Patents

Literature

587results about How to "Low wettability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

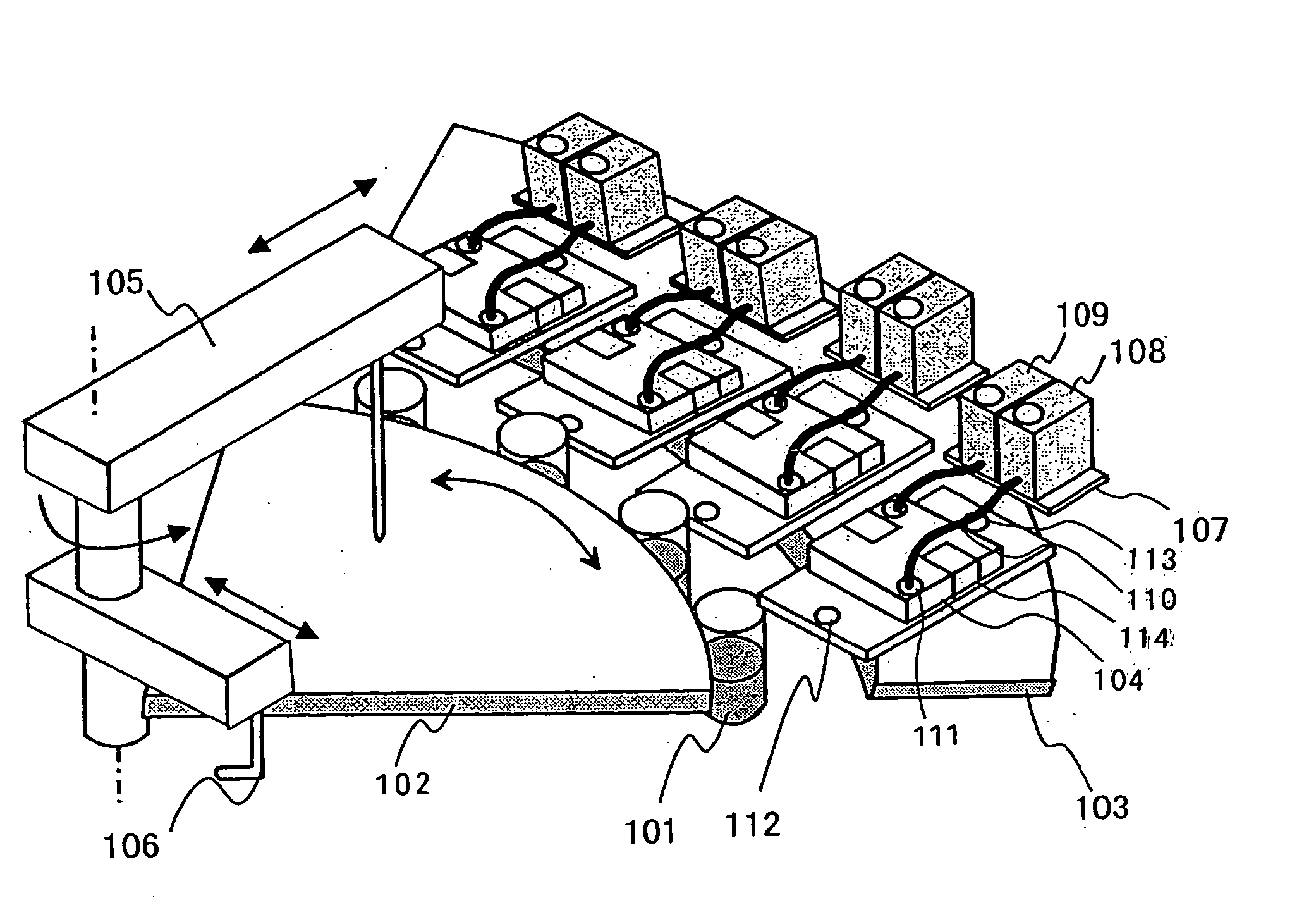

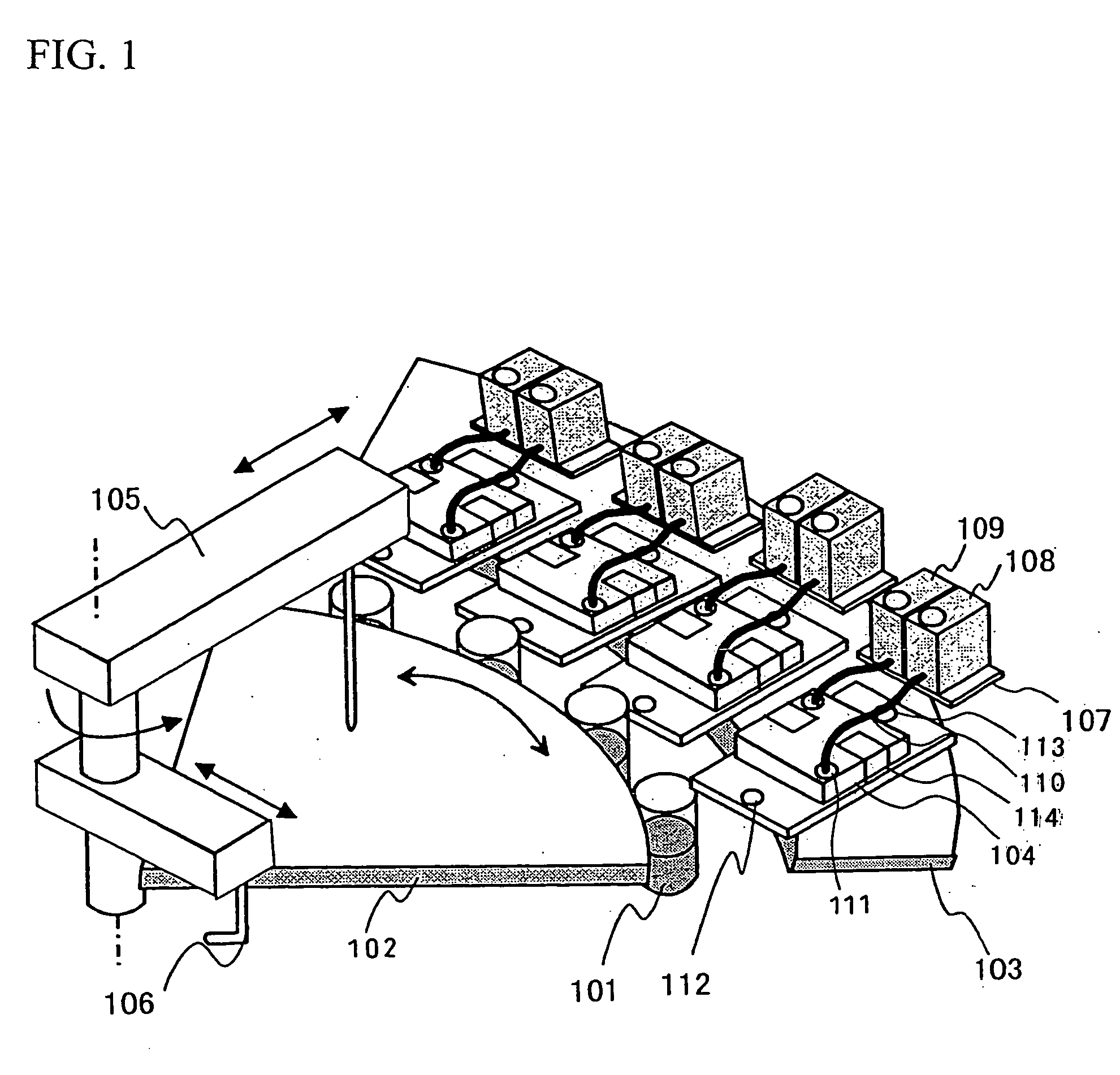

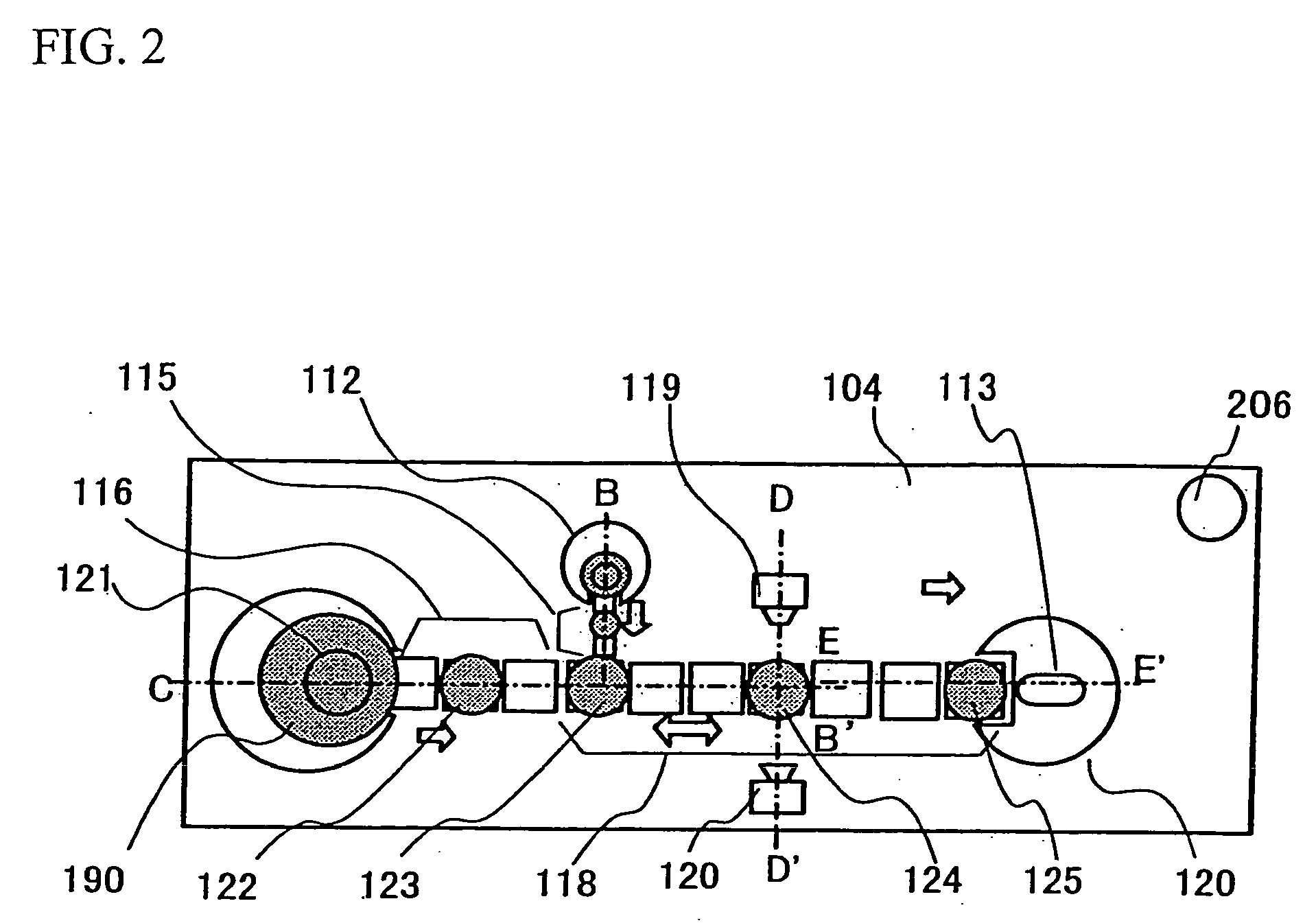

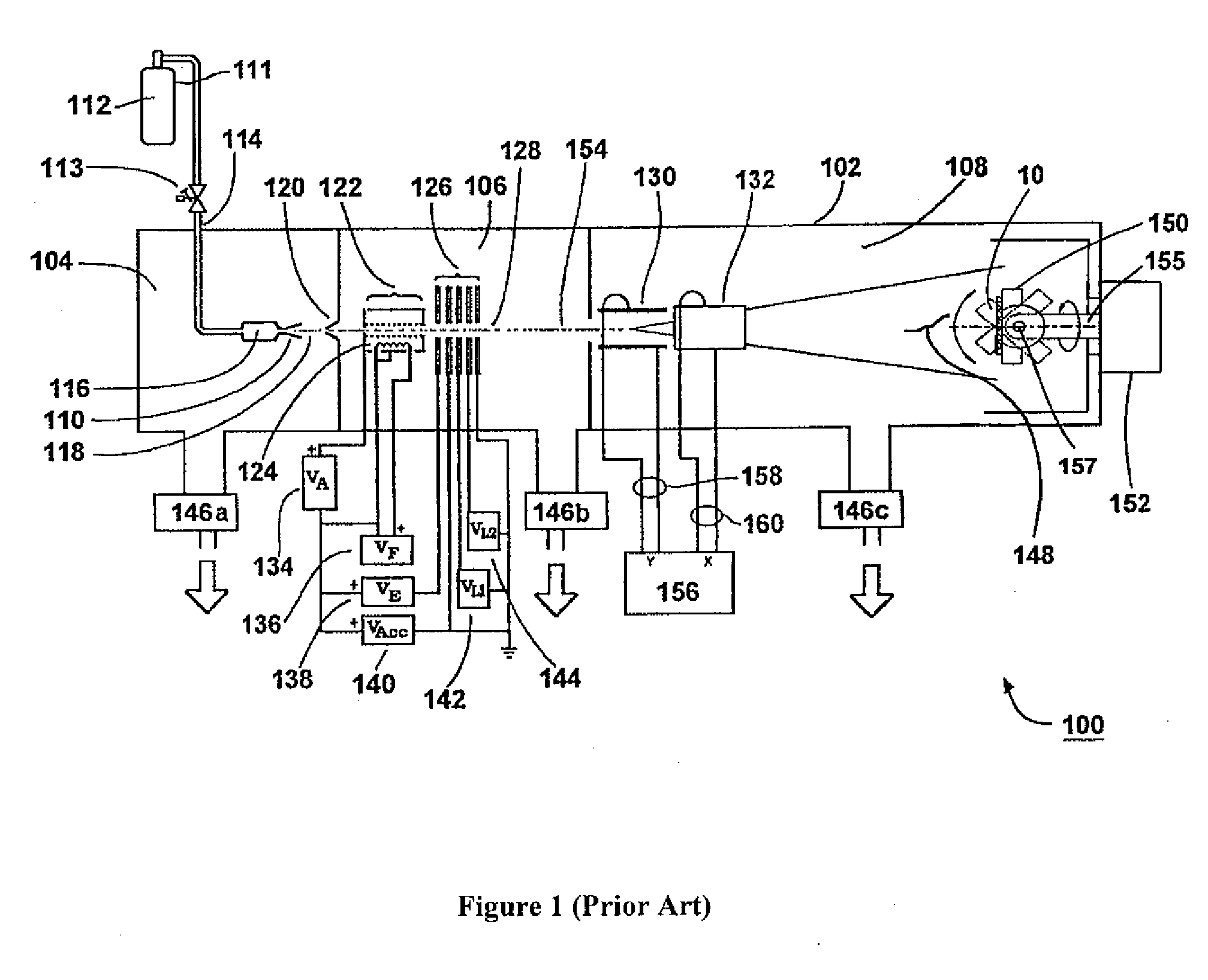

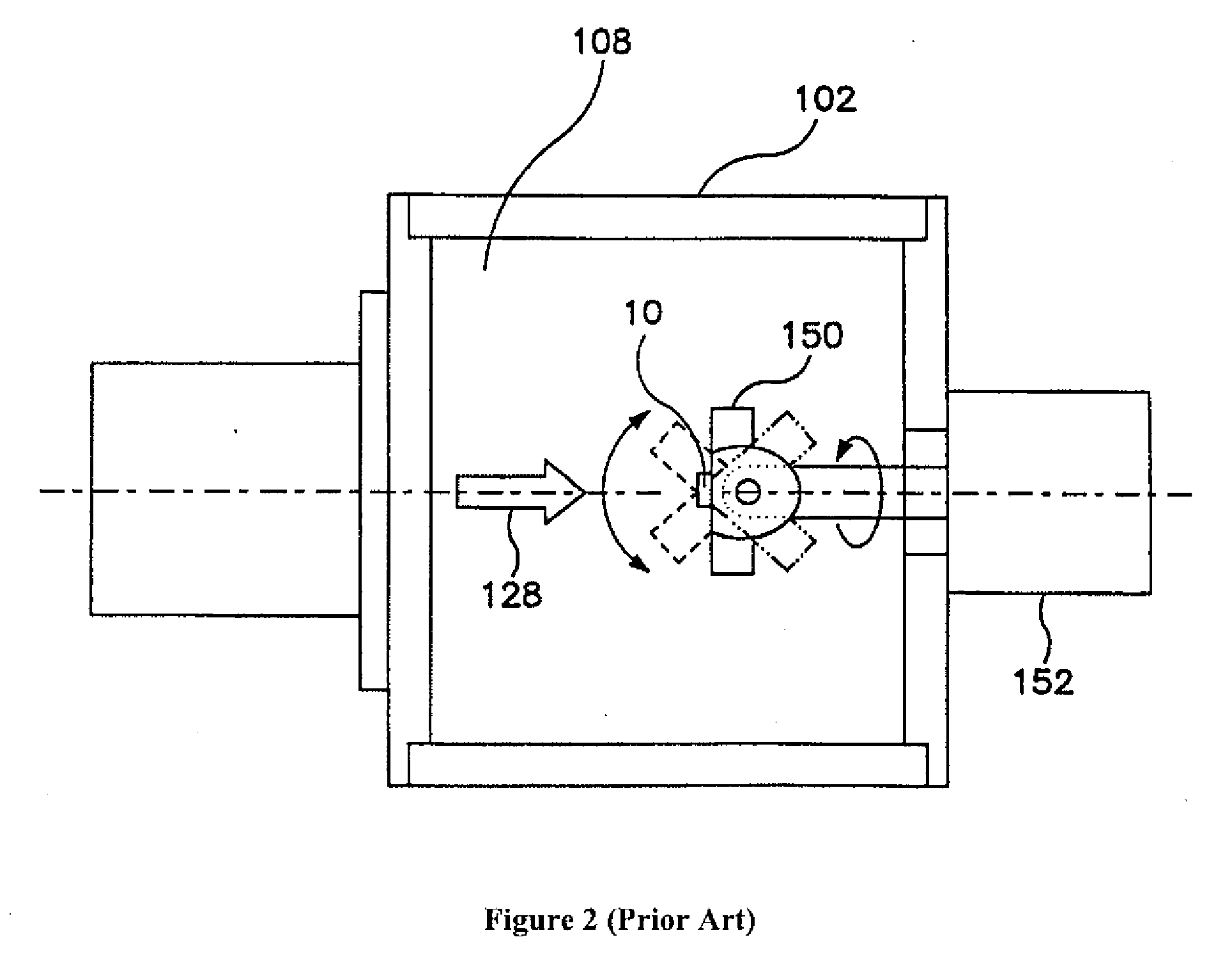

Chemical analysis apparatus

InactiveUS20060039823A1Improve accuracyHigh mixing precisionAnalysis using chemical indicatorsShaking/oscillating/vibrating mixersCompound (substance)Engineering

A chemical analysis apparatus is equipped with analysis sections having openings, means for supplying samples or reagents from the openings, means for combining and mixing samples with reagents to obtain droplets as liquids to be measured, and means for measuring the physical properties of the liquids to be measured during reaction or after completion of reaction. Furthermore, plate members are provided facing each other in analysis sections and a plurality of electrodes are provided on the plate member faces that face each other. Voltage is applied from the plurality of electrodes to the droplets of the samples and the reagents.

