Flexible silencer

A muffler, a flexible technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of inconvenient construction, small space, and affecting the quality of the project, and achieve good noise reduction effect, low cost, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

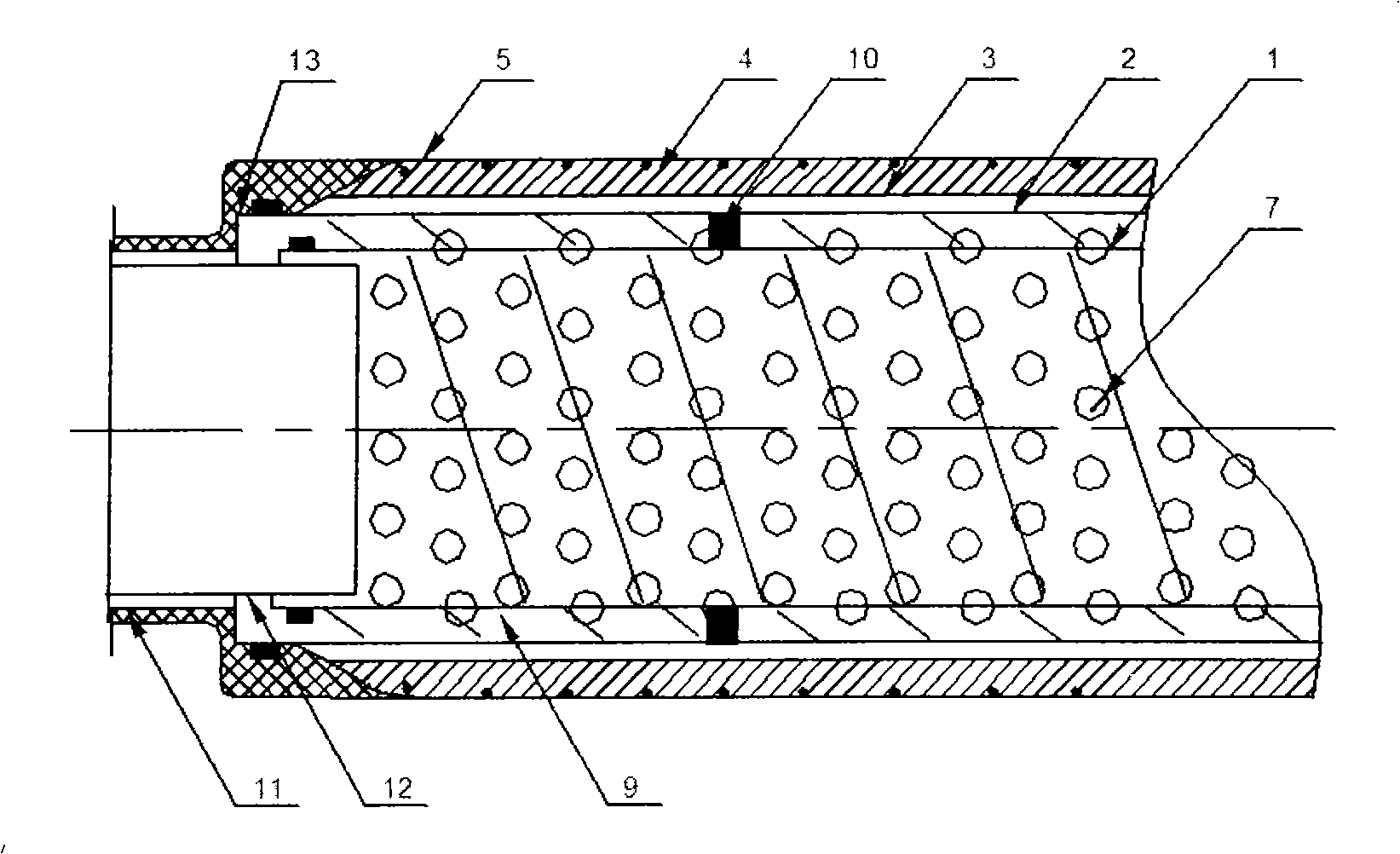

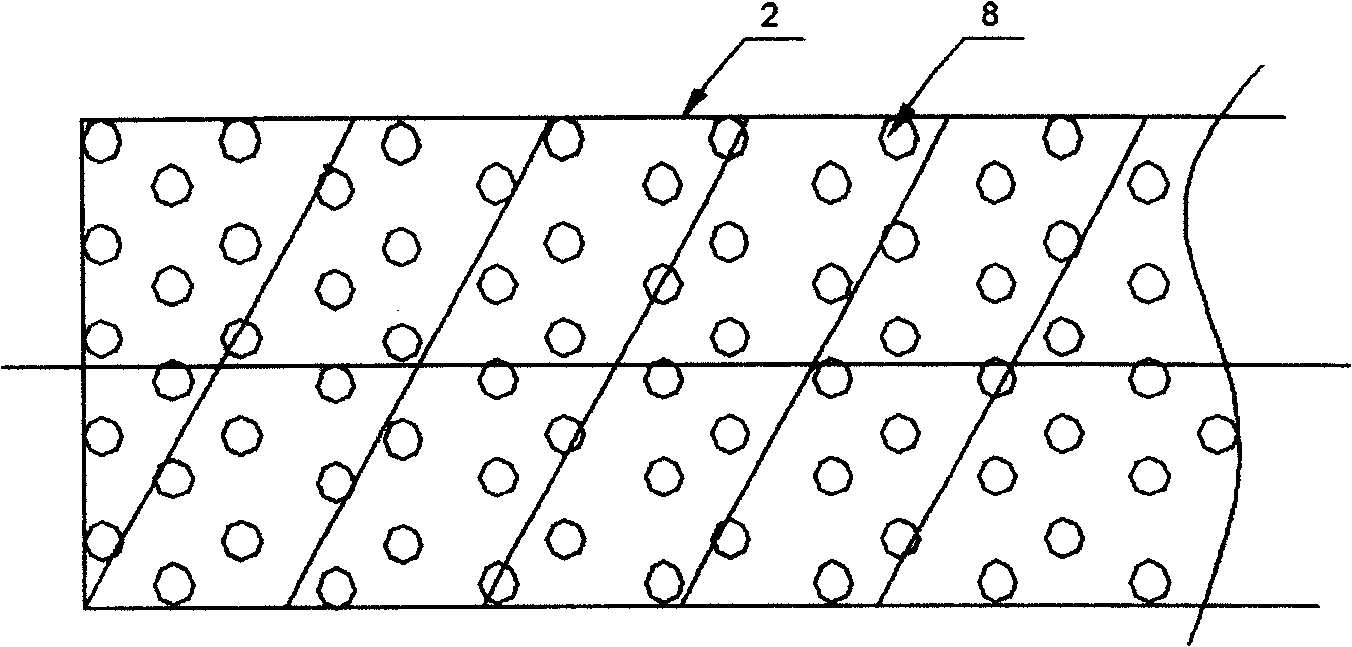

[0032] A flexible muffler, the two ports are interface flanges 11, the middle part is provided with a muffler inner hose 1, the muffler inner hose 1 is densely covered with muffler holes 7, and the outside of the muffler inner hose 1 is covered with a muffler outer hose 2; The outer silencing hose 2 is densely covered with silencing holes 8 . A sound-absorbing cavity 9 is provided between the sound-absorbing inner hose 1 and the sound-absorbing outer hose 2, and a fixing ring 10 is arranged in the middle of the sound-absorbing cavity 9 to ensure that the sound-absorbing cavity 9 still works when the present invention is bent. to the noise reduction effect. The outside of the noise-absorbing outer hose 2 is provided with an isolation layer plastic film 3. The function of the isolation layer plastic film 3 is to prevent the tiny fibers of the sound-absorbing layer 4 from entering the air duct through the silencer hole 8 of the noise-absorbing outer hose 2. The isolation layer pl...

Embodiment 2

[0035] In Embodiment 1, the caliber of the inner hose 1 in the silencer is a fixed value, while in Embodiment 2, under the condition that the caliber of the outer sleeve 2 of the sound-absorber remains constant, the caliber of the inner hose 1 in the silencer is variable, namely : In the present embodiment, the inner hose 1 of the silencer, the caliber of one section will be greater than or smaller than the diameter of the inner circle interface 12 of the interface flange 11, but the condition is to be less than the caliber of the outer hose 2 of the silencer. In this way, a variable diameter area can be formed in the gas flow channel of the present invention, so that the gas delivery path can be changed, causing the noise and vibration to be reflected in this variable diameter area, thereby achieving a better noise reduction effect.

