Patents

Literature

137results about How to "Low mechanical failure rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

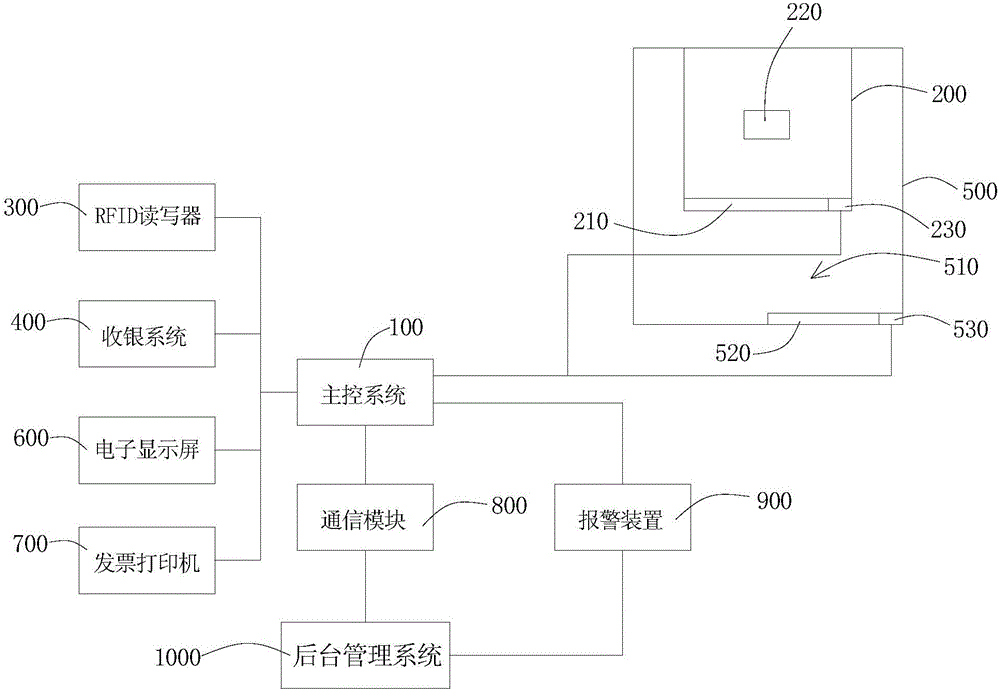

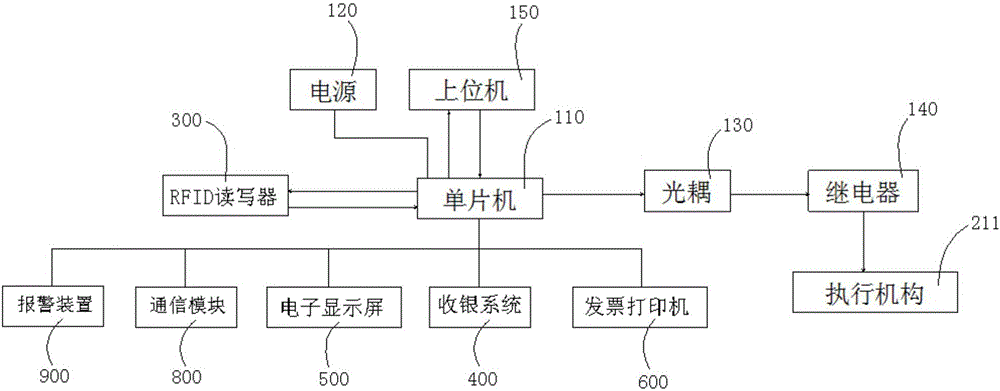

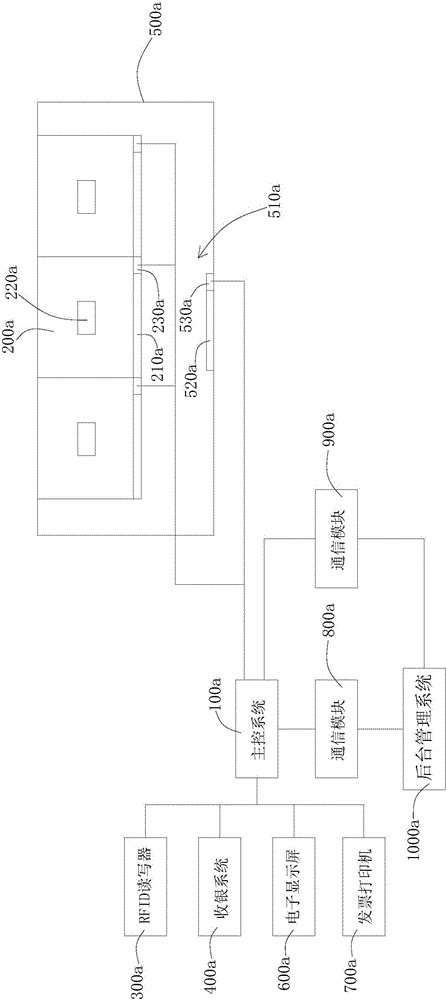

Intelligent automatic vending machine based on IOT technology

ActiveCN104992499AMake sure to leavePrivacy protectionCoin-freed apparatus detailsCash registersPaymentControl system

The invention discloses an intelligent automatic vending machine based on IOT technology. The intelligent automatic vending machine comprises a main control system, at least one cabinet storing RFID-labeled goods, an RFID reader connected with the main control system and reading information of RFID labels attached to the goods stored in the at least one cabinet via each RFID antenna, a cashier system connected with the main control system and further a peripheral enclosure structure at least accommodating each cabinet and the cashier system and forming an activity area for customers to selecting goods, wherein each cabinet is provided with a cabinet door connected with the main control system; one RFID antenna is disposed in each cabinet; and the peripheral enclosure structure is provided with a pass door communicated with a first electronic lock of the main control system and the activity area. With the peripheral enclosure structure, customers can be guaranteed to leave after payment and purchasing privacy of the customers can be protected.

Owner:SHANGHAI YUKE SMART TECH

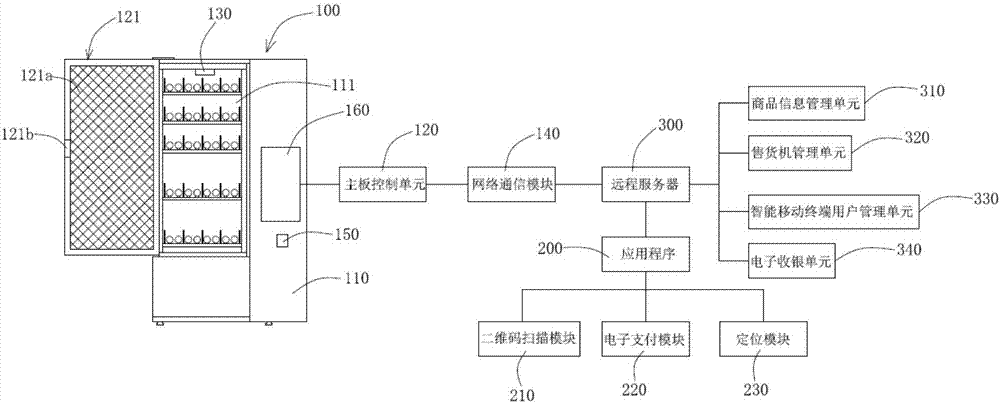

Self-service intelligent vending machine system

InactiveCN107134050AAvoid malfunctionLow mechanical failure rateCoin-freed apparatus detailsCo-operative working arrangementsElectronic cashNetwork communication

The invention discloses a self-service intelligent vending machine system. The system comprises vending machine, wherein the vending machine comprises a goods container, a mainboard control unit, a RFID reader, a network communications module and a two-dimensional bar code; an application program implantable in an intelligent mobile terminal, wherein the application program comprises a two-dimensional bar code scanning module and an electronic payment module; a remote server, wherein communications and interactions are conducted by the remote server through the network communications module with the mainboard control unit of the vending machine, the remote server comprises a goods information management unit, a management unit of the vending machine, a user management unit of the intelligent mobile terminal, and an electronic cash register unit. The self-service intelligent vending machine system has the profitable effects that more stable running of the vending machine is guaranteed, and buying experiences of the customers' are improved.

Owner:SHANGHAI YUKE SMART TECH

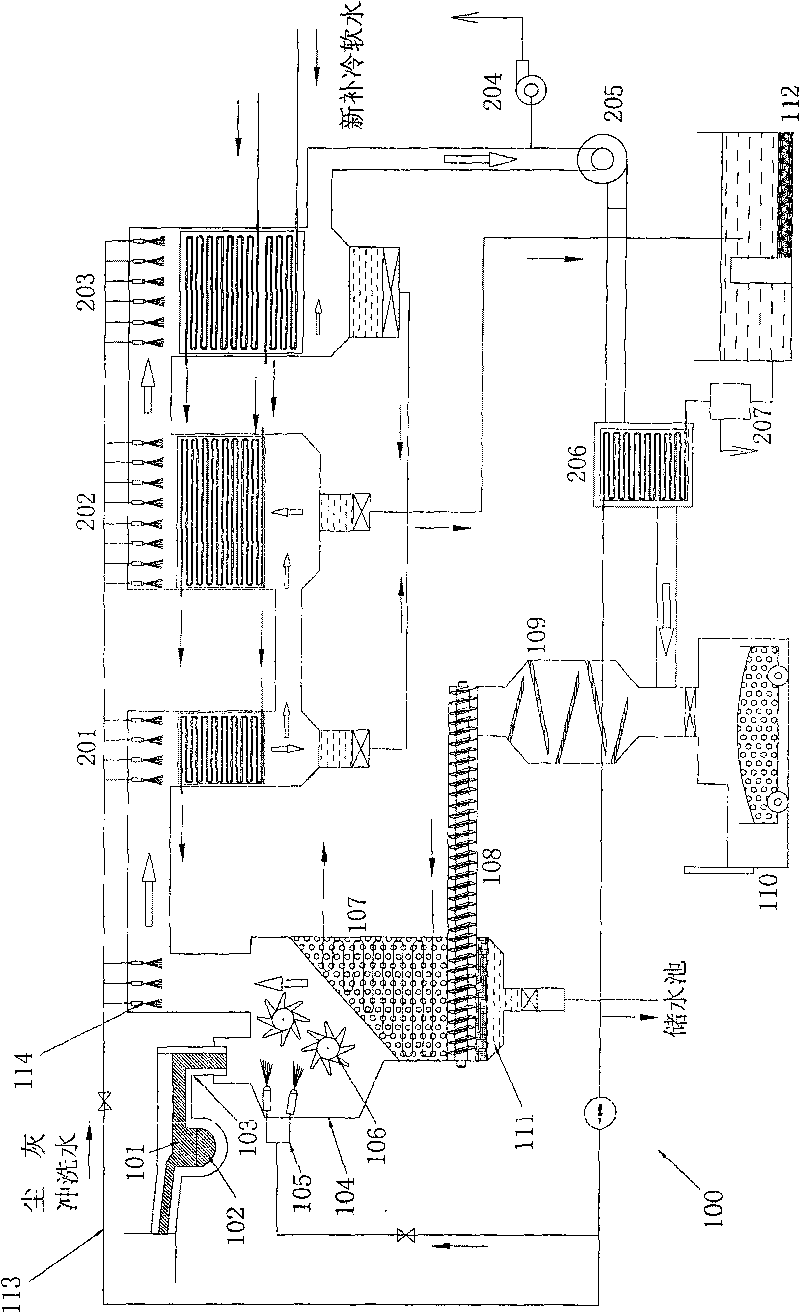

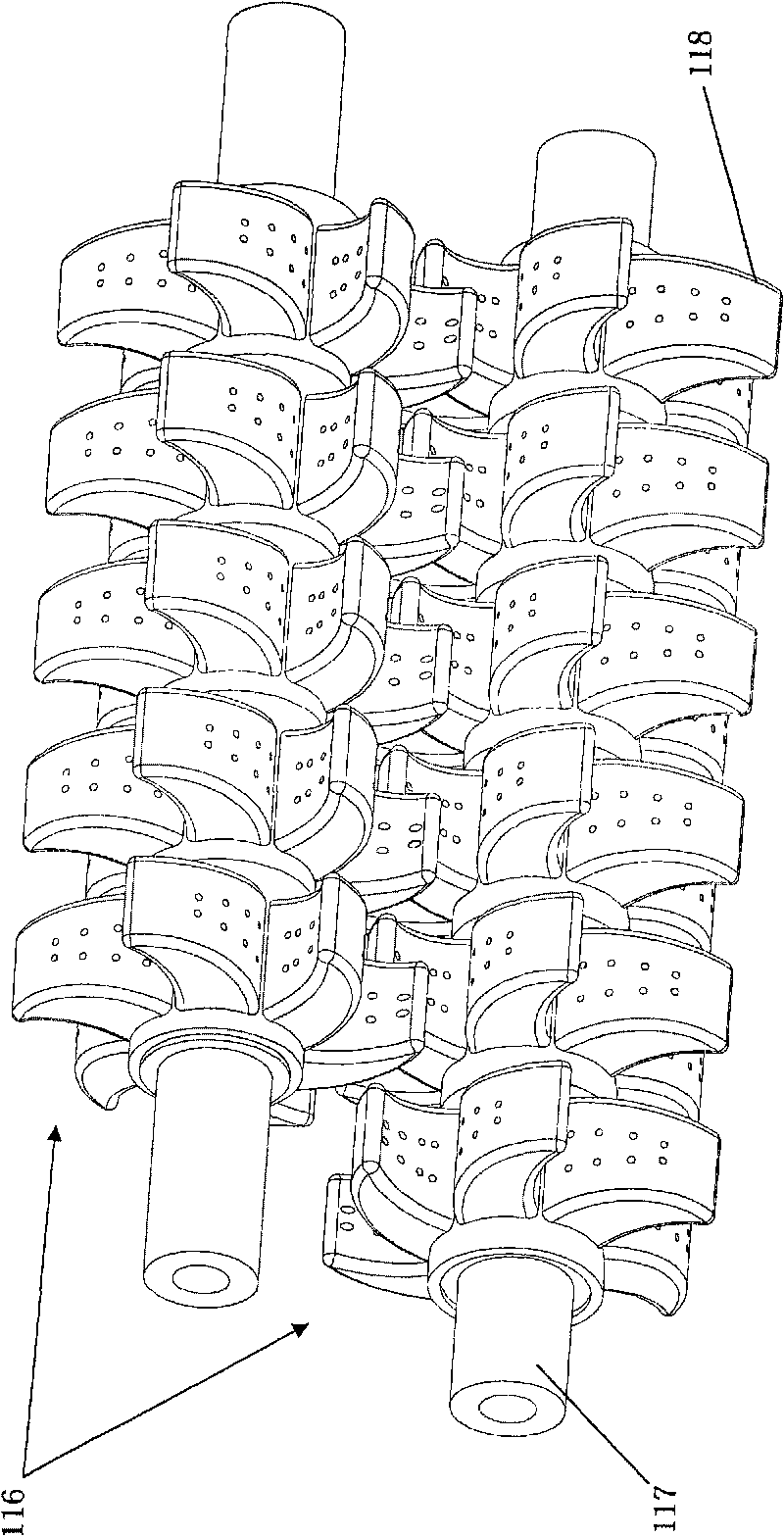

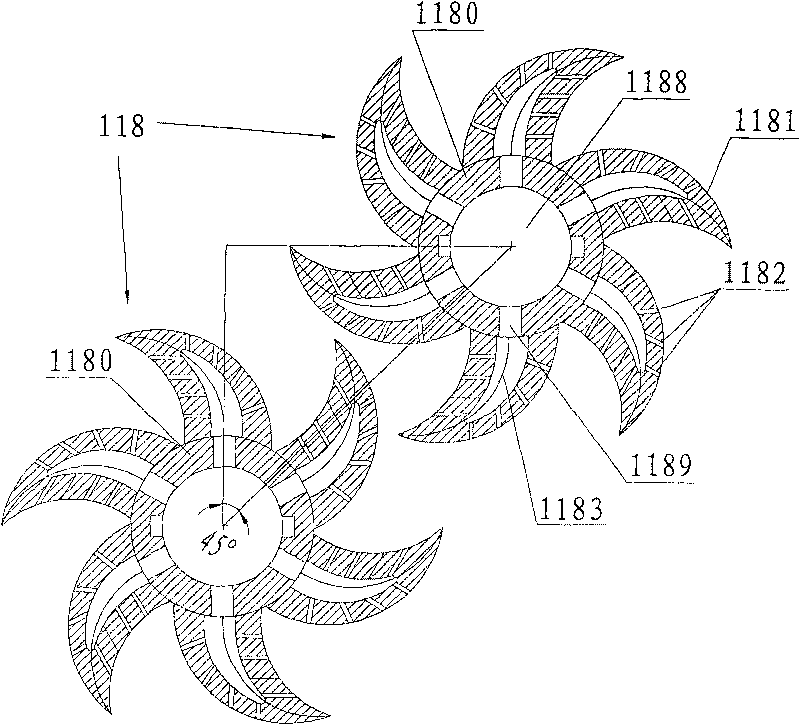

Half-wet method slag processing system and method

InactiveCN101709338AIncrease cooling intensityUniform cooling inside and outsideRecycling and recovery technologiesSlagWater resources

The invention discloses half-wet method slag processing system and method, wherein the half-wet method slag processing system comprises a slag storage bin, a high-pressure atomizing nozzle and a crushing device with high-speed revolution, wherein the upper part of the slag storage bin is provided with a high-temperature liquid slag inlet which is connected with a slag outlet of a blast furnace; the high-pressure atomizing nozzle and the crushing device are arranged in the slag storage bin and positioned below the high-temperature liquid slag inlet; the high-pressure atomizing nozzle sprays high-pressure aerial fog towards the crushing device to impact and cool the liquid slag of the blast furnace; and the crushing device is used to further mechanically crush and cool the slag and process the slag into materials for preparing cement. The invention overcomes the defects of the high use level and the waste of water resources, difficult heat energy recovery and the high cost of the reprocessing of slag secondary products in the traditional slag processing method.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

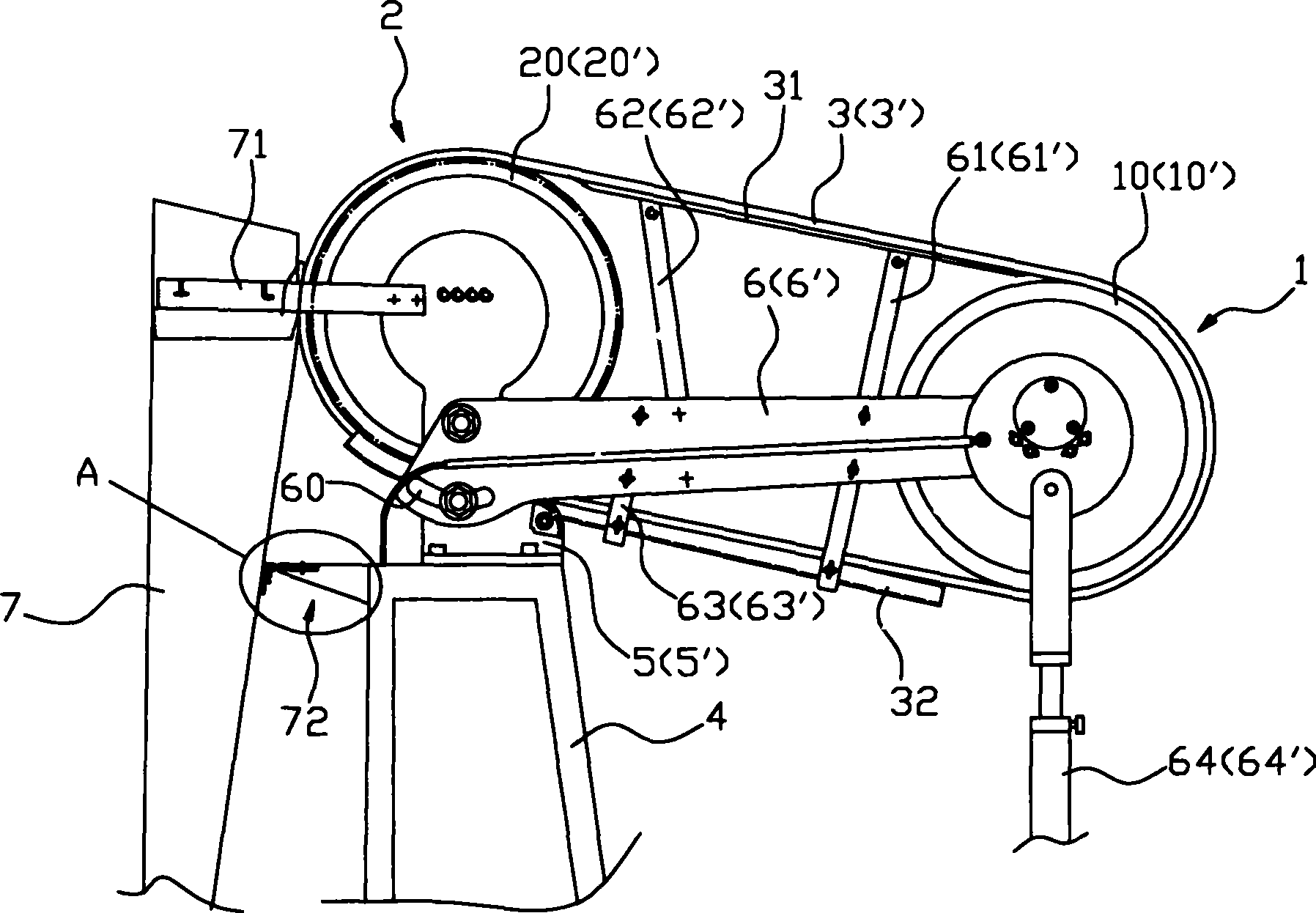

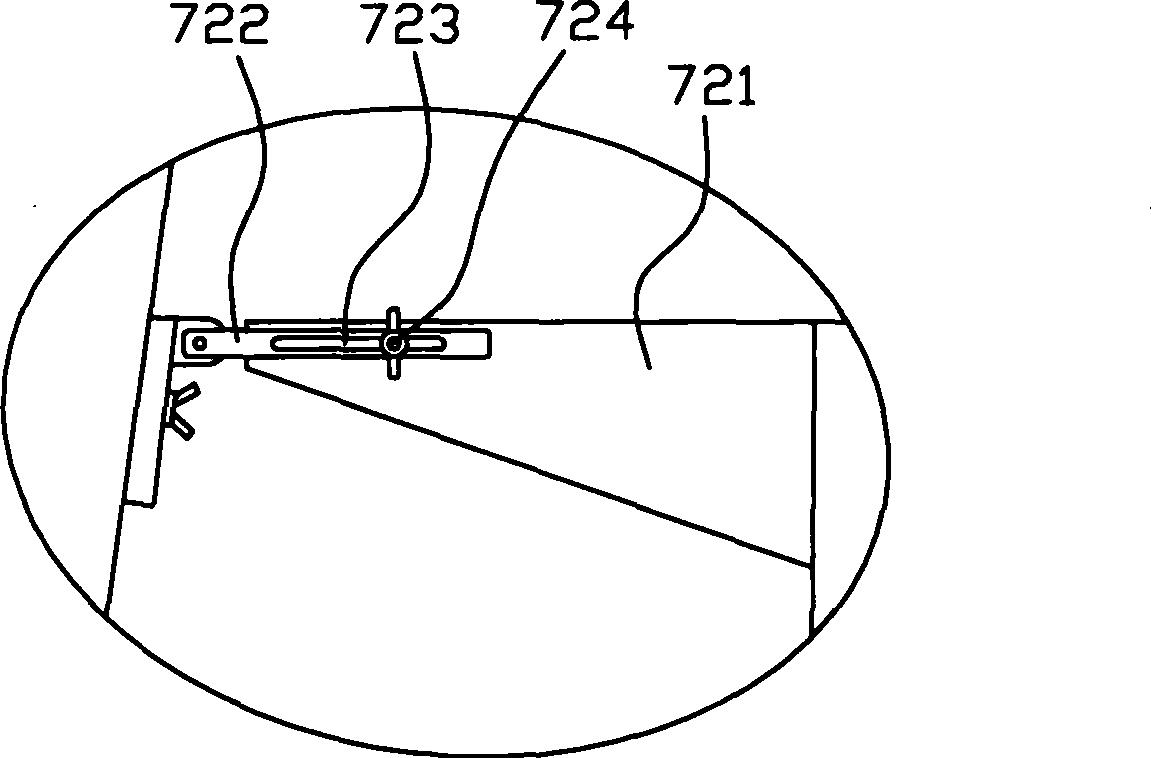

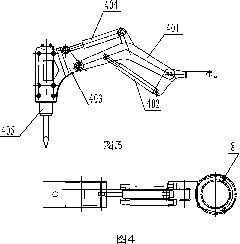

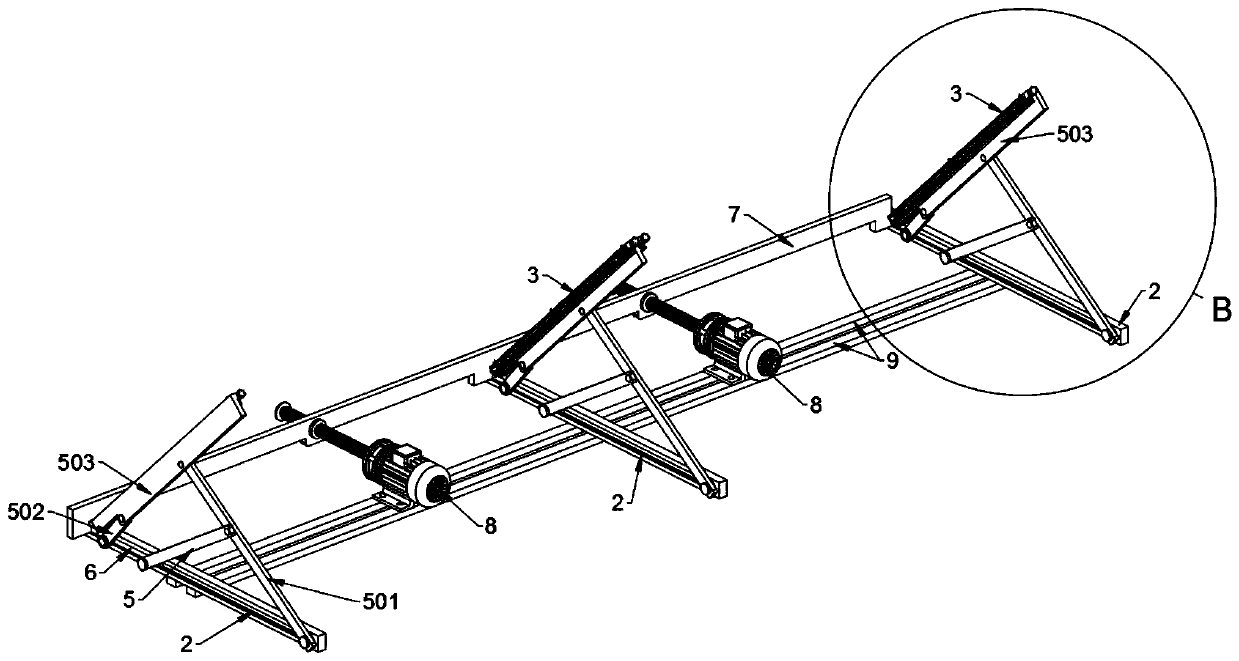

Rice bowl seedlings cast-seedling device

InactiveCN101455145ASimple structureGood throwing effectTransplantingDrive wheelReciprocating motion

A paddy rice pot seedling throwing machine includes a driving wheel comprising a first left synchronizing wheel and a first right synchronizing wheel which rotate synchronously, wherein, inside of one of the wheels is provided with a stepper motor for driving the wheel to rotate; a driven wheel comprising a second left synchronizing wheel and a second right synchronizing wheel which rotate synchronously, and a frontward seedling-pulling head and a cylinder for driving the seedling-pulling head to perform reciprocating motions; the first left synchronizing wheel and the first right synchronizing wheel, the second left synchronizing wheel and the second right synchronizing wheel being connected through a left synchronous belt and a right synchronous belt respectively; a seedling disk, of which the left and right ends are respectively positioned on the left synchronous belt and the right synchronous belt, earthen bowl grooves being arranged in the left and right directions on the seedling disk, a seedling-pulling corresponding to the seedling-pulling head being provided on the bottom of the earthen bowl groove; a seedling-guiding tube positioned below the front side of the driven wheel. The present invention has advantages of simple transmission structure, low fault rate, convenient use and the like.