Owner:HITACHI HIGH-TECH CORP

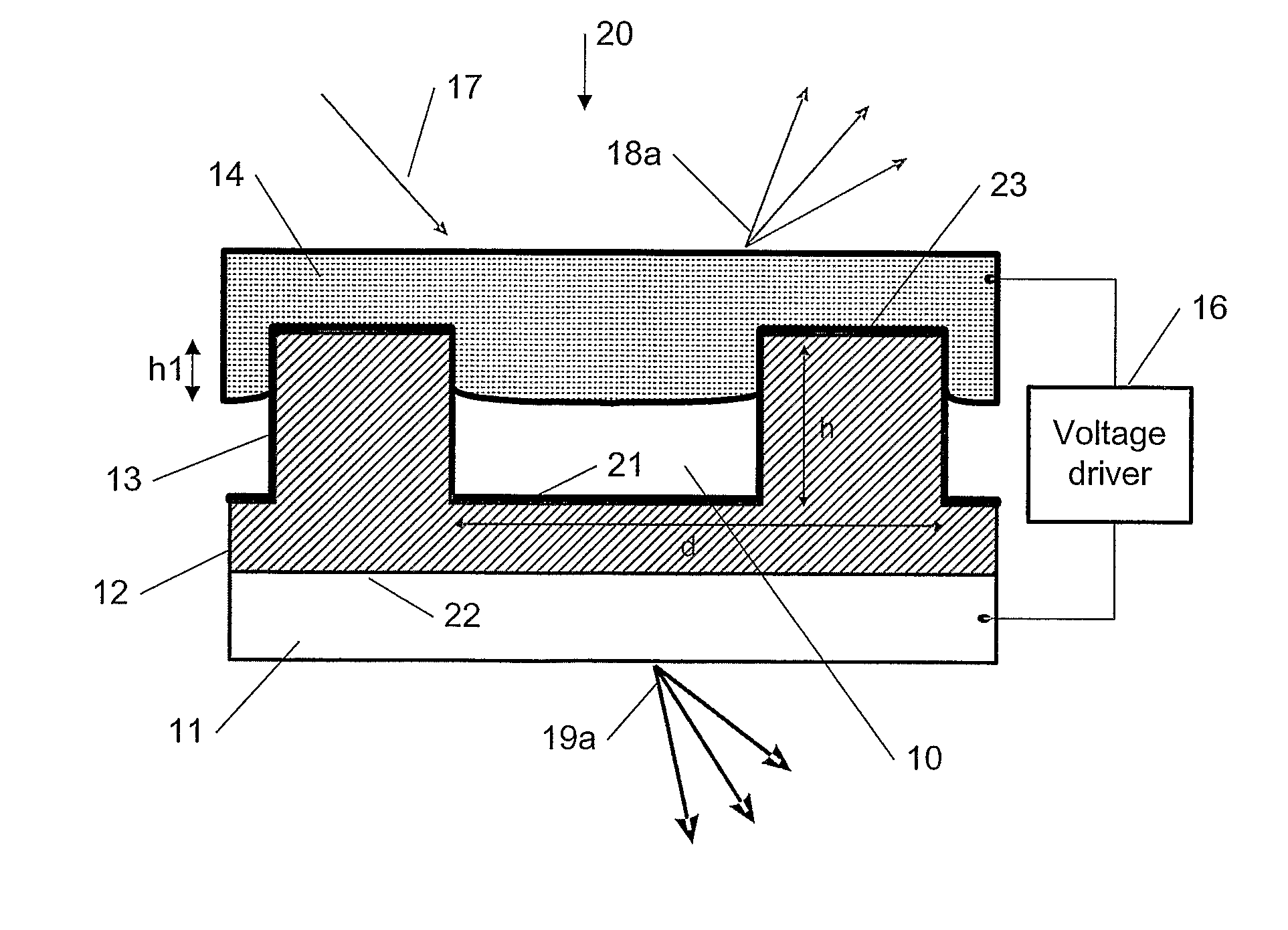

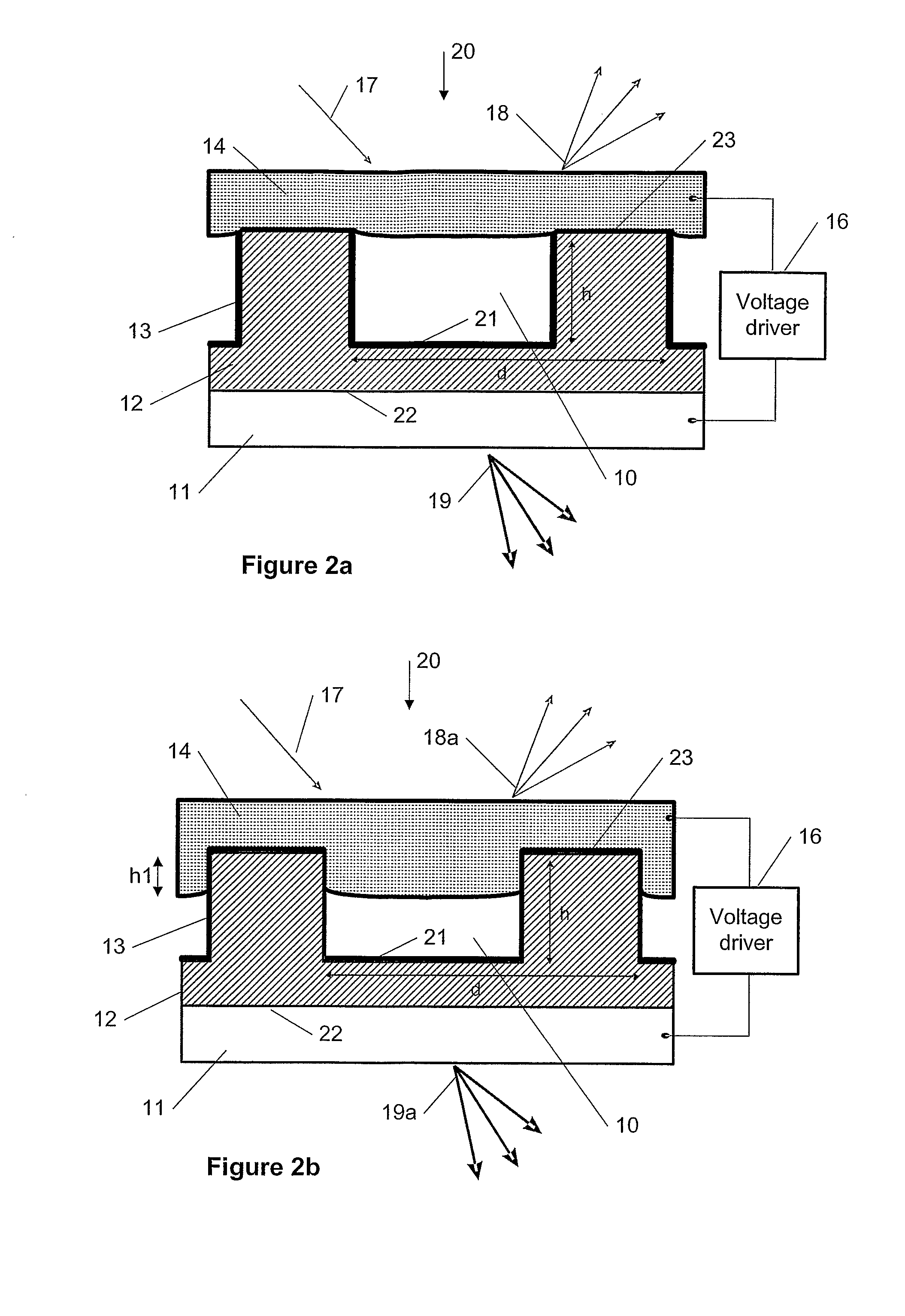

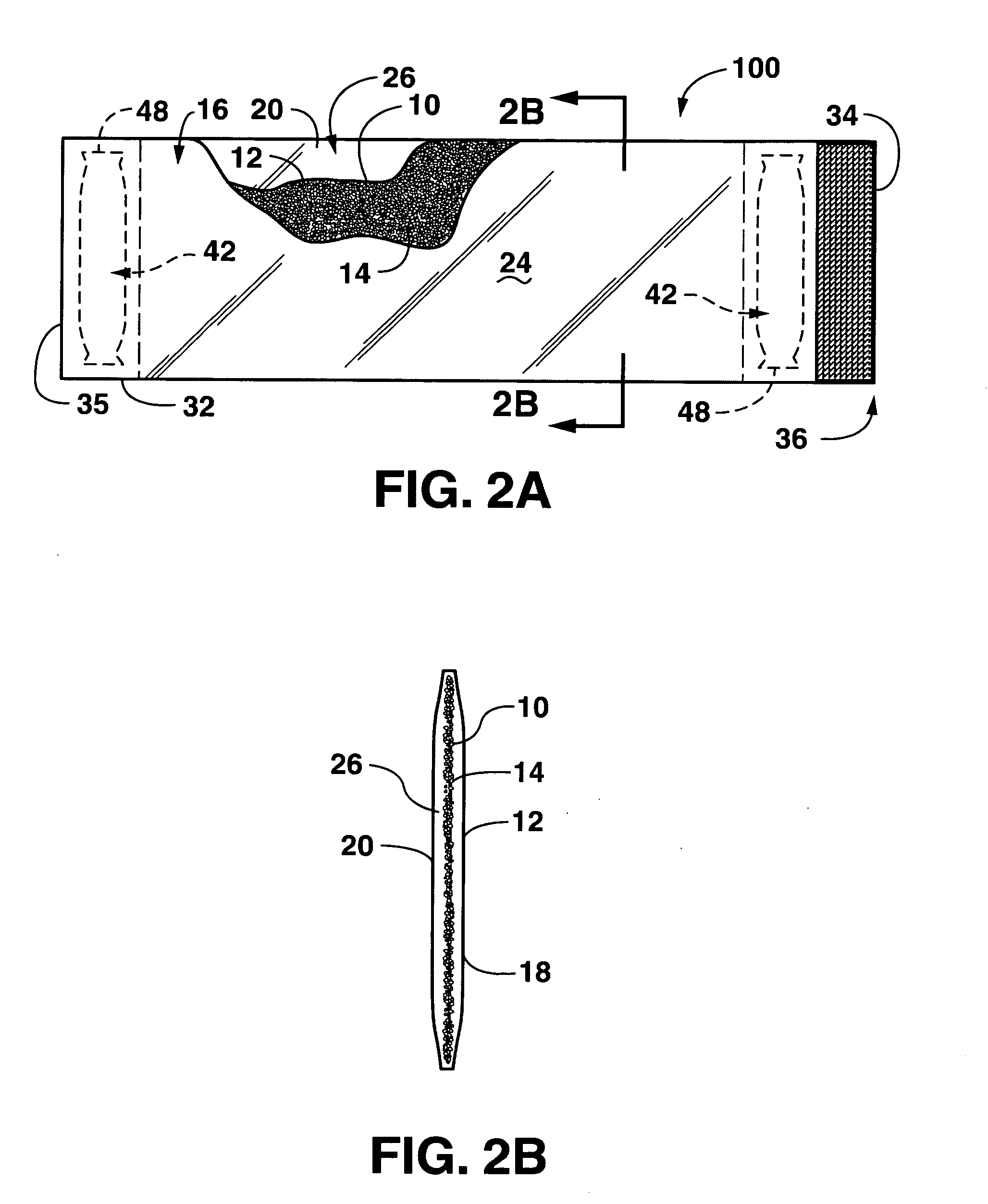

Diffraction Gratings With Tunable Efficiency

ActiveUS20090296218A1Reduce wettabilityLow wettabilityRecord information storageOptical beam guiding meansElectrical controlElectricity

The specification and drawings present a new method, apparatus and software product for modulation of the optical intensity using electro-wetting (EW) diffraction gratings in the electronic devices with an electrical control signal. The EW diffraction gratings can be components of an element (e.g., a display) of the electronic device. Applications may include but are not limited to color displays, projection displays, front illuminating displays, field sequential displays, auto-stereoscopic displays, etc. Also, applications in areas other than displays are possible.

Owner:NOKIA TECHNOLOGLES OY

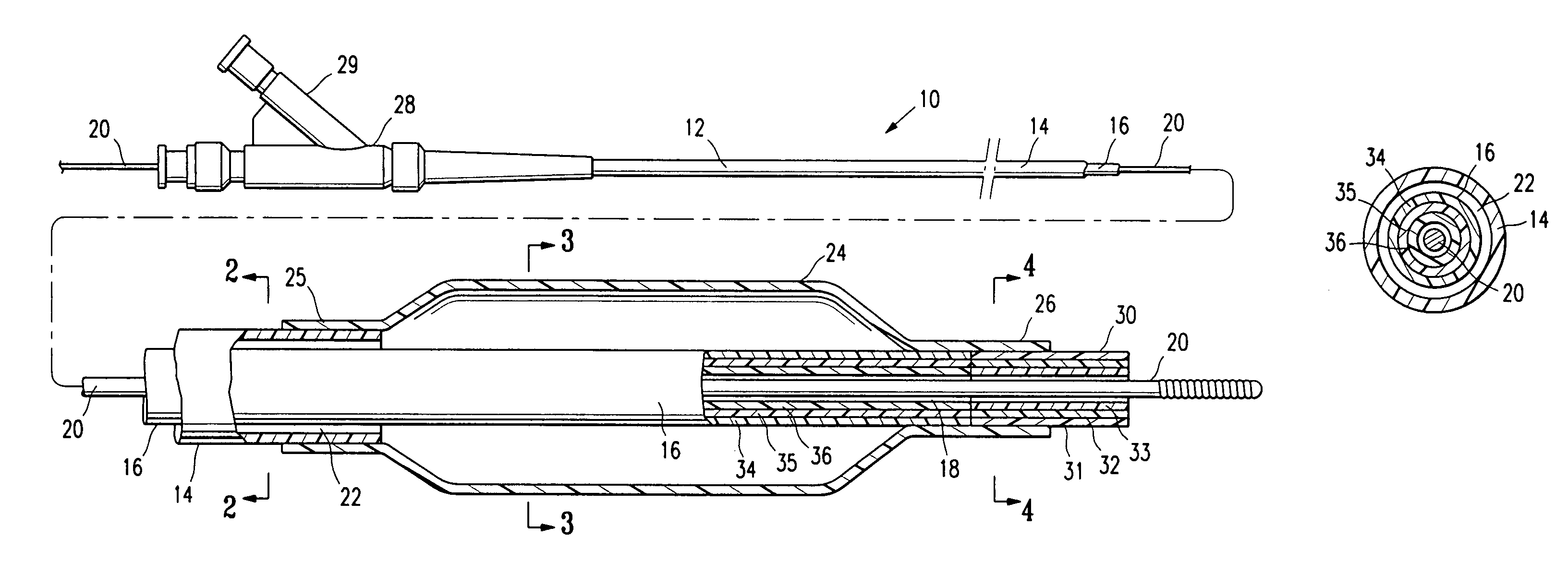

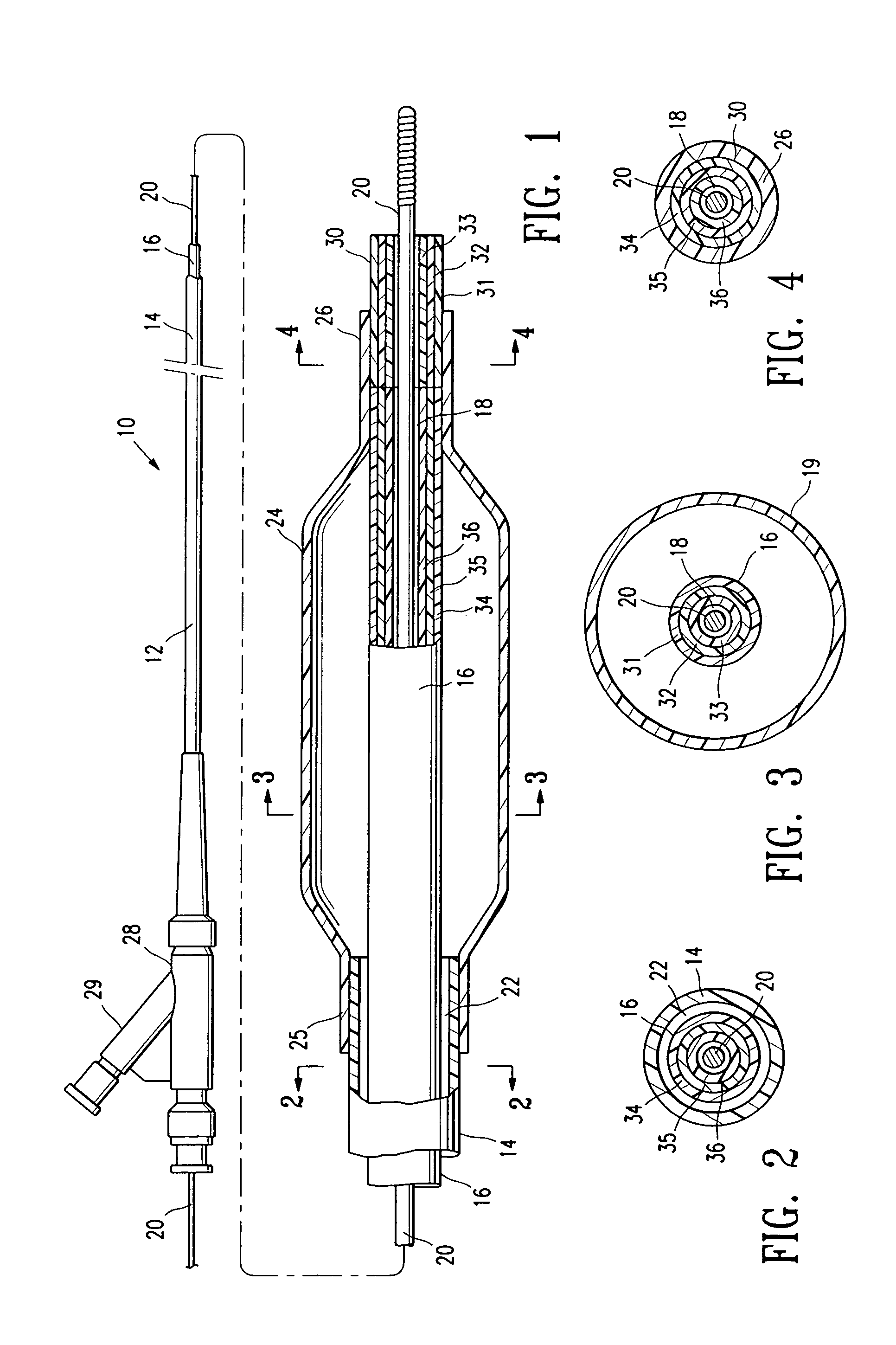

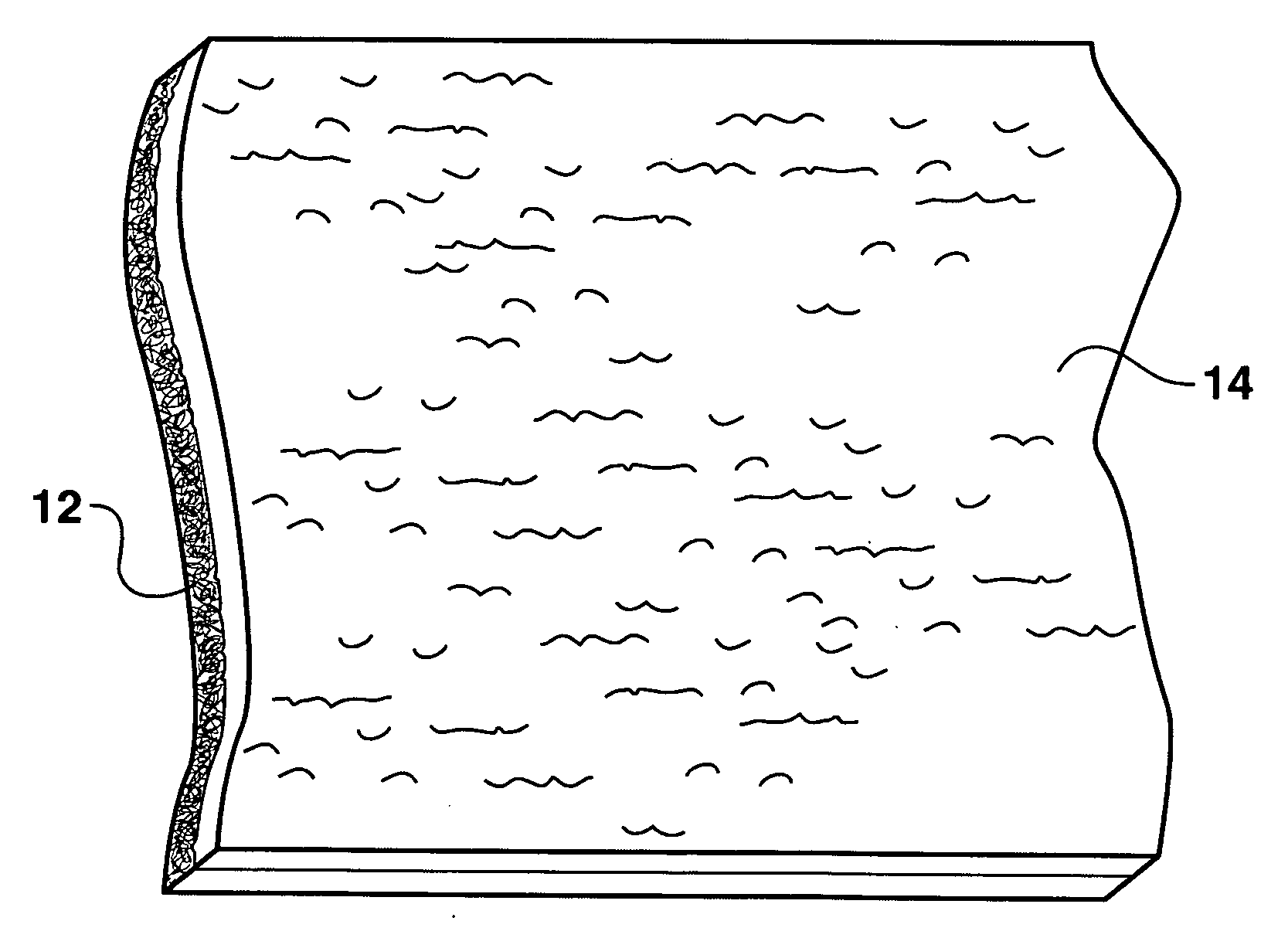

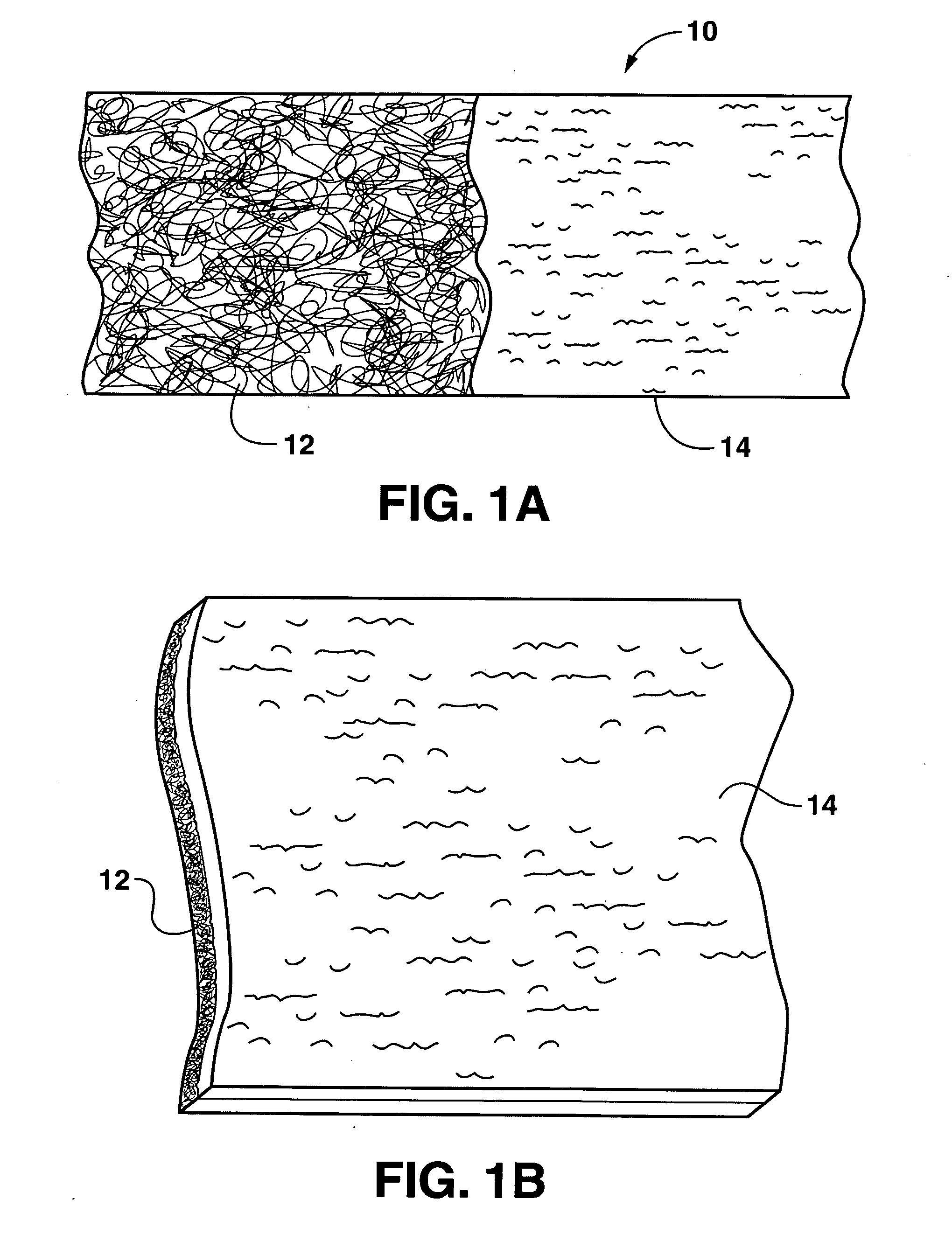

Balloon catheter having a multilayered distal tip

ActiveUS7341571B1Reduce coefficient of frictionDrag minimizationBalloon catheterSurgeryBalloon catheterBlood coagulations

A catheter having a distal tip with an inner layer formed of a polymeric material having a coefficient of friction and surface energy which are relatively low, such that the inner layer has a lubricious, non-polar inner surface repulsive to polar liquids. As a result, blood coagulation in the distal tip, and adherence of the distal tip on the guidewire are prevented or minimized.

