Sound-proof door structure

A technology for soundproof doors and soundproof strips, which is applied to soundproof doors/windows, door leaves, windows/doors, etc., which can solve problems such as abnormal reflection, affecting sound insulation effect, and insufficiency of brain nerves, so as to improve sound insulation performance and reduce noise obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

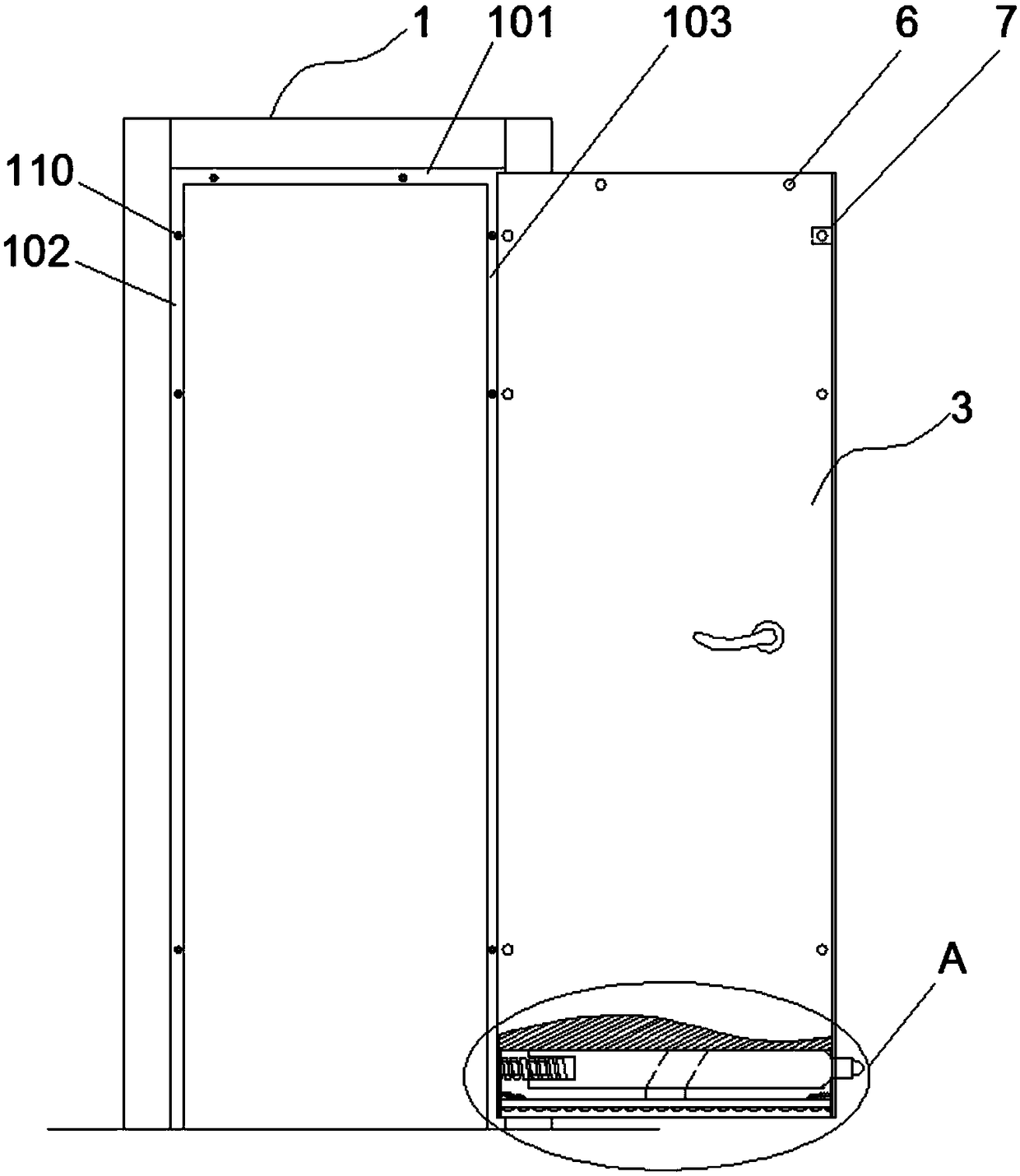

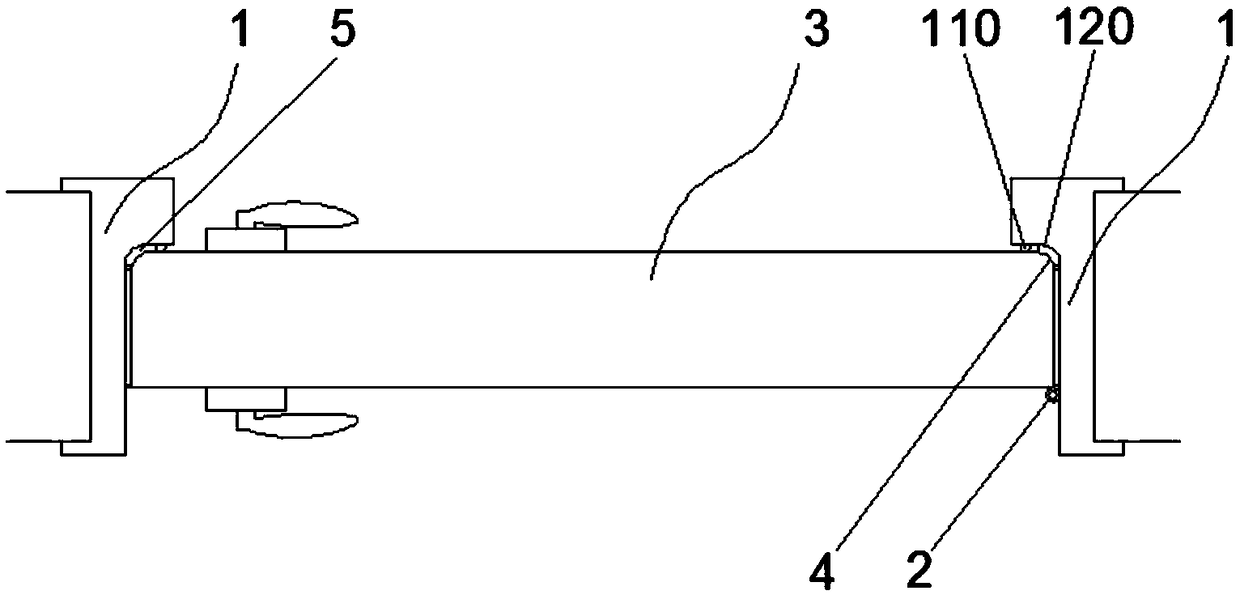

[0038] like figure 1 and figure 2 As shown, the present invention is a soundproof door structure, including: a door frame 1 and a door panel 3 arranged on the wall, the door panel 3 is connected to the door frame 1 through a hinge 2, and the door panel 3 is opened inwardly Direction, inward opening direction not only has good sound insulation effect, but also has a good anti-theft effect. The upper frame 101, the left frame 102 and the right frame 103 of the door frame 1 are respectively provided with an inner arc surface 120 of the same radian, and a sound insulation strip 5 is pasted and fixed on the inner arc surface 120, in order to make the sound insulation strip 5 and the inner arc surface The bonding effect of the arc surface 120 is better, and the sound insulation strip 5 is designed to be the same as the arc of the inner arc surface 120 . The door panel 3 is provided with an outer arc surface 4 corresponding to the inner arc surface 120 of the door frame 1, and the...