Owner:张国梁

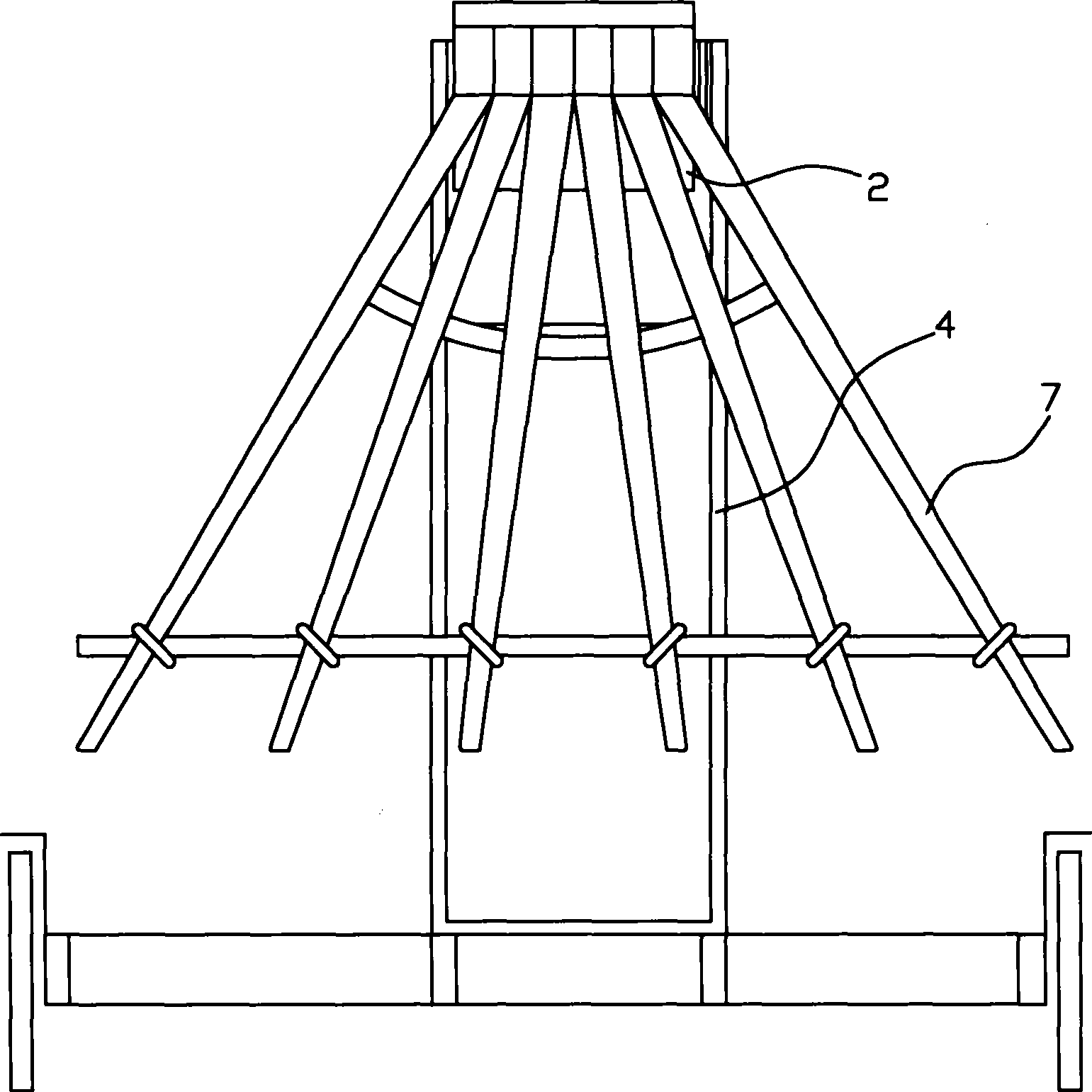

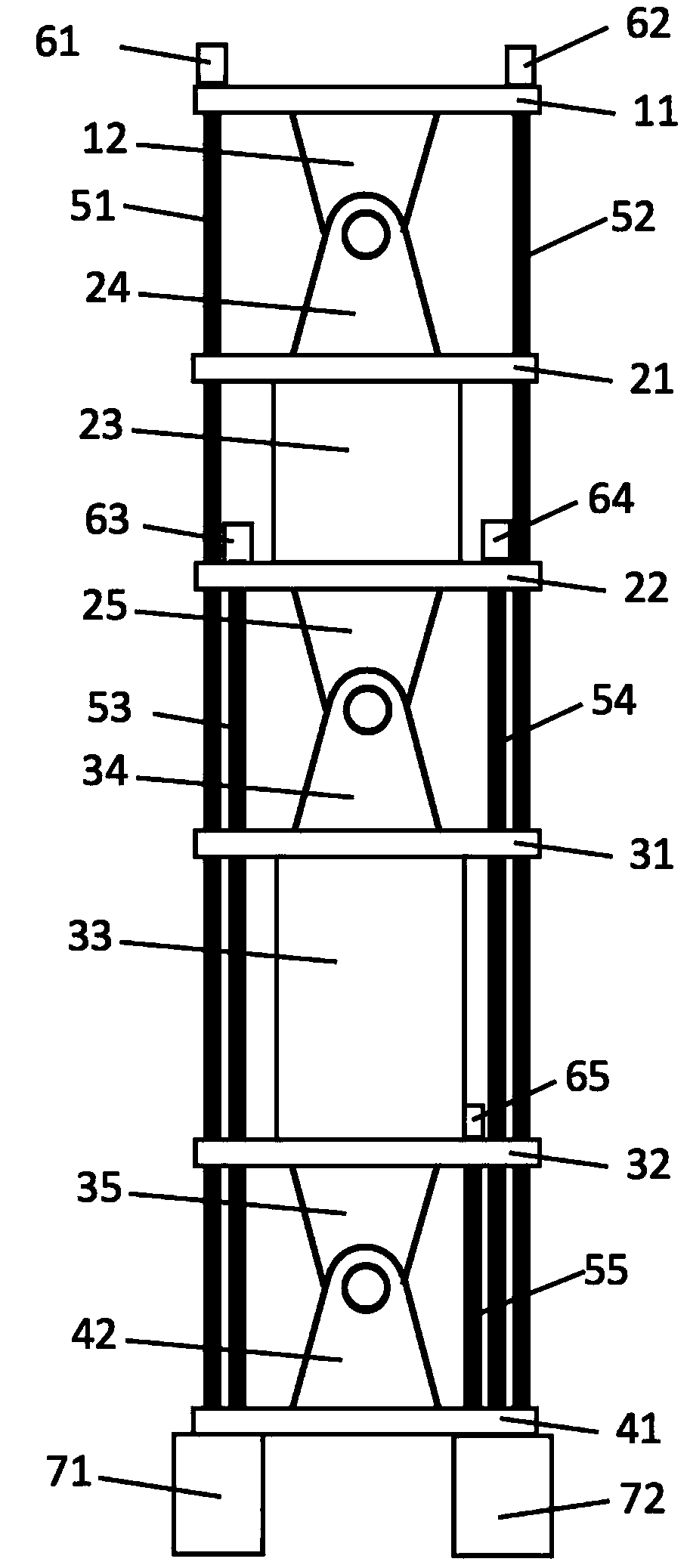

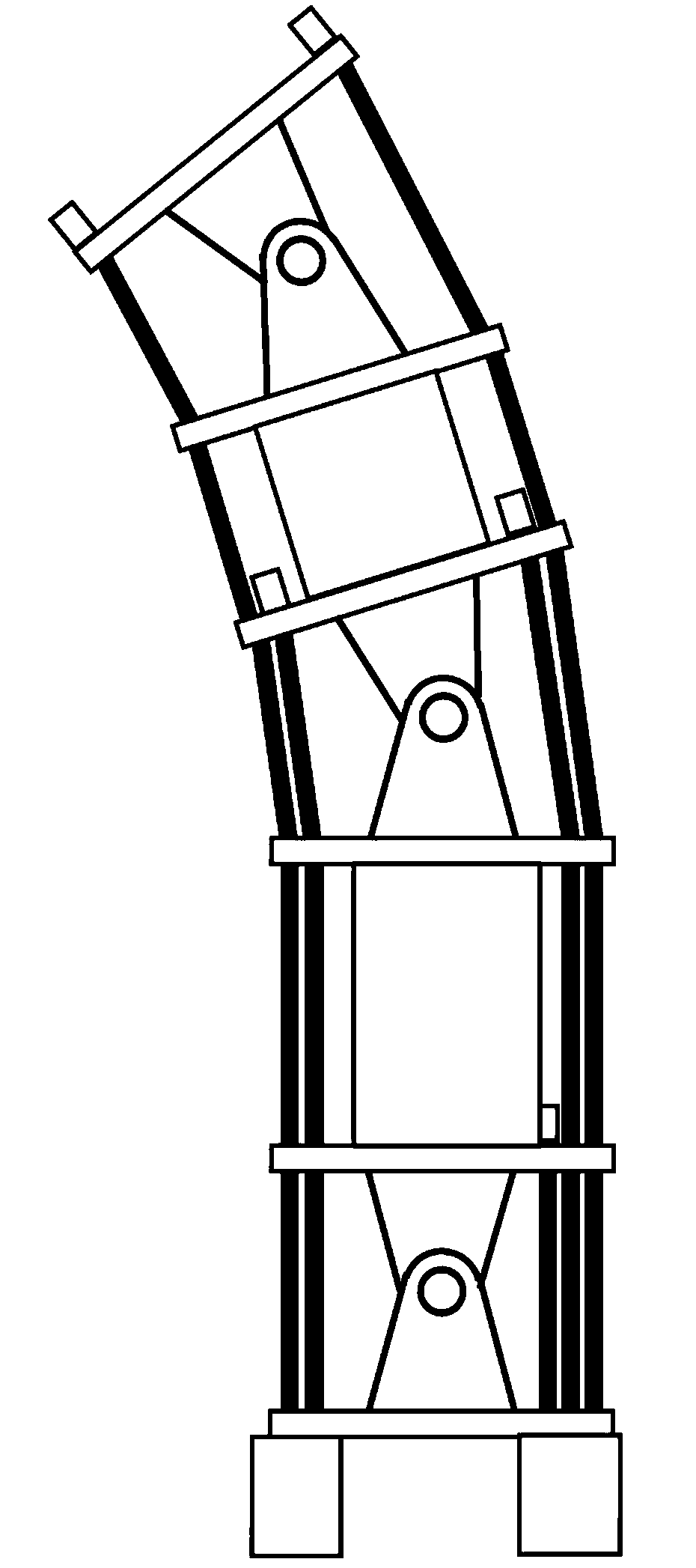

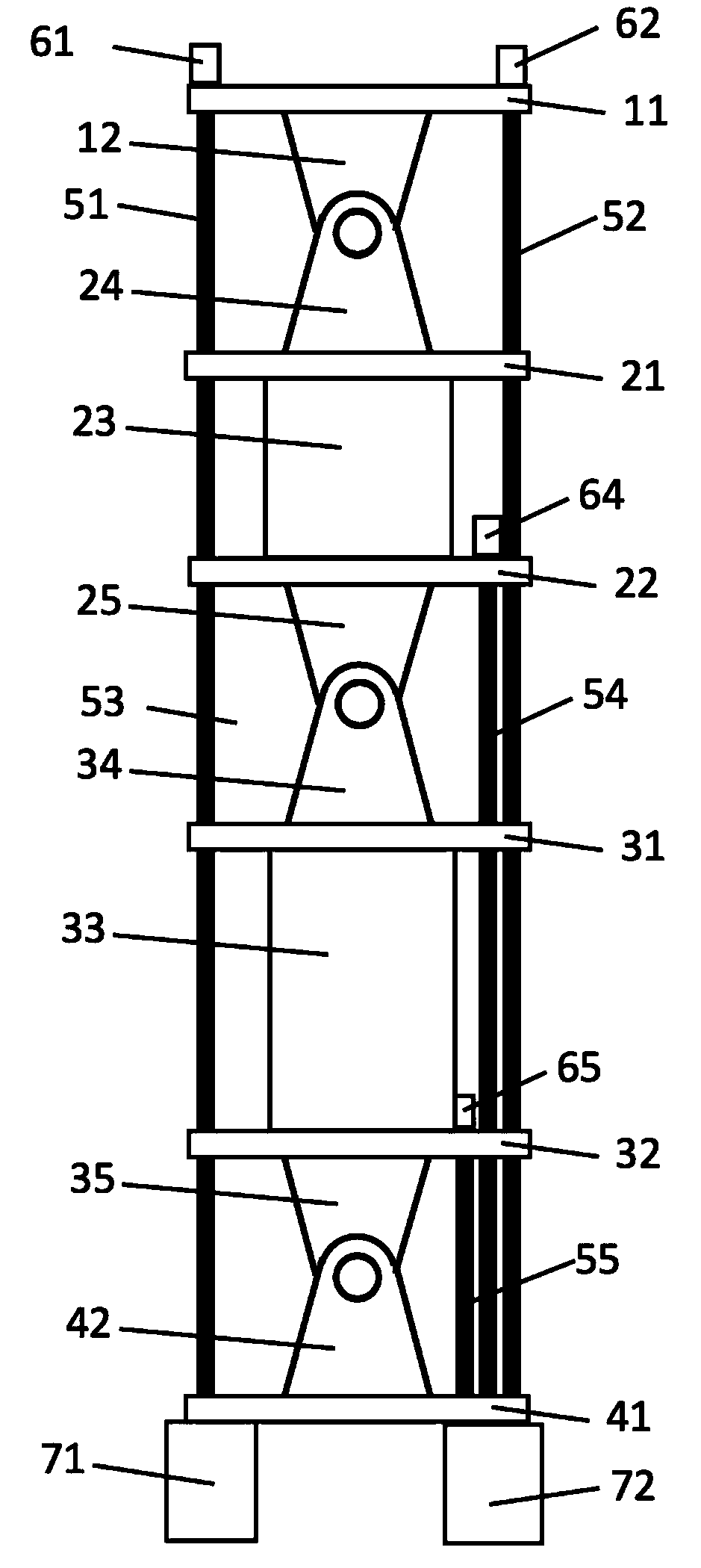

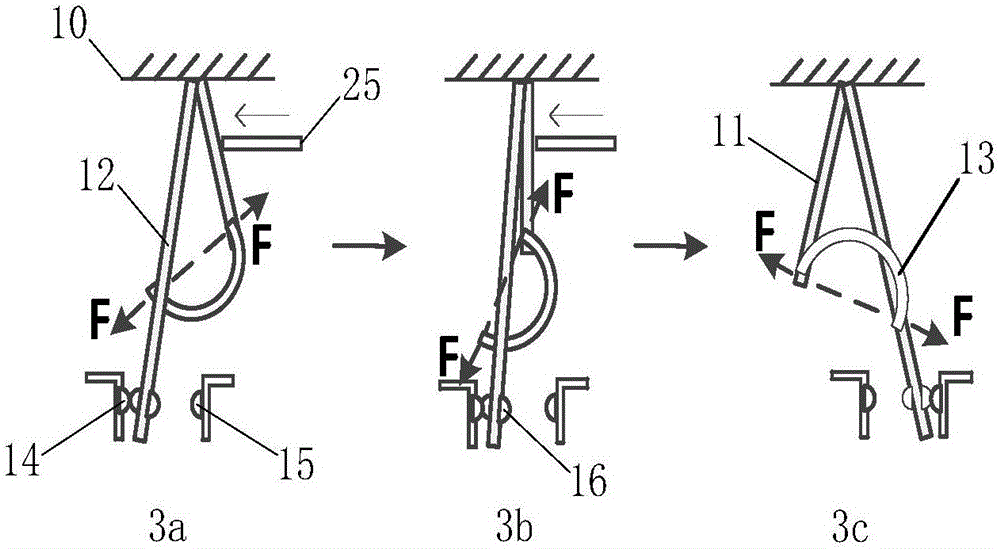

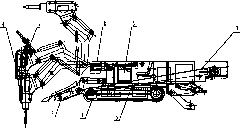

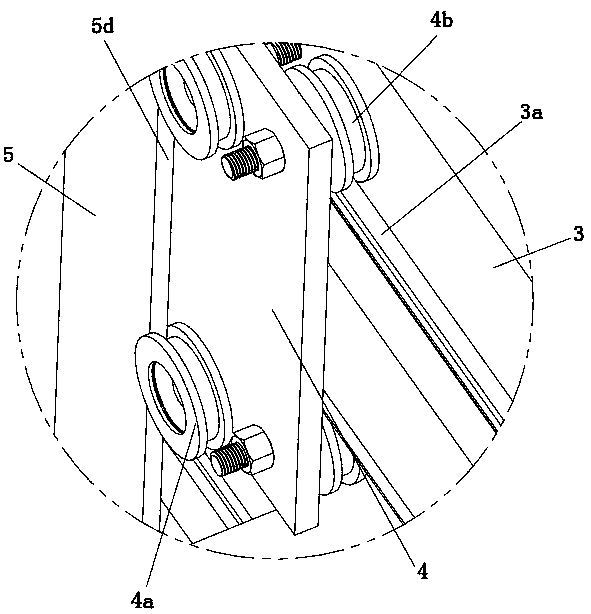

Under-actuated rope-drive mechanical arm

InactiveCN109278032AReduce in quantityThe overall structure is simple and reliableProgramme-controlled manipulatorEngineeringMechanical failure

The invention discloses an under-actuated rope-drive mechanical arm which comprises a plurality of rotatable joints, driving ropes and a plurality of rope retracting-releasing devices, wherein the driving ropes are connected among the joints; the rope retracting-releasing devices are used for rope retracting and / or releasing; the joints comprise a first joint, a second joint and a plurality of third joints; the first joint is positioned at the bottom; the second joint is positioned at the top; the third joints are positioned between the first joint and the second joint; two sides of the secondjoint are directly or indirectly connected with the first joint through first driving ropes; and at least one side of each third joint is directly or indirectly connected with the first joint throughsecond driving ropes. The under-actuated rope-drive mechanical arm has the beneficial effects that the structure is simple and reliable; the control is convenient; the quantity of the driving ropes is reduced; the mechanical failure rate is lowered; and the mechanical arm manufacturing cost is reduced.

Owner:享奕自动化科技(上海)有限公司

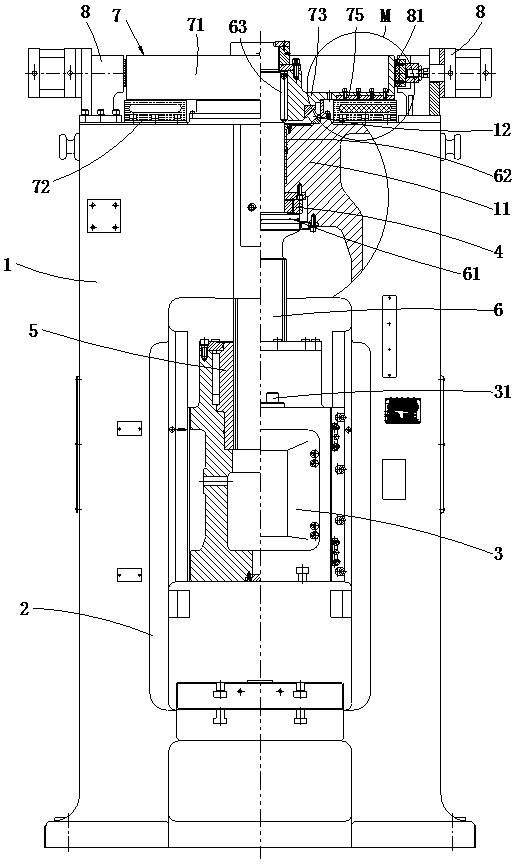

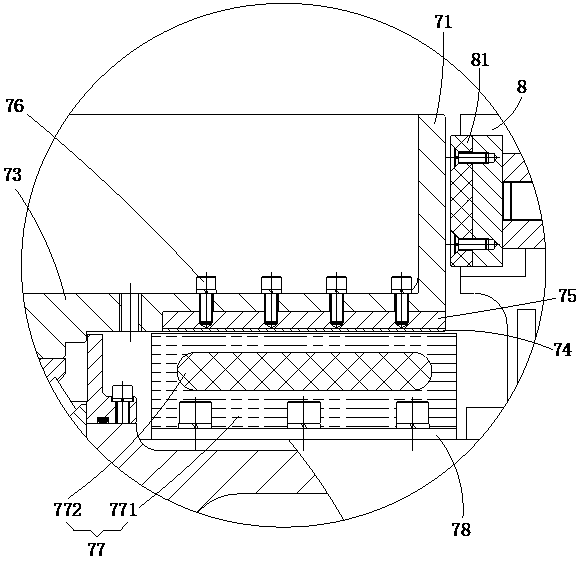

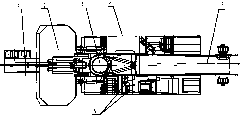

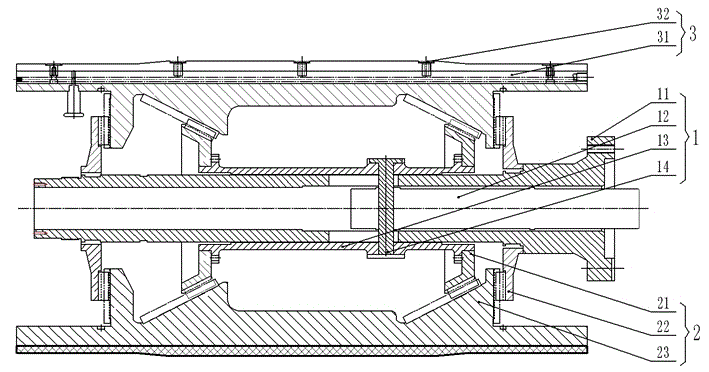

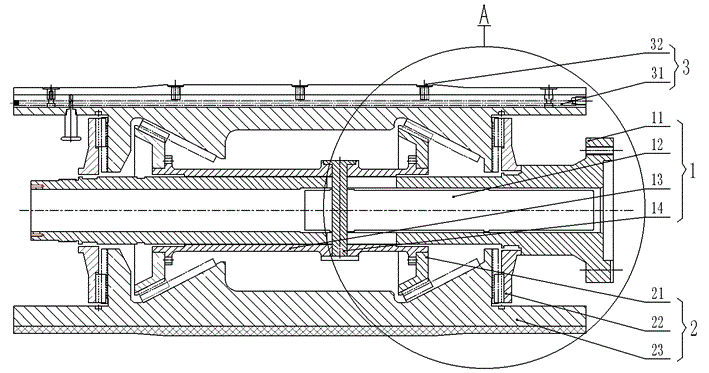

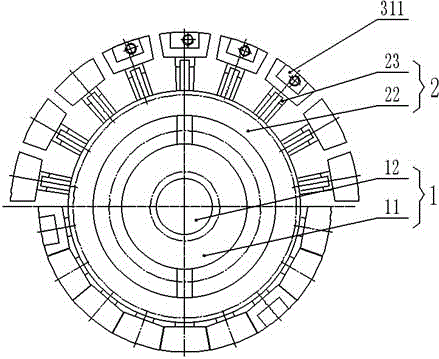

Numerical control electric screw press driven by disk type linear motor

The invention relates to a numerical control electric screw press driven by a disk type linear motor. The numerical control electric screw press comprises a press body provided with a beam. A press body guide track, a sliding block hammer, a thrust bearing, a copper nut and a main screw are arranged on the press body. The press body guide track is fixed on the press body, the sliding block hammer is arranged on the lower portion of the beam and can slide on the press body guide track, the thrust bearing is fixed on the bottom of the beam, the copper nut is fixed on the sliding block hammer, one end of the main screw and the copper nut form a screw pair to drive the sliding block hammer to move linearly, and the disk type linear motor is arranged on top of the beam. The disk type linear motor comprises a flywheel rotor and a stator assembly. The stator assembly is fixed on the top of the beam and arranged at the bottom of the flywheel rotor, and the other end of the main screw is fixed at the rotary axis position of the flywheel rotor. A brake is arranged on the lateral side of the outer circumference of the flywheel rotor and brakes rotation of the main screw by braking the flywheel rotor. The numerical control electric screw press has the advantages of being convenient to maintain, low in energy consumption, small in noise, precise in control, high in safety performance and the like.