Owner:ABBOTT CARDIOVASCULAR

Method and system for modifying the wettability characteristics of a surface of a medical device by the application of gas cluster ion beam technology and medical devices made thereby

InactiveUS20090074834A1Improve wettabilityLow wettabilityElectric discharge tubesPharmaceutical containersEtchingGas cluster ion beam

Irradiation of a surface of a material with a gas cluster ion beam modifies the wettability of the surface. The wettability may be increased or decreased dependent on the characteristics of the gas cluster ion beam. Improvements in wettability of a surface by the invention exceed those obtained by conventional plasma cleaning or etching. The improvements may be applied to surfaces of medical devices, such as vascular stents for example, and may be used to enable better wetting of medical device surfaces with liquid drugs in preparation for adhesion of the drug to the device surfaces. A mask may be used to limit processing to a portion of the surface. Medical devices formed by using the methods of the invention are disclosed.

Owner:EXOGENESIS CORP

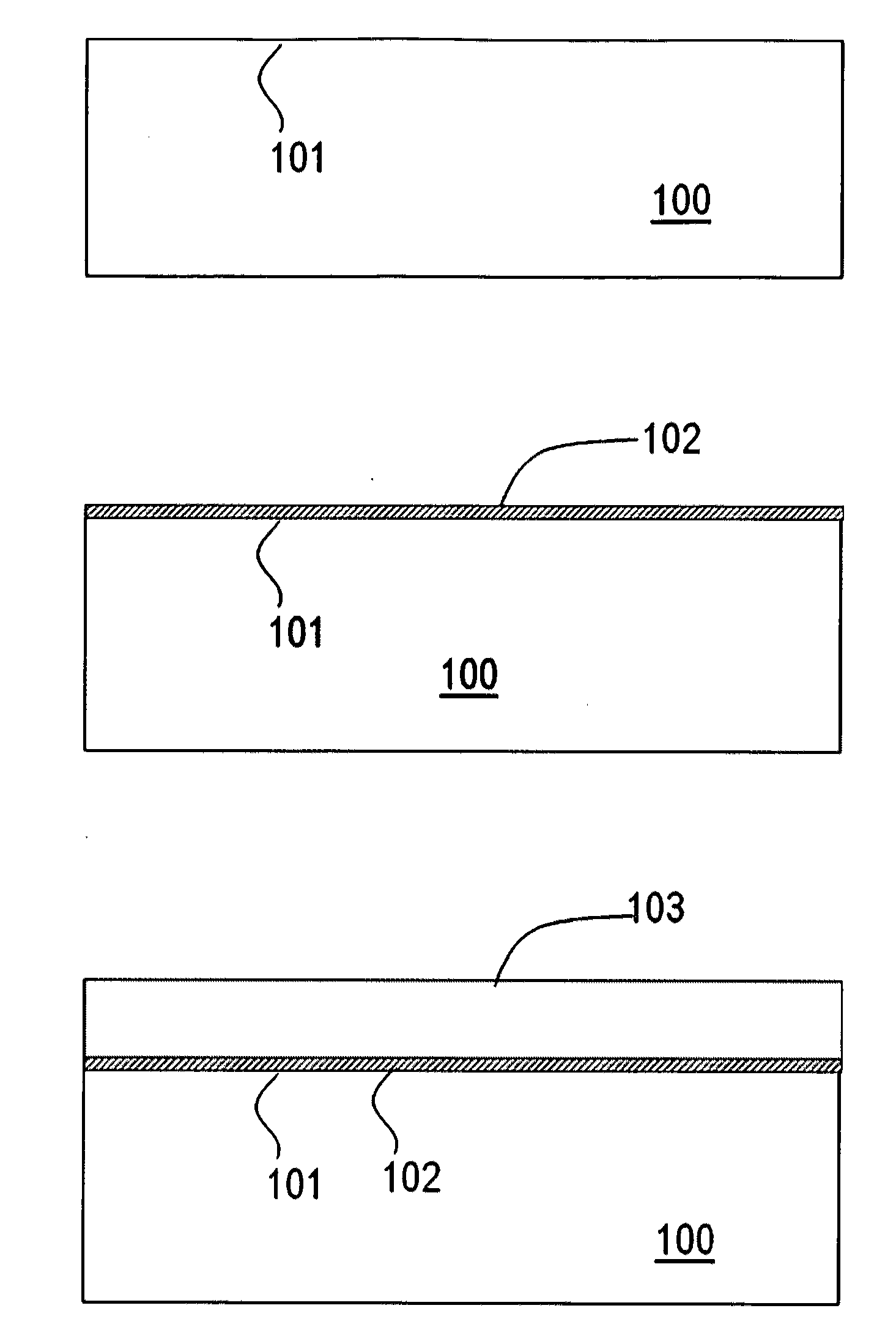

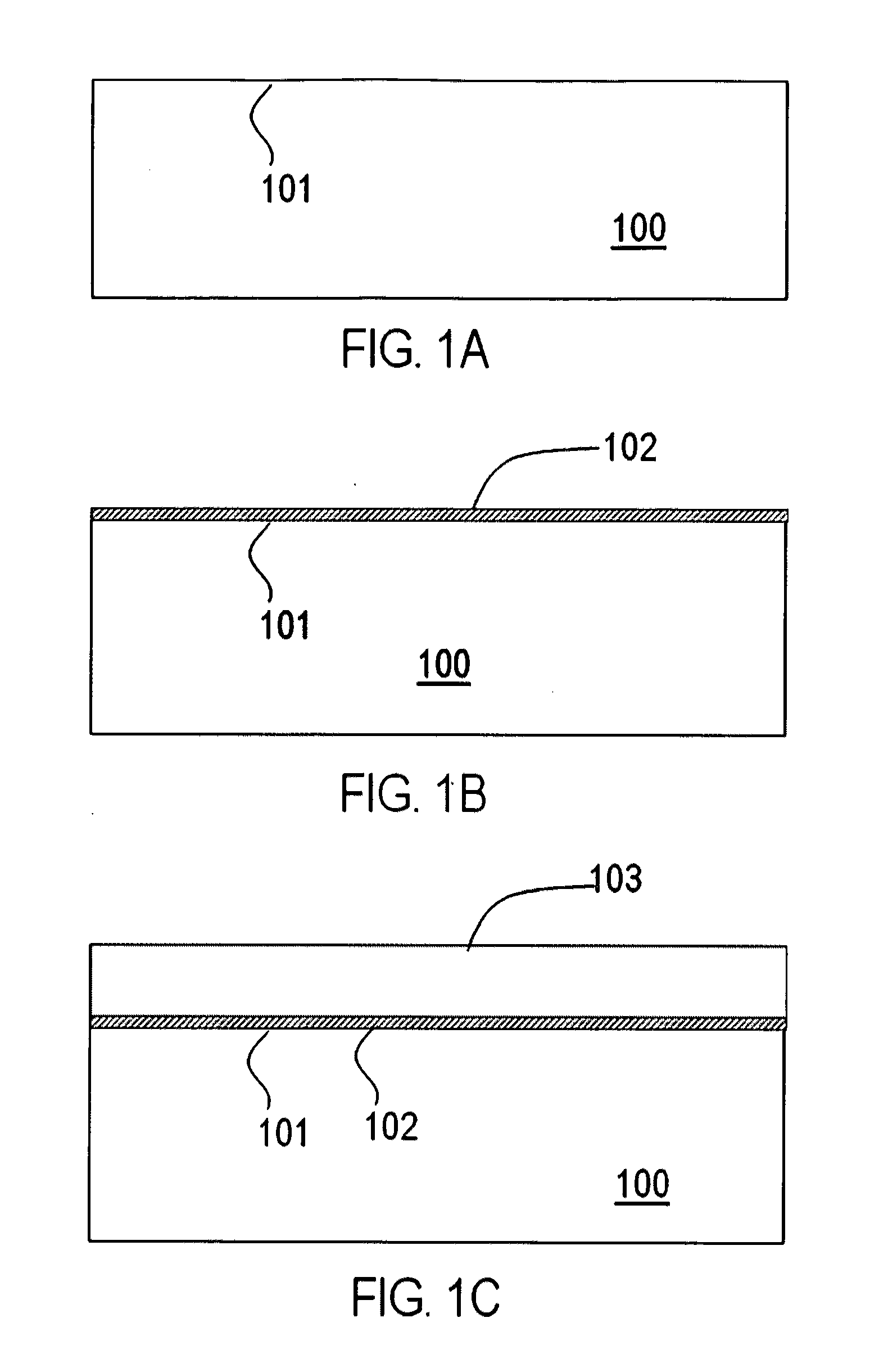

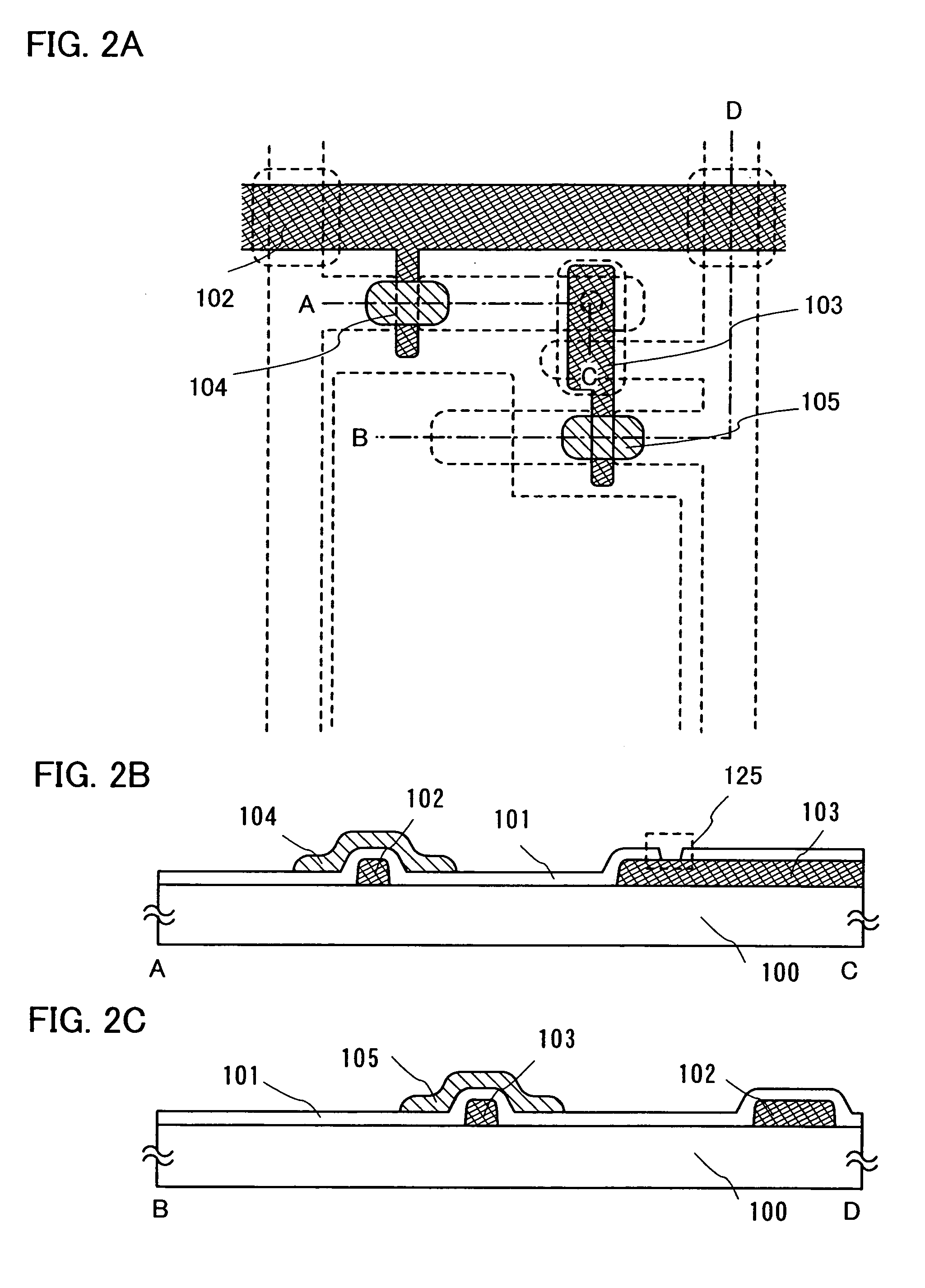

Method for manufacturing display device

InactiveUS20060121745A1Improve controllabilityLow costSolid-state devicesSemiconductor/solid-state device manufacturingLight irradiationDisplay device

The present invention, the quality of the surface of a substrate is improved and the wettability thereof is controlled by light irradiation from the reverse side with respect to the substrate having the conductive layer. A conductive material or an insulating material is adhered on the modified surface by discharging it (including jetting, etc.), or the like to form a conductive layer and an insulating layer. The processing efficiency by the light can be enhanced by function of the light absorption and energy radiation of the photocatalytic substance. Furthermore, the mask layer is formed selectively on the conductive layer and the wettability of the region on the conductive layer that is a non-irradiation region is also controlled.

Owner:SEMICON ENERGY LAB CO LTD

Metal deposition using seed layers

InactiveUS20120217165A1Easy to operateLower surface energySuperimposed coating processNanoparticleSilanes

Methods of forming a conductive metal layers on substrates are disclosed which employ a seed layer to enhance bonding, especially to smooth, low-roughness or hydrophobic substrates. In one aspect of the invention, the seed layer can be formed by applying nanoparticles onto a surface of the substrate; and the metallization is achieved by electroplating an electrically conducting metal onto the seed layer, whereby the nanoparticles serve as nucleation sites for metal deposition. In another approach, the seed layer can be formed by a self-assembling linker material, such as a sulfur-containing silane material.

Owner:GMZ ENERGY +2

Circular diamond saw blade bit and manufacturing method thereof

The invention discloses a circular diamond saw blade bit and a manufacturing method thereof. The circular diamond saw blade bit is made of diamond particles and matrix powder used for consolidation of the diamond particles. The matrix powder comprises, by mass percent, 40%-80% of Fe, 15%-30% of Cu, 0%-10% of Ni, 2%-8% of Sn, 0%-10% of Co, 0%-5% of Me and the balance inevitable impurities. Me is at least one of Mn, Ti, Si, Cr, P and Al. The manufacturing method comprises the steps of mixing raw materials, conducting cold-press molding and free sintering. The manufacturing method is simple and can effectively avoid the loss of a graphite mould and reduce manufacturing cost. Meanwhile, a volume production requirement can be met, and blade bits in complicated shapes can be produced; production efficiency is prolonged, and the service life of the tool is similar to that of a tool manufactured through a hot-press sintering method; the purpose that high-quality diamond cutting tools are produced under the condition of low cost can be achieved; and the circular diamond saw blade bit and a manufacturing method thereof are easy to popularize in an industrialized manner.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Protective coating comprising boron nitride for refractory material members of an ingot mold for continuous casting of metals

InactiveUS6051058AImprove protectionLow wettabilityMelt-holding vesselsAlkali metal silicate coatingsIngot castingCarbon nitride

The invention relates to a protective coating for a refractory material member of an ingot mold for continuous casting of metals, especially of steel, which consists of a dispersion of particles in a solvent, said particles including essentially boron nitride and at least one of the following metal oxides: zircon, zirconia, alumina and silica, the boron nitride representing between 20 and 50% by weight of said particles.

Owner:USINOR SA +1

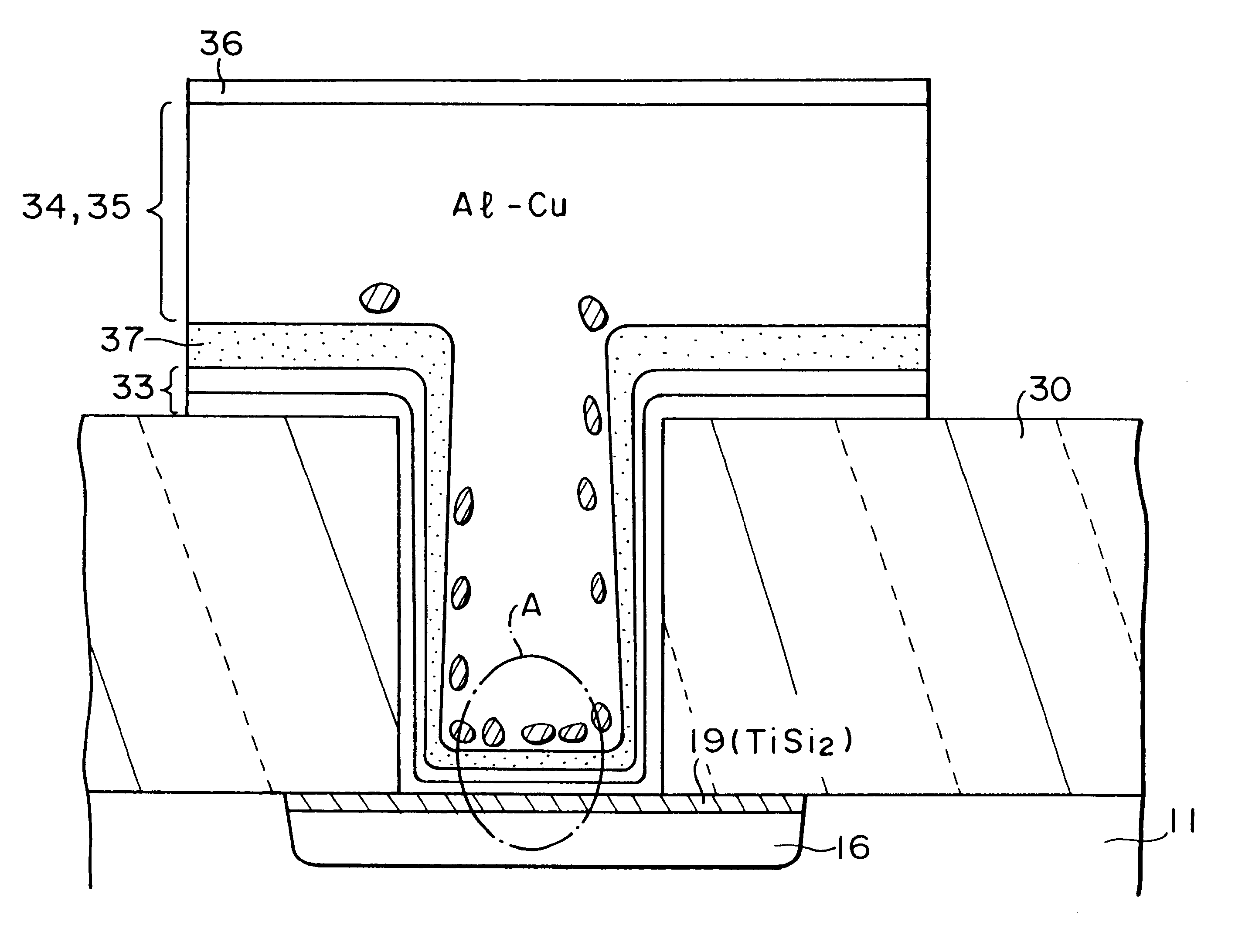

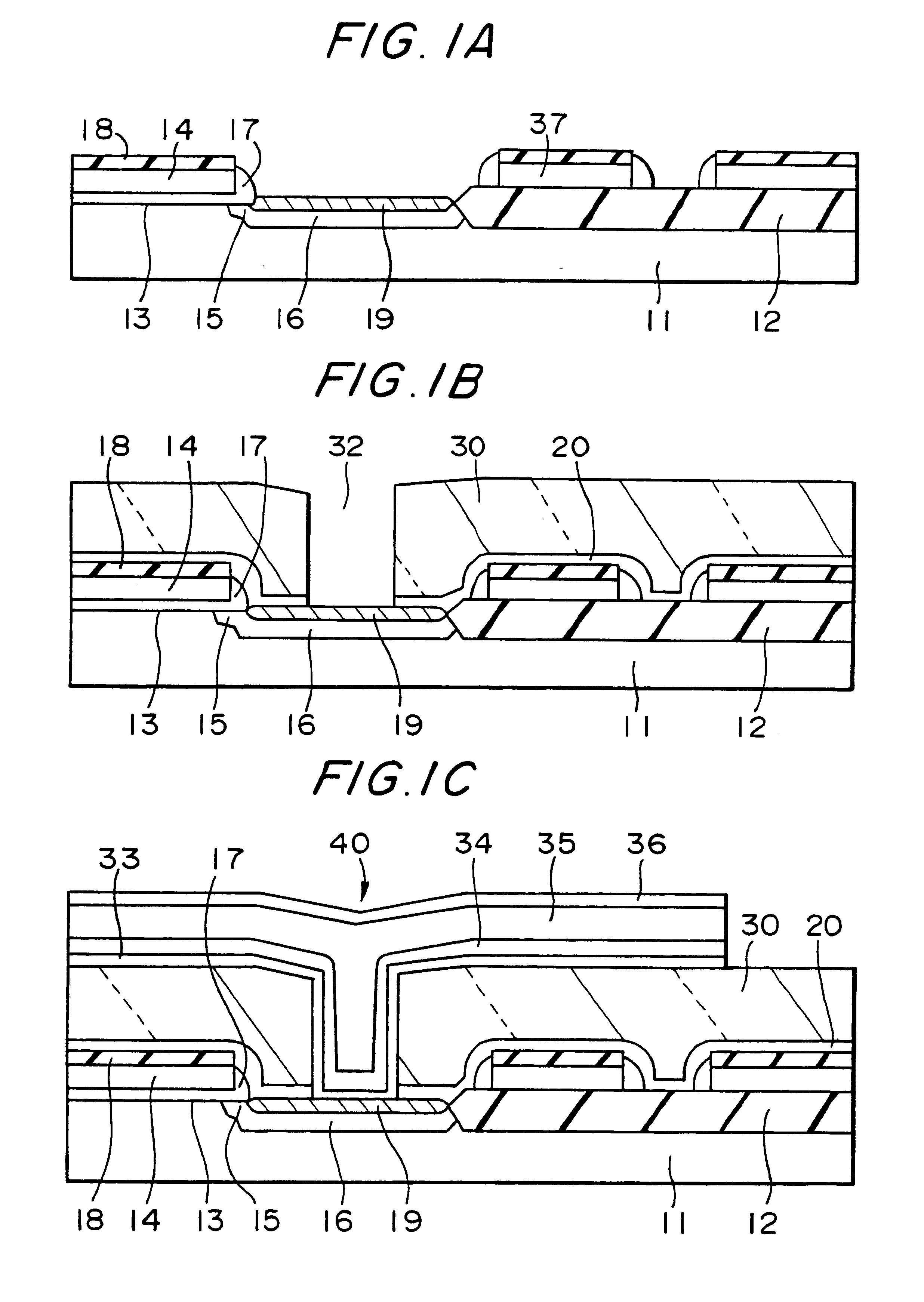

Semiconductor device and method of fabricating the same

InactiveUS6326287B1Improve liquidityLow wettabilitySemiconductor/solid-state device detailsSolid-state devicesMOSFETDielectric

A semiconductor device comprising a semiconductor substrate including an electronic element such as a MOSFET, interlayer dielectric (silicon oxide layer or BPSG layer) formed on the semiconductor substrate, a through-hole formed in the interlayer dielectric, a barrier layer formed on a surface of the interlayer dielectric and on a surface of the through-hole, and a metal wiring layer formed on the barrier layer. The metal wiring layer contains aluminum as its major component and 0.1 wt % to 3 wt % of beryllium. An aluminum alloy can be embedded in the through-hole without creation of any void or breaking of wire, and the semiconductor device is highly resistant to electro-migration.

