Noise reduction structure and noise reduction method of high-speed and high-pressure centrifugal blower

A centrifugal blower, high-speed technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of low noise reduction coefficient, high-frequency aerodynamic noise, complex structure, etc. The effect of length, good noise reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

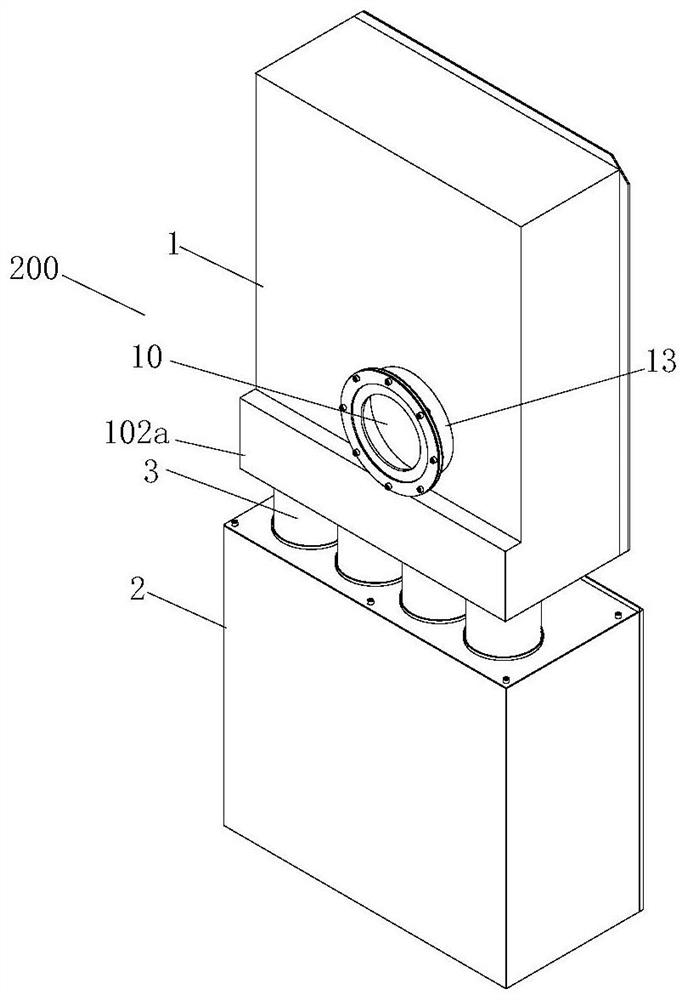

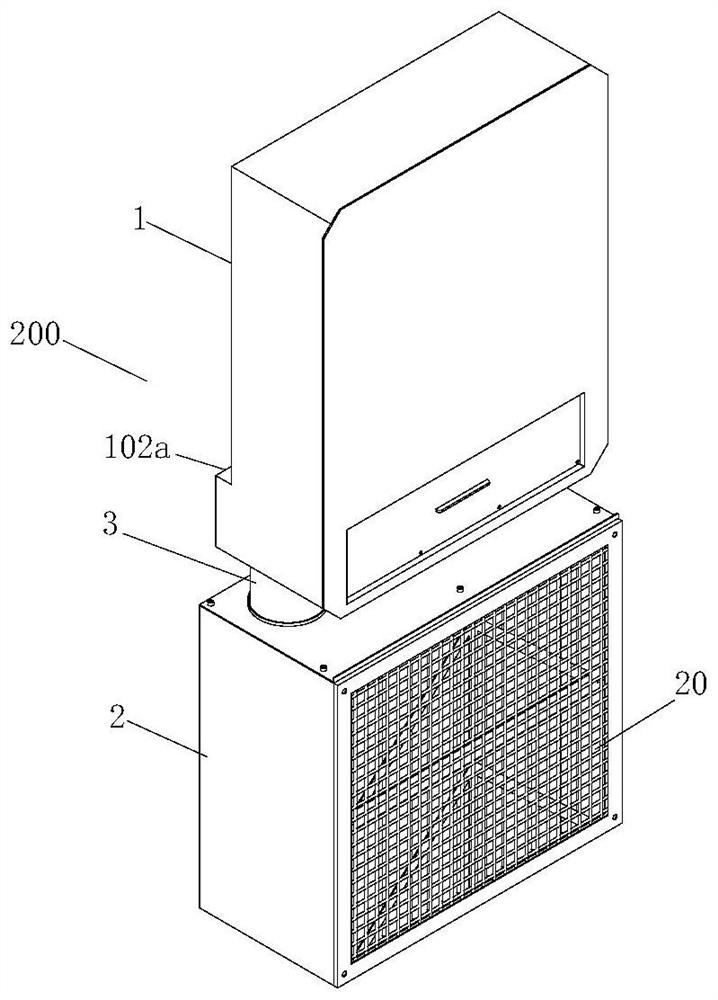

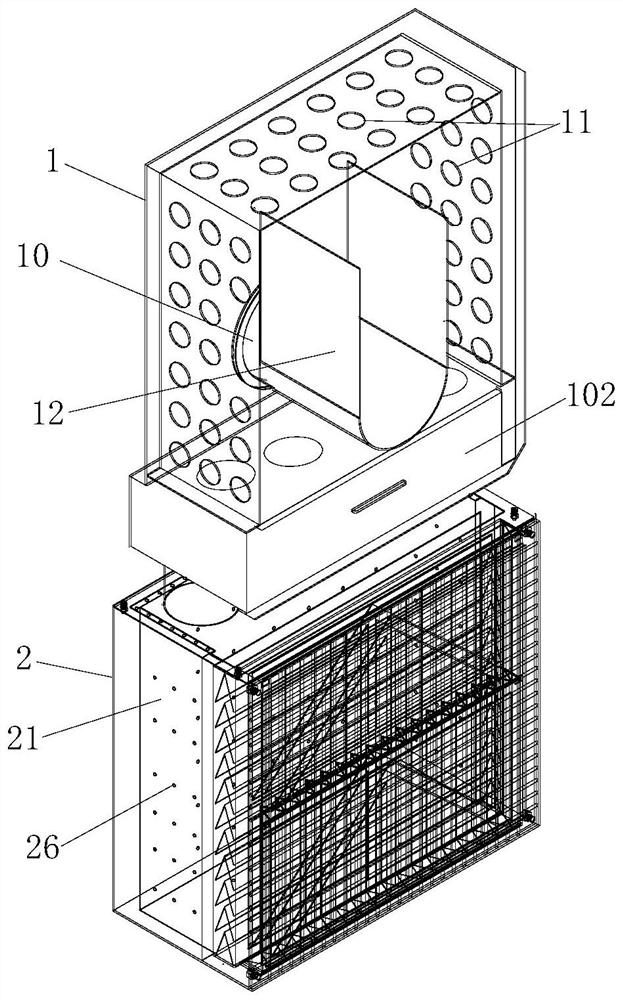

[0025] combine figure 1 , figure 2 , image 3 with Figure 4As shown, according to a noise reduction structure of a high-speed and high-pressure centrifugal blower of the present invention, the noise reduction structure includes a noise reduction box body 200, and the noise reduction box body 200 includes an upper box body 1, a lower box body 2 and a connecting air cylinder 3 , the number of the connecting air cylinder 3 is 1 or more, the number of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com