A cantilever roadheader cutting head suitable for hard rock

A technology of cantilever roadheader and cutting head, which is applied in the field of cutting head, can solve the problems of low penetration of hard rock, poor ability of breaking rock and digging, and excessive wear of picks, so as to increase the penetration of picks , increase work efficiency, enhance the effect of material guiding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment and accompanying drawing, further describe the present invention.

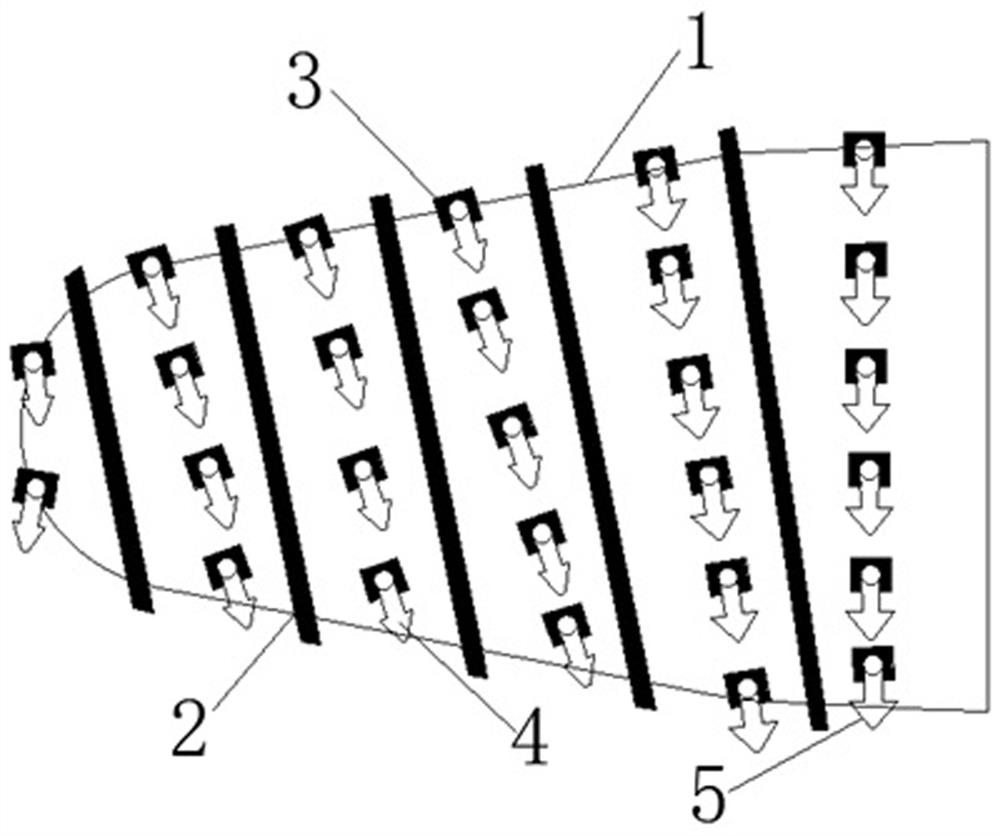

[0017] Such as figure 1 , The embodiment of the present invention includes a cutting head main body 1, a material guide plate 2 and a tooth seat 3 are welded on the cutting head main body 1, and a pick-shaped pick is installed on the tooth seat 3.

[0018] The material guide plate 2 and the gear seat 3 are arranged in a helical form along the main body of the cutting head 1 from the front end to the tail end respectively, wherein about 70% of the length of the front part of the main body 1 of the cutting head is a double helix line form, and the rest of the range is in the form of a single helix.

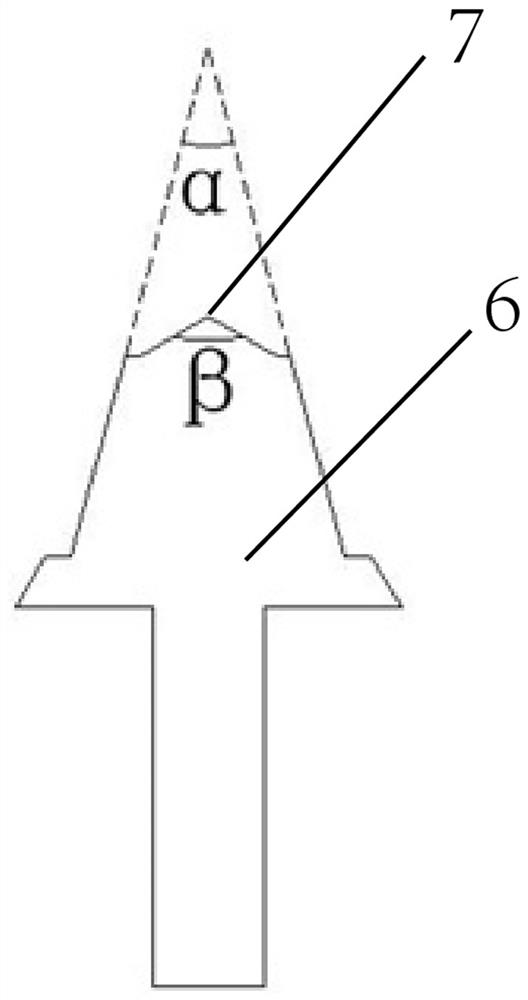

[0019] Such as figure 2 , the front end of the pick has a conical alloy head 6, and the front end of the conical alloy head 6 has a conical head 7.

[0020] The picks within the length range of about 70% (accounting for 70% of the whole body of the cutting head) of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com