Double-cavity resonant type muffler

A muffler and resonant cavity technology, applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problem of single frequency range, etc., achieve the effects of suppressing noise, improving space utilization, and good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

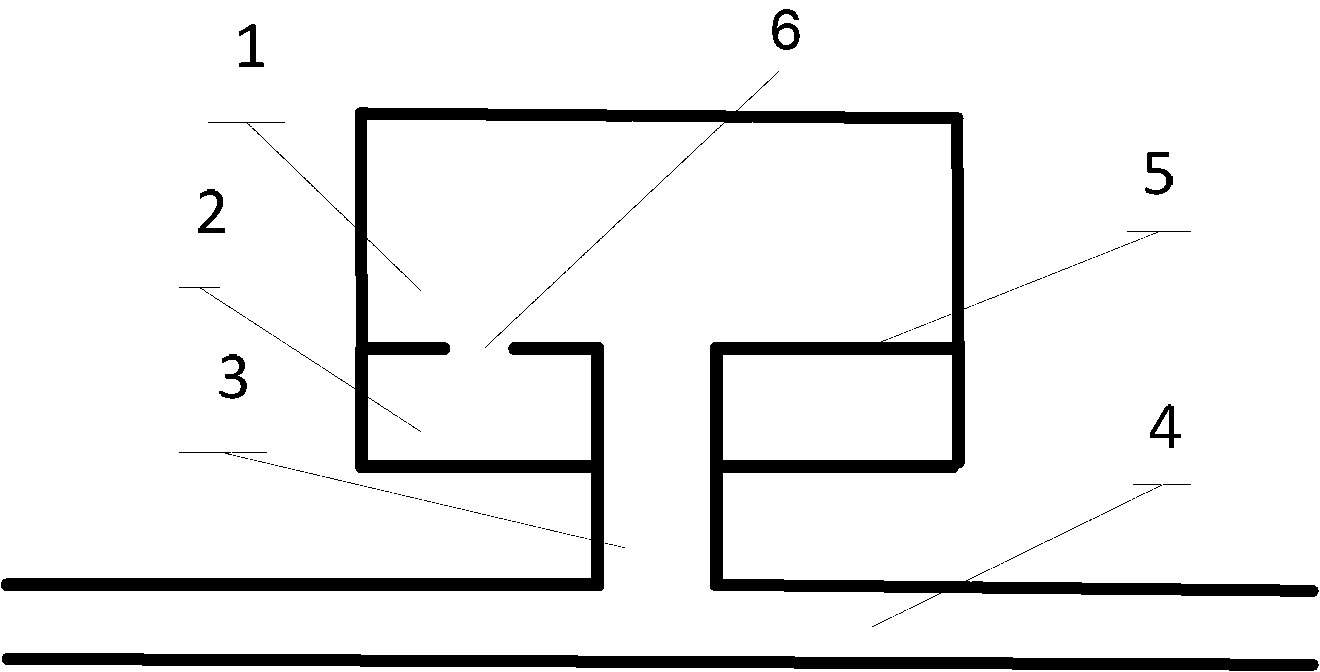

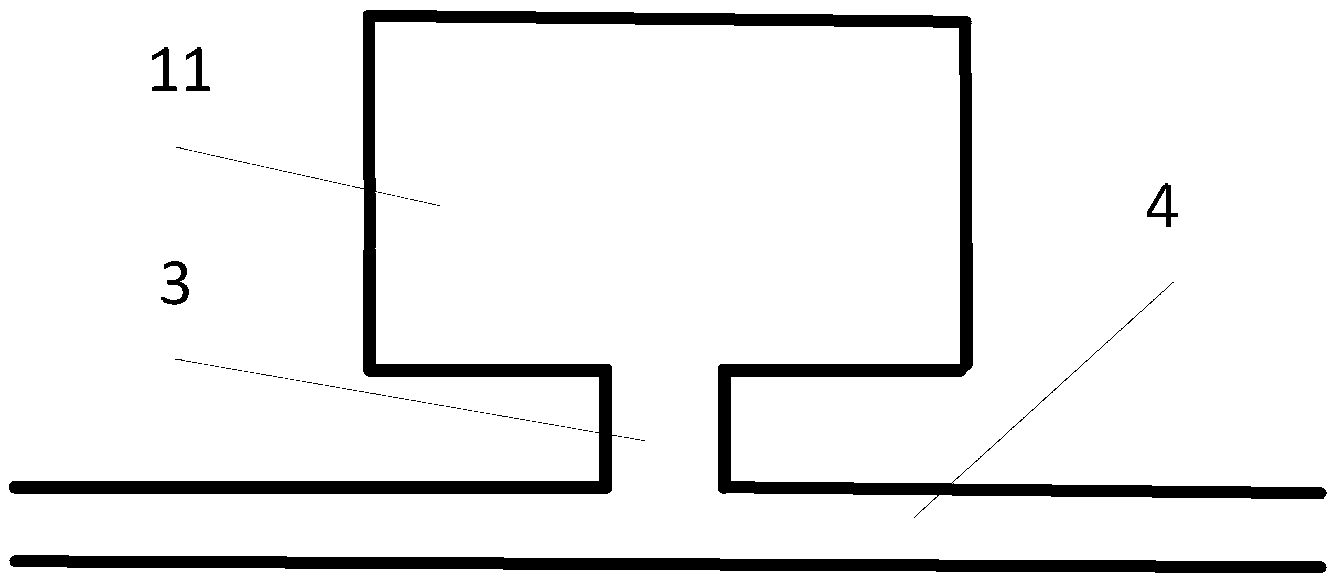

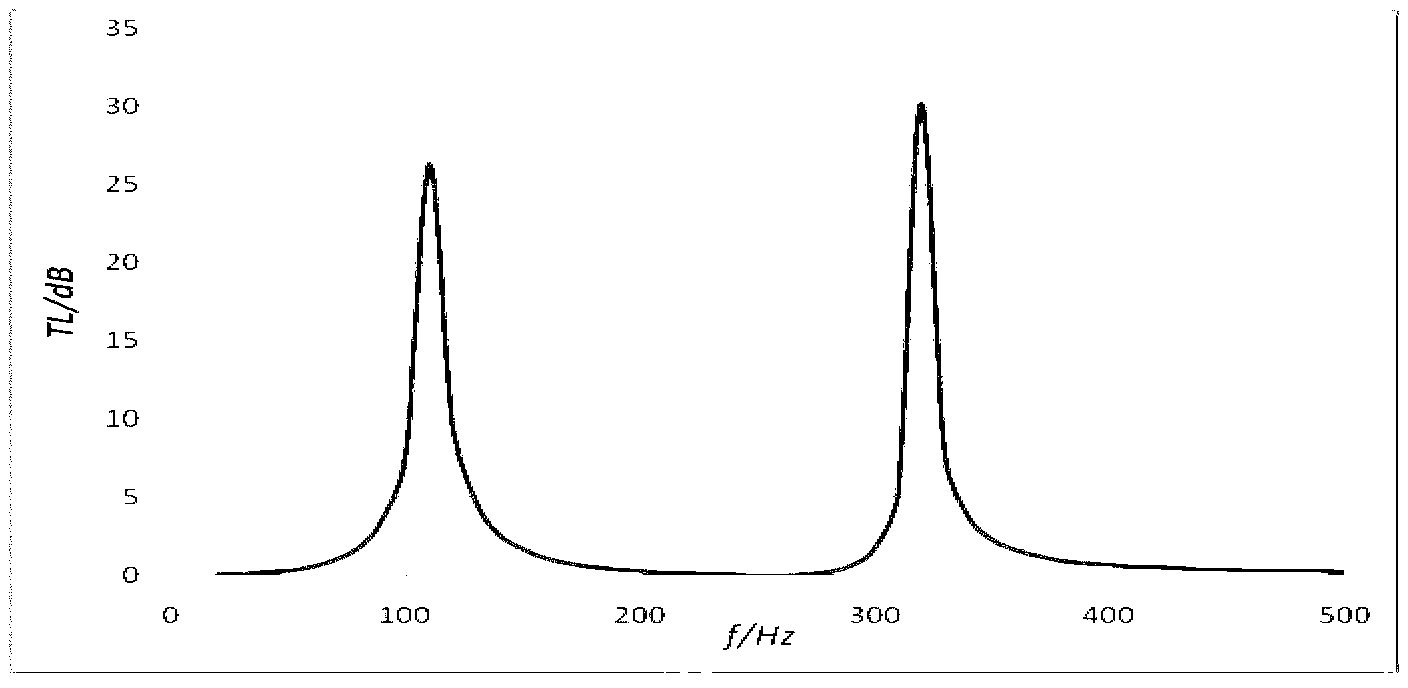

[0030] figure 2 It is a structural schematic diagram of the present invention, image 3 It is the transmission loss diagram of the example of the present invention, as shown in the figure: the dual-cavity resonance muffler provided by the present invention includes a main pipe, a side branch pipe, an upper resonant cavity and a lower resonant cavity; the upper resonant cavity and the lower resonant cavity are connected in series The method is set on the side branch pipeline connected to the main pipeline.

[0031] The upper resonance cavity is connected with the main pipeline through a side branch pipeline.

[0032] The lower resonant cavity is connected with the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com