Patents

Literature

75results about How to "Prevent sticky sand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintering-strippable red cast iron coating and preparation method thereof

InactiveCN102601300APrevent sticky sandAvoid sand inclusionsFoundry mouldsFoundry coresCrack resistancePreservative

The invention relates to a sintering-strippable low-cost red water-based cast iron coating, which is prepared by the following raw materials in percent by mass: 20-45 percent of bauxite powder or powder quartz, 0-25 percent of mullite powder, 1-6 percent of talcum powder, 1-5 percent of iron trioxide powder, 1-3 percent of suspending agent, 1.5-4.5 percent of organic binding agent, 1.5-6 percent of inorganic binding agent, 0.01-0.05 percent of wetting agent, 0.02-0.05 percent of preservative, 0.02-0.1 percent of defoaming agent, 0-0.5 percent of water reducing agent and 30-42 percent of tap water. The sintering-strippable low-cost red water-based cast iron coating has the characteristics that the raw materials are cheap and the source is wide; the product is low-cost, safe, environmental-friendly and convenient to transport; the brushing property, the flowing resistance and the leveling property of the product are good, the suspension percentage, the coating strength and the crack resistance are high and the gas evolution is low; and the sintering-stripping performance is excellent, the most part of the coating can be vastly stripped after castings are taken out of a casting box and are cooled, the defects of sand sticking, sand inclusion, sand drop, voids and the like existing the castings can be effectively avoided, and the castings with excellent surface quality can be obtained.

Owner:湖北省机电研究设计院股份公司

Pre-coated sand

ActiveCN101934346AHigh strengthImprove heat resistanceFoundry mouldsFoundry coresAdhesiveGranularity

The invention relates to pre-coated sand which comprises crude sand, an adhesive, a curing agent and a coupling agent. The amount of the curing agent accounts for 40-60 percent of the total amount of the adhesive, the amount of the coupling agent accounts for 0.2-0.5 percent of the total amount of the adhesive, the amount of the adhesive accounts for 1-1.5 percent of the total amount of the crude sand, the crude sand has the granularity of 100-150 meshes and is prepared from the components in parts by weight: 70-80 parts of yellow sand, 10-20 parts of diatomite and 5-15 parts of high-temperature cement, and the adhesive is prepared from the following components in parts by weight: 5-10 parts of thermosetting phenolic resin and 90-95 parts of thermoplastic phenolic resin. The invention not only has favorable heat resistance, smaller roughness and better permeability but also can prevent sand from adhering to a casting.

Owner:陕西悦森安晟石油科技有限公司

High temperature resistance precoated sand

InactiveCN103231008AGood heat resistanceReduce roughnessFoundry mouldsFoundry coresWater soluble polymersRosin

The invention discloses high temperature resistance precoated sand, which comprises base sand, a binder, hexamethylenetetramine, a phenol formaldehyde resin, a silane coupling agent and an additive A, wherein the base sand comprises, by weight, 55-60 parts of iron ore sand, 60-70 parts of forsterite sand, and 7-10 parts of diatomite, a particle size of the base sand is 100-150 mesh, 3-5 parts by weight of boric acid, 1-2 parts by weight of water-soluble polymer glue powder, 3-5 parts by weight of starch, 0.5-0.8 part by weight of rosin, 4-5 parts by weight of dextrin and 4-6 parts by weight of water are subjected to a reaction and drying to obtain the binder, 4-6 parts by weight of a straw powder material, 2-4 parts by weight of sepiolite and 5-8 parts by weight of water are subjected to a mixing calcination treatment to obtain the additive A, a particle size of the straw powder material is 0.5-0.8 mm, and the obtained calcined product, 2-4 parts by weight of montmorillonite powder and 3-4 parts by weight of water glass are subjected to mixing granulation. The high temperature resistance precoated sand has the following characteristics that: moisture absorption resistance is good, roughness is low, high temperature resistance is provided, and sand sticking on a cast is not easily generated.

Owner:FANCHANG COUNTY HENGXIN AUTO PARTS

Carburization prevention coating for ultralow carbon stainless steel casting

The invention discloses a carburization prevention coating for an ultralow carbon stainless steel casting. The carburization prevention coating is prepared by mixing 50 to 60 weight percent of white corundum powder, 5 to 10 percent of oxidant, 3 to 8 percent of sintering aid, 1 to 3 percent of organic binder, 2 to 5 percent of bentonite suspending agent, 0.2 to 0.4 percent of aid, and 28.8 to 38.2 percent of solvent; the granularity of the white corundum powder is less than or equal to 3 mu m, the granularity of the oxidant is less than or equal to 5 mu m, and the granularity of talcpowder isless than or equal to 5 mu m; the oxidant is one or more of potassium nitrate, potassium permanganate, potassium dichromate, and potassium chlorate; the sintering aid is one or more of talcpowder, feldspar powder, mica powder, and clay; and the organic binder is rosin or resin; and the solvent is ethanol or isopropanol, the concentration of ethanol is more than or equal to 95 percent, and the concentration of the isopropanol is more than or equal to 98 percent. The coating is poured into some ultralow carbon stainless steel castings of water turbine blades, and the thickness of a surface carburization layer of the ultralow carbon stainless steel casting on which the carburization prevention coating prepared according to the formula is poured is less than or equal to 3mm, and is obviously superior to that of the common coating.

Owner:SHENYANG RES INST OF FOUNDRY

Alcohol-group dry powder sand mould foundry coating

InactiveCN102873266AGood high temperature strength and stabilityLow gas productionFoundry mouldsFoundry coresBrown iron oxideAluminium

The invention discloses alcohol-group dry powder sand mould foundry coating, which comprises the following components in percentage by weight: 60-75% of bauxite, 2-10% of amorphous graphite, 3-15% of lamellar graphite, 2-10% of iron oxide red, 1-5% of attapulgite, 0.5-1.5% of sodium bentonite, 1-5% of polyvinyl butyral, 0.1-0.5% of surfactant and 0.1-0.5% of dispersing agent. The dry powder coating has the advantages of simple preparation technology, convenience in use and good high-temperature sand adhesiveness resistance.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Alcoholic-group coating

The invention discloses a novel alcoholic-group coating which comprises forsterite, high aluminium bauxite, crystalline graphite powder, talcum powder, quartz powder, composite adhesives, composite suspoemulsions and solvents, wherein the forsterite can be replaced with a mixture of 150-200-mesh forsterite, 200-250-mesh forsterite and 250-300-mesh forsterite. The novel alcoholic-group coating has the advantages that crystalline graphite powder and talcum powder are added in refractory aggregates with different particle sizes, and cooperate with the composite adhesives and the composite suspoemulsions, so as to ensure the coating strength, the effect that the coating is not cracked in use and is easy to strip in clean is achieved, and the surface precision of a casting is high.

Owner:CHINA THREE GORGES UNIV +1

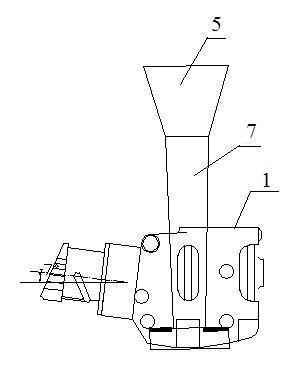

Modeling method of large-size ring-structure casting

ActiveCN102069152AAvoid deformationAvoid sinking deformationFoundry mouldsFoundry coresModel methodLarge size

The invention relates to a modeling method, in particular to a modeling method of a large-size ring-structure casting, which is characterized in that the method comprises the following steps: mould manufacturing, modeling, unpacking and packing. The method improves the prior independent modeling scheme of rings, greatly improves the production efficiency, and enhances the strength of a mould, and the cost for manufacturing, modeling and smelting the mould is greatly reduced.

