Novel damping composite and thermal compounding process

A damping composite material and composite material technology, applied in the field of damping composite material processing, can solve problems such as cold resistance, poor elasticity and aging resistance, pollute the air quality in the car, and non-recyclable materials, etc., achieve good aging resistance and overcome hardening Brittle, good elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

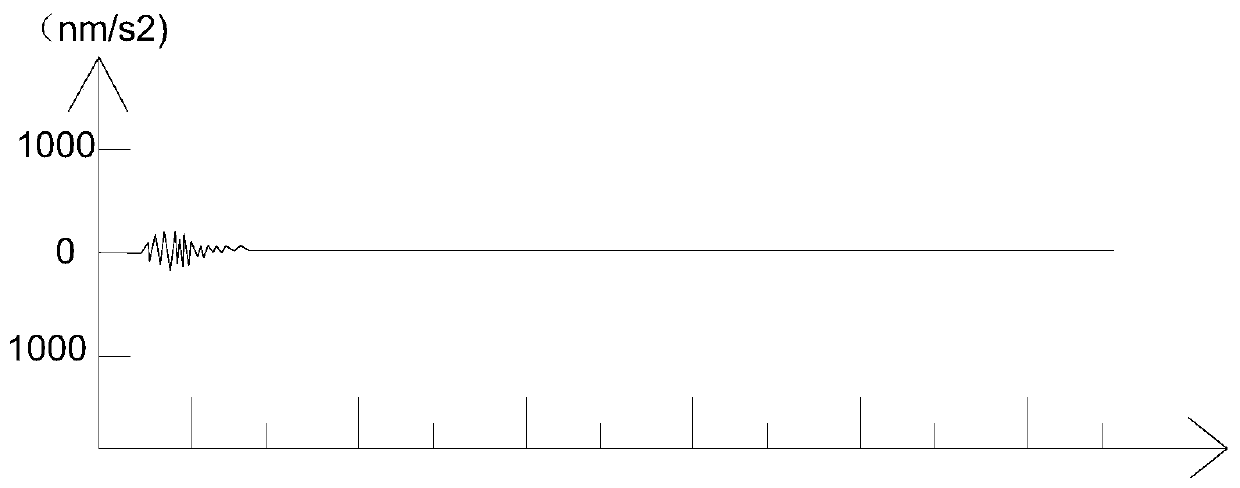

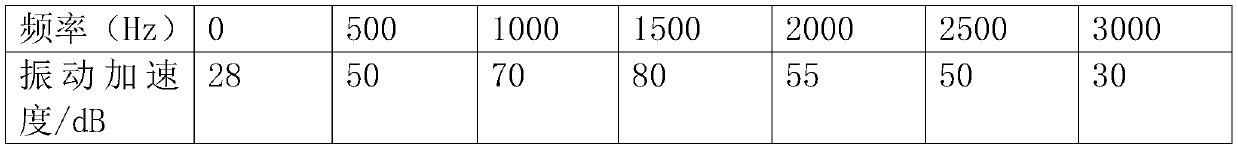

Image

Examples

Embodiment 1

[0019] The new damping composite material includes the following components in parts by mass: 180 parts of thermoplastic elastomer, 50 parts of low-density polyethylene, 80 parts of auxiliary agent, 60 parts of oleic acid amide, and 30 parts of polyethylene wax.

Embodiment 2

[0021] The new damping composite material includes the following components in parts by mass: 190 parts of thermoplastic elastomer, 65 parts of low-density polyethylene, 115 parts of additives, 75 parts of oleic acid amide, and 40 parts of polyethylene wax.

Embodiment 3

[0023] The new damping composite material includes the following components in parts by mass: 200 parts of thermoplastic elastomer, 80 parts of low-density polyethylene, 150 parts of additives, 90 parts of oleic acid amide, and 50 parts of polyethylene wax.

[0024] In this embodiment, the auxiliary agent includes flame retardant, calcium carbonate, antioxidant and antistatic agent, and its ratio is 3:2:1:1. The flame retardant improves the flame retardancy of the damping material, and the calcium carbonate is The smoke absorbent, on the one hand, can effectively absorb a large amount of smoke generated during the action of the flame retardant, improving the safety of use, on the other hand, it can be used as a filler to reduce the production cost of the product. The antistatic agent improves the antistatic property of the damping material and improves the convenience of using the damping material.

[0025] In this embodiment, the thermoplastic elastomer is a mixture of thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com