Patents

Literature

90results about How to "Good noise reduction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automobile noise reduction system with one-fourth wavelength pipes combined with Helmholtz silencer

InactiveCN103790743AIncreased transmission lossSpeed up the flowAir cleaner and silencer combinationAir filtrationAir filter

The invention discloses an automobile noise reduction system with one-fourth wavelength pipes combined with a Helmholtz silencer, and belongs to the technical field of environment control and improvement in order to solve the problems that an existing automobile noise reduction system is high in manufacturing cost, poor in noise elimination effect, high in air inlet resistance and consumed power, poor in fuel economy and not suitable for various automobiles. The Helmholtz silencer is communicated with the side wall of a front air inlet guide pipe, the front air inlet guide pipe is communicated with an air filter, an air filtering net is arranged in the air filter, the air filter is communicated with a first rear air inlet guide pipe, the first rear air inlet guide pipe is communicated with a second rear air inlet guide pipe through a flexible connecting pipe, an air throttling valve is arranged on the second rear air inlet guide pipe, the second rear air inlet guide pipe is communicated with an air inlet header pipe, the air inlet header pipe is communicated with an air inlet manifold, and one ends of the two one fourth wavelength pipes are both connected and communicated with the side wall of the first rear air inlet guide pipe. According to the system, while power property and economy of an automobile are maintained, the noise of the whole automobile can be lowered particularly, the environment quality can be improved, and the system is suitable for various automobiles.

Owner:HEILONGJIANG INST OF TECH

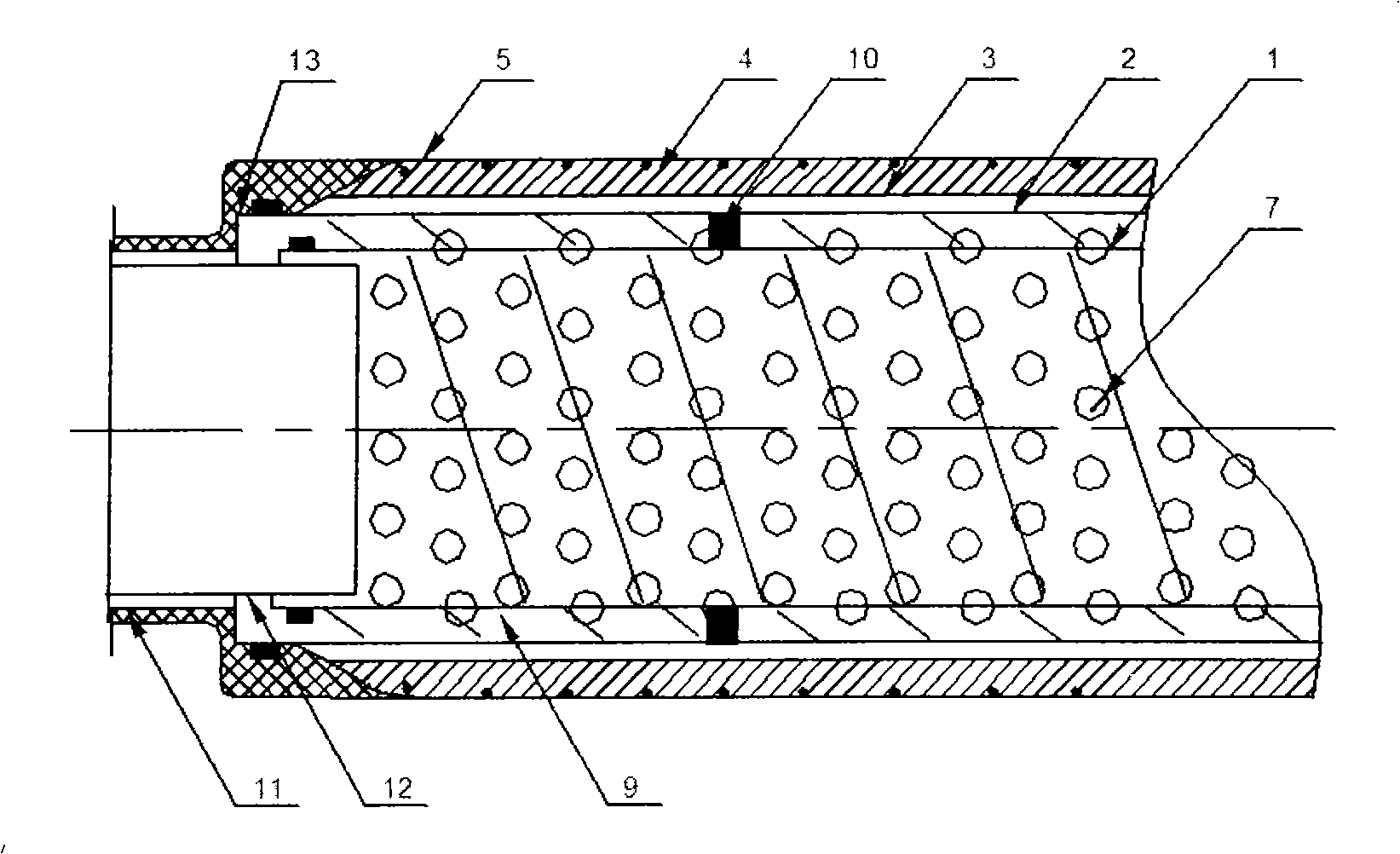

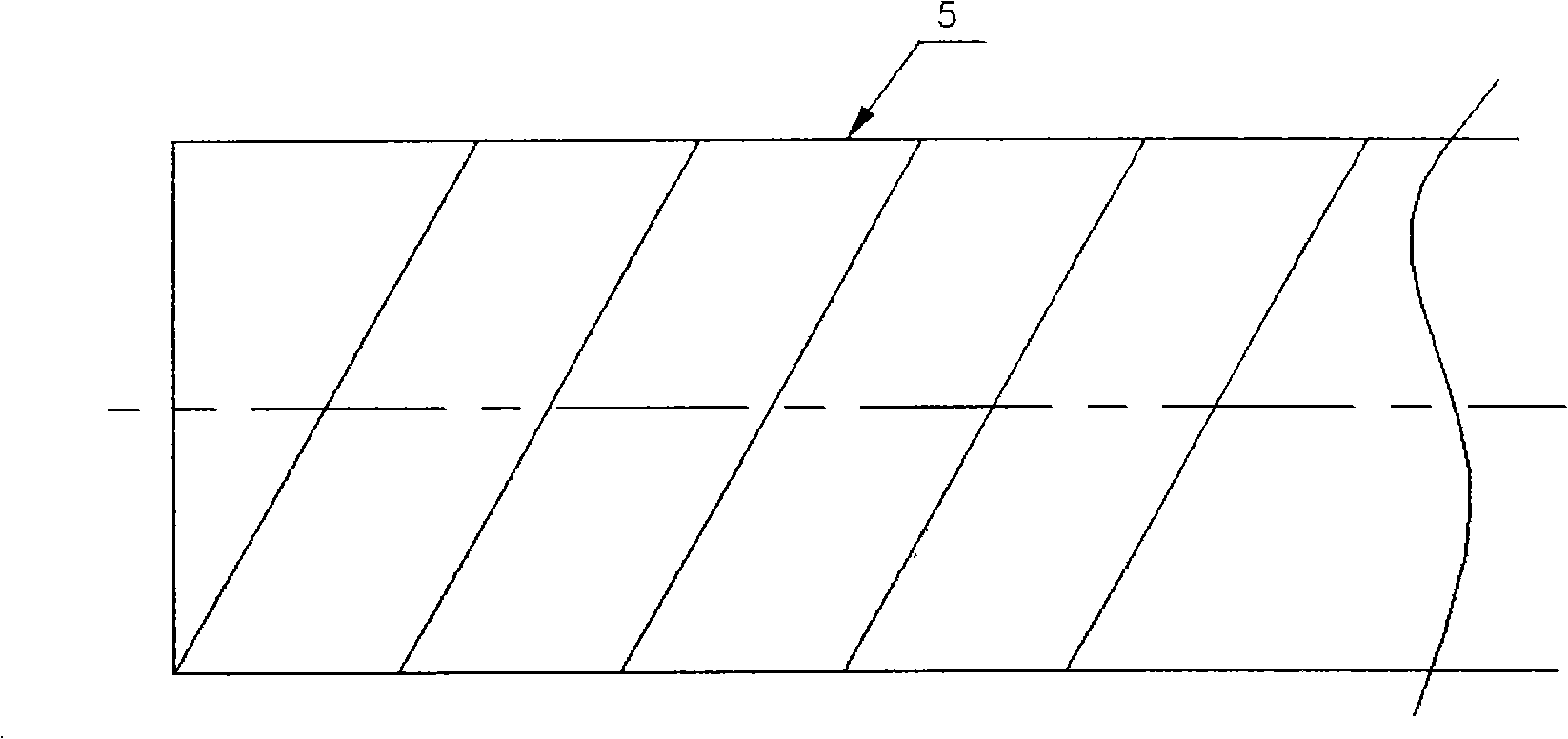

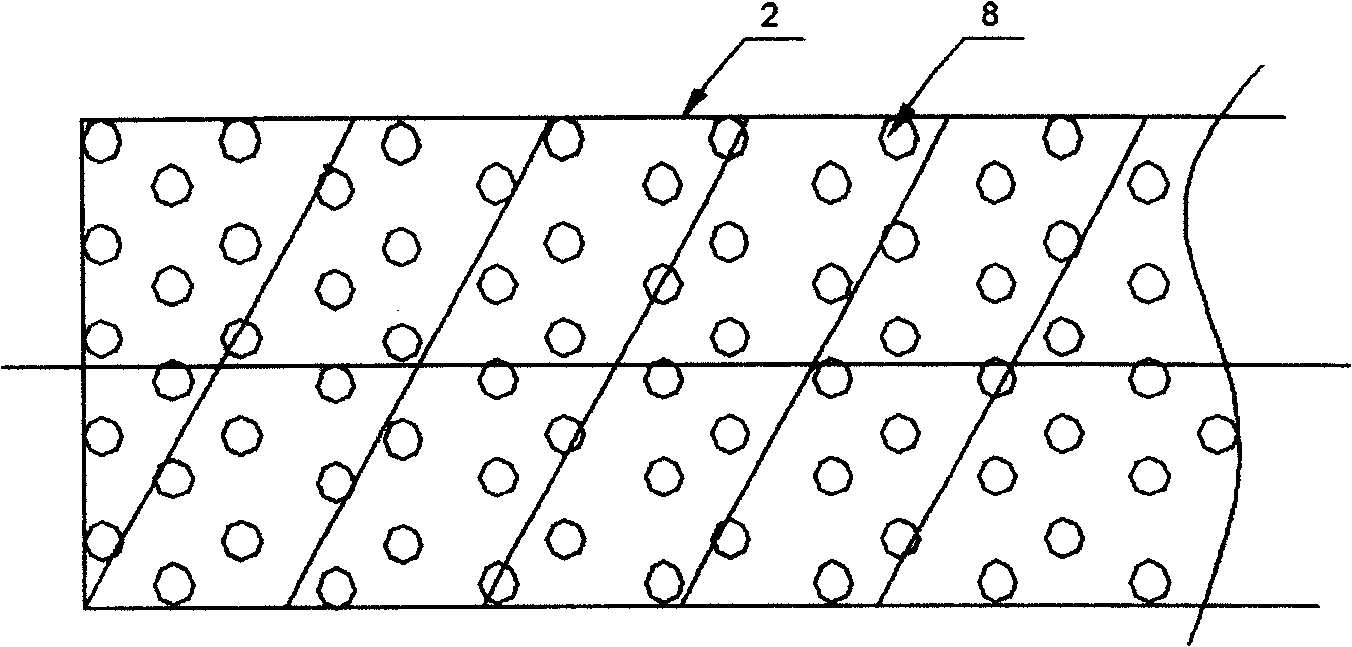

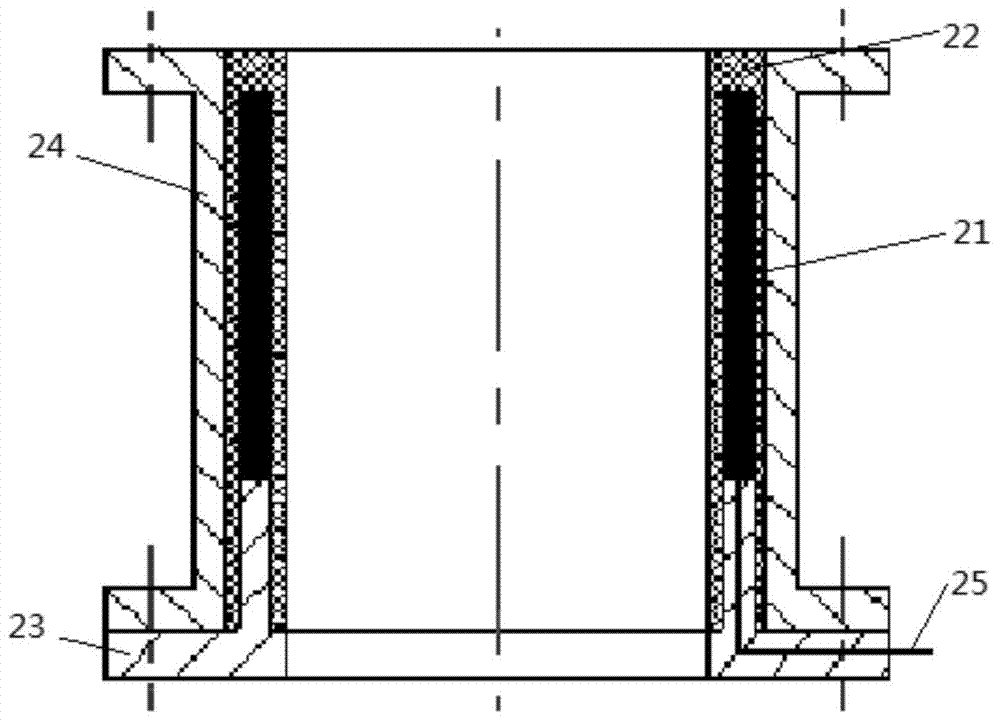

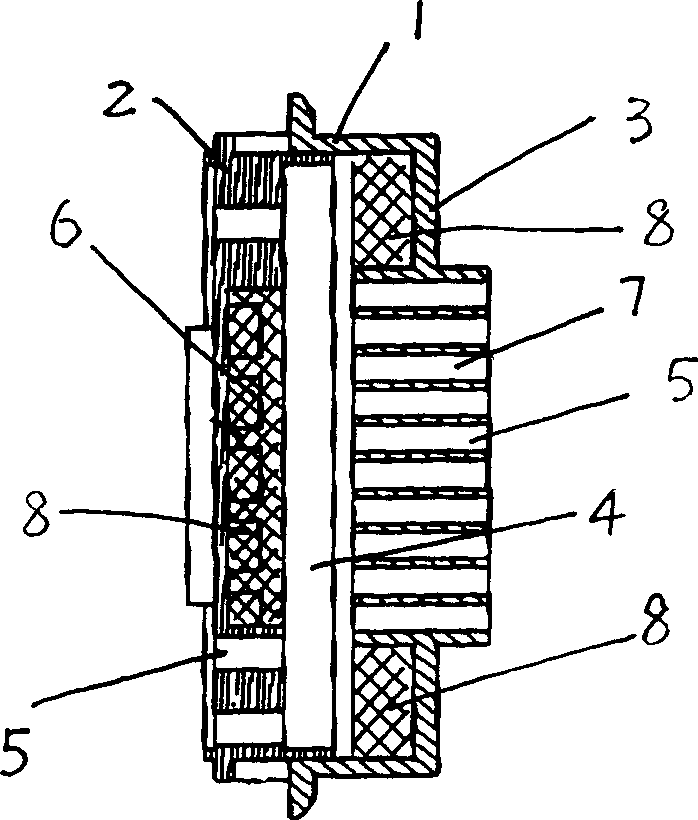

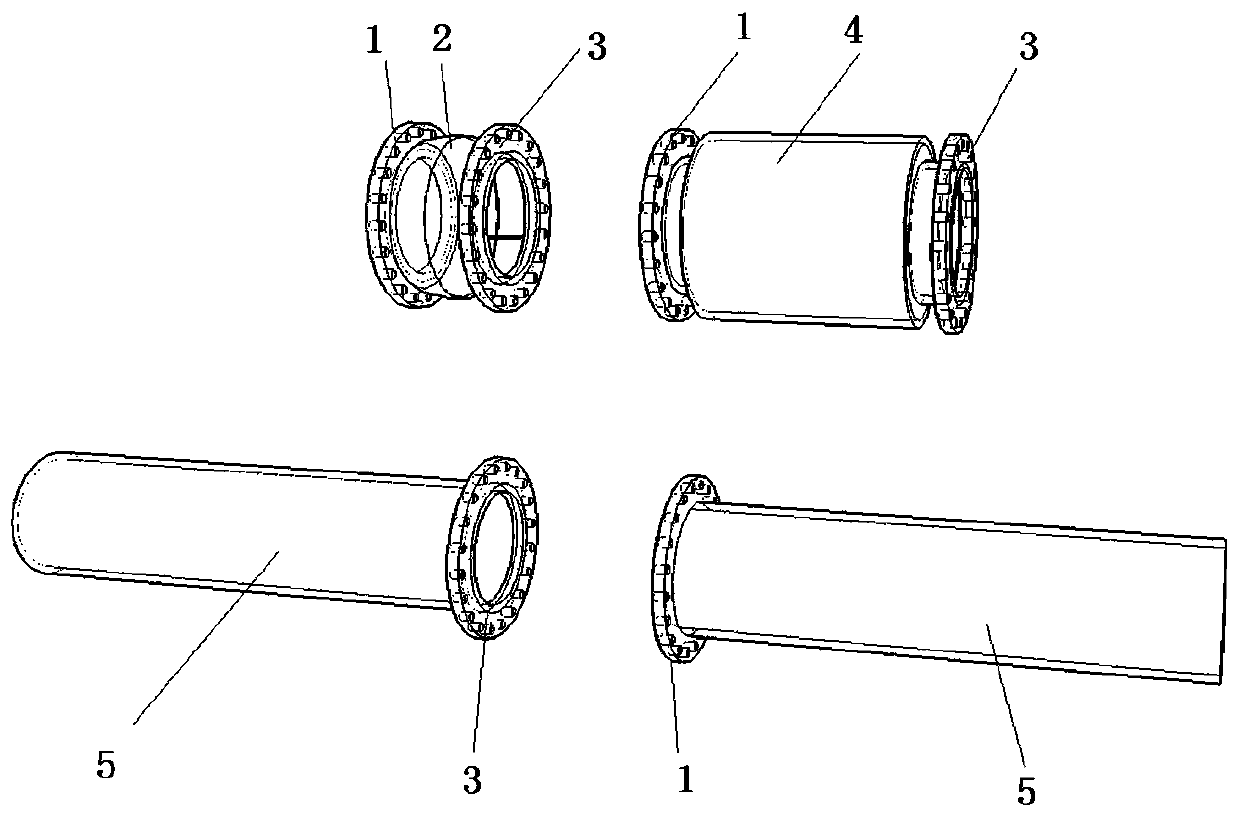

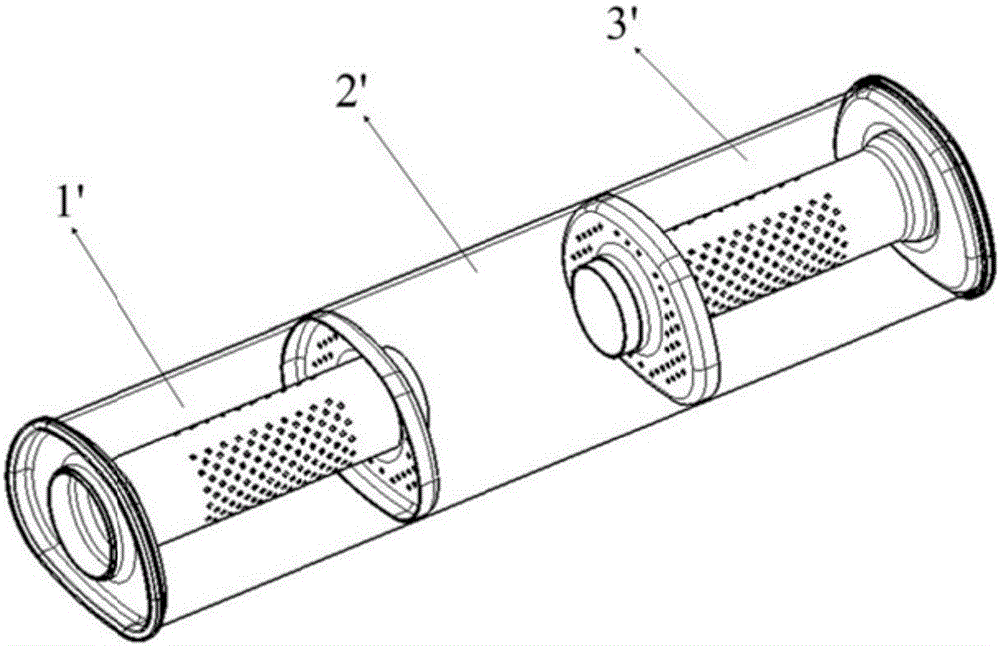

Flexible silencer

The invention discloses a flexible silencer which comprises a termination flange, a silencing internal hose, a silencing external hose, an isolation layer, a sound absorbent lining and a composite hose. The flexible silencer is characterized in that: the silencing internal hose is densely equipped with a plurality of silencing holes, the external part of the silencing internal hose is covered with the external silencing hose; the silencing external hose is densely equipped with a plurality of silencing holes, a sound absorbent cavity is positioned between the silencing internal hose and the silencing external hose, a plurality of fixing rings are arranged in the sound absorbent cavity in interval, the external part of the silencing external hose is equipped with the isolation layer, the external part of the isolation layer is equipped with the sound absorbent lining, the external part of the sound absorbent lining is covered with the composite hose, and the silencing internal hose and the internal-circular connector of the termination flange are fixedly connected; the silencing external hose, the composite hose and the connector of the external-circular turned-edge connector of the termination flange are fixedly connected mutually. The flexible silencer is made of the flexible material which can be bent, the sound absorbent material and the reasonable silence structure, the invention can be configured according to the environment condition, and has the advantages of low cost, good silence effect and convenient installation.