Owner:HUBEI FUSHENG FORGING MACHINE

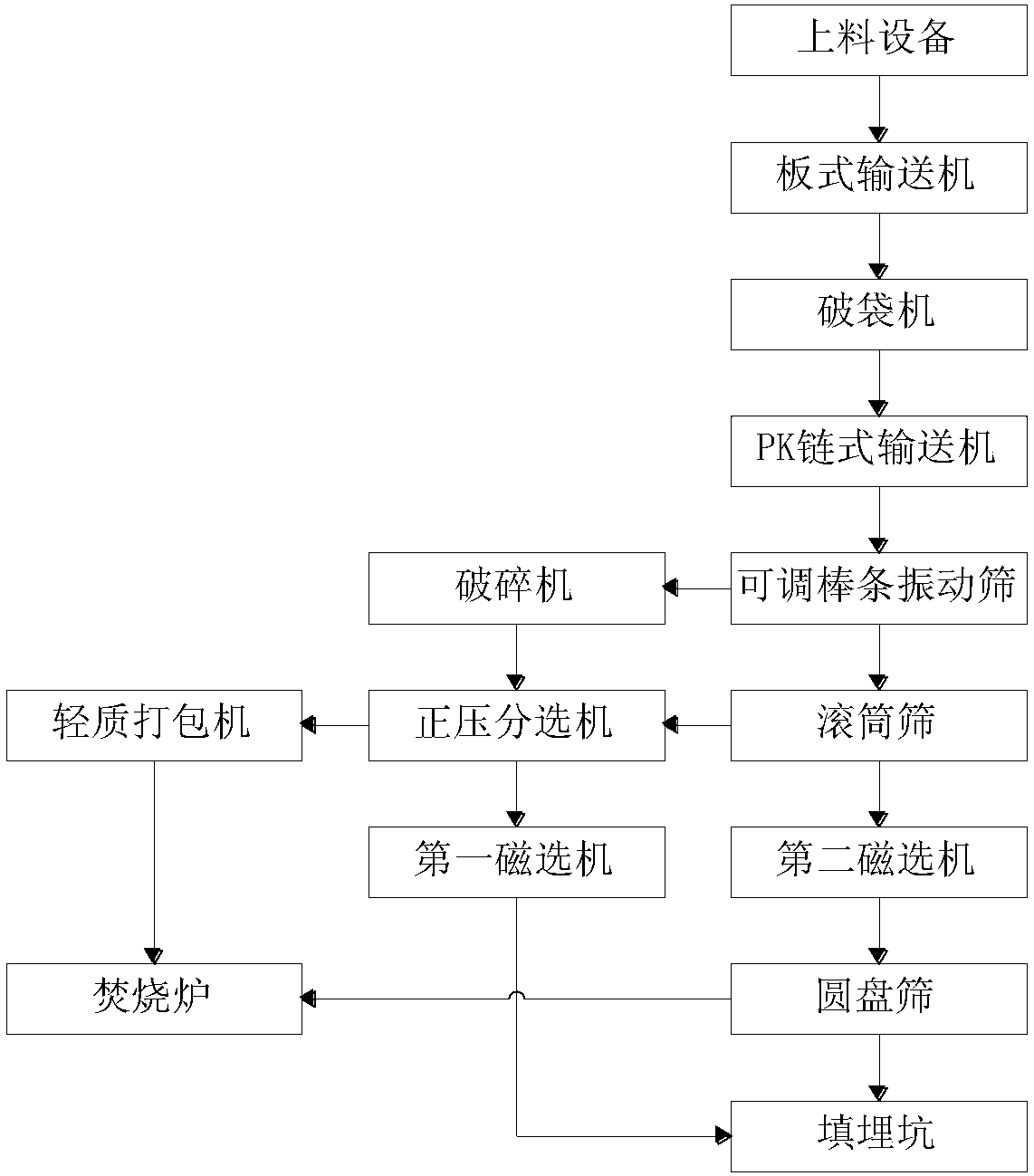

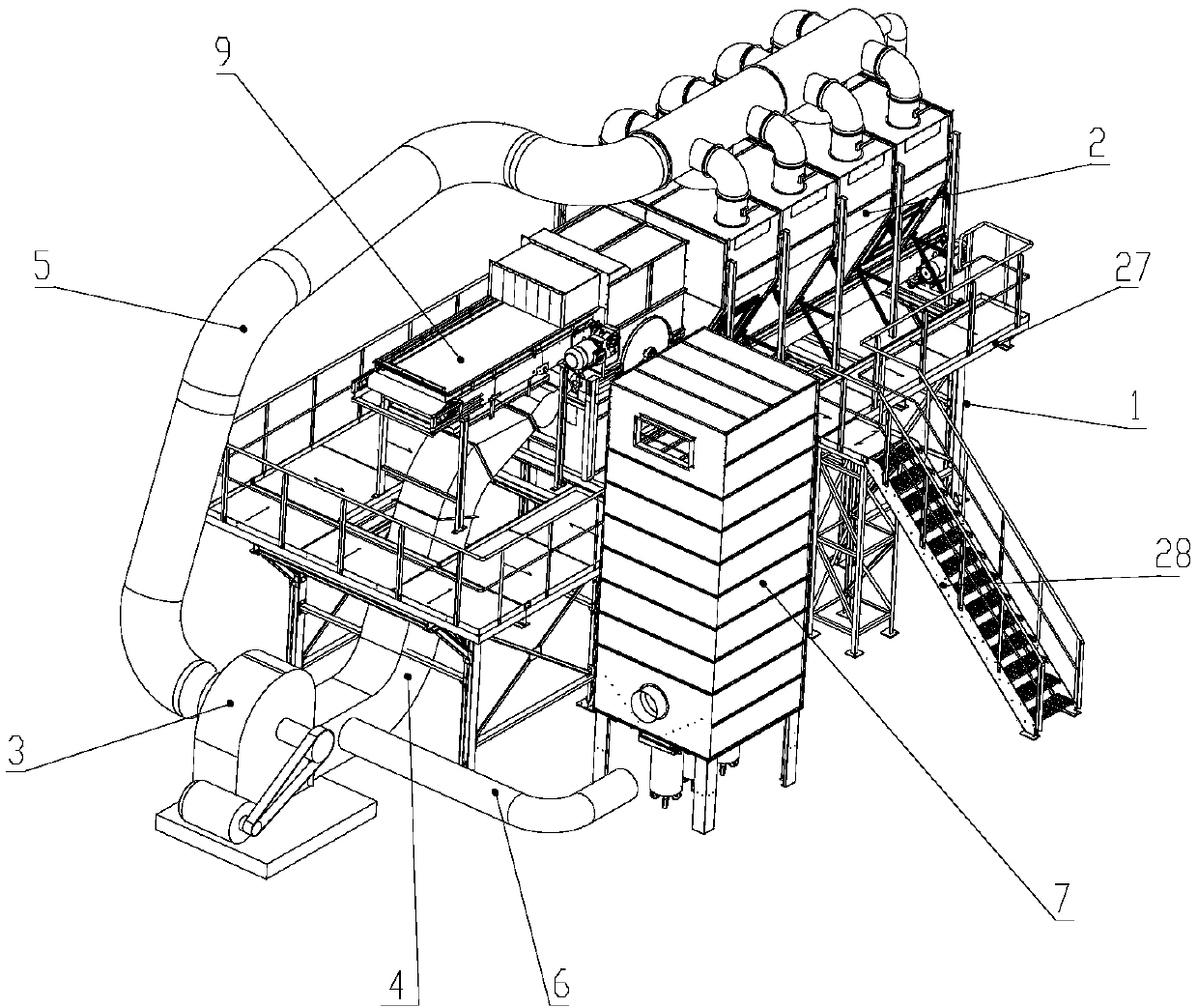

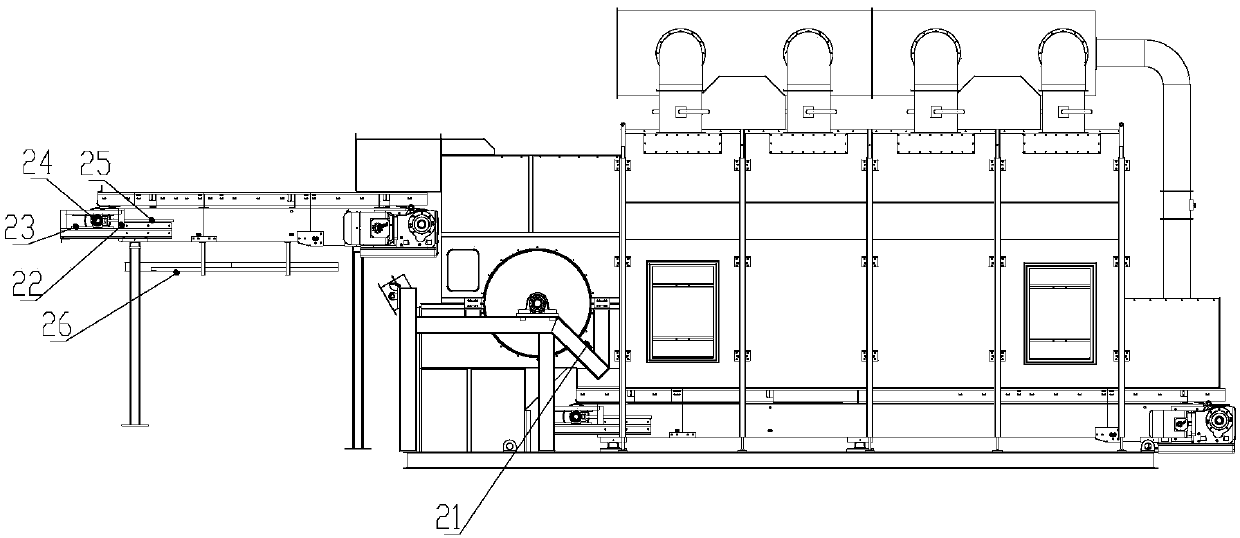

Sorting device and technical method before incineration treatment of urban household garbage

PendingCN107685068AReduce labor intensityImprove sorting efficiencySievingGas current separationMagnetic separatorProcess engineering

The invention belongs to the field of sorting devices, and particularly relates to a sorting device and a technical method before the incineration treatment of urban household garbage. A feeding apparatus, a plate conveyer, a bag breaker and a PK chain conveyer are connected with an adjustable bar vibrating screen in sequence; an oversize product discharge opening of the adjustable bar vibrating screen is connected with a charging opening of a drum screen; an undersize product discharge opening of the adjustable bar vibrating screen is connected with a charging opening of the breaker; an oversize product discharge opening of the drum screen is connected with a feeding conveying belt of a positive-pressure wind separator; an undersize product discharge opening of the drum screen is connected with a charging opening of a second magnetic separator. The invention provides the sorting device and the technical method before the incineration treatment of the urban household garbage, through which an apparatus is used for replacing manual hand picking to sort a large article when the urban household garbage is sorted, meanwhile, a flexible entanglement can be also sorted out, the labor intensity of a worker is decreased, the occurrence that the apparatus is entangled is reduced, and the work efficiency of a sorting line for the urban household garbage is improved.

Owner:天津百利阳光环保设备有限公司

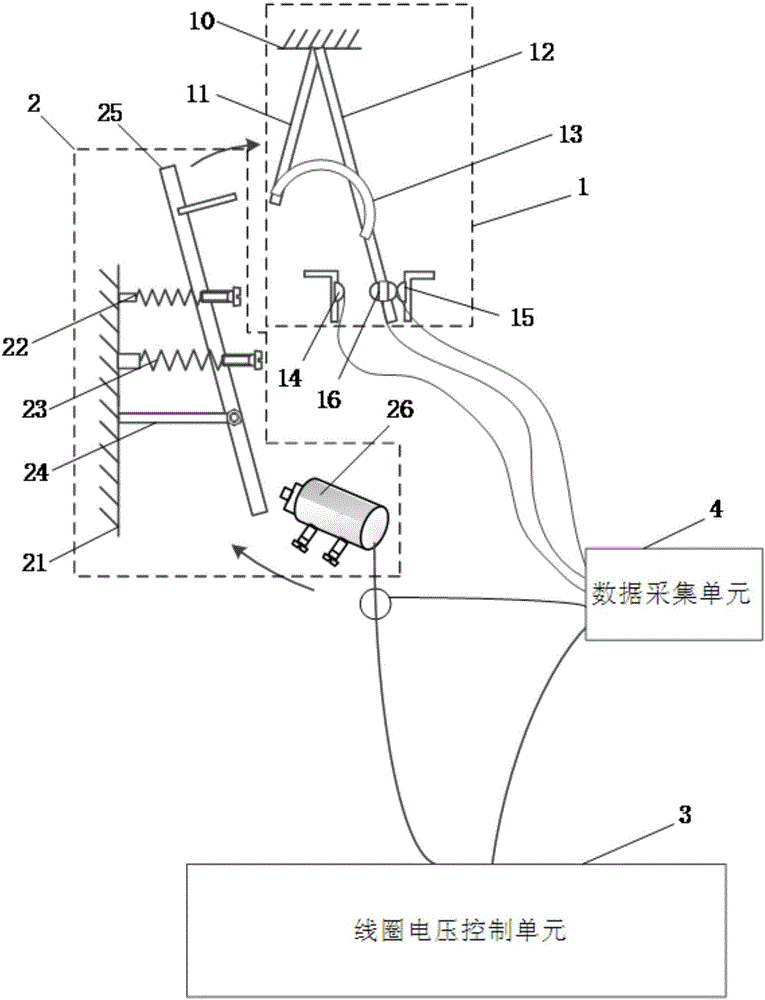

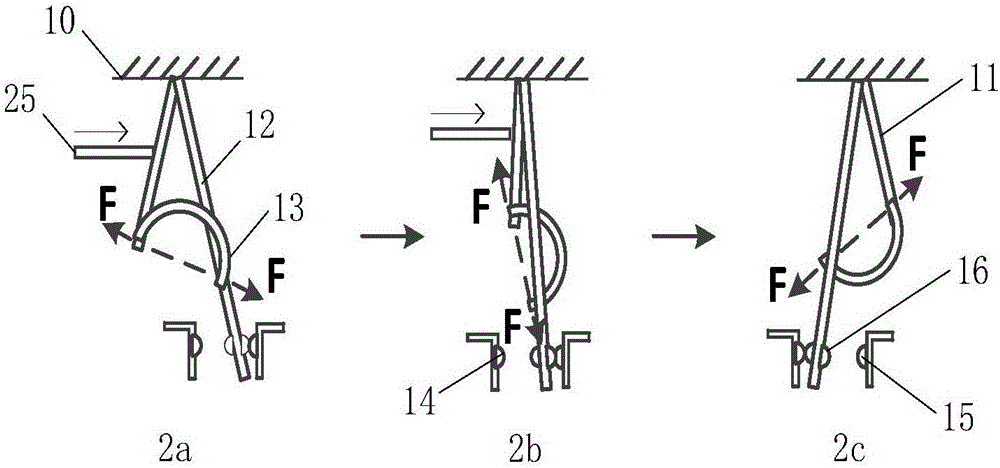

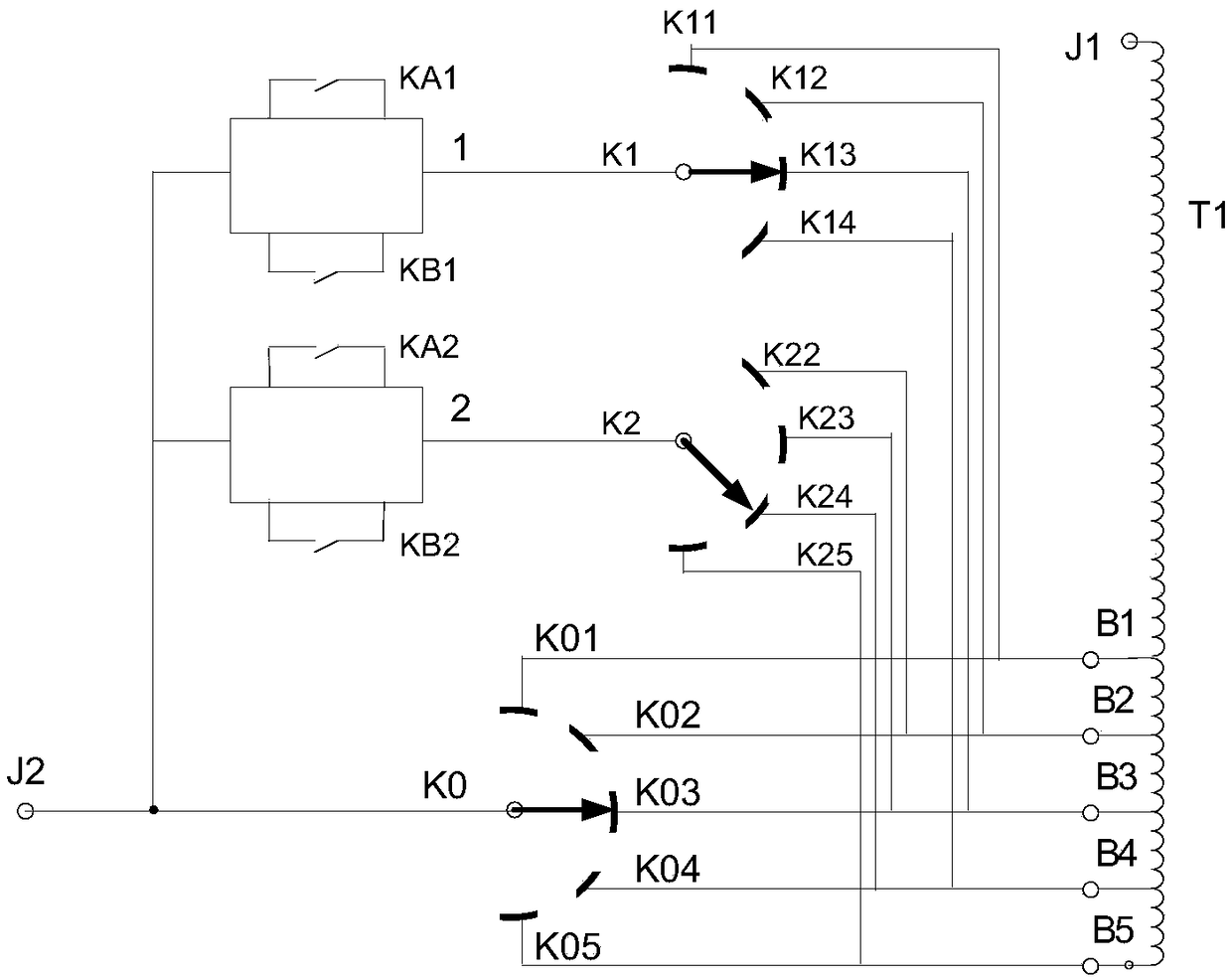

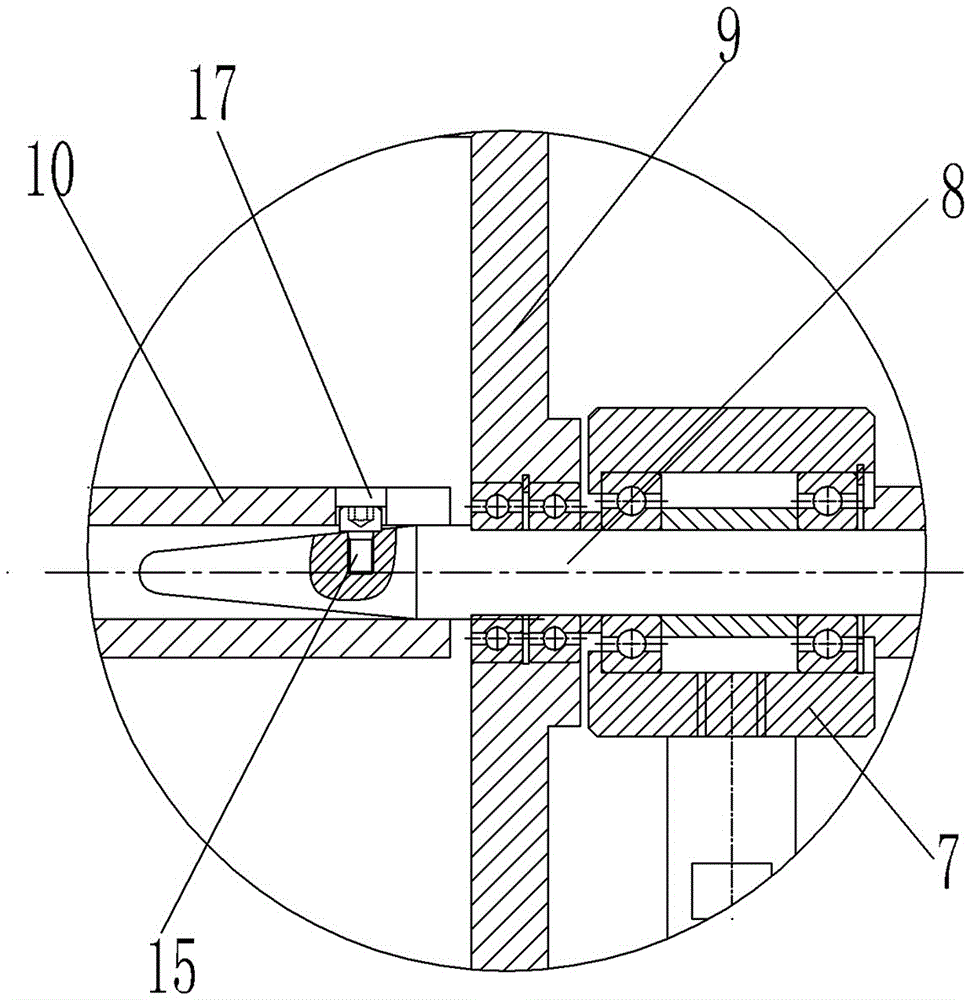

Simulated test device and method for opening/closing of circuit breaker

ActiveCN106771993AGuaranteed accuracyLow mechanical failure rateCircuit interrupters testingEngineeringVoltage control

The invention discloses a simulated test device and method for opening / closing of a circuit breaker, relates to the field of electrical technology, and aims at solving the problems that a breaker operation state determination method in the prior art cannot be used to determine the practical operation state of the circuit breaker accurately or predict the residual life of the circuit breaker. The simulated test device comprises an opening / closing simulation unit for simulating the operation state of the circuit breaker, a trigger unit triggers the opening / closing simulation unit to switching among different states according to a triggering voltage signal, a coil voltage control unit providing the triggering voltage signal, and a data collection unit which collects simulation state, current and triggering voltage signals, and stores and analyzes the signals to form a database. The simulated test device for opening / closing of the circuit breaker is used to simulate operation of the circuit breaker.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

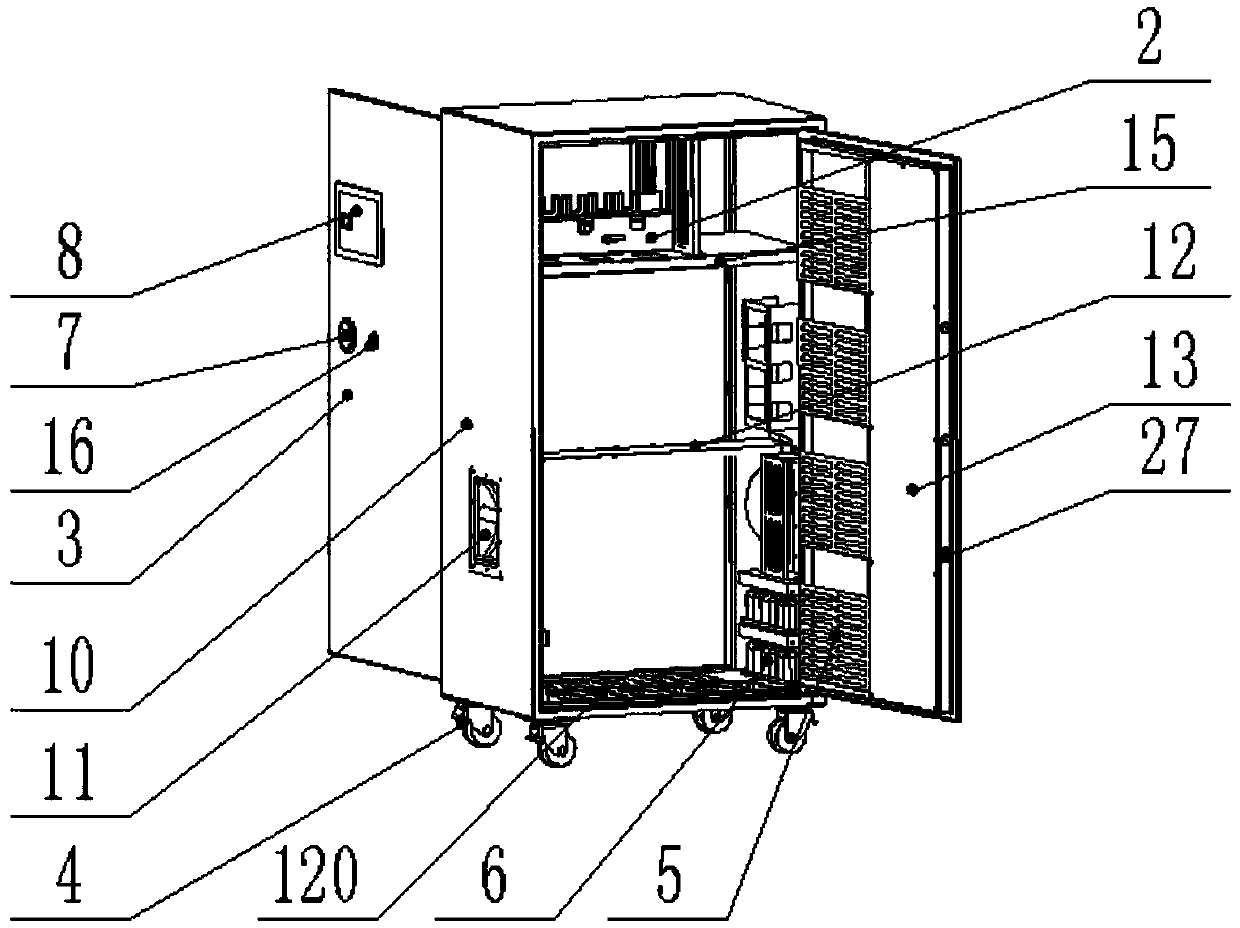

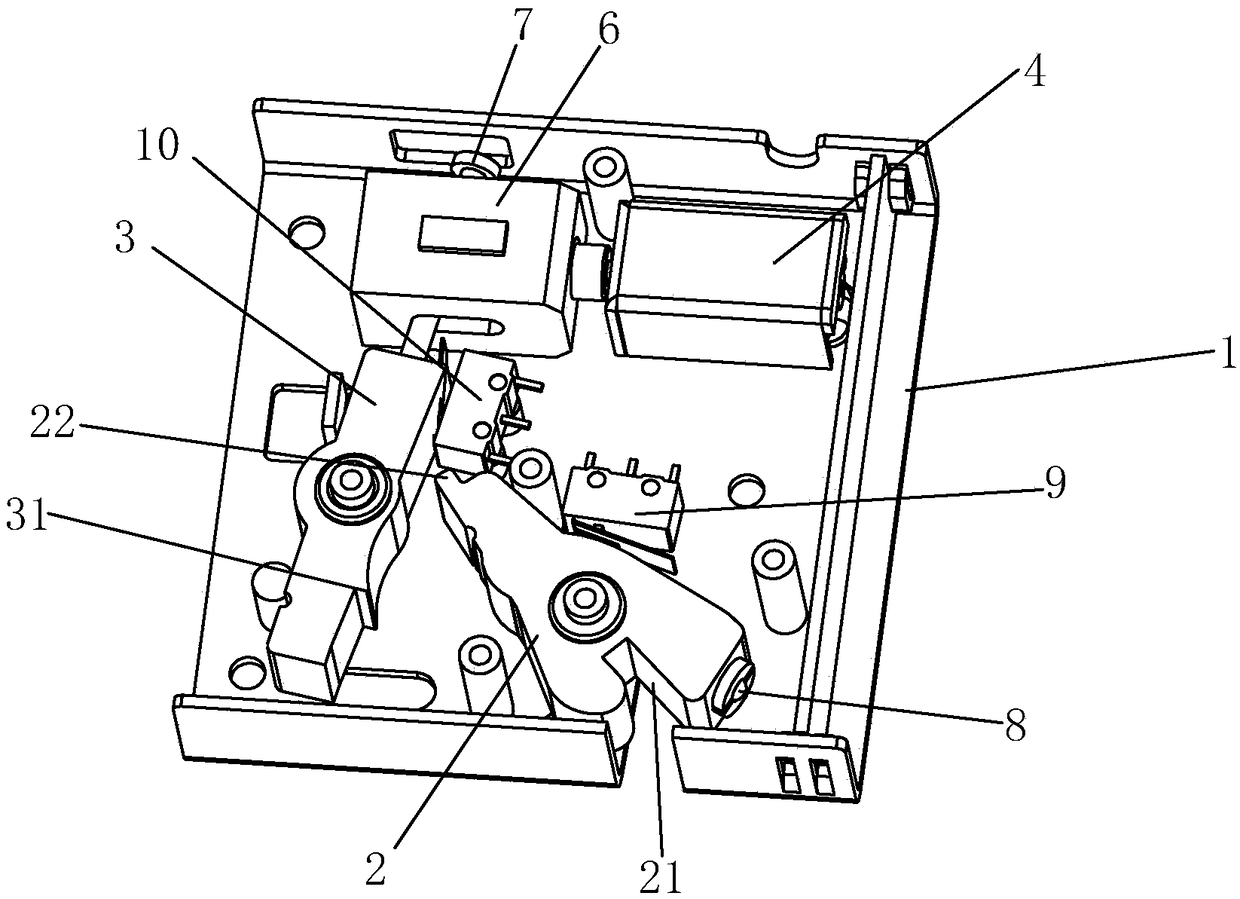

Intelligent emergency cartridge cabinet with front and rear doors

PendingCN109090862AReduce manual operationsLow mechanical failure rateNon-mechanical controlsCabinetsComputer moduleEngineering

The invention discloses an intelligent emergency cartridge cabinet with front and rear doors. The intelligent emergency cartridge cabinet comprises a cabinet body, long-gun locking devices, a gun locking device, a front door, a rear door, a handle and a control host; the control host is installed on the cabinet body to monitor surrounding temperature and humidity of the cartridge cabinet, personnel is recognized for each picking and placing, and information of time, quantity, times, personnel and the like for each picking and placing is recorded, so that information record is extracted conveniently; an independent database is established in the control host, and management personnel can check the previous picking and placing records or check in the background server at any time; if abnormal data is detected, an alarm module sends out an alarm and the control host sends information to the background server for alarm.