Embodiment 3

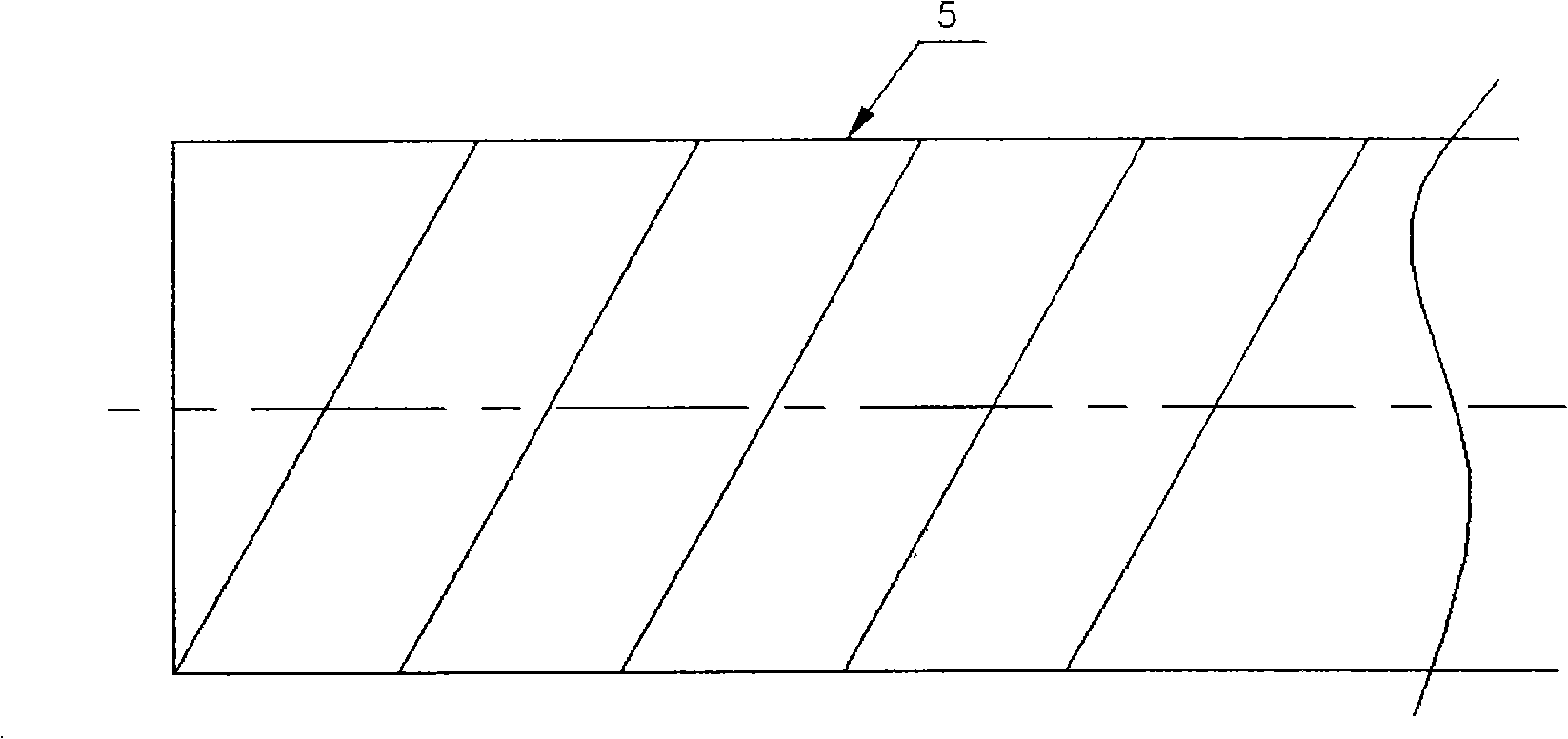

[0037] In the above-mentioned embodiments, the inner sound-absorbing hose 1 is arranged inside the outer sound-absorbing hose 2 in a single form. In this embodiment, the sound-absorbing inner hose is arranged inside the composite hose 5 in the form of a sound-absorbing inner hose bundle 13 .

[0038] Such as Figure 4-Figure 7 As shown, the interface flange 14 involved in this embodiment has a plurality of interfaces 15 connected to the ports of the sound-absorbing inner hose bundle 13; the sound-absorbing inner hose bundle 13 is spirally arranged inside the composite hose 5, as Image 6 As shown; the isolation layer plastic film 3 and the sound-absorbing layer 4 are sequentially arranged between the sound-absorbing inner hose bundle 13 and the composite hose 5; When the upper interface 15 is connected, it is fixed with a clip 16, and the composite hose 5 is connected with the outer circle of the interface flange 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com