Noise reduction type extractor hood

A range hood and noise reduction technology, which is applied in the direction of removing oil fumes, mechanical equipment, machines/engines, etc., can solve problems such as inability to reduce noise, and achieve good noise reduction and noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

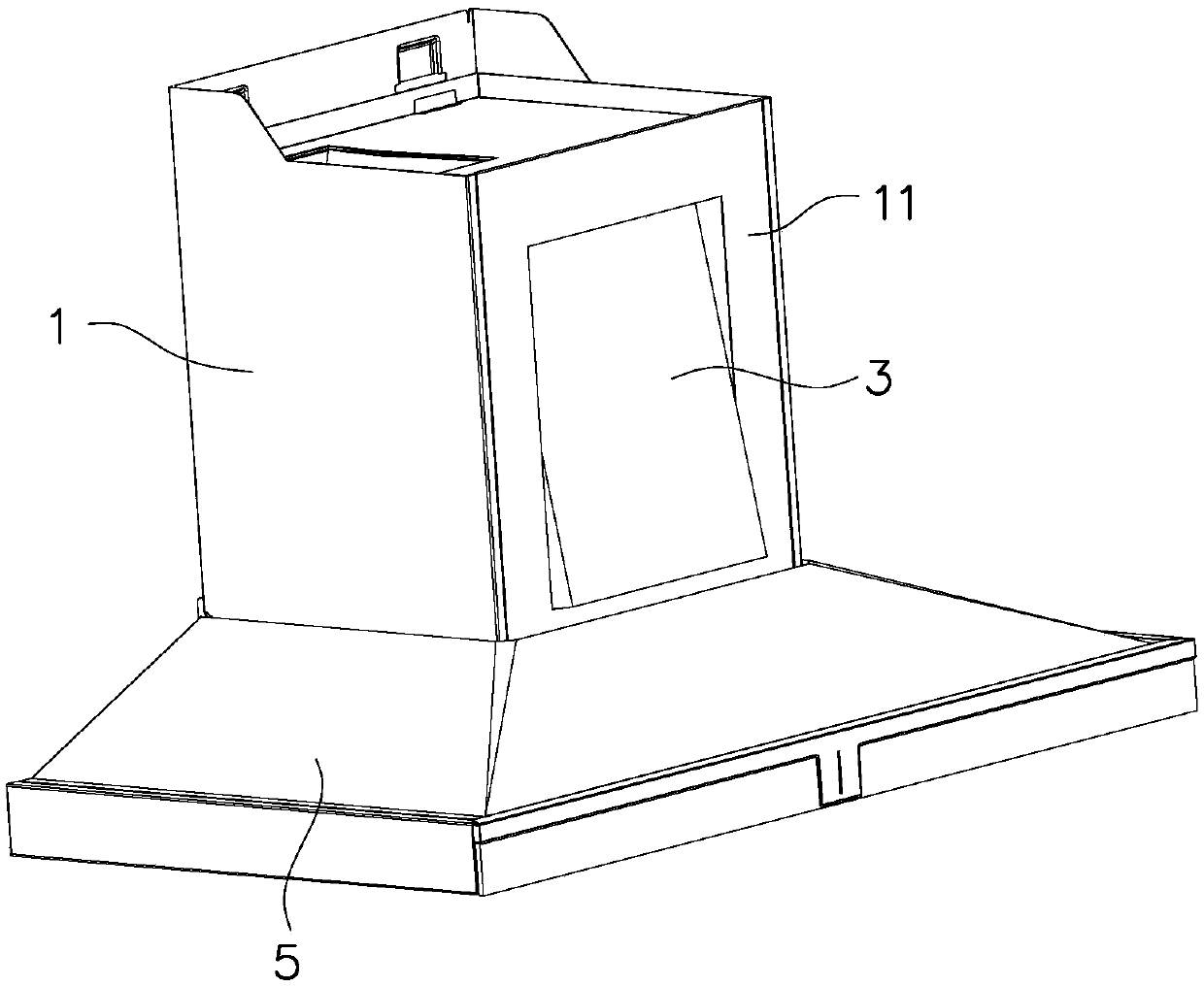

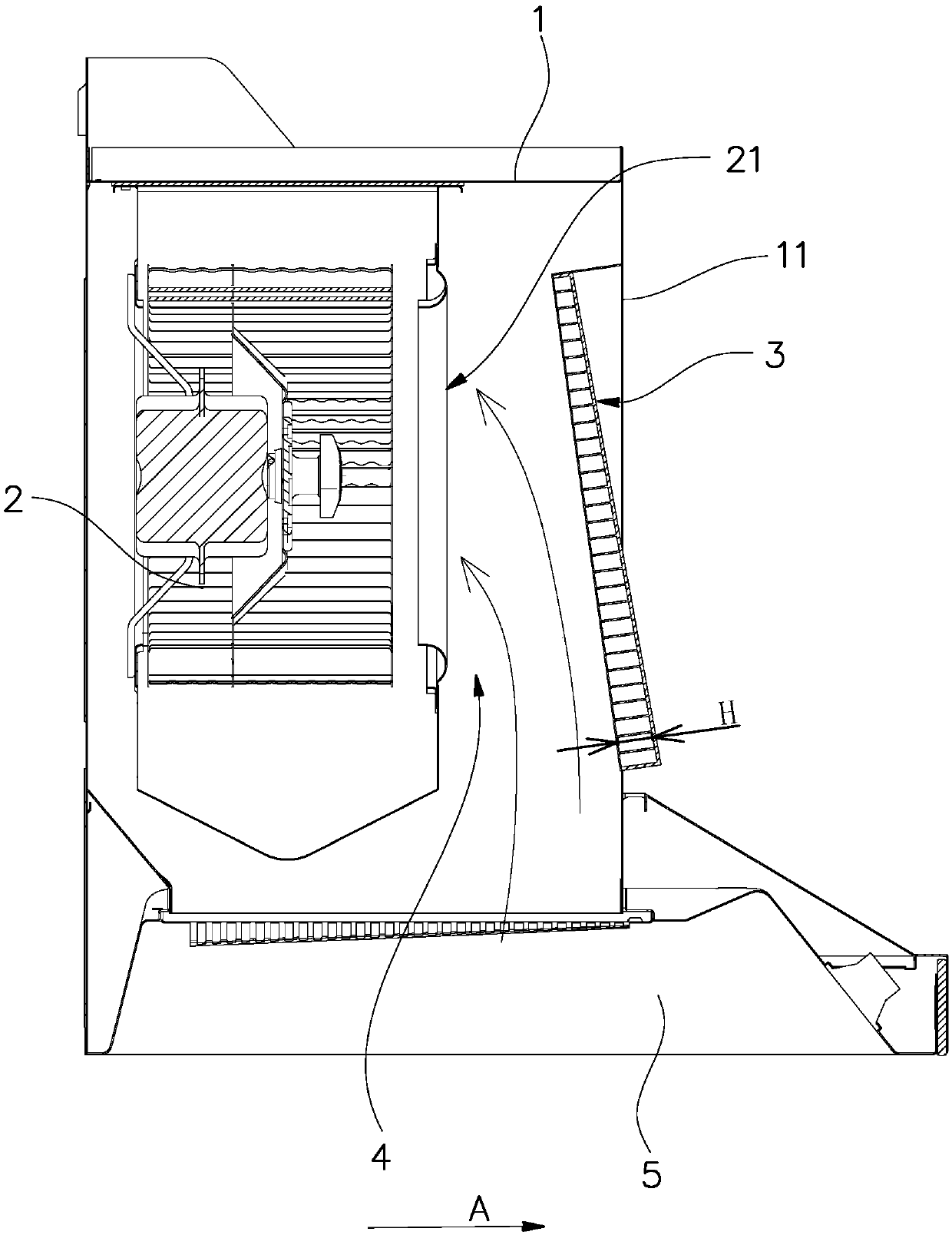

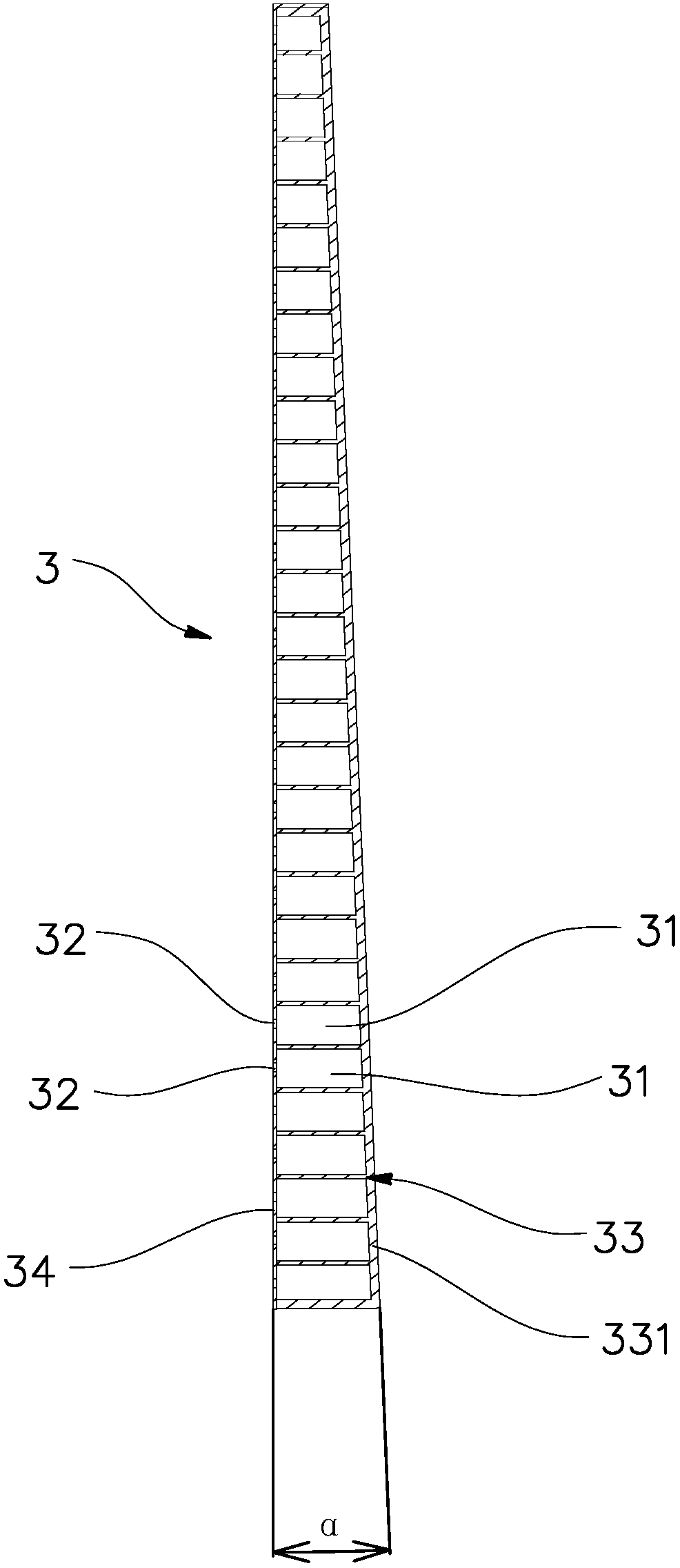

[0029] like Figure 1 to Figure 5 shown, with figure 2 The direction shown by the middle arrow A is forward. The noise reduction type range hood in this embodiment includes a fan frame 1, a fan 2 is installed inside the fan frame 1, a fume collecting hood 5 is installed under the fan frame 1, and the fan 2 has a fan air inlet 21 on the front side, the fume collecting hood 5 has an air inlet that communicates