Owner:湖南鑫垒科技有限公司

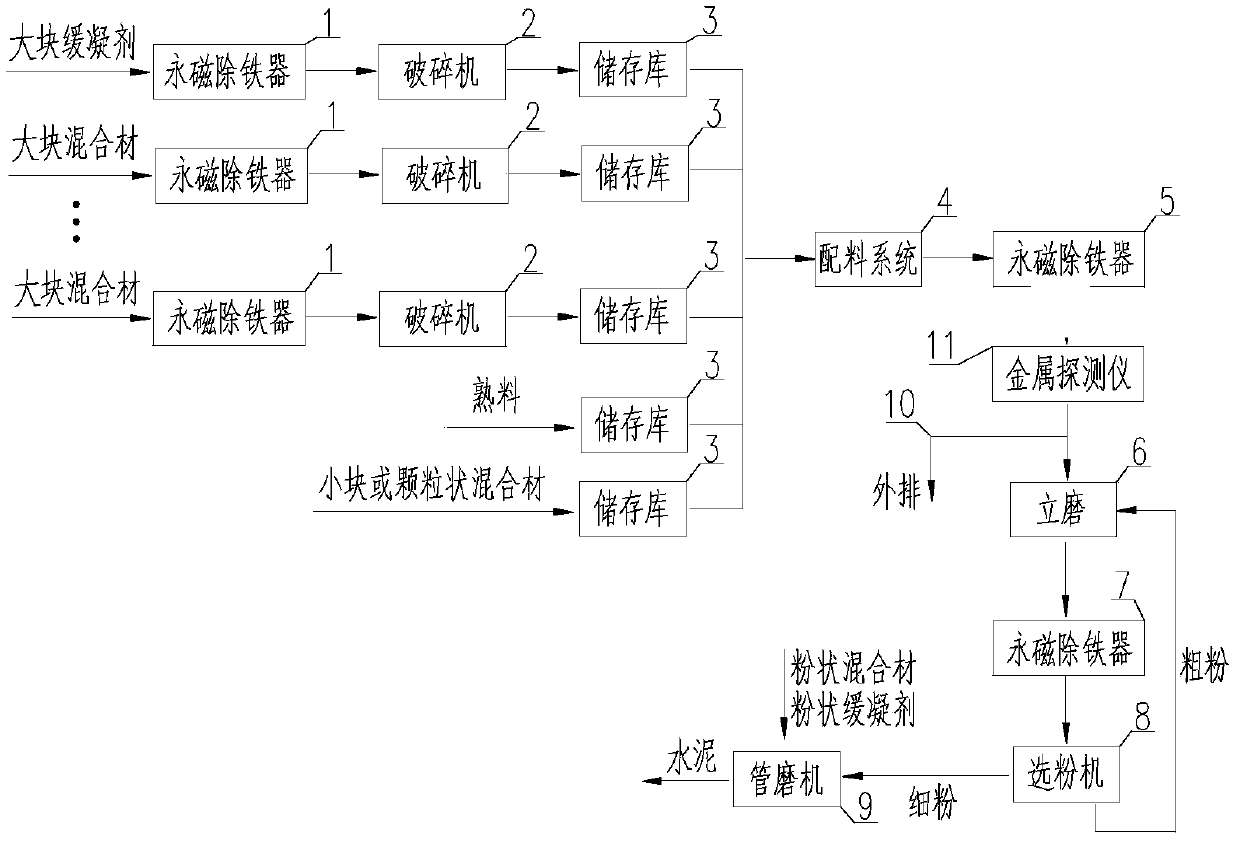

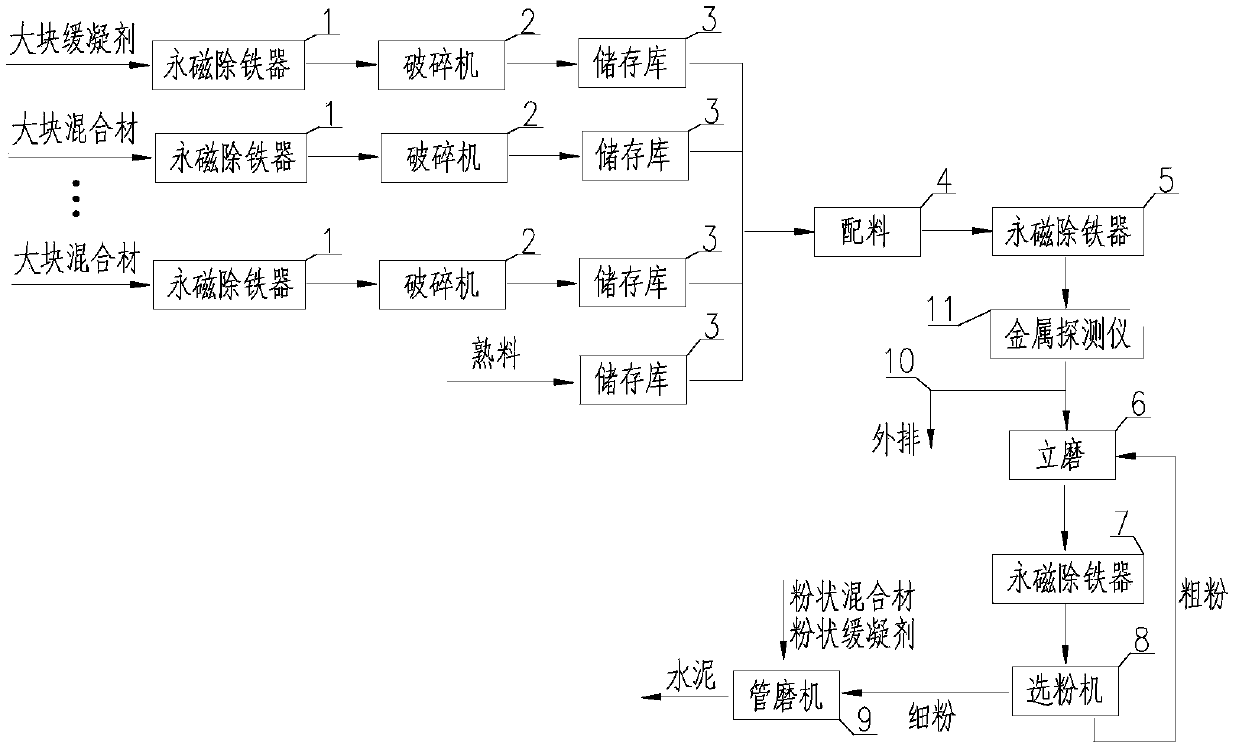

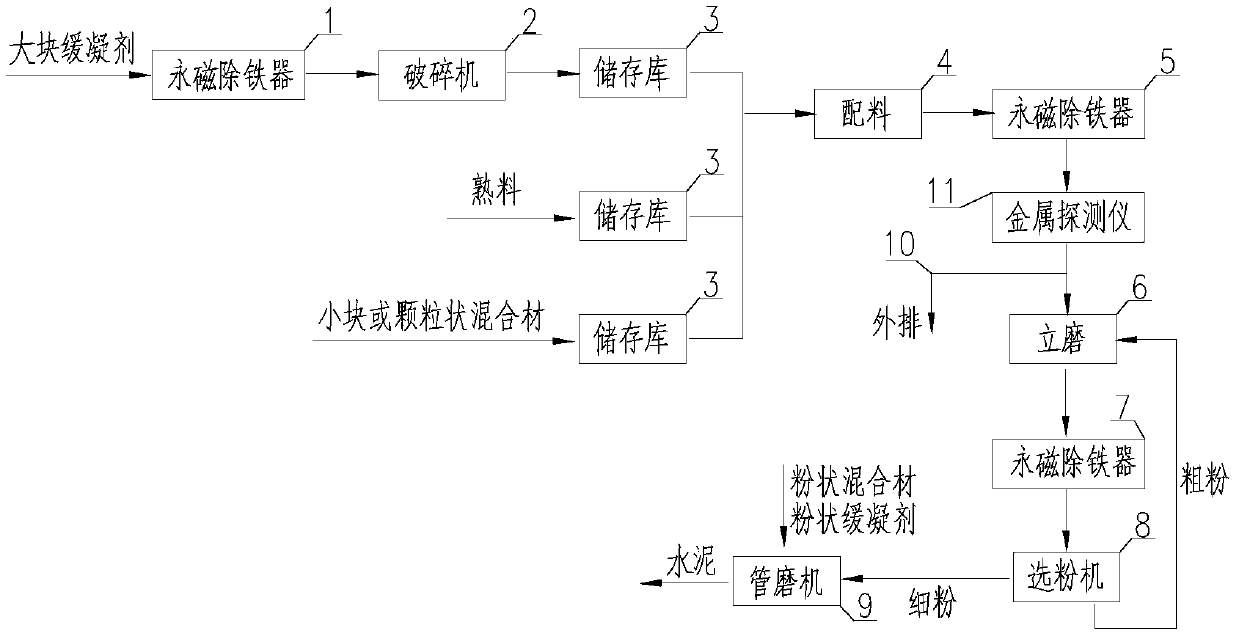

Cement preparation method

ActiveCN103359961ARealize the effect of increasing production and reducing consumptionGuaranteed uptimeCement productionParticulatesCrusher

A cement preparation method comprises the following steps: 1, removing partial magnetic substance from a blocky mixture and a retarder through using a first permanent magnetic iron separator, crushing to the particle size of the blocky mixture to below 40mm through using a crusher (2), and respectively storing in storage warehouses; 2, directly putting a clinker and the obtained particulate or granular mixture in a storage warehouse; 3, allowing cement raw materials in the storage warehouses, comprising the clinker, the mixture and the retarder to enter a burdening system, removing partial magnetic substances from the obtained burdened mixture through using a second permanent magnetic iron separator, sending to a vertical mill, and pre-grinding; 4, further removing partial magnetic substances from the obtained pre-ground powder through using a third permanent magnetic iron separator, and sending to a powder separator for powder grading; and 5, sending the separated fine powder to a tube mill for cement final-grinding, returning the obtained coarse powder to the vertical mill for cycle grinding, directly sending the obtained powdery mixture and the retarder to the tube mill, and grinding the powdery mixture, the retarder and the separated fine powder in the tube mill to form cement.

Owner:NANJING KISEN INT ENG

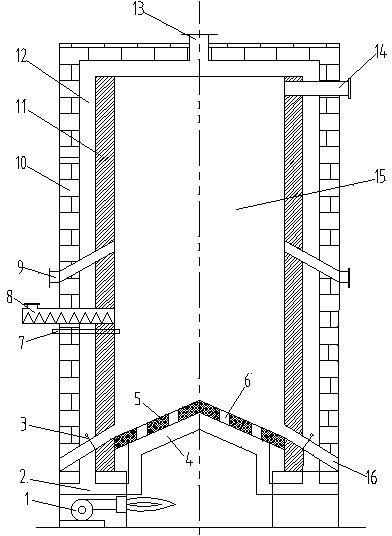

Efficient oil sludge incinerator

ActiveCN103939919AReduce the temperatureHigh thermal efficiencyIncinerator apparatusInlet channelDiesel combustion

An efficient oil sludge incinerator comprises an incinerator body formed by an inner incinerator wall (11) and an outer incinerator wall (10). The efficient oil sludge incinerator is characterized in that an air interlayer (12) is formed between the inner incinerator wall and the outer incinerator wall, a primary air inlet (13) is formed in the outer incinerator wall, an incinerator bottom (5) is arranged on the lower portion of an incinerator chamber (15), an incinerator bottom air outlet (6) communicated with an air outlet of an air distribution plate (4) placed on the outer portion of an incinerator bottom (5) is formed in the incinerator bottom, an air inlet of the air distribution plate (4) is communicated with the air interlayer, a secondary air inlet channel (9) is arranged in the middle of the incinerator body, a screw feeder (8) which conveys oil sludge into the incinerator chamber is arranged on the middle-lower portion of the incinerator body, a diesel combustion-supporting device (1) is arranged on the lower portion of the incinerator body, a smoke outlet channel (14) is arranged on the upper portion of the incinerator body, and a controllable deslagging channel (16) is arranged on the lower portion of the incinerator body. The efficient oil sludge incinerator has the advantages of being high in burning efficiency, stable in incineration and low in mechanical fault rate, and ideal equipment is provided for oil sludge efficient cleaning processing.

