Air suction silencer

A muffler and air chamber technology, which is applied in the field of mufflers, can solve problems such as unsatisfactory muffler effects, achieve good muffler effects, eliminate noise, and avoid aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

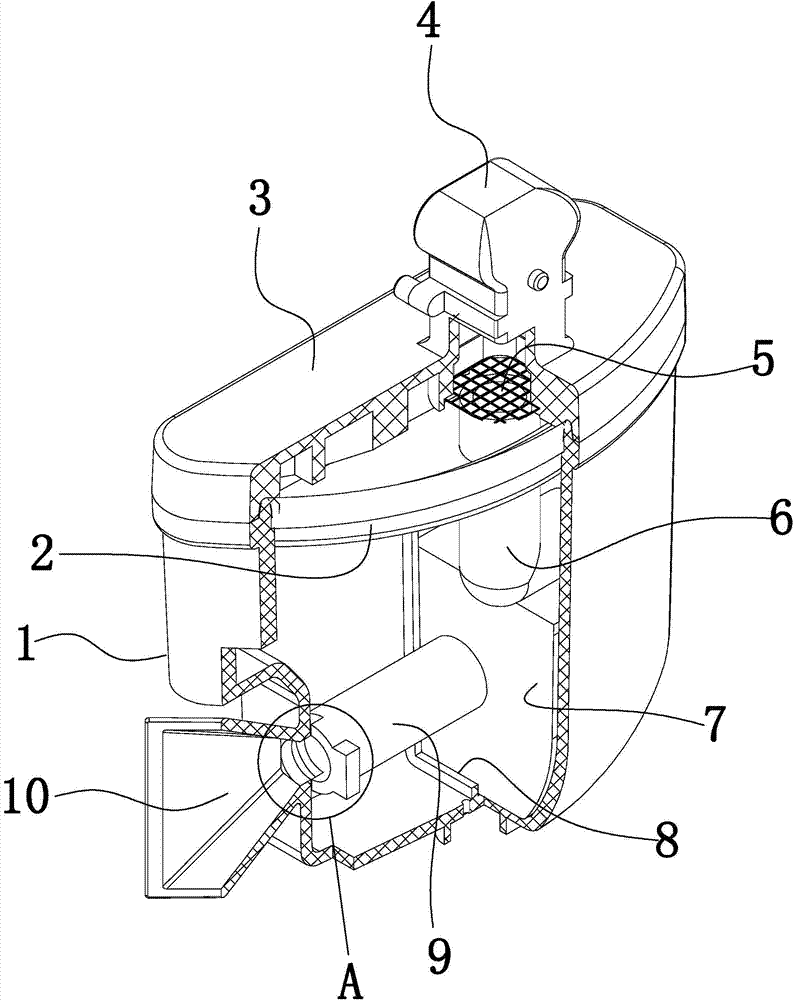

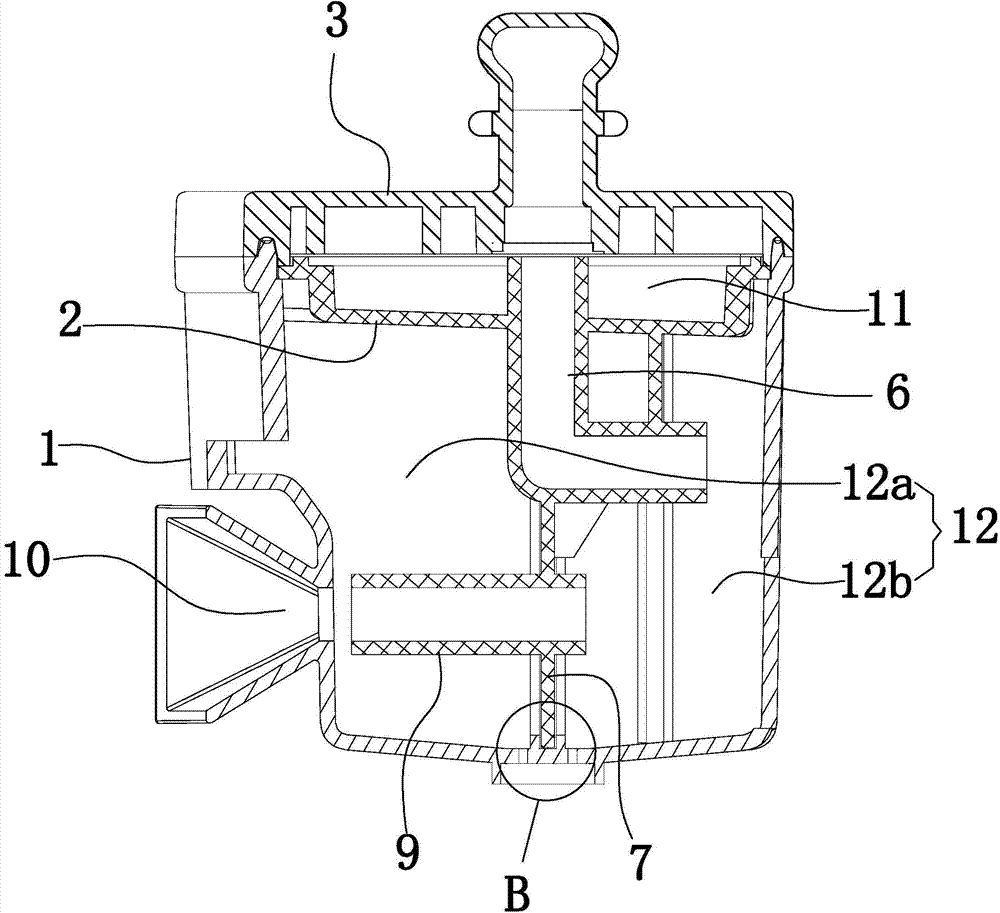

[0033] Embodiment 1: as figure 1 , figure 2As shown, a suction muffler includes a muffler housing. The muffler housing includes a muffler body 1 with an upper end opening, an upper cover 3 with a lower end opening, a second partition 2 arranged at the upper port of the muffler body and a first partition 7 arranged in the muffler body below the second partition . The inner edge of the upper port of the muffler body 1 is provided with an annular concave step. The second partition 2 is arranged in the annular recessed step, and the second partition is provided with a downwardly depressed sunken groove. The first partition 7 is arranged vertically, and the first partition and the second partition are integrally formed. Slots 8 for inserting a first baffle are respectively provided on opposite side surfaces and a bottom surface of the muffler body 1 , and the first baffle is inserted in the slot. The lower end of the upper cover is buckled on the upper port of the muffler bod...