Embodiment 2

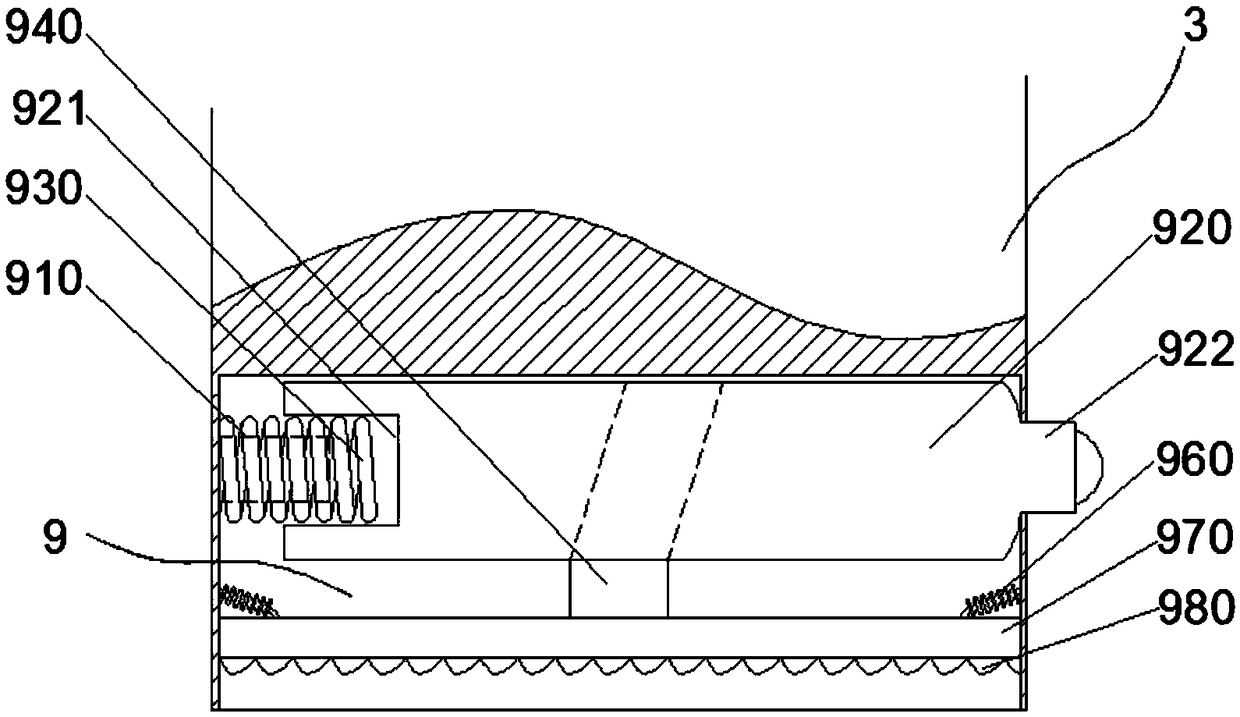

[0043] The difference between Embodiment 2 and Embodiment 1 lies in that the structure of the contact part of the horizontal rod 920 and the lifting mechanism is different. like Image 6 As shown, the bottom of the horizontal rod 920 in contact with the lifting mechanism is a downwardly protruding wave-shaped protrusion 924. The lifting mechanism includes a vertical rod 950, a horizontal baffle 970 and a roller 951. The horizontal baffle 970 Fixed on the bottom of the pole, the roller 951 is arranged on the top of the pole 950 , and the roller 91 is in rolling contact with the wave-shaped protrusion 924 at the bottom of the horizontal pole 920 . When the protruding head 922 is located inside the bottom channel 9, the roller 951 is located on a wavy protrusion 924 of the horizontal rod 920, the position of the lifting mechanism moves down, and the sound-absorbing strip 980 is located outside the bottom channel 9; when the protruding head 922 is located on the bottom channel Wh...

Embodiment 3

[0045] Embodiment 3 On the basis of Embodiment 1 or Embodiment 2, the following solutions are proposed for the gap between the left and right sides and the upper part of the door panel 3 and the door frame 1, resulting in no sound insulation. like figure 1 As shown, on the surface of the upper frame 101, the left frame 102 and the right frame 103 of the door frame 1, a plurality of tapered protrusions 110 are respectively arranged at intervals along the length direction or width direction of the door panel 3, between the door panel 3 and the door frame 1 A blind hole 6 corresponding to each tapered protrusion 110 is provided on the mating surface, and a side channel 7 communicating with the blind hole 6 is provided on the side wall of the door panel 3, and an extension mechanism is provided in the side channel 7 , the protruding end of the extending mechanism is connected to the sealing edge strip 8, and the sealing edge strip 8 is located in the side channel 7, and the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com