Owner:KOCEL EQUIP

Method for preparing water-based coating for sand mold casting

InactiveCN102407279AExcellent overall performancePrevent sticky sandFoundry mouldsFoundry coresSodium carboxymethylcelluloseCarboxymethyl cellulose

The invention discloses a method for preparing a water-based coating for sand mold casting, wherein the coating is prepared from zircon powder, fused mullite powder, quartz powder, lithium based bentonite, flake graphite, silicon sol, sodium carboxymethyl cellulose, sodium alkyl benzene sulfonate, sodium sulfate, sodium carbonate, n-caprylic alcohol, fatty alcohol-polyoxyethylene ether and water;and the preparation method comprises the following steps: 1) firstly, uniformly mixing the zircon powder, the fused mullite powder and the quartz powder aggregates with a proper amount of water in anattrition mill so as to obtain a base material; 2) sequentially adding the silicon sol, the sodium carboxymethyl cellulose, the sodium alkyl benzene sulfonate, the sodium sulfate, the sodium carbonate, the n-caprylic alcohol and the fatty alcohol-polyoxyethylene ether into the wet base material which is mixed, then adding a proper amount of water into the obtained mixture; and 3) adding the rest of water into the attrition mill, uniformly stirring and grinding.

Owner:福建港星建筑材料集团有限公司

Expendable casting process method for heat-resistant steel perforated grate plate

An expendable casting process method for a heat-resistant steel perforated grate plate comprise employing a copolymerization material for foaming for preparing an expendable-casting-process heat-resistant steel perforated grate plate foam model, singly preparing a pouring gate, binding the heat-resistant steel perforated grate plate model with the pouring gate for combination, so as to form a combined model; putting the combined model in a special coating pool for three-time sagging of a coating and three-time baking, and controlling the accumulated thickness of the coating subjected to three-time baking to be 0.8 mm-1.5 mm; again combining the baked combined model in a negative-pressure sandbox by taking 10 models as a pouring body, and forming two pouring bodies; adding sand into the sandbox and compacting through shaking; vacuumizing the sandbox and performing oxygen-enriched combustion on the model to form a hollow shell; and finally performing casting. The casting method is simple in steps, convenient to operate, high in casting efficiency and good in effect, is capable of effectively improving the surface quality of the casting and preventing disadvantages that the casting generates burnt-on sand, sand inclusions, pores and carburets, and helps to reduce labor intensity and save production cost.

Owner:渠县金城合金铸业有限公司

Method for solving problem of burnt-on sand of thick-wall steel casting

InactiveCN102794426ASmall modulusUnique process methodFoundry mouldsFoundry coresWater basedIsolation layer

The invention relates to a method for solving the problem of burnt-on sand of a casting, in particular to a method for solving the problem of burnt-on sand of a thick-wall steel casting. The method comprises the following steps of: preparing the materials Q235 steel and Phi 80 sand-isolation chiller; uniformly distributing and welding the sand-isolation chiller on an arbor, and placing the arbor in a core box, wherein the thickness of the sand-isolation layer of the sand-isolation chiller is controlled at 30-50mm; enabling a layer of 50mm-thick chrome ore to flow on the inner surface in the core box; reinforcing and compacting the key corner parts; enabling silica sand to flow; and opening the box and coating the whole box with water-based paint for three times. The method provided by the invention is unique and can solve the problem of burnt-on sand of the thick-wall casting.

Owner:NINGXIA KOCEL GRP CO LTD +1

Casting coating for stainless steel valve body and preparation method thereof

InactiveCN103586406APrevent sticky sandIngredient prices are lowFoundry mouldsFoundry coresAcetic acidAlcohol

The invention relates to a casting coating for a stainless steel valve body. The casting coating for the stainless steel valve body comprises the following components by weight percent: 100% of quartz powder, 20-26% of ethyl silicate with the silicon dioxide content of 30-34%, 13-15% of alcohol, 7-15% of hydrochloric acid with the concentration of 36-38%, 7-10% of acetic acid, 7-10% of sulfuric acid with the concentration of 95-98%, 3-5% of distilled water and 2-5% of modified water glass. The formula components of the casting coating for the stainless steel valve body are low in price, so that the casting cost of the valve body is reduced; the modified water glass is used as a binder, so that the suspension of the coating is greatly improved, sand sticking of a cast product is avoided, and further the requirements for the surface quality and the dimensional accuracy of the cast product are met.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Iron casting green sand and preparation method thereof

InactiveCN103567361APrevent sticky sandAvoid sand inclusionsFoundry mouldsFoundry coresGlucose-Fructose SyrupMonopotassium phosphate

The invention discloses an iron casting green sand and a preparation method thereof. The iron casting green sand is prepared from the following raw materials in parts by weight: 80-90 parts of old sand, 10-20 parts of fresh sand, 3-5 parts of attapulgite, 2-4 parts of composite powder, 1.5-2.5 parts of graphite powder, 4-6 parts of sepiolite, 2-3 parts of alums, 3-4 parts of monopotassium phosphate, 2-3 parts of sodium tetraborate, 1.5-2.5 parts of magnesium oxide, 1-2 parts of glucose syrup, 1-1.5 parts of heavy oil and 3-7 parts of water. The iron casting green sand is reasonable in formula, low in cost and simple in preparation method, and sand burning and inclusion of iron casting can be effectively prevented. Besides, the surface of the iron casting prepared by using the green sand is smooth and clean, and the yield of the iron casting is greatly improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Sodium silicate silica sand anti-sticking additive for cast steel and application method of additive

InactiveCN103056285APrevent sticky sandReduce manufacturing costFoundry mouldsFoundry coresSodium silicateCasting

The invention provides a sodium silicate silica sand anti-sticking additive for cast steel and application method of the additive. The sodium silicate silica sand anti-sticking additive is characterized by comprising the following materials: Al2O3, SiO2, Cr2O3 and Fe2O3; and the application method of the additive is characterized by comprising the following steps of: firstly adding the sodium silicate silica sand anti-sticking additive for cast steel and water in silica sand, equally mixing, adding sodium silicate, and continuously mixing equally, thus preparing the casting sand. The sodium silicate silica sand anti-sticking additive for cast steel and the application method of the additive, disclosed by the invention, have the advantages of effectively preventing sand sticking by forming a moderately sintered peelable sintering layer on a casting and molding surface during pouring process, reducing production cost, simplifying formative technology and decreasing clear-up works of the casting. Therefore, the surface of the produced casting is clean without sand sticking.