Owner:周菊明

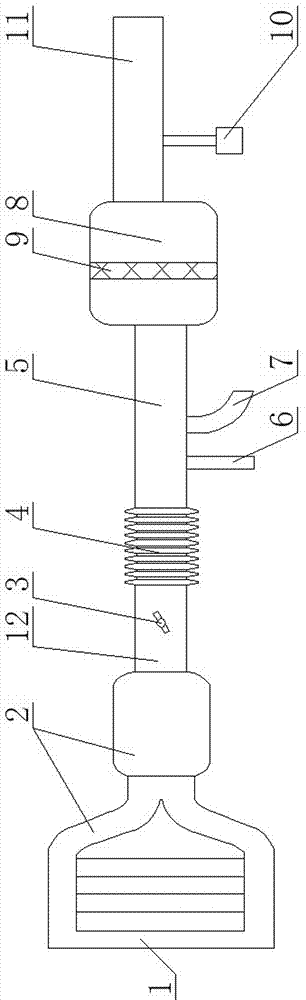

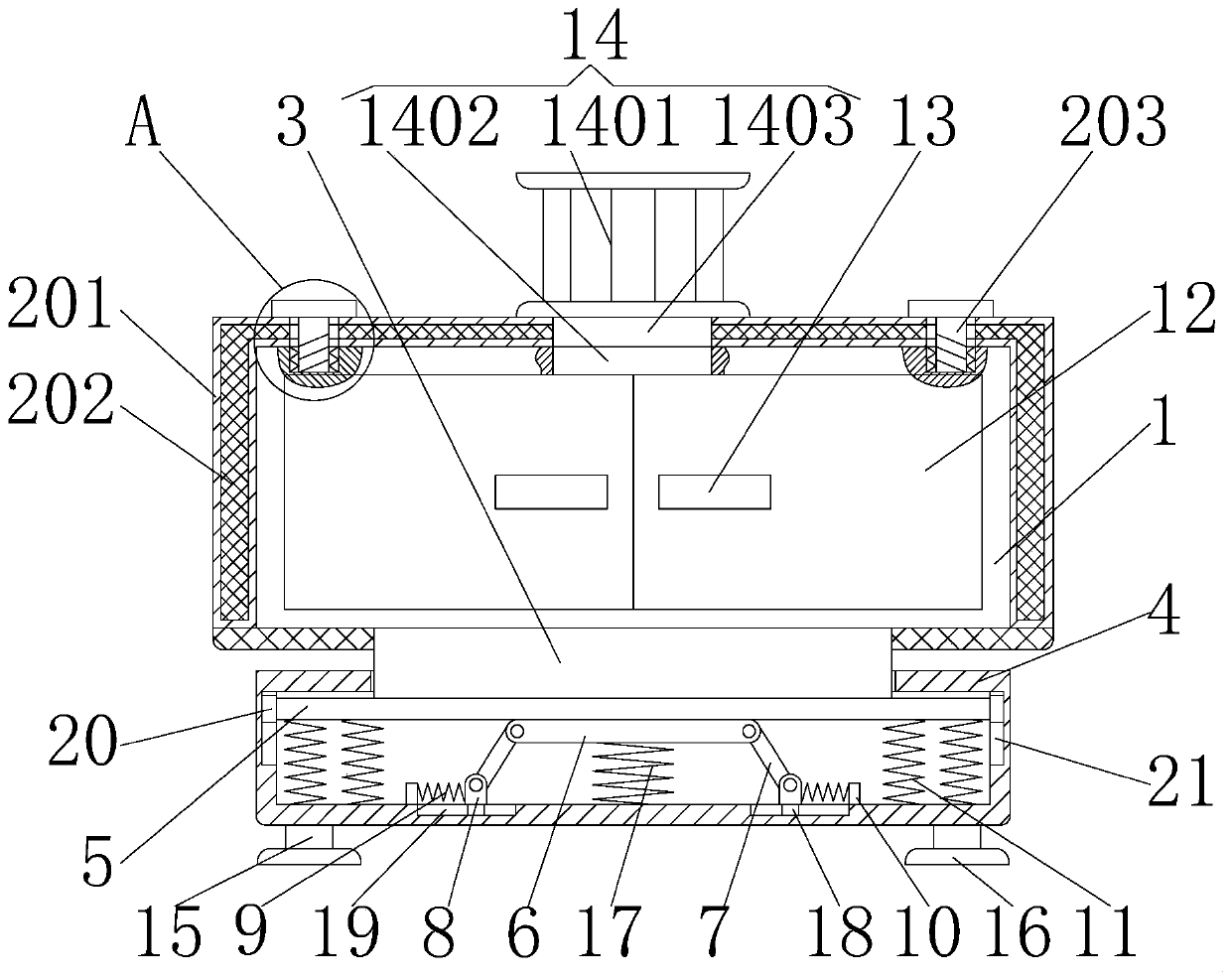

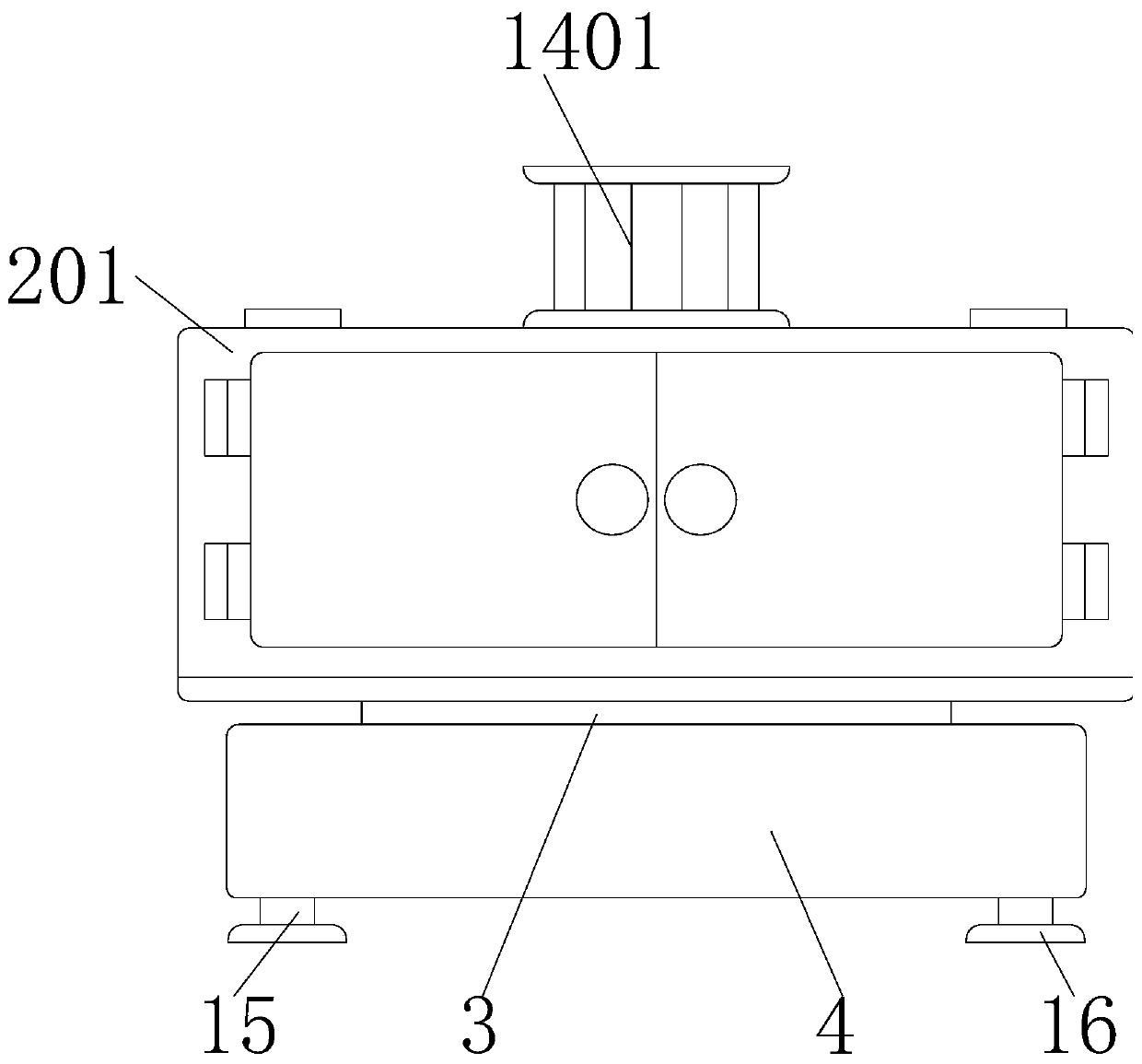

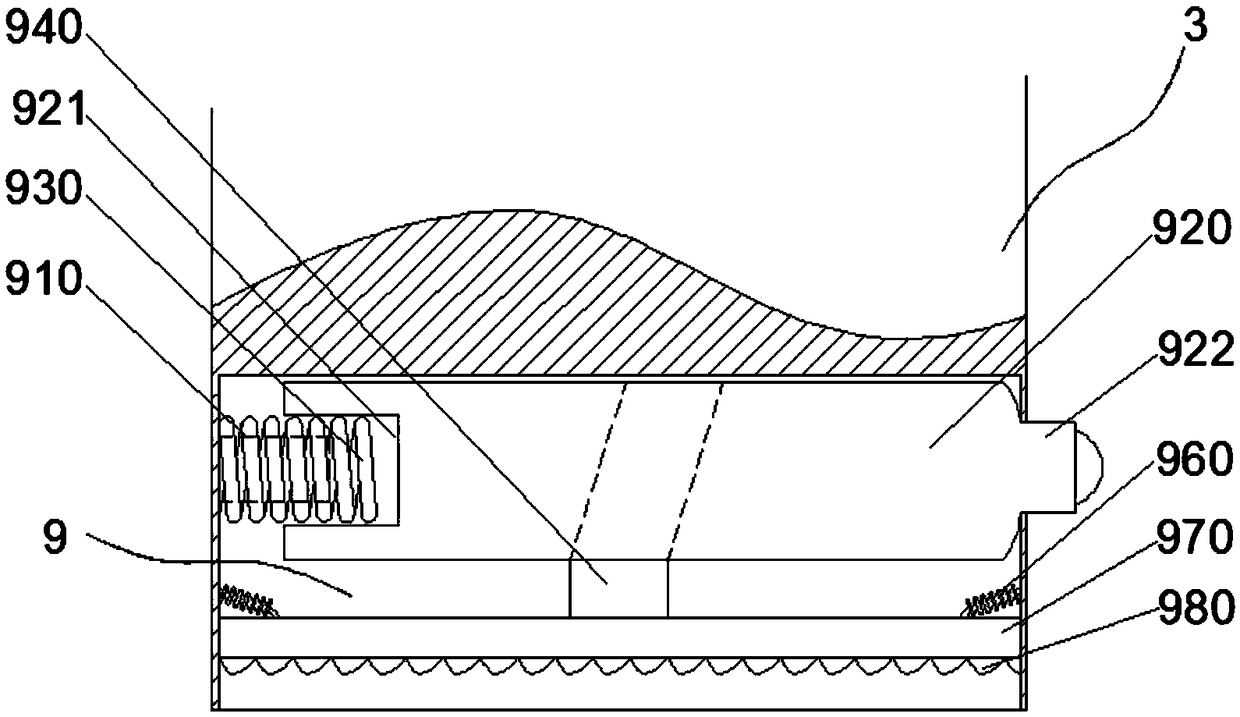

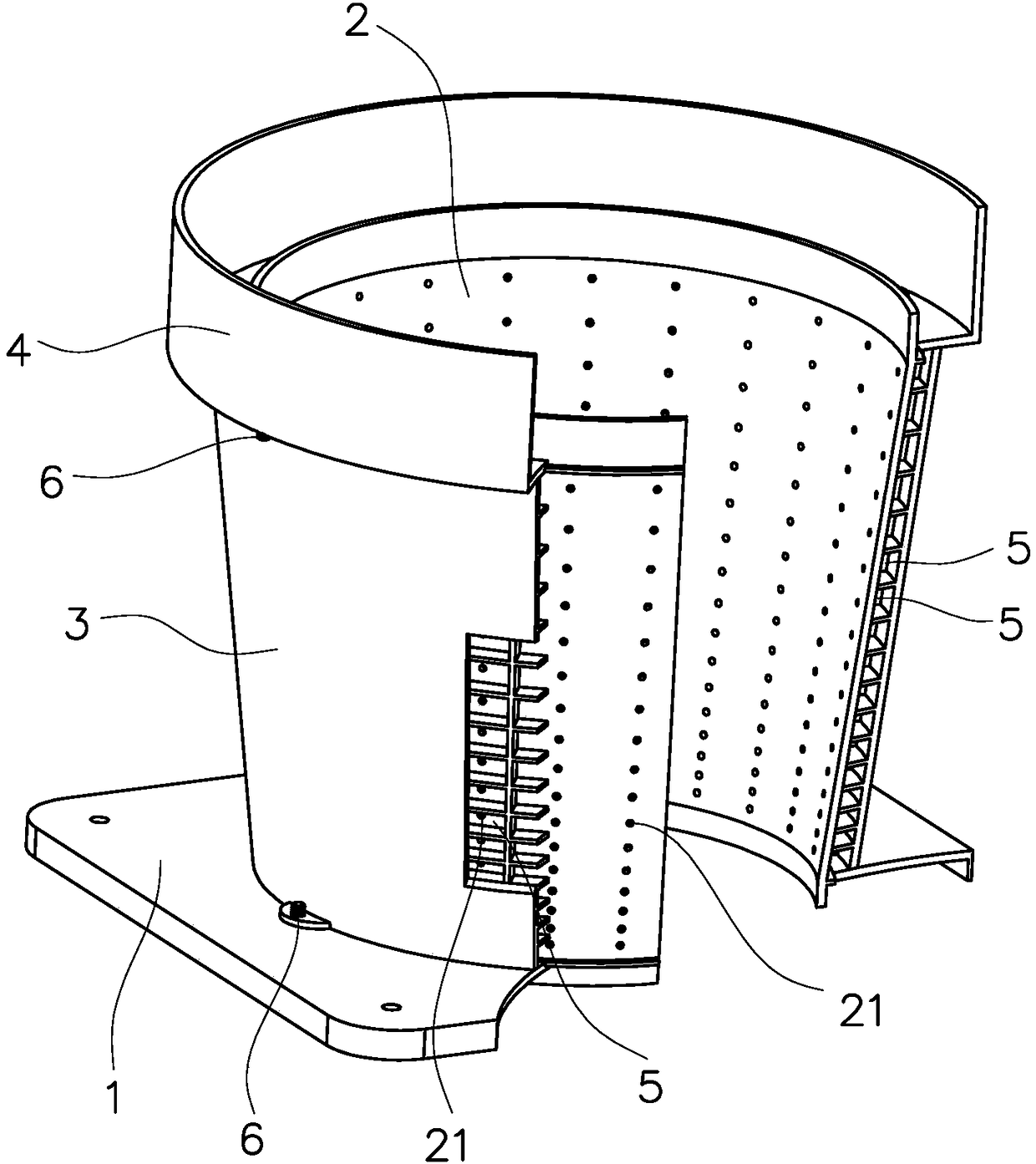

Silent diesel generator set silencing mechanism

InactiveCN109882290AGood noise reduction effectProtect environmentMachine framesNon-rotating vibration suppressionEngineeringDiesel generator

The invention discloses a silent diesel generator set silencing mechanism, which comprises a generator set body, wherein the surface of the generator set body is sleeved with a silencing mechanism; the bottom of the generator set body is fixedly connected with a positioning block; the bottom of the positioning block is provided with a silencing damping box; the bottom of the positioning block penetrates through the siliencing damping box and extends to the interior of the siliencing damping box so as to connect with a damping plate fixedly; and the bottom of the damping plate is fixedly connected with a lifting connecting block. Through the cooperation of the generator set body, the silencing mechanism, the silencing plate, a silencing filler, a limiting bolt, the positioning block, the silencing damping box, the silencing damping plate, the lifting connecting block, a first connecting rod, a connecting block, a first damping spring, a limiting block, a second damping spring, a cabinetdoor and a handle, the generator set body vibrates and drives to compress or extend the first damping spring and the second damping spring; and the vibration of the generator set body can be slown down through the first damping spring and the second damping spring.

Owner:JIANGSU TAIPU POWER MACHINERY

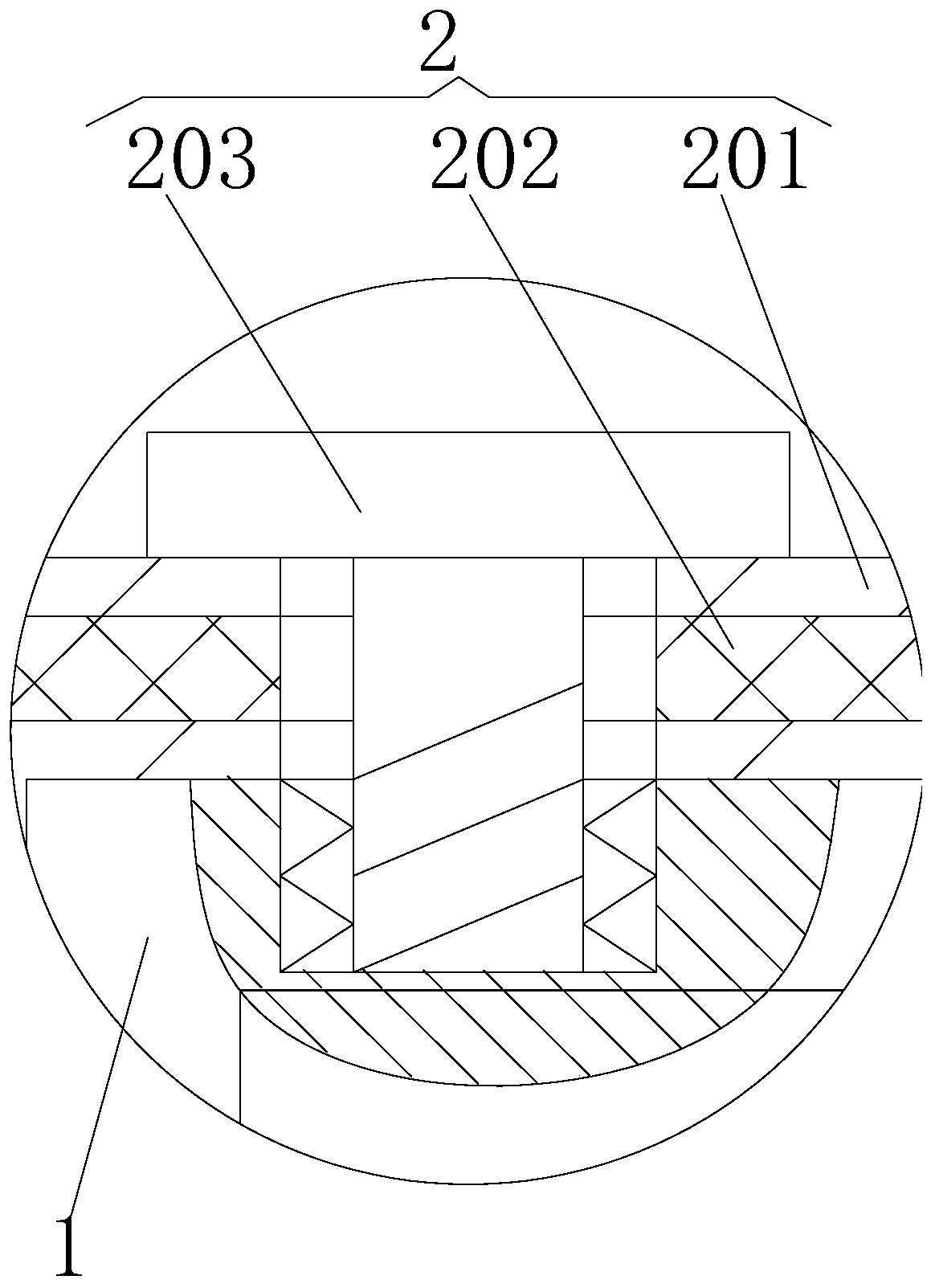

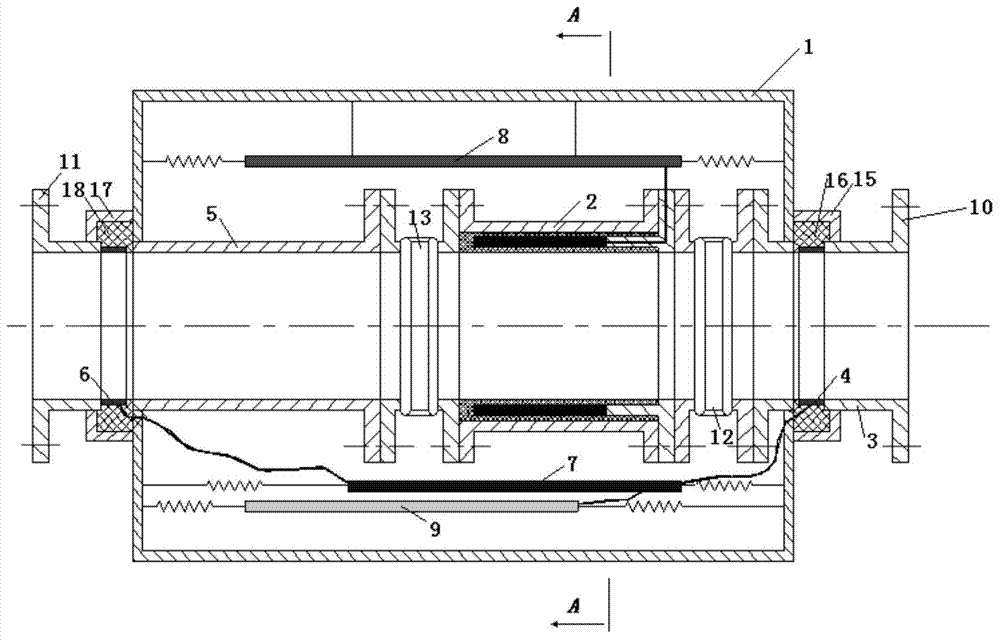

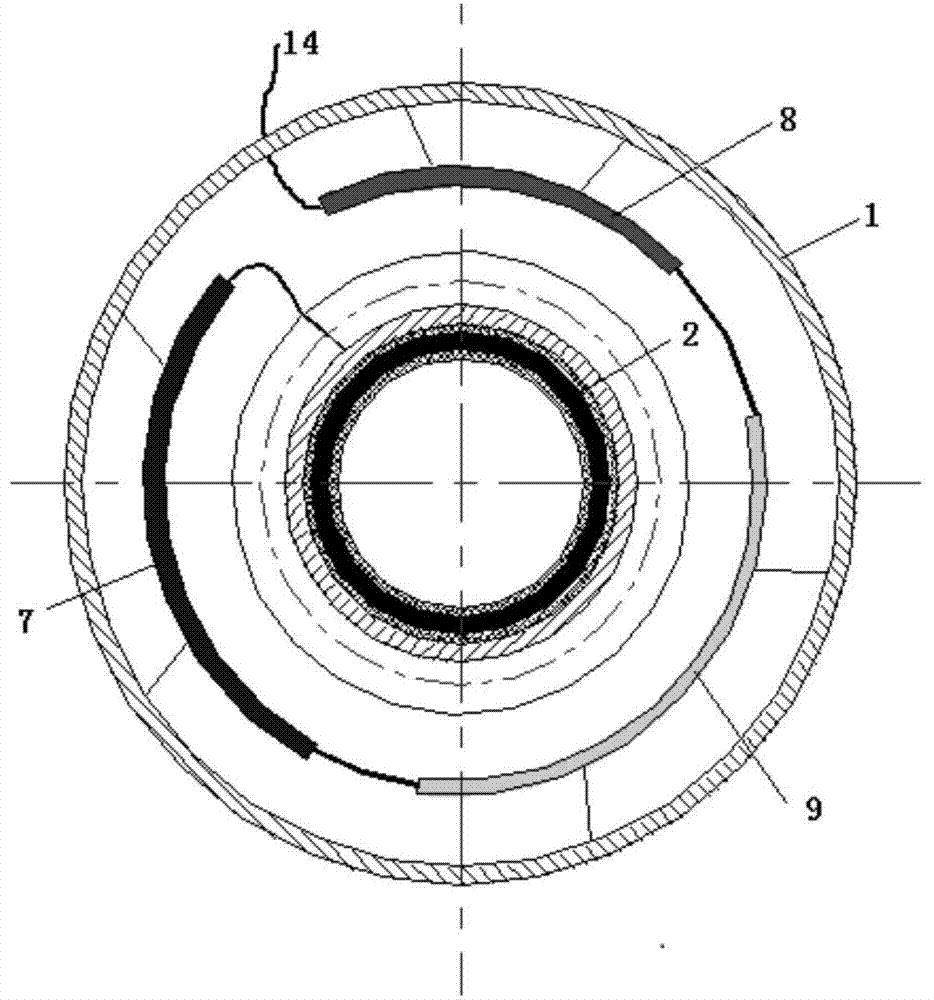

High-pressure liquid charging pipeline integrated active silencer

ActiveCN104500904AAnechoic frequency bandwidthGood noise reduction effectPipe elementsCeramicElectricity

The invention provides a high-pressure liquid charging pipeline integrated active silencer. The high-pressure liquid charging pipeline integrated active silencer mainly comprises a cylindrical housing, an actuator arranged in the middle of the housing and based on tubular piezoelectric ceramics, sensors on the inner side of upstream and downstream pipe sections, and a signal pick-up and conditioning system, a power amplifying system and a DSP-based high-speed signal processing system between the housing and the pipe section of the actuator. The high-pressure liquid charging pipeline integrated active silencer is usable for a high-pressure liquid charging pipeline, based on the tubular piezoelectric ceramic-based actuator, and highly integrated. The active pipeline silencer is capable of providing counter noise to counteract the original noise in the pipeline according to the frequency, the size and the phase of the internal flow noise in the pipeline measured in real time, and therefore, the silencer is capable of adapting to the change of the noise frequency, wide in silencing bandwidth and good in silencing effect.

Owner:HARBIN ENG UNIV

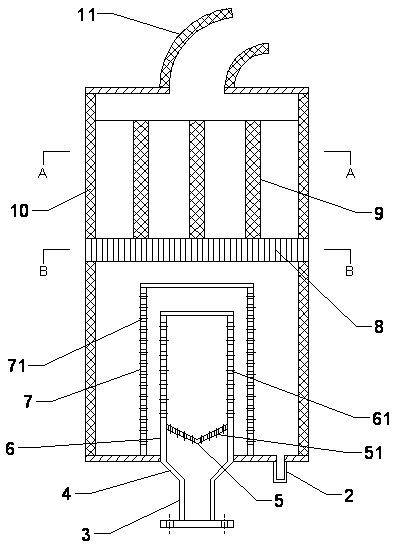

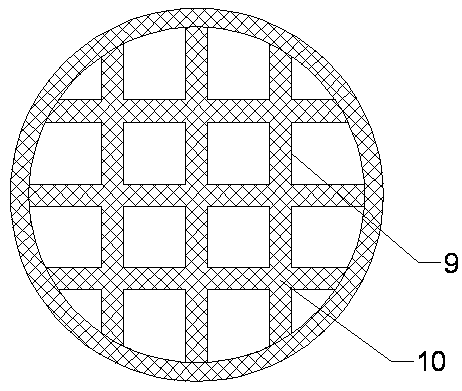

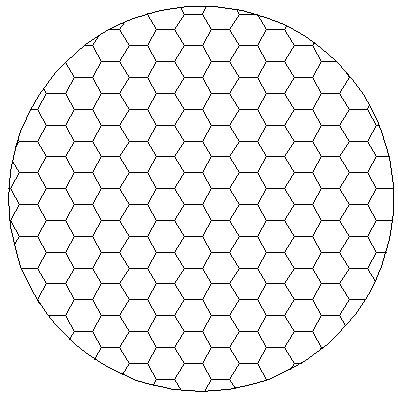

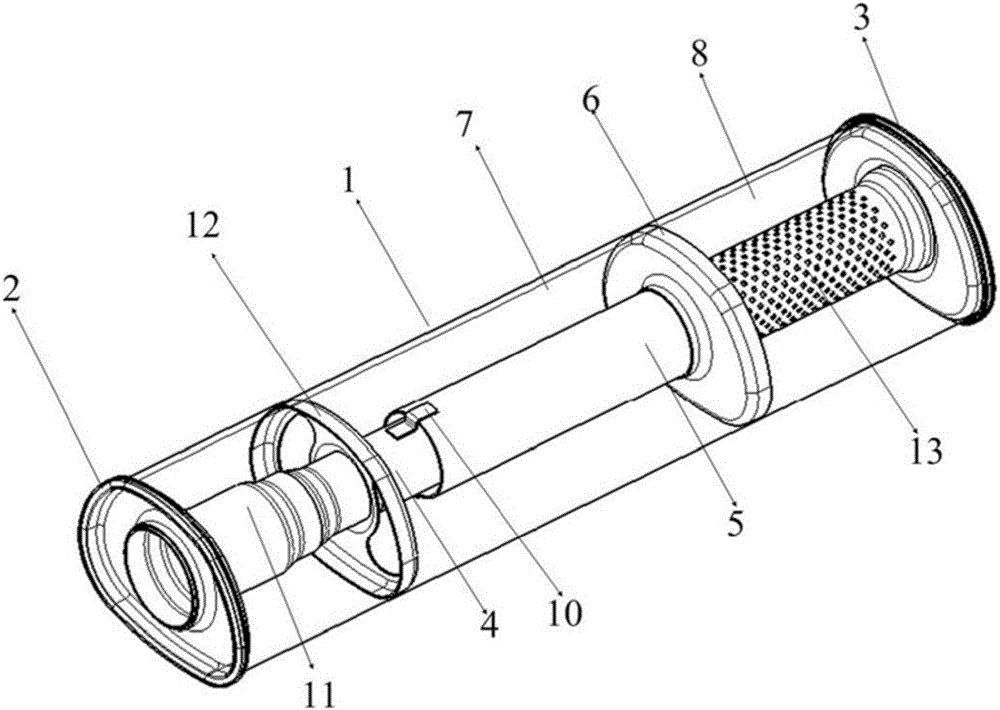

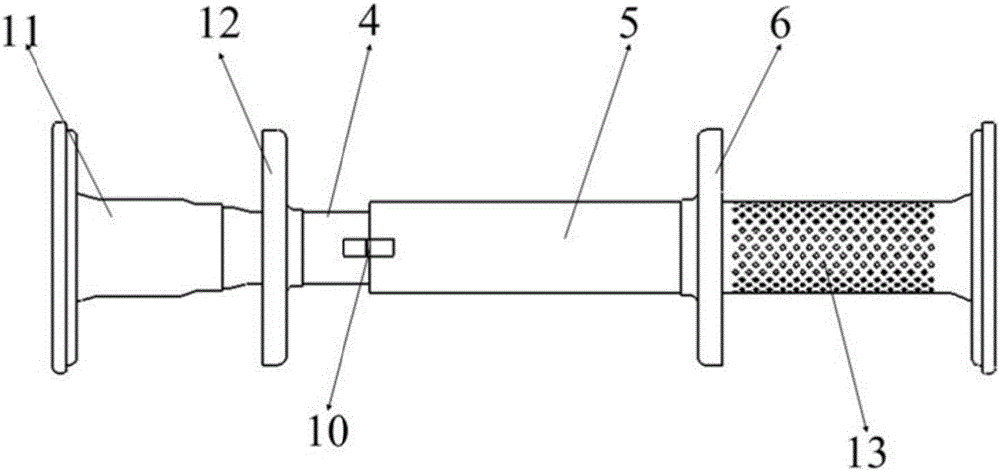

Composite exhausting evacuation silencer

The invention discloses a composite exhausting evacuation silencer which is composed of an intake section, a noise elimination section and an exhausting section. The intake section is composed of a silencer cylinder, a first-stage silencing device, a second-stage silencing device and a fairing, wherein the first-stage silencing device includes a throttling pressure-reducing pipe, a small hole injection pipe and a tapered hole plate, the second-stage silencing device is a honeycomb resistive silencing section, the honeycomb resistive silencing section is formed by a plurality of silencing pieces which are vertically arranged, a bottom opening of the silencer cylinder is connected with the intake section, the intake section is formed by a conical increasing coupling and an intake straight tube, an exhaust section is connected to a top opening of the silencer cylinder, and the exhaust section is an exhaust bend with the inner wall provided with a layer of resistive sound absorbing material in an attached manner. The composite exhausting evacuation silencer comprehensively utilizes a plurality of silencing principles to perform noise reduction processing on the released air, and has the advantages of the large noise reduction amount, the wide noise elimination frequency bandwidth, the wide application range, more smooth airflow discharge and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Air suction silencer

ActiveCN103590999AIncrease flow resistanceIncrease lossPositive displacement pump componentsPositive-displacement liquid enginesAir chamberAerospace engineering

The invention discloses an air suction silencer which comprises a silencer shell. An upper air chamber and a lower air chamber are arranged in the silencer shell, and the lower air chamber is divided into a left lower air chamber and a right lower air chamber by a first partition plate; an air inlet and an exhaust port are formed in side surfaces of the silencer shell, the air inlet is communicated with the left lower air chamber, and the exhaust port is communicated with the upper air chamber; the left lower air chamber is communicated with the right lower air chamber via a first ventilating pipeline, and a port of the first ventilating pipeline extends into the left lower air chamber and faces the air inlet; the right lower air chamber is communicated with the upper air chamber via a second ventilating pipeline. The air suction silencer has the advantages that noise at different frequencies can be effectively eliminated by the aid of the air suction silencer, and the air suction silencer is good in silencing effect and compact in structure.

Owner:HANGZHOU QIANJIANG REFRIGERATION COMPRESSOR GRP CO LTD

Multi-cavity direct-through dual-layer perforating silencer capable of eliminating wide-band noise

InactiveCN106837625ACompact structureLarge noise reductionPipe elementsMachines/enginesTransfer matrixEngineering

The invention provides a multi-cavity direct-through dual-layer perforating silencer capable of eliminating wide-band noise. The multi-cavity direct-through dual-layer perforating silencer capable of eliminating the wide-band noise comprises an inlet end, a silencer body and an outlet end. At least two dual-layer perforating pipes are arranged in the silencer body. The dual-layer perforating pipes are connected in series and separated through partition plates. Each dual-layer perforating pipe comprises an outer pipe body and an inner pipe body, wherein through holes are distributed in the outer pipe body and the inner pipe body, a closed cavity is defined by the outer pipe body, the silencer body and the corresponding partition plate, and another closed cavity is defined by the inner pipe body, the outer pipe body and the corresponding partition plate. The silencer has the advantages that airflow circulates directly from the inlet end to the outlet end, the pressure loss is low, the size is small, the structure is simple, cost is low, and by designing the structure parameters through a multi-cavity one-dimension transfer matrix method, the high-amplitude and wide-band silencing effect can be achieved.

Owner:TONGJI UNIV

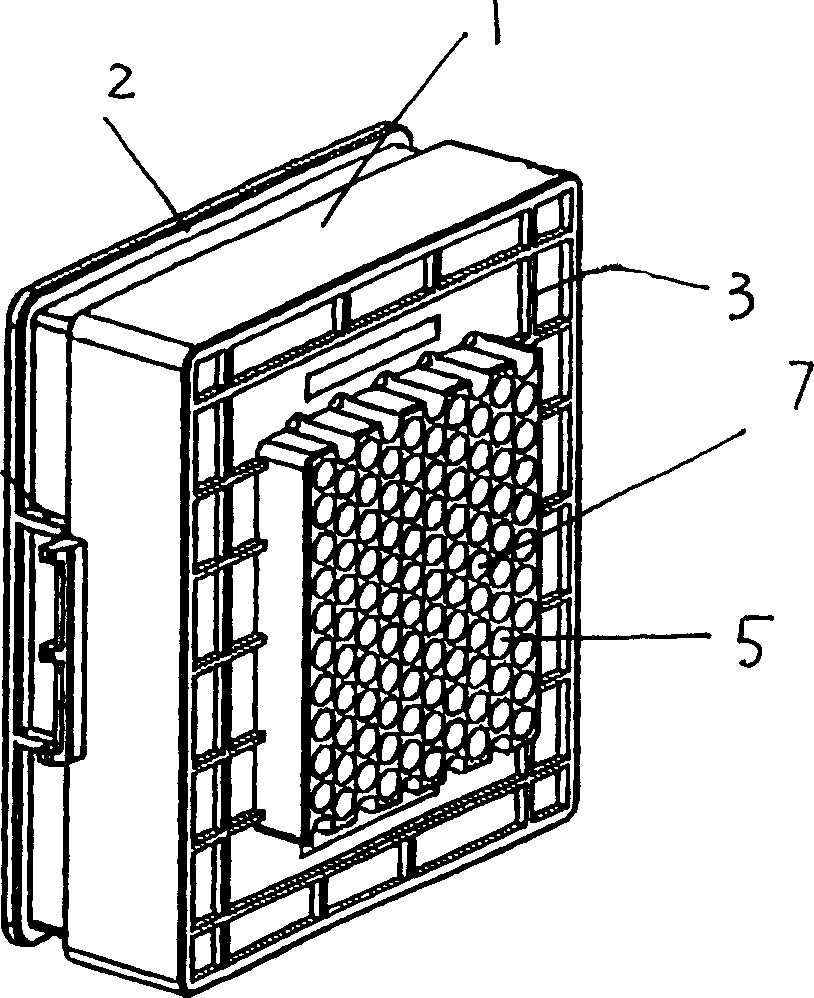

Quieter used in cleaner

InactiveCN1430935AReduce exhaust noiseGood noise reduction effectSuction cleanersEngineeringSmall hole

A silencer of cleaner is composed of an enclosed casing with wind inlet and outlet, a silencing cavity between said wind inlet and outlet, and the wind entrance region and exit region consisting of dense tubular exhaust pinhole, and features that the cross-section for wind entrance and exit is less than that of said silencing cavity. Its advantage is high effect on reducing noise.

