High-strength wear-resistant carbon sliding plate for pantograph and preparation method thereof

A high-strength, pantograph technology, applied in the direction of current collectors, electric vehicles, manufacturing tools, etc., can solve the problems of non-wear resistance, large loss, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

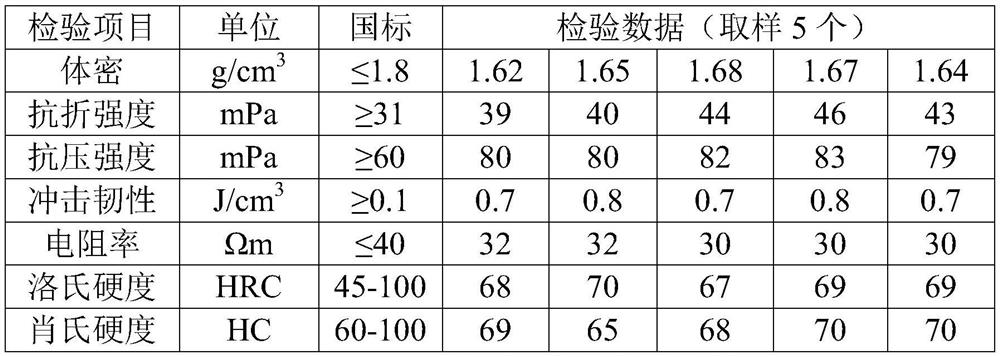

Embodiment 1

[0027] The high-strength wear-resistant carbon slide plate used for pantographs uses 25% of pitch coke particles with a particle size of 0.5-0.2mm, 20% of pitch coke particles with a particle size of 0.2-0mm, 30% of pitch coke powder, 20% of graphite powder, carbon Black 5% is fully mixed to obtain a dry powder mixture, wherein the particle size of 0.5-0.2mm is the size of a 32-mesh sieve, the particle size of 0.2-0mm is the size of a 65-mesh sieve, and the powder material is a size of a 200-mesh sieve. The dry powder mixture passes through the mixing equipment Mix evenly, such as using a biaxial Z-type kneader for dry mixing, it can be mixed evenly in about 40 minutes. When using a biaxial Z-type kneader for dry mixing, the dry mixing temperature can be adjusted to 150°C. On the basis of ensuring uniform mixing, it can also ensure the internal temperature of the dry powder mixture for subsequent direct kneading. Then add softened liquid asphalt into the kneader according to (...

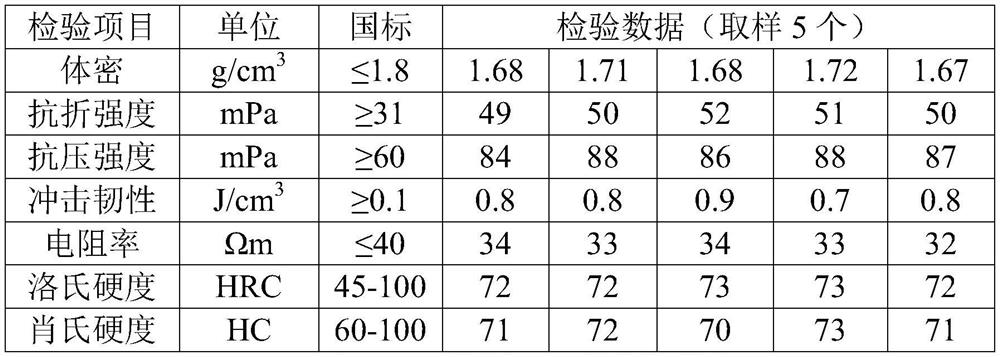

Embodiment 2

[0032] The high-strength wear-resistant carbon skateboard is formed by fully mixing the following dry powder mixtures with the following mass percentages of raw materials: 25% of asphalt coke particles with a particle size of 0.5-0.2mm, 25% of asphalt coke particles with a particle size of 0.2-0mm, and asphalt Coke powder 33%, graphite powder 10%, carbon black 7%. The liquid pitch used accounts for (29±2)% of the mass of the dry powder mixture.

[0033] Other preparation process is identical with embodiment 1.

Embodiment 3

[0035] The high-strength wear-resistant carbon skateboard is formed by fully mixing the following dry powder mixtures with the following mass percentages of raw materials: 20% of asphalt coke particles with a particle size of 0.5-0.2mm, 30% of asphalt coke particles with a particle size of 0.2-0mm, and asphalt Coke powder 30%, graphite powder 10%, carbon black 10%. The liquid asphalt used accounts for (28±2)% of the mass of the dry powder mixture.

[0036] Other preparation process is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com