Embodiment 2

[0040] Embodiment 2: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

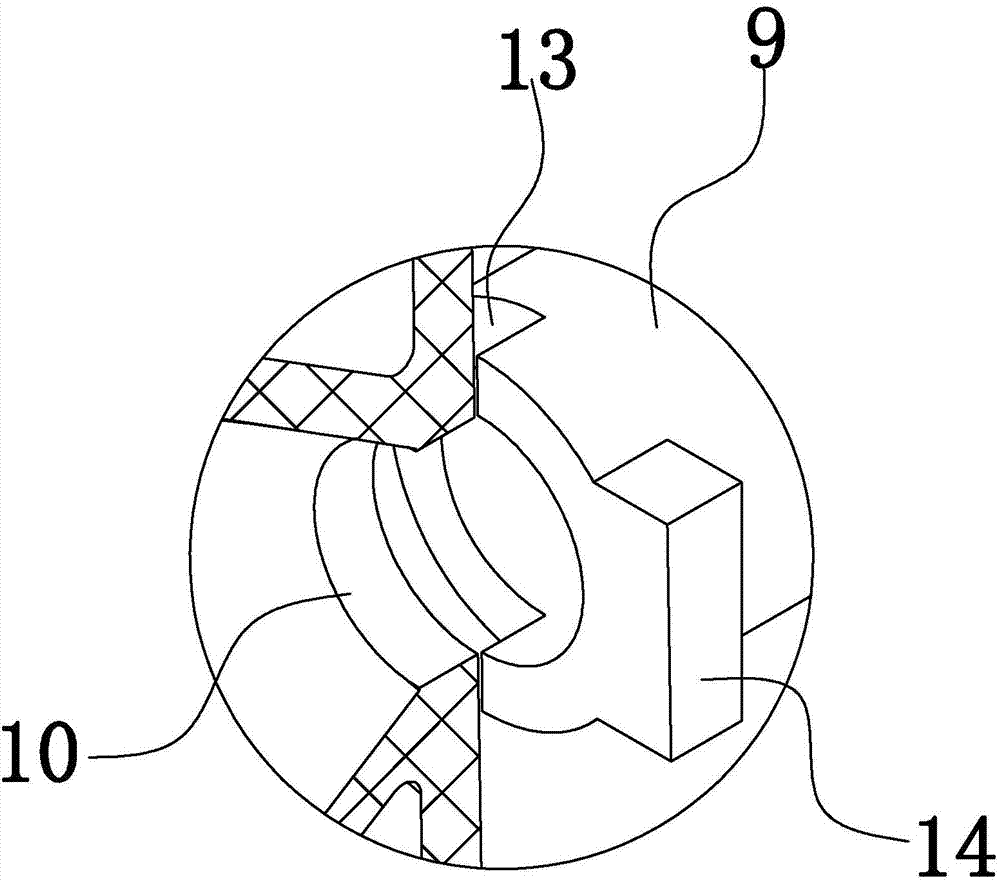

[0041] Such as Figure 5 As shown, a support plate 23 is provided on the inner wall of the lower left air chamber 12a near the air inlet. The surface of the support plate faces the air inlet 10 , and the support plate is provided with a first air hole 24 facing the air inlet 10 . The second vent hole 29 and the third vent hole 17 connecting the left lower air chamber 12 a and the right lower air chamber 12 b are provided on the first partition 7 , and the second vent hole is opposite to the first vent hole. The cross-sections of the first ventilation hole, the second ventilation hole and the third ventilation hole are all circular. The first air hole 24 and the second air hole 29 are respectively provided with electromagnetic switch valves or electric switch valves for controlling the opening and closing of the air holes. The electromagnetic switch val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com