Film vibration absorber installed on air inlet system of automobile

A technology of air intake system and vibration absorber, which is applied in the direction of charging system, intake muffler, machine/engine, etc., which can solve the problems of high cost, time and effort, and limited space, and achieve low cost and solve the problem of low frequency noise , good effect of shock absorption treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

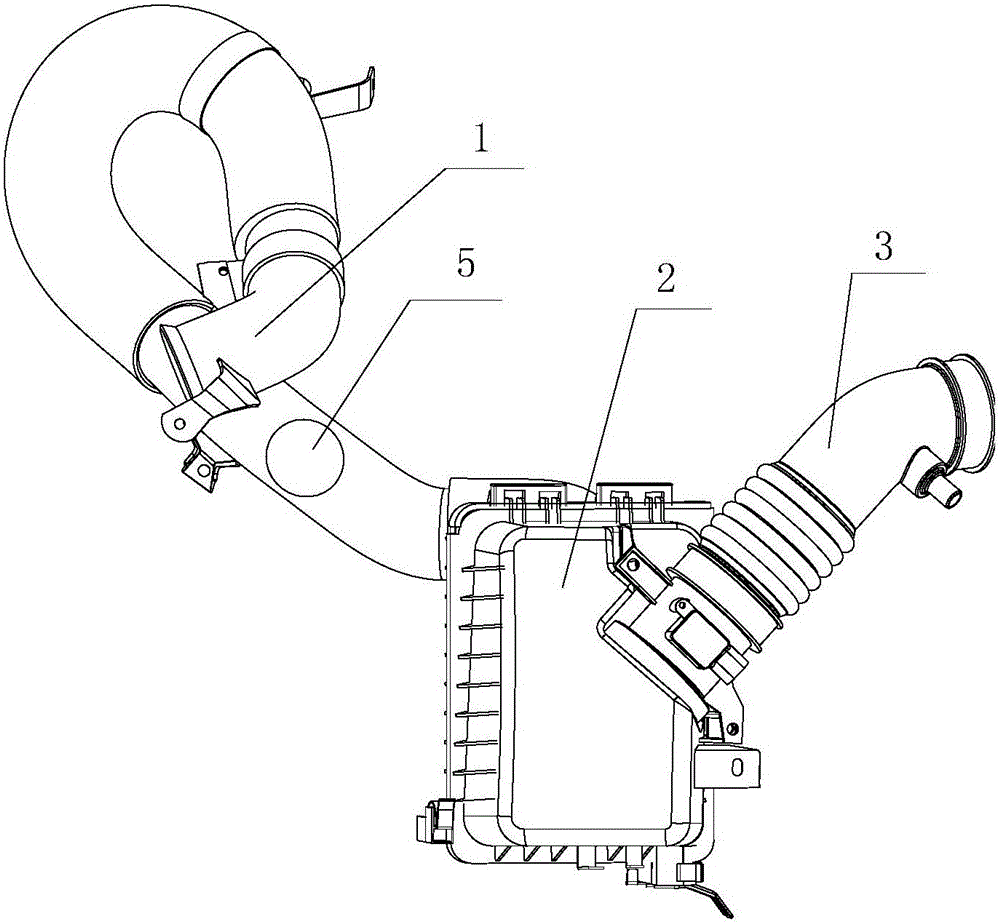

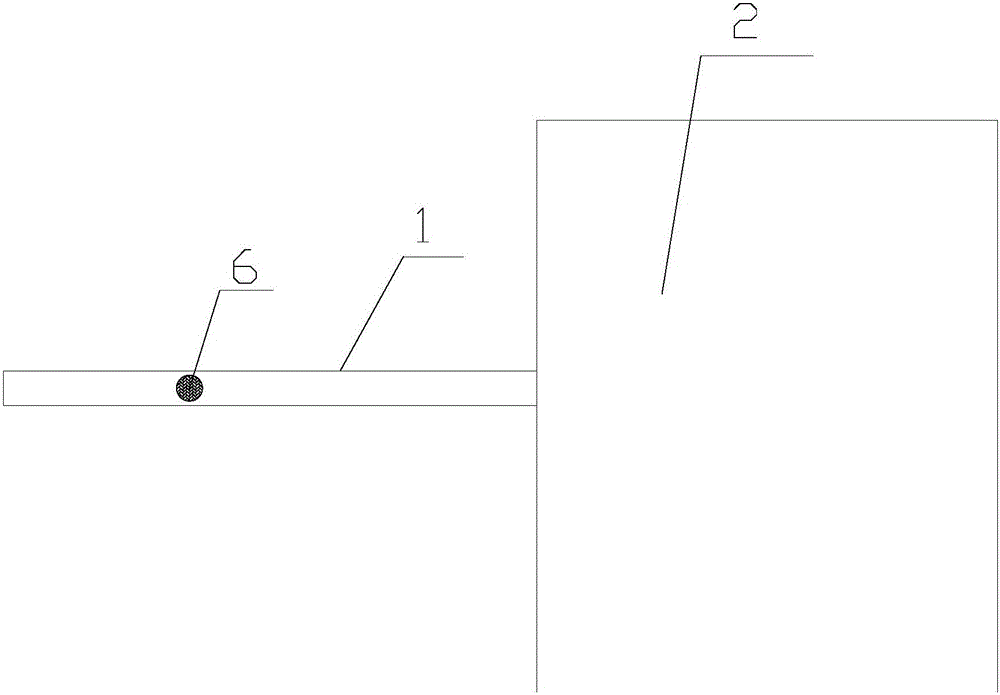

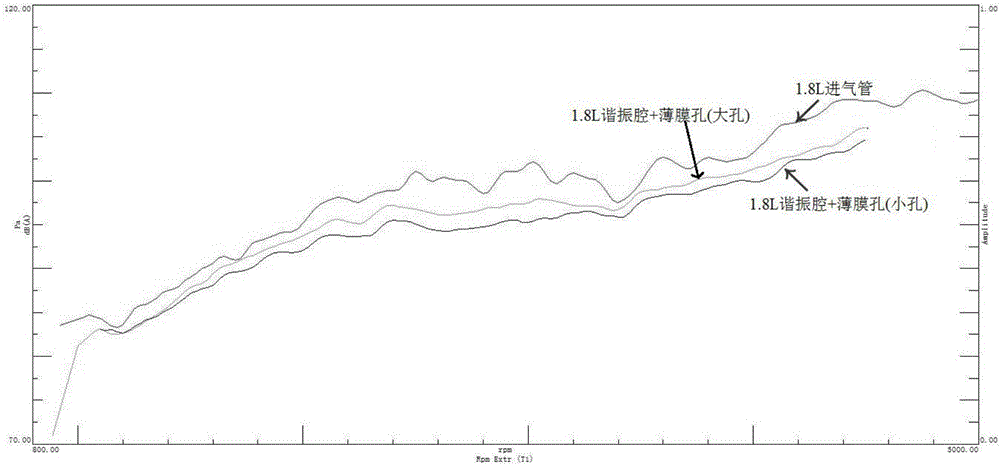

[0019] Such as figure 1 , figure 2 As shown, a thin-film shock absorber installed on the air intake system of an automobile is used to eliminate at least one kind of noise inside the vehicle caused by the air intake system. The air intake system of the automobile includes an air intake pipe 1 and an air filter 2 connected in sequence And the air outlet pipe 3, the vibration absorber includes an opening 5 opened at the abnormal vibration place of the intake pipe 1 (ie, the place with the largest vibration) and a film 6 sealingly covering the outside of the opening 5, and the aperture of the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com