Owner:DONGHUA UNIV

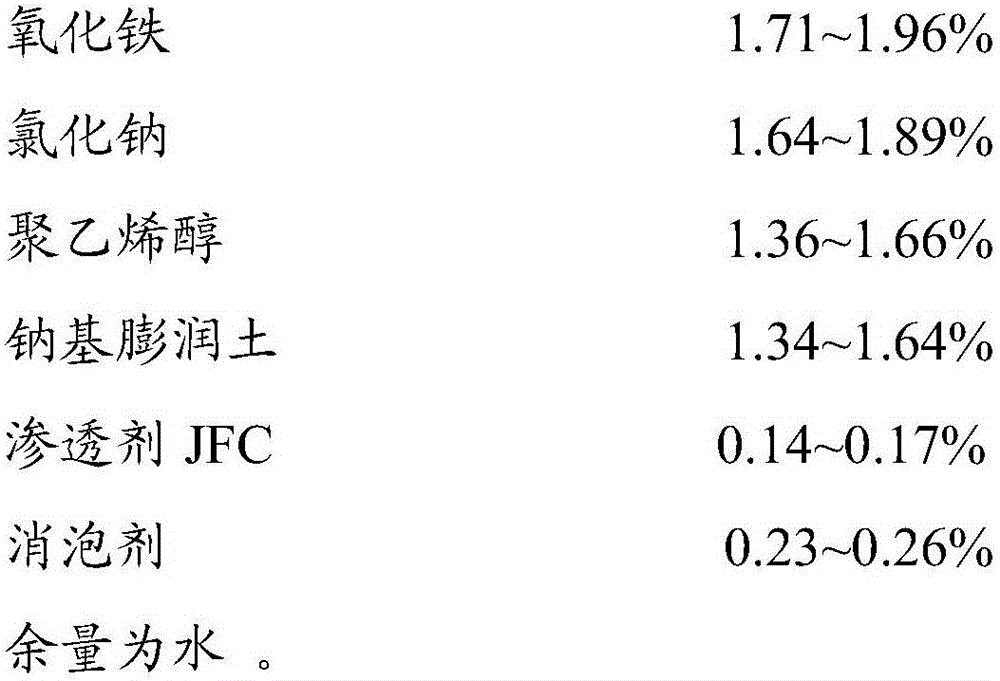

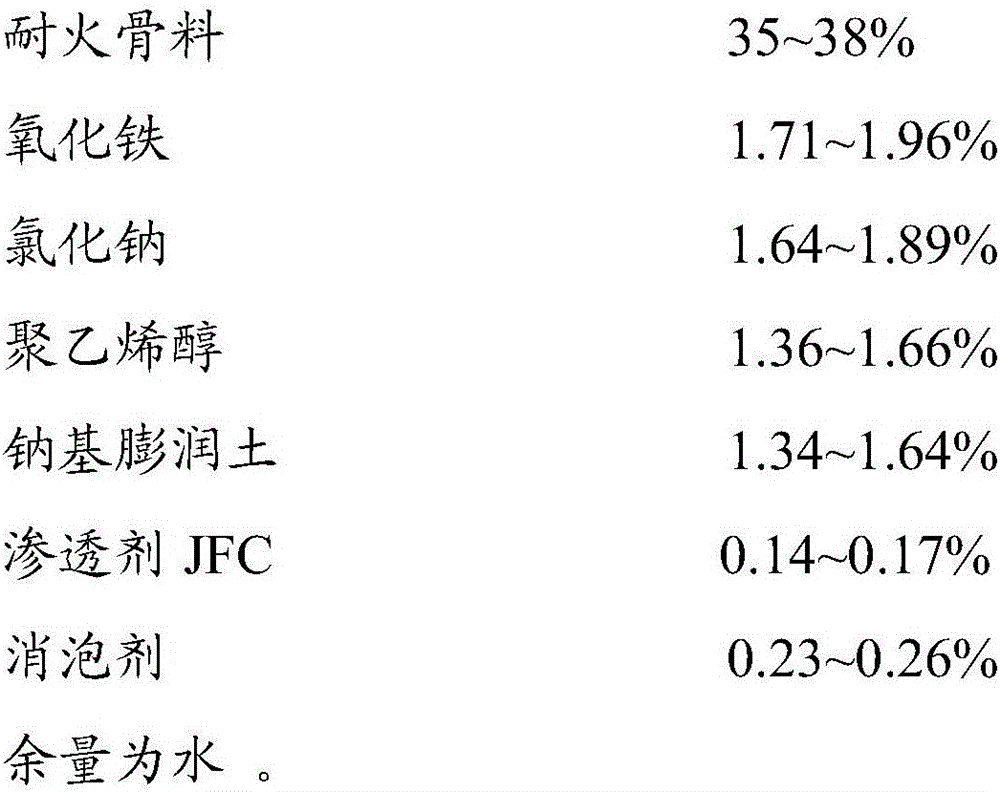

Water-based casting coating for precoated sand casting and preparation method thereof

The invention provides a water-based casting coating for precoated sand casting and a preparation method thereof. The powdery casting coating provided by the invention is prepared from the following components in percentage by weight: 35 to 38 percent of refractory aggregate, 1.71 to 1.96 percent of ferric oxide, 1.64 to 1.89 percent of sodium chloride, 1.36 to 1.66 percent of polyving akohol, 1.34 to 1.64 percent of sodium bentonite, 0.14 to 0.17 percent of penetrating agent JFC, 0.23 to 0.26 percent of defoamer, and the balance water. The water-based casting coating for precoated sand casting provided by the invention can enable the surface finishment of castings casted by precoated sand to achieve the surface finishment effect of lost-wax precision castings.

Owner:HUBEI UNIV OF TECH

Sand casting water-based coating

InactiveCN102397982AImprove performanceImprove the finishFoundry mouldsFoundry coresWater basedMullite

The invention discloses a sand casting water-based coating. The coating consists of the following components in part by weight: 20 to 30 parts of zircon powder, 15 to 20 parts of electro-fused mullite powder, 15 to 20 parts of quartz powder, 2 to 3 parts of lithium-based bentonite, 5 to 10 parts of flake graphite, 2 to 3 parts of silica sol, 0.5 to 0.8 part of sodium carboxymethylcellulose, 0.3 to 0.5 part of sodium alkyl benzene sulfonate, 0.4 to 0.6 part of sodium sulfate, 0.2 to 0.3 part of sodium carbonate, 0.2 to 0.3 part of n-octanol, 0.2 to 0.3 part of fatty alcohol-polyoxyethylene ether and 30 to 40 parts of water, wherein the granularity of the zircon powder, the electro-fused mullite powder and the quartz powder can be 200 to 320 meshes.