Owner:JIANGSU JINDING BOILER

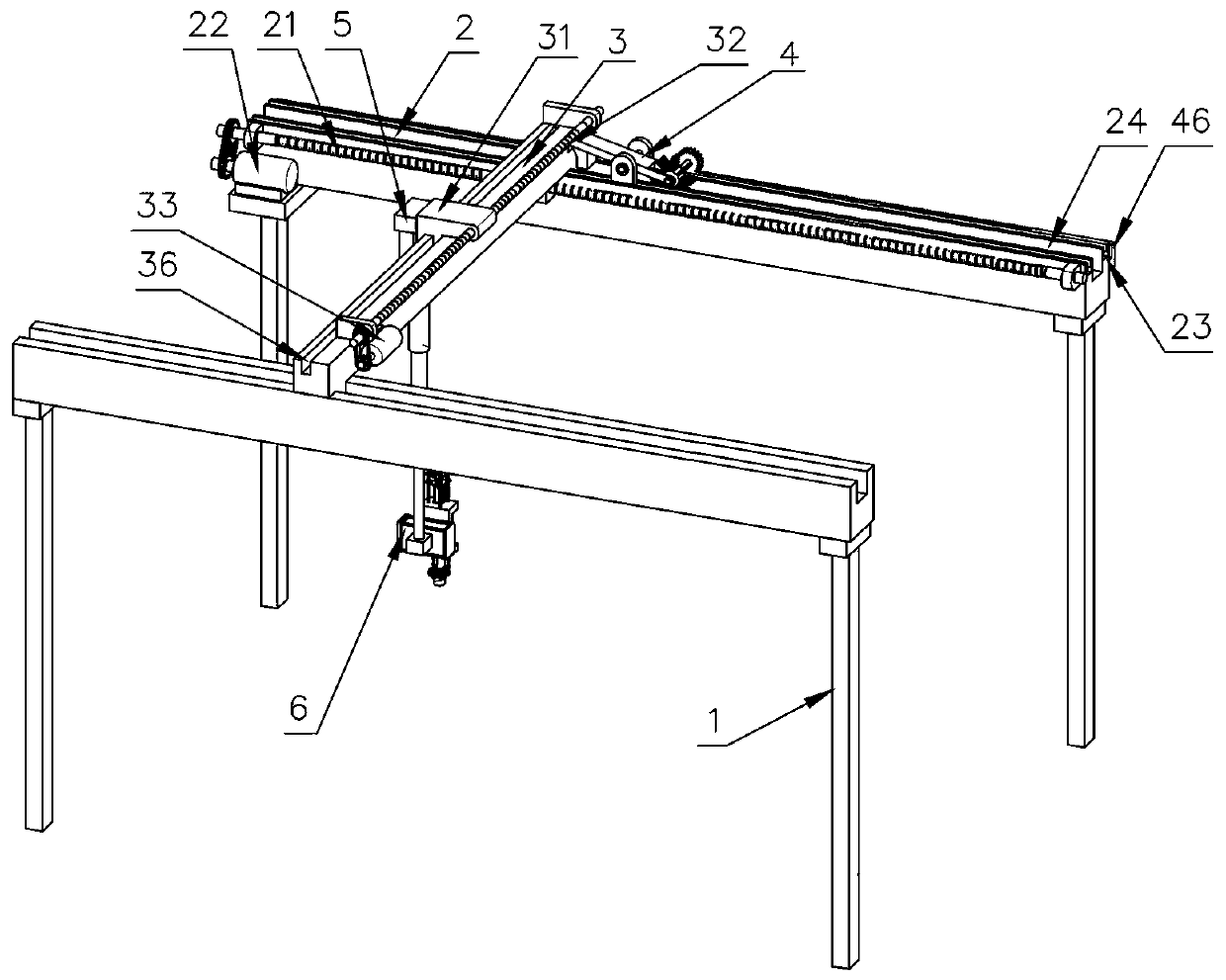

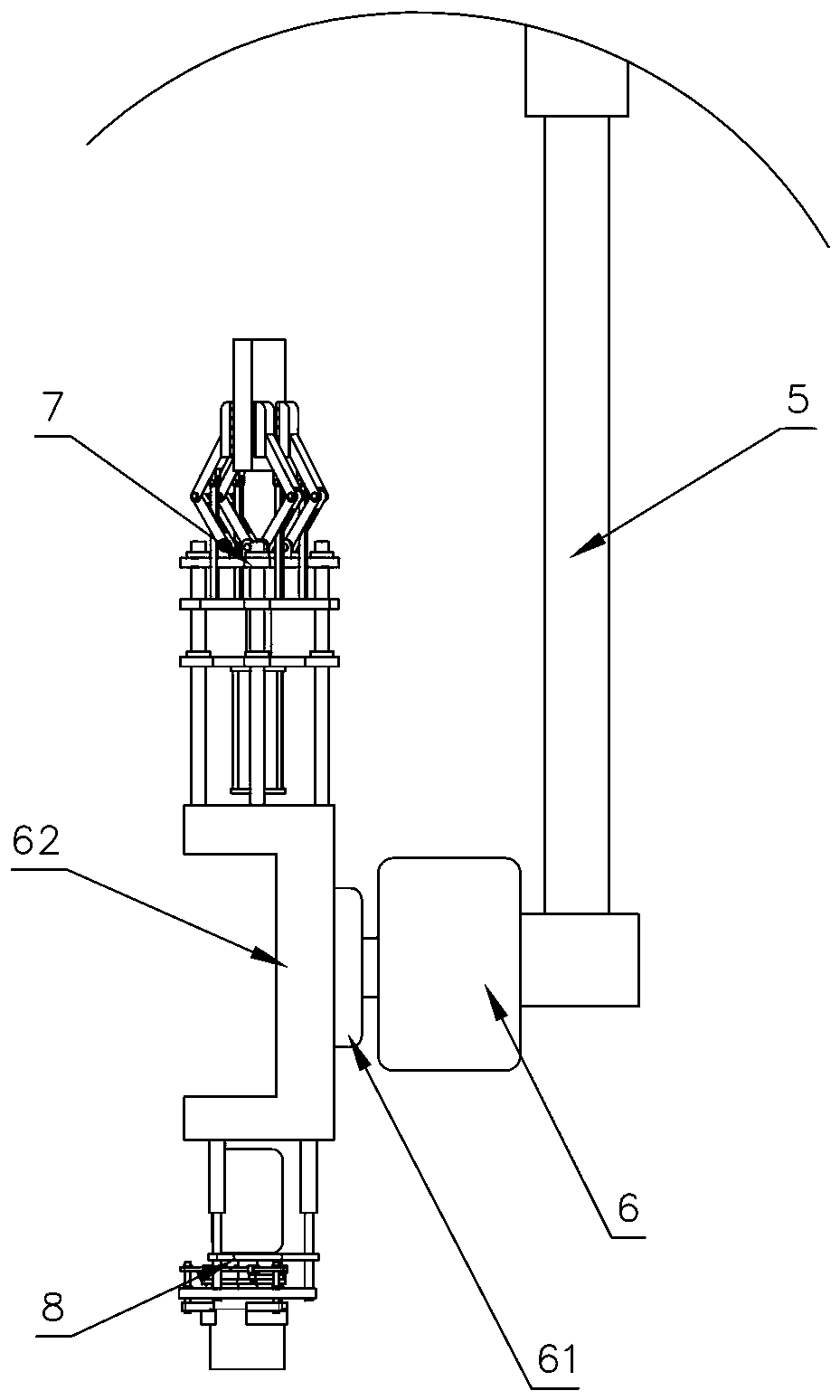

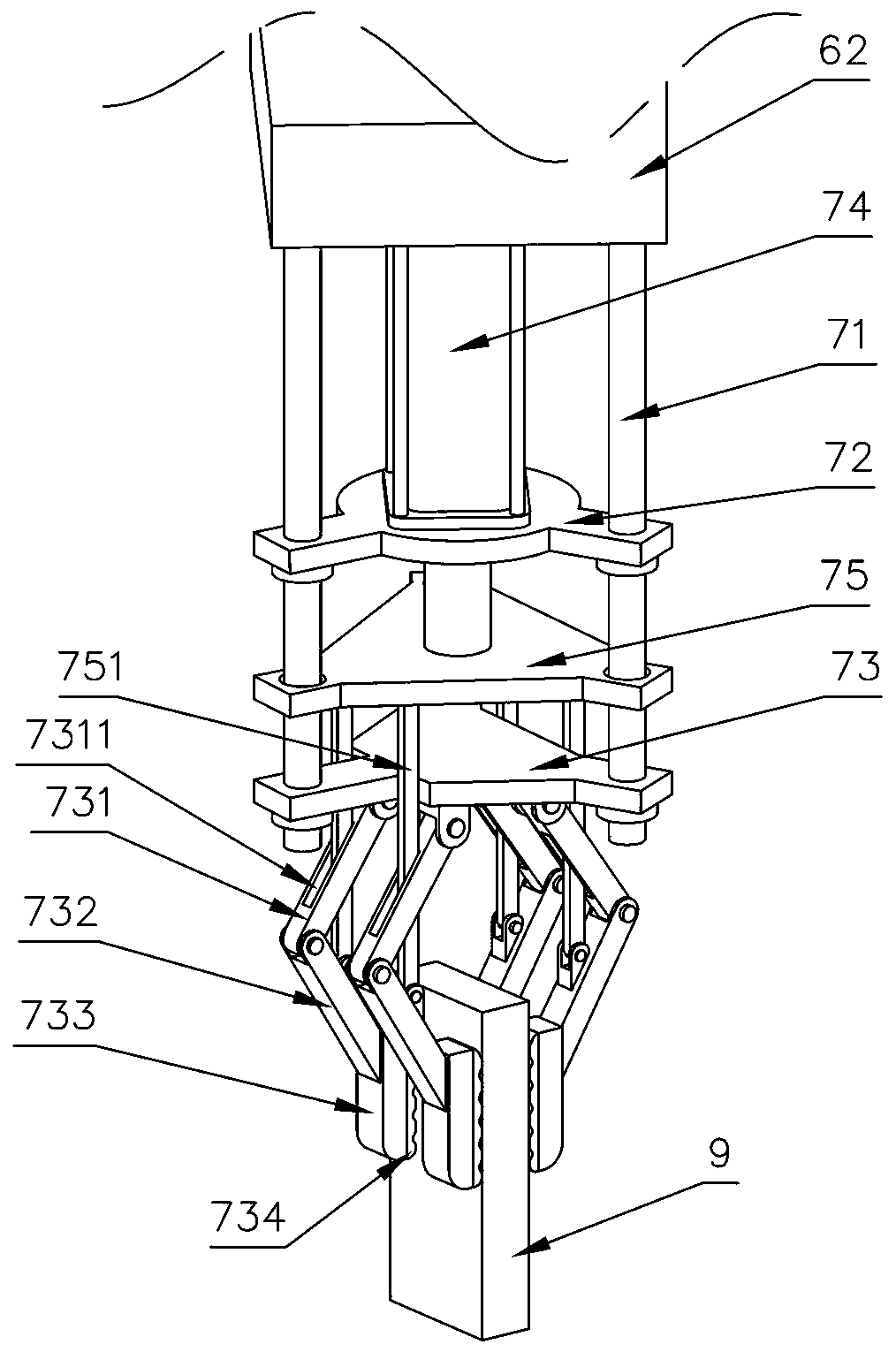

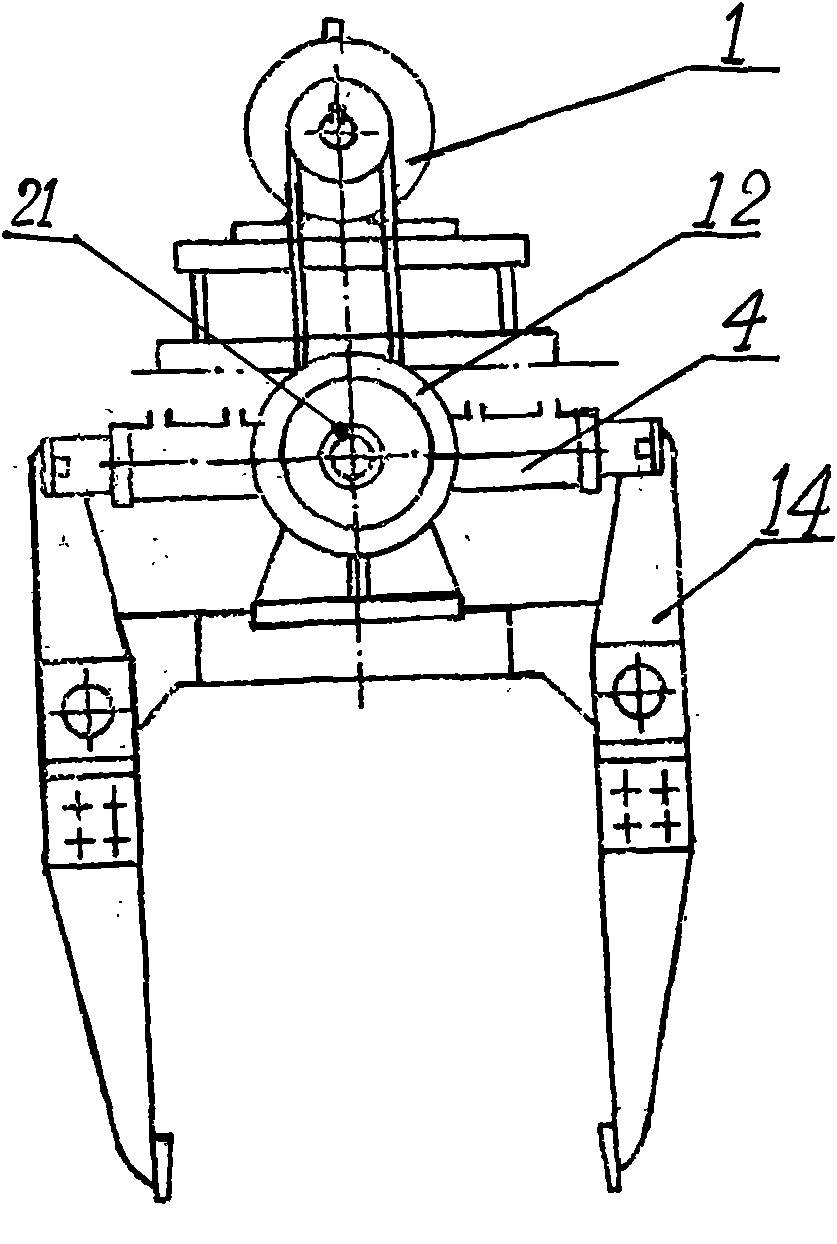

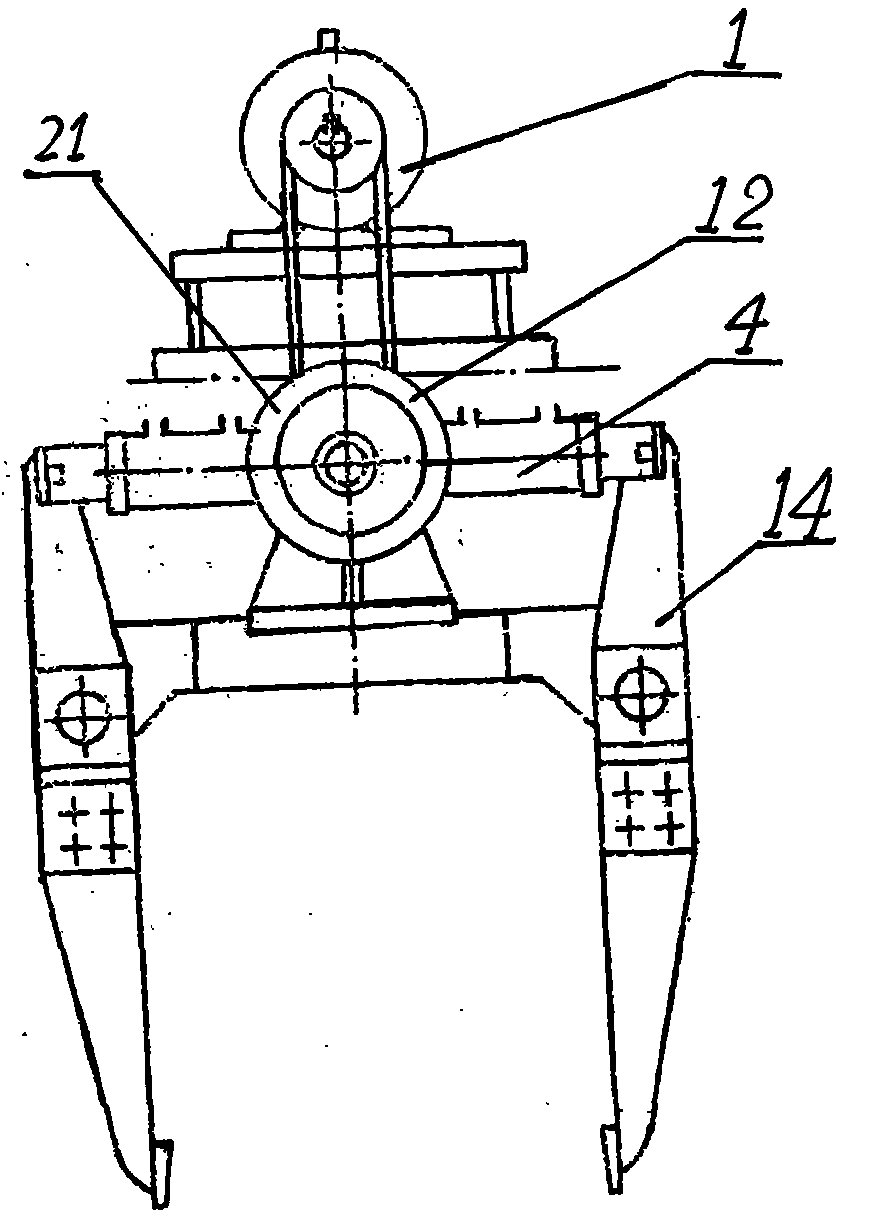

Gantry type lathe mechanical hand

ActiveCN111069632ALow mechanical failure rateImprove functionalityProgramme-controlled manipulatorGripping headsRobot handStructural engineering

The invention discloses a gantry type lathe mechanical hand which comprises stand columns, cross beams, a longitudinal beam, a chip removing device, a telescopic electric cylinder, a rotating electriccylinder, a gripper arm I and a gripper arm II. The two ends of the cross beams are fixed to the top ends of the stand columns. The two ends of the longitudinal beam are movably connected with the cross beam. The chip removing device is located at one end of the longitudinal beam and is movably connected with the cross beams and the longitudinal beam. The telescopic electric cylinder is movably connected with the longitudinal beam, and the rotating electric cylinder is fixedly connected with the telescopic electric cylinder. The gripper arm I and the gripper arm II are fixedly connected withthe rotating air cylinder. By means of the gantry type lathe mechanical hand, the chip removing device, the gripper arm I and the gripper arm II are arranged, clamping of square and round blank materials can be completed, and meanwhile, removing of waste materials accumulated in the mechanical hand can be completed through the chip removing device in the clamping process.

Owner:众智机械(临沂)有限公司

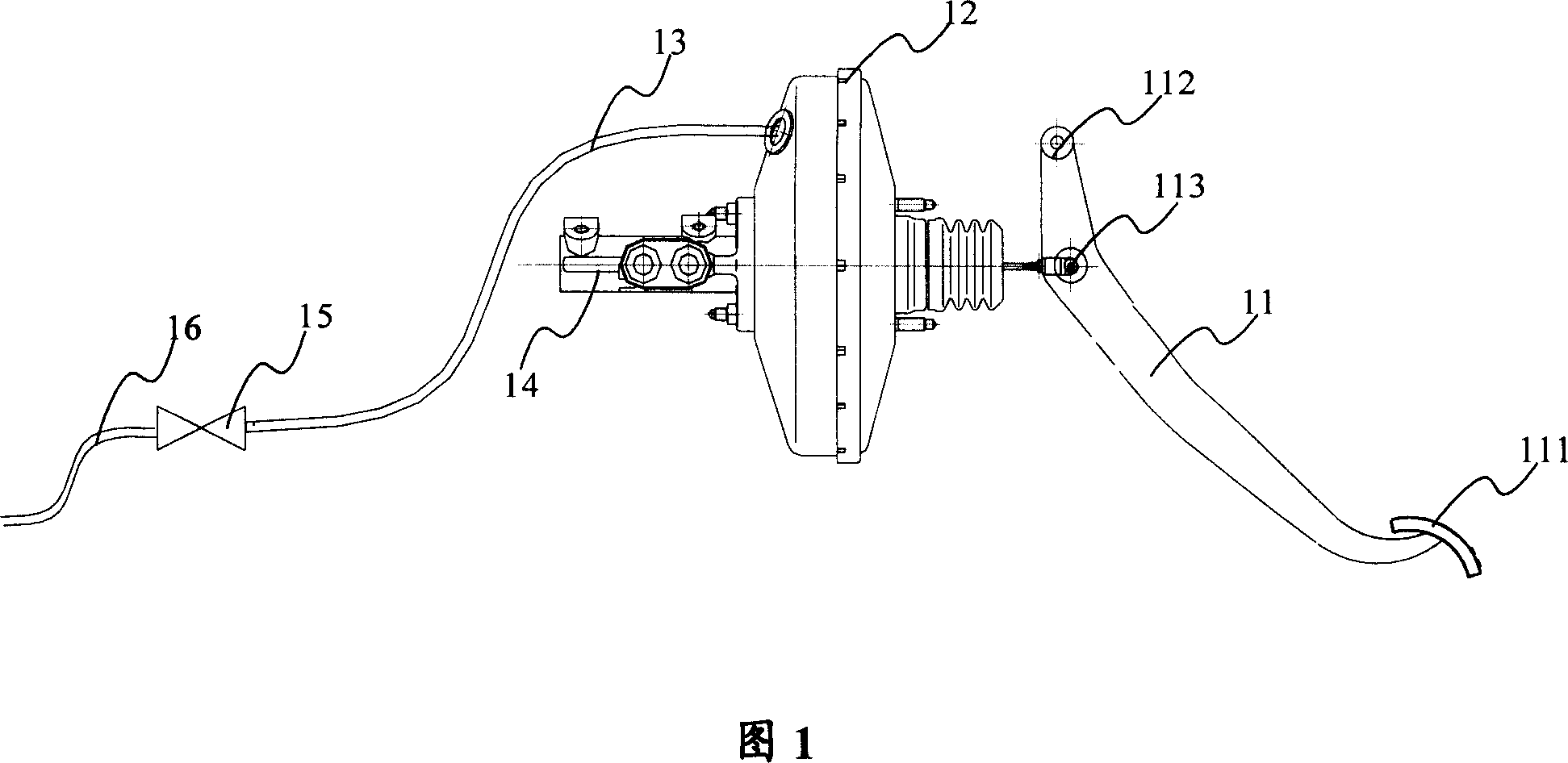

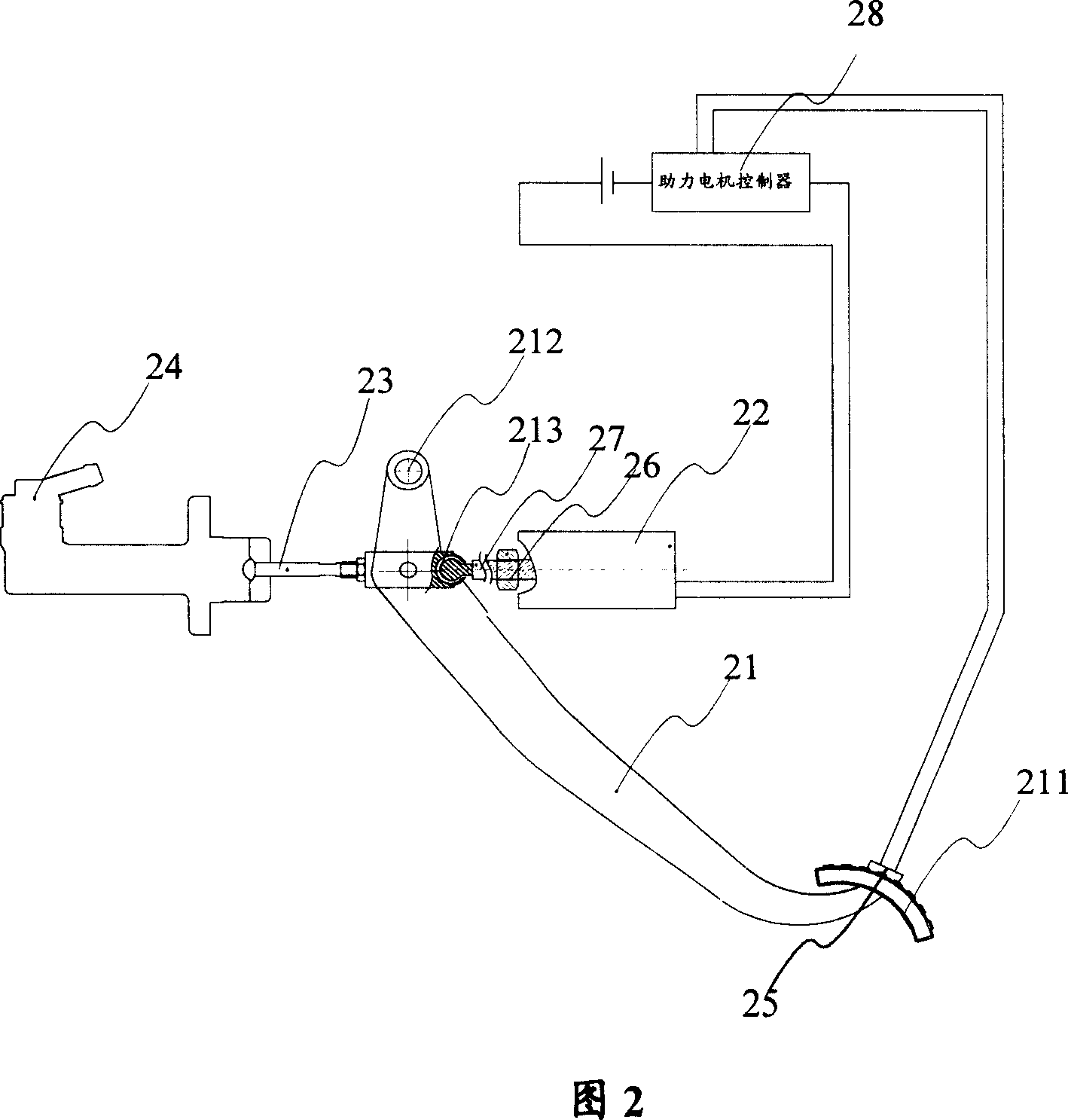

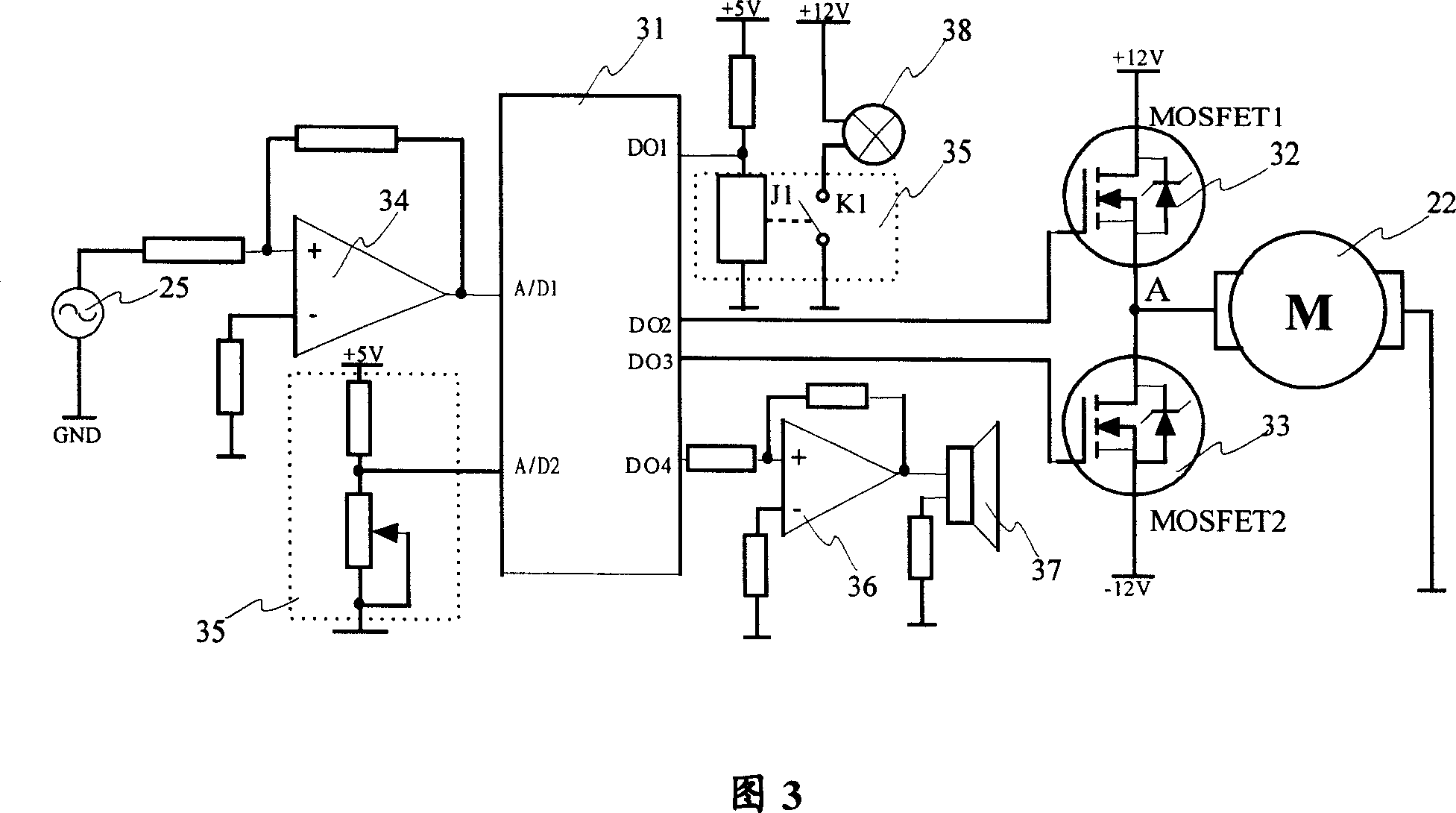

Booster braking device for automobile

InactiveCN101058311ANot affected by working conditionsNo loss of brake boostBraking action transmissionRotational axisMaster cylinder

The invention relates to a vehicle brake assistant system that comprises the brake pedal, master cylinder, assistant generator that pushes the master cylinder push rod to provide assistant force, with the said assistant generator rotary shaft fixed with the nut, and the nut with the lead screw that directly push the master cylinder. The lead screw and the master cylinder are linked in loose joint by ball hinges. The said brake pedal installs with pressure sensor to inspect the existence of the brake force to control brake assistance. It will not be affected by the working conditions of the vehicle engine.

Owner:SHANGHAI HUAPU AUTOMOBILE CO LTD

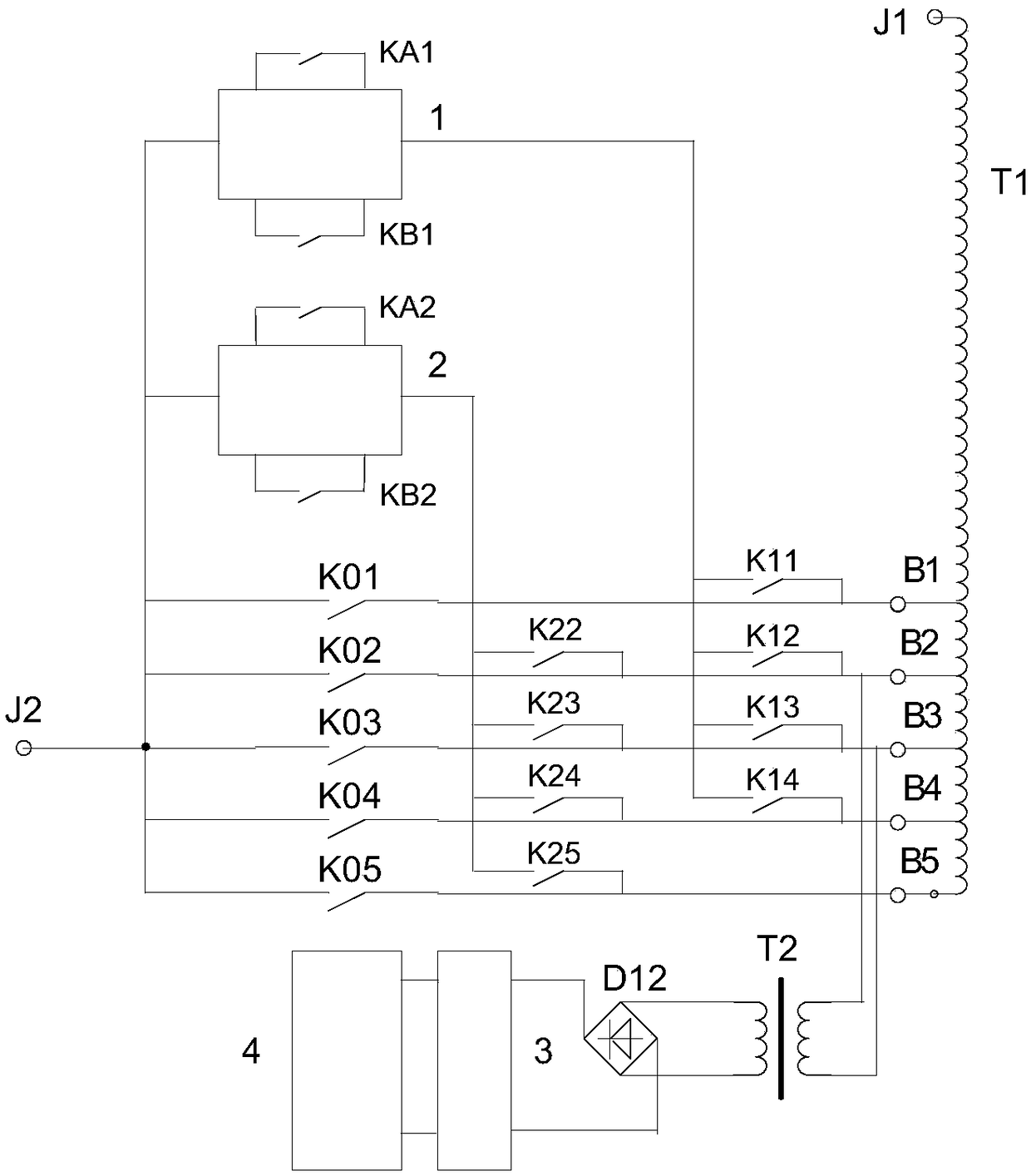

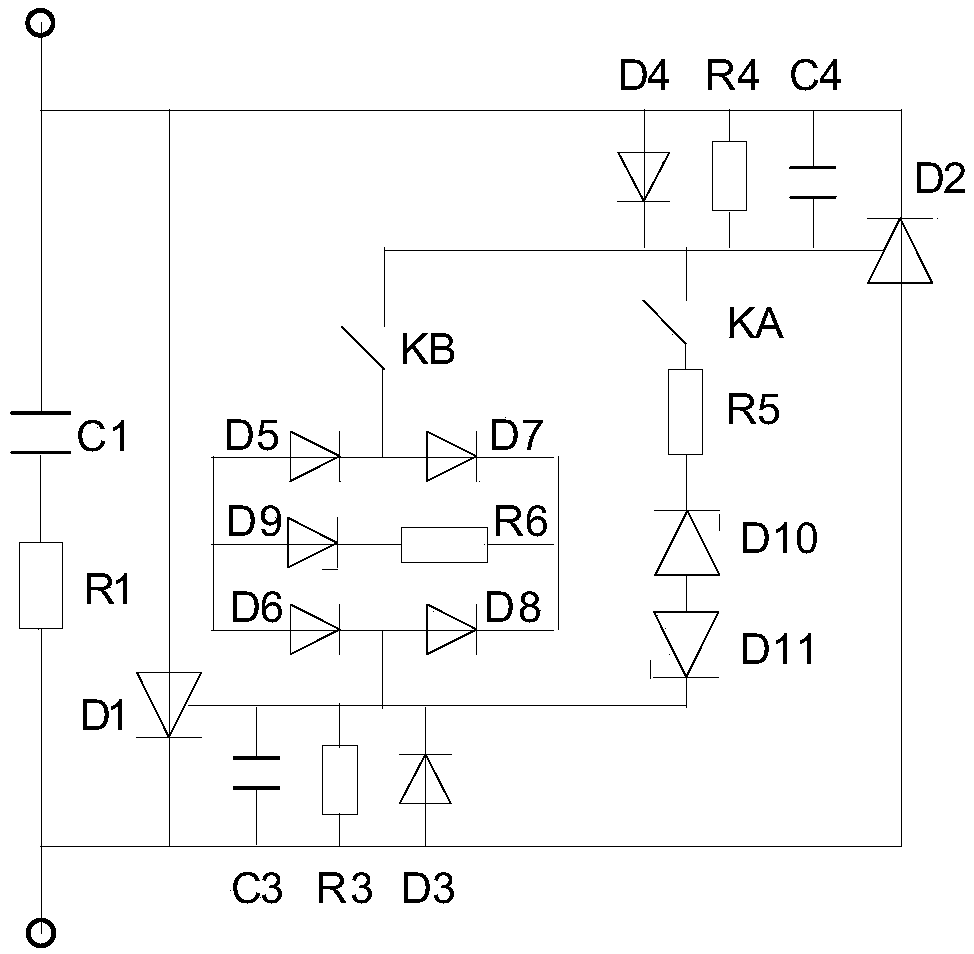

On-load tap changer and method thereof

ActiveCN108768359ASimple structureTo achieve mutual integrationThyristorElectronic switchingThyratronEngineering

The invention discloses an on-load tap changer and a method thereof. The on-load tap changer comprises master switches, thyristor auxiliary circuits and selection switches. Each master switch is connected in series in different loops of the voltage regulating coil of a voltage regulating transformer through at least one tap. The voltage regulating coil can form a current flow path if any one of the master switches is closed. When different master switches are closed, the voltage regulating transformer outputs different voltage. When any one master switch is connected in parallel with a certainthyristor auxiliary circuit through the selection switch, the adjacent master switch can be connected in parallel with another thyristor auxiliary circuit through the selection switch so as to form two paths of switchers of the master switches connected in parallel with the thyristor auxiliary circuits. The on-load tap changer does not include the shared switcher inside. All the switches operatein turn so that on-load switching of the load current from the originally closed master switch to the master switch to be closed can be realized.