Owner:SEIKO EPSON CORP

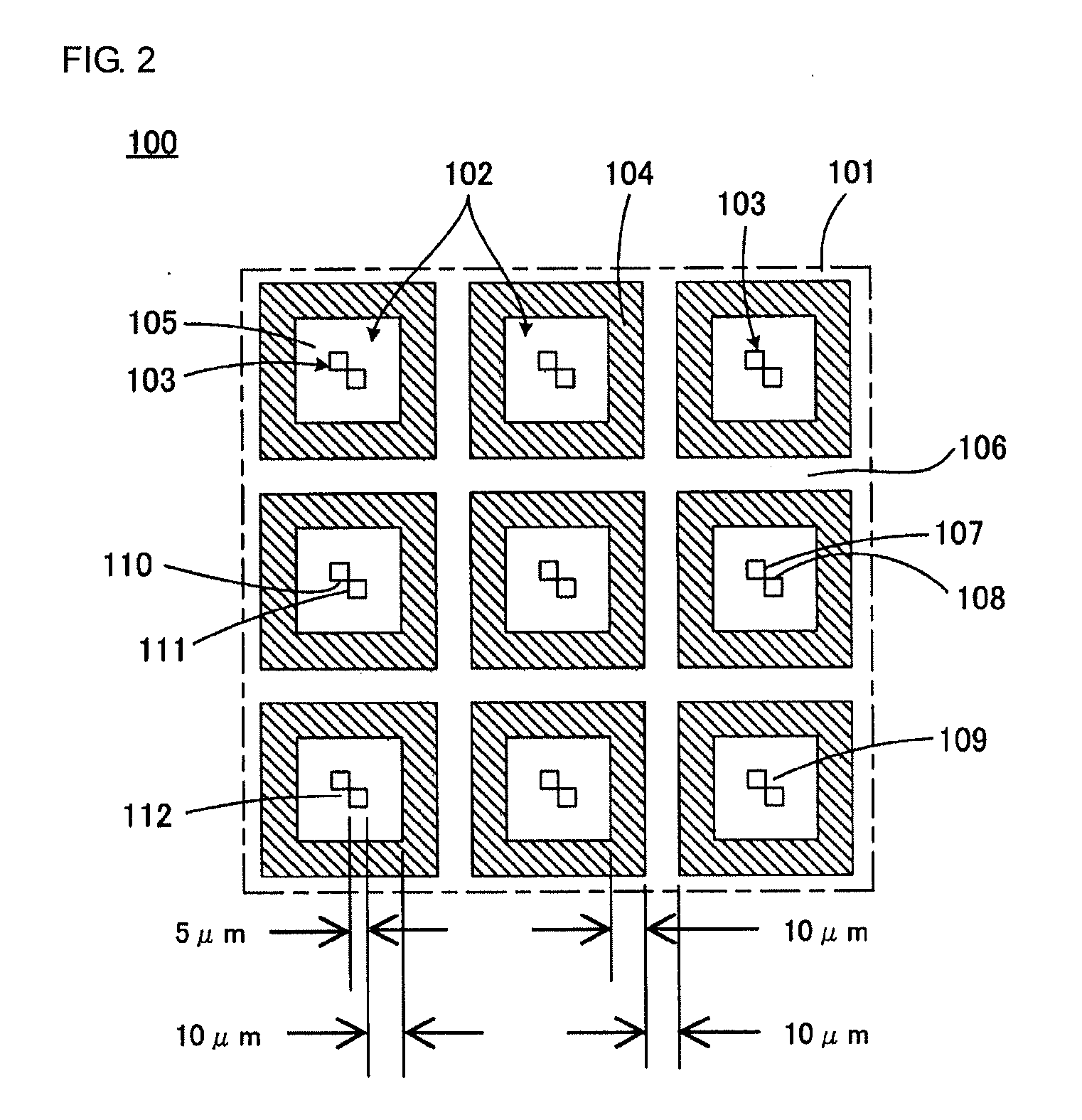

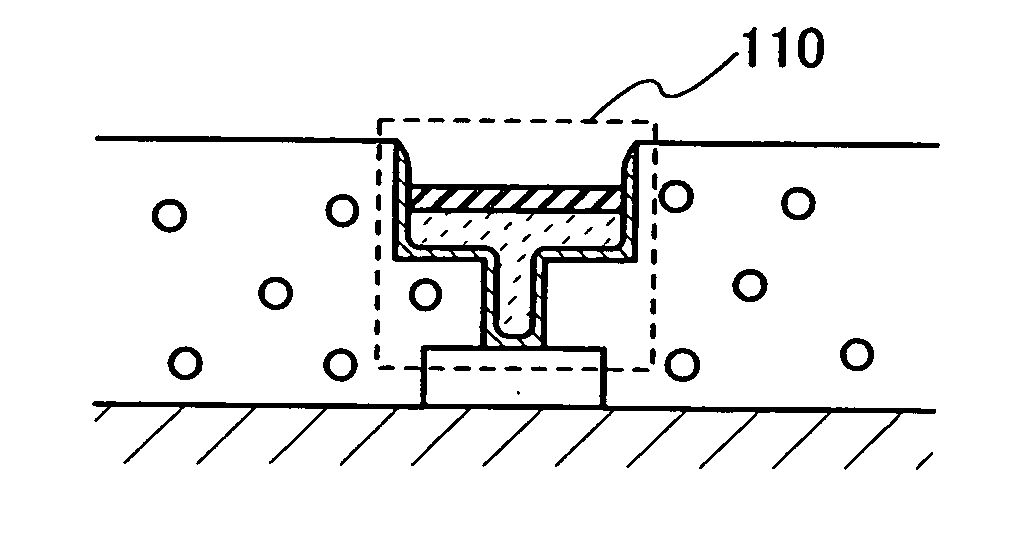

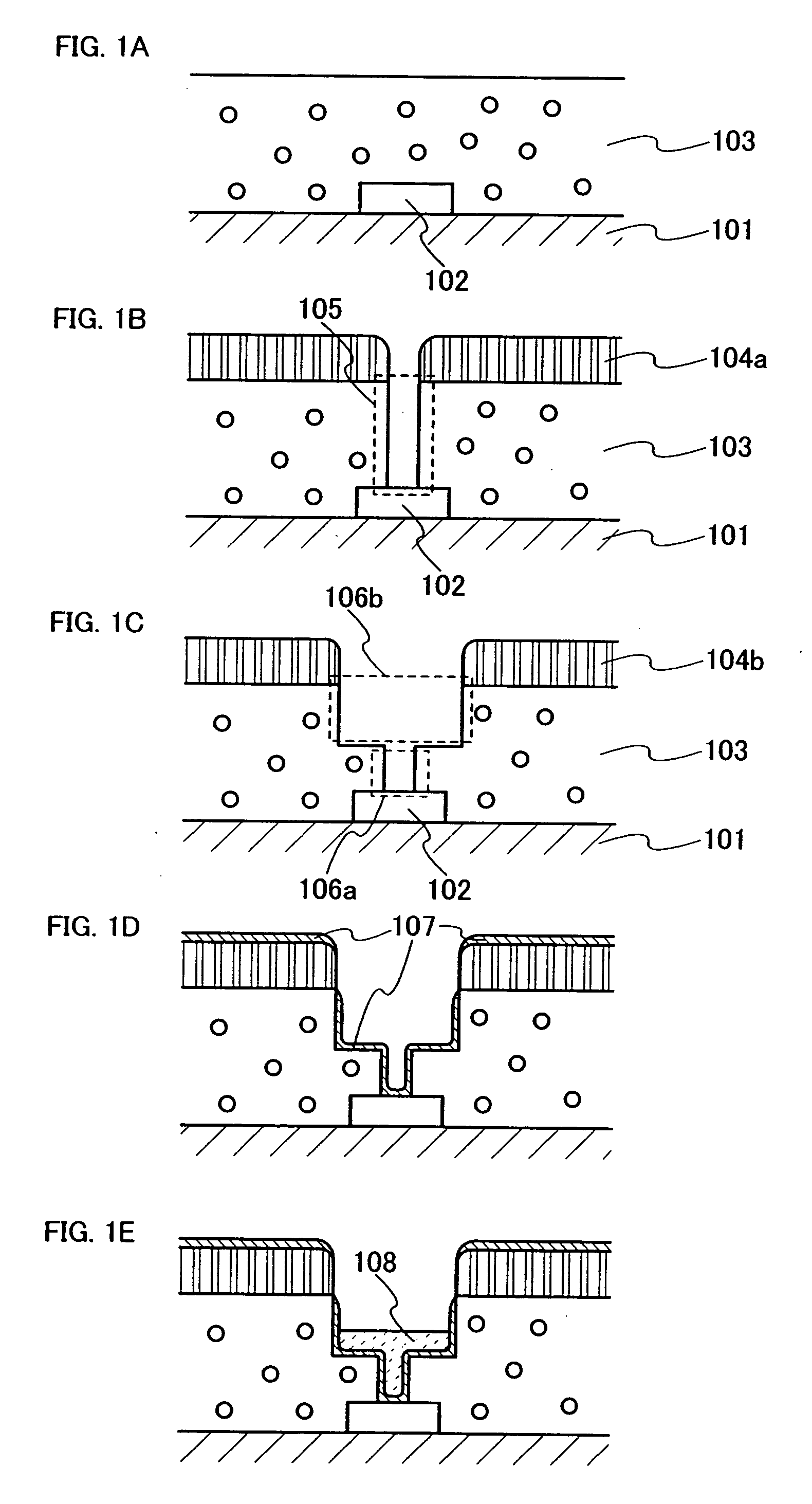

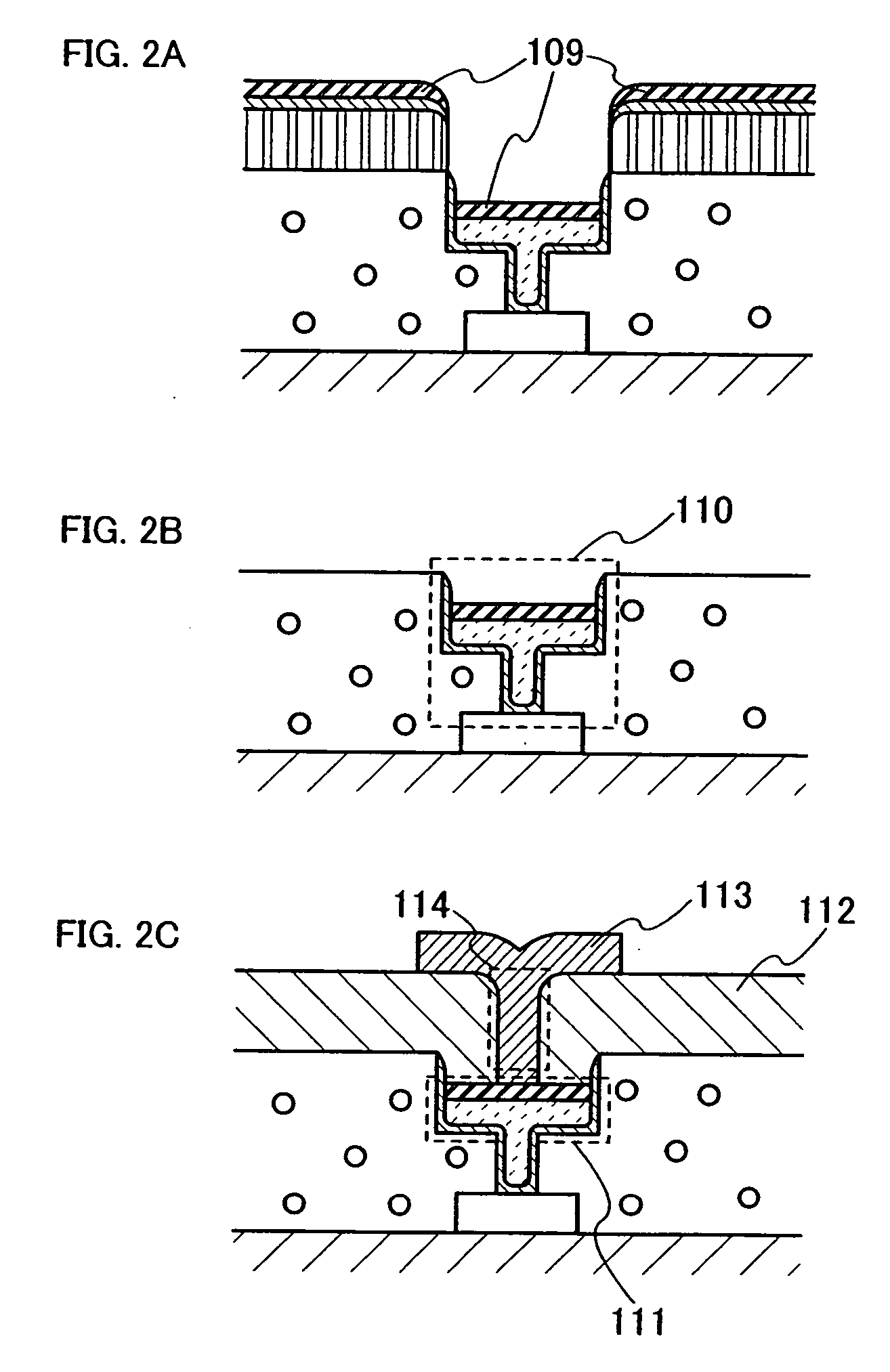

Probe-array substrate, probe array, and method of producing the same

InactiveUS20100004143A1Efficient productionLow costSequential/parallel process reactionsNucleotide librariesBiomedical engineeringProbe array