Owner:TANGSHAN DONGFANG HUASHENG GOOD WEAR RESISTING HIGH TECH

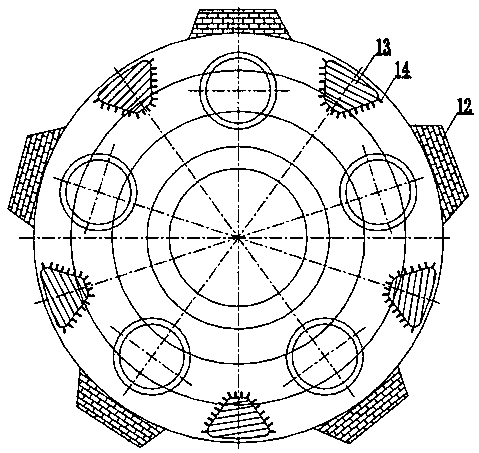

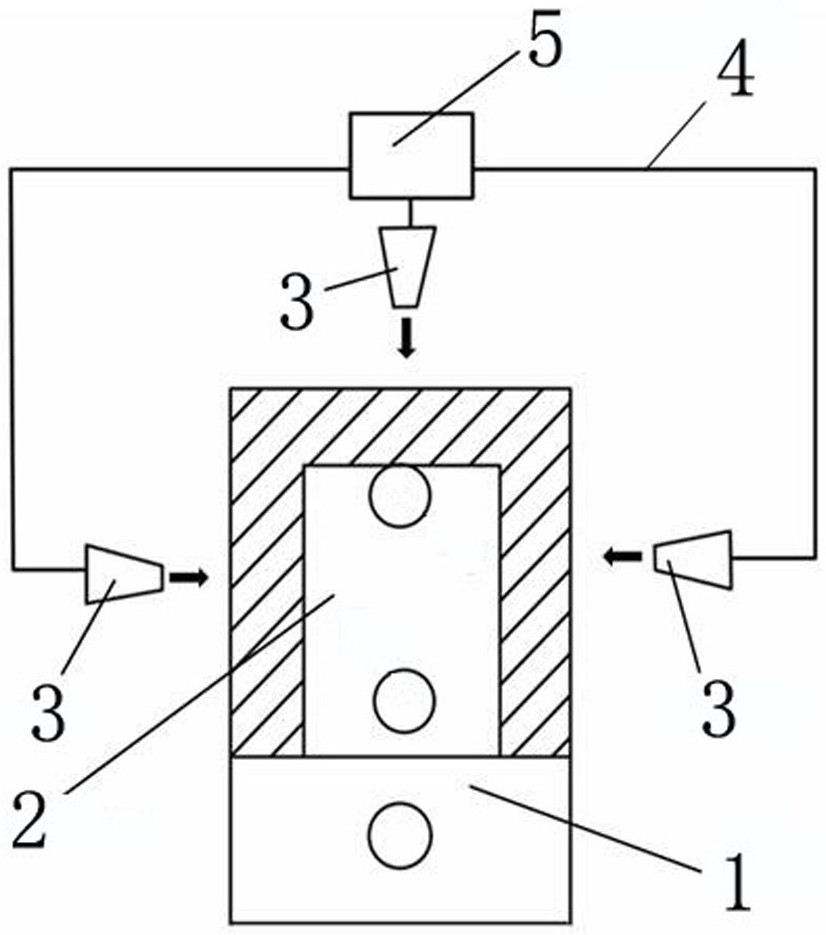

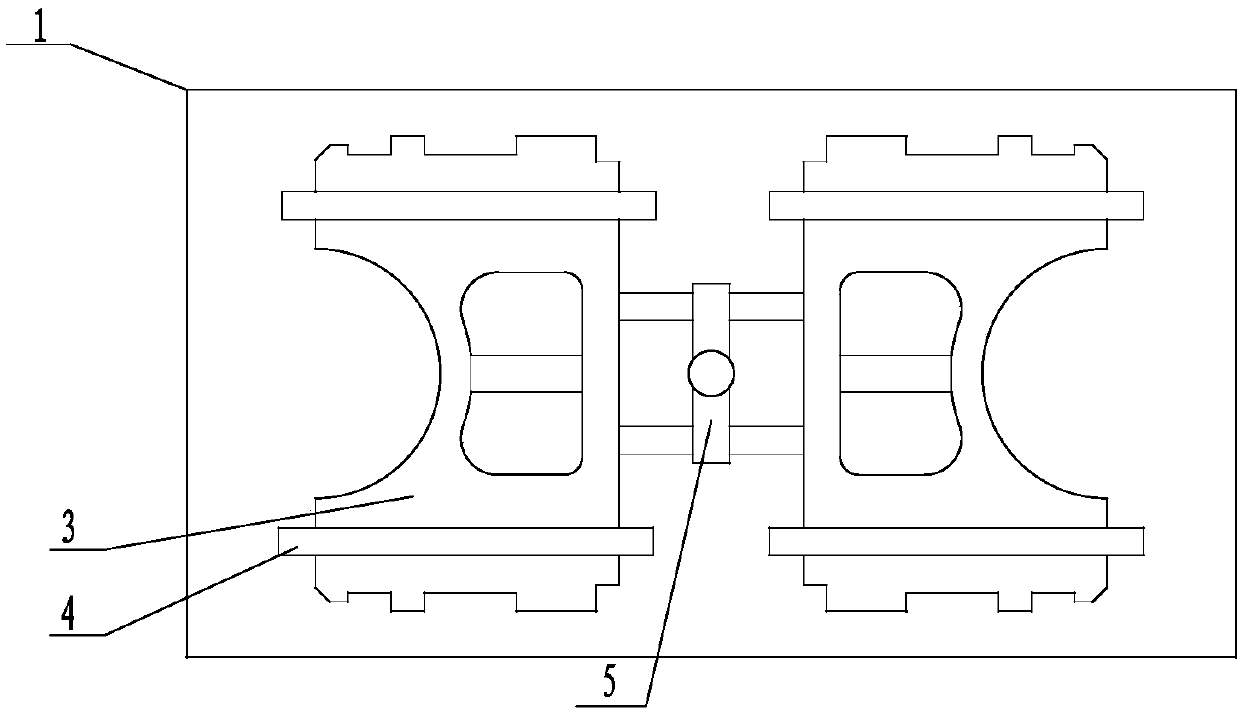

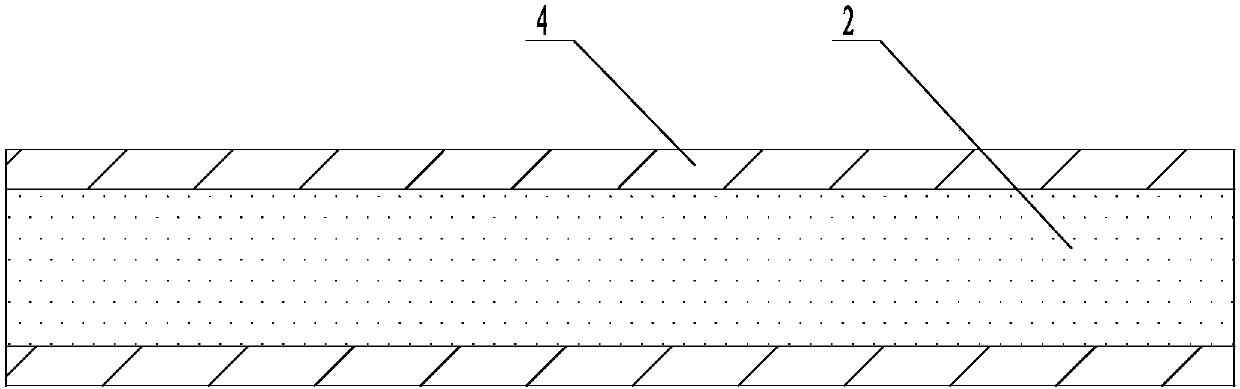

Casting forming process for large wind power planetary carrier

ActiveCN107790641ASmall size deviationEasy to operateFoundry mouldsFoundry coresElectricityEconomic benefits

The invention discloses a casting forming process for a large wind power planetary carrier casting. The planetary carrier casting comprises an upper annular plate and a lower annular plate which are vertically connected with triangular vertical columns, and a parting face of the planetary carrier casting is arranged on the interfaces of the upper annular plate and the triangular vertical columns;a first sand core and a second sand core are arranged between the upper annular plate and the lower annular plate, a triangular air outlet channel is formed in the outer sides of the sand cores, and vertical air outlet channels are formed in the centers of the sand cores; open risers are arranged right above the intersections of the upper annular plate and the triangular vertical columns, blinderrisers are arranged on the lower annular plate, and external chills are arranged under the lower annular plate. Pouring is carried out by adopting combined pouring mode of bottom-back pouring gates and stepped pouring gates. The planetary carrier produced by the method is good in forming and qualified in size, the matric structure of the casting is compact, joint parts of the triangular verticalcolumns and the upper annular plate and the lower annular plate has no crack defect, the other parts only need to undergo modification repair welding, the production cost of the casting is reduced, and higher economic benefits are achieved.

Owner:兰州兰石铸锻有限责任公司

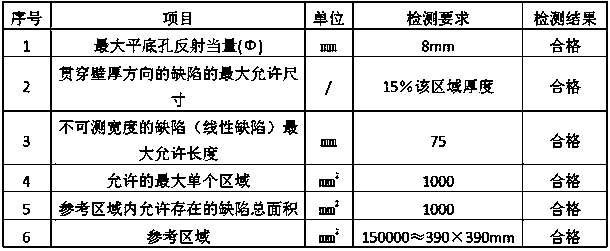

Casting process for high-temperature water-pressure-resisting combined flange

InactiveCN105689653AImprove heat resistanceHigh thermal conductivityFoundry mouldsFoundry coresFlangeHigh heat

The invention discloses a casting process for a high-temperature water-pressure-resisting combined flange. The cast high-temperature wear-resisting combined flange mainly comprises a flange body. The flange body is composed of a first flange plate and a second flange plate. The shape and the size of the second flange plate are the same as those of the first flange plate. The first flange plate and the second flange plate are each of a saddle-shaped structure. Threaded holes and through holes are evenly distributed in the first flange plate and distributed at intervals. The two ends of the first flange plate extend outwards to form fixing edges. Fixing holes are formed in the fixing edges. At least two lug plates are arranged on the edge of the outer side of the first flange plate. The first flange plate and the second flange plate are connected together in a fastened manner through bolts after butting the fixing holes in the fixing edges, and the first flange plate and the second flange plate are connected in the fastened manner to form a mounting hole. The casting process is simple and easy to implement. The cast combined flange is simple in structure and has good high-temperature water-pressure-resisting performance, the service life of the flange is prolonged, and cost is lowered.

