Lost foam casting method of double-layer exhaust pipe for engine

A lost foam casting and exhaust pipe technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve problems such as succulent, casting residues or pores, etc., to prevent too much heat absorption and prevent castings from sticking sand. , to prevent the dry sand filling is insufficient and the effect is not tight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

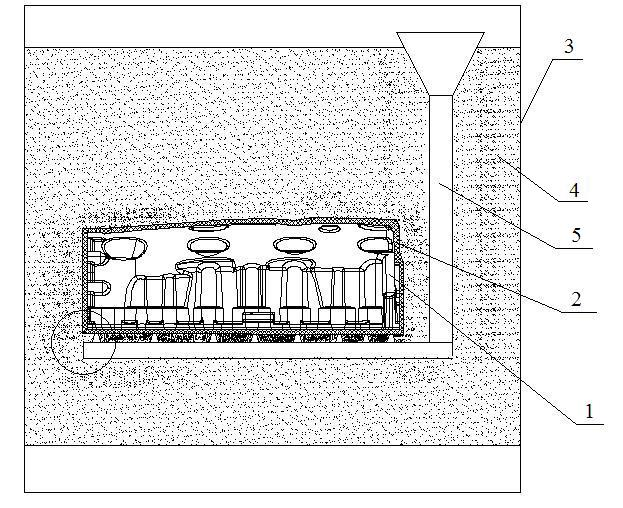

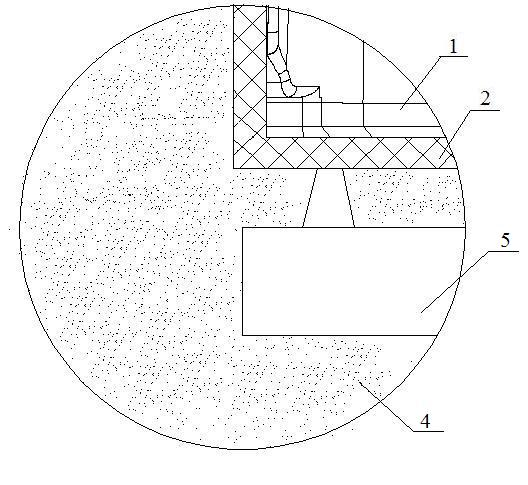

[0036] Such as image 3 and Figure 4 As shown, the pouring pipeline 6 includes a sprue cup 5, a sprue 7 and a runner 8. After the molten iron is poured into the sprue cup 5, it flows into the foam mold 1 along the sprue 7 and the runner 8 to complete the casting process.

specific Embodiment 2

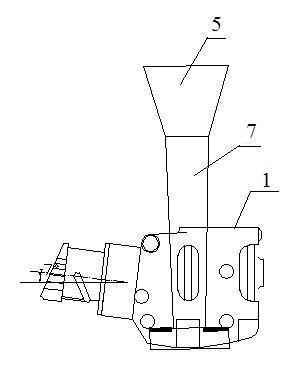

[0037] Such as Figure 5 As shown, the pouring pipeline 6 includes a sprue cup 5, a sprue 7 and a runner 8. After the molten iron is poured into the sprue cup 5, it flows into the foam mold 1 along the sprue 7 and the runner 8 to complete the casting process.

specific Embodiment 3

[0038] Such as Figure 6 As shown, the above-mentioned pouring pipeline 6 includes a sprue cup 5, a sprue 7, a runner 8 and an ingate 9. After the molten iron is injected into the sprue cup 5, it flows into the ingate 9 along the sprue 7 and the runner 8. , and then respectively flow into the foam model 1 from the inrunner 9 to complete the casting process.

[0039] The invention has novel conception, reasonable design and great popularization value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com