with the fan air inlet 21, and a noise reduction device 3 is installed on the front cover 11 of the fan frame 1, and the noise reduction device 3 Facing the air inlet 21 of the fan, the noise reduction device 3 includes a grid plate 33 closed on the front side and a micro-porous plate 34 arranged on the rear side of the grid plate. The micro-orifice plate 34 is facing the air inlet 21 of the fan, and the micro-orifice plate 34 is inclined forward from top to bottom. Since the end face of the air inlet 21 of the fan is located on the vertical plane, the noise reduction de...

Embodiment 2

[0034] like Image 6 and Figure 7 As shown, the depth of the noise reduction cavity 31 of the noise reduction device 3 of this embodiment remains unchanged in the vertical direction, and the cross-section of the noise reduction cavity 31 gradually decreases from bottom to top, so as to satisfy the noise reduction hole area S The ratio S / V to the corresponding noise reduction cavity volume V gradually increases from bottom to top. The rest of the structure of this embodiment is the same as that of the first embodiment, and will not be described here.

Embodiment 3

[0036] like Figure 8 As shown, the area S of the noise reduction cavity of the noise reduction device 3 in this embodiment gradually increases from bottom to top, and the volume V of the noise reduction cavity remains unchanged in the vertical direction, so that the area S of the noise reduction hole and the corresponding The ratio S / V of the volume V of the noise reduction cavity gradually increases from bottom to top. The rest of the structure of this embodiment is the same as that of the first embodiment, and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com