Owner:MURATA MFG CO LTD

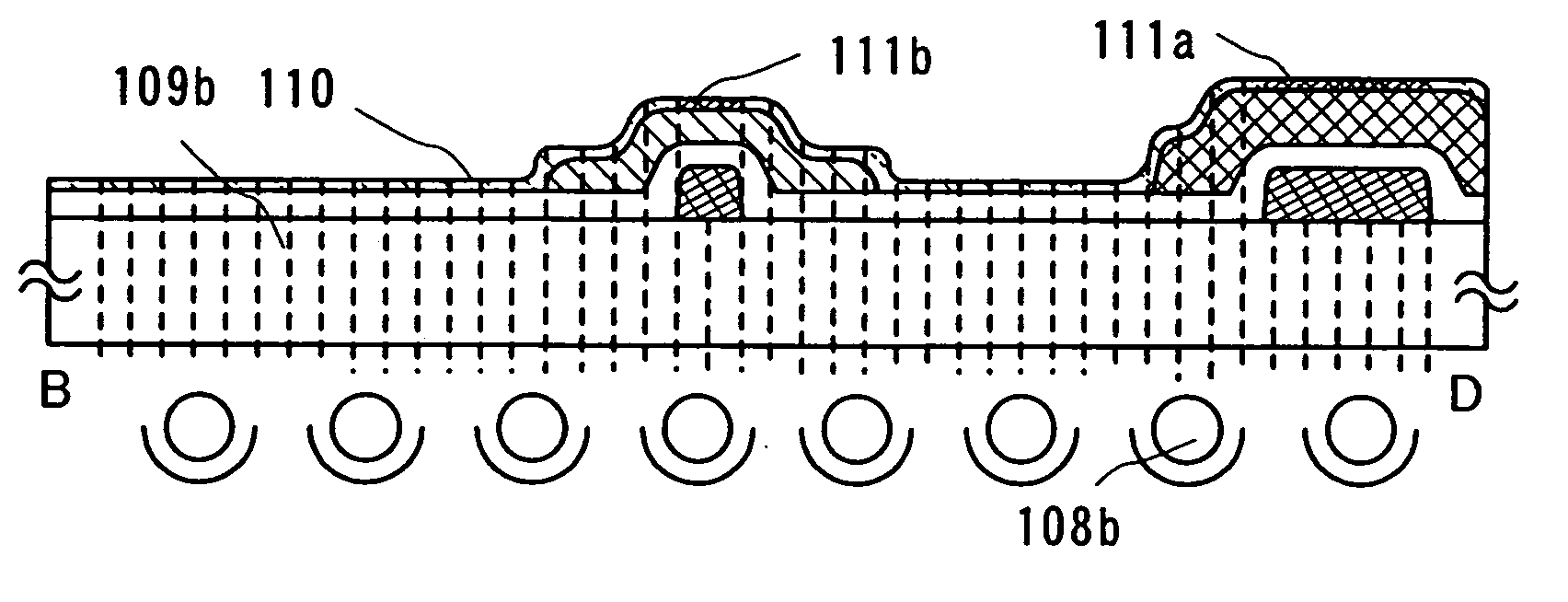

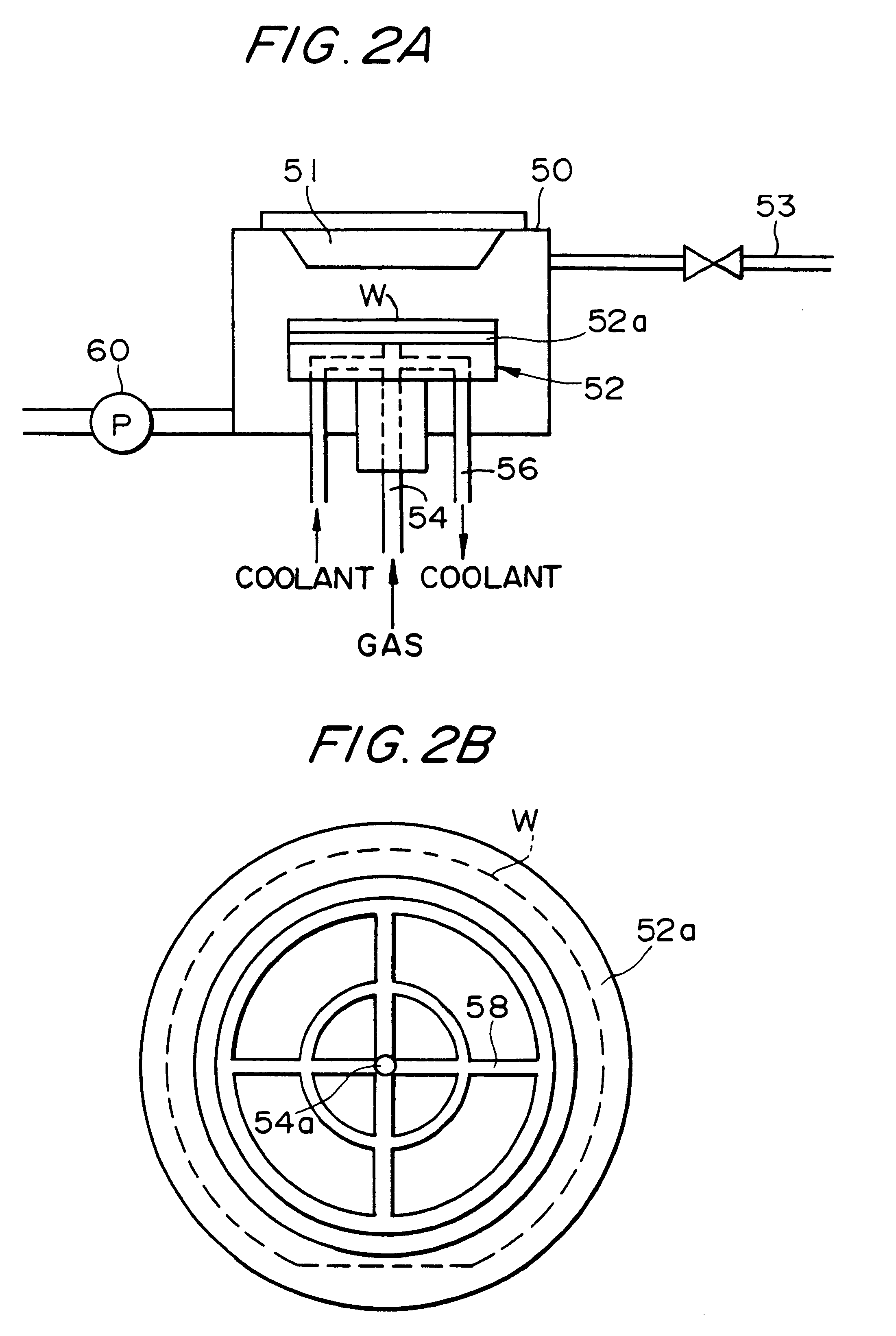

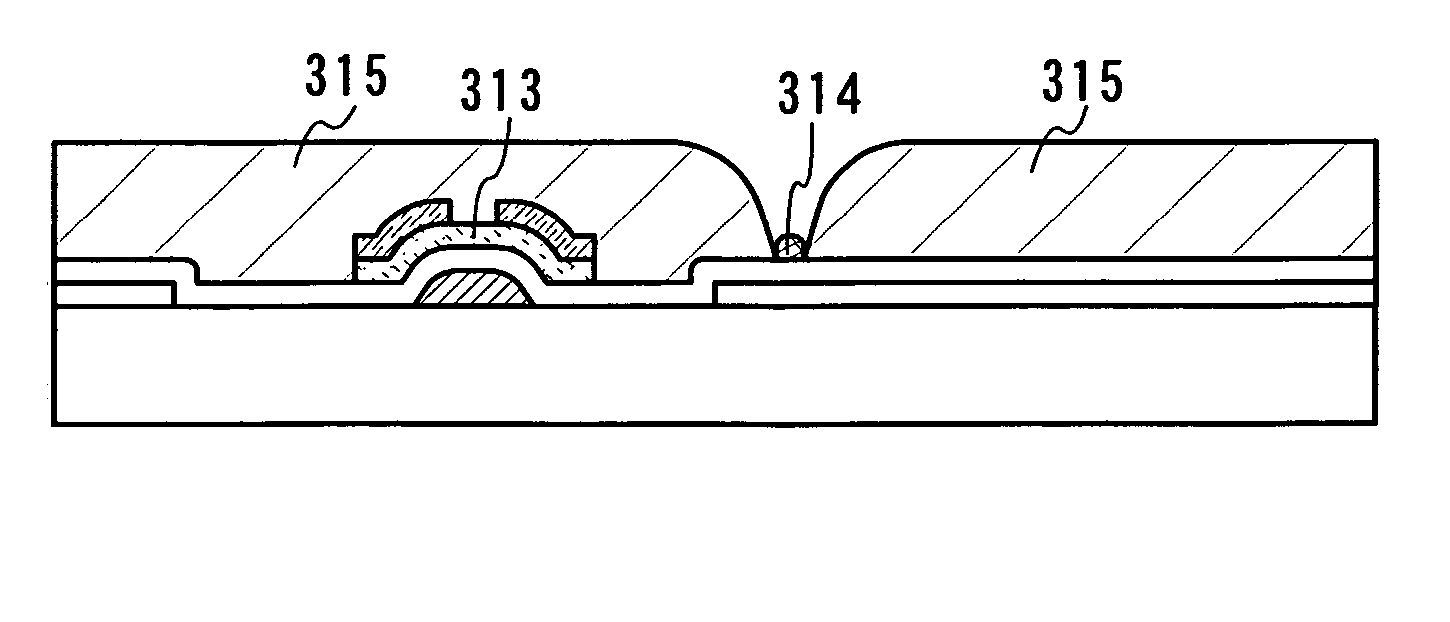

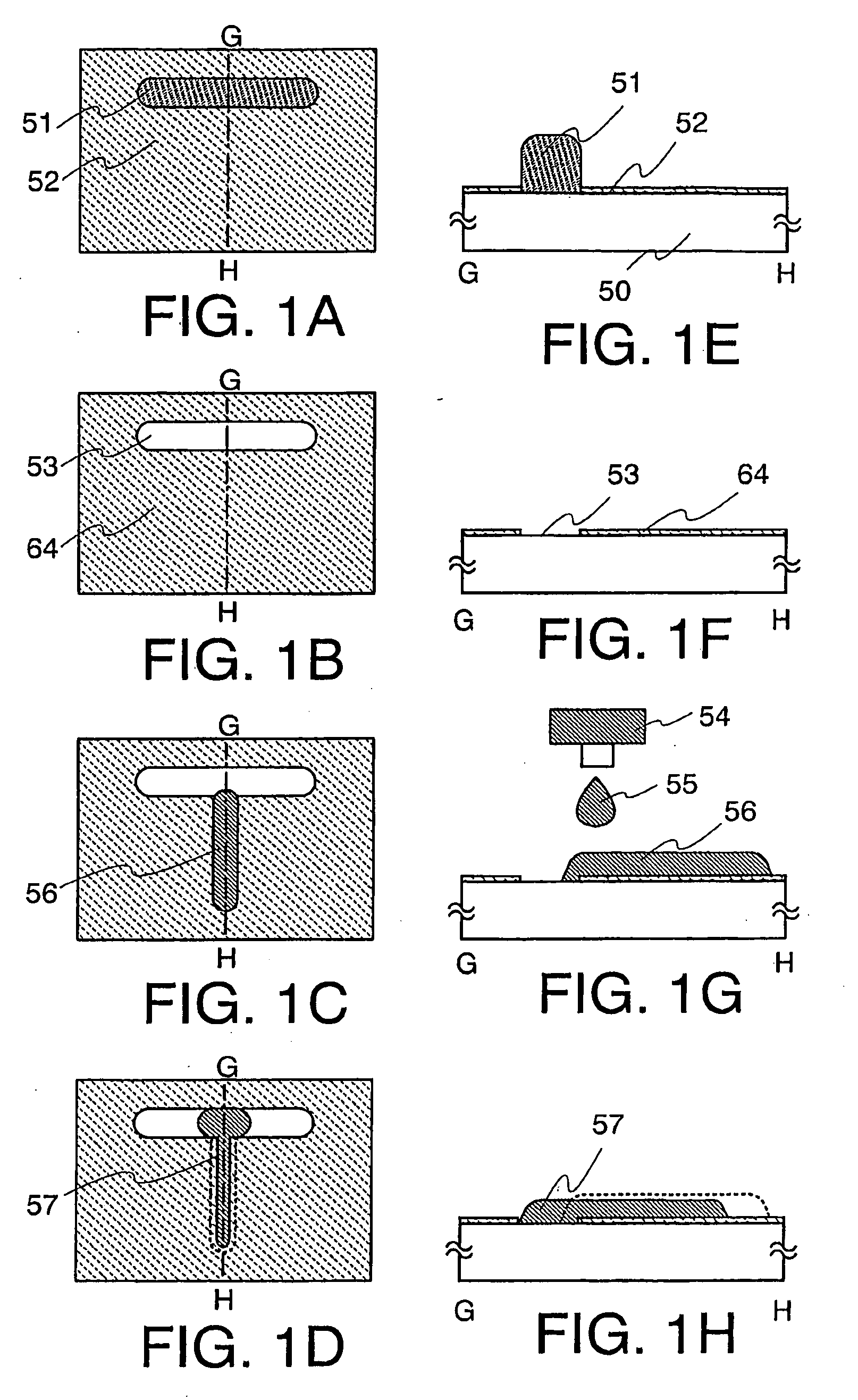

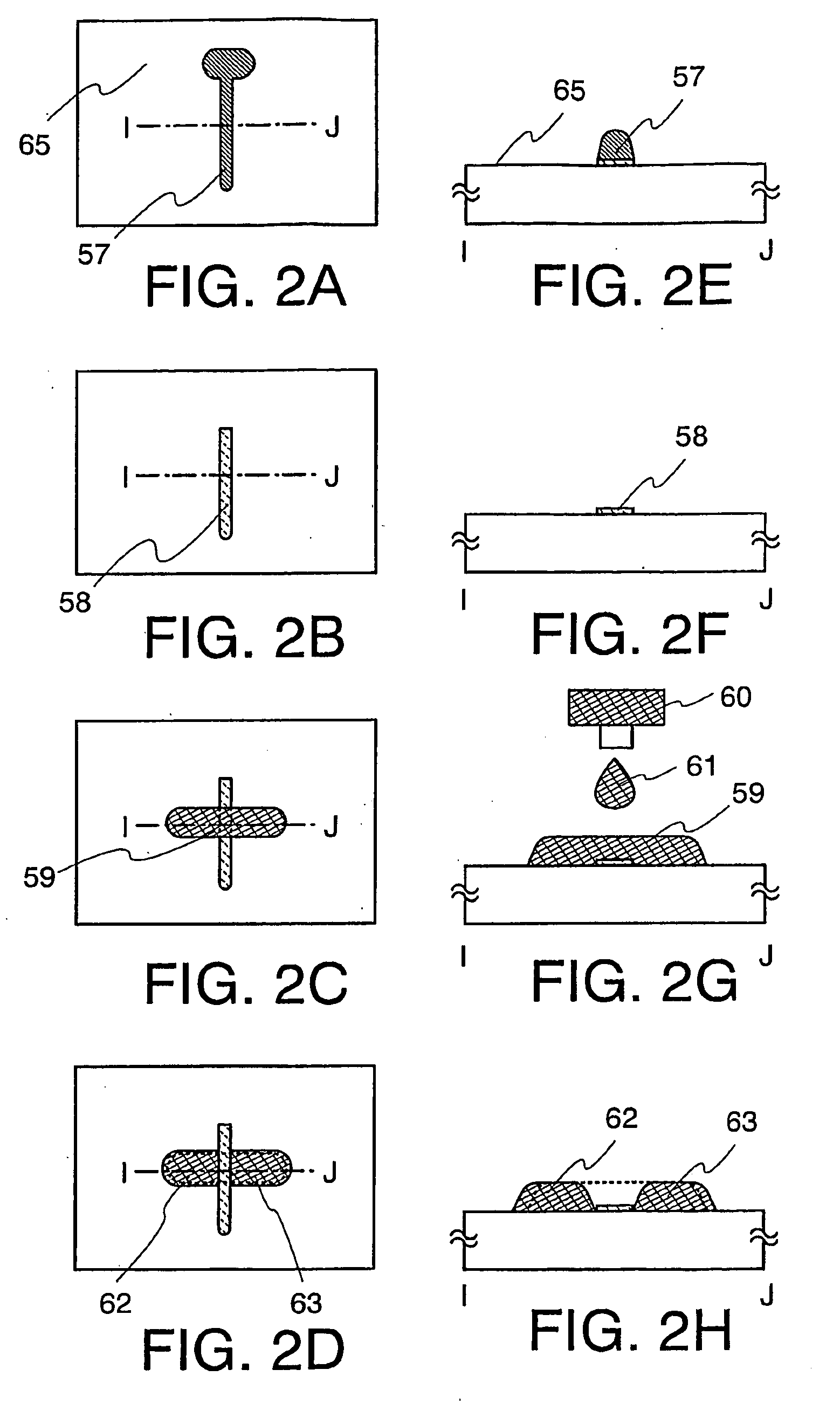

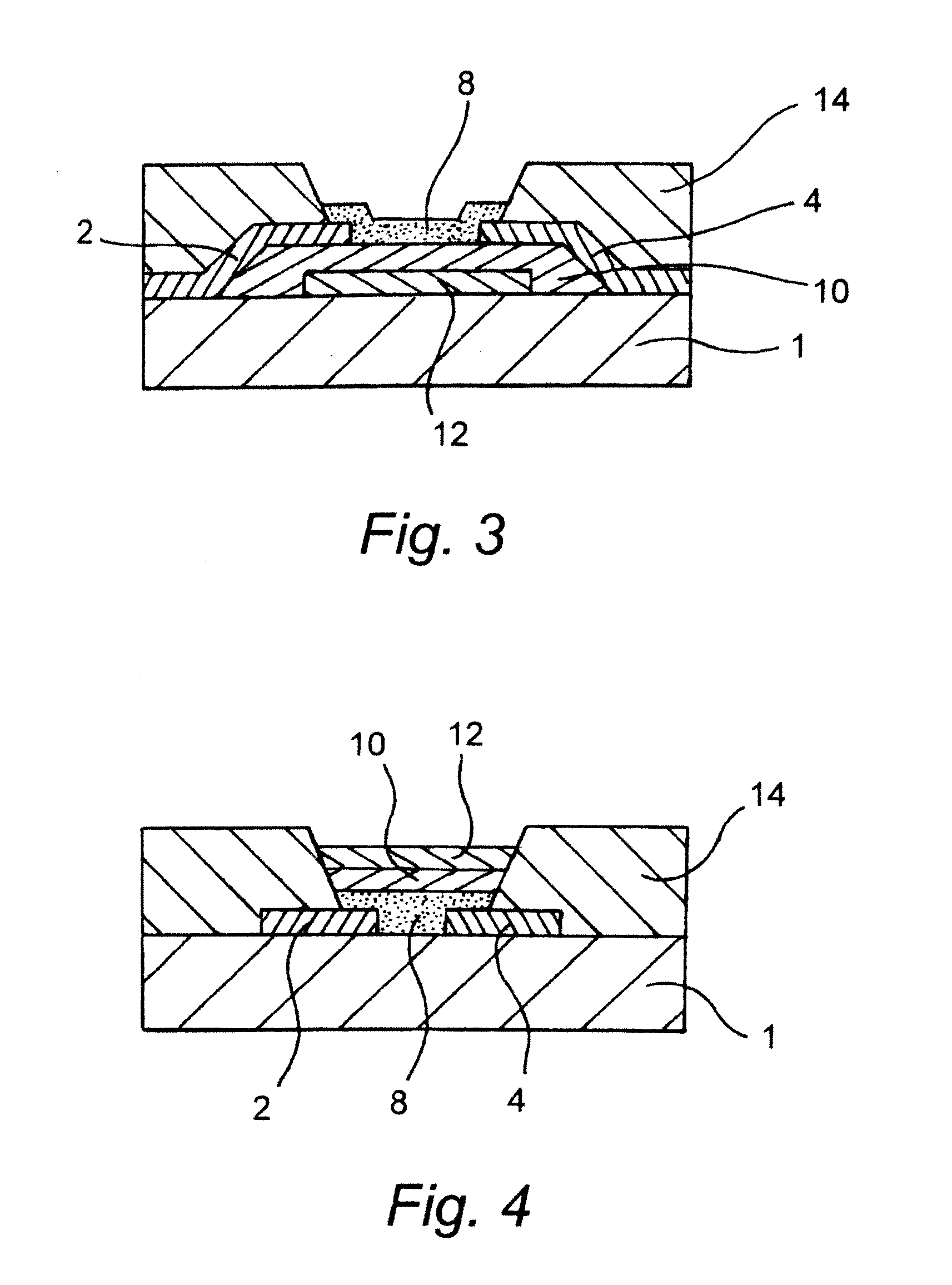

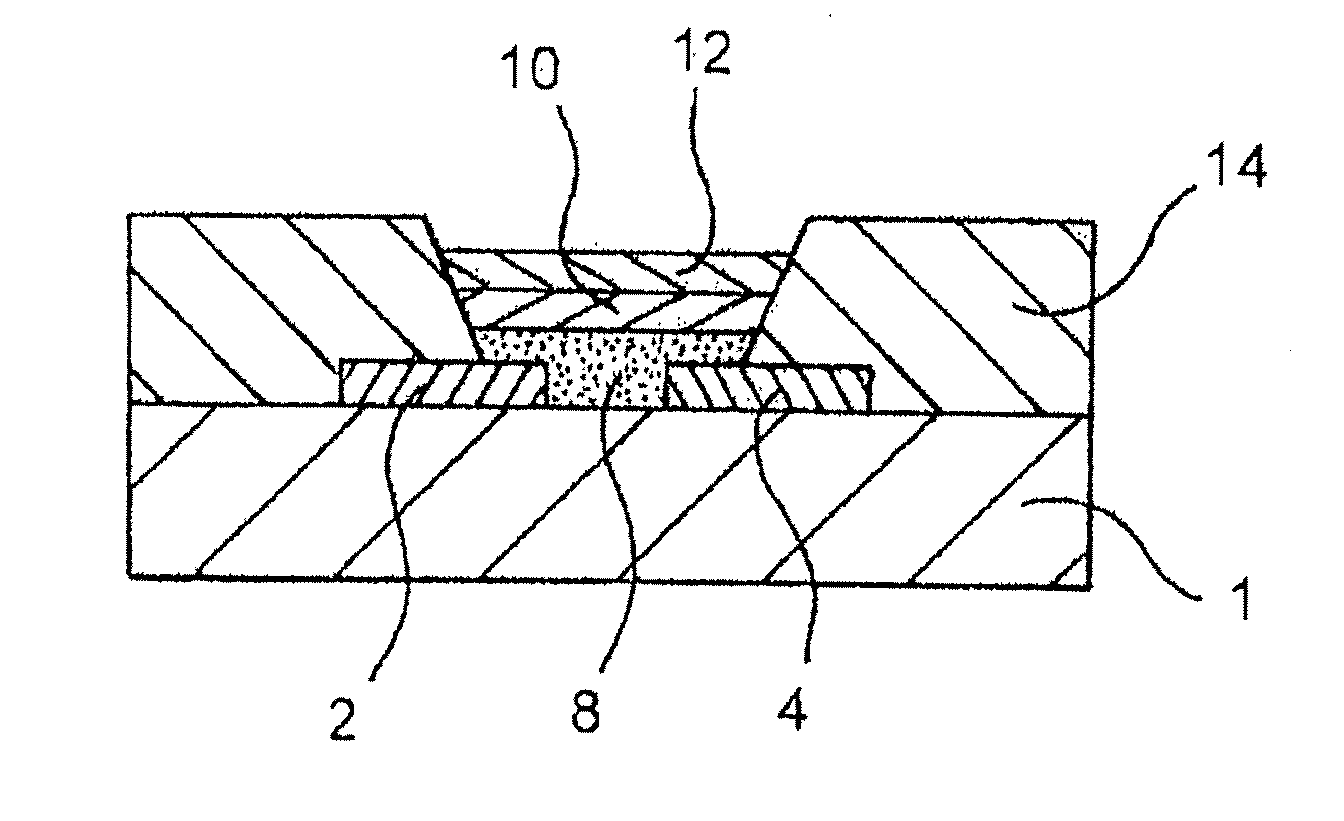

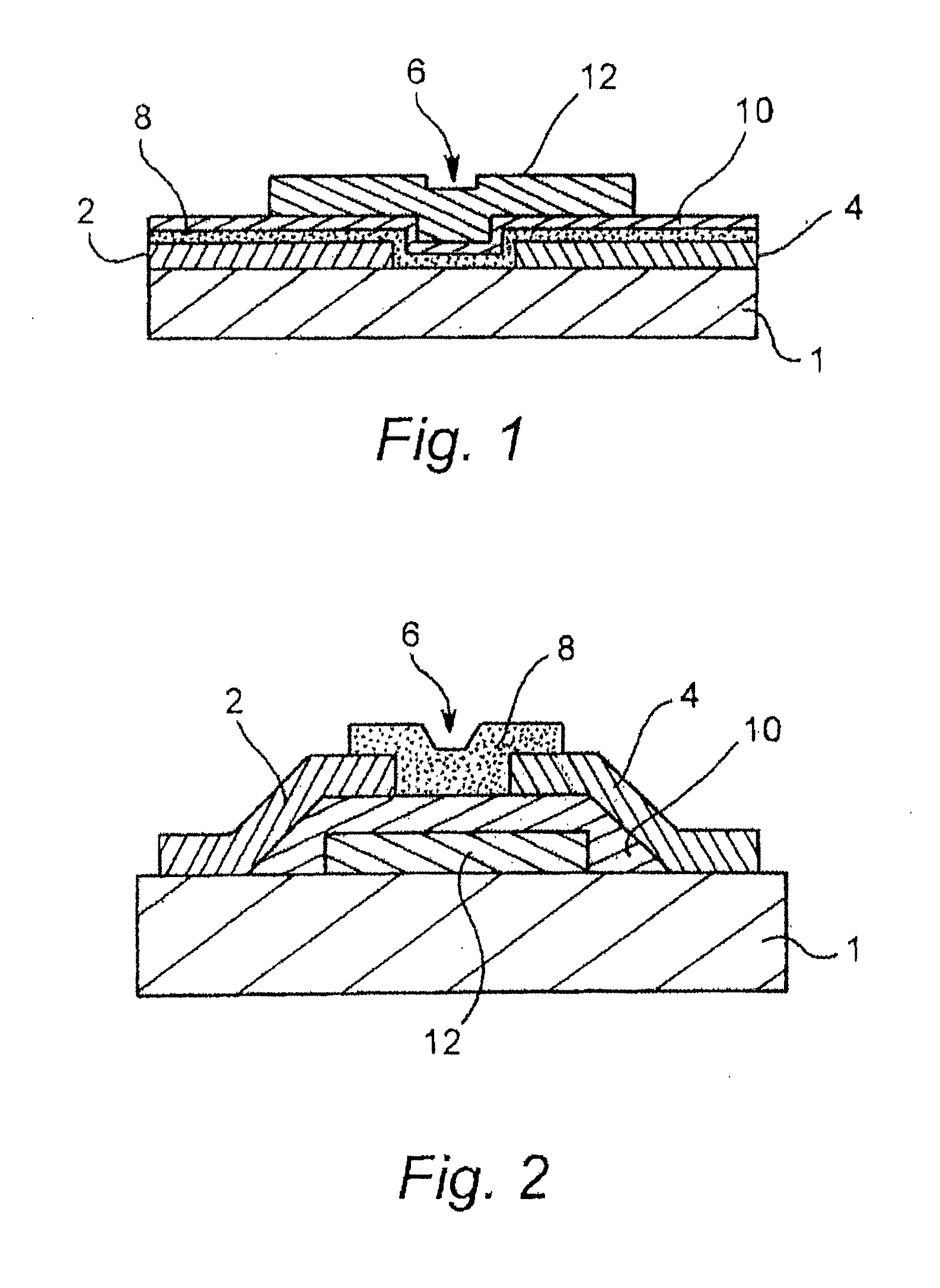

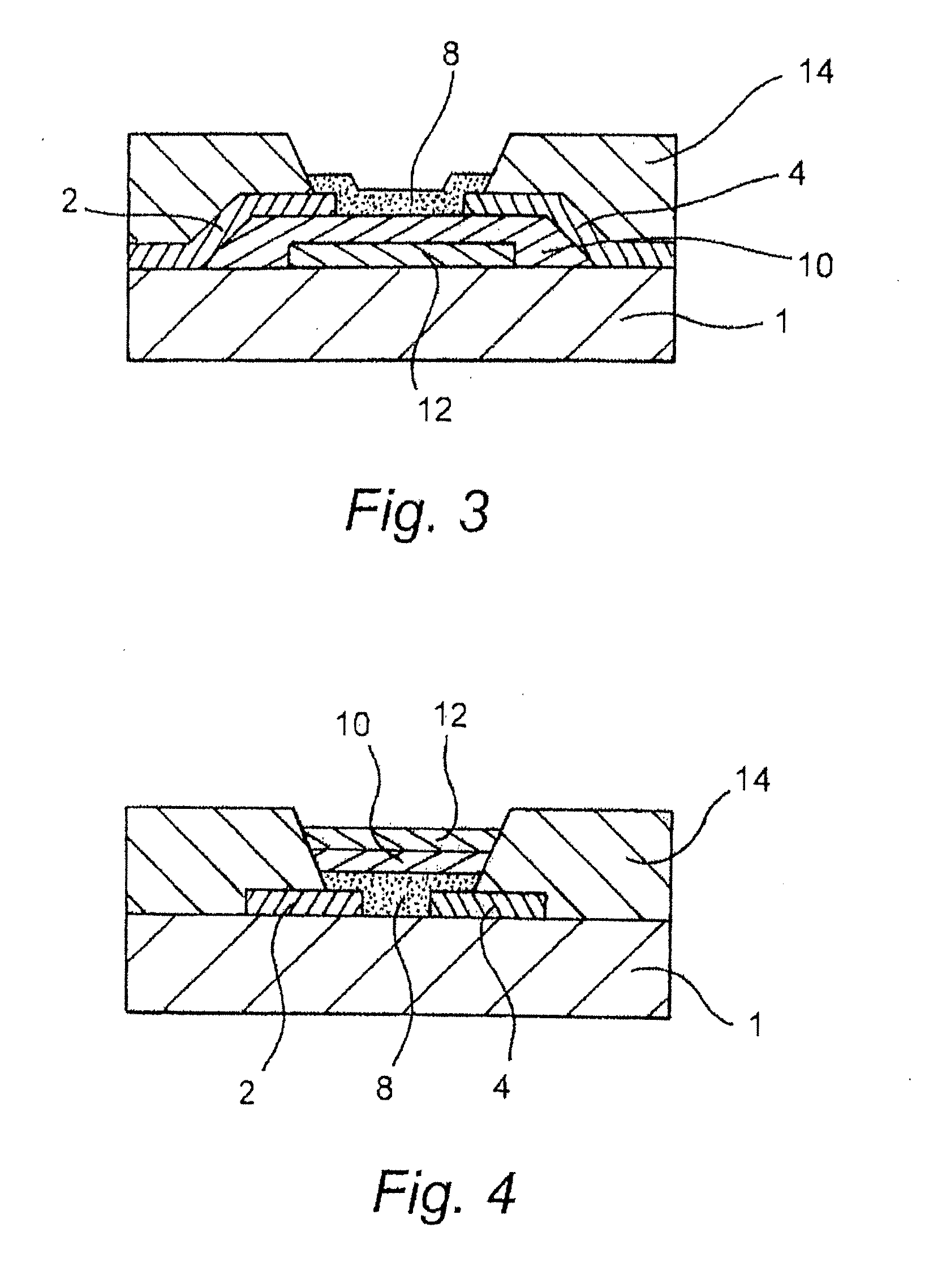

Semiconductor device and method for manufacturing the same

InactiveUS20060113671A1High aspect ratioReduce the number of processesSemiconductor/solid-state device detailsSolid-state devicesSputteringDevice material

In a manufacturing process of a semiconductor device, electroplating and CMP have had a problem of increase in manufacturing costs for forming a wiring. Correspondingly, an opening is formed in a porous insulating film after a mask is formed thereover, and a conductive material containing Ag is dropped into the opening. Further, a first conductive layer is formed by baking the conductive material dropped into the opening by selective irradiation with laser light. Subsequently, a metal film is formed over the entire surface by sputtering, and the mask is removed thereafter to have only the metal film remain over the first conductive layer, thereby forming an embedded wiring layer formed with a stack of the first conductive layer containing Ag and the second conductive layer (metal film).