Owner:DAFENG HONGLIAN CAST STEEL

Anti-sticking sand casting coating and preparation method thereof

InactiveCN108787996AHigh densityReduce voidsFoundry mouldsFoundry coresMulliteVolumetric Mass Density

The invention relates to an anti-sticking sand casting coating and a preparation method thereof, and belongs to the technical field of casting. According to the anti-sticking sand casting coating andthe preparation method thereof, a refractory aggregate is selected, an irreversible phase change is generated at a relatively low temperature and large expansion is generated, so that the surface of powder particles in a coating layer sintering shell is sintered more sufficiently, and the particles are in general adhesion due to surface fusion; the coating layer is in a glassy state, the gap of the coating layer is less, the density is higher, the shielding effects of element migration and diffusion are stronger, high-viscosity square quartz generated during high-temperature transformation canresist permeation of metal liquid, and the defect of mechanical sand sticking of castings can be prevented; and the line shrinkage coefficient differences between the glass state coating layer and the casting metal are also large after cooling, the cutting stress of the interface between the casting and the coating layer is increased, so that the coating layer and the casting are peeled off automatically, so that a casting with a smooth surface is obtained; and the thermal chemical stability of a generated mullite phase is high, the generated mullite phase is not easy to react with acid and alkaline oxides, and the prevention of the chemical sand sticking defects of castings is facilitated.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

Quick-dry fireproof paint for evanescent mold manufacturing

The invention discloses quick-dry fireproof paint for evanescent mold manufacturing and relates to the technical field of casting. The quick-dry fireproof paint is prepared from, by weight, 50-60 parts of acrylic resin, 20-25 parts of polyvinyl acetate, 15-20 parts of volcanic ash, 10-15 parts of carclazyte, 10-15 parts of zeolite powder, 8-12 parts of glyceryl monostearate, 6-10 parts of sodium carboxymethylcellulose, 4-7 parts of soap powder, 4-7 parts of glucoside, 3-5 parts of silicone emulsion, 2-3 parts of nano-zirconia, 2-3 parts of adhesion promoter, 1-2 parts of dibutyltin dilaurate, 1-2 parts of methyl ethyl ketoxime and 400-500 parts of isopropanol. The paint can be solidified at normal temperature after being sprayed onto an evanescent mold, solidification time is less than an hour, a formed coating is dense and hard, sand burning of castings can be effectively prevented, sand cleaning workload can be reduced, a casting cavity can be protected, and then the quality of castings can be improved.

Owner:ANHUI SOLID FOUNDRY CO LTD

Environment-friendly molding sand additive and using method thereof

InactiveCN108356214ALow moisture requirementsLow wettabilityFoundry mouldsFoundry coresCombustionCasting mold

The invention relates to the field of casting industry, in particular to an environment-friendly molding sand additive and a using method thereof. The environment-friendly molding sand additive is formed by mixing the following raw materials of, by mass, 50-85% of SiO2, 9-45% of Al2O3, 0.2-3% of MgO, 1-8% of Fe2O3, 1-7% of CaO and 0.5-8% of Fe3O4. The additive does not generate combustion reaction, and no toxic and harmful gas is generated in the casting process, so that the additive belongs to a pollution-free and environment-friendly material which is beneficial to energy conservation and emission reduction; the additive is mainly used for replacing organic matter additives such as coal powder used in traditional wet casting; and the additive has excellent sand-sticking resistance, wettability of a casting mold and a metal liquid is reduced, and the surface quality of a casting is improved.

Owner:云南衡纬科技有限公司

Molding sand capable of preventing sand penetration of cylinder pedestal casting

InactiveCN107008850AIncrease wind speedPrevent sticky sandFoundry mouldsFoundry coresRejection rateLoss on ignition

The present invention discloses a molding sand capable of preventing sand penetration of a cylinder pedestal casting. The mass fractions of used sand, silica sand, bentonite, pulverized coal and water are 96-98%, 0.5-1.5%, 0.7-0.9%, 0.3-0.4%, and 0.3-1.4% respectively, and the total of the mass fractions of the above components is 100%. The molding sand is obtained after mixing the above components, and as for the molding sand, a silt content is 11-12%, a water content is 3.2-3.6%, a bentonite content is 7.5-8.0%, an average particle size is 62-68 meshes, a loss on ignition is 3.5-4.5%, a sand compactibility is 32-36%, a green compression strength is 160-180 KPa, and an air permeability is 100-140. With adoption of the molding sand provided by the invention, sand penetration of the cylinder pedestal casting can be effectively prevented, a rejection rate of the cylinder pedestal casting is reduced at the same time, the production cost is thus lowered, and the molding sand can adapt to fast and efficient production.

Owner:黄石东贝铸造有限公司

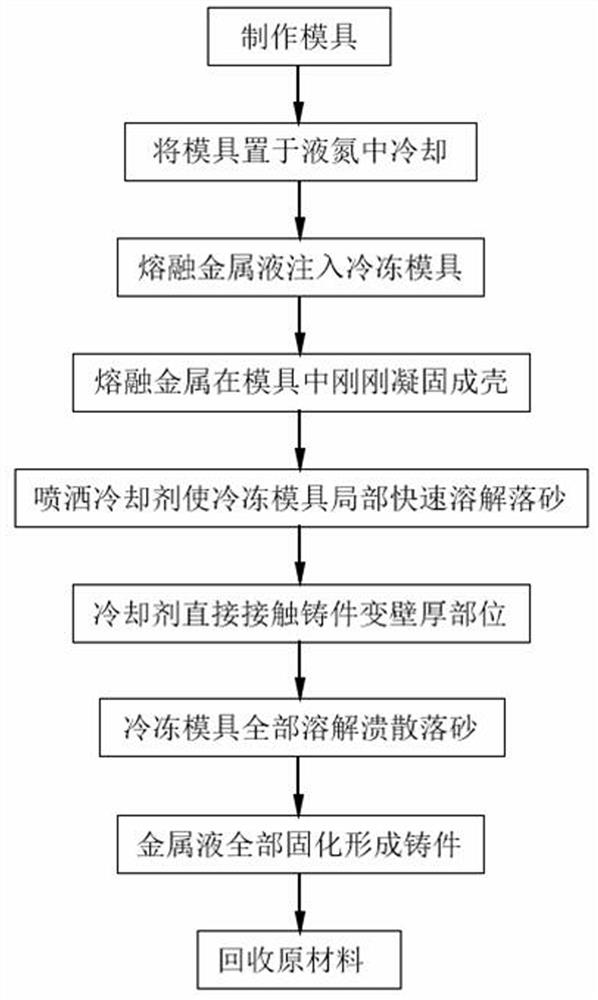

Environment-friendly freezing-dissolving casting process

ActiveCN112642994AHigh strengthSpeed up coolingFoundry mouldsFoundry coresManufactured materialMaterials science

The invention provides an environment-friendly freezing and dissolving casting process and belongs to the technical field of casting. The process comprises the steps that a mold is fabricated by using molding sand and water, the mold is frozen to obtain a frozen mold, molten metal liquid is injected into the frozen mold, molten metal is solidified into a shell in the mold, cooling water is sprayed to the wall thickness portion of the mold, the frozen mold is made to be locally and quickly dissolved and collapsed, the cooling water makes direct contact with the variable wall thickness portion of a casting for cooling, and the molten metal is completely cured to form a target casting to recycle the molding sand, a coolant and other raw materials. By means of the environment-friendly freezing and dissolving casting process, the cooling speed of the casting can be increased, the cooling speed rate of the variable wall thickness portion of the casting is balanced, and the mechanical performance of the variable wall thickness complex casting is greatly improved; and meanwhile, the sand falling cleaning link is omitted along with final freezing mold dissolution and collapse sand falling, furthermore, casting wastes are few, and the environment-friendly freezing and dissolving casting process is a novel environment-friendly casting technology and has a great development prospect.

Owner:ZHONGBEI UNIV

Special coated sand for stainless steel and preparation process thereof

InactiveCN110918867AIncrease special performanceImprove high temperature resistanceFoundry mouldsFoundry coresStearic acidPhenol formaldehyde resin

The invention discloses special coated sand for stainless steel and a preparation process thereof, and particularly relates to the field of coated sand. The special coated sand comprises the followingraw materials: crude sands, zircon sands, ceramsite sands, kaolin, high-strength high-temperature-resistant phenolic resin, urotropine, calcium stearate, a high-temperature-resistant additive and a hardening accelerator. The preparation process comprises the following steps: carrying out weighing, mixing and heating the crude sands, heating the mixed sands, adding the high-strength high-temperature-resistant phenolic resin, the urotropin and the calcium stearate, adding the high-temperature-resistant additive and hardening accelerator, and carrying out cooling, crushing, screening, detecting, packaging and warehousing. The special performance of the coated sand can be improved; the high-temperature resistance of the coated sand can be improved; the quality of the coated sand can be effectively improved; the high-temperature resistance of the coated sand is improved; the high-temperature resistance of the coated sand can be effectively improved, and furthermore, the refractoriness ofthe coated sand can be improved; the surface of a casting is smooth and clean, so that sand sticking to the surface of the stainless steel casting can be effectively avoided; and the coated sand can be completely suitable for production of the stainless steel casting, and the finished product percent of pass is high.