Owner:李晓明

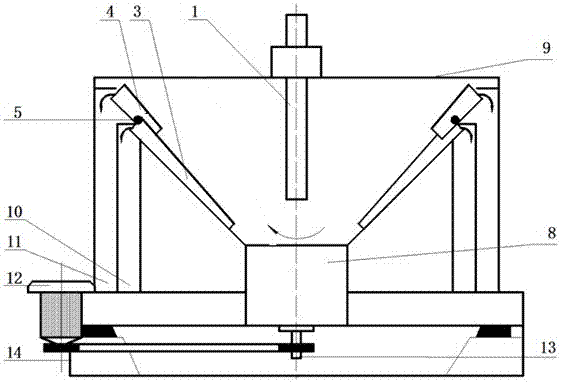

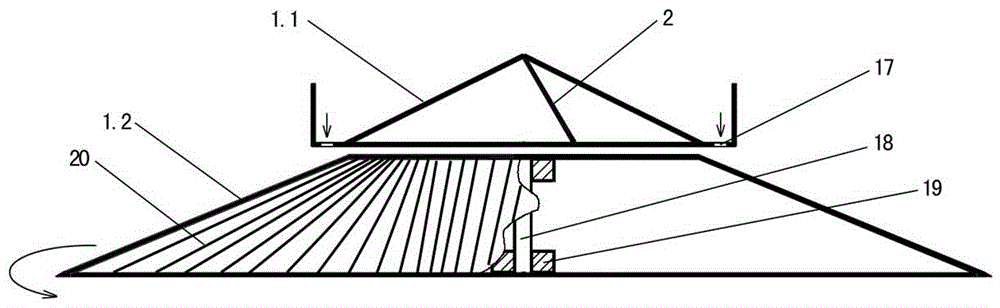

Tapered centrifugal beneficiation equipment

ActiveCN106925436APromote loosePromote stratificationRotary centrifugesElectric machineClassical mechanics

The invention discloses tapered centrifugal beneficiation equipment. The tapered centrifugal beneficiation equipment comprises a central ore feeding pipe, a centrifugal rotating drum, shunting grooves, intercepting grooves, a hollow shaft rotating platform, a shell, a concentrate groove, a tailing groove, a driving motor, a hollow shaft and a machine frame, wherein the centrifugal rotating drum, the intercepting grooves, the hollow shaft rotating platform, the concentrate groove and the tailing groove are arranged in the shell, the centrifugal rotating drum is located in the center of the interior of the shell, the central ore feeding pipe penetrates through the shell from outside to be right opposite to the bottom of the centrifugal rotating drum, the shunting grooves are uniformly formed in the periphery of the centrifugal rotating drum, the intercepting grooves are formed in the tail ends of the shunting grooves, the concentrate groove is formed in the outlets of the shunting grooves, the tailing groove is formed in the outlets of the intercepting grooves, the centrifugal rotating drum is arranged on the hollow shaft rotating platform, the hollow shaft rotating platform is connected with the hollow shaft, the hollow shaft is connected with the driving motor, and the driving motor is arranged on the machine frame. The tapered centrifugal beneficiation equipment is environment-friendly, efficient, energy-saving, capable of automatically and continuously discharging concentrate and tailings, high in efficiency, low in cost and suitable for high-efficiency sorting of fine-grain mineral so that the sustainable development of resources can be realized.

Owner:KUNMING UNIV OF SCI & TECH

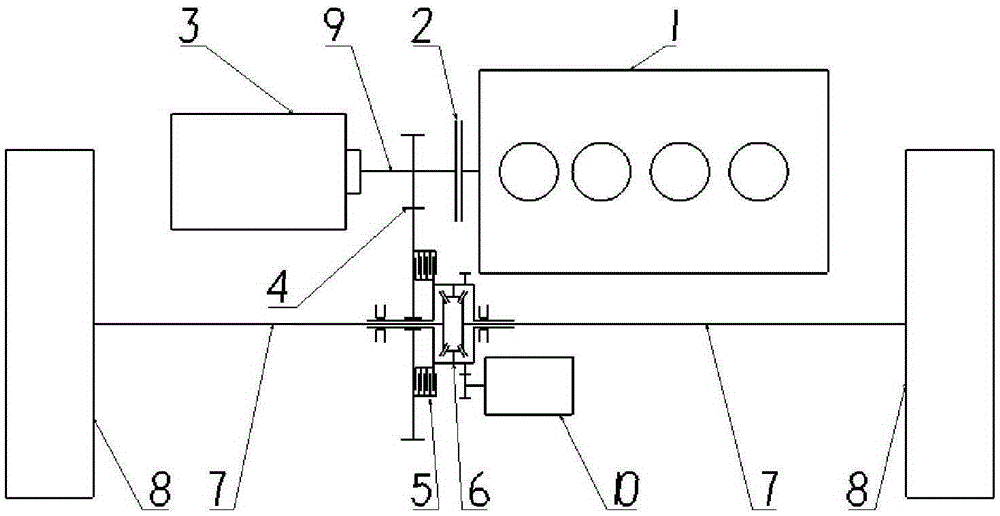

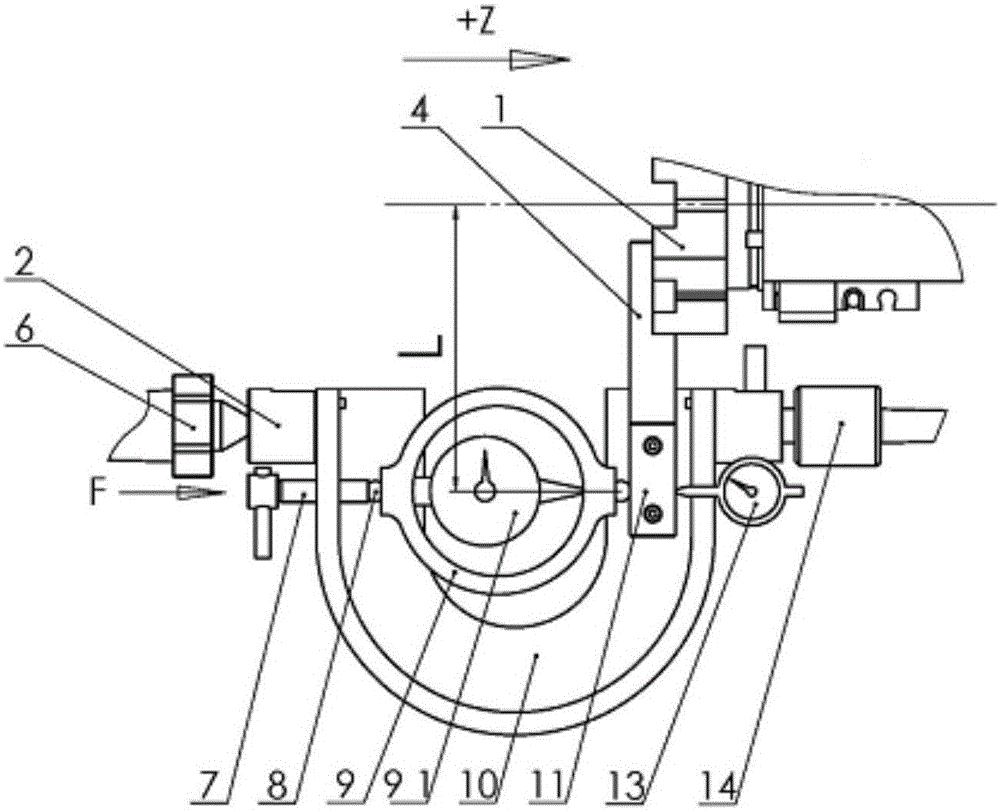

Vehicle transmission method and vehicle transmission mechanism of hybrid power system

InactiveCN105329087AExcellent accelerationEfficient emissionsGas pressure propulsion mountingPropulsion using engine-driven generatorsPower exchangeElectric generator

The invention discloses a vehicle transmission method and a vehicle transmission mechanism of a hybrid power system. The vehicle transmission mechanism at comprises an engine, a first clutch, a motor / power generator, a power transmission gear pair, a second clutch and a motor, wherein the first clutch is arranged between the engine and the motor / power generator; the second clutch is arranged between the motor / power generator and wheels as well as between the first clutch and the wheels; the power transmission gear pair is arranged between the first clutch and the wheels as well as between the motor / power generator and the wheels; the wheels can be driven by the motor directly or through a gear. According to the vehicle transmission method and the vehicle transmission mechanism, disclosed by the invention, the advantages of the hybrid power system are remained; meanwhile, on the premise that uninterrupted connection between the hybrid power system and the wheels is ensured, parts and structures such as a transmission, a starter and a small power generator in a common hybrid power system can be removed, the structure of the hybrid power system is simplified, the weight of the hybrid power system is reduced, impact in the hybrid power system due to power exchange can be reduced, and meanwhile, the hybrid power system can be very conveniently allocated into a two-wheel-drive or all-wheel-drive system.

Owner:WUXI TONGJIE AUTO DESIGN

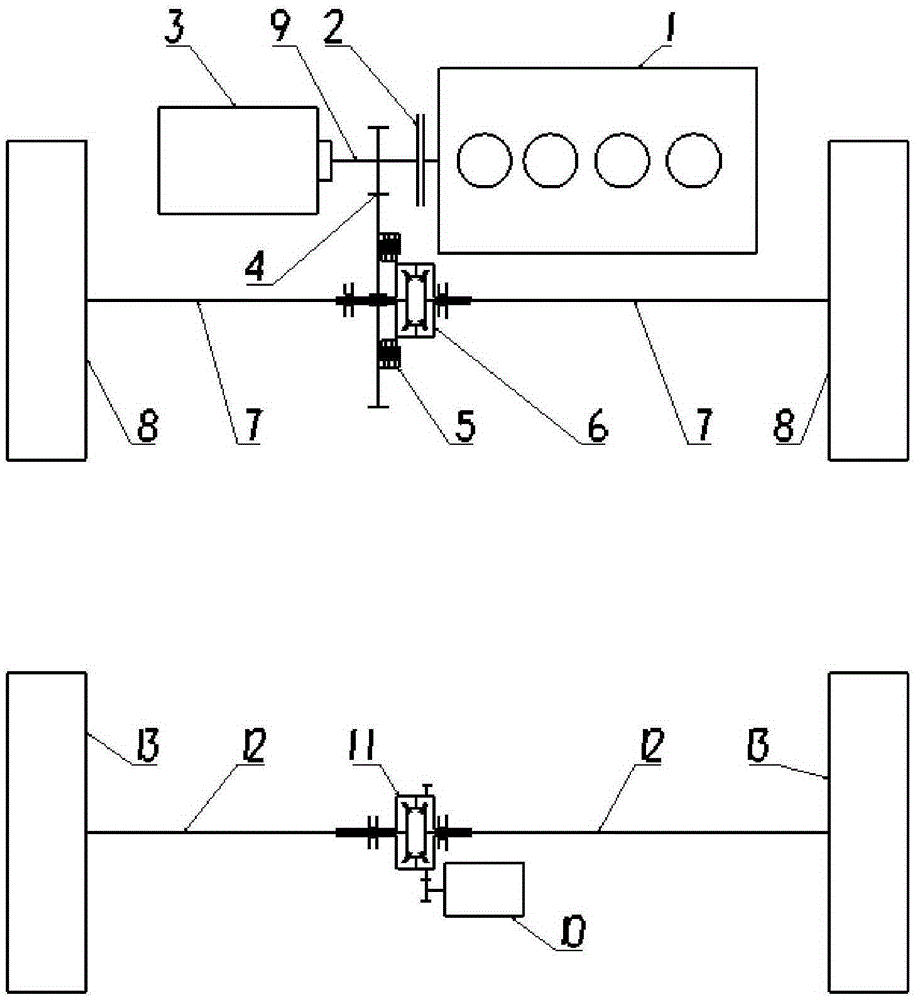

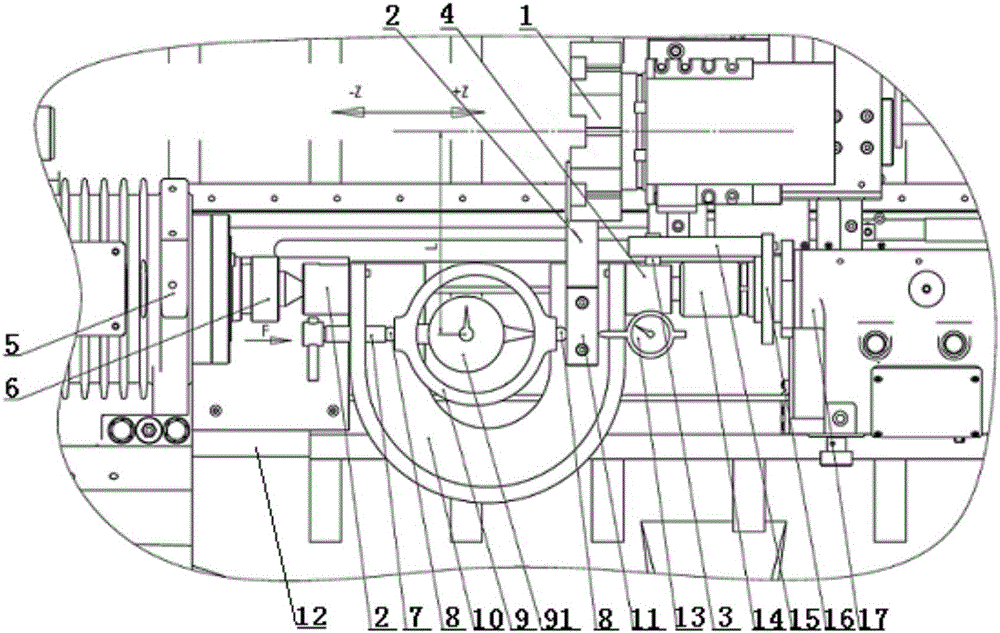

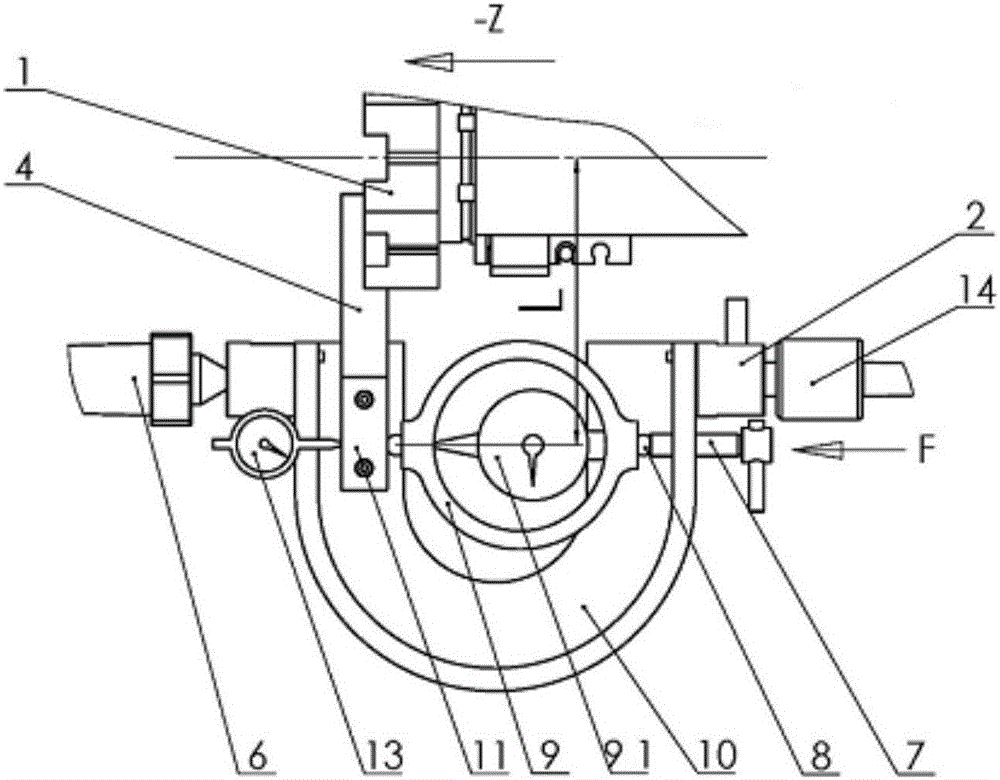

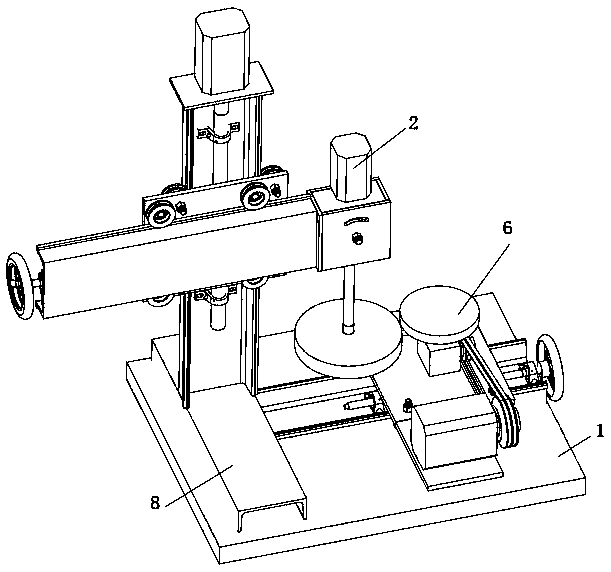

Static loading experiment device for turret of numerically controlled lathe

ActiveCN106018093AThe persuasiveness of the measurement resultsSimple structureMachine part testingMaterial strength using tensile/compressive forcesStress conditionsTailstock

The invention discloses a static loading experiment device for a turret of a numerically controlled lathe. The static loading experiment device comprises the turret, a spindle box, a spindle centre, an arch-shape frame, a tailstock centre and a tailstock. The arch-shaped frame is arranged between the spindle box and the tailstock, the turret is arranged on one side of the upper end of the arch-shaped frame, the spindle centre penetrates through a spindle hole of the spindle box, the tailstock centre is inserted in a tailstock sleeve, the opposite ends of the spindle centre and the tailstock centre are inserted into arch-shaped frame connecting sleeves connected to the two ends of the arch-shaped frame through screws, a tool bar is installed at the lower end of the turret, a measuring block extending into the arch-shaped frame is fixedly connected to the lower end of the tool bar, an ejector rod is arranged on one side of the arch-shaped frame in a penetrating mode, a force measuring ring is movably clamped in the arch-shaped frame through the opposite ends of the ejector rod and the measuring block, and a force measuring ring detection meter is arranged in the force measuring ring. According to the device, a certain amount of static loading is carried out on the turret in three directions, the deformation of the turret is detected, and the actual condition installation state and the working stress condition of the turret are simulated; besides, the device is simple in structure, convenient to operate, capable of providing a visible measuring result and low in mechanical failure rate.

Owner:宝鸡忠诚机床股份有限公司

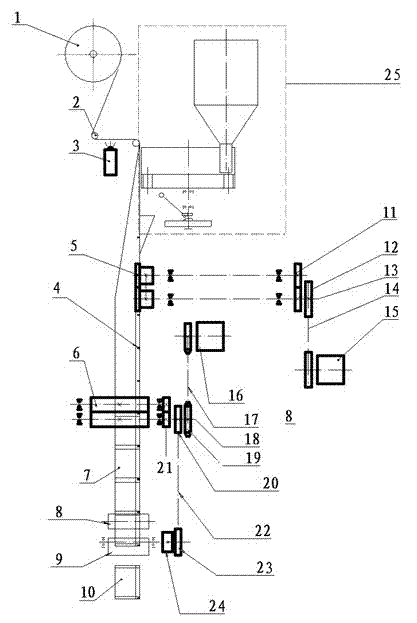

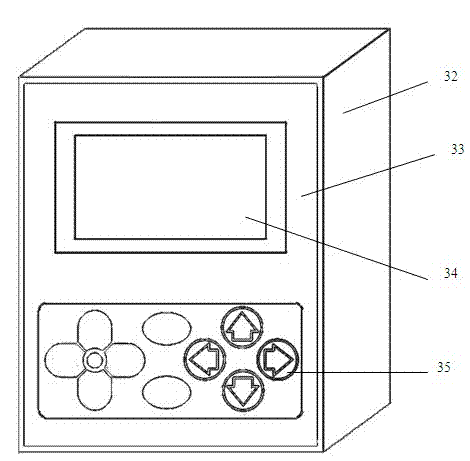

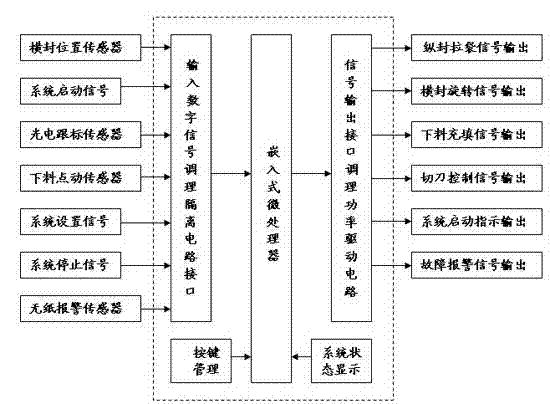

Continuous type stepping motor drive transverse longitudinal sealing roller packing machine and control method thereof

InactiveCN103085999AImprove electrical automation production levelSimplify the use of spaceWrapper twisting/gatheringPackaging automatic controlMechanical componentsElectric machinery

The invention relates to a continuous type stepping motor drive transverse longitudinal sealing roller packing machine and a control method thereof. The packing machine comprises a longitudinal sealing dragging drive mechanism, a transverse sealing rotary drive mechanism, a finish product bag cutting mechanism, a material stuffing device and a packing machine system controller. Embedded type control technology is adopted, a longitudinal sealing roller and a transverse sealing roller are driven by a stepping motor directly to drag bag and rotate and moving speed of the longitudinal sealing roller and the transverse sealing roller is uniform in linear speed in a transverse sealing point. The packing machine reasonably avoids the phenomenon and shortage that a finish product bag is swelled and wrinkled. The number of mechanical components of the whole packing machine are small, so that assembly modulation cost is low, mechanical maintenance volume is small and production period of the whole packing machine is short. The control method comprises that the production process of the packing machine needs three elements, namely, bag making, bag sealing and bag stuffing. The three elements become moving main bodies which are respectively independent on a mechanical structure, namely, longitudinal sealing bag dragging, transverse sealing rotary sealing and feeding stuffing and dependent on a moving principle.

Owner:TIANJIN POLYTECHNIC UNIV +7

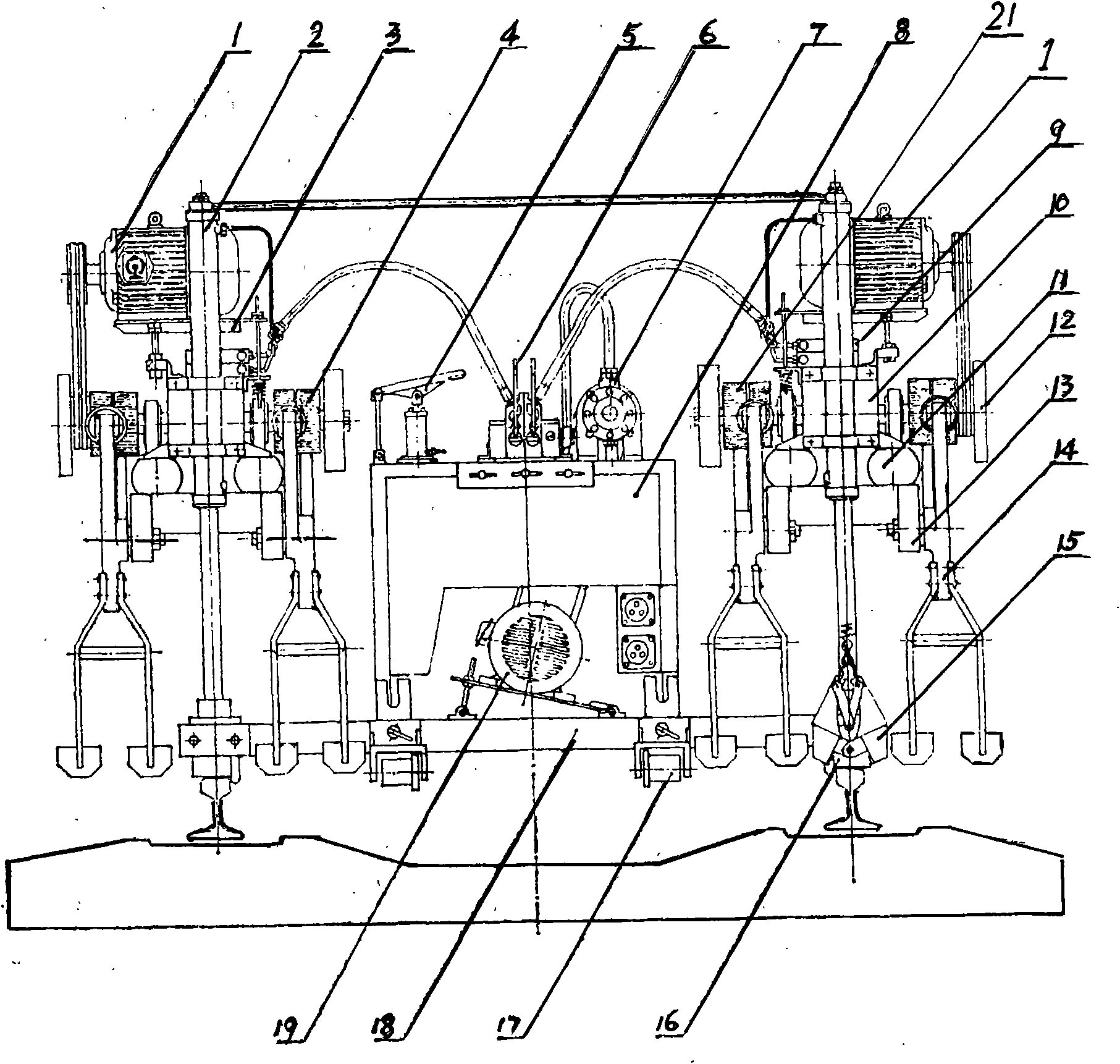

Small forced vibrating asynchronous-clamping hydraulic tamper

InactiveCN101871191AReduce manufacturing costReduce use costBallastwayVibration amplitudeEngineering

The invention discloses a hydraulic tamper, in particular to a small forced vibrating asynchronous-clamping hydraulic tamper, which is formed by a lifting part, a travelling part and an exciting and clamping part. The exciting and clamping part is formed by a flywheel, a spline shaft, eccentric bearings, clamping oil cylinders and pick plates. One end of a belt is sheathed on the output shaft of a motor and the other end of the belt is sheathed on the spline shaft. The flywheel is sheathed at the external side end of the spline shaft. Four eccentric bearings are sequentially installed on the spline shaft. The external side of each eccentric bearing is connected with the corresponding clamping oil cylinder. The two ends of each clamping oil cylinder are connected with the upper fulcrums of the corresponding pick plate. Preferably, the exciting frequency of the exciting and clamping part is 45-50Hz. The vibration amplitude of the pick head of the pick plate is 4-5mm. Moreover, the invention has the advantages that the safety performance is good, i.e. the railway transport safety and the personal safety of operators can be ensured, the mechanical fault rate is low, the reliability is very good, the structure is simple, the volume is small, the weight is light, the movement is convenient and the quality of tampering operation is superior to the quality of the tampering operation of the existing small eccentrically-vibrating hydraulic tamper.