Owner:SEMICON ENERGY LAB CO LTD

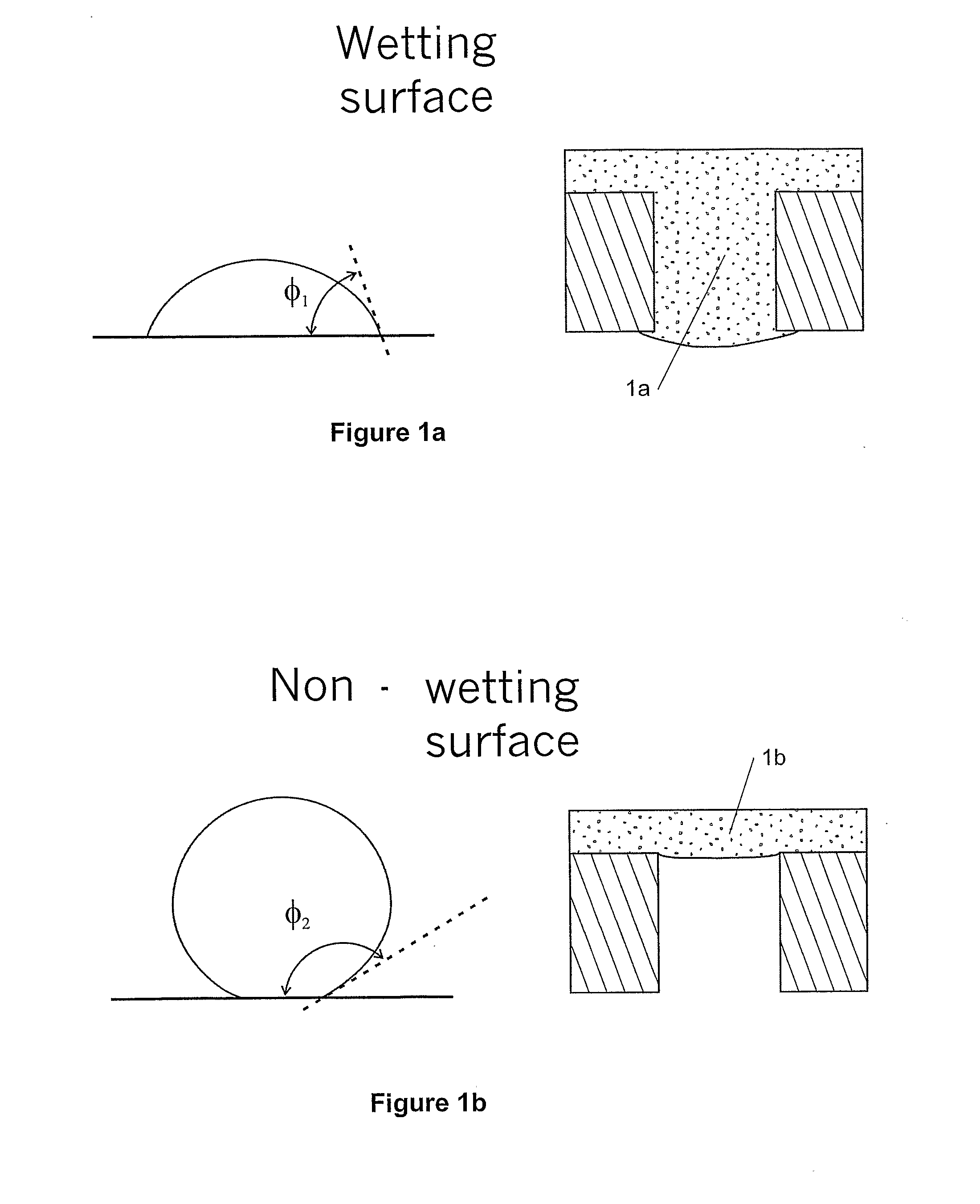

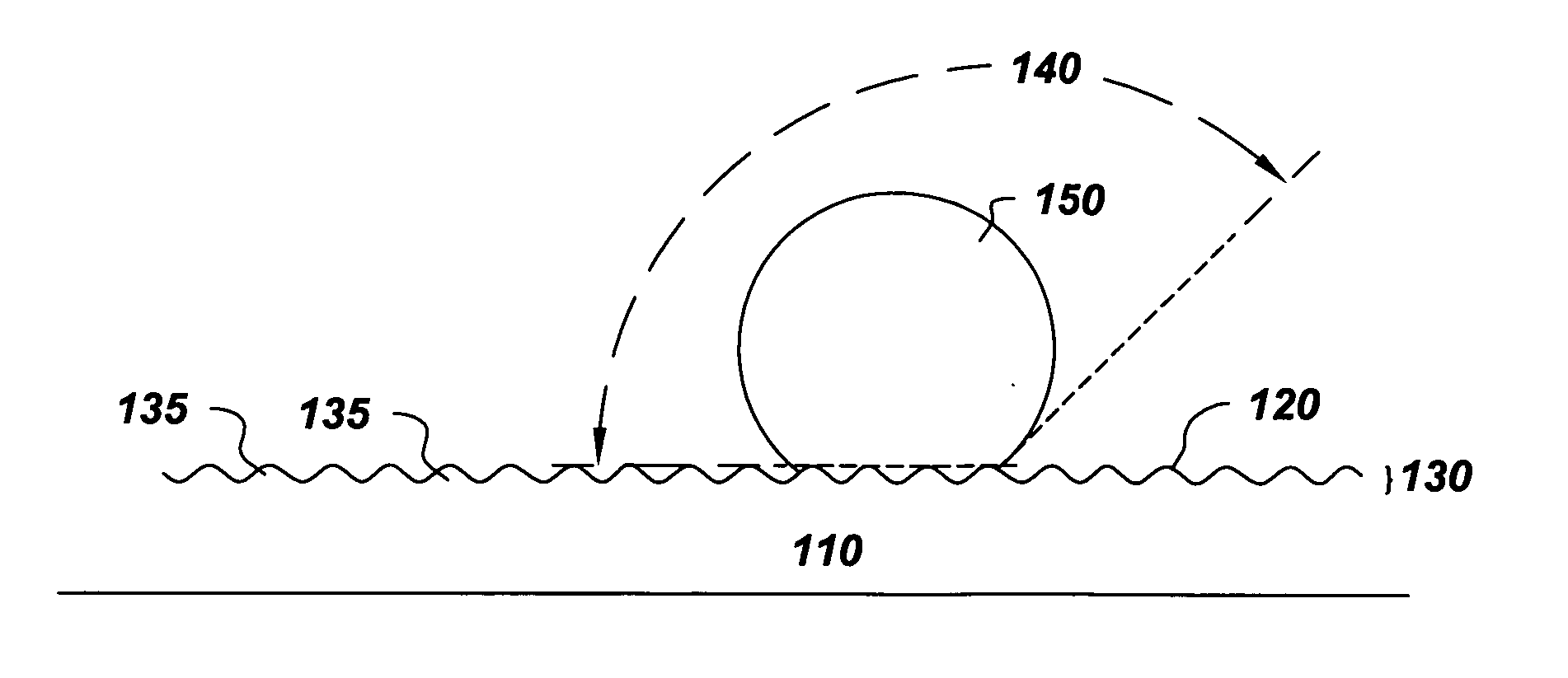

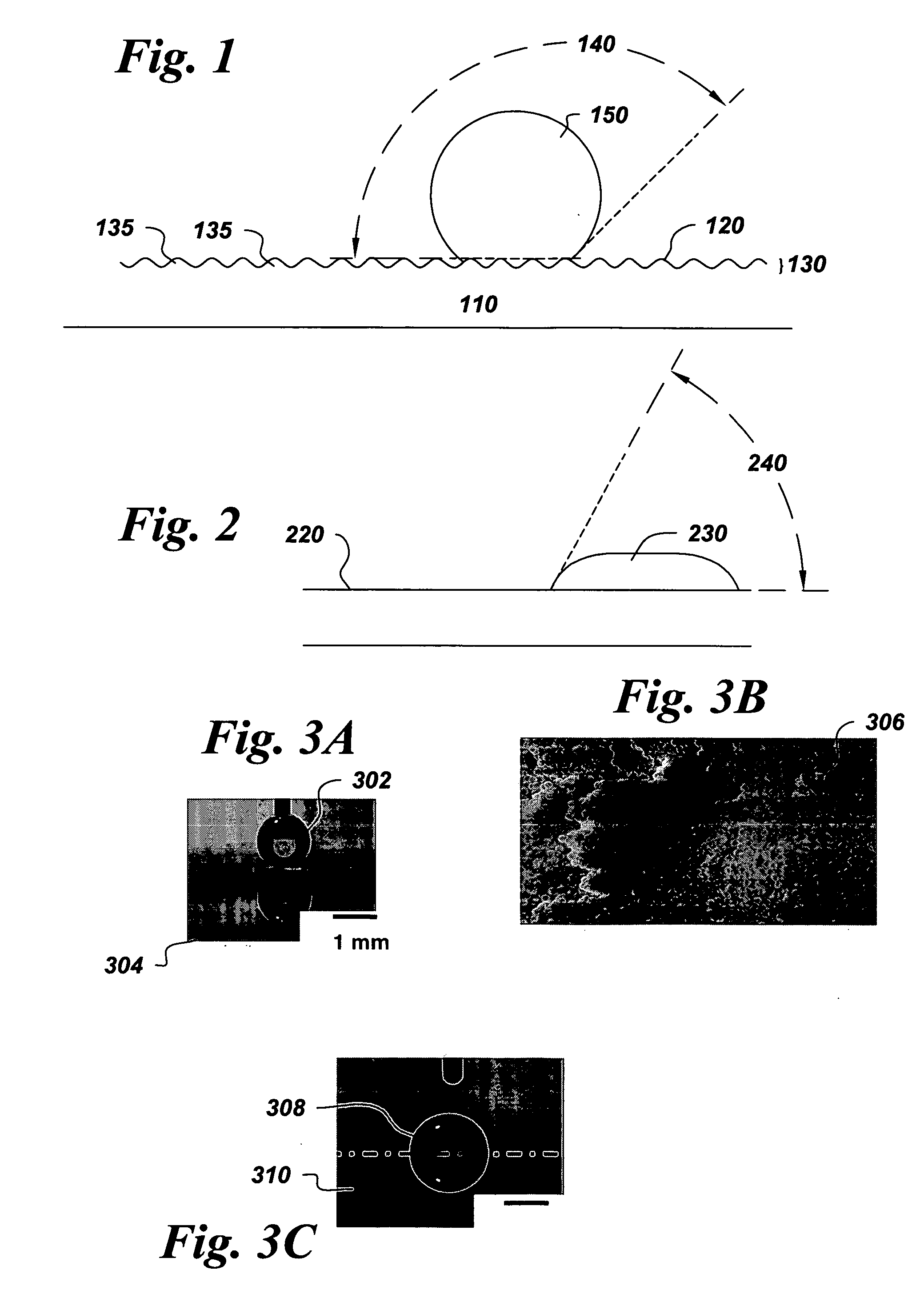

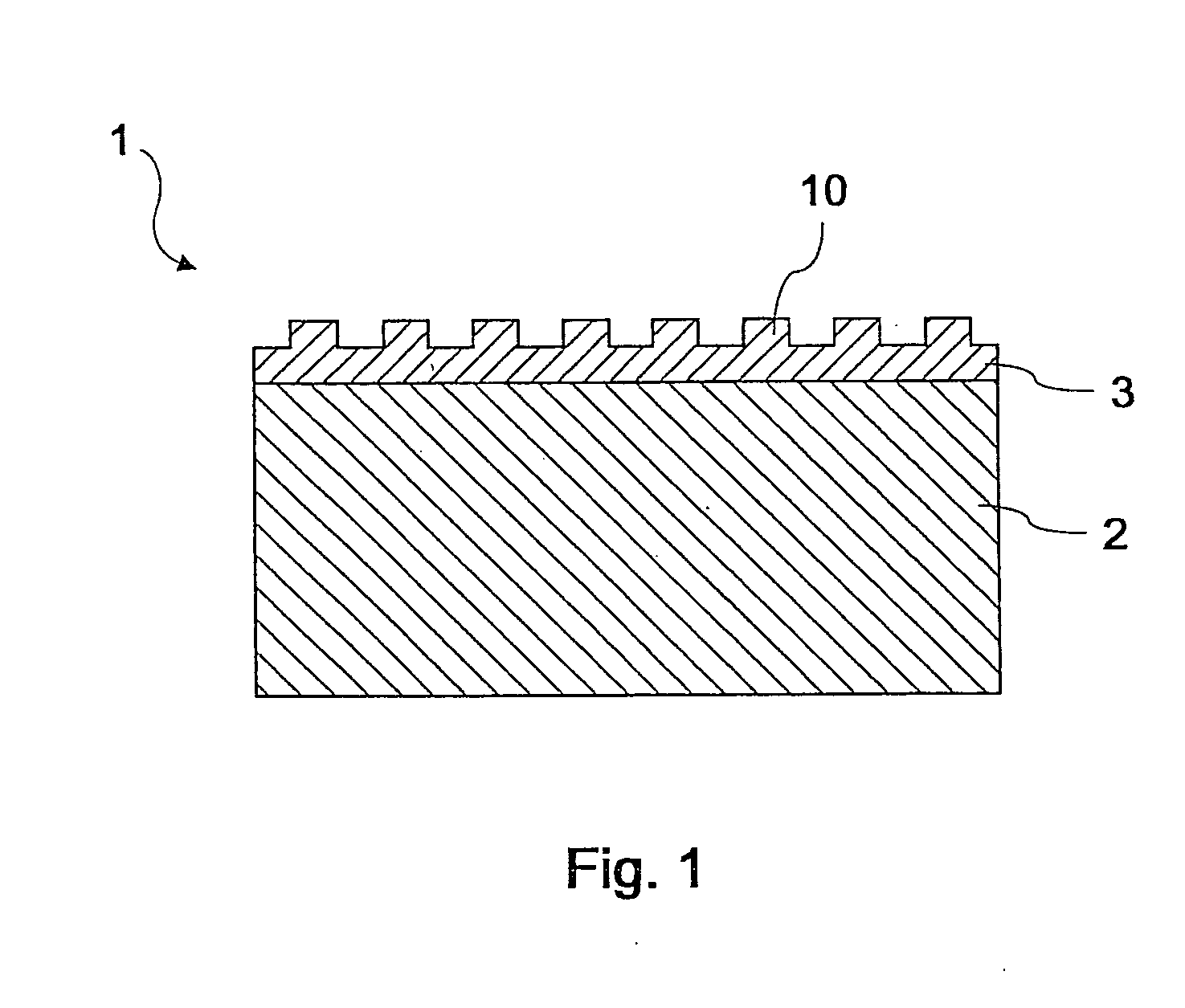

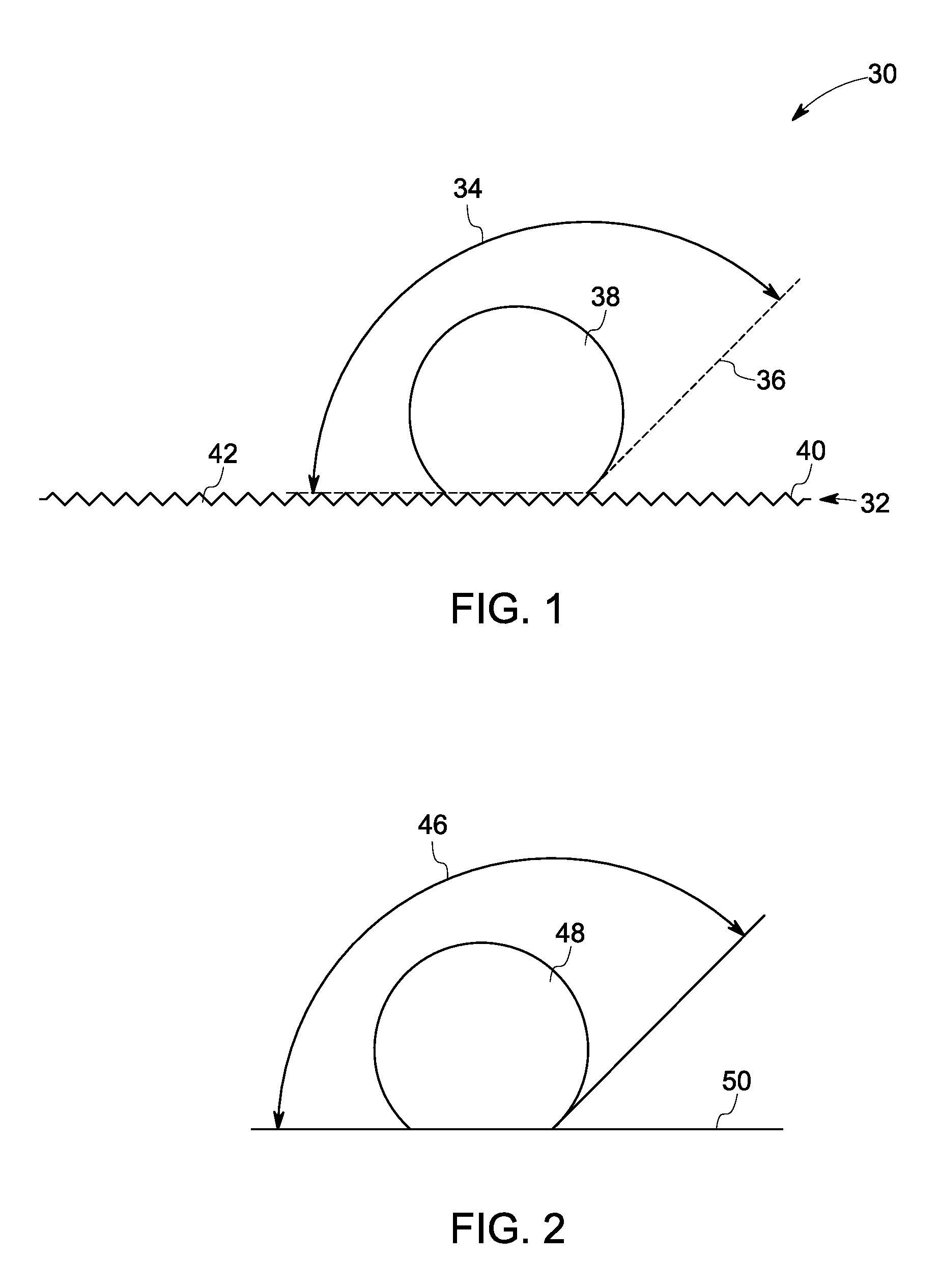

Articles having a surface with low wettability and method of making

InactiveUS20060216476A1Low liquid wettabilityLow wettabilityRecord information storageLiquid/solution decomposition chemical coatingPolymer scienceCeramic

An article comprises a textured surface disposed on a substrate. The surface has an effective liquid wettability sufficient to generate, with a reference liquid, a contact angle in a range from about 120° to about 180°. The surface comprises a material having a nominal liquid wettability sufficient to generate, with the reference liquid, a nominal contact angle in a range from about 60° to about 90°, the material comprising at least one material selected from the group consisting of a polymer and a ceramic. The properties of the surface may include low-drag or low-friction, self-cleaning capability, and resistance to icing, fouling, and fogging, and the like. Methods of making such a surface are also described.

