Silencing method for gas exhaustion/steam discharging pipe of electric power plant, and novel environment friendly silencer

A technology for steam exhaust pipes and mufflers, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of complex structure and high cost of muffler equipment, and achieve obvious muffling effect, low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

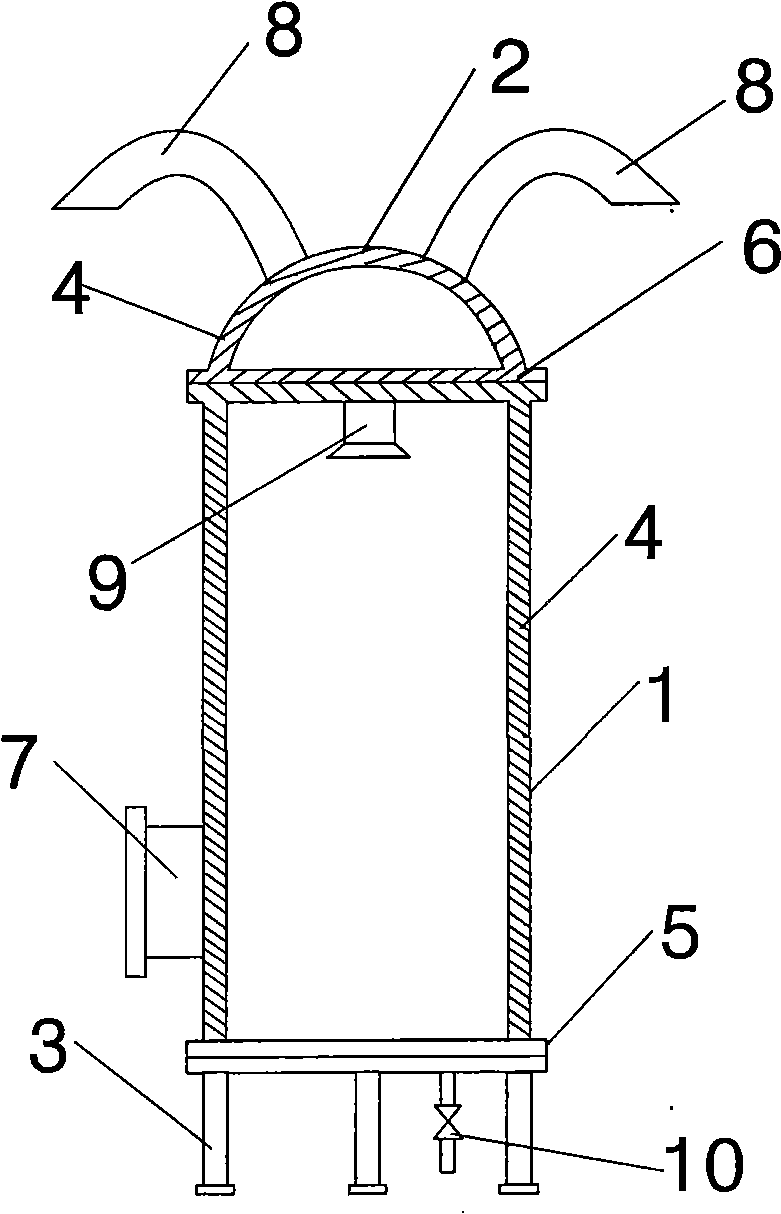

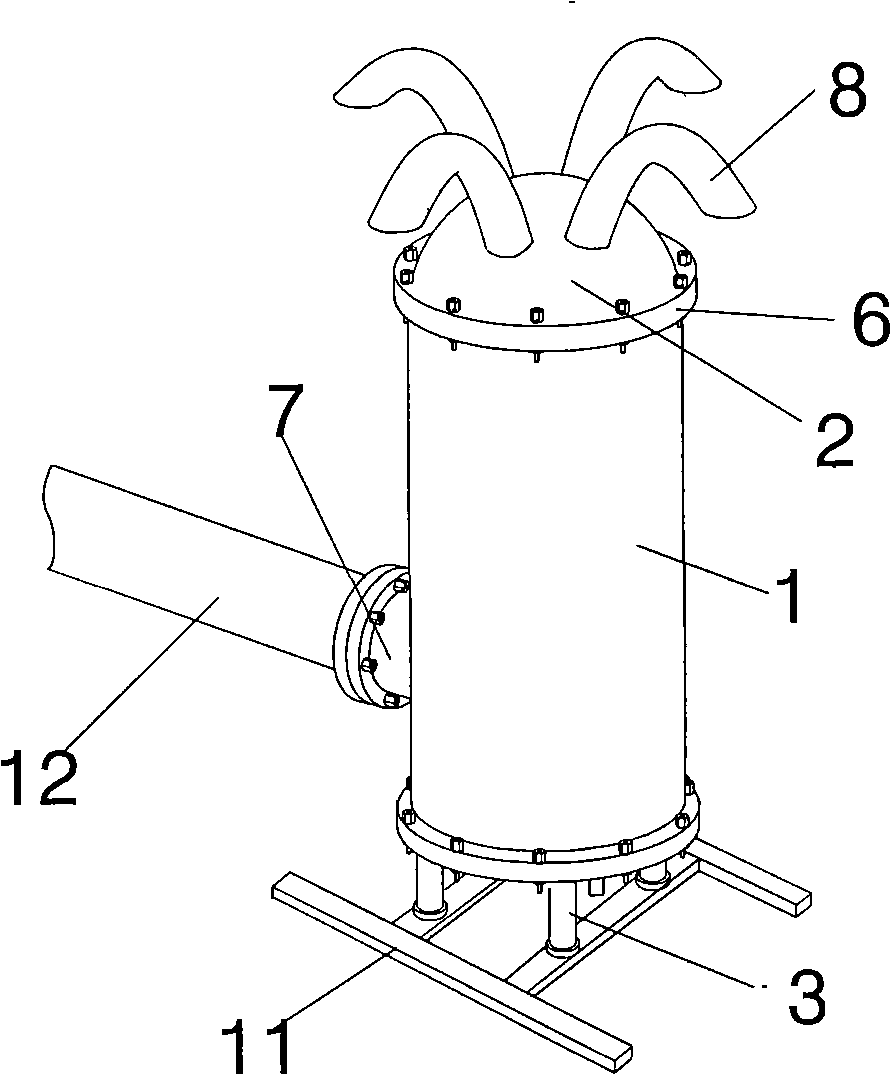

[0024] refer to figure 1 , the muffler of the present invention includes a main body 1 and a cover body 2, and a sound-absorbing layer 4 is provided on the inner cavity walls of the main body 1 and the cover body 2; The cover body 2 is fixedly connected; the side wall of the main body 1 is provided with a pipe connection port 7, the cover body 2 is provided with four exhaust pipes 8 whose cross-section is smaller than that of the main body 1, and the cover plate 6 is provided with a guide that communicates with the inner cavity of the cover body 2. Flow tube 9.

[0025] In this example:

[0026] The bottom surface of the main body 1 is further provided with a base 3 , and the base 3 is fixedly connected to the main body 1 through a bottom plate 5 , and a drain pipe 10 communicating with the inner cavity of the main body 1 is arranged in the bottom plate 5 . The base 3 consists of three or four supporting feet 31 made of angle steel. The exhaust pipe 8 is composed of four pi...

specific Embodiment 2

[0034] The feature of this embodiment is that the main body 1 and the cover body 2 are integrally formed, and the inner cavity of the main body 1 and the inner cavity of the cover body 2 are separated by the cover plate 6 . The rest are the same as in specific embodiment 1.

specific Embodiment 3

[0035] The features of this embodiment are: the inner cavity wall of the main body 1 is provided with a sound-absorbing layer 4; the main body 1 and the cover body 2 can be integrally formed, and the inner cavity of the main body 1 and the inner cavity of the cover body 2 are separated by the cover plate 6 , it can also be a separate structure, and the main body 1 and the cover body 2 are fixedly connected through the cover body 6 . The rest are the same as in specific embodiment 1.

[0036] Other examples:

[0037] The best embodiment of the present invention is to use angle steel as the base 4, so as to realize the most convenient fixed connection with the roof and save costs. The number of exhaust pipes 8 can be two, three, five, six, eight or ten; the sound absorbing layer 4 can be made of soft thermal insulation material. The drain pipe 10 is provided with a water valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com