40-50%; 4. also can use cation exchange column to further purify the concentrate, the spraying or freeze-drying so as to obtain the lactoferritransfer protein powder product whose content is 90-95%.

Owner:徐跃

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com