Owner:KINGCLEAN ELECTRIC

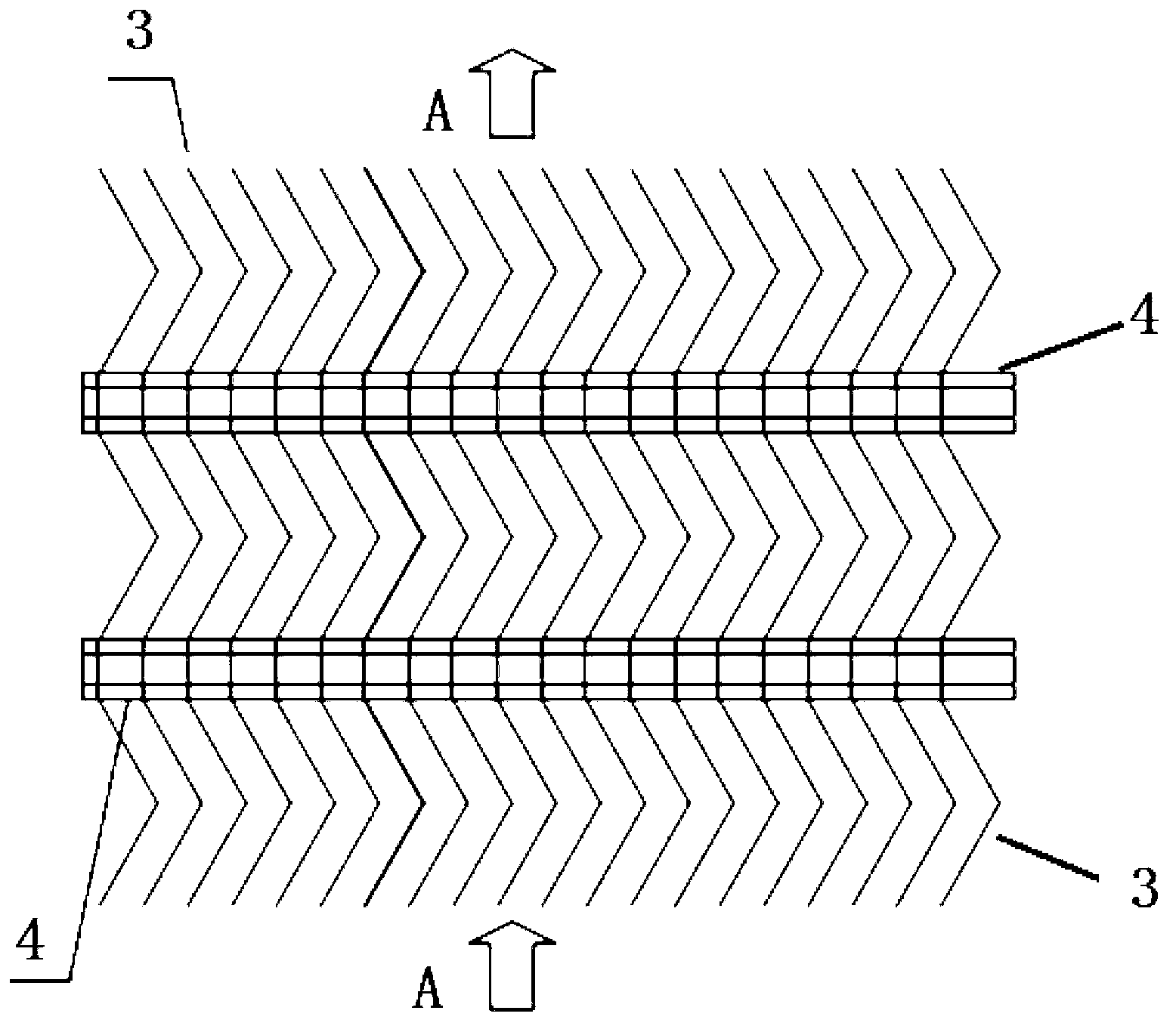

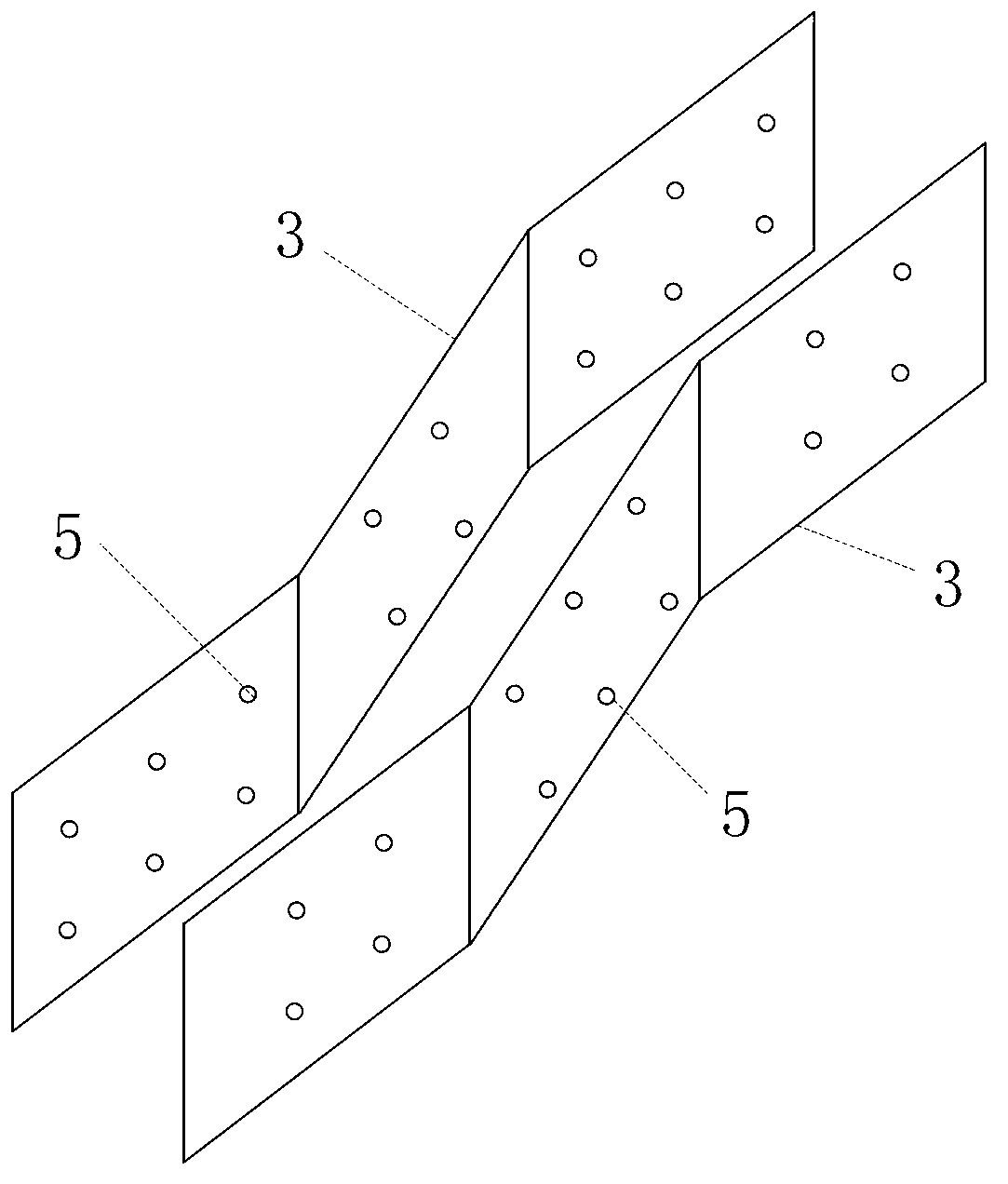

Silencing and noise-reducing coil pipe heat exchanger as well as ultra-silencing fan coil pipe and soundproofing heat exchanger

InactiveCN102937348AReduce aerodynamic noiseLow costEvaporators/condensersNoise suppressionMicro perforated plateEngineering

The invention relates to a silencing and noise-reducing coil pipe heat exchanger as well as an ultra-silencing fan coil pipe and a soundproofing heat exchanger, wherein the coil pipe heat exchanger is internally provided with a plurality of groups of bending-type heat exchange fins which are arranged along the air flowing direction and form a plurality of groups of air flowing channels in the coil pipe heat exchanger; micro holes with the diameters of 0.3-1.0mm are formed in the heat exchange fins at two sides of the air flowing channels in a left-right alternative way along the air flowing direction or micro holes with the diameters of 0.3-1.0mm are formed in the interval heat exchange fins; when air flows, air flow passes through the micro holes in a heat exchange fin on a plane vertical to the air flowing direction; and the micro holes and fin bodies at the opposite sides of the heat exchange fins at least locally form a micro hole plate sound absorption cavity body space. According to the silencing and noise-reducing coil pipe heat exchanger as well as the ultra-silencing fan coil pipe and the soundproofing heat exchanger, various complex and high-cost soundproofing devices are not required to be installed, and the silencing and noise-reducing coil pipe heat exchanger as well as the ultra silencing fan coil pipe and the soundproofing heat exchanger have the advantages of simple structure, obvious soundproofing effect, extremely low cost and the like.

Owner:BEIJING KCALIN NEW ENERGY TECH

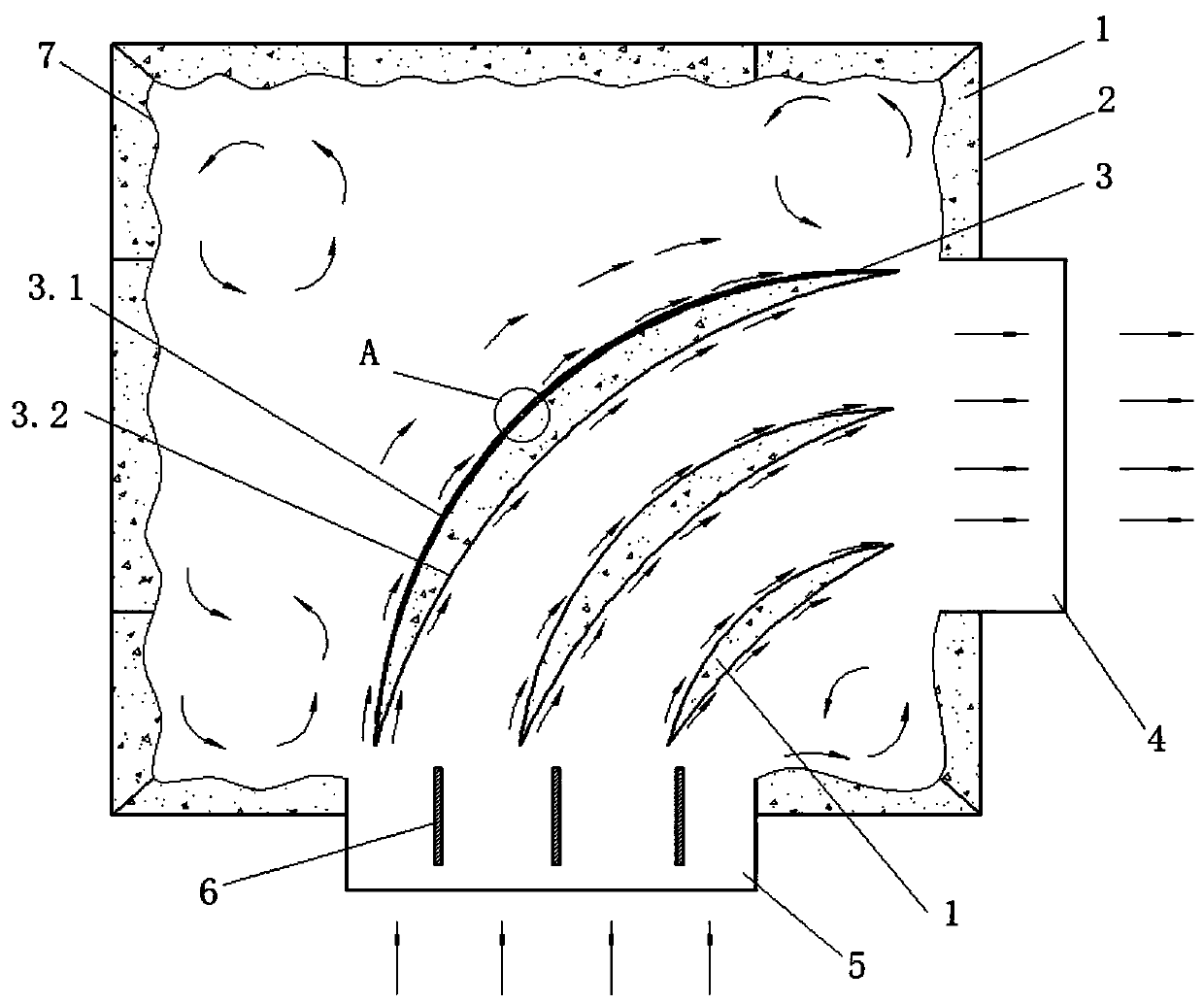

Impedance type silencing static pressure box

PendingCN110715436ASmall running resistanceQuiet operation without abnormal noiseNoise suppressionAir-flow control membersEngineeringMechanical engineering

The invention provides an impedance type silencing static pressure box. The impedance type silencing static pressure box comprises a box body, at least one flow guide blade and at least one air guidesheet, wherein an air outlet and an air inlet are formed in the box body; the plurality of air guide sheets are arranged in the box body at intervals and are positioned at the air inlet; the pluralityof flow guide blades are arranged in the box body at intervals and are positioned between the air outlet and the air inlet; the flow guide blades are of an arc-shaped structure and are bent from theair inlet to the air outlet; and airflow entering the box body from the air inlet is guided through the plurality of flow guide blades and then flows out from the air outlet. The impedance type silencing static pressure box provided by the invention has the characteristics of simple structure, easiness for manufacturing and low cost, has small operation resistance and effectively reduces energy consumption; and meanwhile, low-frequency, medium-frequency and high-frequency silencing can be realized and the silencing effect is excellent.

Owner:中建五局安装工程有限公司

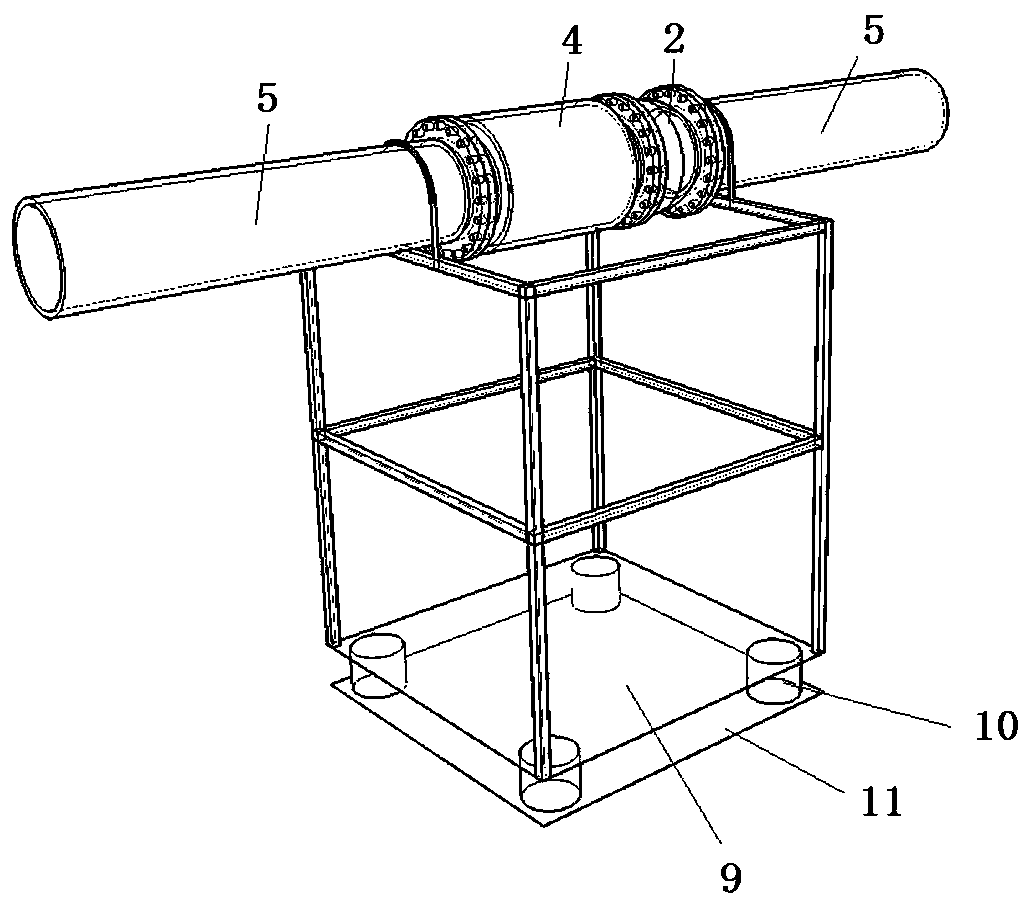

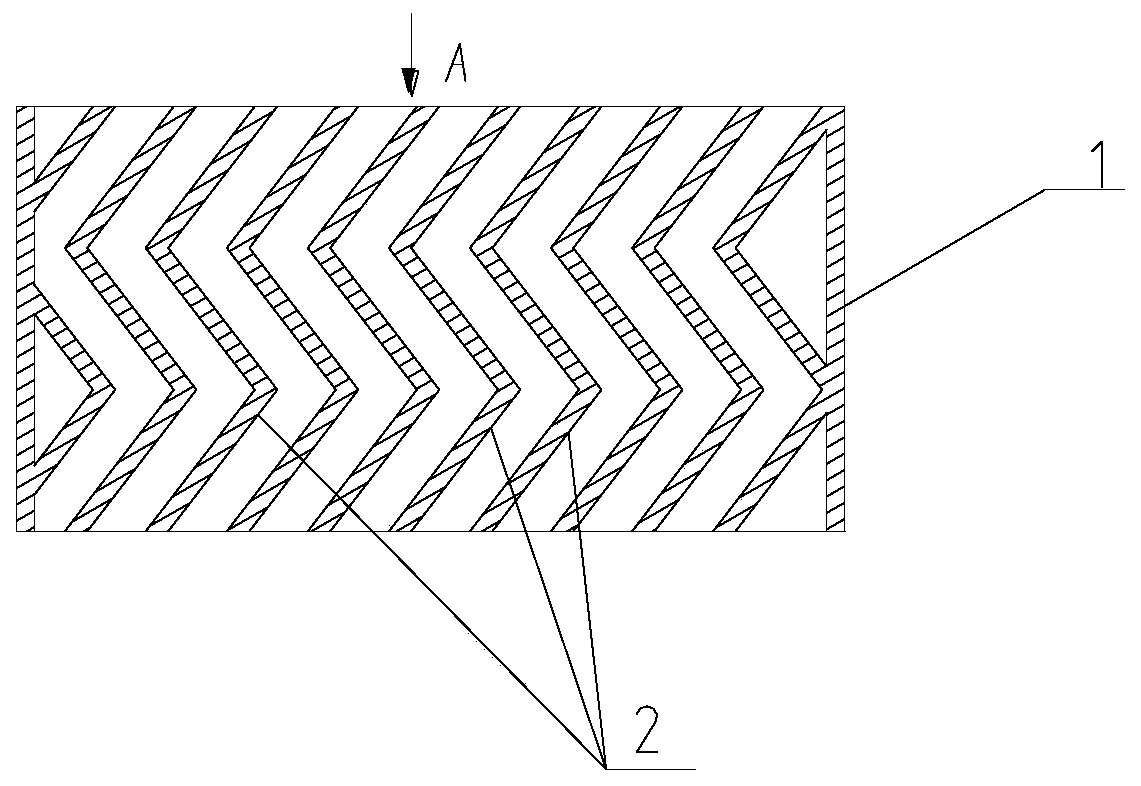

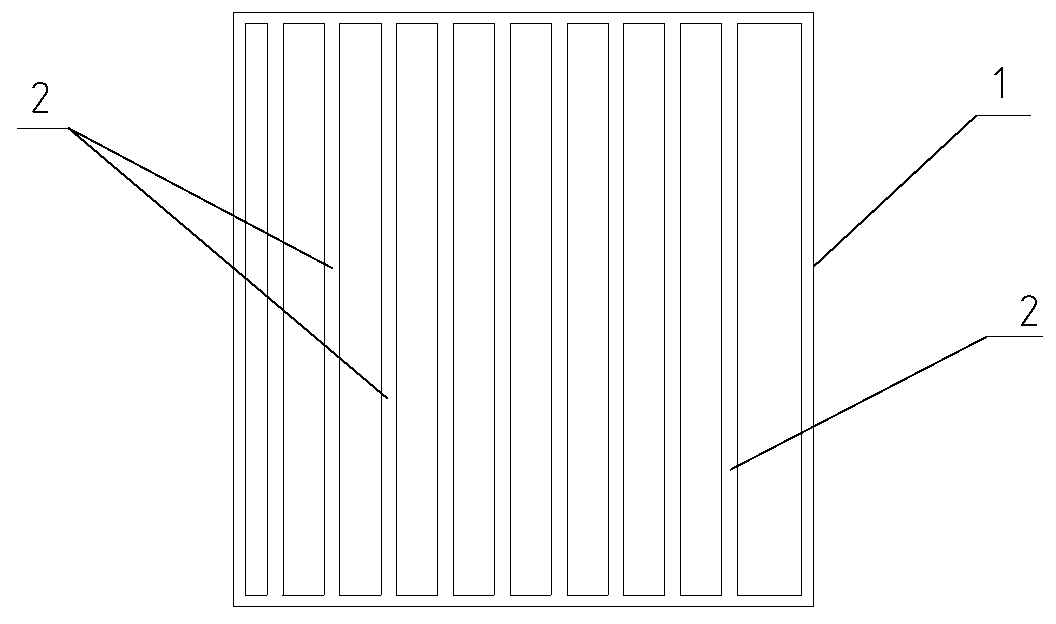

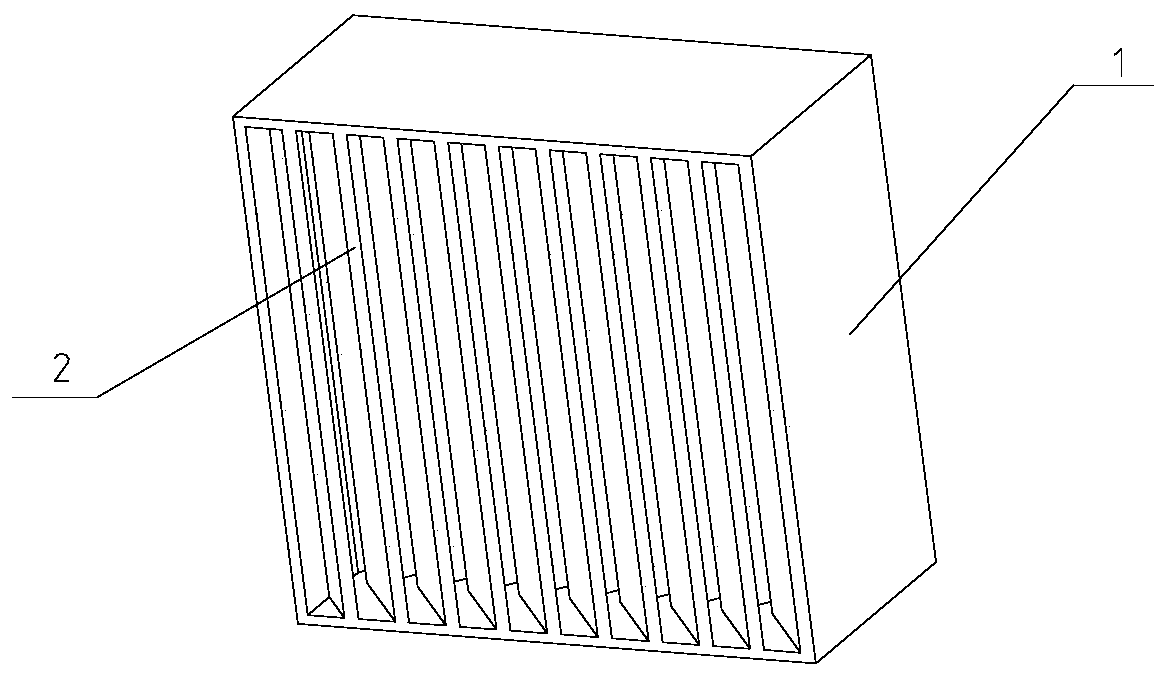

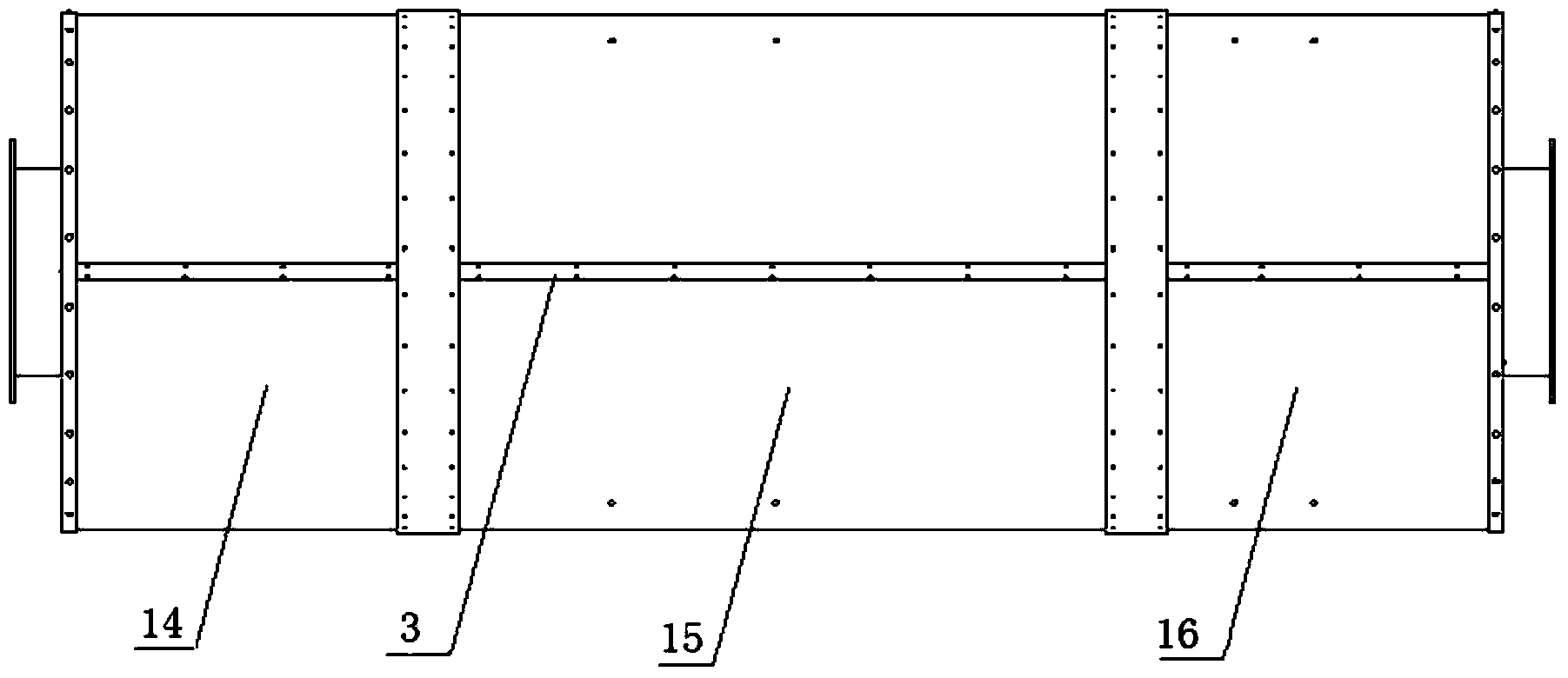

Sound attenuation and noise reduction device applied to air duct

PendingCN110848497AReduce transmissionReduce operating and maintenance costsPipe supportsPipe elementsNoise generationNoise

The invention relates to a sound attenuation and noise reduction device applied to an air duct. The sound attenuation and noise reduction device includes a flexible joint and a muffler. Flange piecesare arranged at both ends of the flexible joint and the muffler. A pipe at the original air duct is cut and removed, and the flange pieces are installed at pipe orifices by welding. The flange piece at one end of the flexible joint is connected with the flange piece on the end part of the pipe on one side, and the flange piece at the other end of the flexible joint is connected with the flange piece at one end of the muffler. The flange piece at the other end of the muffler is connected with the flange piece on the end part of the pipe on the other side. The sound attenuation and noise reduction device can realize arbitrary combination, disassembly and installation. Meanwhile, the sound attenuation and noise reduction device can be quickly connected and installed with the pipes at any desired position in an original pipeline. Through the installation of the sound attenuation and noise reduction device in the middle of the existing pipe, the impact of vibration generated during the operation of the air duct on existing surrounding structures can be efficiently and safely reduced, the decibel value of noise generated during the operation is reduced, and it is ensured that the factoryboundary noise meets the standard.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