Owner:青岛宜泰源铸造材料有限公司

Alcohol-based paint for sand casting and preparation method thereof

InactiveCN102873267BImprove high temperature strengthImprove high temperature stabilityFoundry mouldsFoundry coresSodium BentonitePolyvinyl alcohol

The invention discloses an alcohol-based paint for sand casting and a preparation method thereof. The density of the paint is 1200-1400 kg / m<3>, and the paint is composed of solutes and an organic solvent, wherein the organic solvent is one of methanol, ethanol and isopropanol or a mixture thereof; and the solutes include the following components in percentage by weight: 60-75% of alumina, 1-5% of attapulgite, 0.5-1.5% of sodium bentonite, 2-10% of amorphous graphite, 3-15% of lamellar graphite, 2-10% of iron red, 1-5% of polyvinyl butyral, 0.1-0.5% of surfactant, 0.1-0.5% of dispersant and 1-5% of hydrochloric acid solution. The alcohol-based paint is simple in preparation process, high in stability and easy to store.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

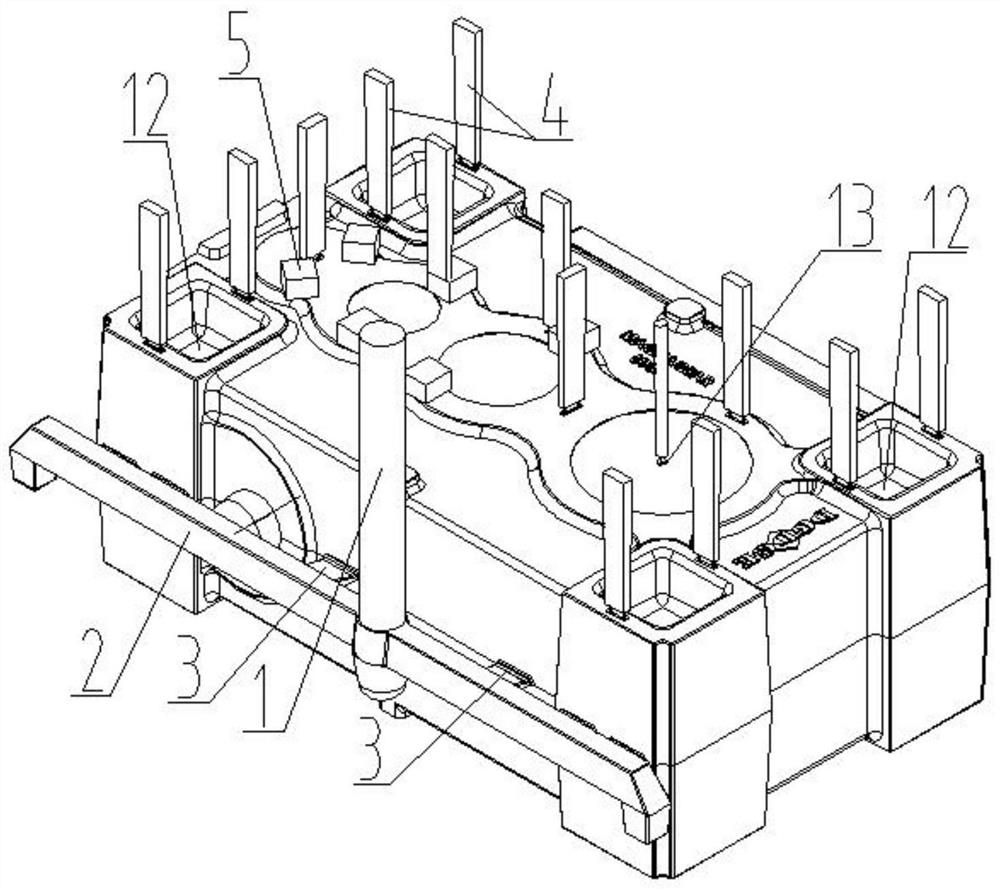

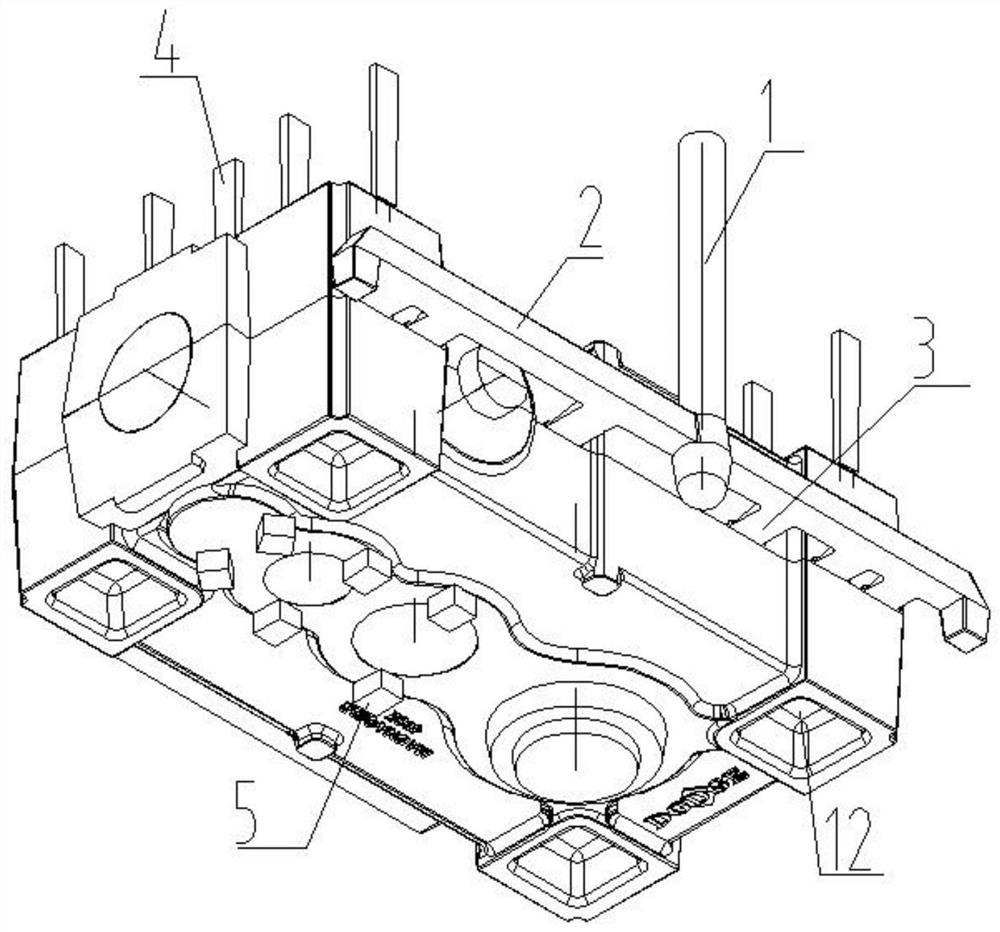

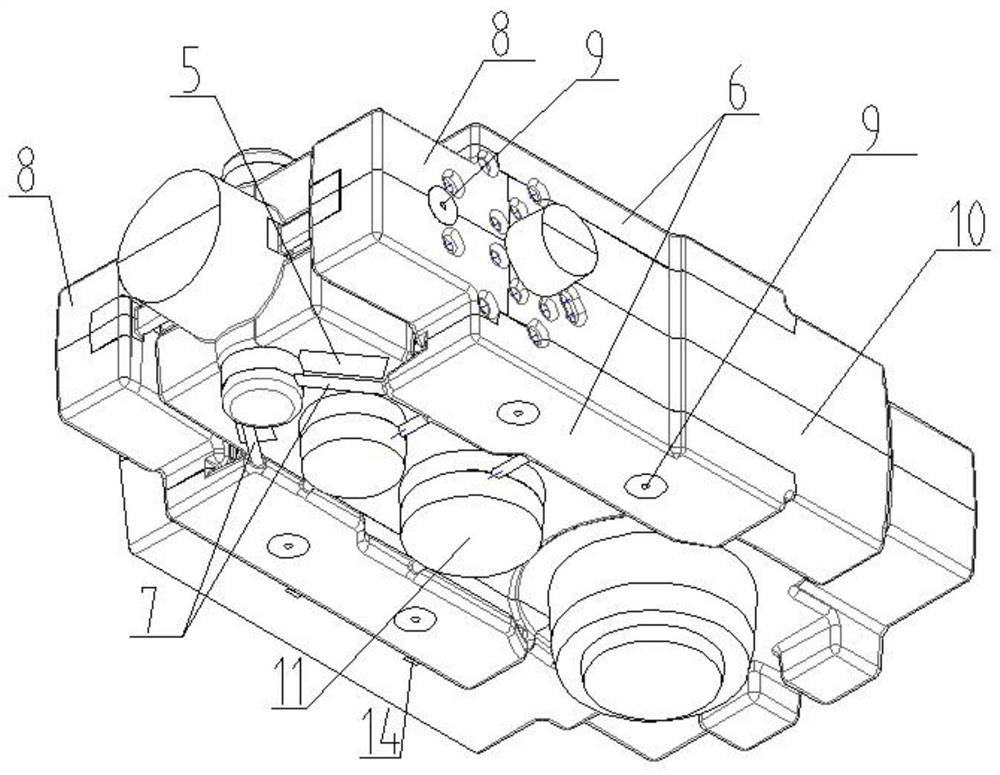

Casting method of gearbox casting

ActiveCN113070453APlay a feeding roleGuaranteed surface qualityFoundry mouldsFoundry coresMechanical engineeringCasting

The invention discloses a casting method of a gearbox casting, and belongs to the technical field of casting processes. The casting method of the gearbox casting comprises the steps of carrying out reverse deformation design on a die, preparing a special core bar, manufacturing upper and lower die sand molds and a plurality of single sand cores, carrying out pretreatment, assembling in sequence, carrying out flow coating repairing and drying, and finally, carrying out pouring through molten iron. According to the casting method of the gearbox casting, deformation and cracking of the gearbox casting can be improved, and the problems of oil duct blockage, sand burning and the like are solved.

Owner:慈溪汇丽机电股份有限公司

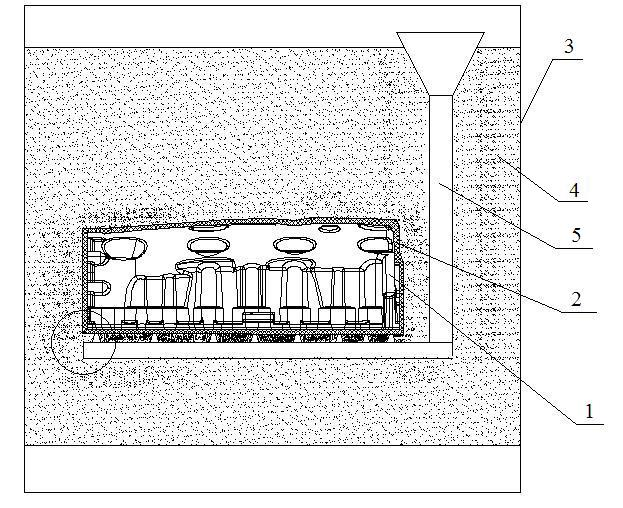

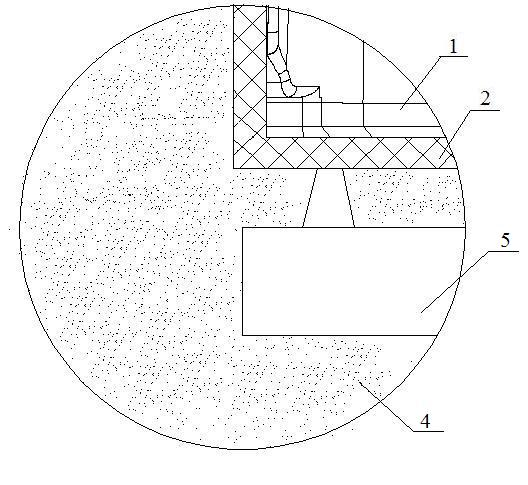

Casting process for bolt hole of large-scale ductile iron main bearing cover casting process

The invention is mainly applied to the technical field of casting of the diesel engine bearing cover, in particular to a casting process for a bolt hole of a large-scale ductile iron main bearing cover. The casting process is characterized by comprising the steps that 1, a corundum mullite ceramic tube is selected; 2, a ceramic tube fixing core head is arranged, and resin sand is used for molding;3, the casting sand mold is coated with coatings and then is dried; 4, resin sand is filled in the middle of the dried ceramic tube; 5, the outer wall of the filled ceramic tube is coated with an alcohol-based fire-resistant coating and then is aired after being ignited; 6, the coated casting sand mold and the aired ceramic tube are dried again, and the dried ceramic tube is placed in the ceramictube fixing core head; and 7, mold assembling, pouring and cleaning are carried out. According to the casting process, the defects of using a sand core and a cast steel tube process such as penetration, deformation, blowholes, hard spots and the like are overcome; meanwhile, the operation of workers is simple, multiple pieces can be manufactured at the same time, the production efficiency is greatly improved, and the production cost of manufacturing a core box is also saved; and the ceramic tube has the advantages that the strength can be high, sand sticking and penetration can be prevented,and the defects of porosity and shrinkage can be overcome.

