Novel automotive silencing equipment

A technology for noise reduction equipment and vehicles, which is applied to mechanical equipment, noise reduction devices, engine components, etc., can solve the problems of poor low frequency noise noise reduction effect, single noise reduction method, and narrow application range, and achieves fast noise reduction, Improve noise reduction efficiency and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

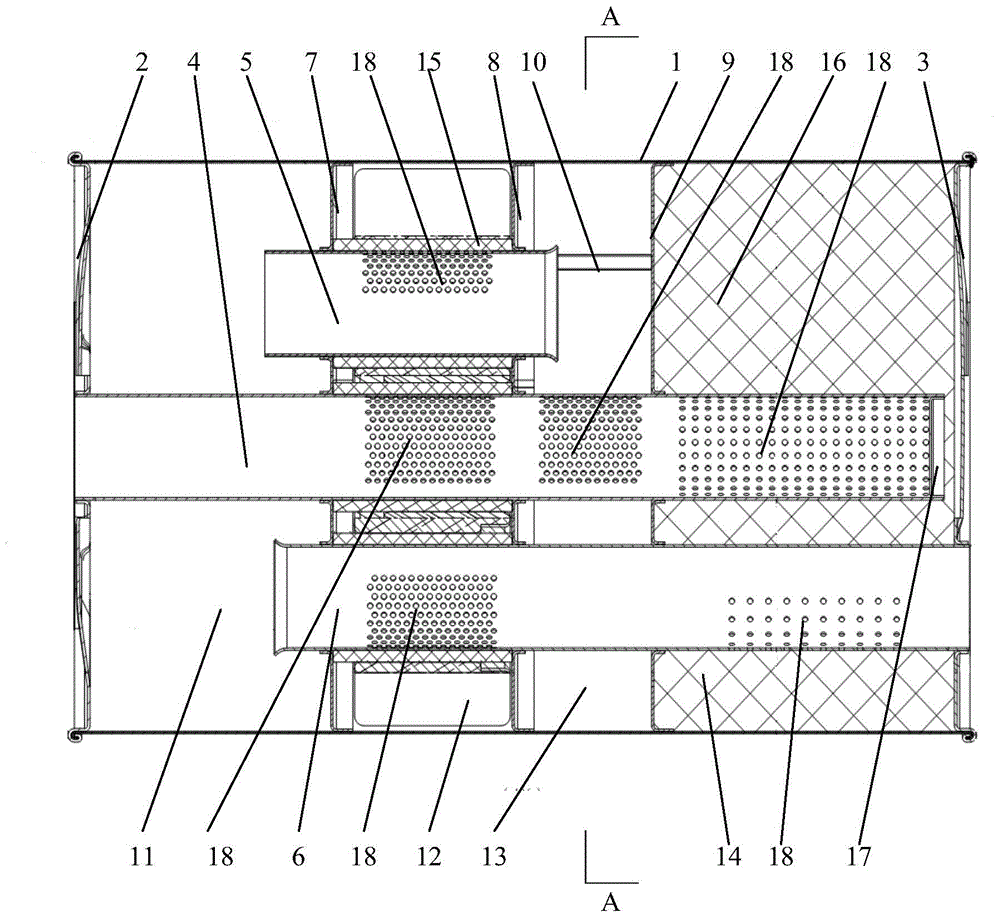

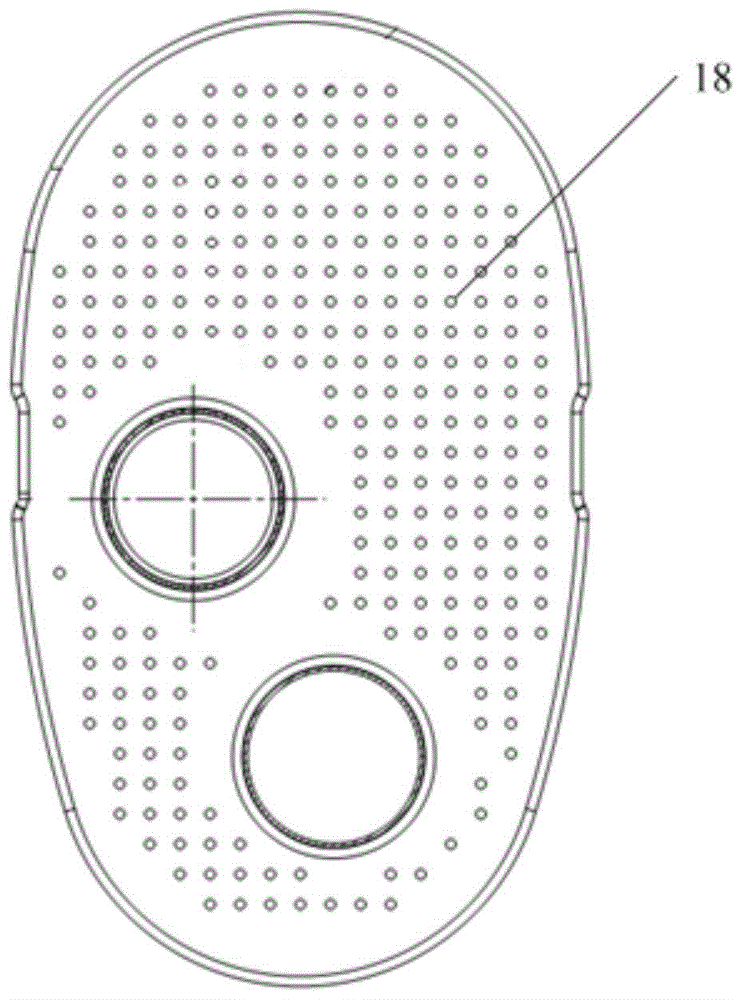

[0022] like Figure 1-Figure 2 As shown, this embodiment includes a housing 1, a front end cover 2, a rear end cover 3, an air intake pipe 4, a buffer pipe 5, an air outlet pipe 6, a first partition 7, a second partition 8, a third partition 9, Partition support 10, first chamber 11, second chamber 12, third chamber 13, fourth chamber 14, sound-absorbing cotton 15 and glass fiber cotton 16, the two ends of the housing 1 are respectively provided with front end covers 2 And the rear end cover 3, the material of the housing 1, the front end cover 2 and the rear end cover 3 are all stainless steel materials, and the inside of the housing 1 is successively provided with a first partition 7, a second partition 8 and a third partition 9, The first dividing plate 7 and the second dividing plate 8 are all sound-absorbing dividing plates, and the second dividing plate 8 is connected with the third dividing plate 9 by the dividing plate support 10, and the first dividing plate 7, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com