Owner:王暹剡

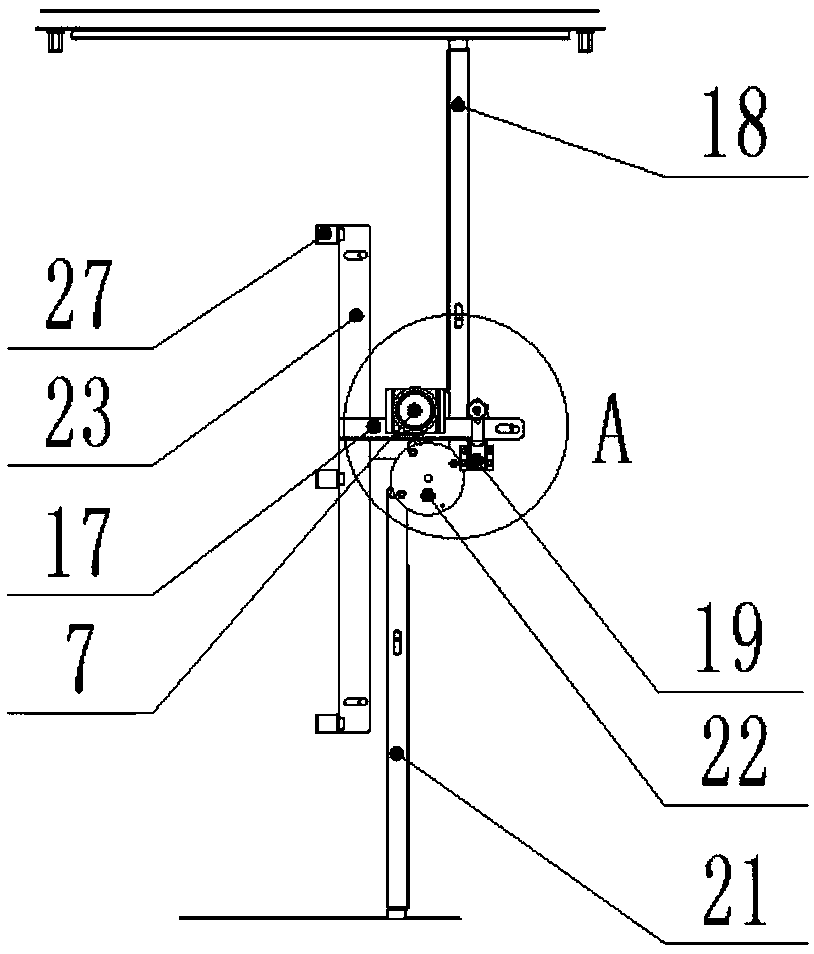

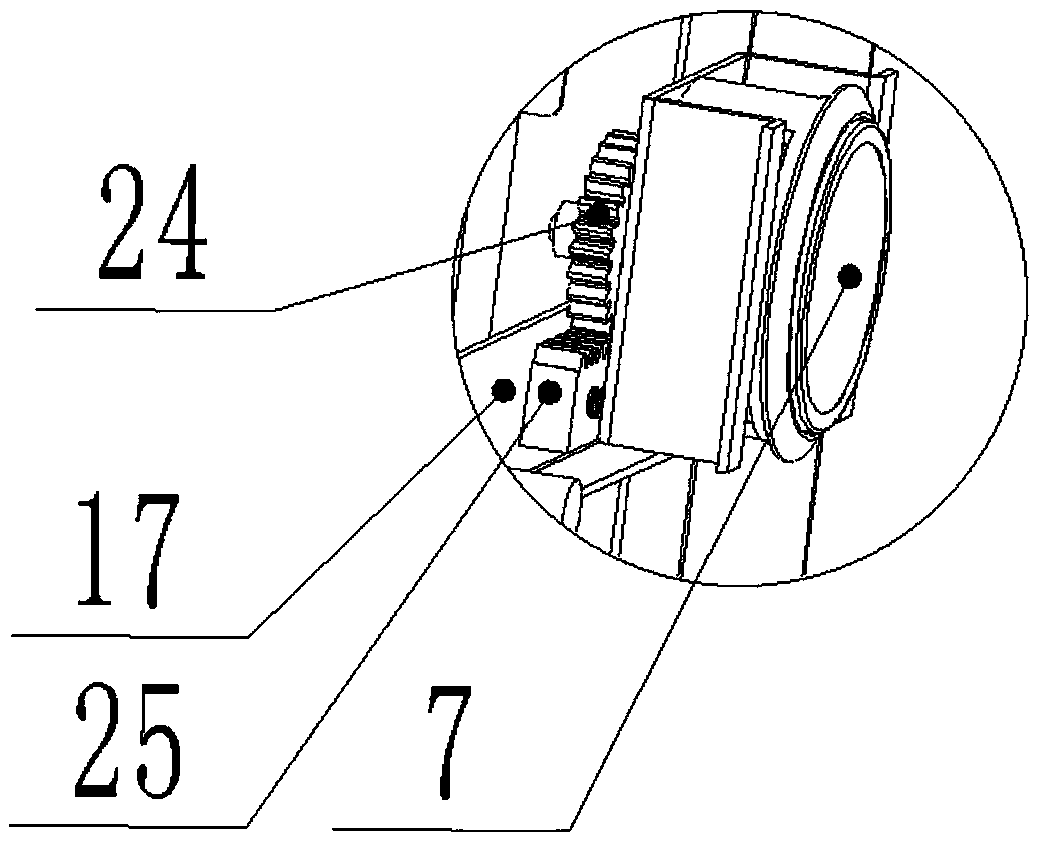

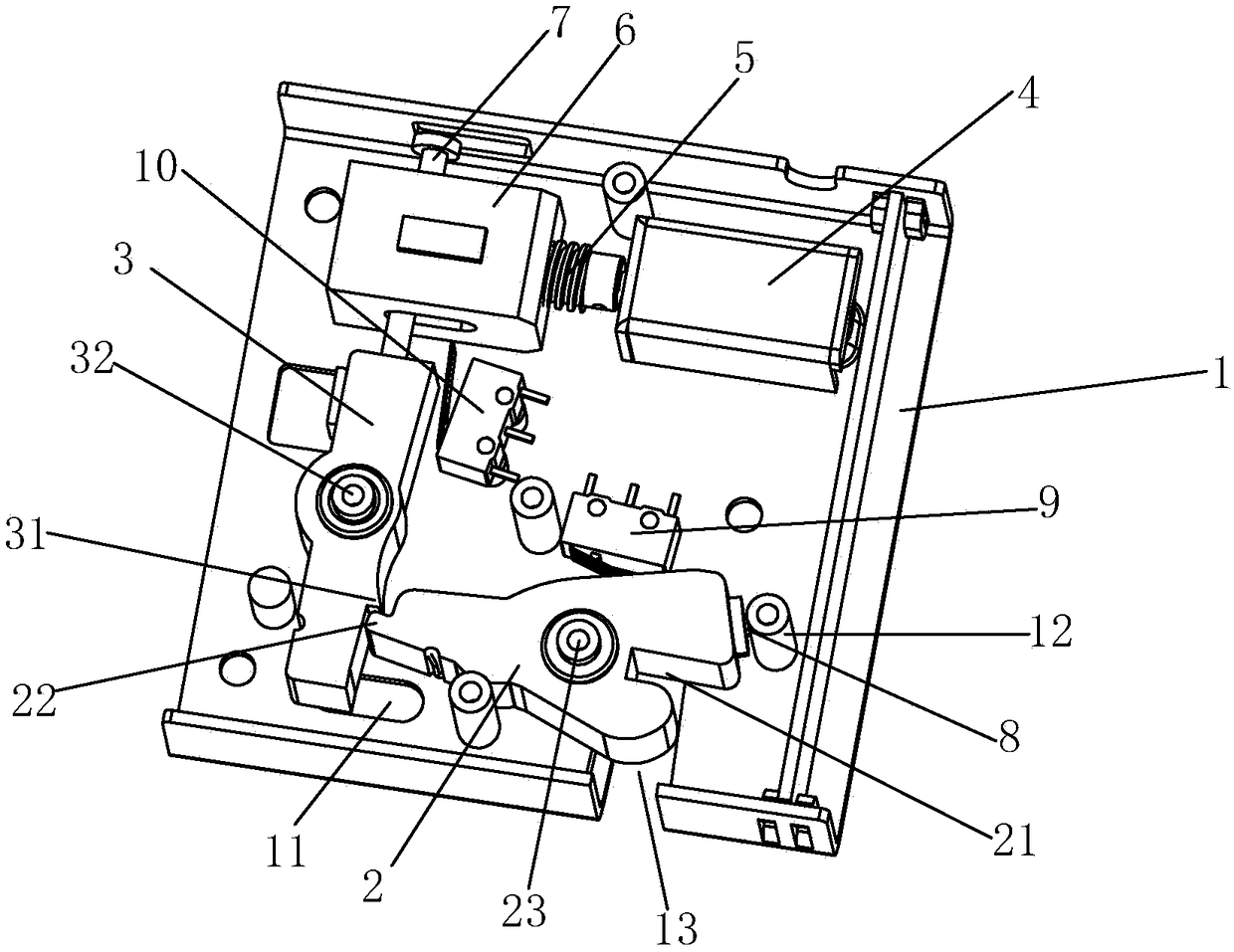

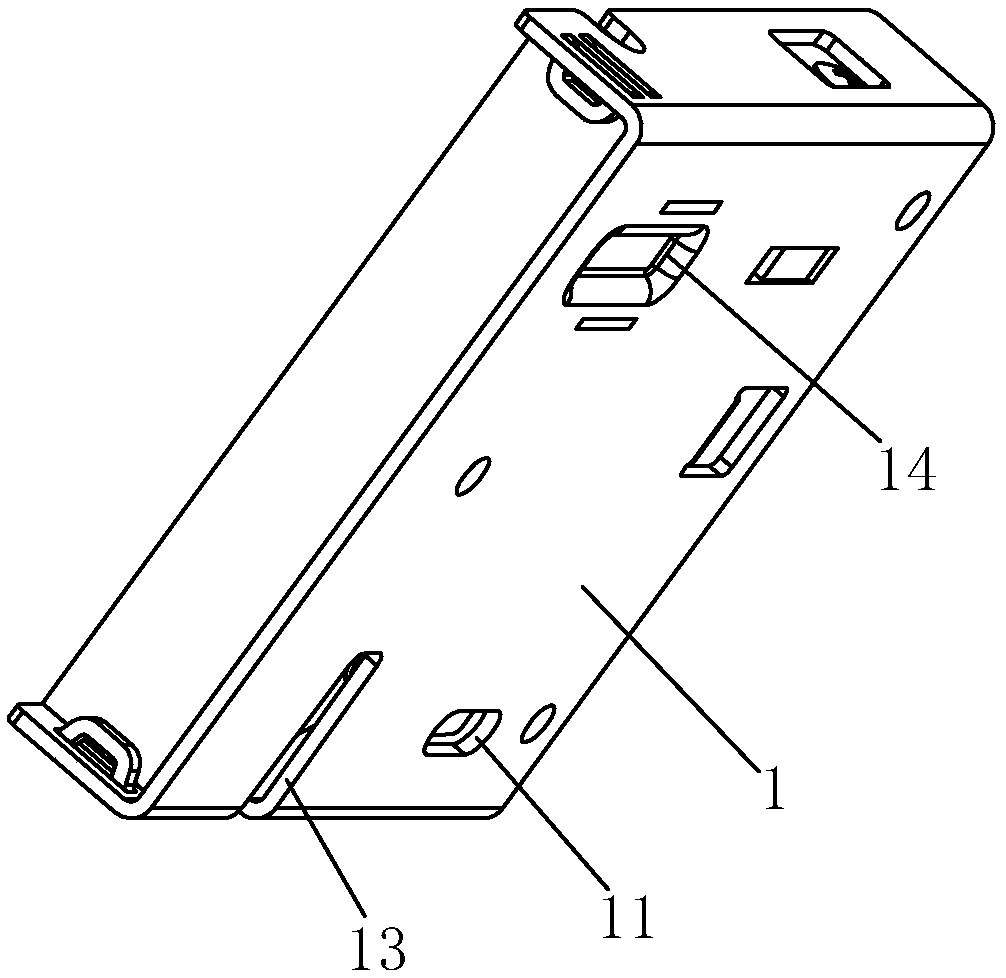

Bin electronic lock

InactiveCN109441253ASimple structureSimple emergency unlocking structureWing accessoriesNon-mechanical controlsElectricityElectric machine

The invention discloses a bin electronic lock. The bin electronic lock comprises a lock shell, a lock body, a limiting part, a motor and a main control panel. The lock body and the limiting part are rotationally connected to the lock shell, and a first elastic part allowing the lock body to reset is arranged between the lock body and the lock shell in an abutting manner. The lock body is providedwith a clamp groove matched with a lock hook on a door. The lock body and the limiting part are provided with a locking structure in a cooperation manner. The motor is electrically connected with themain control panel and is in transmission connection with the limiting part through a transmission mechanism. The transmission mechanism comprises a sliding block and a screw, and the sliding block isarranged on the lock shell in a sliding manner through a sliding guide structure and is movably connected with the limiting part. The screw is driven by the motor to rotate and is in threaded connection with the sliding block so as to drive the sliding block to slide. The transmission mechanism of the bin electronic lock is provided with few components, the structure is quite simple, assembling is convenient, and the mechanical failure rate is low.

Owner:XIAMEN HEADLEADER TECH CO LTD

Take-up reel and cable dividing machine using take-up reel

InactiveCN106044371ARealize assembly and disassemblyEasy and fast assembly and disassemblyFilament handlingEngineeringMechanical engineering

Owner:HENAN COMM CABLE

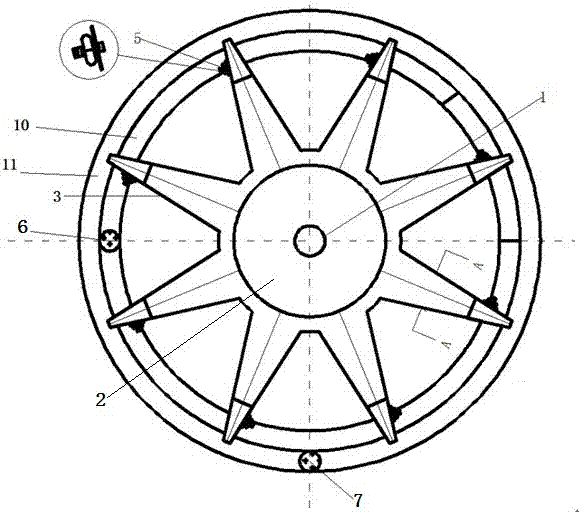

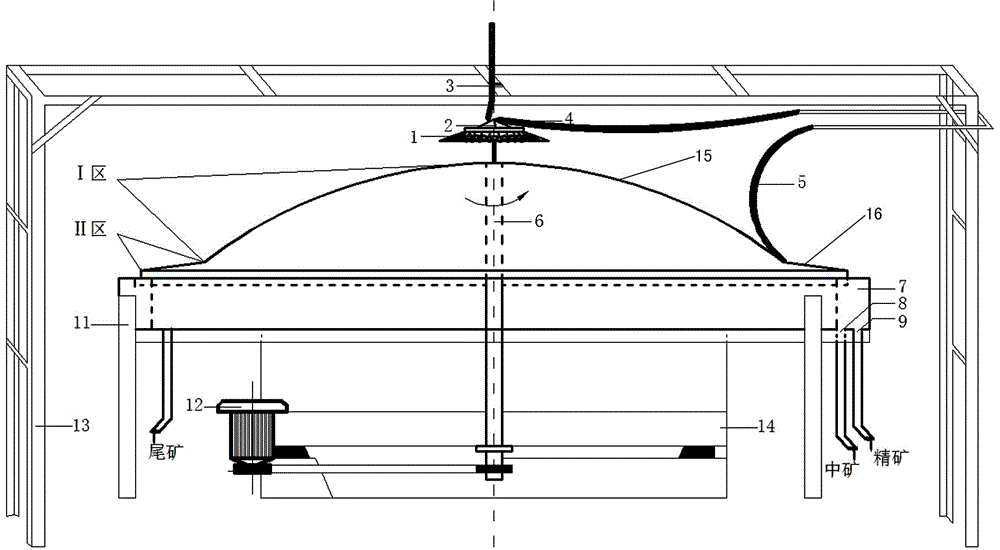

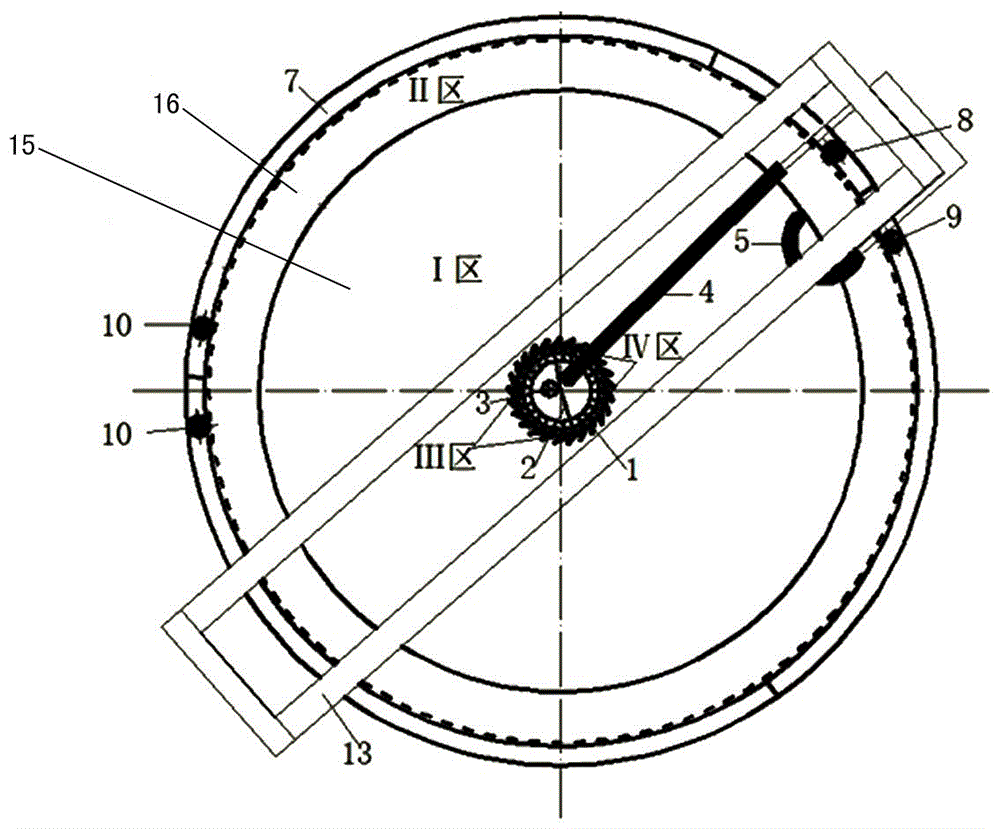

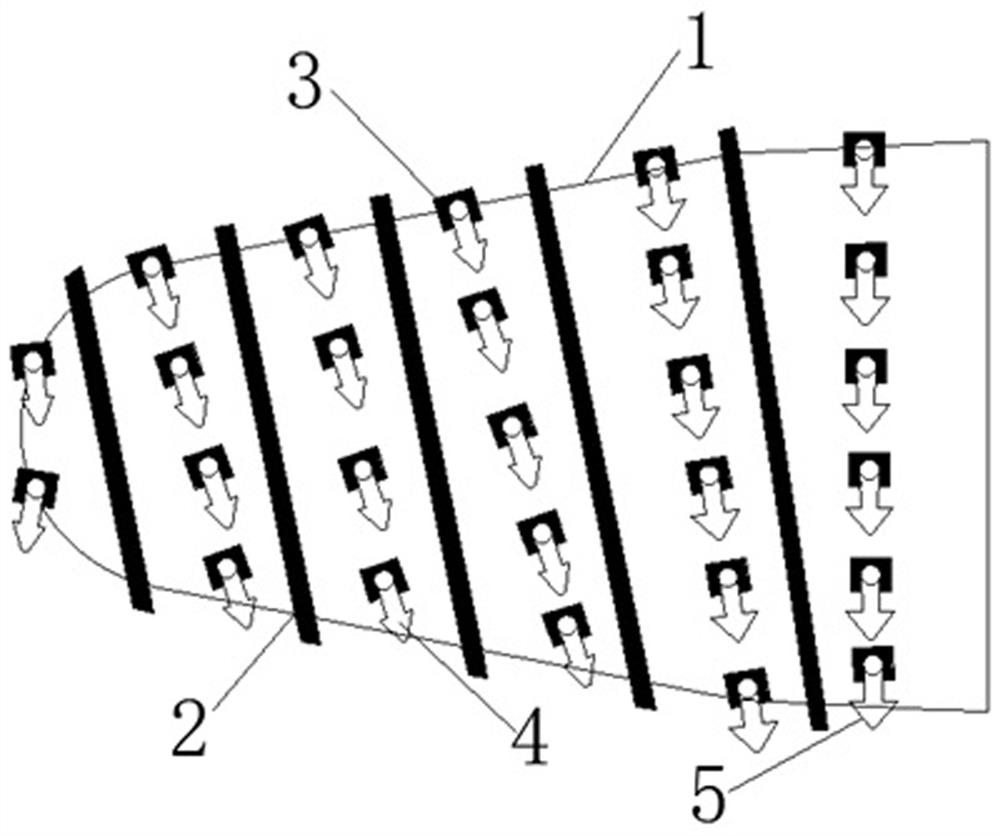

Arc surface spreading flow film sorting machine

ActiveCN106824500AIncrease centrifugal accelerationRaise the lower limit of granularityWet separationSurface spreadingEngineering

The invention discloses an arc surface spreading flow film sorting machine, and relates to equipment capable of continuously sorting fine-particle refractory minerals under combined effect of gravity and turning force. The equipment mainly consists of a rotary sorting disc driven by a driving device, an ore and water feeding device and an ore receiving and discharge device; the upper surface of the sorting disc is a spherical arc surface with a curvature radius of 0.58-2.27 m; the outer edge of the spherical arc surface is connected with a lap of annular inclined surface for forming an angle of 3-8 degrees with the horizontal plane; a flushing water pipe is mounted on the annular inclined surface; an ore receiving groove below the sorting disc in the flushing water pipe is provided with middling, concentrate and tailing discharge ports in sequence at intervals; an ore separation flushing disc is arranged rightly above the sorting disc; the upper part of the disc is a conical surface fixed disc, and the lower part is a movable disc provided with a rotating shaft; an ore feeding pipe mouth and a water feeding pipe mouth are aligned to the fixed disc; a series of leakage holes are formed in the bottom of the fixed disc, and are aligned to the movable disc; and a series of baffle plates aslant dispersed are arranged on the surface of the movable disc. The machine is suitable for environment-friendly, efficient, energy-saved and continuous sorting of 0.2-0.037 mm fine-particle valuable minerals.

Owner:昆明理工凯吉思科技有限公司

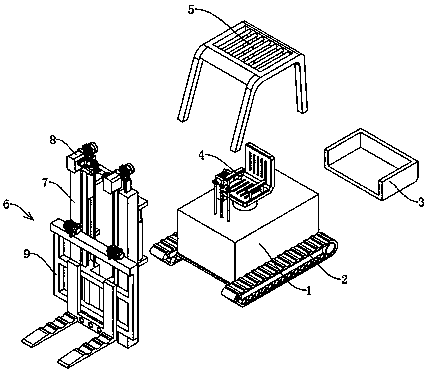

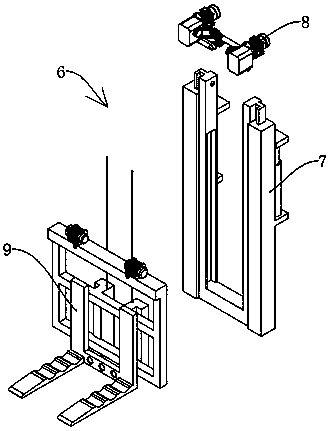

Integrated machine for breaking, loading, carrying, spraying and tunneling of rock roadway

InactiveCN101824989AHighlight substantive featuresSpeed up shipping timeTunnelsEngineeringUltimate tensile strength

The invention relates to an integrated machine for breaking, loading, carrying, spraying and tunneling of rock roadway, comprising a crawler walking part, a gangue pushing and rock rake plate, a belt transportation machine, a rock breaking part, a hydraulic and operation system and a body platform, wherein, the gangue pushing and rock rake plate is arranged at the front of the crawler walking part; and the belt transportation machine is arranged at the back of the plate and at the middle of the crawler walking part. The invention is characterized in that the integrated machine is also provided with a spouting device and a base; the hydraulic and operation system is arranged on the body platform of the upper side of the crawler walking part; and the base is fixed at the front center of the body platform; the rock breaking part is moveably connected on the base; and the spouting device is arranged at one side of a rock-breaking air-hammer. The integrated machine improves cycling schedule and speed of rock roadway tunneling, reduces labor intensity and numbers of constructers, creates safe operation environment, and has the functions of self-moving, gangue breaking, transportation, mechanical wet spouting and the like.