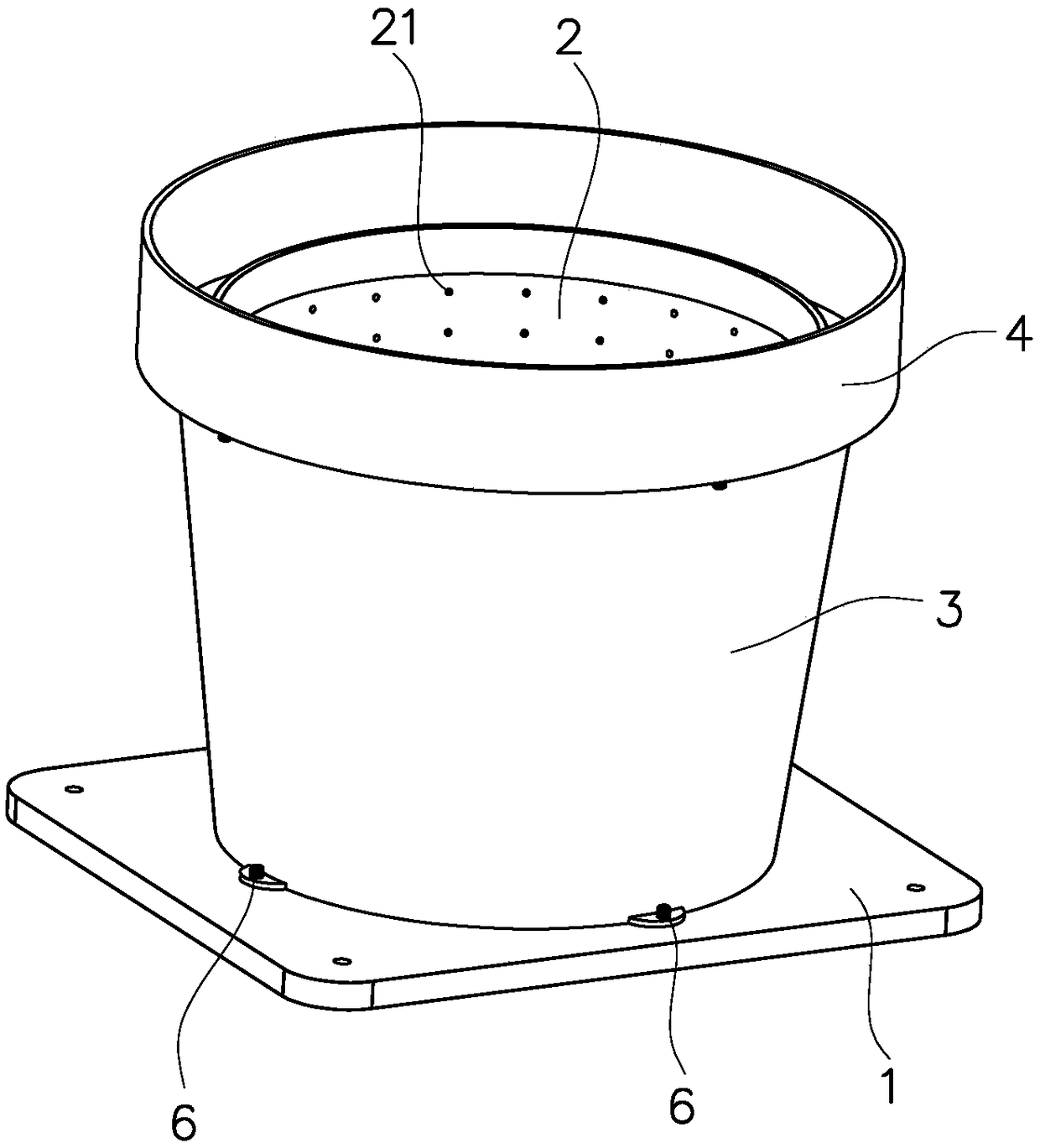

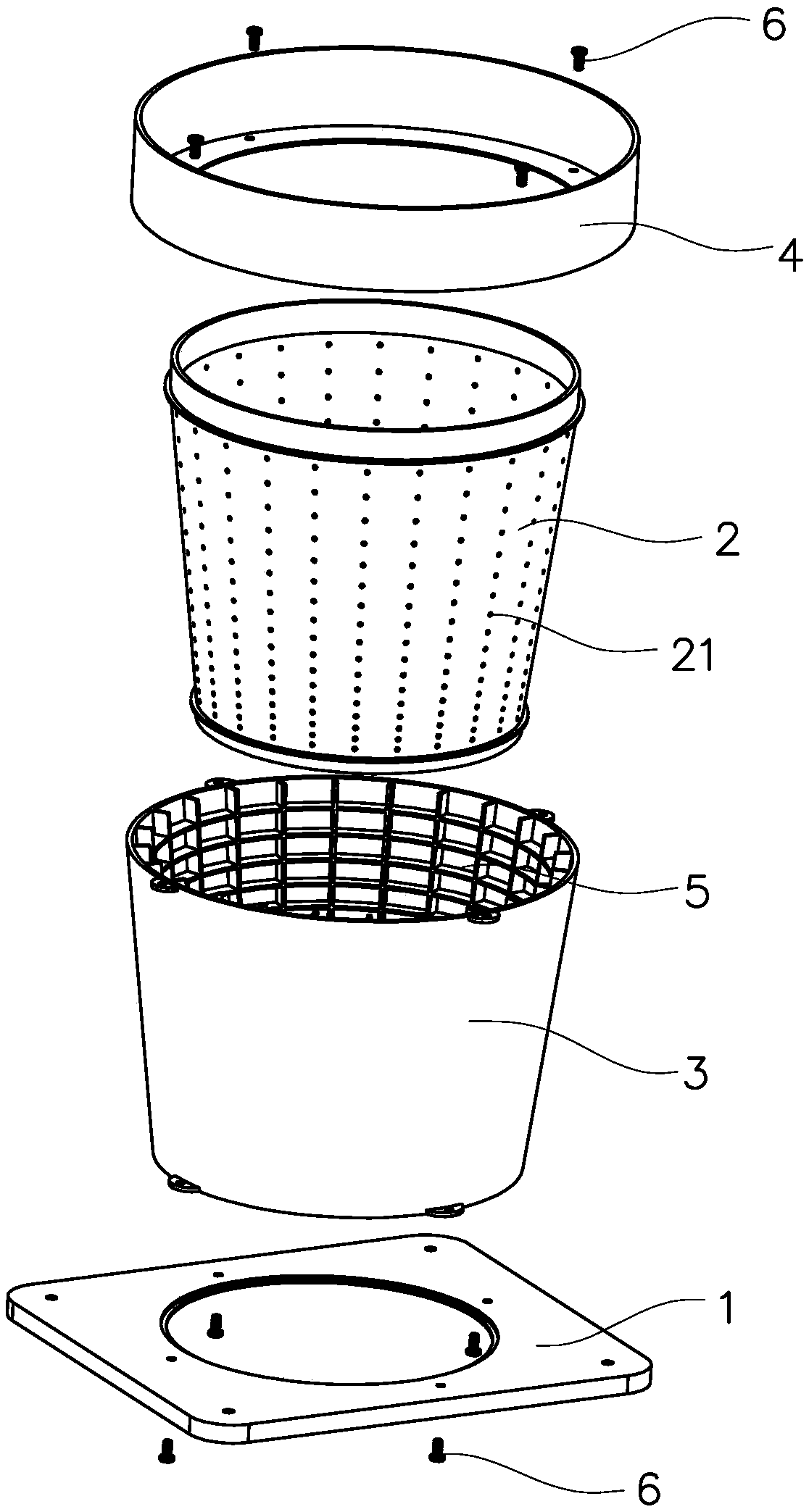

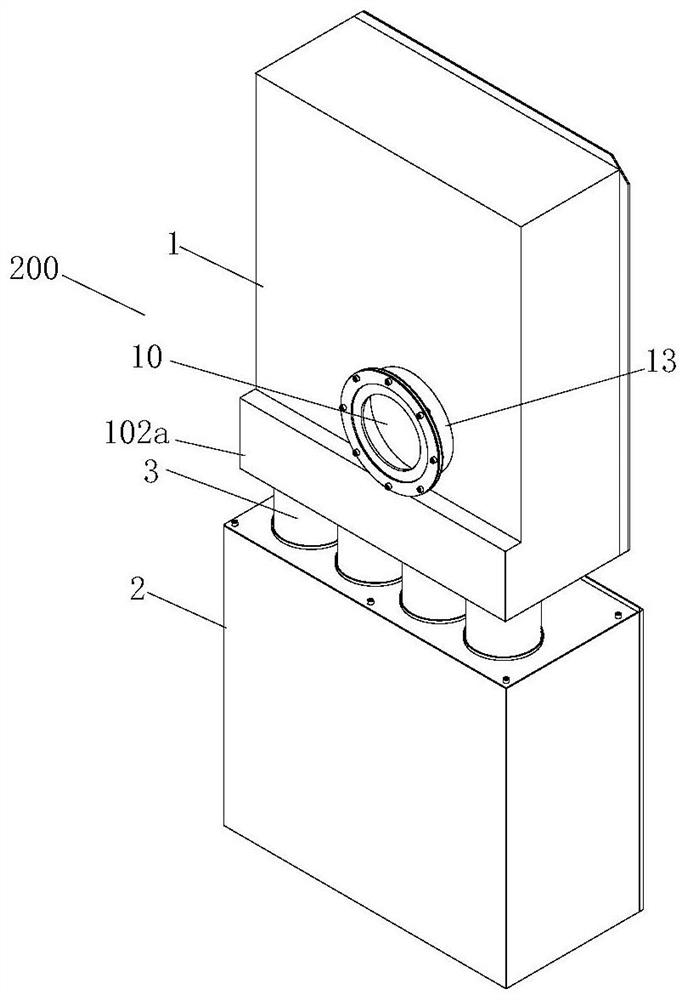

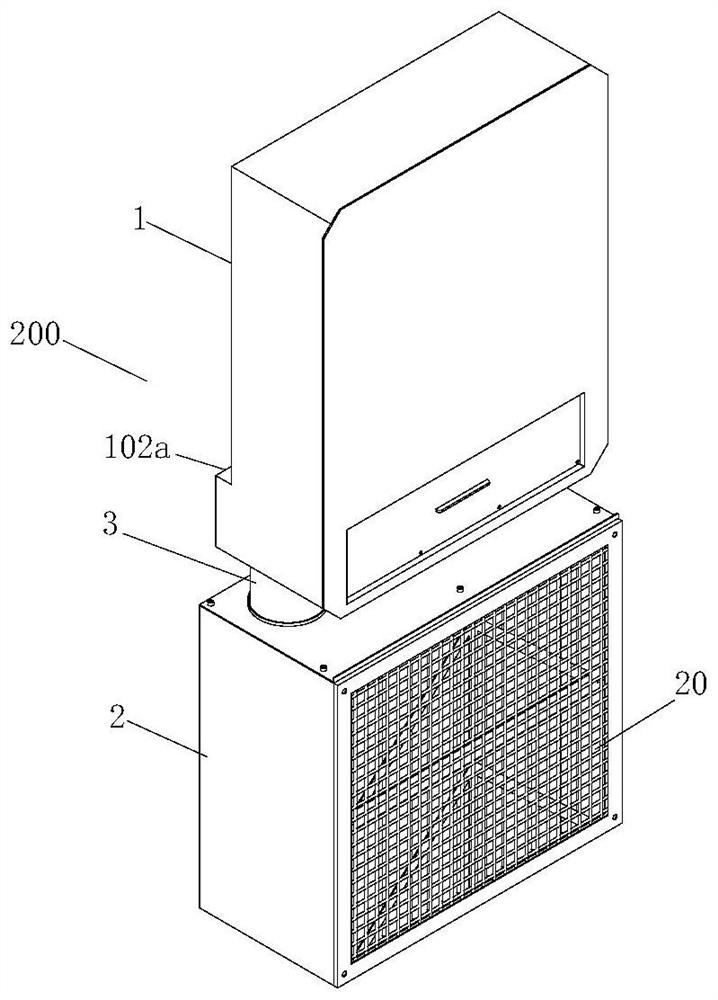

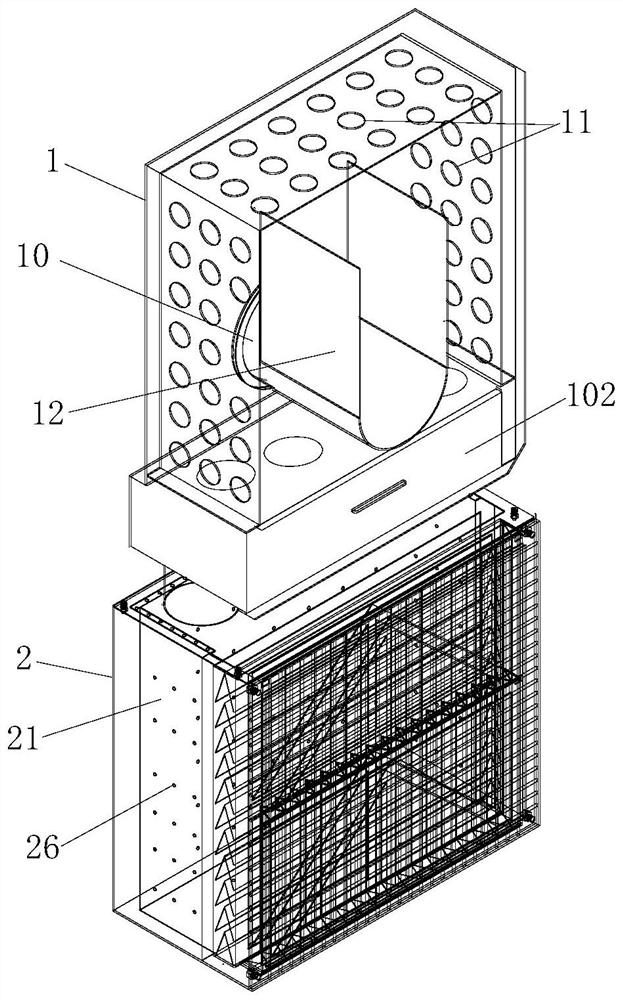

Power generator set

InactiveCN110500182AGood noise reduction effectIncrease noise reductionMachines/enginesEngine componentsElectric energyElectric generator

The invention relates to a power generator set. The power generator set comprises an engine, a power generator providing electric energy for the engine and a soundproof cover with a soundproof function and a protective function. The soundproof cover is provided with a functional opening and a silencing component located inside the functional opening. The silencing component is provided with a functional channel of a labyrinth structure. According to the power generator set, by arranging the silencing component of the special structure, in combination with the optimization of the structural parameter of the silencing component, the sound absorption area is increased beneficially, the transmission path of noise is prolonged beneficially, noise can form multiple reflections in the noise channel beneficially, more energy is dissipated, the silencing effect is better, dust blockage is facilitated, on the premise of guaranteeing that the silencing component meets normal intake and exhaust requirements of the engine and meeting the heat dissipation performance of the power generator set, the noise reduction of the noise within the wide band range (such as 50-6300Hz) is increased, outwardnoise radiation is reduced, and noise of the power generator set is lowered.

Owner:CHONGQING IONCIN NAVIGATION ENGINE MFG C0 LTD

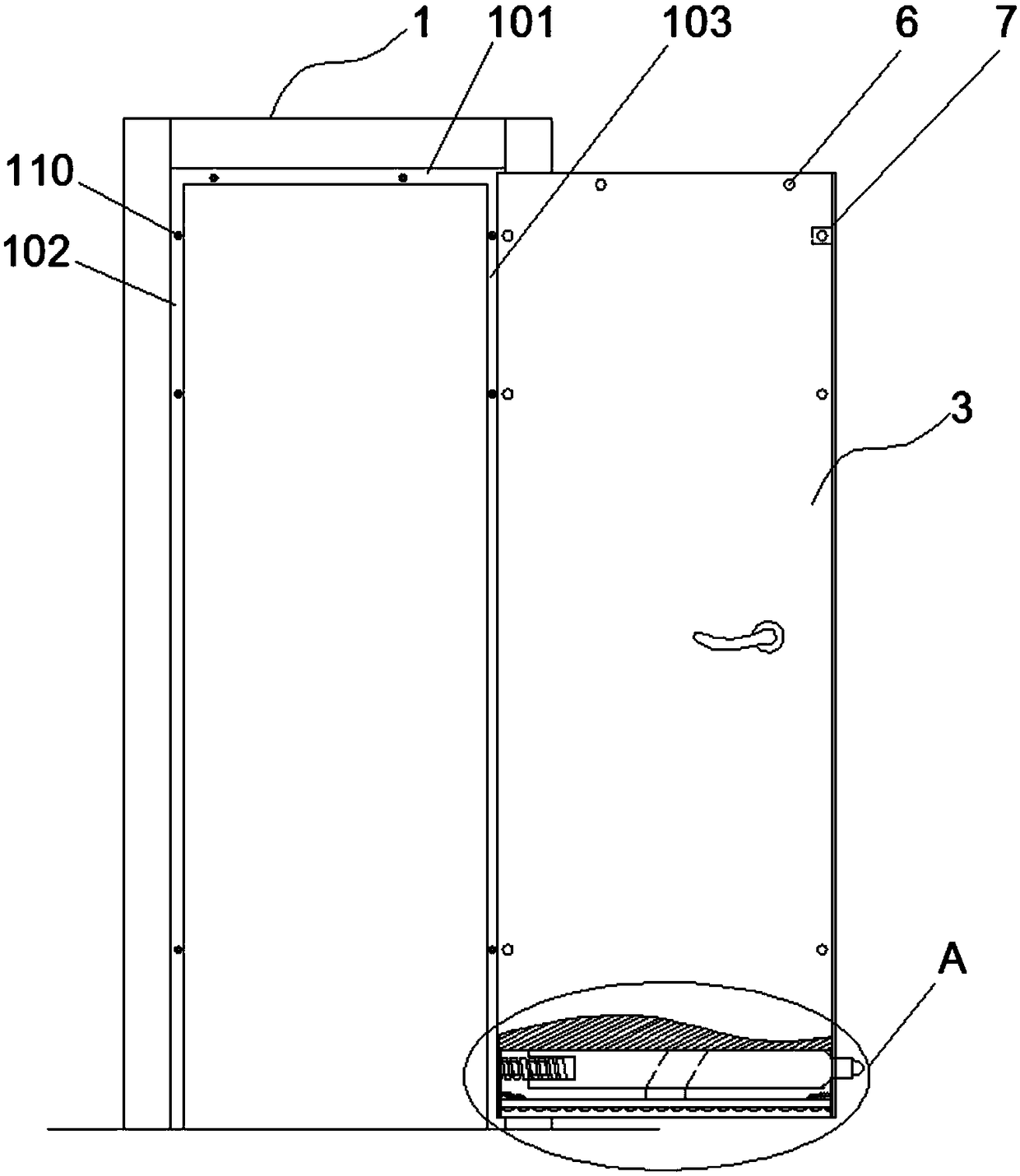

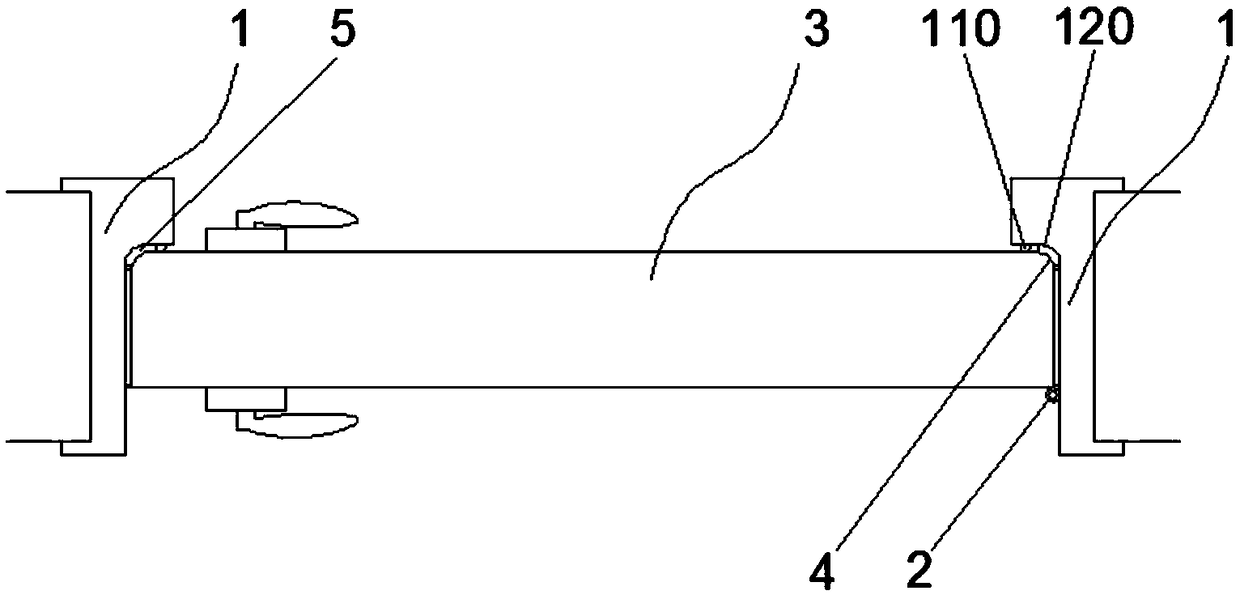

Sound-proof door structure

ActiveCN109184514ASolve the problem of no sound insulationImprove sound insulationWindow/door framesNoise insulation doors/windowsNoise reductionComputer engineering

The invention relates to a sound-proof door structure, which comprises a door frame and a door plate, wherein an inner arc surface is arranged on the door frame, a sound-proof bar is arranged on the inner arc surface, and the door plate is provided with an outer arc surface corresponding to the inner arc surface; sealing edge bars are arranged on the top, the left side and the right side of the door plate respectively, a bottom through groove is opened in the bottom part of the door plate, the bottom through groove is internally provided with a horizontally-arranged horizontal rod, a lifting mechanism and a sound absorption bar, the lifting mechanism is located below the horizontal rod, the inner wall of the bottom through groove is symmetrically provided with pull springs connected with the lifting mechanism, and the sound absorption bar is fixed on the bottom part of the lifting mechanism; and one end, close to a hinge, of the horizontal rod is provided with a groove and the other end is provided with a nose, the nose of the horizontal rod reaches out from the side wall of the door plate, the inner wall of the bottom through groove is vertically provided with a positioning rod matched with the groove, the top end of the positioning rod is placed in the groove of the horizontal rod, and the outer wall of the positioning rod is sleeved with a positioning spring matched with thegroove. The sound-proof door is easy to process, easy to manufacture, good in sound-proof performance and obvious in noise reduction.

