Cement preparation method

A cement preparation and cement technology, which is applied in the direction of cement production, etc., can solve the problems of aggravated vertical mill, high utilization rate of column-plate energy, damage of roller surface and grinding disc of vertical mill, reduce vibration and mechanical failure rate, improve vertical mill Grinding efficiency, reducing the effect of vertical mill overgrinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

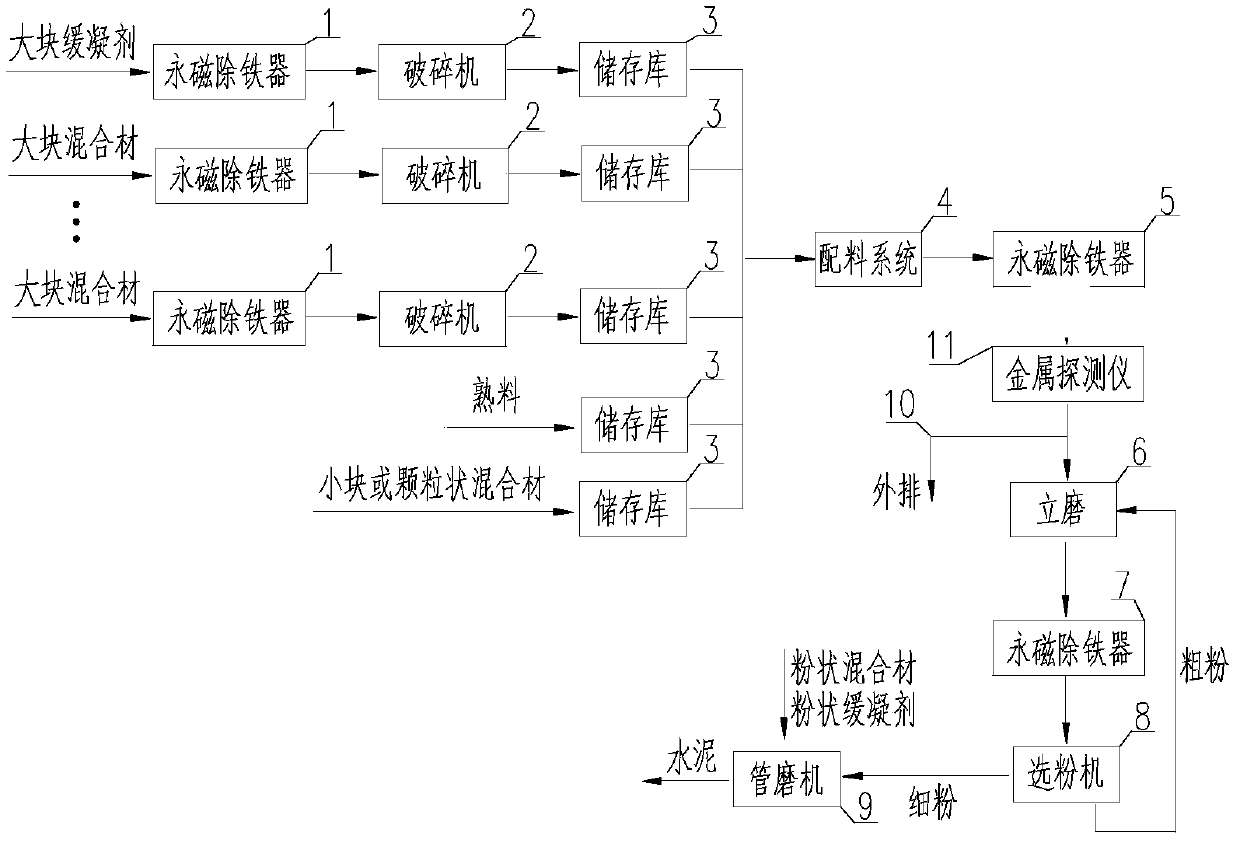

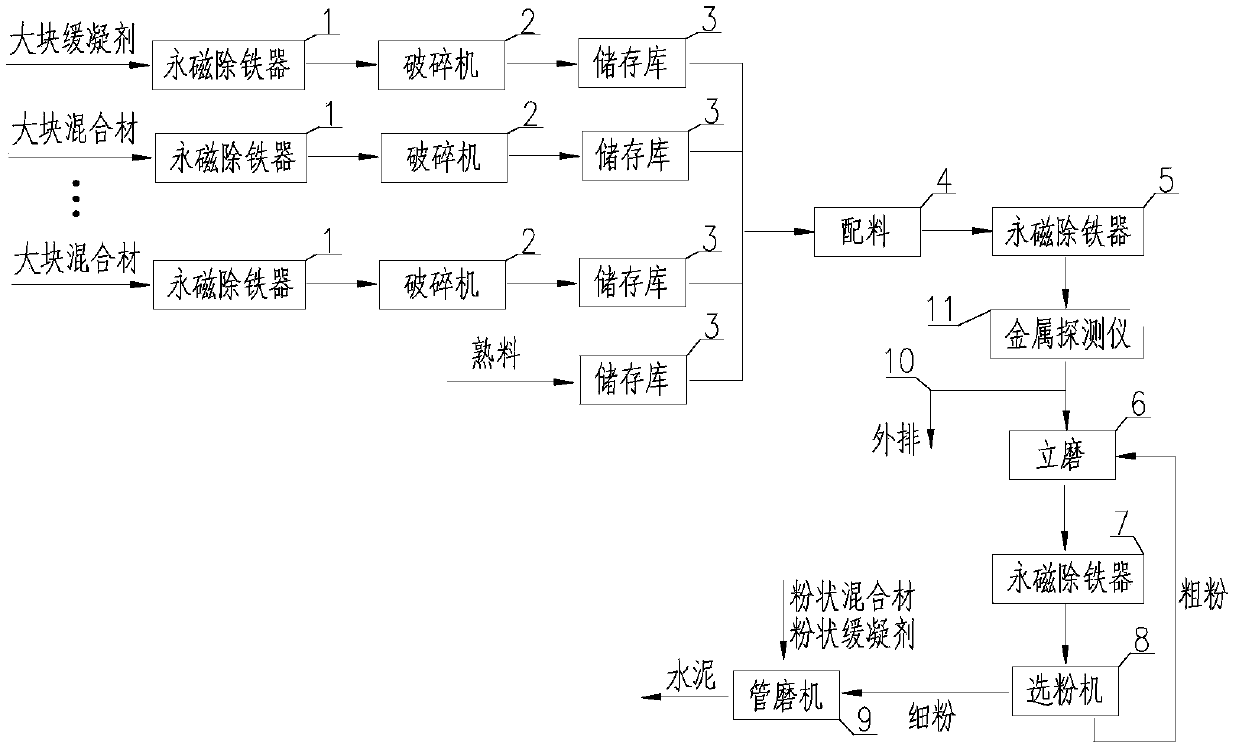

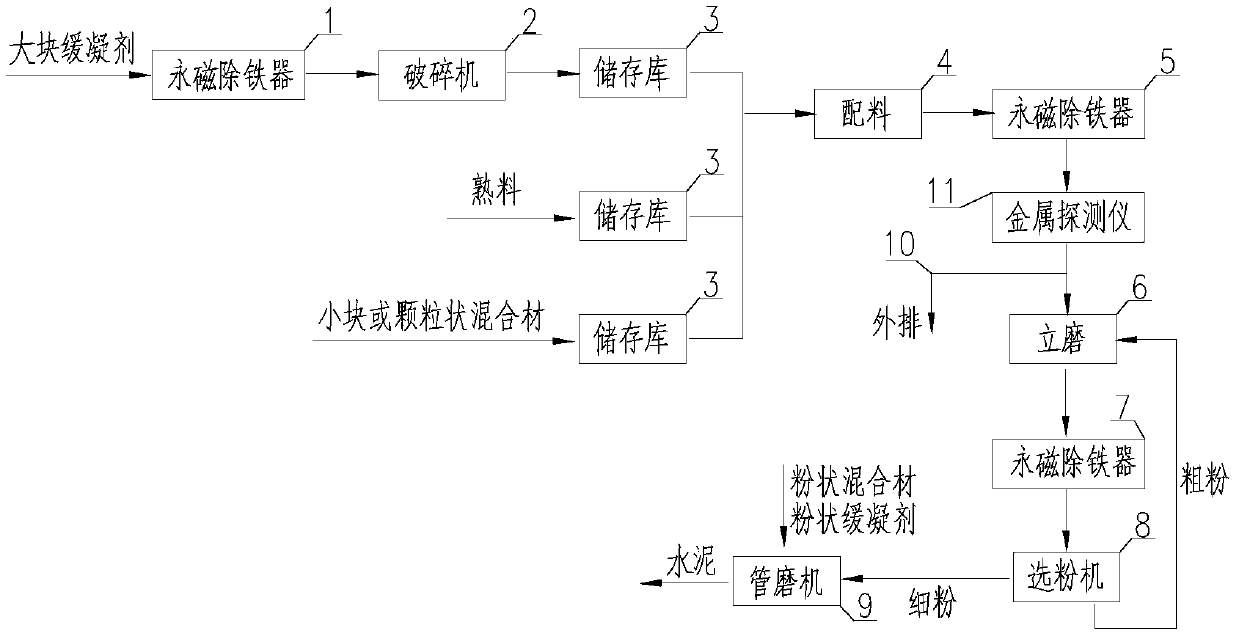

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] Such as Figure 1 to Figure 6 Shown, a kind of cement preparation method comprises the following steps:

[0037] The first step: the bulk mixed material and retarder first pass through the first permanent magnetic iron remover 1 to remove some magnetic substances such as magnets, and then pass through the crusher 2 to crush the bulk material to a particle size below 40mm, and then put them into the storage warehouse 3;

[0038] The first permanent magnetic iron remover 1 removes the magnetic substance (magnetic metal substance) in the bulk mixed material and retarder, which can reduce the damage of the metal magnetic substance to the crusher and subsequent grinding equipment.

[0039] Step 2: Put the clinker (at present, the particle size of the clinker is basically less than 25mm), small pieces or granular mixed materials directly into the storage warehouse 3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com