Sound attenuation and noise reduction device applied to air duct

A noise reduction and noise reduction technology, applied in the direction of pipe elements, pipe supports, pipes/pipe joints/pipes, etc., can solve problems such as vibration and noise of blower operation, achieve good vertical bearing effect, meet conventional displacement requirements, and reduce noise and vibration. the effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The content of the present invention is further described below through specific examples.

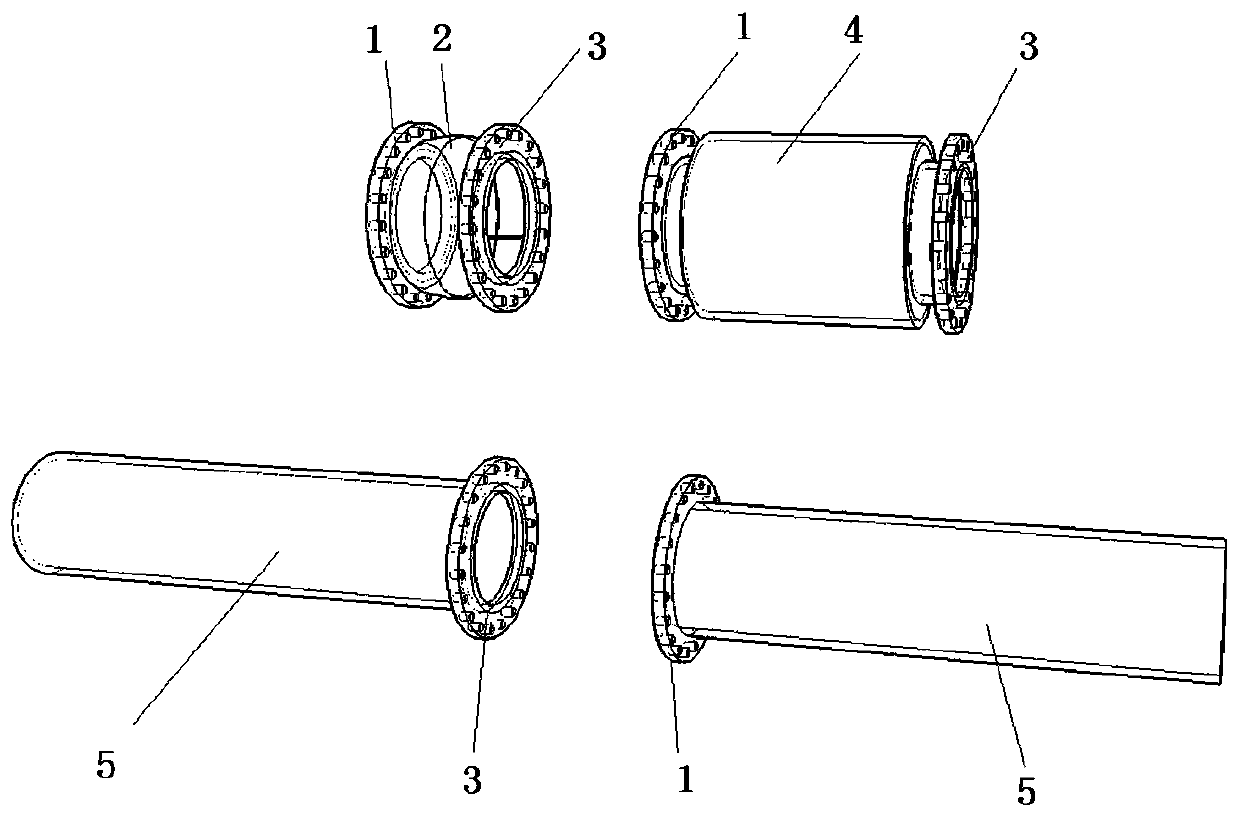

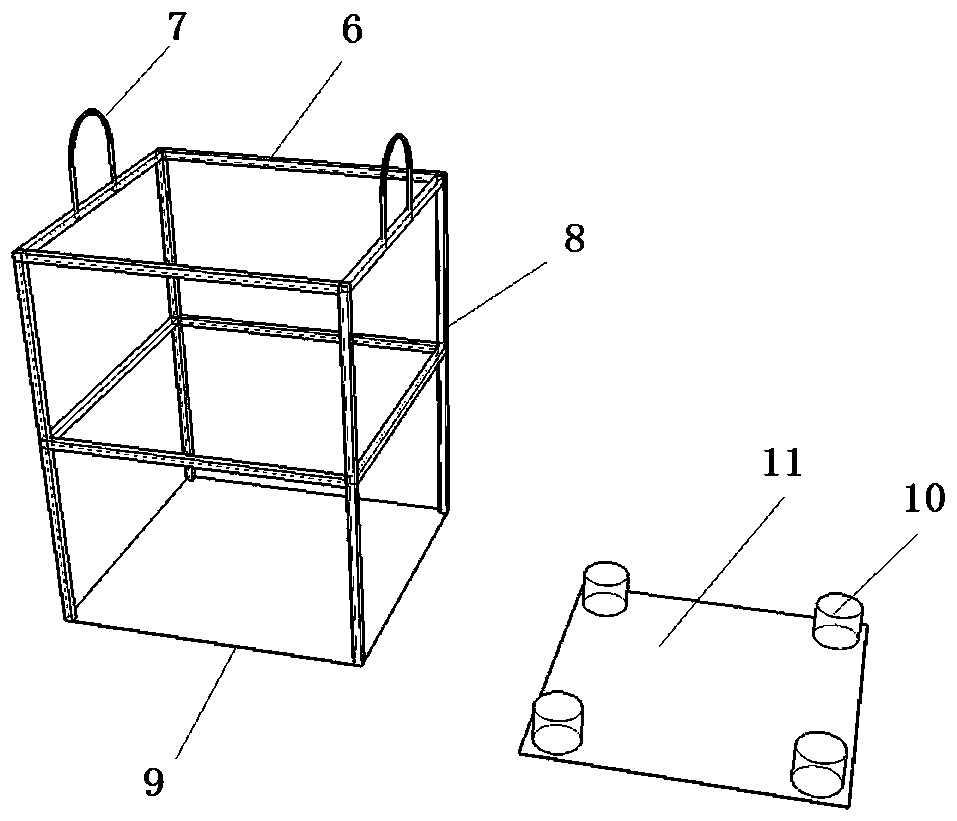

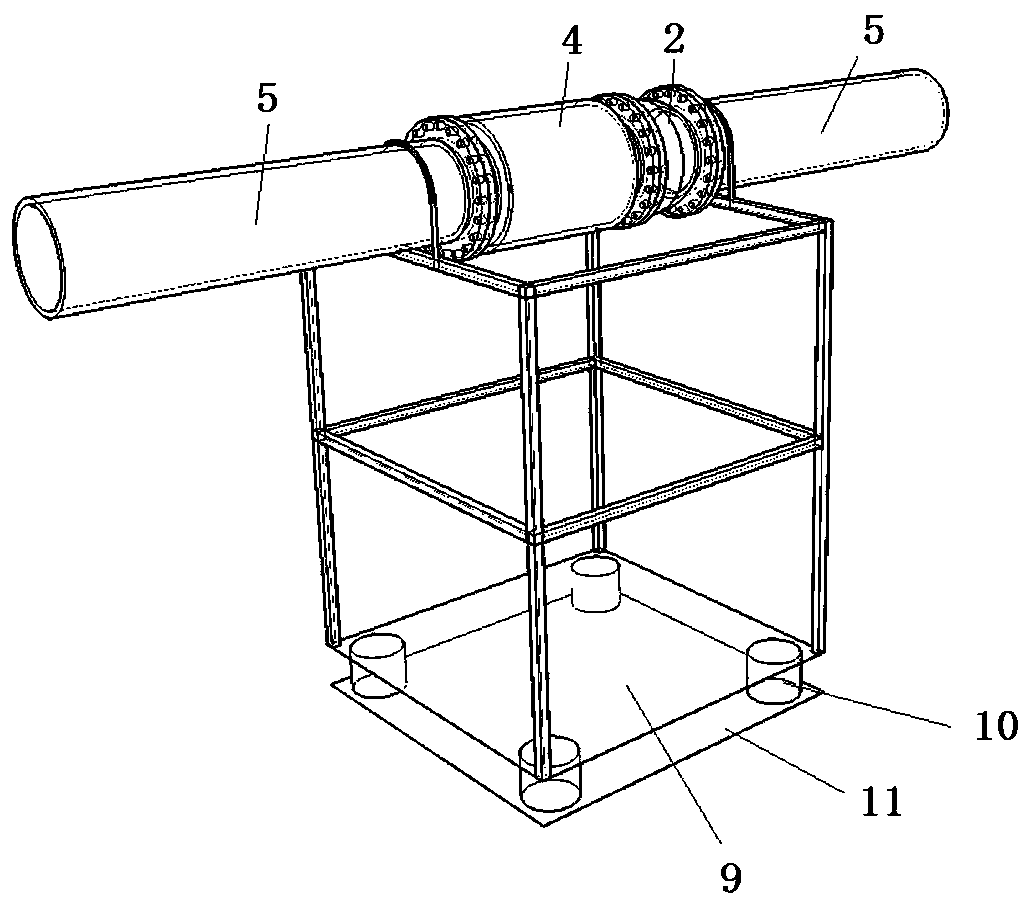

[0042] A combined and quick-connect noise reduction device for air ducts, characterized in that the noise reduction device includes a flange piece 1, a flexible joint 2, a flange piece 1, a muffler 4 and a flange Combination components such as the blue piece 1, the support member and the shock absorber can be combined, disassembled and installed arbitrarily. At the same time, the noise reduction and noise reduction device can be quickly connected to the pipeline at any desired position in the original pipeline.

[0043] The material of the flange piece 1 can be metal, glass fiber reinforced plastic, etc., and its strength is equal to or higher than the design strength of the original pipeline.

[0044] The flange piece can be spliced with other components through standard bolts, and a flexible shock-absorbing material is arranged in the middle of the flange piece.

[0045] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com