Owner:徐强

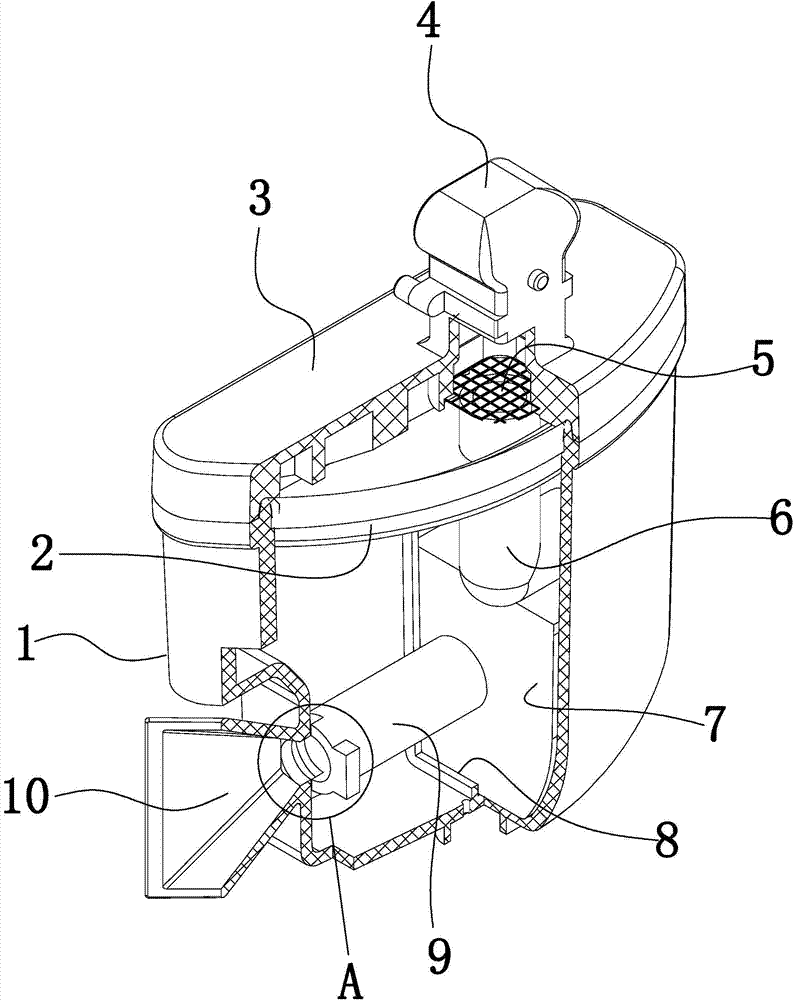

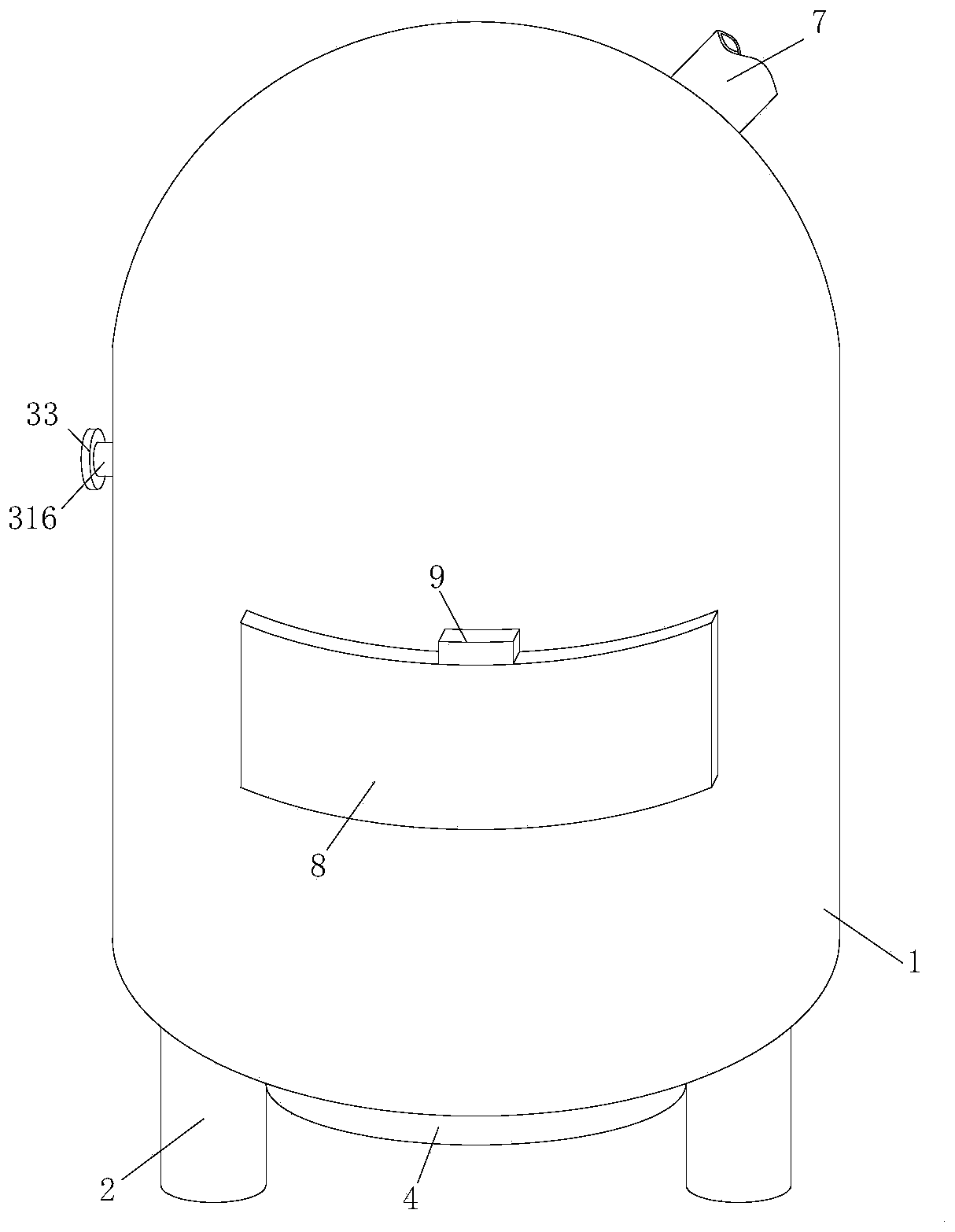

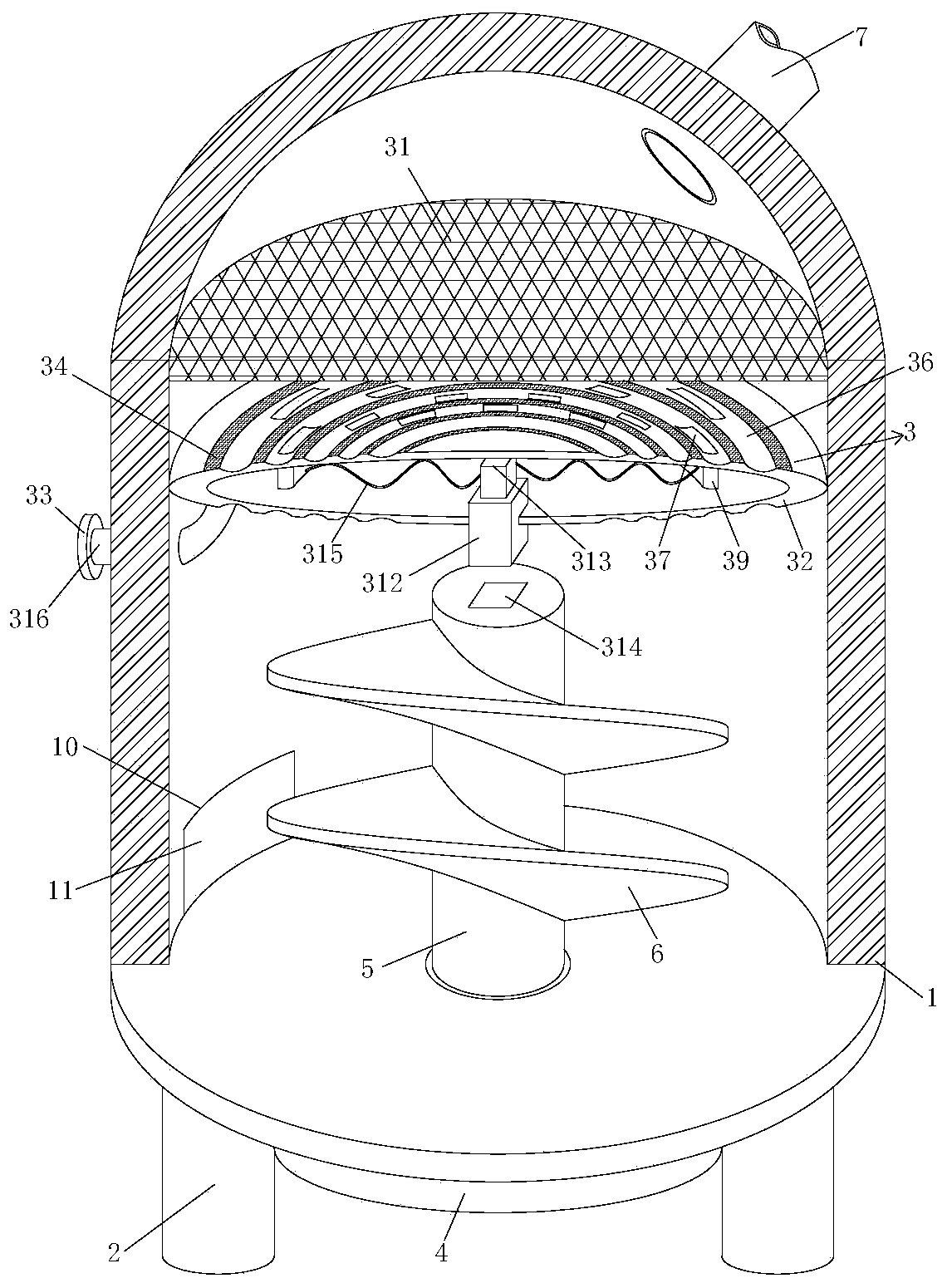

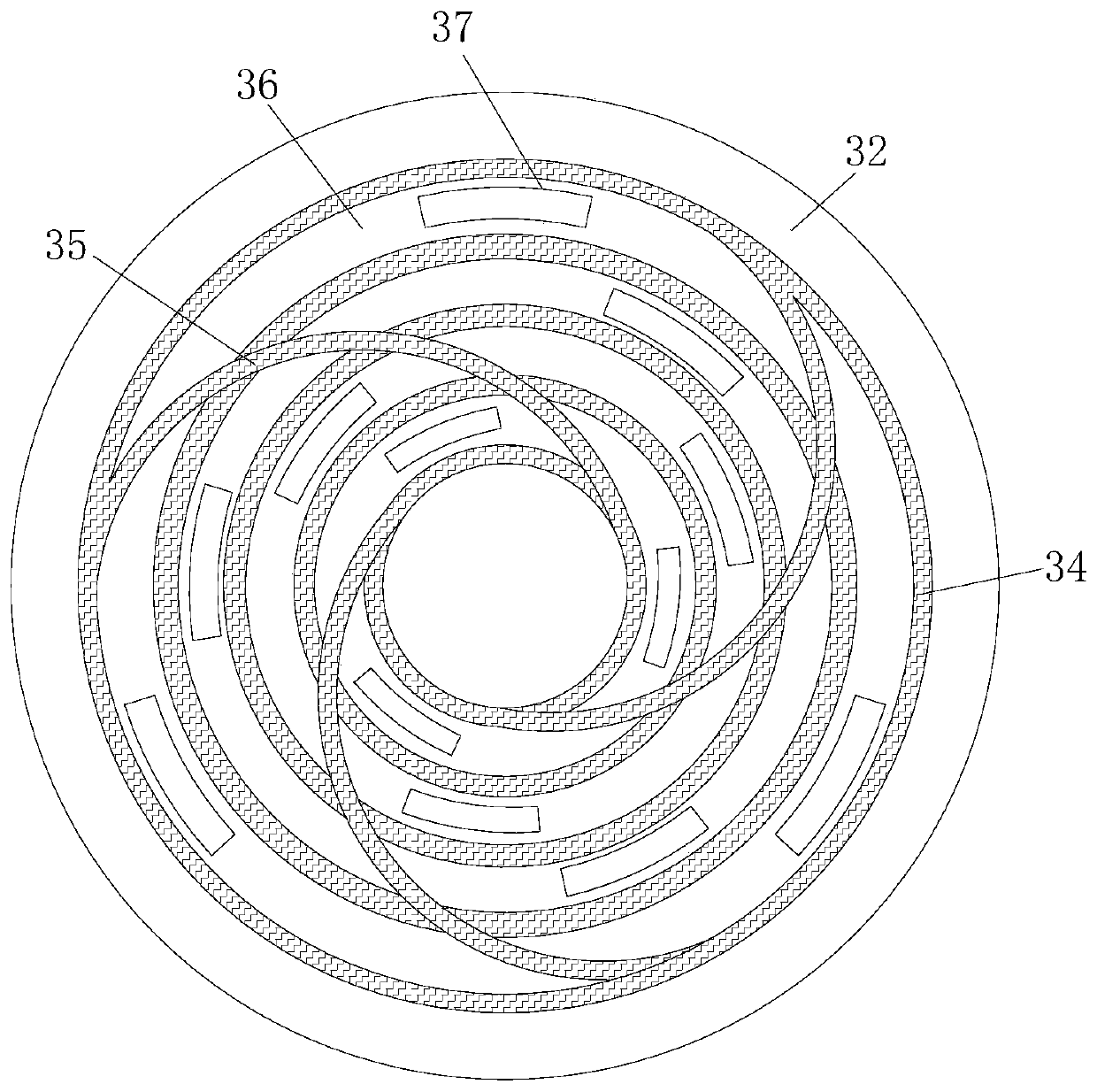

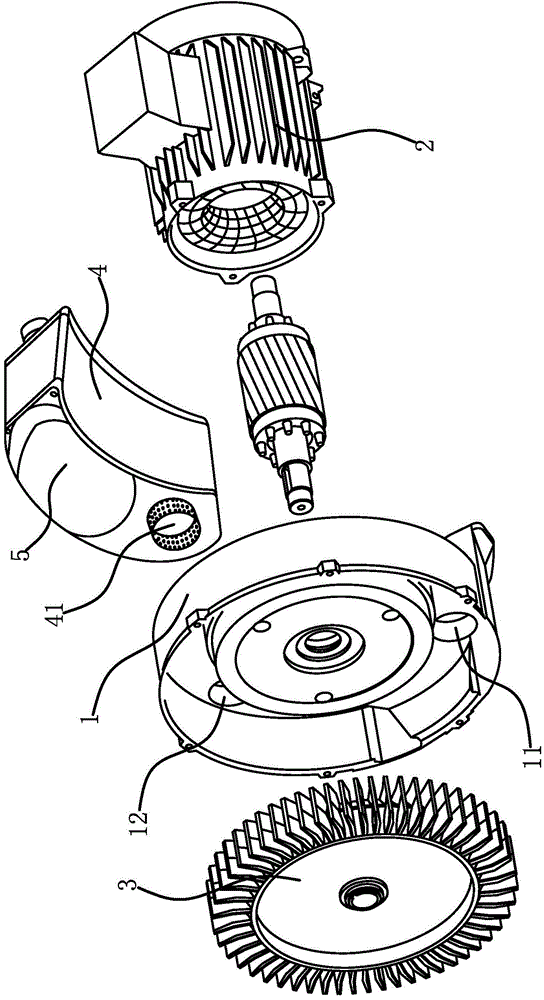

Pollutant treatment device for production line of asphalt mixing plant

InactiveCN111408310AImprove filtration efficiencyClean thoroughlyDispersed particle filtrationRotary stirring mixersProduction lineHazardous substance

The invention provides a pollutant treatment device for a production line of an asphalt mixing plant. The pollutant treatment device comprises a stirring tank body used for asphalt stirring processing, supporting legs used for supporting the stirring tank body and a self-cleaning filtering mechanism used for filtering emissions generated in asphalt production. The supporting legs are fixedly installed at the bottom of the stirring tank body, and a driving motor is fixedly installed at the bottom of the stirring tank body. The present invention relates to the field of asphalt processing. The pollutant treatment device for the production line of the asphalt mixing plant solves the problem of pollutants existing in the existing asphalt mixing process; a self-cleaning special structure capableof adapting to a small-aperture filter screen is designed, the problem of blockage of the filter screen can be solved in time, waste materials can be recycled in time, noise of the equipment is reduced, and therefore the problems that a large number of easily-stuck harmful substances are generated by common asphalt stirring and processing equipment, the filtering effect of a large-aperture filterscreen is poor, a small-aperture filter screen needs to be cleaned frequently, and the asphalt production and processing efficiency is affected are effectively solved.

Owner:湖南均佳路面材料有限公司

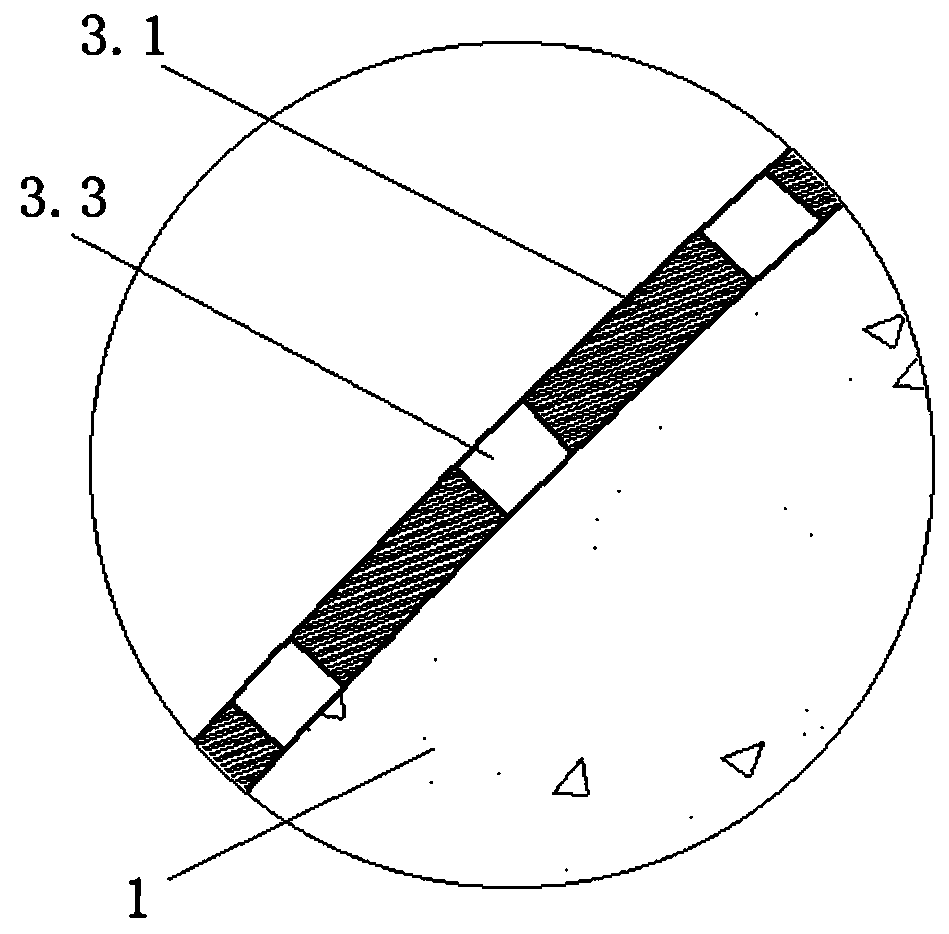

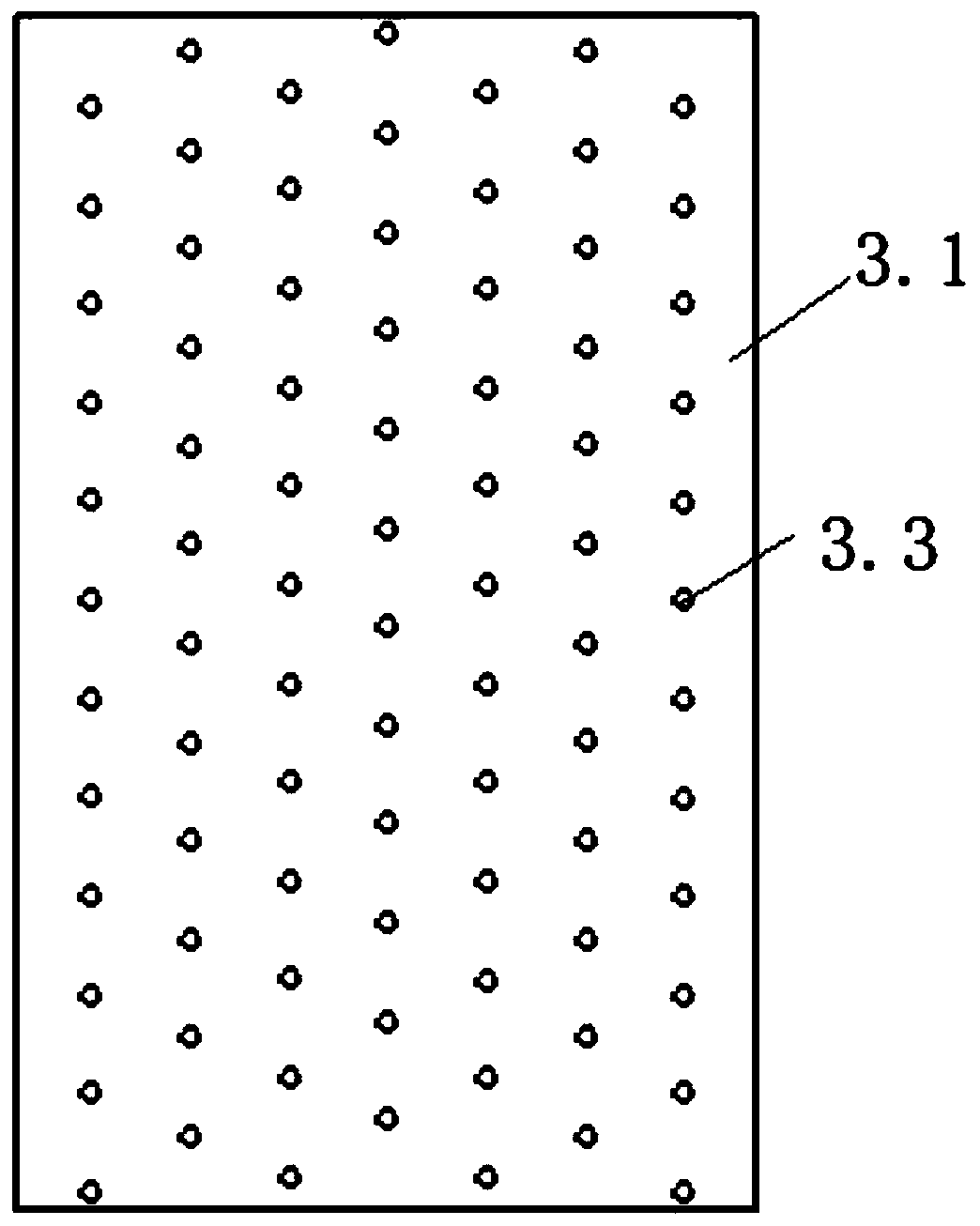

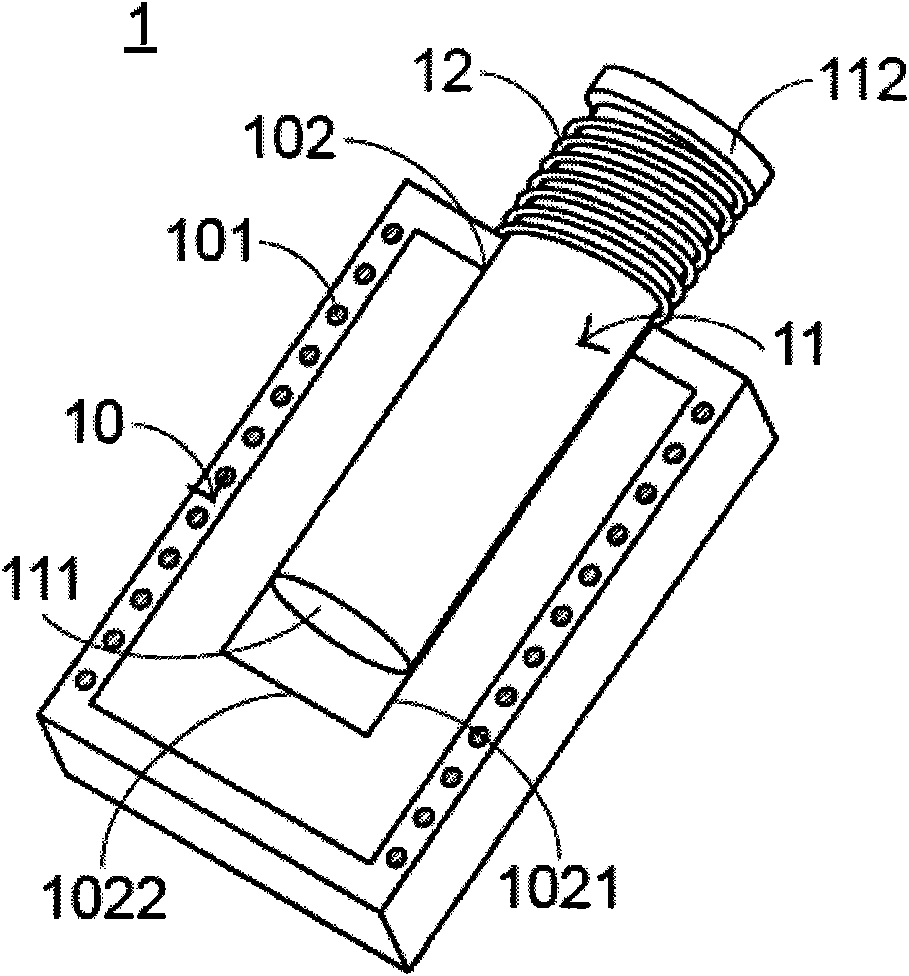

Strip silencer

InactiveCN102330588AIncreased disorderReduced audible componentsSilencing apparatusMachines/enginesAcoustic waveEngineering

The invention relates to the technical field of silencers, and particularly provides a silencer which is better in noise elimination effect. The silencer comprises a silencer main body, an air inlet pipe, an exhaust pipe and a strip outer cover, wherein the silencer main body is accommodated in at least part of the strip outer cover; the strip outer cover and the silencer main body are fixed through screws; the air inlet direction of the air inlet pipe is perpendicular to the exhaust direction of the exhaust pipe; an exhaust port is formed on the strip outer cover; and the exhaust pipe is connected with the exhaust port after being bent. In the silencer, by arranging a shell, a certain silencing and heat insulation effect can be enhanced, and the silencer is more attractive in appearance;the air inlet direction of the air inlet pipe is perpendicular to the exhaust direction of the exhaust pipe, so more collision can be produced during flowing of airflow, and the disorder degree of the airflow is increased to achieve a better silencing effect; and the exhaust pipe is bent, so nearly axial waves in sound waves can be absorbed and reflected at a bending position, and the energy of the nearly axial waves can be transformed into the energy of oblique waves during bending to be easily absorbed.

Owner:重庆神驰通用动力有限公司

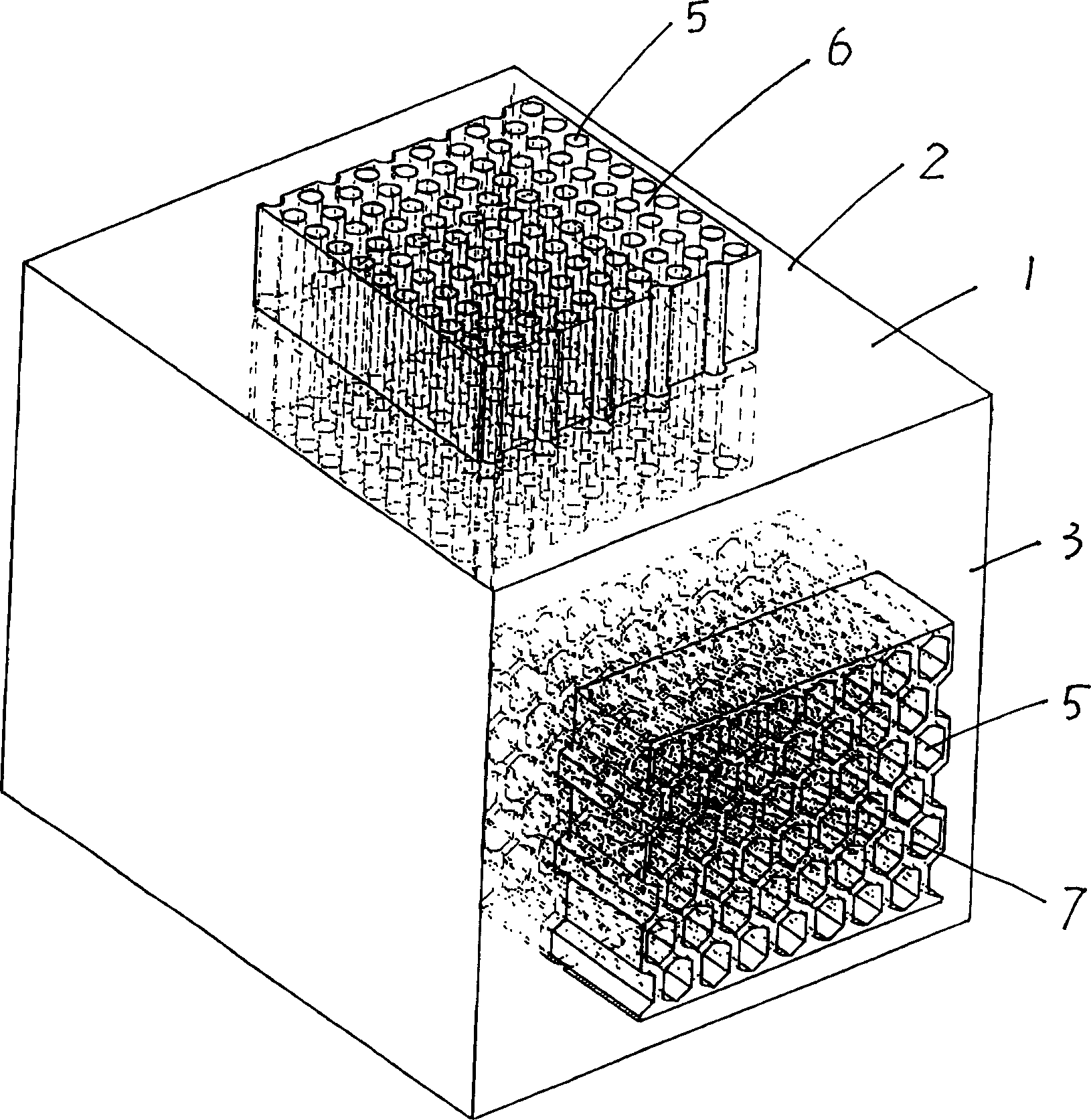

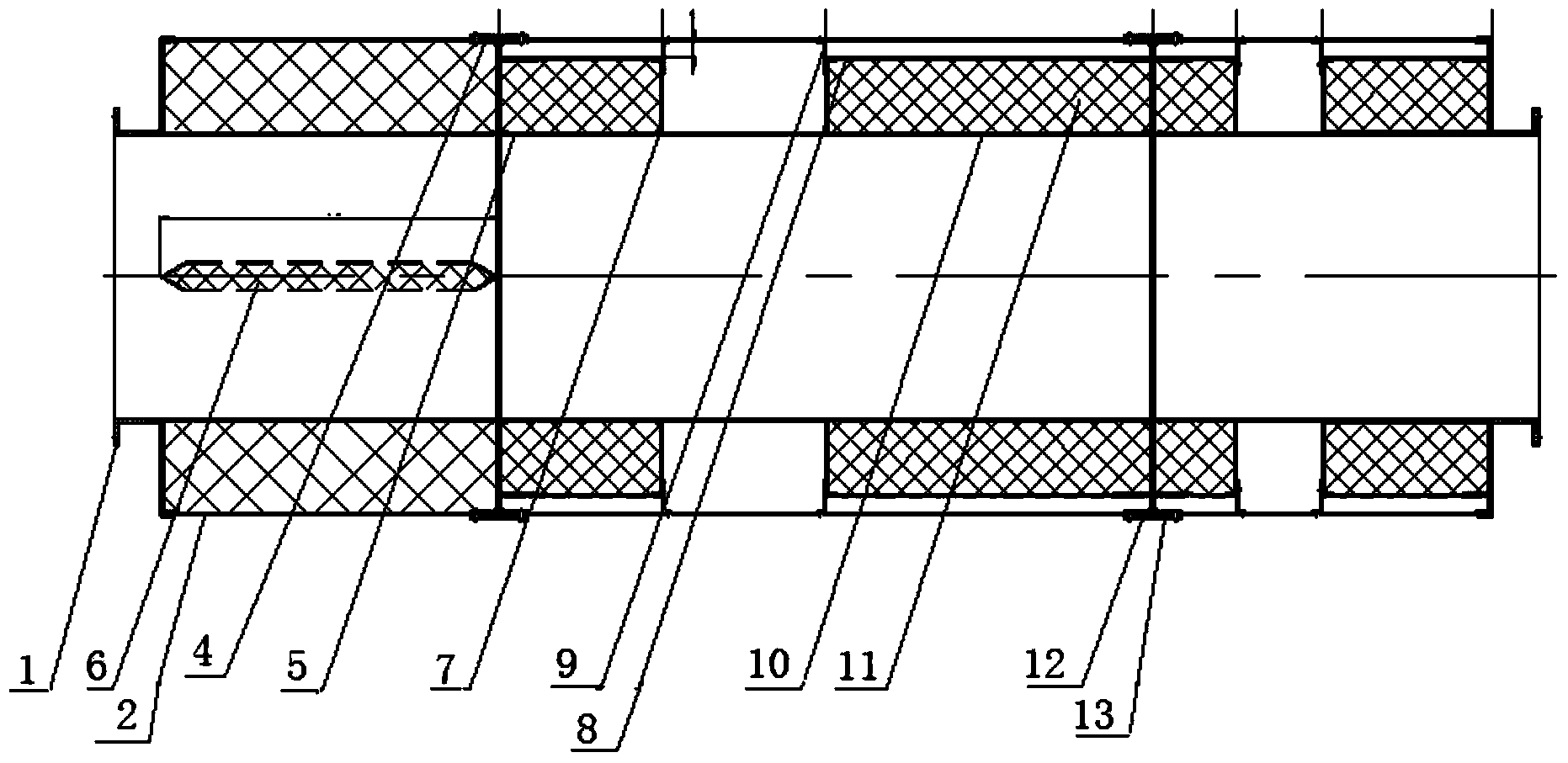

Modular blocking, resisting and compensation composite silencer

InactiveCN103727075AIngenious structural designGood noise reduction effectPump componentsNoise suppressionFrequency bandAirflow

The invention discloses a modular blocking, resisting and compensation composite silencer. The modular blocking, resisting and compensation composite silencer is formed by connecting at least three pipe sections which are the first pipe section for silencing in a blocking mode, the second pipe section for silencing in a resisting mode and the third pipe section for silencing in a resisting mode. A silencing sheet assembly is arranged in the first pipe section and the face, in contact with air flow, of the first pipe section is provided with an aluminum perforated plate; the second pipe section is not equal to the third pipe section in length and comprises an outer panel, an inner mesh plate, a mesh annular frame, a mesh annular frame support and a mesh annular frame covering board, an expansion cavity is formed by the mesh annular frame and the mesh annular frame support, and a resonating cavity is formed between the outer panel and the mesh annular frame covering board. The aluminum perforated plate is arranged outside the silencing sheet assembly, the inner portion of the silencing sheet assembly is filled with sound absorption materials, and the first pipe section, the second pipe section and the third pipe section are riveted into a whole through rivets via a rubber sheet and a hoop. The modular blocking, resisting and compensation composite silencer is simple in structure, convenient to install and capable of enabling each frequency band to be good in silencing effect through a blocking and resisting type silencing and mutual compensation method.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