Owner:GENERAL ELECTRIC CO

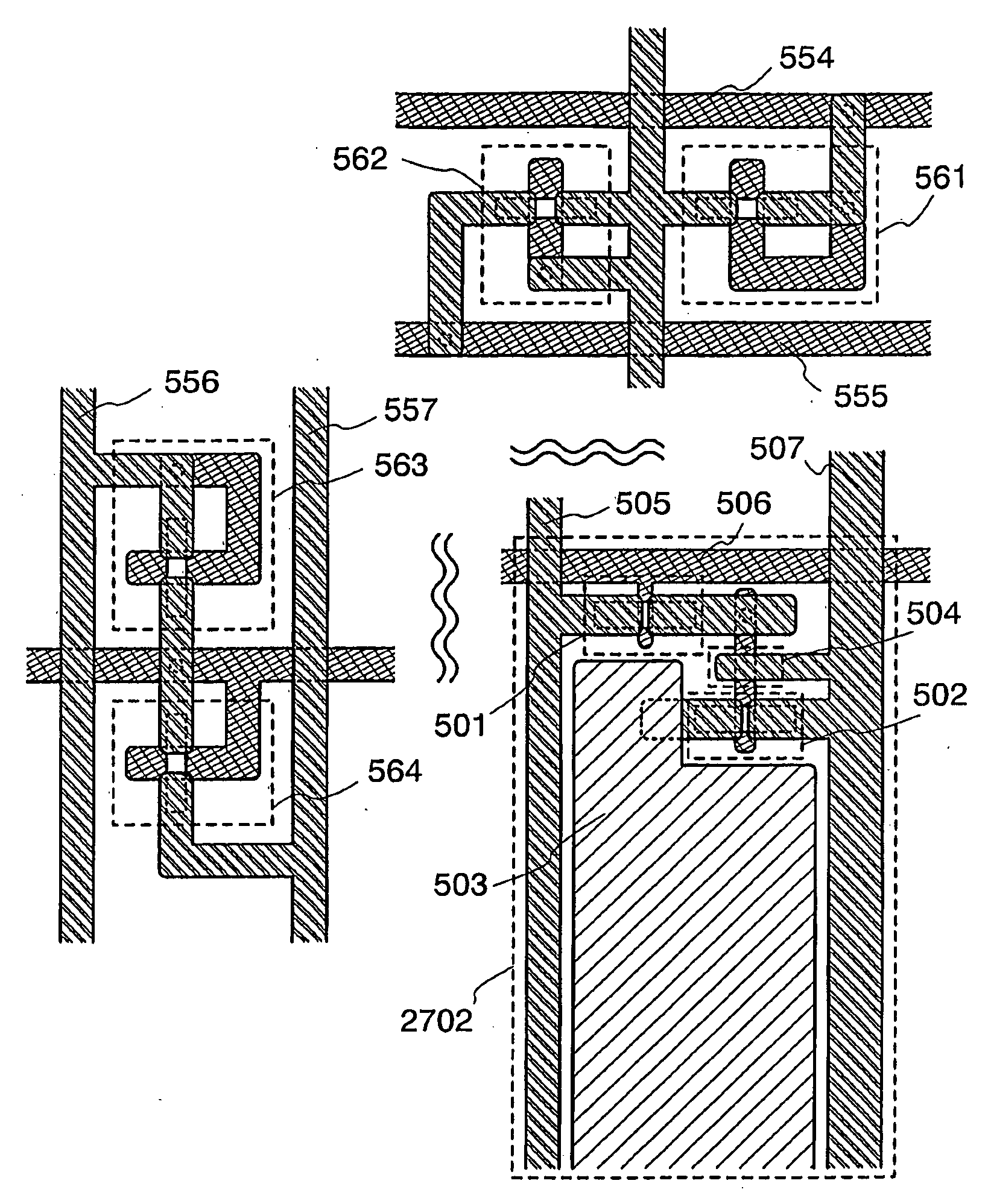

Semiconductor device and manufacturing method thereof and method for writing memory element

InactiveUS20060263634A1Low manufacturingHigh yieldNanoinformaticsSolid-state devicesEngineeringVoltage

An object is to provide a higher-performance and higher-reliability memory device and a semiconductor device provided with the memory device at low cost and with high yield. A semiconductor device of the invention has a memory element including an insulating layer and an organic compound layer between first and second conductive layers. When melting, an organic compound of the organic compound layer aggregates due to surface tension of the organic compound. By applying a voltage to the first and second conductive layers, writing to the memory element is carried out.

Owner:SEMICON ENERGY LAB CO LTD

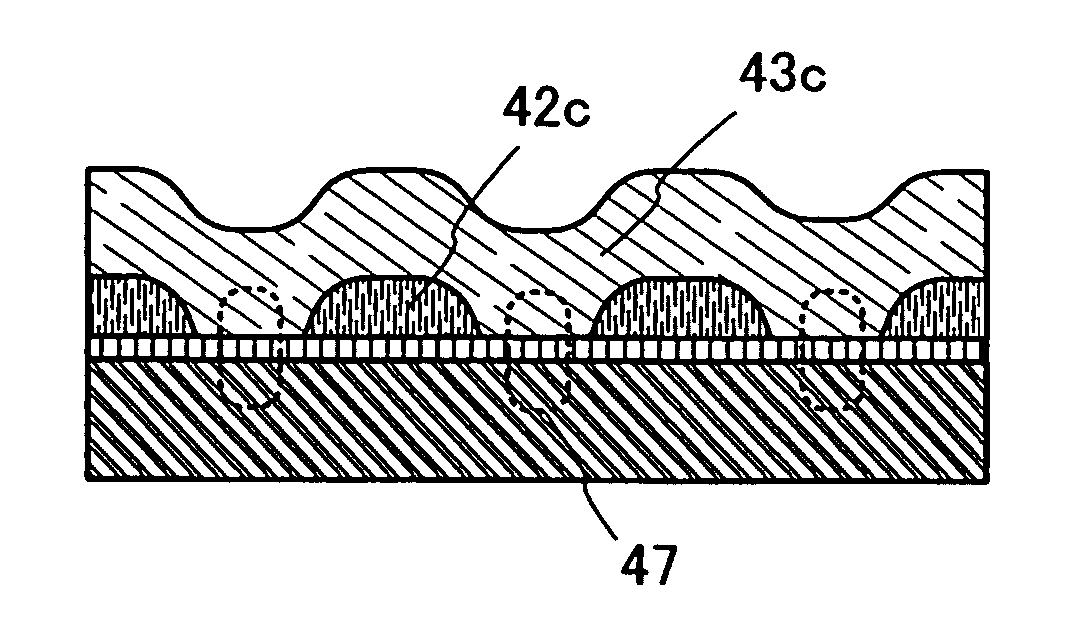

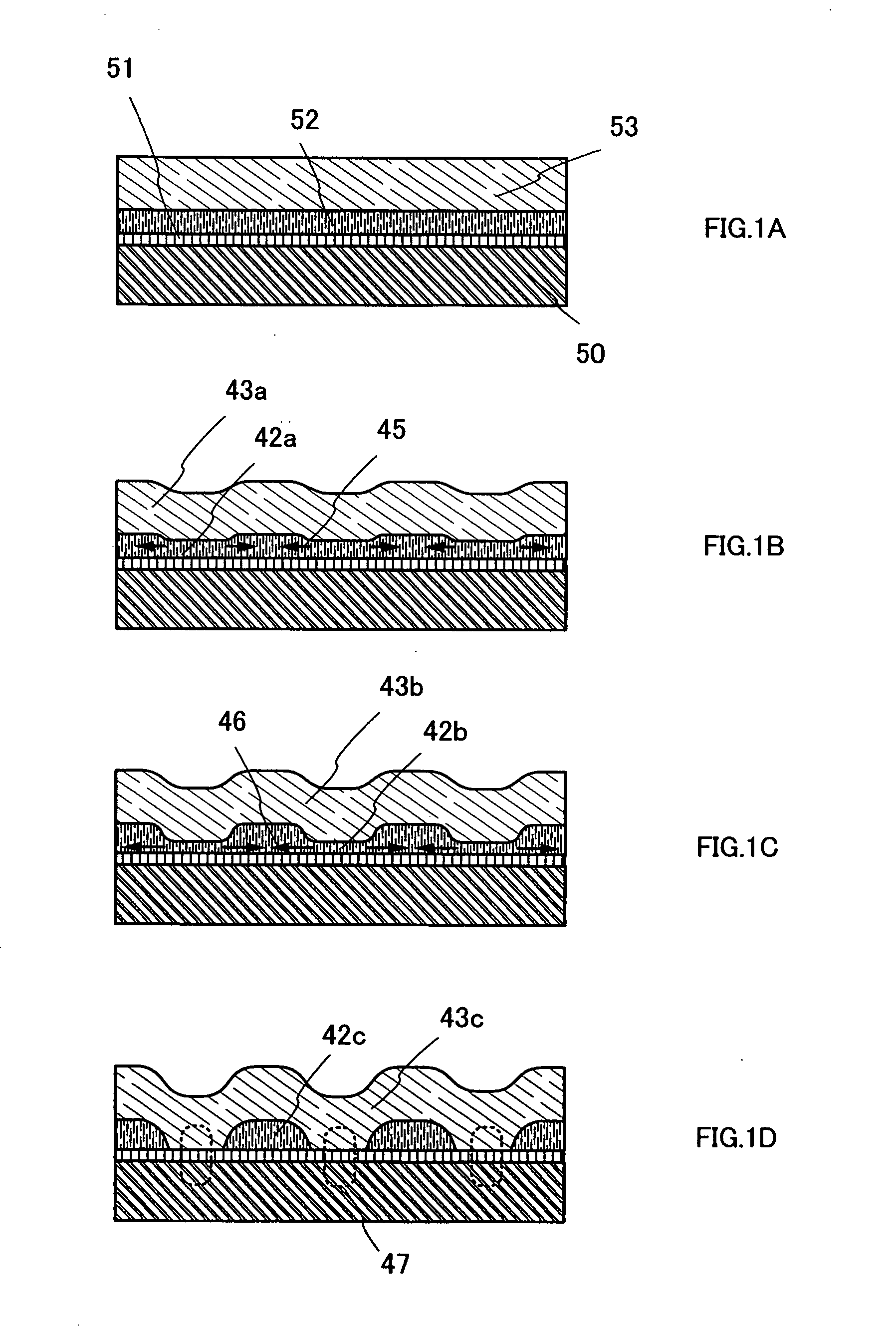

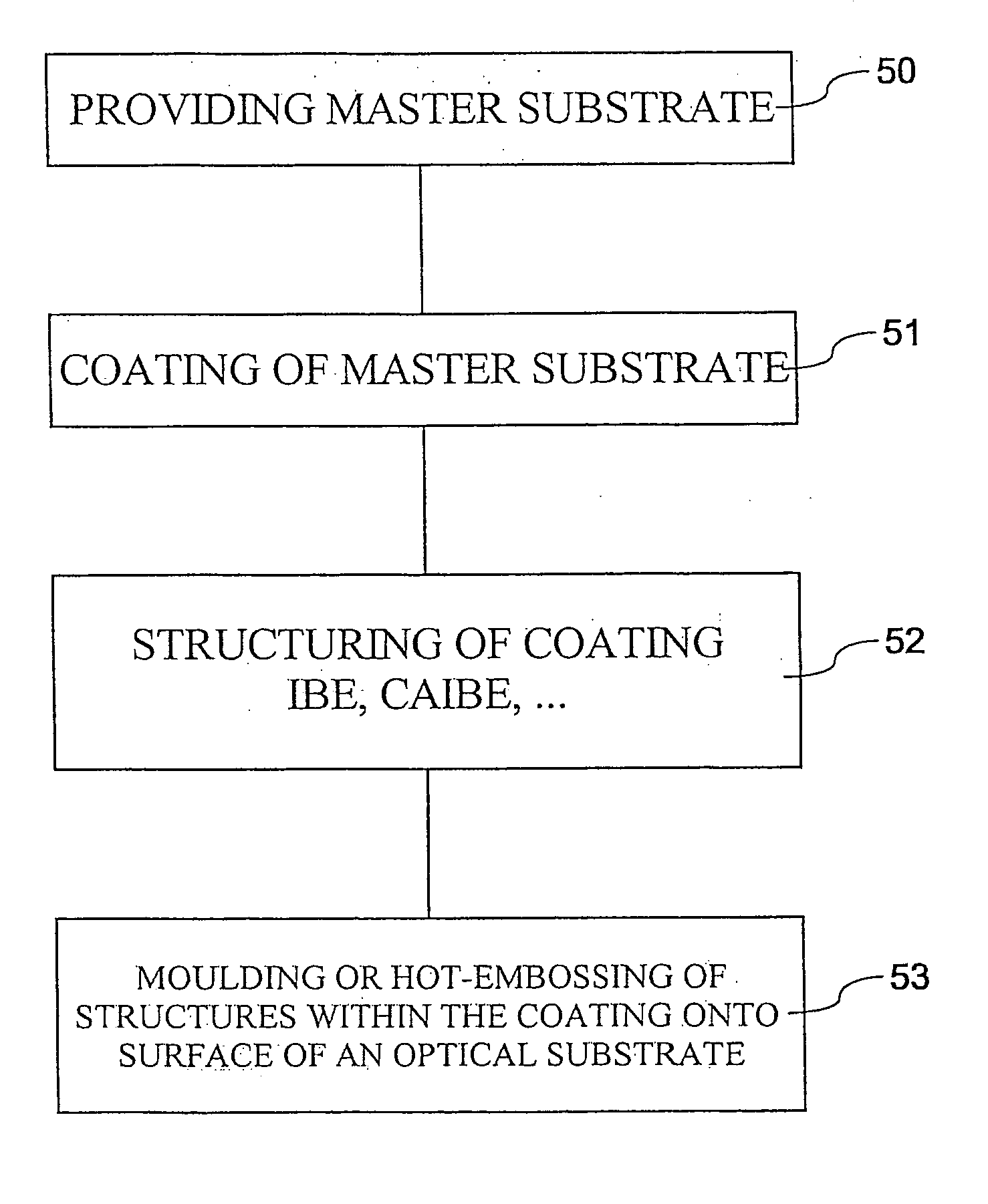

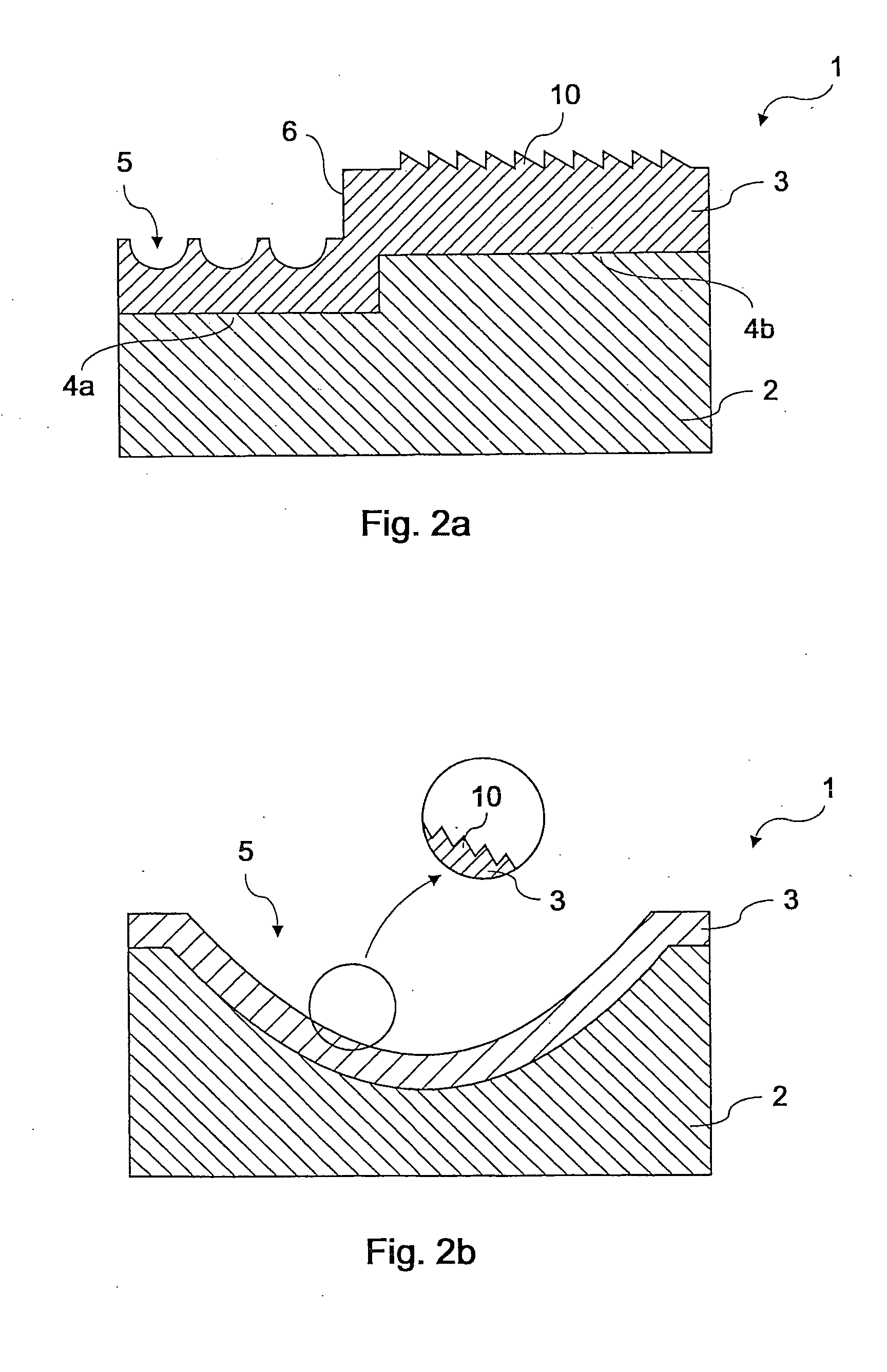

Method for manufacturing a master, master, method for manufacturing optical elements and optical element

InactiveUS20050260349A1Improve optical qualityQuality improvementDecorative surface effectsOptical articlesOptoelectronicsCoating

The invention relates to a method for manufacturing of a master for manufacturing of optical elements having optically effective structures by moulding structures, which are formed on the master, onto a surface of an optical substrate, comprising the steps of: providing a substrate; coating a surface of said substrate for forming a coating on said substrate; and patterning said coating for forming structures in said coating. The invention also relates to a master for manufacturing of optical elements, to a method for manufacturing of optical elements as well as to an optical element having at least one surface, wherein at least in portions of said surface optically effective structures are formed.

Owner:SCHOTT AG

Self-activated cooling device

ActiveUS20080147153A1Prevent wettingLow wettabilityDomestic cooling apparatusLighting and heating apparatusInterior spaceEngineering

A cooling device for placement against a body part or object includes a shell member having an outer face and an inner face disposed against a surface to be cooled. A first cooling substrate is disposed within the shell member and is an absorbent web having a generally uniform application of a first cooling composition applied thereto, the cooling composition activated by contact with an aqueous liquid. An aqueous liquid source is disposed within the shell member and is separated from the first cooling substrate by a barrier member. The device is activated by manual manipulation to breach the barrier member causing liquid from the liquid source to move within the interior space of the shell member to contact and activate the cooling composition whereby a cooling reaction is generated.

Owner:KIMBERLY-CLARK WORLDWIDE INC

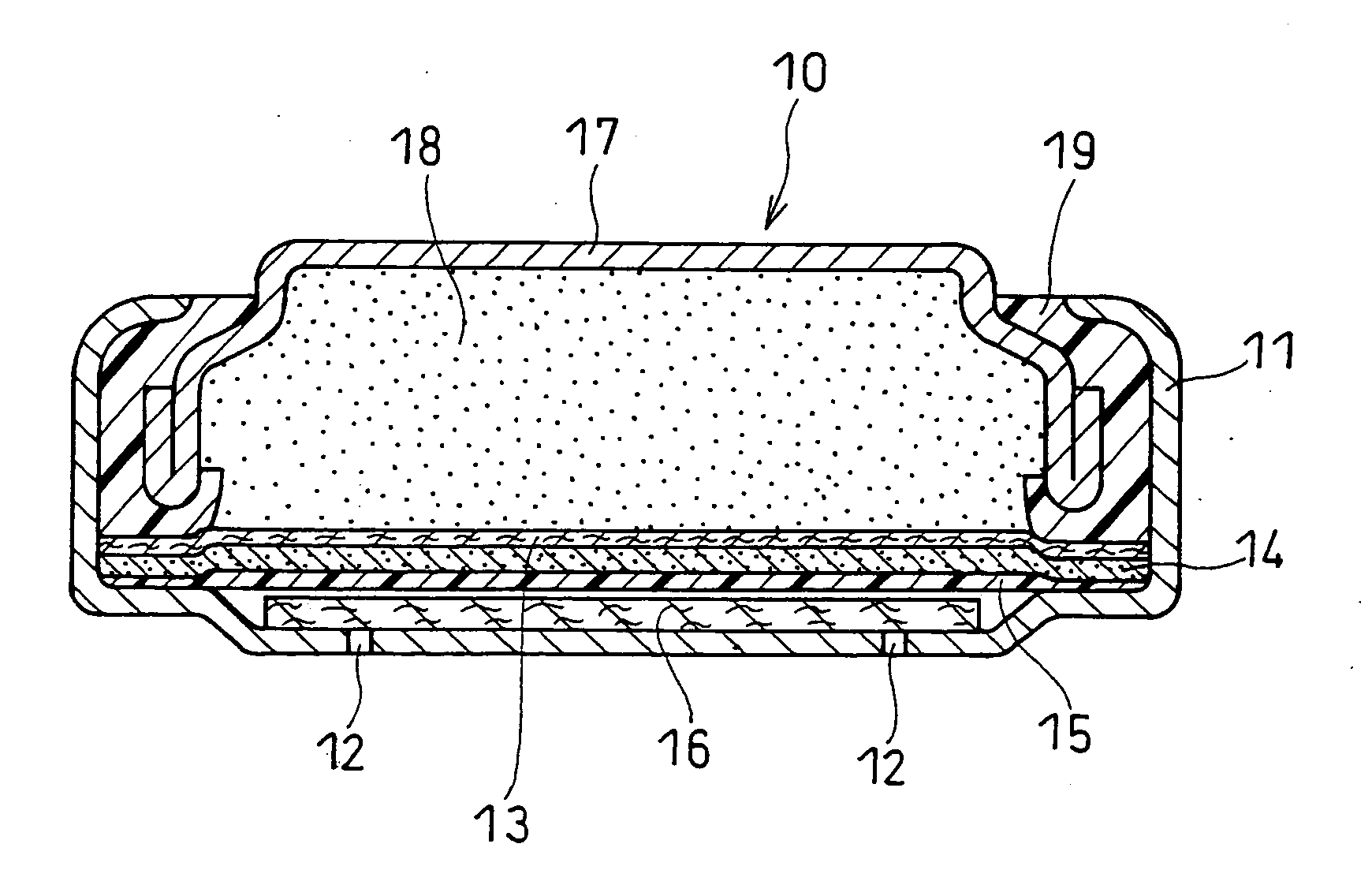

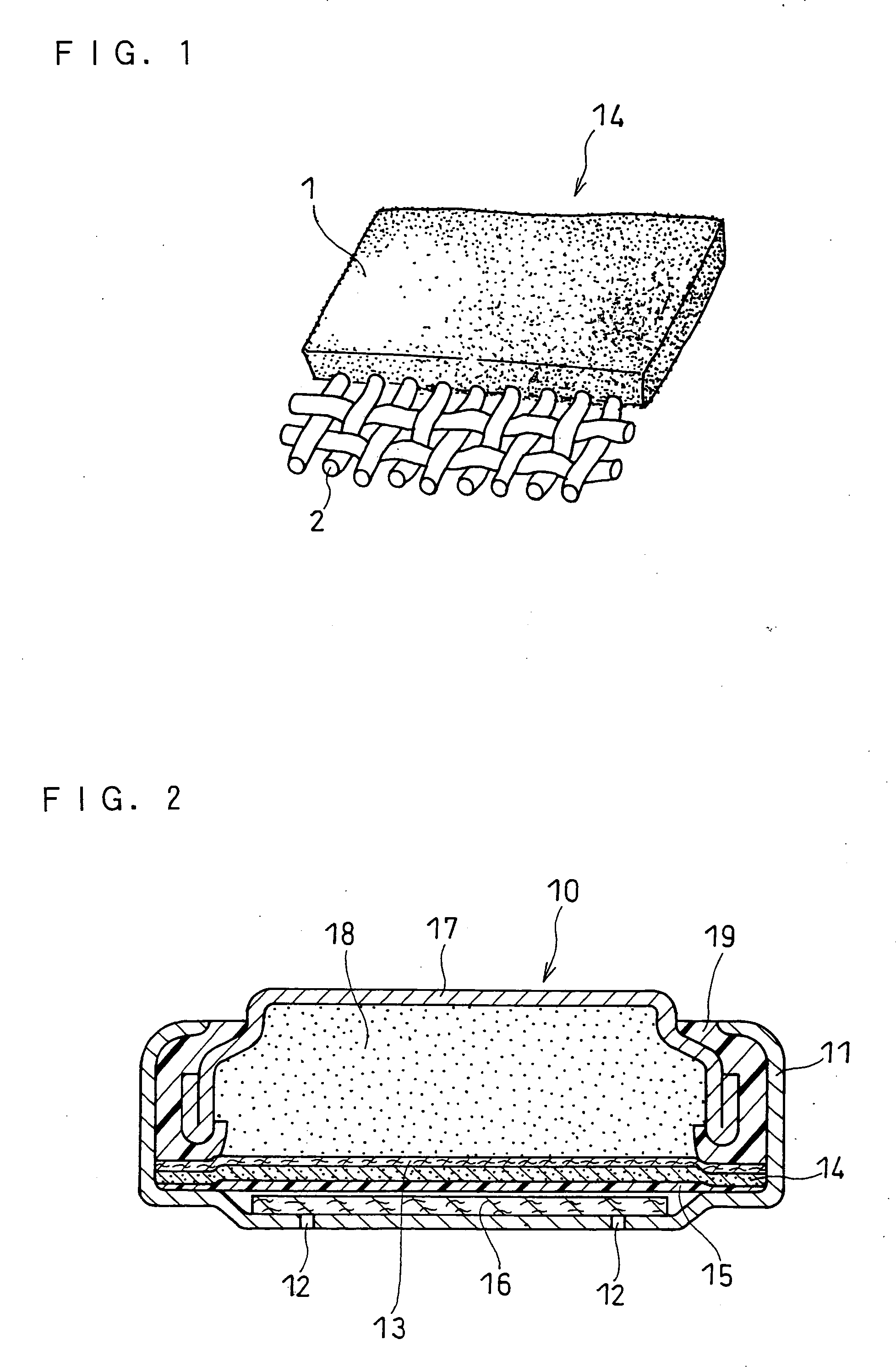

Air battery and method for producing air electrode for air battery

InactiveUS20070160898A1Excellent in heavy-load discharge characteristicImprove storage characteristicsFuel and primary cellsPrimary cellsCompound (substance)Three-phase

An air battery that is excellent in heavy-load discharge characteristics and storage characteristics is provided by ensuring the stability of the three-phase interface of a catalyst layer of an air electrode. The air battery has an air electrode including a catalyst layer that is bonded under pressure to a current collector and a water-repellent film. The catalyst layer includes a catalyst for reducing oxygen, a promoter for decomposing a product of the oxygen reduction, conductive carbon, and a binder. A non-polymeric fluorine compound is added to the catalyst layer in order to enhance the water repellency of the catalyst layer.