Owner:ZICHAI POWER CO LTD

White corundum powder coating method

ActiveCN102259169APrevent sticky sandWon't happenMoulding toolsFoundry mouldsAir bubbleSurface layer

The invention provides a method for brushing white alundum powder paint, and the method comprises the following steps of: 1, preparing the white alundum powder paint with a baume degree of 76-84 [Be], carrying out primary brushing of the white alundum powder paint on a surface layer of a sand cavity, lighting the white alundum powder paint immediately after brushing is completed, and then coolingto a room temperature; 2, preparing the white alundum powder paint with the baume degree of 52-58 [Be], carrying out secondary brushing of the white alundum powder paint on the surface layer of the sand cavity, lighting the white alundum powder paint 30-60 seconds after the brushing, and then cooling to the room temperature; and 3, preparing the white alundum powder paint with the baume degree of42-50 [Be], carrying out tertiary brushing of the white alundum powder paint on the surface layer of the sand cavity, lighting the white alundum powder paint 30-60 seconds after the brushing, and then cooling to the room temperature so as to complete the brushing, thereby ensuring that a brushed coating layer cannot generate air bubbles after being lighted and preventing a casting from being subjected to sand fusion.

Owner:SUFA HENGDIAN MACHINERY CNNC

Lost foam casting method of double-layer exhaust pipe for engine

InactiveCN101829760APrevent heat absorptionPrevent large amount of gasFoundry mouldsFoundry coresPolystyrene beadSlag

The invention relates to a lost foam casting method of a double-layer exhaust pipe for an engine, which is characterized by comprising the following steps of: dividing the engine into at least four separating units by using a double-layer exhaust pipe model to make a polystyrene foam forming die, injecting polystyrene beads into dies of the four separating units to make a polystyrene foam model of each separating unit, adhering the separating units into an exhaust pipe integral model; coating a venting paint on the surface of the integral model; combining the exhaust pipe model into a die string according to a casting process, and adhering on a casting system; implanting the combined integral model into a cast box and adding dried sand in the sand box while compacting the dried sand by using a compaction table, exposing a pouring cup; and pouring molten iron into a pouring pipe mouth at suitable casting temperature. The invention provides a lost foam casting method of a double-layer exhaust pipe for an engine, which can effectively solve the problems of cold lap, left residual slag or air holes of casting, bulges, sand penetration and the like occurring in the lost foam casting process of the double-layer water-cooling exhaust pipe and is beneficial to lowering the production cost and improving the casting quality of the double-layer exhaust pipe for the engine.