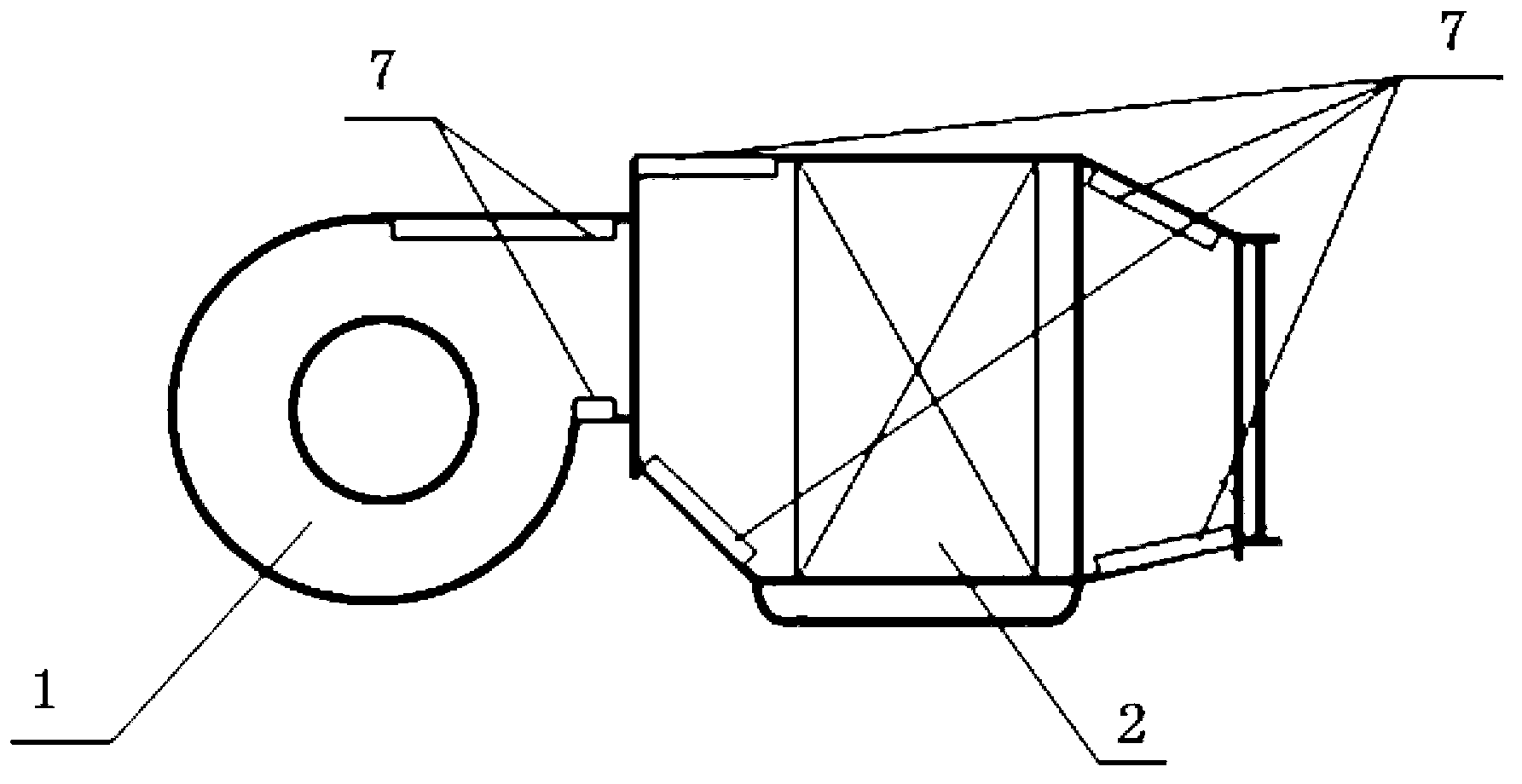

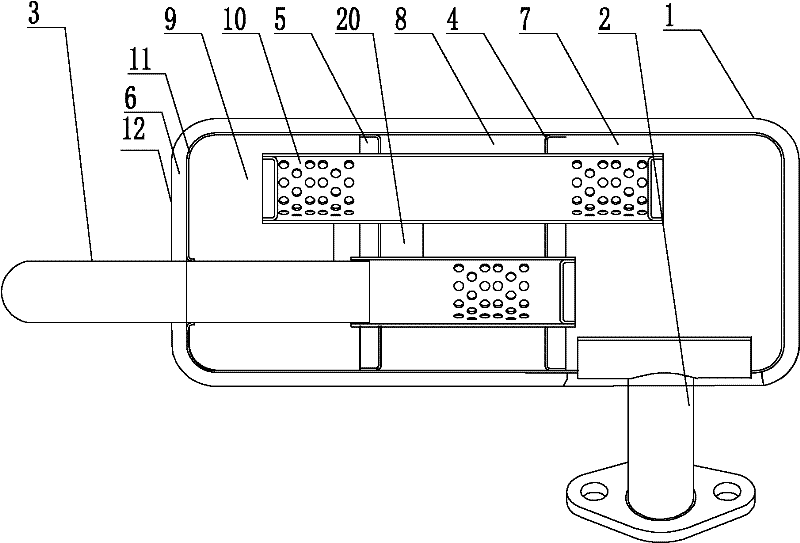

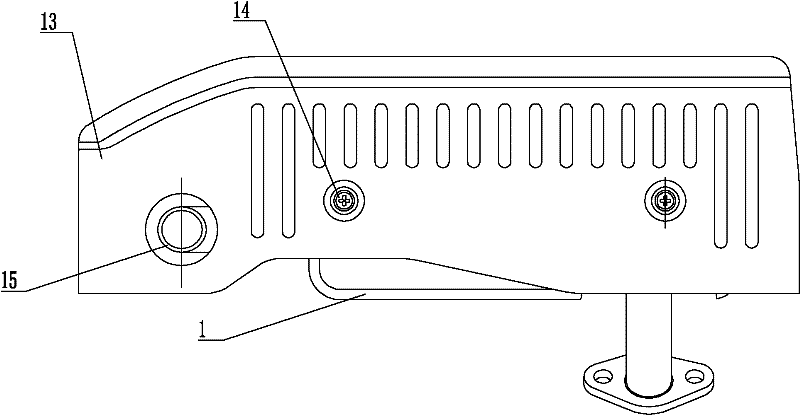

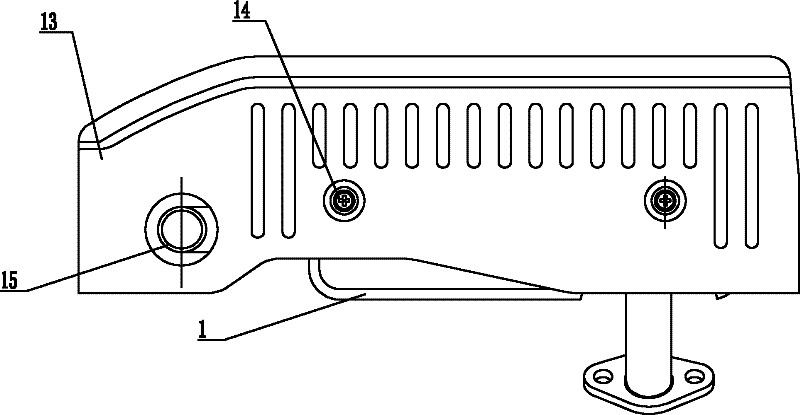

Silencer of high-pressure blower

ActiveCN104088819AGood noise reduction effectIncrease productionPump componentsRadiation-absorbing paintsAirflowEngineering

The invention relates to a silencer of a high-pressure blower. The silencer comprises a wind tub and a motor, wherein the output shaft of the motor extends into the wind tub, and the extending-in end of the output shaft is fixedly connected with a wind blade; a wind inlet and a wind outlet are formed in the wind tub; the silencer comprises a strip-shaped box body, a wind intake hole is formed in the end surface of one end of the box body, and a wind exhaust hole is formed in the end surface of the other end of the box body; the wind intake hole is communicated with the wind outlet in the wind tub; a plurality of strip-shaped partition boards are fixedly connected to the inner part of the box body, and the box is divided into a plurality of chambers through the partition boards; every two adjacent chambers are communicated, and the wind intake hole is communicated with the chamber in one side of the box body; the wind exhaust hole is communicated with the chamber in the other side of the box body; both ends of the box body are respectively and fixedly connected with one cover plate, and the inside surfaces of the cover plates are fixedly connected with acoustical coatings which are sprayed by anti-noise paint. When air currents generate impact on the partition boards, the inner wall of the box body and the cover plates, noise is absorbed, so that the silencer of the high-pressure blower has a better erasing effect, and the whole quality of the blower is improved.

Owner:NINGBO SHENGHONG MACHINERY EQUIP

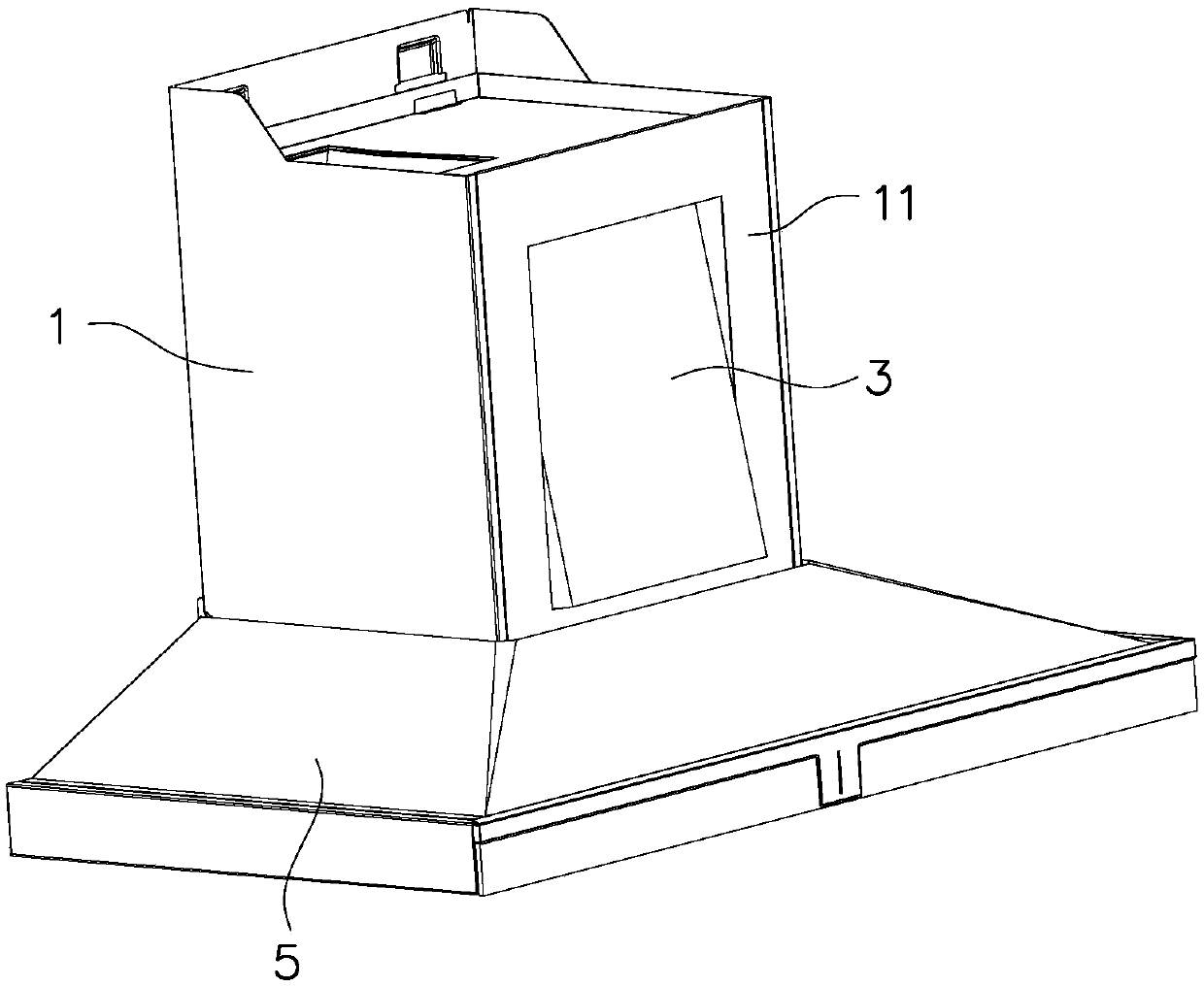

Noise reduction type air outlet hood for extractor hood

PendingCN108240651AGood noise reduction effectGood noise reductionDomestic stoves or rangesLighting and heating apparatusEngineeringHeating energy

The invention discloses a noise reduction type air outlet hood for an extractor hood. The noise reduction type air outlet hood comprises a base and a hood body on the base and is characterized in thatthe hood body comprises an inner hood and an outer hood, the peripheral wall of the inner hood is provided with multiple noise reduction holes and the inner hood and the outer hood form multiple noise reduction cavities corresponding to the noise reduction holes. The peripheral wall of the inner hood is provided with the multiple noise reduction holes, the inner hood and the outer hood form multiple noise reduction cavities corresponding to the noise reduction holes, air columns in the noise reduction holes and air in the noise reduction cavities form an elastic resonance system, when a partof the noise frequency of the extractor hood is the same to the inherent frequency of the resonance system, the air columns in the noise reduction holes produce resonance and violent friction with thehole walls and through the friction, the acoustic energy is converted into heat energy so that the noise elimination is realized. The noise reduction type air outlet hood has good noise reduction andelimination effects based on the Helmholtz resonance sound elimination principle. According to the diversion form of the air outlet hood, the noise reduction effects on all parts of the air outlet hood are optimal.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

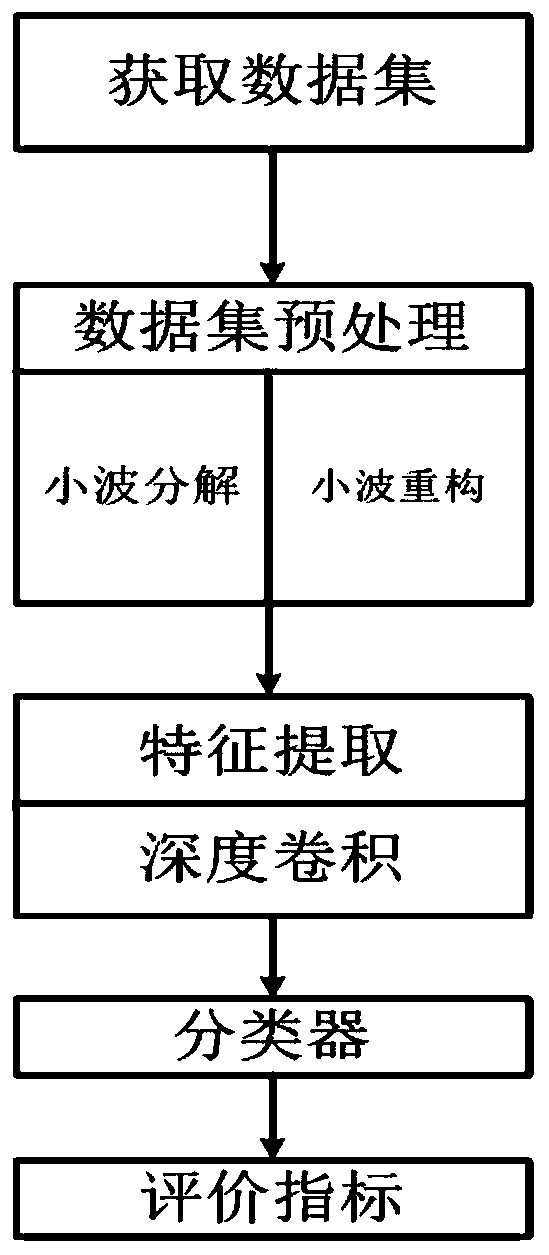

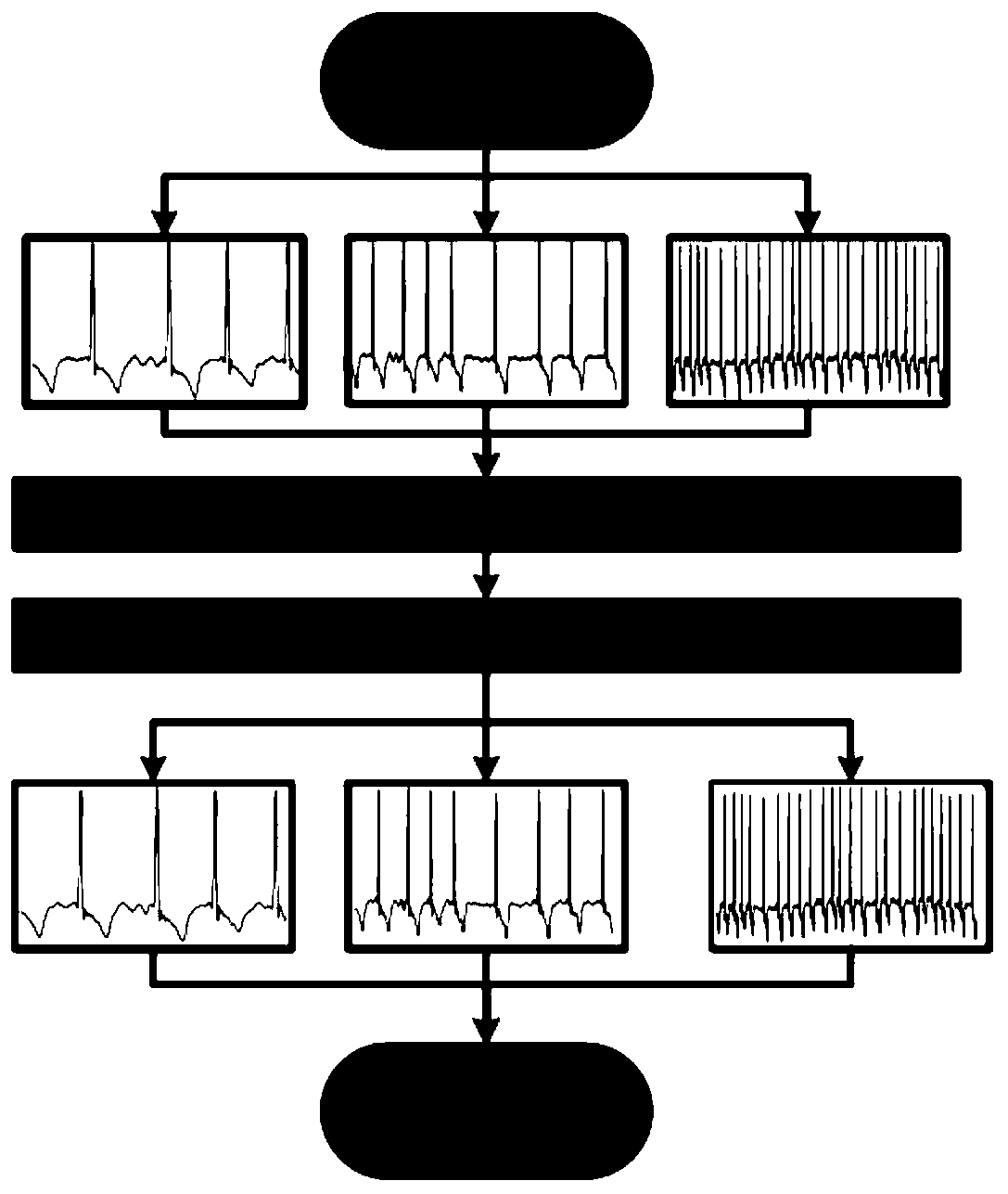

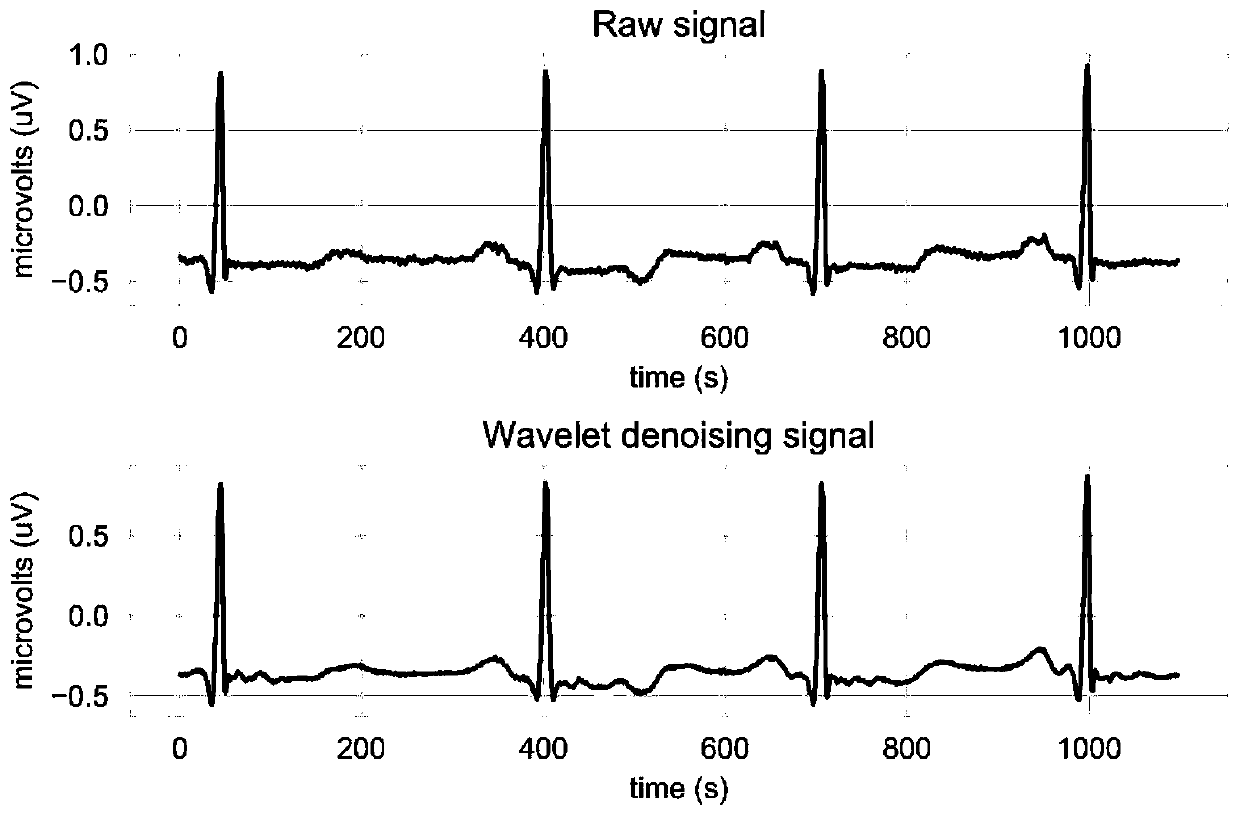

Electrocardiogram classification method and device based on wavelet transform and DCNN (Deep Convolutional Neural Networks)

PendingCN111202512APreserve signal eigenvaluesGood noise reduction effectCharacter and pattern recognitionDiagnostic recording/measuringPhysicsBiomedicine

The invention provides an electrocardiogram classification method and device based on wavelet transform and DCNN (deep convolutional neural networks), and belongs to the field of biological medicinesand modes. According to an automatic classification method and device of electrocardiogram signals based on the wavelet transform and the deep convolutional neural networks, by utilizing wavelet functions, the electrocardiogram signals are decomposed into sub-signals of different frequency scales, and the sub-signals are filtered in sectional modes and are subjected to wavelet reconstruction; by utilizing 24 layers of convolutional neural networks, characteristic extraction is carried out by adopting crossed-size convolution kernels, data overfitting is prevented by adopting dropout and BatchNormalization when characteristic information is transmitted; and finally, classification is carried out by adopting a softmax classifier. The method is already verified on an ECG data set provided by2017 PhysioNet / CinC Challenge, and the accuracy rate is 0.871, and an F1 score is 0.8652. A research proves that noises of the electrocardiogram signals can be eliminated more effectively through thewavelet transform, and extraction of multi-layer characteristics can be performed by utilizing the 24 layers of convolutional neural networks, and meanwhile, a receptive field can be improved by increasing the sizes of the convolution kernels, so that the classification performance of a model is improved.

Owner:QILU UNIV OF TECH

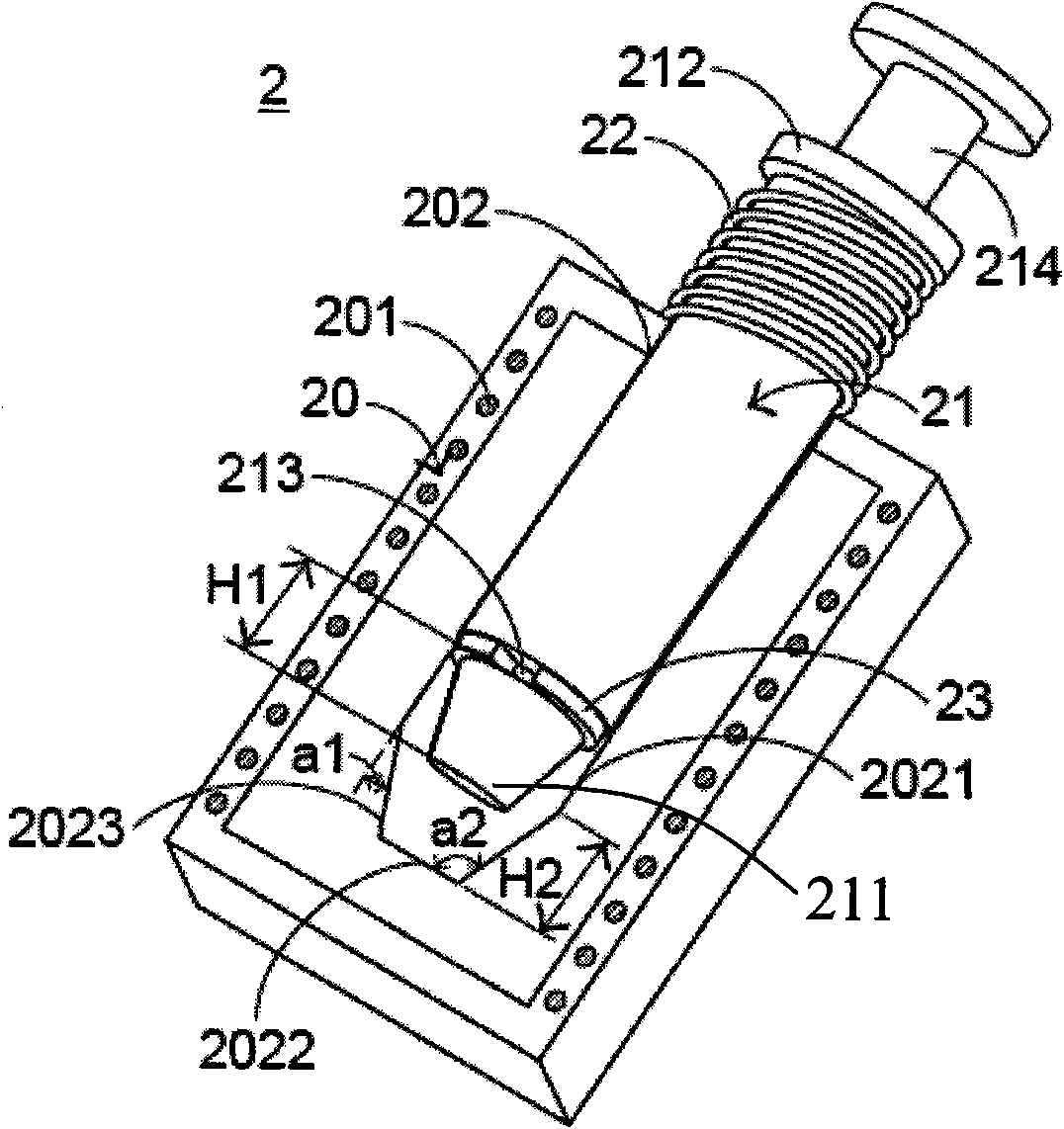

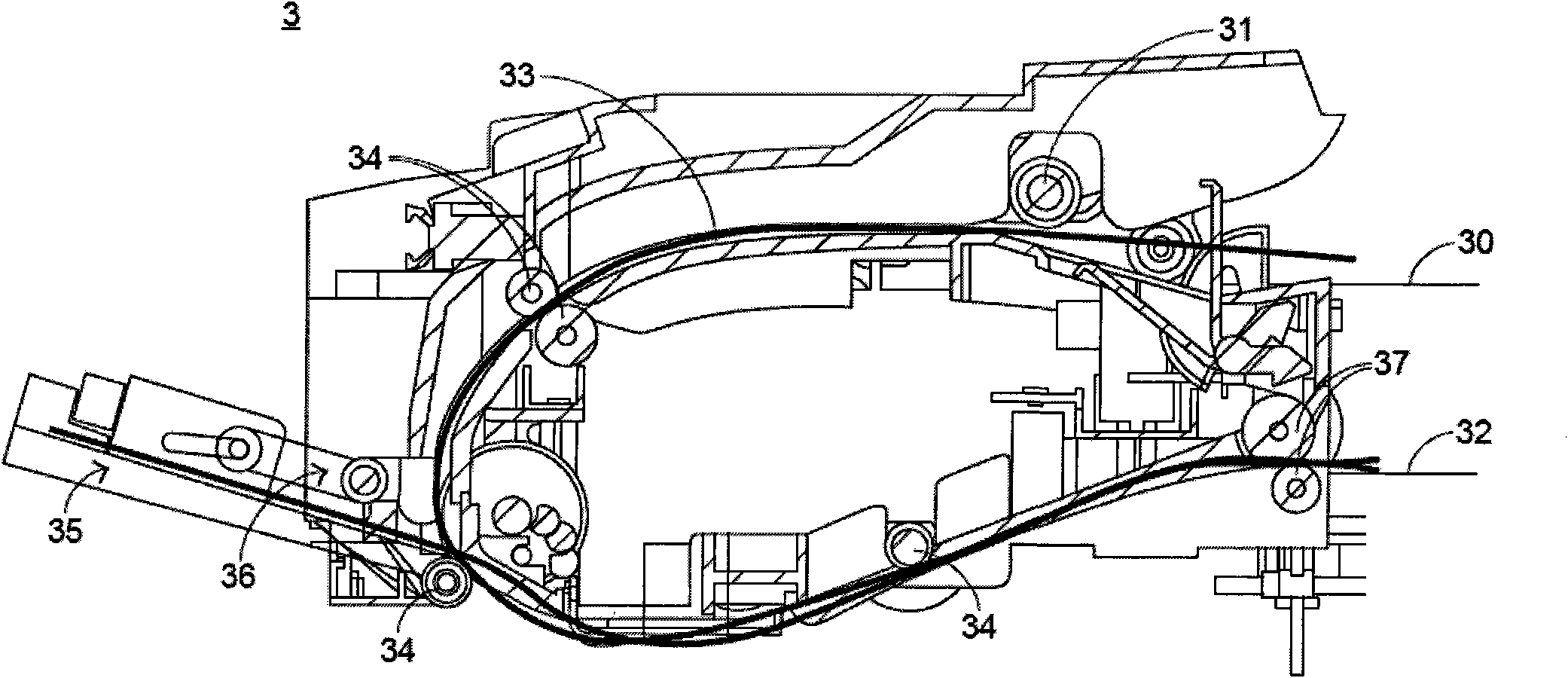

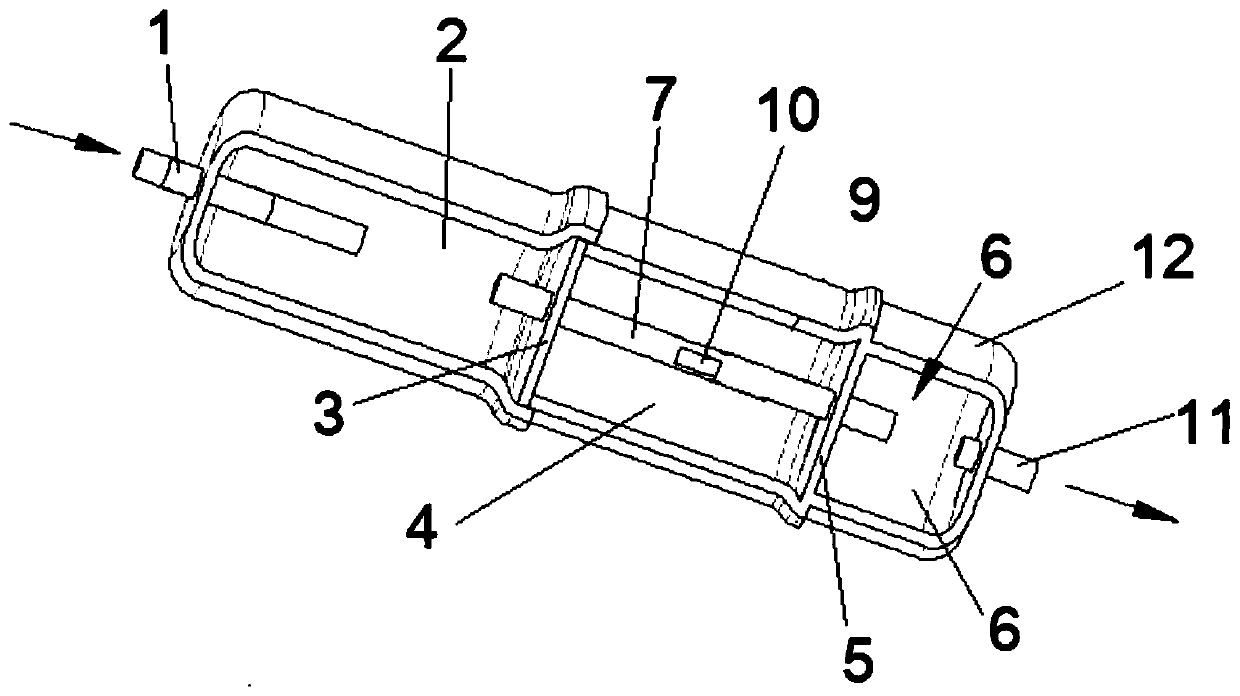

Solenoid valve device and automatic paper feeder using same

InactiveCN101886702AReduce crash soundGood noise reduction effectOperating means/releasing devices for valvesLift valveEngineeringSolenoid valve

The invention relates to a solenoid valve device and an automatic paper feeder using the same. The solenoid valve device comprises a solenoid valve body, a solenoid valve shaft center, a spring, an annular groove and a muffling ring, wherein the annular groove surrounds the solenoid valve shaft center and is provided with the muffling ring. When the solenoid valve body is excited to adsorb the solenoid valve shaft center, the solenoid valve shaft center moves in the solenoid valve body and enables the muffling ring to collide with the solenoid valve body to reduce the colliding sound.