Owner:闫振东

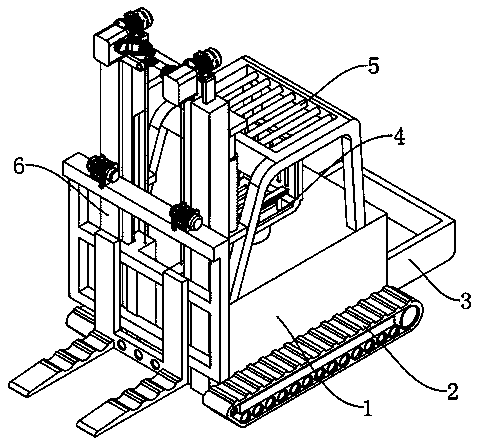

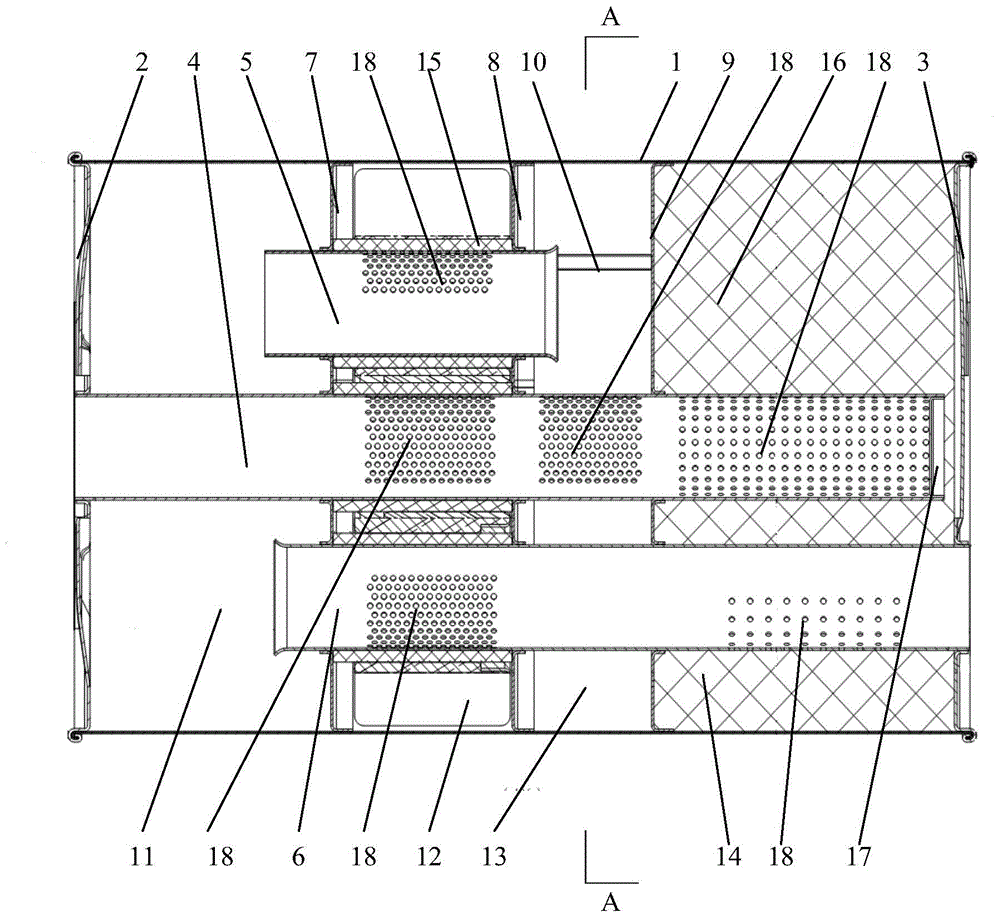

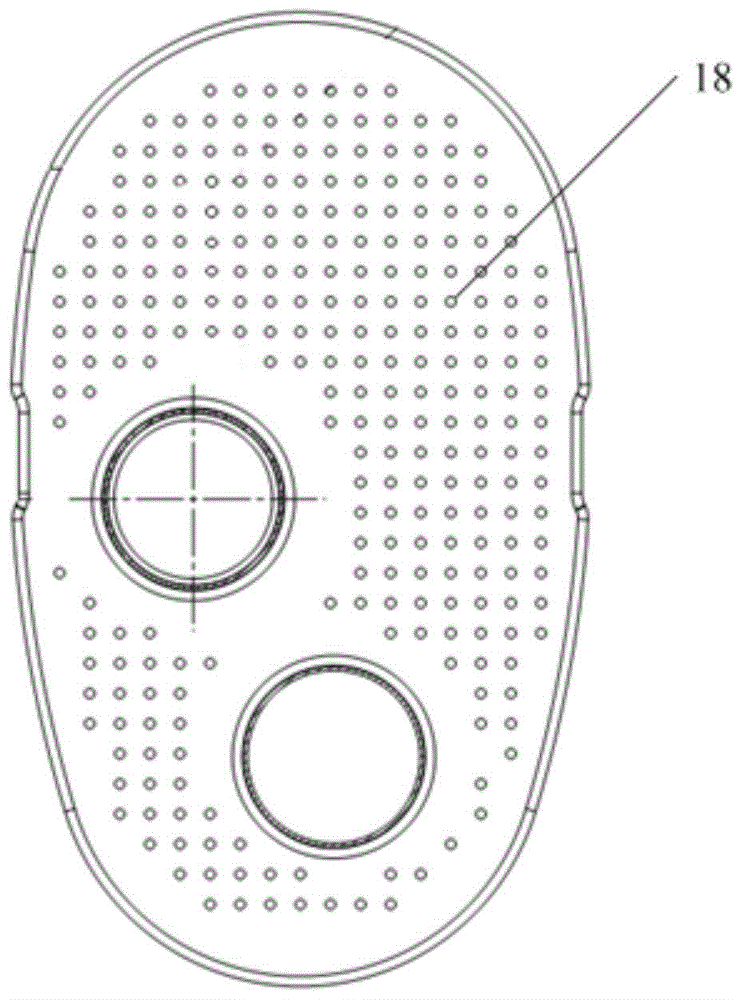

Lifting and transferring machinery for construction of construction site

InactiveCN111099521AImprove passabilityImprove skid resistanceLifting devicesEndless track vehiclesIndustrial engineeringSteel rope

The invention discloses a lifting and transferring machinery for construction of a construction site and belongs to the technical field of building machinery. The lifting and transferring machinery comprises a machinery main body and marching tracks, wherein the marching tracks are fixedly mounted on the two sides of the lower end of the machinery main body; a carrying box is fixedly connected with the tail part of the machinery main body; a cab is arranged above the machinery main body; a driving seat and a control device are fixedly mounted in the cab; a protective rest is fixedly connectedwith the periphery of the cab; a lifting and transferring device is connected with the front end of the machinery main body and comprises a hydraulic lifting mechanism, a wire rope driving mechanism and a wire rope lifting mechanism; the hydraulic lifting mechanism is connected onto the machinery main body; and the wire rope driving mechanism and the wire rope lifting mechanism are connected ontothe hydraulic lifting mechanism. The lifting and transferring machinery effectively solves the problems that the existing design structure is excessively simple, likely to break down and is not provided with an insurance self-locking device, as a result, the article is likely to be damaged and even the personal safety of a worker is threatened if a mechanical failure takes place.

Owner:枣庄职业学院

Novel automotive silencing equipment

InactiveCN105464771AImprove the noise reduction effectFast mufflerExhaust apparatusSilencing apparatusGlass fiberManufacturing technology

The invention belongs to the technical field of silencer manufacturing and particularly relates to novel automotive silencing equipment. The novel automotive silencing equipment comprises a shell, a front end cover, a rear end cover, an air inlet pipe, a buffer pipe, an air outlet pipe, a first partition plate, a second partition plate, a third partition plate, a partition plate support, a first cavity, a second cavity, a third cavity, a fourth cavity, silencing cotton and glass fiber cotton. The front end cover and the rear end cover are arranged at the two ends of the shell respectively. The first partition plate, the second partition plate and the third partition plate are sequentially arranged inside the shell. The second partition plate is connected with the third partition plate through the partition plate support. The shell is divided into the first cavity, the second cavity, the third cavity and the fourth cavity through the first partition plate, the second partition plate and the third partition plate. The novel automotive silencing equipment is good in silencing effect and high in silencing speed.

Owner:天津华瑞达汽车消声器有限公司

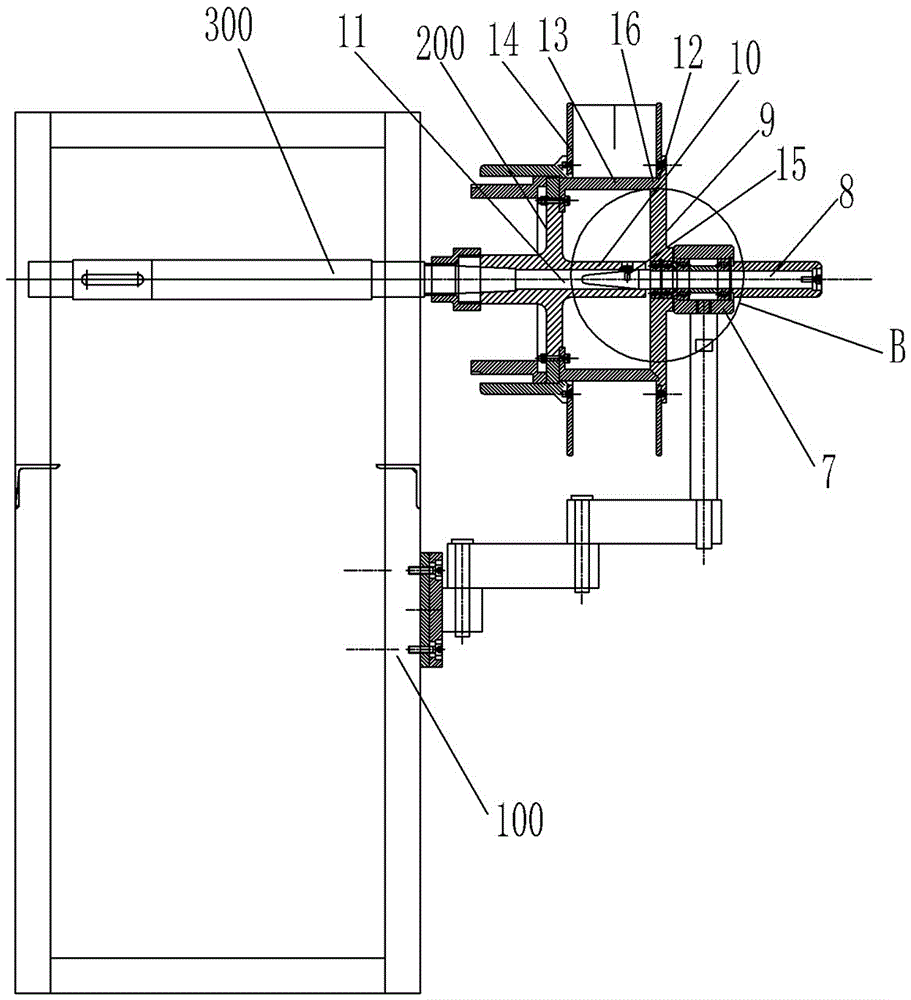

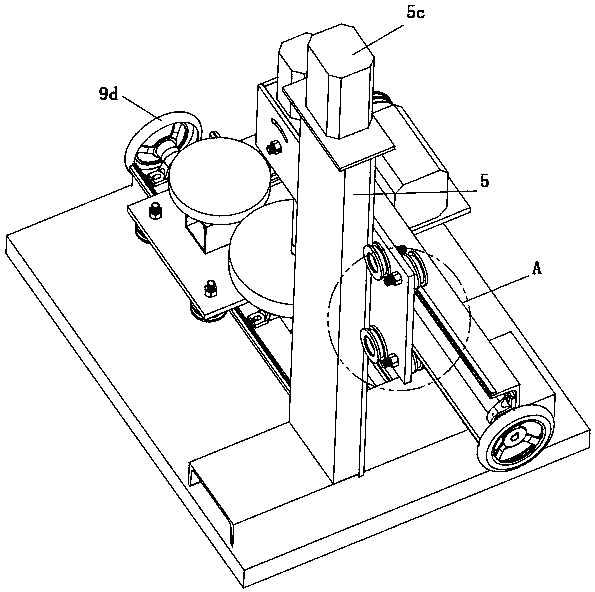

Fabric ring drum device capable of expanding and contracting and used for tire forming

The invention discloses a fabric ring drum device capable of expanding and contracting and used for tire forming. The device comprises a main sliding shaft sleeve part, a linear guide rail assembly and a capsule fixing mechanism. The main sliding shaft sleeve part is connected with the capsule fixing mechanism through the linear guide rail assembly and comprises a rotary main shaft, a driving rod, a sliding shaft sleeve and a connecting pivot. The rotary main shaft is a hollow shaft which is arranged on the driving rod in an empty-sleeving mode, the sliding shaft sleeve is installed on the rotary main shaft, and the sliding shaft sleeve, the rotary main shaft and the driving rod are connected through the connecting pivot. The linear guide rail assembly comprises two slant guide rails, two radial guide rails and eighteen drum plates. The capsule fixing mechanism comprises six insertion strips and four vacuum suction nozzles. The driving rod is used for driving the linear guide rail assembly to slide on the rotary main shaft to achieve expansion and contraction of the capsule fixing mechanism, and processes of charging, forming gluing and discharging of semi-finished fabric rings are achieved. The device is easy to operate, convenient to use and high in automation degree.

Owner:DINGHAN TECH XIAMEN

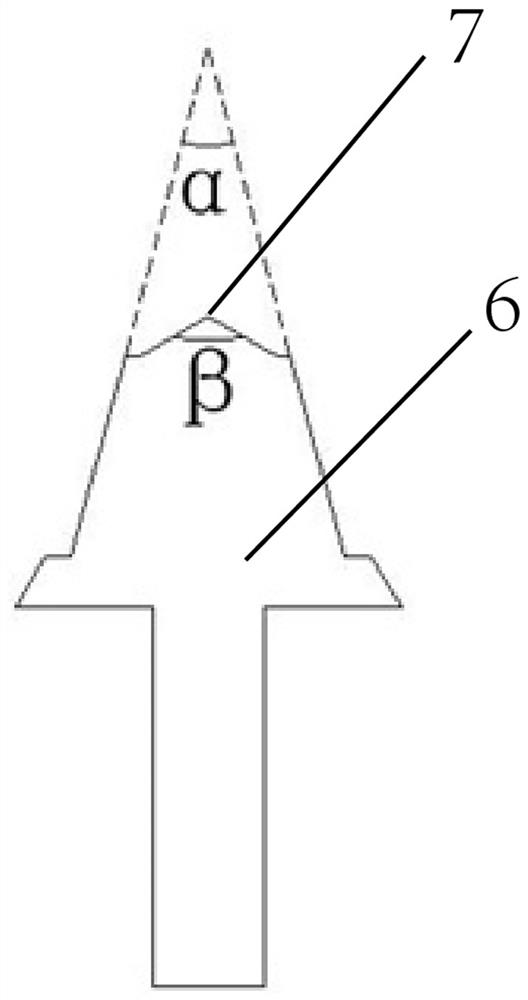

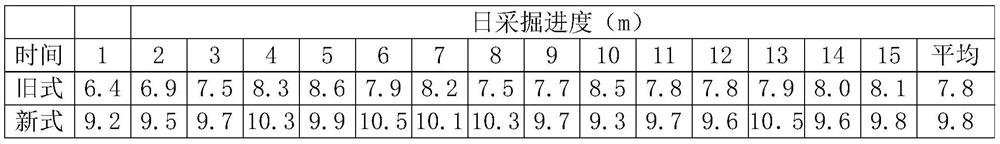

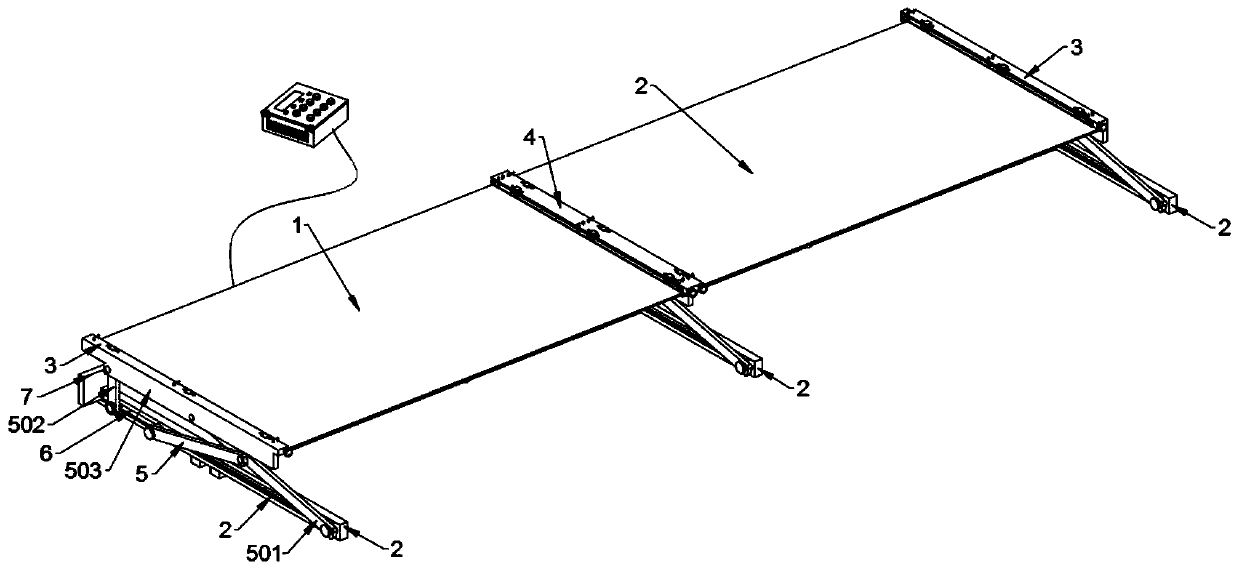

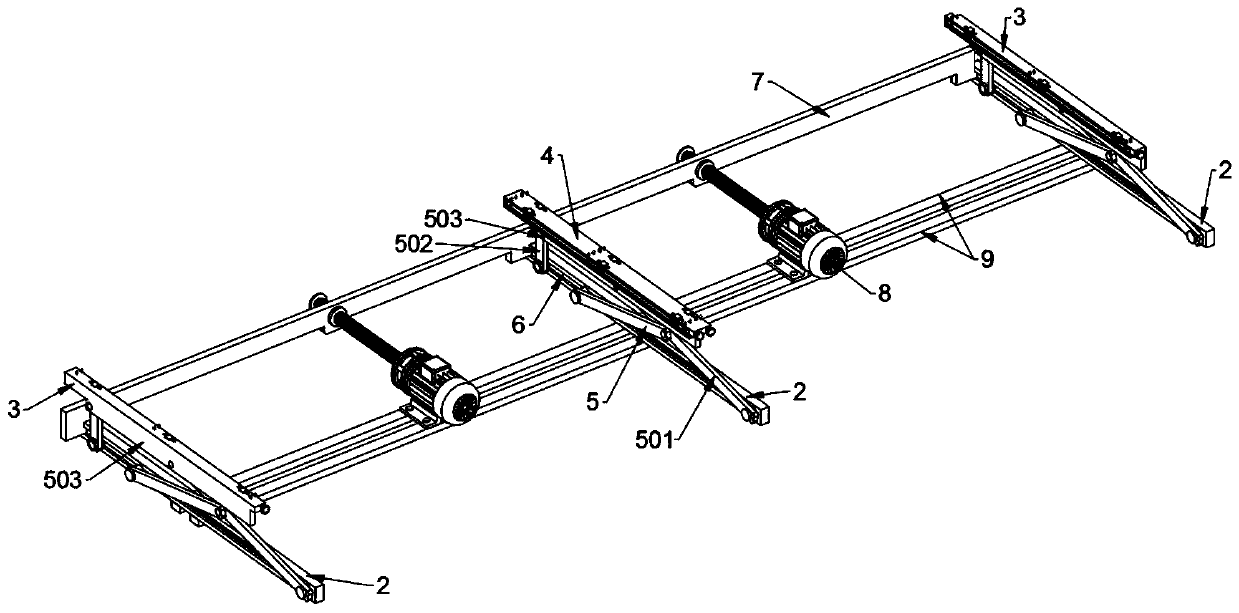

A cantilever roadheader cutting head suitable for hard rock

ActiveCN112145173BLow mechanical failure rateIncrease productivitySlitting machinesCutting machinesClassical mechanicsCantilever

The invention relates to a cutting head of a cantilever roadheader suitable for hard rock. A material guide plate is welded on the main body of the cutting head; The rear end is arranged; the pick at the front of the main body of the cutting head is the front pick, the taper of the front pick is 70~75°, and the cone angle of the front end of the front pick is 108~112°; the main body of the cutting head (1 ) The rear pick is the rear pick, and the taper of the rear pick is 78~82°. The cone angle of the front end of the rear pick is 108~112°. The pick is more reasonable in force, reduces the failure rate of the cutting head, and improves the working efficiency of the cantilever roadheader.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

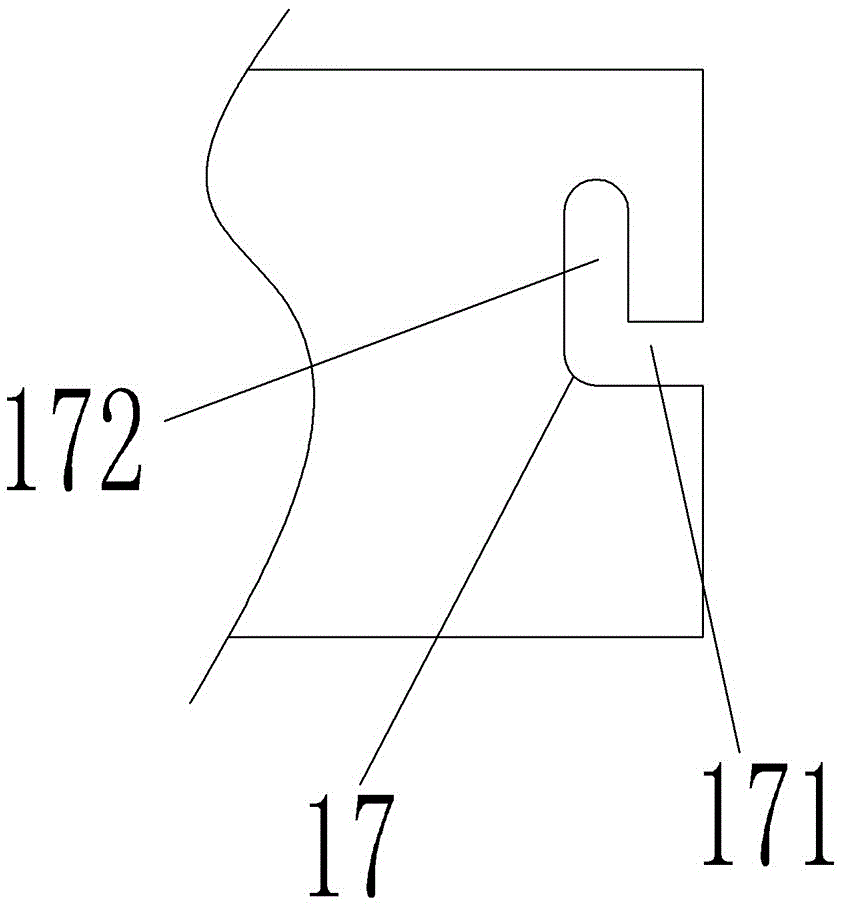

Agricultural adjustable-overturn-type greenhouse cover structure for early maturing culture of vegetables

PendingCN109892141AEasy to slide outEasy sliding combination installationClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention provides an agricultural adjustable-overturn-type greenhouse cover structure for early maturing culture of vegetables. The structure comprises top wedge-shaped blocks, locating blocks, bilateral clamping grooves, first top bracing plates, second top bracing plates, third top bracing plates, clamping groove installing plates, slide plates, a top pushing plate, motors and motor installing rods; three rail rods are arrayed at equal intervals, three slide grooves are formed in the middles of the three rail rods, and the three slide plates are slidably arranged in the three slide grooves; the second top bracing plates are rotatably connected with the back ends of the rail rods, and the first ends of the second top bracing plates are rotatably connected with the portions of three fifth length of the clamping groove installing plates; through the arrangement of the three top wedge-shaped blocks and three wedge-shaped pressing blocks, it is only required that top threaded rods are contrarotated and loosened, the three wedge-shaped blocks slide backward and are separated from the three wedge-shaped pressing blocks, transparent PVC cover plates lose locating, and therefore thetransparent PVC cover plate can be conveniently slidably drawn out for replacement after being damaged.

Owner:GUIZHOU UNIV

Vertical polishing machine

InactiveCN108274363ASimple structureLow costGrinding carriagesPolishing machinesEngineeringFault rate

The invention relates to the technical field of polishing machines and particularly relates to a vertical polishing machine. The vertical polishing machine comprises a bearing table, a first polishingpart and a second polishing part; the top of the bearing table is provided with a first adjusting base and a second adjusting base; the first polishing part comprises a first motor, a length adjusting base and a first bearing plate; the back side of the first bearing plate is connected with the front side of the first adjusting base; the back side of the length adjusting base is connected with the front side of the first bearing plate; the first motor is arranged at one end of the length adjusting base; an output shaft of the first motor is provided with a first polishing wheel; the top end of the first adjusting base is provided with a lifting motor; the second polishing part comprises a second motor and a second bearing plate; the second bearing plate is arranged on the second adjustingbase; the second motor is arranged at one end of the top of the second bearing plate; and the other end of the top of the second bearing plate is provided with a second polishing wheel. The verticalpolishing machine provided by the invention has the advantages of simple structure and low manufacturing cost, is applicable to small enterprises and individuals and is also low in mechanical fault rate because of the simple structure.

Owner:康忠根

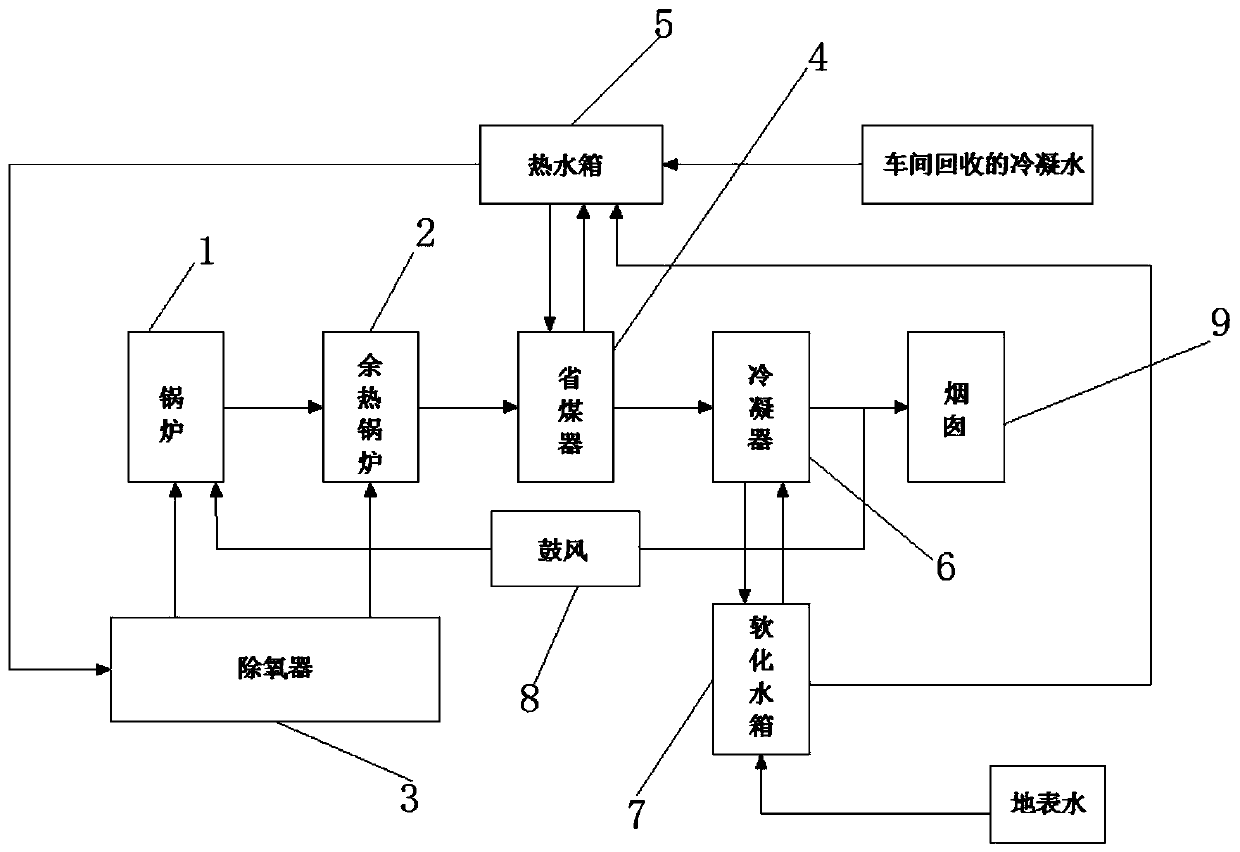

Intelligent recovery system for water circulation heat energy

InactiveCN111396854ATake advantage ofEmission reductionLiquid degasificationFeed water supplyCooling effectWastewater

The invention discloses an intelligent recovery system for water circulation heat energy. Compared with a traditional situation that smoke generated by a boiler is directly exhausted after being cooled by an economizer and a condenser, the design temperature ranges from 80 DEG C to 90 DEG C, heat energy is wasted, water resources are wasted due to cooling, and the cooling effect is not obvious, the system comprises a high-temperature heat generating area, an intermediate-temperature hot water generating area and a low-temperature smoke exhausting area, the temperature of the exhausted smoke can be lower than 45 DEG C and is far superior to the traditional smoke exhaust temperature, the heat energy of the high-temperature smoke generated by the boiler is fully utilized, full utilization ofthe heat energy is achieved, and the economic benefit is improved; meanwhile, condensate water in a workshop is recycled, and used for the economizer and the condenser, the smoke is cooled, and recycling of the condensate water is achieved; the water resources are saved, waste water drainage is reduced, environmental protection, energy saving and emission reducing can be achieved while the production benefit is improved and developed, and the intelligent recovery system is the development trend of the present age.

Owner:HUZHOU NARNIA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com