Impurity removal agitator tank

A mixing tank and mixing shaft technology, applied in the field of mixing tanks with impurity removal function, can solve the problems of affecting the production process, time-consuming and laborious, increasing the risk factor, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

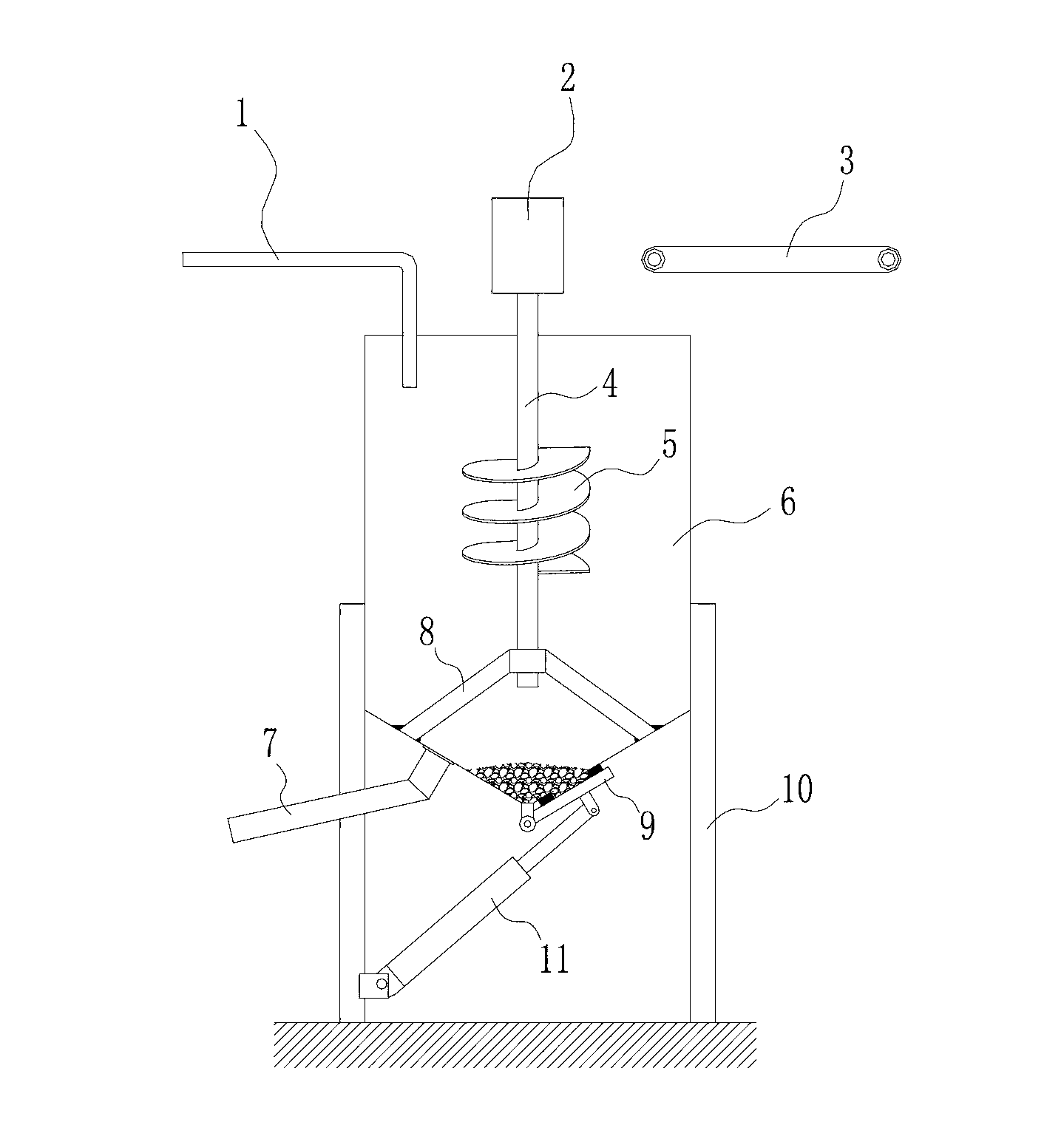

[0012] See figure 1 , the present invention comprises a tank body 6, a driver 2, a stirring shaft 4 connected to the driving machine 2, and a stirring blade 5 positioned on the stirring shaft 4, and a shaft sleeve is sheathed at the bottom of the stirring shaft 4, and the shaft A plurality of support bodies 8 are provided between the sleeve and the inner wall of the tank body 6 to realize stable support for the stirring shaft 4 and make it rotate smoothly. A water inlet pipe 1 is arranged above the tank body 6 for adding water, and a conveyor belt 3 is arranged for conveying raw materials such as fly ash.

[0013] The tank body 6 is supported by a plurality of uprights 10, and its bottom is in an inverted cone shape. The inverted cone-shaped structure facilitates the concentrated precipitation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com