Owner:PRIMAX ELECTRONICS LTD

Preparation method of microporous foamed polymer-based automobile damping mat

The invention discloses a preparation method of a microporous foamed polymer-based automobile damping mat, and belongs to the technical field of preparation of a damping material. The mat comprises, according to a weight part ratio, 40-50 parts of thermoplastic polyurethane elastomer (TPU), 1-5 parts of low-density polyethylene (LDPE), 70-80 parts of calcium carbonate,5-10 parts of a fire retardant, 1-5 parts of an antistatic agent, 0.1-0.5 part of an anti-oxidant, 0.1-0.5 part of oleamide, and 0.1-0.5 part of polyethylene wax. The preparation method comprises: uniformly mixing the raw materials in a high-speed mixer, adding the obtained mixture in a double-screw extruder for melt extrusion, putting the extruded object sample strips in an autoclave, leading supercritical CO2 in to obtain microporous foamed thermoplastic polyurethane elastomer composite material, and performing following processing moulding to obtain a required microporous foamed polymer-based automobile damping mat. The preparation method is low in production cost and good in processing performance, and doesn't produce any toxic or harmful substances in a preparation process. A microporous structure is establishedin a material substrate, so that the sound insulation effect of the polymer-based damping mat is improved.

Owner:ANHUI ZHICHENG ELECTROMECHANICAL SPARE PARTS

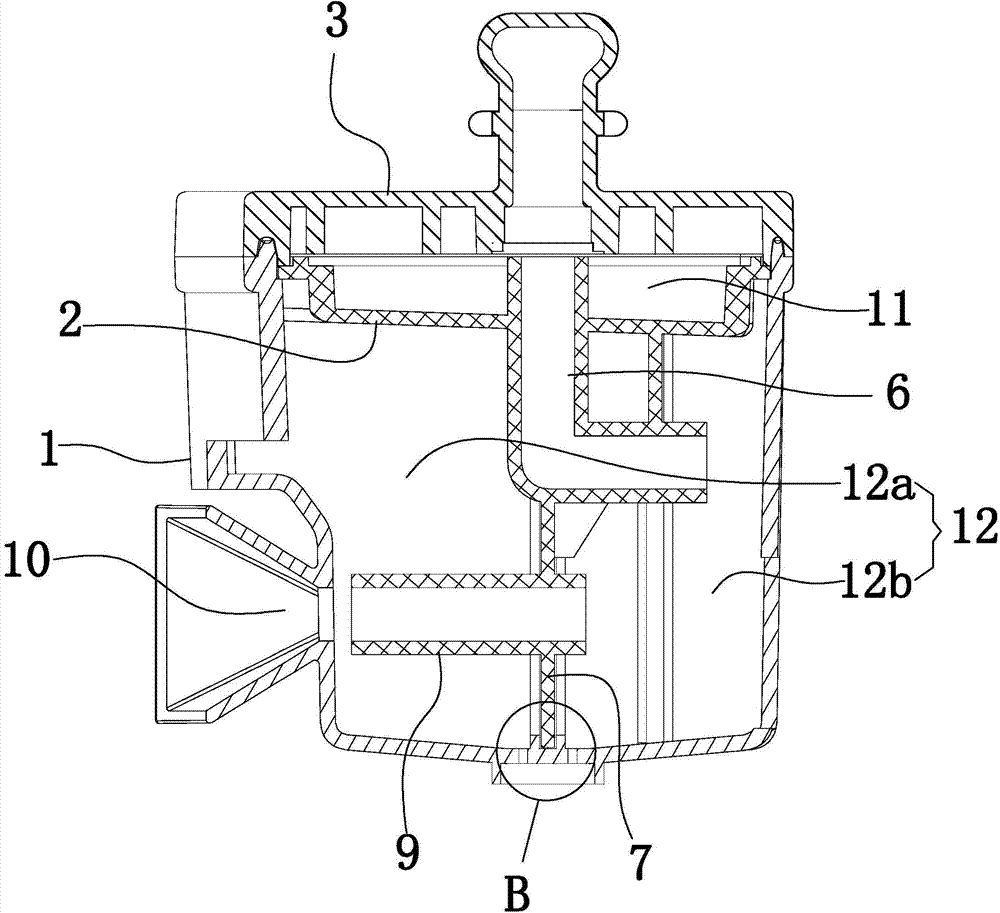

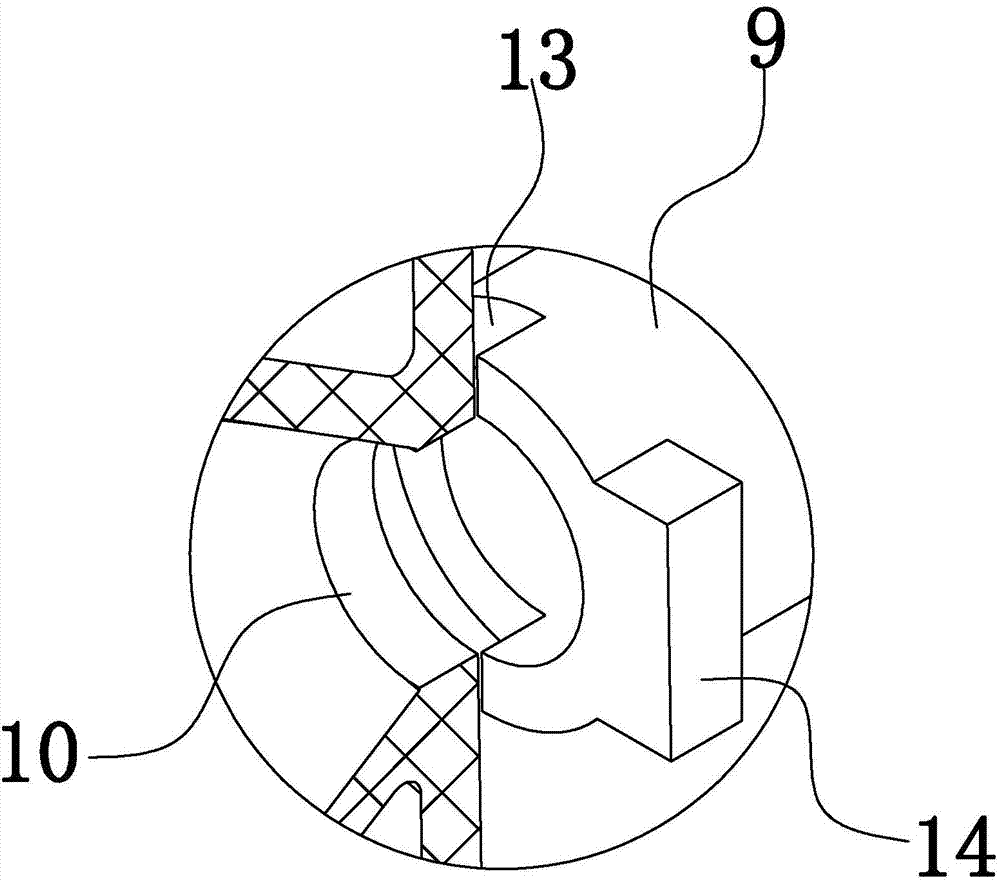

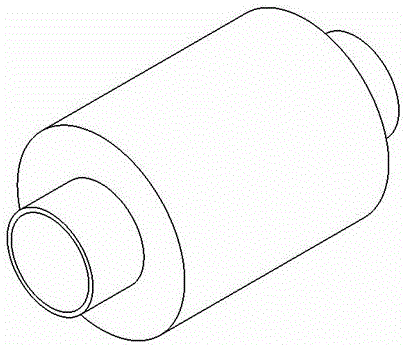

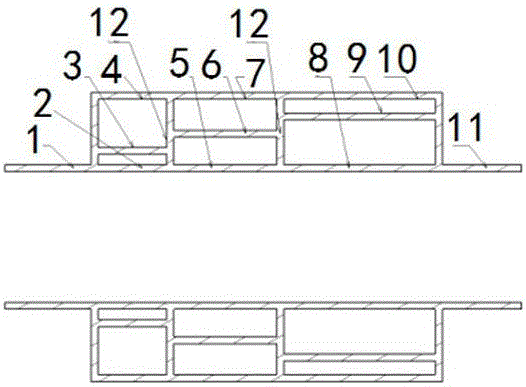

Engine exhaust system silencer

InactiveCN105697103AReduce exhaust noiseGood noise reduction effectSilencing apparatusMachines/enginesLow frequencyHigh Frequency Waves

The invention relates to the technical field of silencing, and discloses an engine exhaust system silencer. The engine exhaust system silencer comprises a cylinder, a front end cover and a back end cover fixed on the cylinder, an intake guide pipe communicated with an intake port in the front end cover, and an exhaust guide pipe communicated with an exhaust port in the back end cover; the internal of the cylinder is divided into a resistance silencing cavity and a blockage silencing cavity by a separation plate; the exhaust guide pipe penetrates through the separation plate, and an intake port thereof is positioned in the resistance silencing cavity; the intake guide pipe is inserted in the exhaust guide pipe from the intake port of the exhaust guide pipe, and the intersecting length of the two pipes is 300-400 mm; the intake guide pipe and the exhaust guide pipe are coaxially arranged; and the single-edge interval is 4-5 mm. The engine exhaust system silencer has a silencing effect on noise of low, medium and high frequency sections of an engine, in particular, has an obvious silencing effect on low-frequency noise under common rotating speed of the engine, and facilitates improvement of NVH performance of the engine.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Noise elimination structure of compressor and noise elimination method thereof

PendingCN110067733AGood noise reduction effectReduce noisePositive displacement pump componentsPositive-displacement liquid enginesEngineeringCommunicating vessels

The invention discloses a noise elimination structure of a compressor and a noise elimination method thereof. The noise elimination structure comprises a shell. The shell is internally provided with afirst partition board and a second partition board which divide the shell into a first noise elimination chamber, a second noise elimination chamber and a third noise elimination chamber. One end ofthe shell is provided with an inlet pipe communicating with the first noise elimination chamber and a coil pipe of the compressor, and the other end of the shell is provided with an outlet pipe communicating with the third noise elimination chamber and the coil pipe of the compressor. A communicating vessel hollow pipe is arranged on the first partition board and the second partition board. The inlet end of the communicating vessel hollow pipe is located in the first noise elimination chamber. The outlet end of the communicating vessel hollow pipe is located in the third noise elimination chamber. The middle section of the communicating vessel hollow pipe is located in the second noise elimination chamber. The position, close to the first partition board, of the middle section of the communicating vessel hollow pipe is provided with an expansion hole. The position, close to the second partition board, of the middle section of the communicating vessel hollow pipe is provided with a reverse collection hole. The expansion hole and the reverse collection hole are located on the two sides of the communicating vessel hollow pipe correspondingly. The noise elimination structure of the compressor can achieve the three-stage noise elimination function and is good in noise elimination effect.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

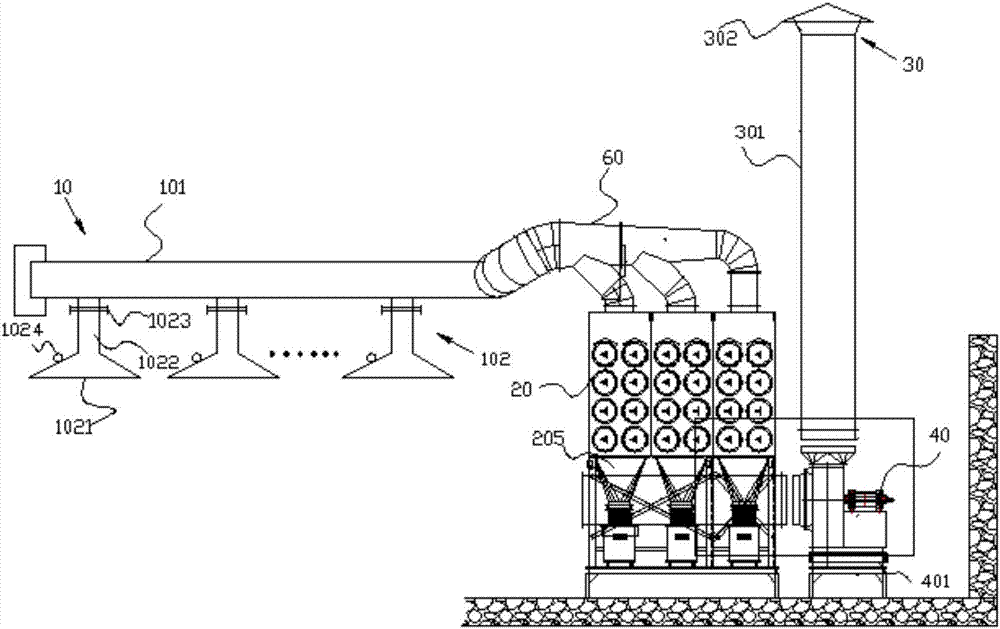

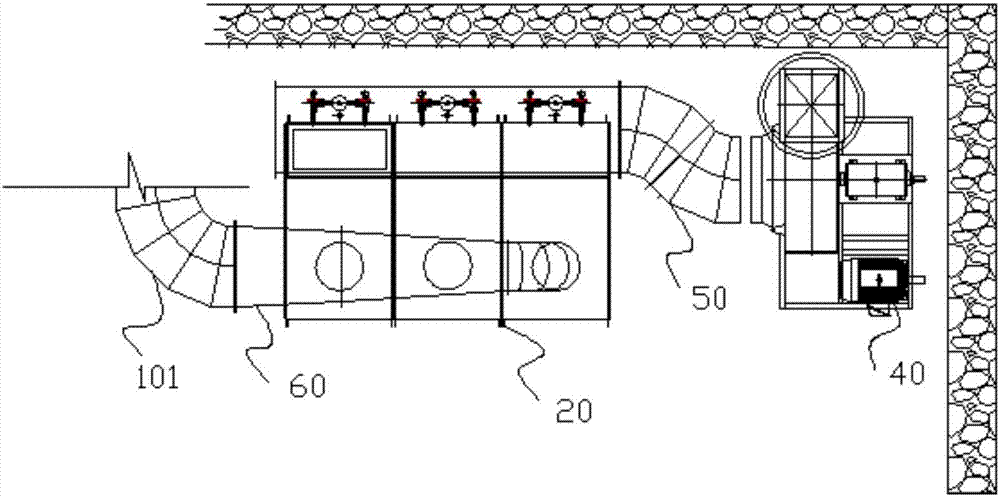

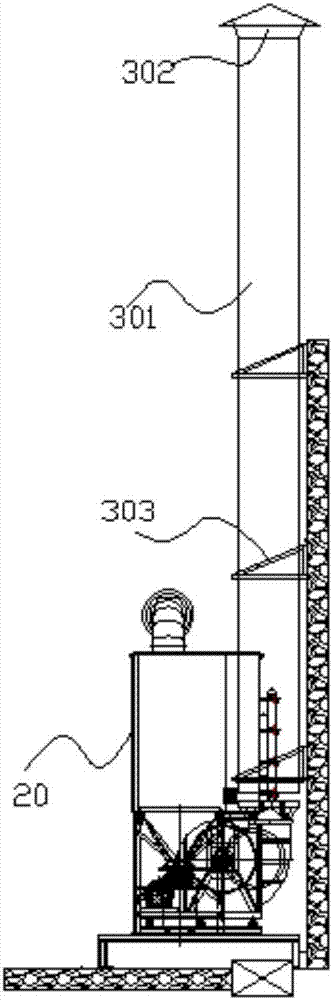

Dust treatment system for dusting workshop

InactiveCN107970705AImprove filtering effectSlow down the flowDispersed particle filtrationTransportation and packagingEmission standardEngineering

The invention discloses a dust treatment system for a dusting workshop. The dust treatment system for the dusting workshop comprises a dust collecting device, a horizontal filter drum type dust collector and a smoke exhausting device which are sequentially arranged in a dust flow direction, and an induced draft fan is further arranged on a dust flow channel; the dust collecting device communicateswith the horizontal filter drum type dust collector, and the horizontal filter drum type dust collector communicates with the smoke exhausting device; the horizontal filter drum type dust collector is provided with at least one dust treatment bin, each dust treatment bin comprises a first support, a bin body, an exhaust gas inlet, a clean air outlet and a dust collecting hopper. The dust treatment system for the dusting workshop, disclosed by the invention, is adopted to perform centralized treatment on dust in the workshop, so that the dust with large particle size is prevented from enteringa filter cylinder, dust airflow flowing into the equipment can be uniform, the flow velocity of the dust airflow on the outer wall of the filter cylinder is decreased, the filter effect of the filtercylinder is improved, the cleanliness of discharged gas is enhanced, the dust concentration in the gas is less than or equal to 30mg / m3, noise can be reduced to 30 to 40dB, the effects of sound elimination and noise reduction are ideal, national emission standards are met, and the standards of the dust treatment system for the dusting workshop are higher than the national emission standards.

Owner:JIANGSU YONGYI ENVIRONMENTAL PROTECTION TECH CO LTD

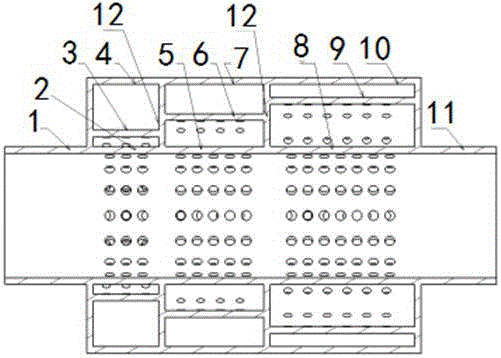

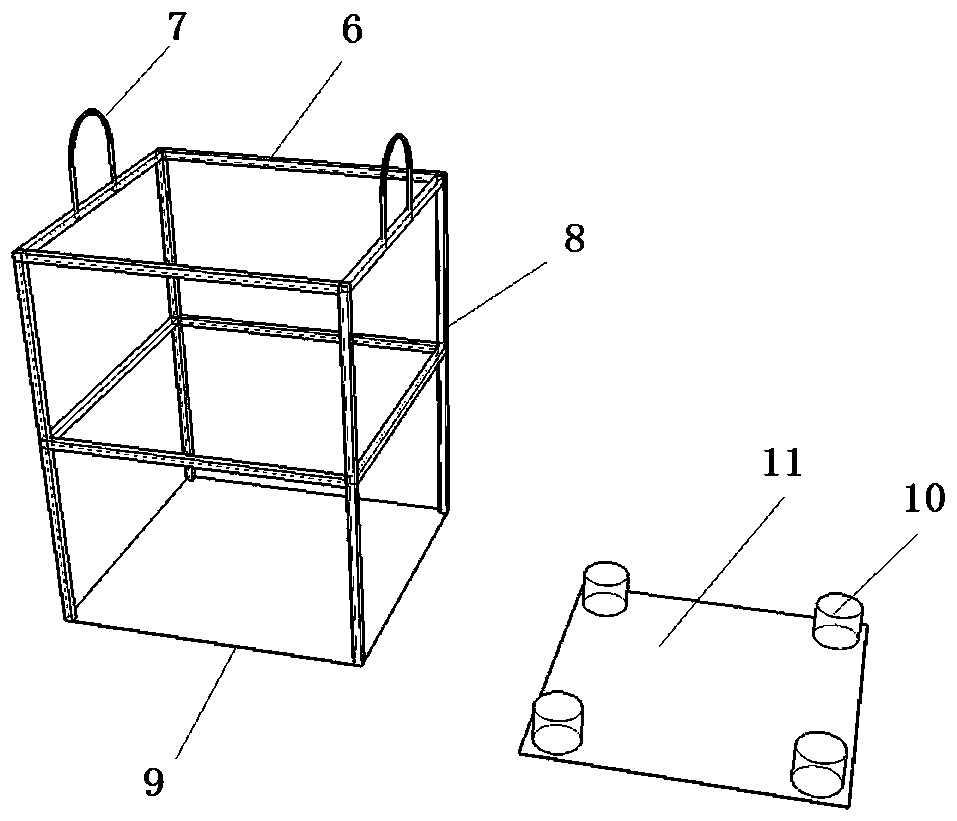

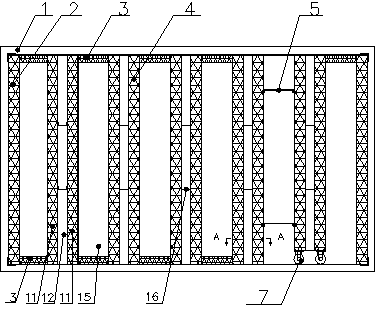

Large air-volume piece type impedance composite muffler

InactiveCN103541787AReduce pollutionReasonable structureSilencing apparatusMachines/enginesAir volumeNoise reduction

A large air-volume piece type impedance composite muffler comprises a frame, side sound absorption pieces and semicircle air deflectors, the left and the right of the inside of the frame are provided with a side sound absorption piece respectively, a plurality of ventilation cavities and sound absorption pieces are arranged between the two side sound absorption pieces at intervals, the upper portion and the lower portion of the inside of the one of the ventilation cavities are provided with sound absorption piece rotating arm devices, universal wheels are arranged below the sound absorption piece of one side of the sound absorption piece rotating arm devices, and positioning blocks are riveted to the upper end and the lower end of the rest ventilation cavities through rivets. The large air-volume piece type impedance composite muffler is reasonable in structure, significant in noise-reduction effect and wide in sound absorption frequency band, and reduces environmental pollution. The large air-volume piece type impedance composite muffler is applicable to ventilation facilities of underground railways and highway tunnels.

Owner:江苏华东正大空调设备有限公司

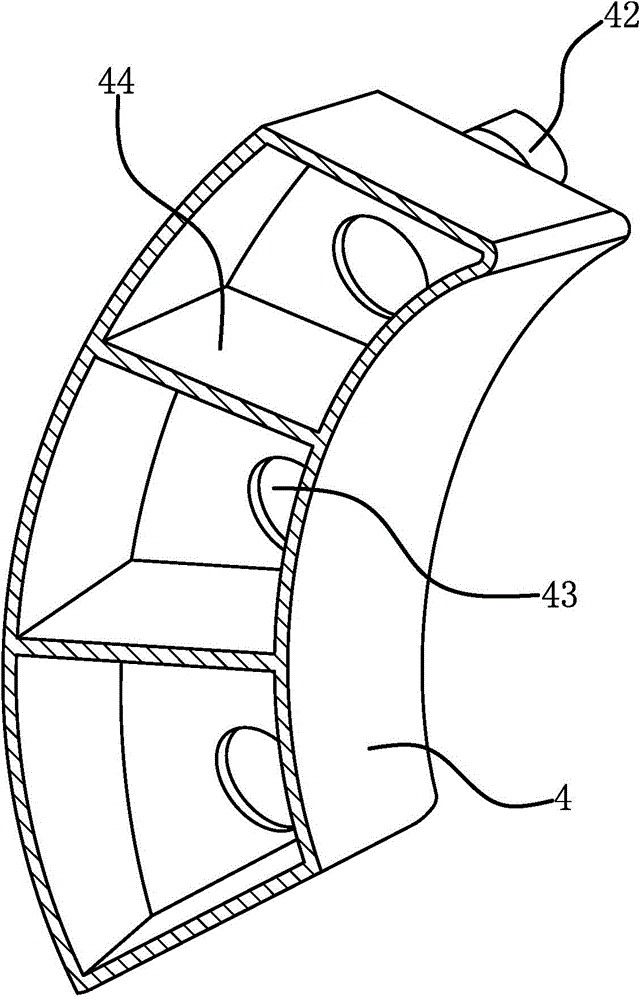

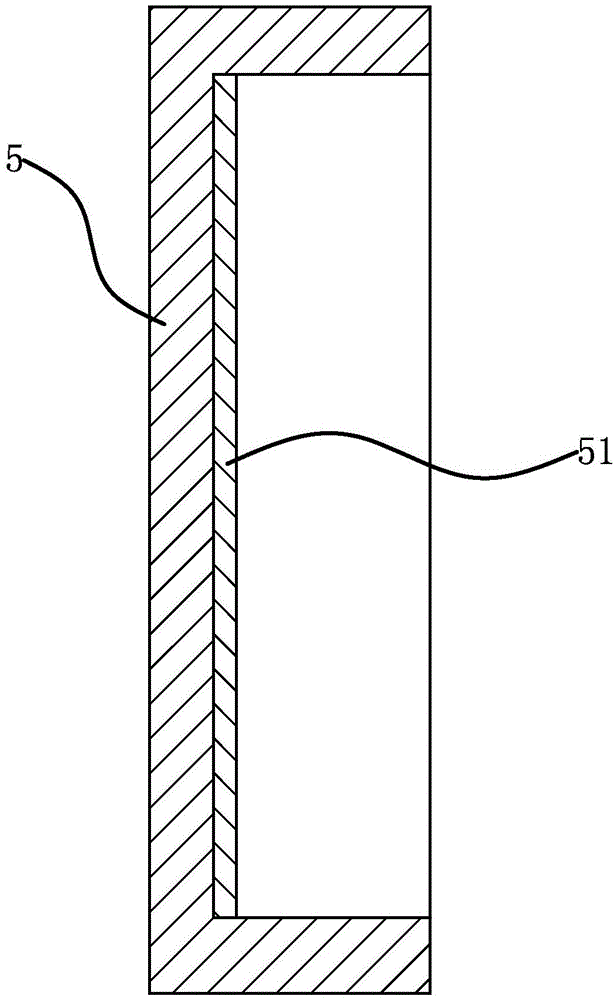

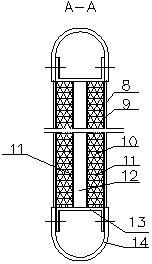

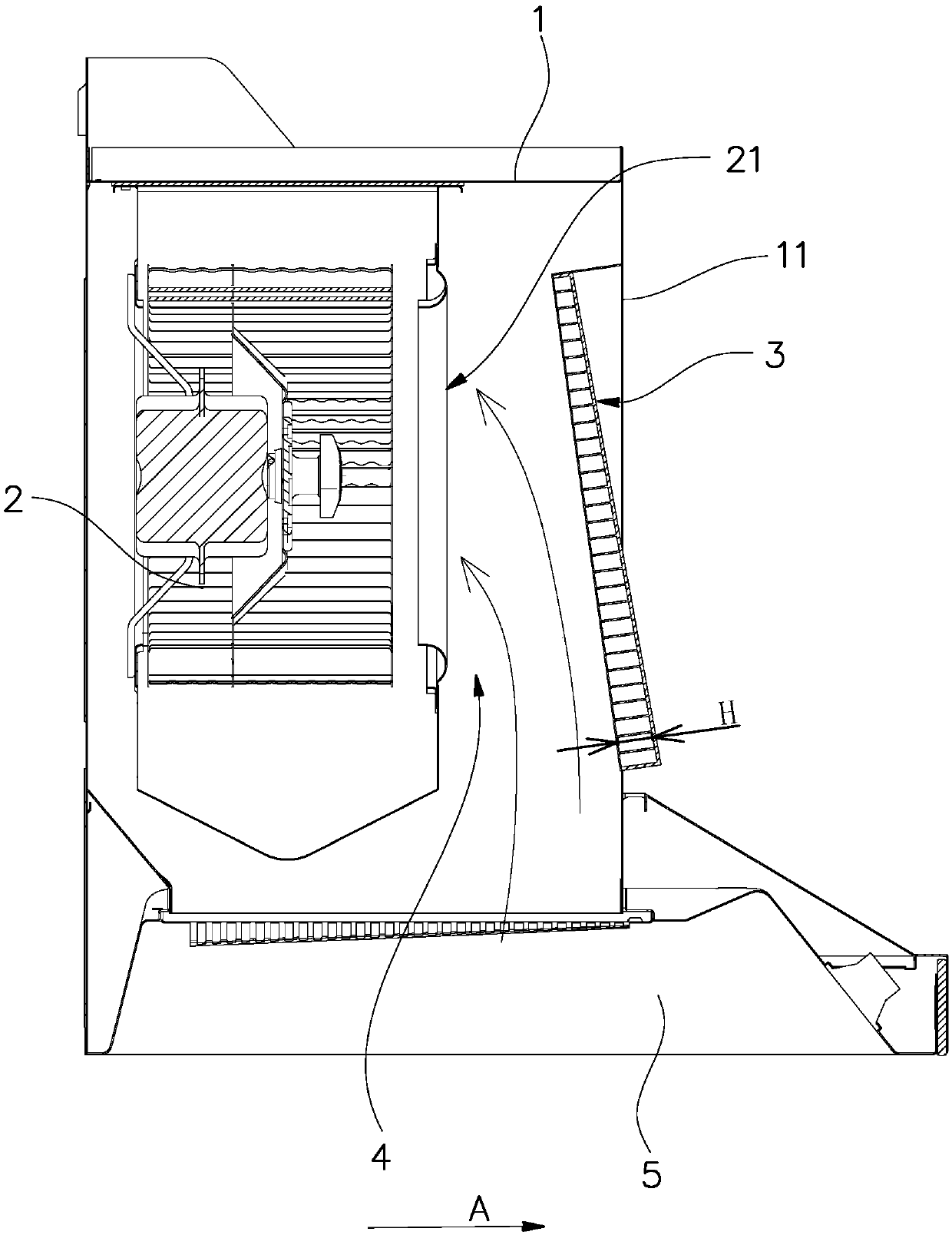

Noise reduction type extractor hood

PendingCN110094775AGood noise reduction effectThe resonant frequency matches theDomestic stoves or rangesPump componentsAirflowEngineering