Owner:福清龙泰机械有限公司

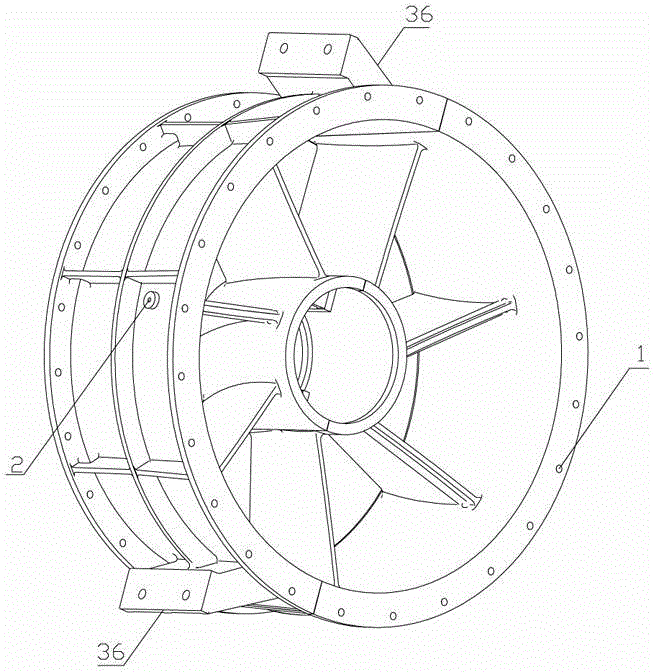

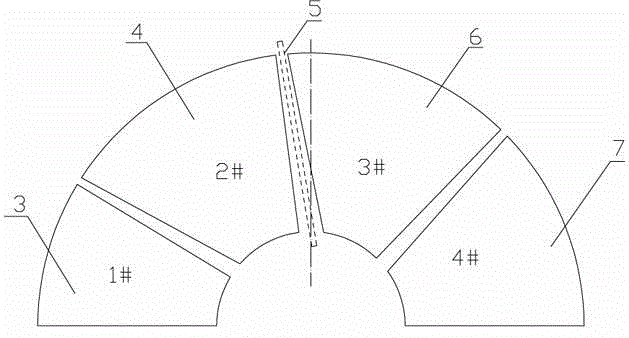

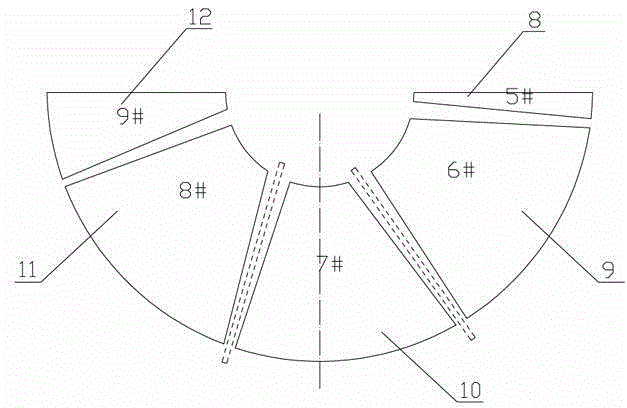

Large horizontal axial flow pump split guide vane casting method

InactiveCN104001864AIngenious designSimple structureFoundry mouldsFoundry coresAxial-flow pumpThick wall

The invention relates to a large horizontal axial flow pump split guide vane casting method. The method is characterized by comprising the steps of: (1) employing a foam module to make an upper half guide vane outer die and a lower half guide vane outer die; (2) designing the upper guide vane into four sand cores, designing the lower guide vane into five sand cores, and specially making a set of molding wood die universal to 1#-9# sand cores; (3) employing the upper half guide vane outer die and the lower half guide vane outer die and the universal molding wood die to manufacture sand molds, and placing coke in the sand cores; (4) pre-embedding a thick-walled seamless steel pipe at the molding position of a guide vane oil pipe hole, and inserting the seamless steel pipe into a foam outer die to fix it; (5) brushing an ISOMOL type special alcohol-based coating on a molding sand casting wall surface twice; (6) carrying out molten iron casting; and (7) controlling the heat preservation time of a casting in the sand mold over 48h. The method provided by the invention adopts the special universal molding wood die, and arranges coke in the sand cores, and employs heat preservation time prolonging and other measures, thus greatly saving the manufacturing cost of the guide vane body and improving the product quality. The method is mainly used for production of large horizontal axial flow pump guide vanes.

Owner:黄石新兴管业有限公司

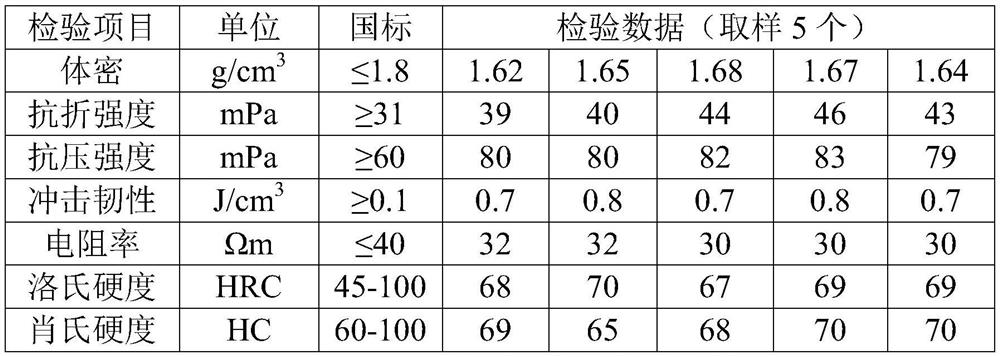

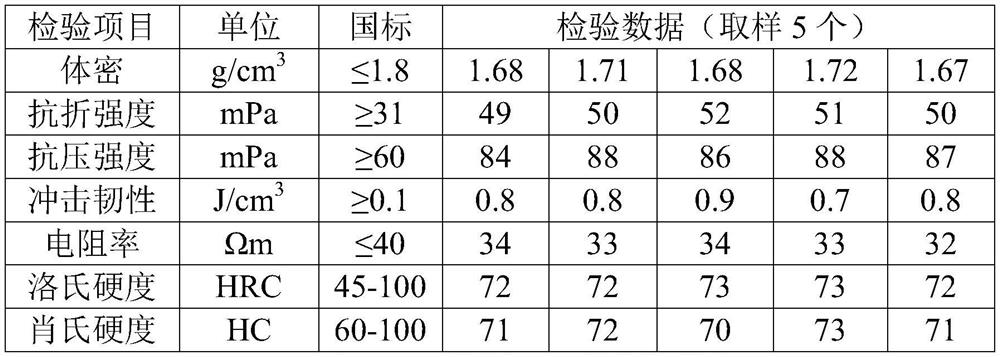

High-strength wear-resistant carbon sliding plate for pantograph and preparation method thereof

InactiveCN111792935AImprove performanceImprove inner structureCeramic shaping apparatusPower current collectorsCrazingCoke

The invention discloses a high-strength wear-resistant carbon sliding plate for a pantograph, which is prepared by kneading, extruding and roasting a dry powder mixture and liquid asphalt which accounts for 27-35% of the mass of the dry powder mixture, wherein the dry powder mixture is prepared by fully mixing the following raw materials in percentage by mass: 10%-30% of pitch coke particles witha particle size of 0.5-0.2 mm, 15%-30% of pitch coke particles with the particle size of 0.2-0 mm, 30%-40% of pitch coke powder, 5%-20% of graphite powder and 5%-10% of carbon black. The invention also discloses a preparation method thereof. According to the invention, the product performance is comprehensively considered, the raw materials of various particle sizes are reasonably configured, andthe basic performance of the product is improved from the raw material ratio; the kneading speed per hour and the kneading temperature are strictly controlled, so that the internal structural state ofthe product is improved; the compactness of the product is uniformized through pre-pressing extrusion forming, and the problem of internal cracking and layering is reduced; and through the design ofa roasting temperature rise curve, roasting deformation cracks are reduced, the configuration of filler avoids sand burning of the product, and the yield is improved, so that the structural performance of the pantograph carbon contact strip is improved on the whole, and various physicochemical indexes of the pantograph carbon contact strip reach the advanced level in China.

Owner:兴和县青山特种石墨碳素有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com