A noise reduction type extractor hood includes a fan frame and a fan disposed in the fan frame; a noise reduction device is installed on a cover plate at a position directly facing an air inlet of thefan; and the extractor hood is characterized in that: an air inlet passage which is gradually narrowed from bottom to top is formed between the noise reduction device and the air inlet of the fan, the noise reduction device is provided with noise reduction cavities and noise reduction holes corresponding to the noise reduction cavities, the noise reduction cavities are arranged up and down in order, the noise reduction holes are disposed on the side surface of the noise reduction device opposite to the air inlet of the fan, and the ratio S / V of the area S of the noise reduction holes to the volume V of the corresponding noise reduction cavities gradually increases from bottom to top. The air inlet passage which is gradually narrowed from bottom to top is formed between the noise reductiondevice of the noise reduction type extractor hood and the air inlet of the fan, the ratio S / V of the area S of the noise reduction holes to the volume V of the corresponding noise reduction cavitiesgradually increases from bottom to top, and a Helmholtz resonance noise elimination principle is utilized, so that the resonance frequency of the noise reduction device is matched with the airflow noise frequency located at a corresponding horizontal plane, and noise reduction and noise elimination effects are good.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

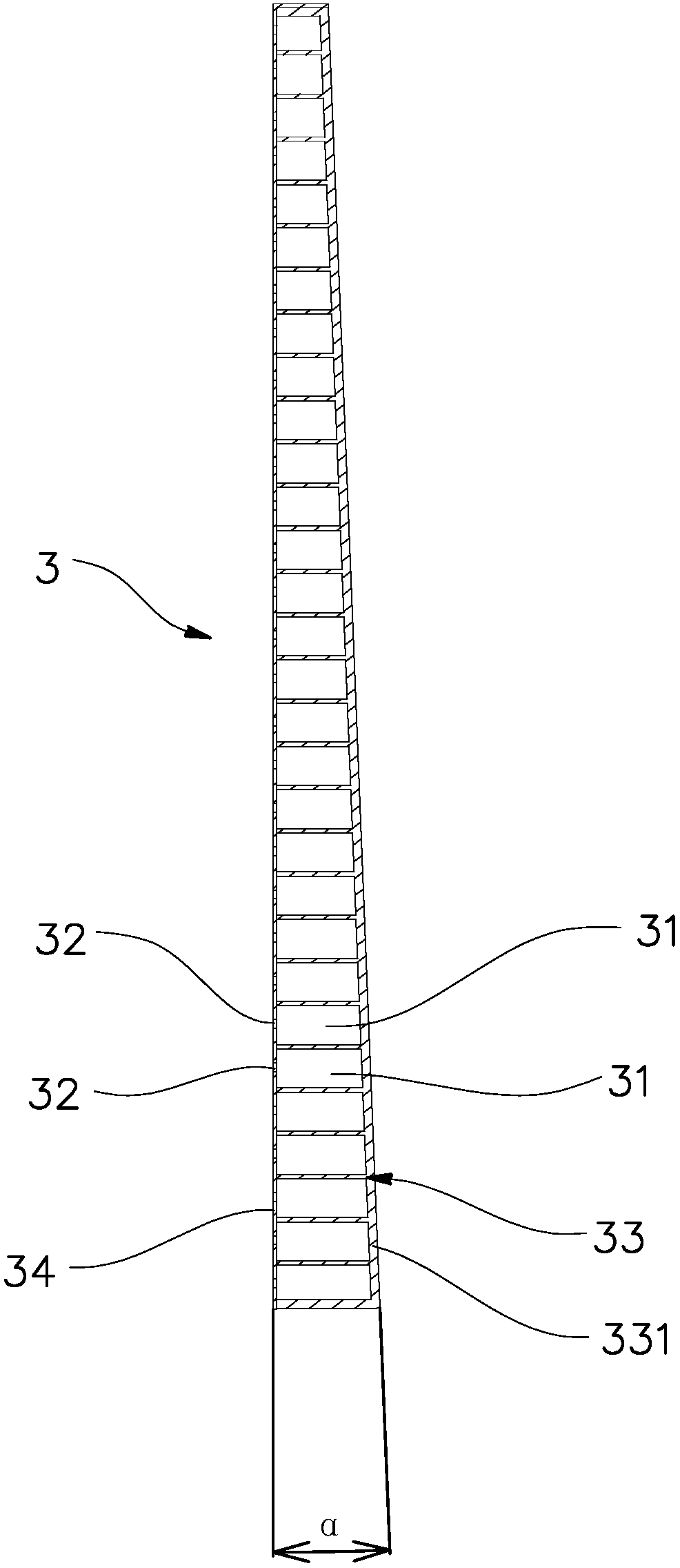

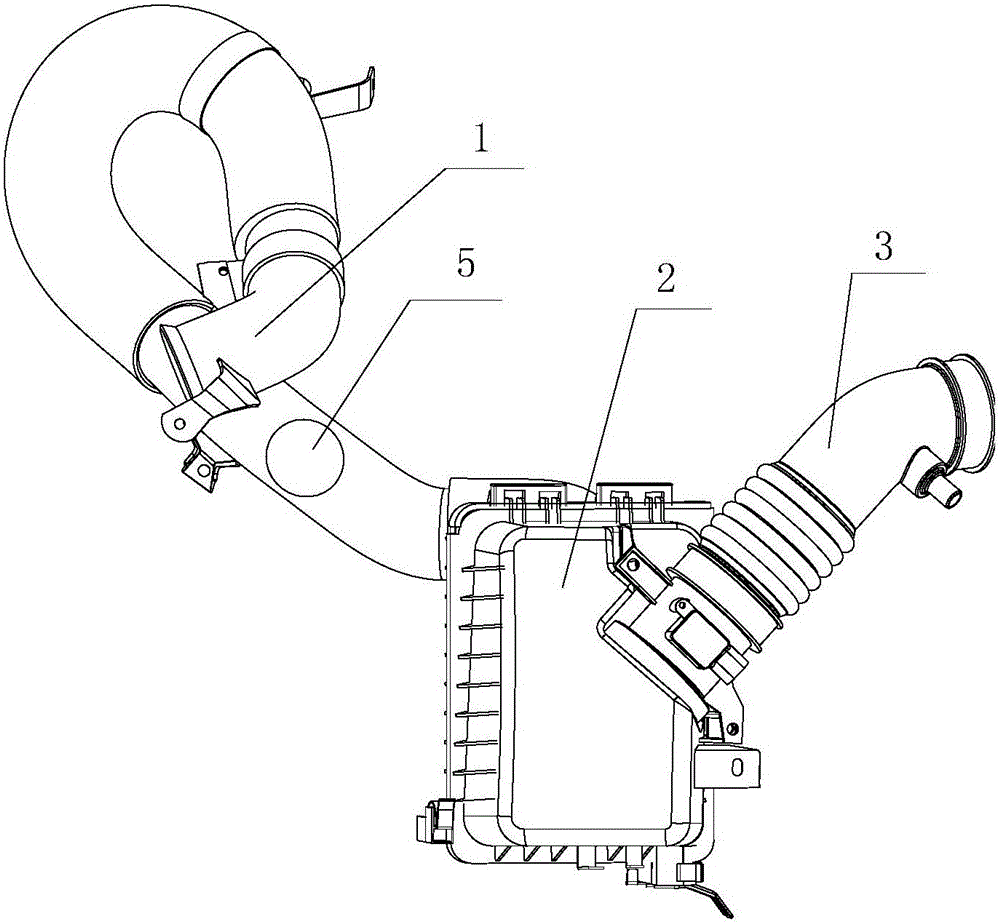

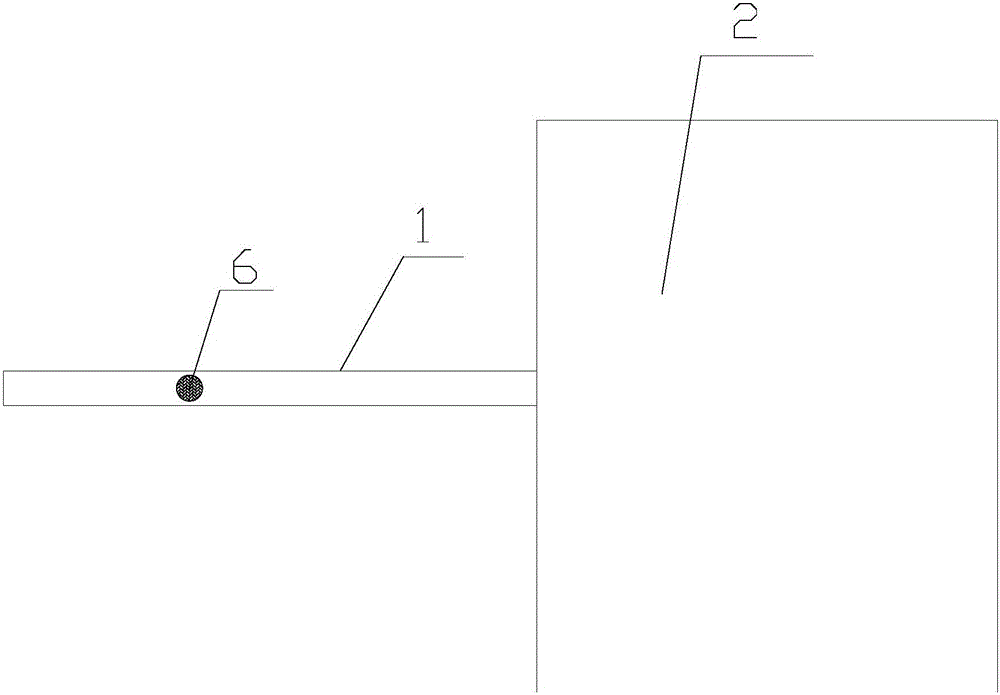

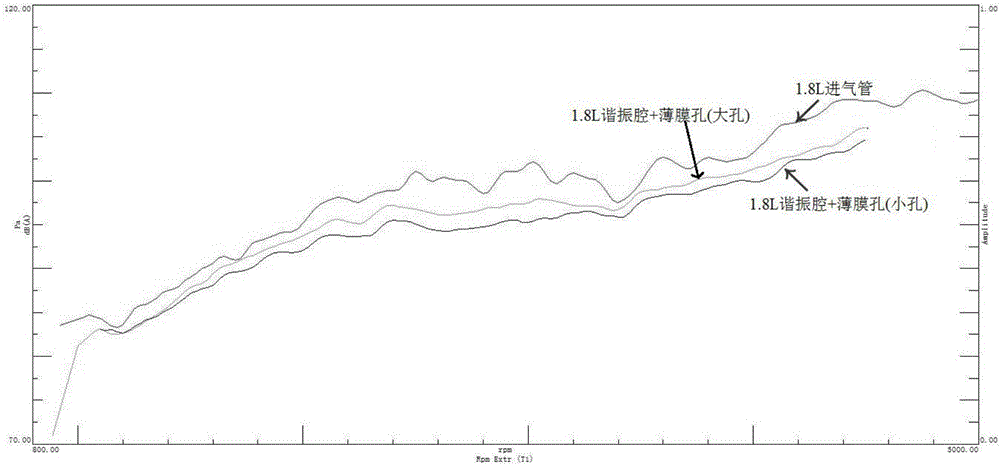

Film vibration absorber installed on air inlet system of automobile

InactiveCN105822467AReduce noiseSolving Low Frequency Noise ProblemsMachines/enginesIntake silencers for fuelAir filterInterior noise

The invention discloses a film vibration absorber installed on an air inlet system of an automobile. The film vibration absorber is used for eliminating at least one kind of interior noise caused by the air inlet system. The air inlet system of the automobile comprises an air inlet pipe, an air filter and an air outlet pipe which are sequentially connected. The vibration absorber comprises an opening hole formed in the portion, which vibrates abnormally, of the air inlet pipe, and a film covering the outer side of the opening hole in a sealing mode. The hole diameter of the opening hole is smaller than the diameter of the air inlet pipe. On the premise of not increasing a noise lowering space of the air inlet system and under the reasonable cost control, the noise of low, medium and high frequency bands in the air inlet system can be effectively lowered.

Owner:WUHAN UNIV OF TECH

Noise reduction structure and noise reduction method of high-speed and high-pressure centrifugal blower

PendingCN113775572AIncrease the lengthIncrease the anechoic areaPump componentsPumpsResonant cavityAir blower

The invention discloses a noise reduction structure and noise reduction method of a high-speed and high-pressure centrifugal blower. The noise reduction structure comprises an upper box body, a lower box body and a connecting air duct, the bottom end of the upper box body is vertically connected to the top end of the lower box body through the connecting air duct, an air outlet is formed in the front side of the upper box body, and an air inlet is formed in the rear side of the lower box body. A resonant cavity, an air outlet noise reduction cavity, a first filter plate and multiple layers of noise reduction channel plates are arranged in the lower box body, the first filter plate and the noise reduction channel plates are sequentially arranged in the resonant cavity between the air inlet and the air outlet noise reduction cavity, and 1 / 4 wavelength pipes are installed on the left side wall, the right side wall and the top in the upper box body. Flow guide plates are arranged on the inner wall of the front side of the upper box body and along the periphery of the air outlet. According to the noise reduction structure and the noise reduction method, the flowing path of high-speed air flow from the lower box body to the upper box body is gradually weakened, and in the high-speed flowing process of high-speed air, the length of a silencing pipeline is increased; and meanwhile, the flow speed of the air is strictly controlled in the resonant cavity, and the good restraining, silencing and noise reduction effect can be achieved.

Owner:湖南泛航智能装备有限公司

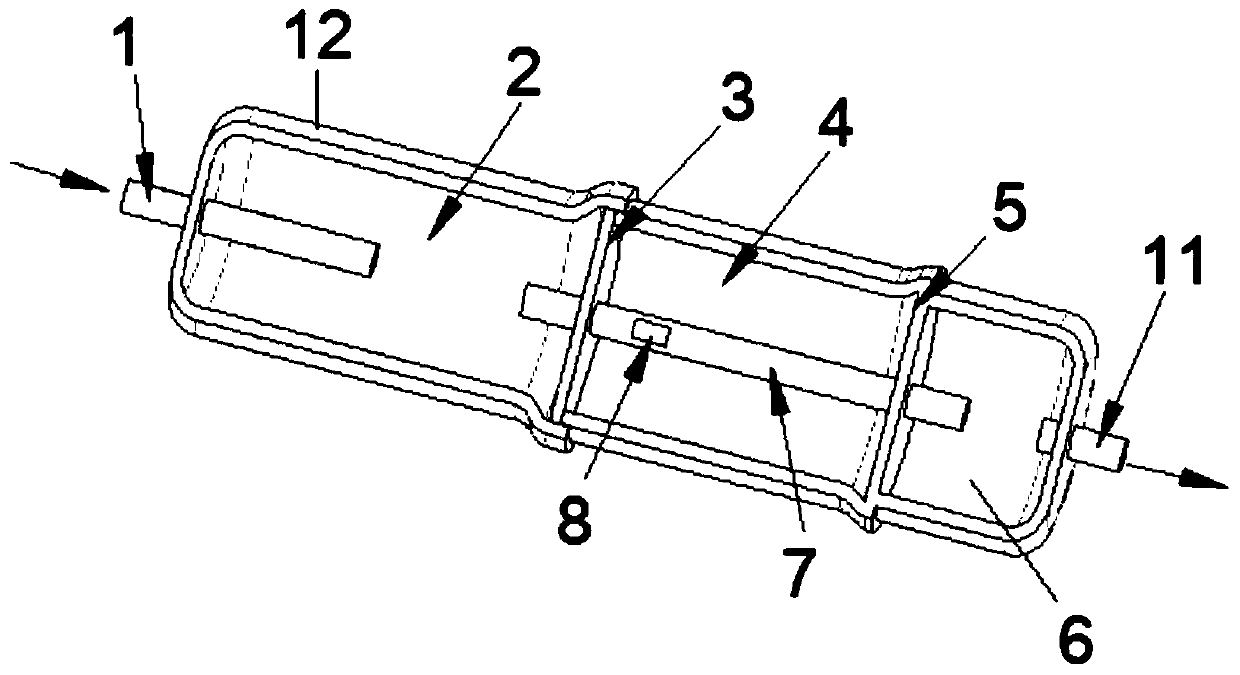

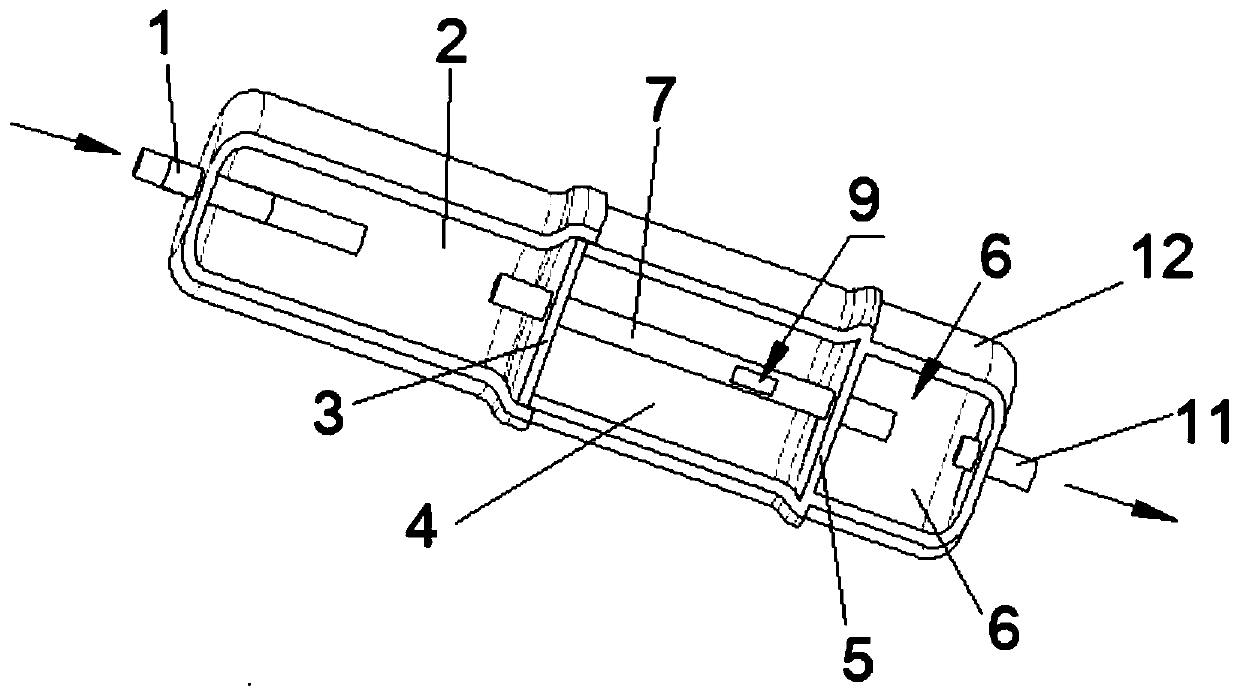

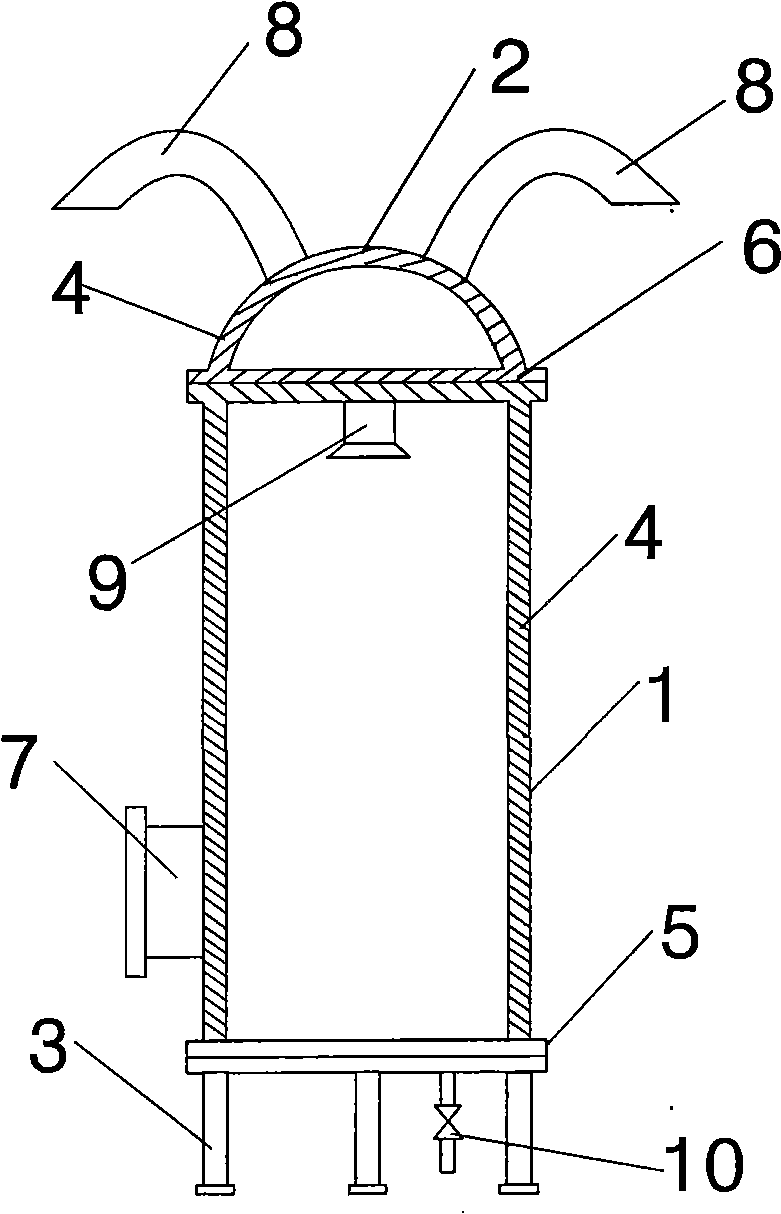

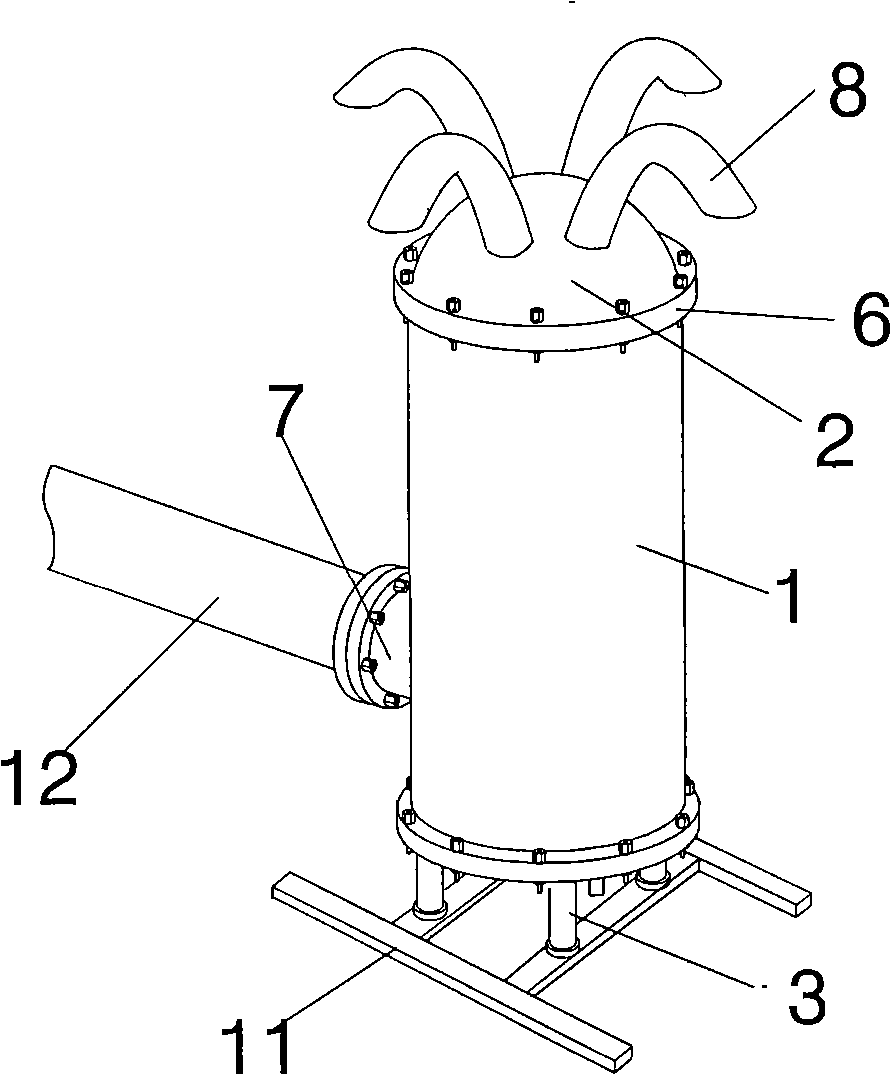

Silencing method for gas exhaustion/steam discharging pipe of electric power plant, and novel environment friendly silencer

The invention relates to a method to muffle the exhaust and the blow-off pipelines of power plants as well as a novel environment-friendly muffler. 1) A novel muffler is used to deaden the noise of the waste gas or water vapor discharged from the exhaust and blow-off pipelines of a power plant, and then the waste gas and water vapor are discharged, and thereby, silencing is achieved; 2) the novel environment-friendly muffler comprises a main body (1) and a cover body (2), a noise-absorbing layer (4) is arranged on the intracavity wall of the main body (1) and the intracavity wall of the cover body (2); a pipeline connecting opening (7) is arranged on the side wall or the bottom surface of the main body (1), a plurality of exhaust pipes (8) with a cross section smaller than the cross section of the main body (1), and a flow guide pipe (9) communicating with the cover body (2) is arranged in the cover plate (6). The invention has the advantages of simple structure, utilization of local materials, low cost, easy assembly and disassembly and remarkable noise muffling effect. The invention can be extensively applied to muffling the exhaust and blow-off pipelines of rotary machines in power plants.

Owner:GUANGDONG ELECTRIC POWER DESIGN INST

Novel damping composite and thermal compounding process

InactiveCN110551386ARecyclableEnvironmental protectionBulk chemical productionLow-density polyethyleneElastomer

The invention discloses a novel damping composite. The composite comprises the following components by mass: 180-200 parts of a thermoplastic elastomer, 50-80 parts of low density polyethylene, 80-150parts of an auxiliary agent, 60-90 parts of oleamide, and 30-50 parts of polyethylene wax. The invention also discloses a thermal compounding process of the novel damping composite. The thermoplasticelastomer is added into the damping composite, so the composite has good elasticity and damping and sound attenuation functions, and can still maintain good elasticity at low temperatures, which effectively overcomes the shortcomings of hardening and embrittlement of a bitumen-based damping material during stirring at low temperatures. The composite has the advantages of good compatibility duringprocessing, good processing performance, no toxic or harmful substance generation during preparation, good aging resistance and high reliability; and the composite is recyclable, environmentally-friendly in using, pollution-free, and energy-saving.

Owner:ANHUI ZHICHENG ELECTROMECHANICAL SPARE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com