Owner:PANASONIC CORP

Hydrophilic coating and a method for the preparation thereof

The present invention provides a method for the preparation of a cross-linked hydrophilic coating of a hydrophilic polymer on a substrate polymer surface of a medical device, involving the use of a polymer solution comprising 1-20% by weight of a hydrophilic polymer, 0-5% by weight of additive(s), and the balance of a vehicle with plasticizing effect on the hydrophilic polymer, wherein the vehicle comprises at least one plasticizer having a solubility in water of at least 6 g / L, a boiling point above 210° C. at 760 mmHg, and Hansen δH parameter of less than 20. Furthermore, the invention provides a medical device, e.g. a catheter or guide wire, provided with such a hydrophilic coating. The invention also provides the use of specific polymer solution for the preparation of a cross-linked hydrophilic coating.

Owner:COLOPLAST AS

Solar cell and semiconductor device, and manufacturing method thereof

InactiveUS20060157105A1Improve throughputSmall sizeDoors/windowsFinal product manufactureConductive pasteDevice material

It is an object of the present invention to minimize an electrode in a solar cell to minimize the solar cell. The present invention provides a method for manufacturing a solar cell comprising the steps of forming a first electrode layer over a substrate, forming a photoelectric conversion layer over the first electrode layer, forming an organic layer over the photoelectric conversion layer, forming an opening reaching the first electrode layer in the photoelectric conversion layer, and forming a second electrode layer by filling the opening with a conductive paste, wherein the organic layer modifies the surface of the photoelectric conversion layer and a contact angle between the conductive paste and the photoelectric conversion becomes greater. According to the present invention, wettability of a photoelectric conversion layer can be decreased by forming an organic layer on a surface of the photoelectric conversion layer. Thereby an electrode layer and an insulating isolation layer can be thinned.

Owner:SEMICON ENERGY LAB CO LTD

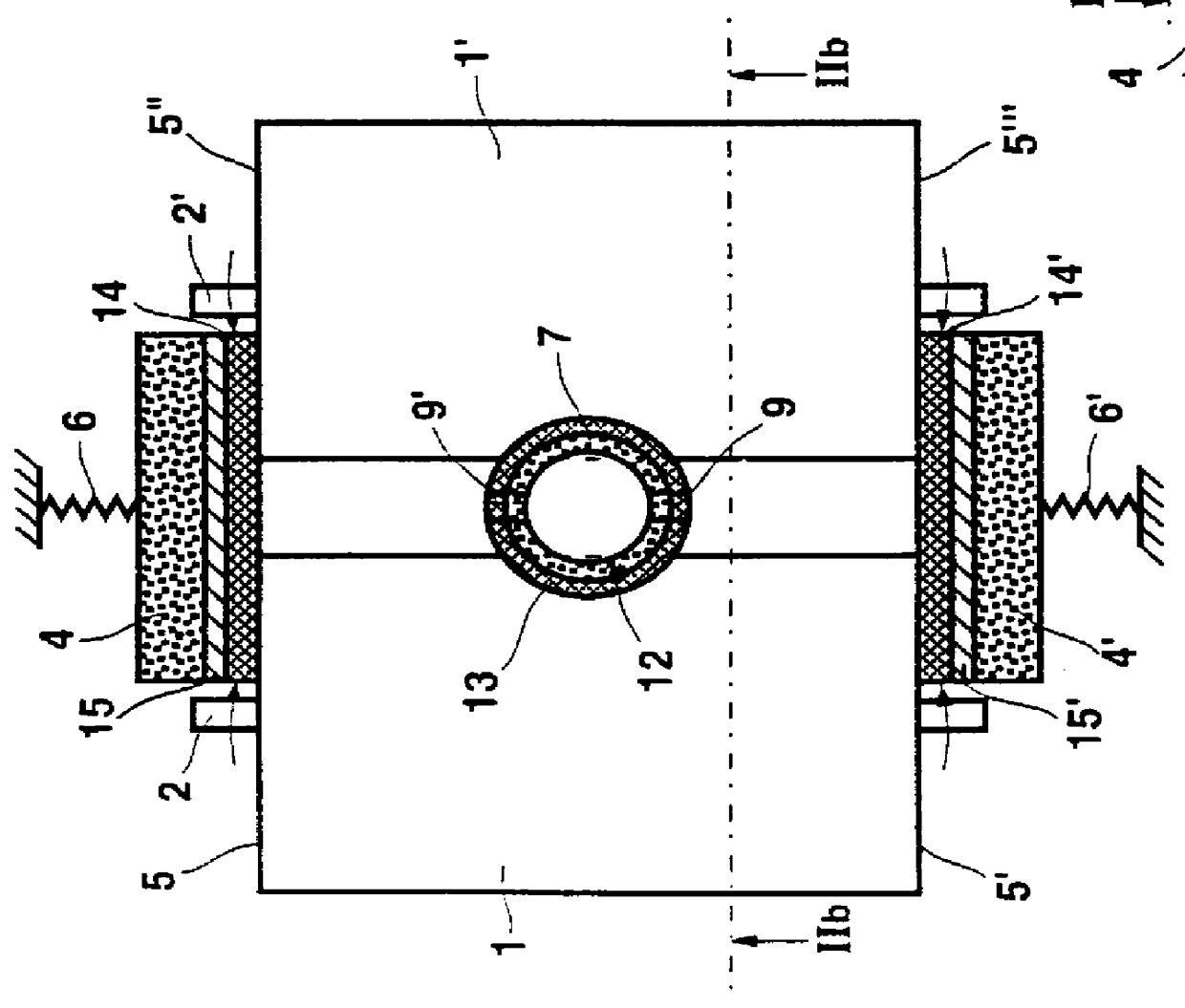

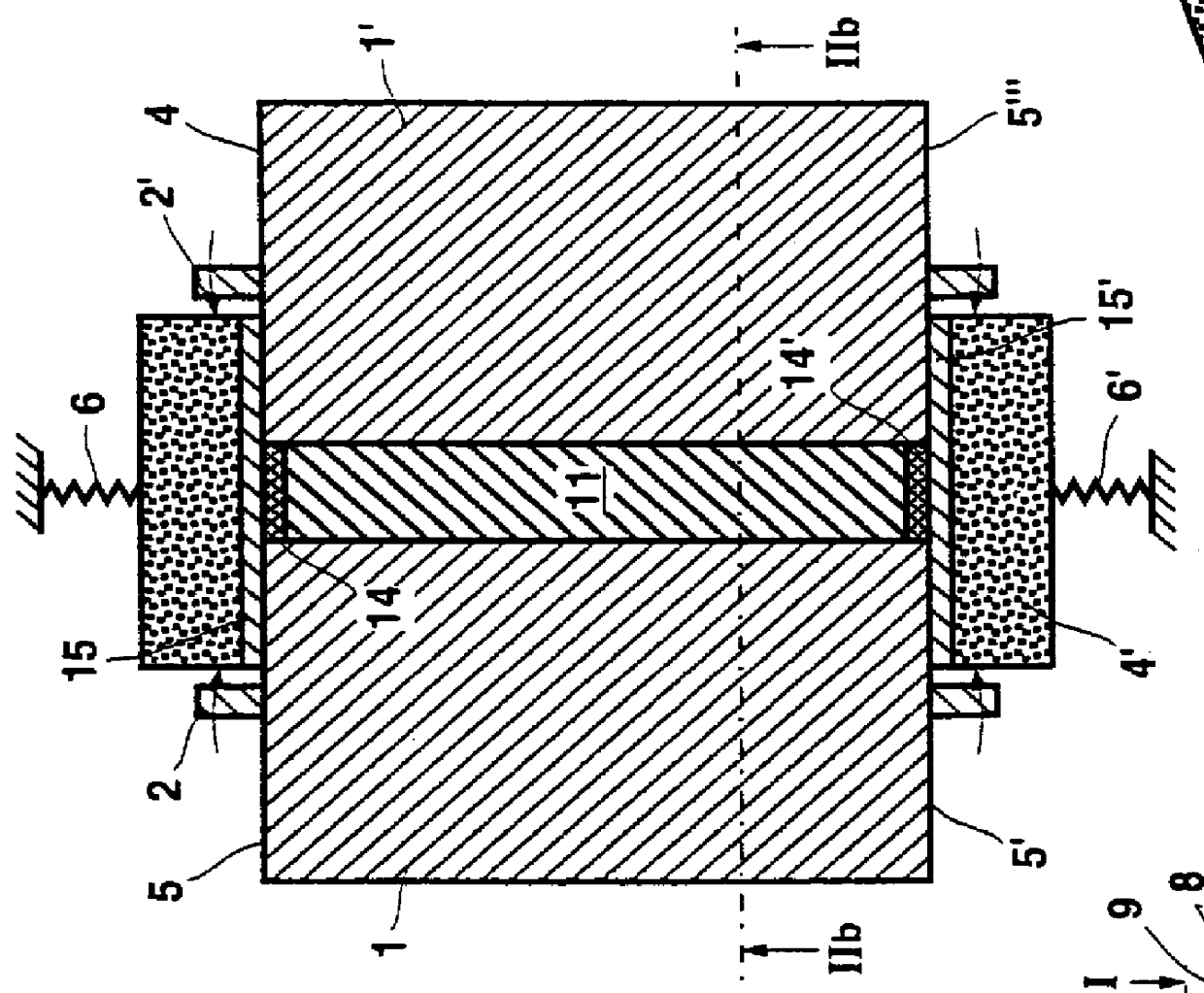

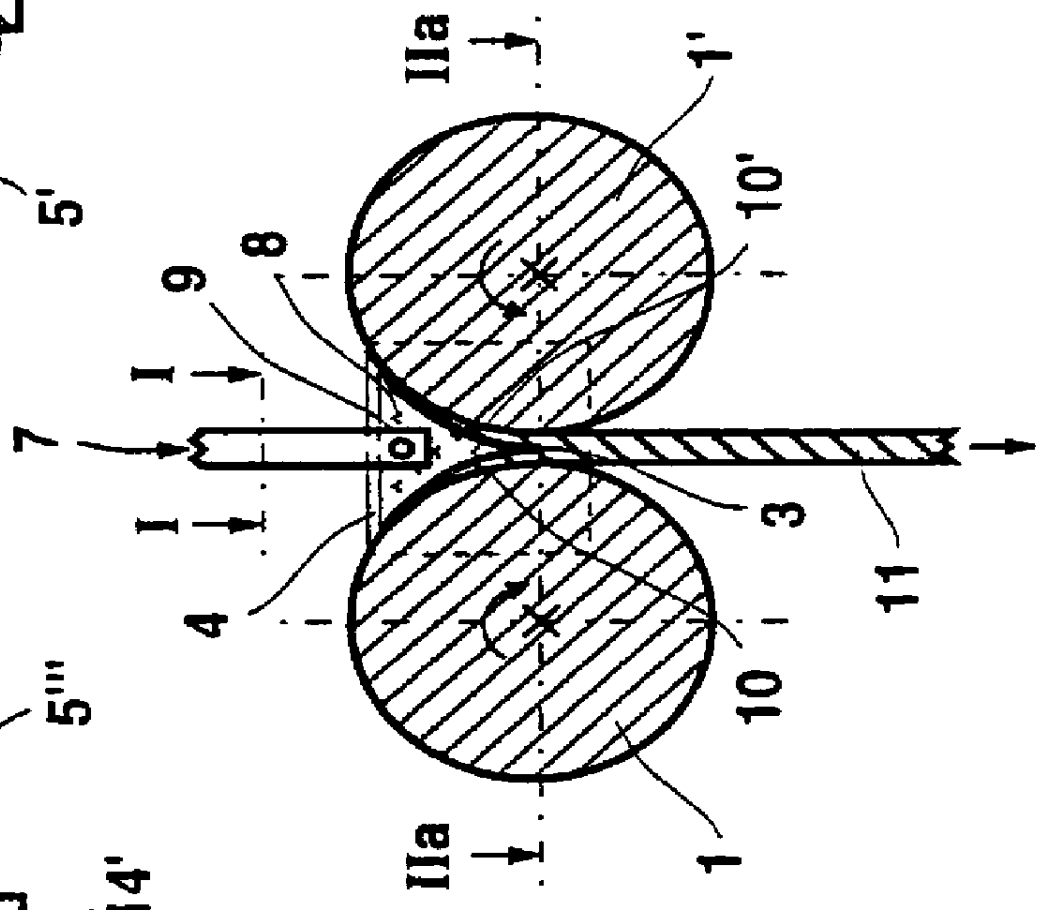

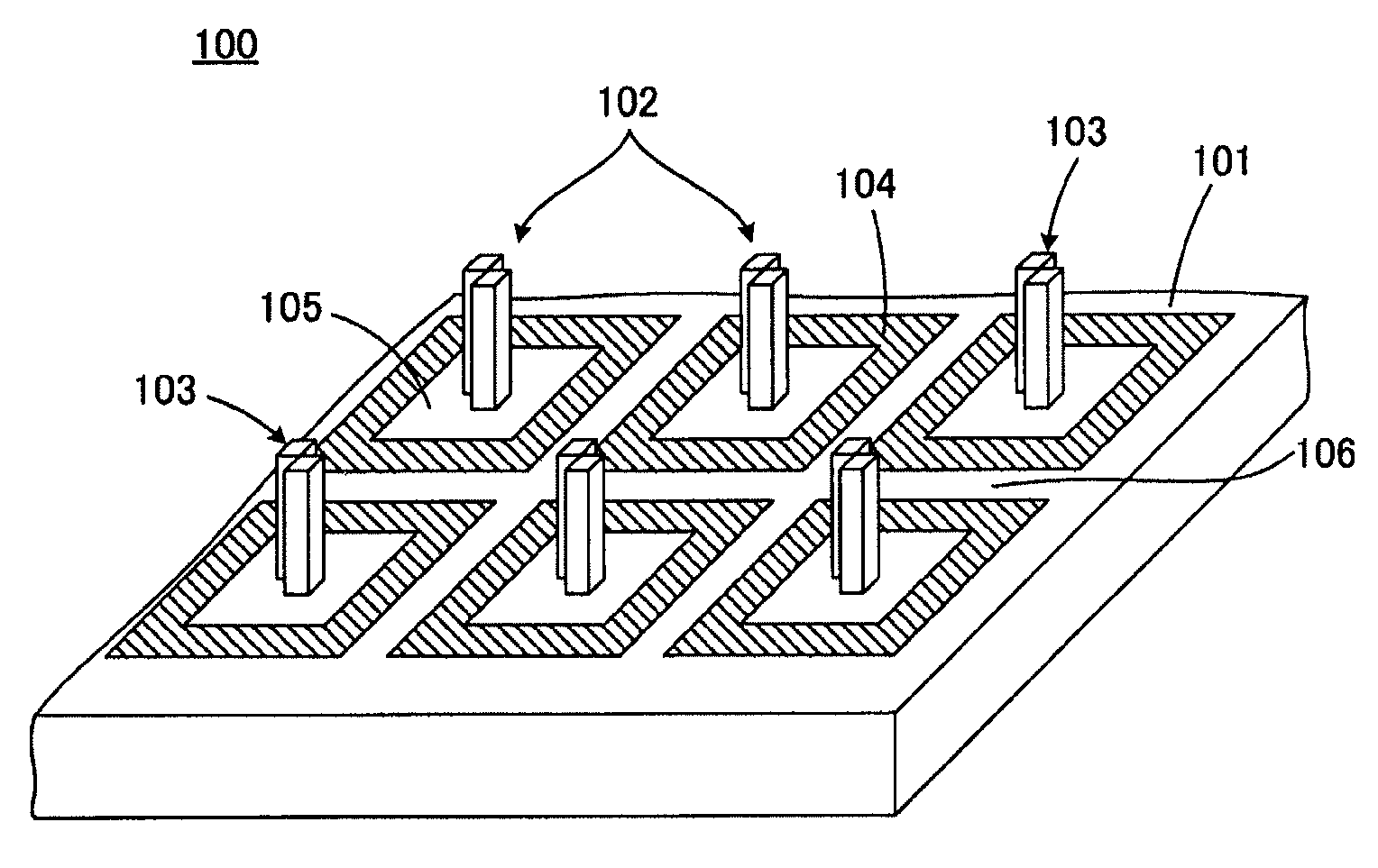

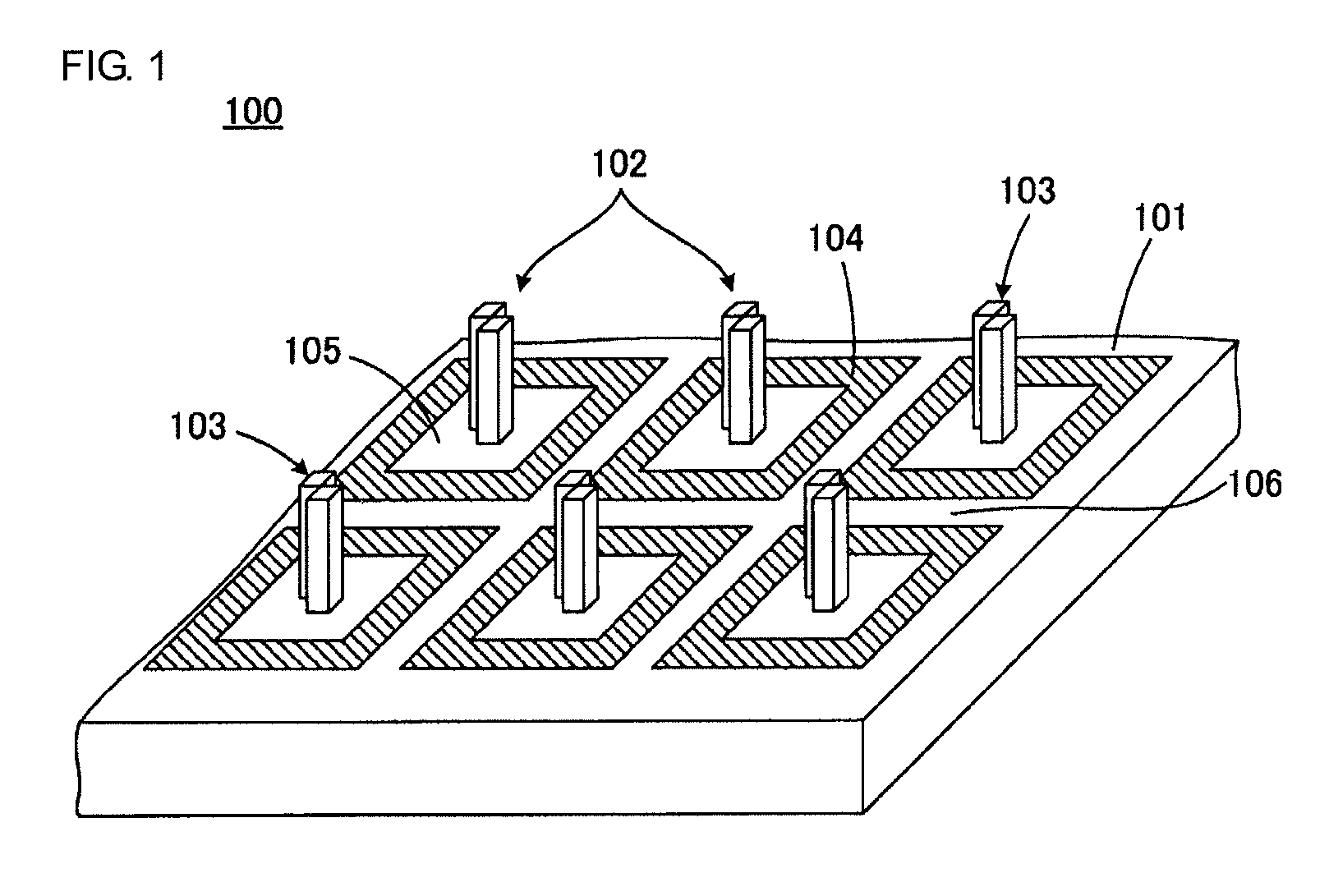

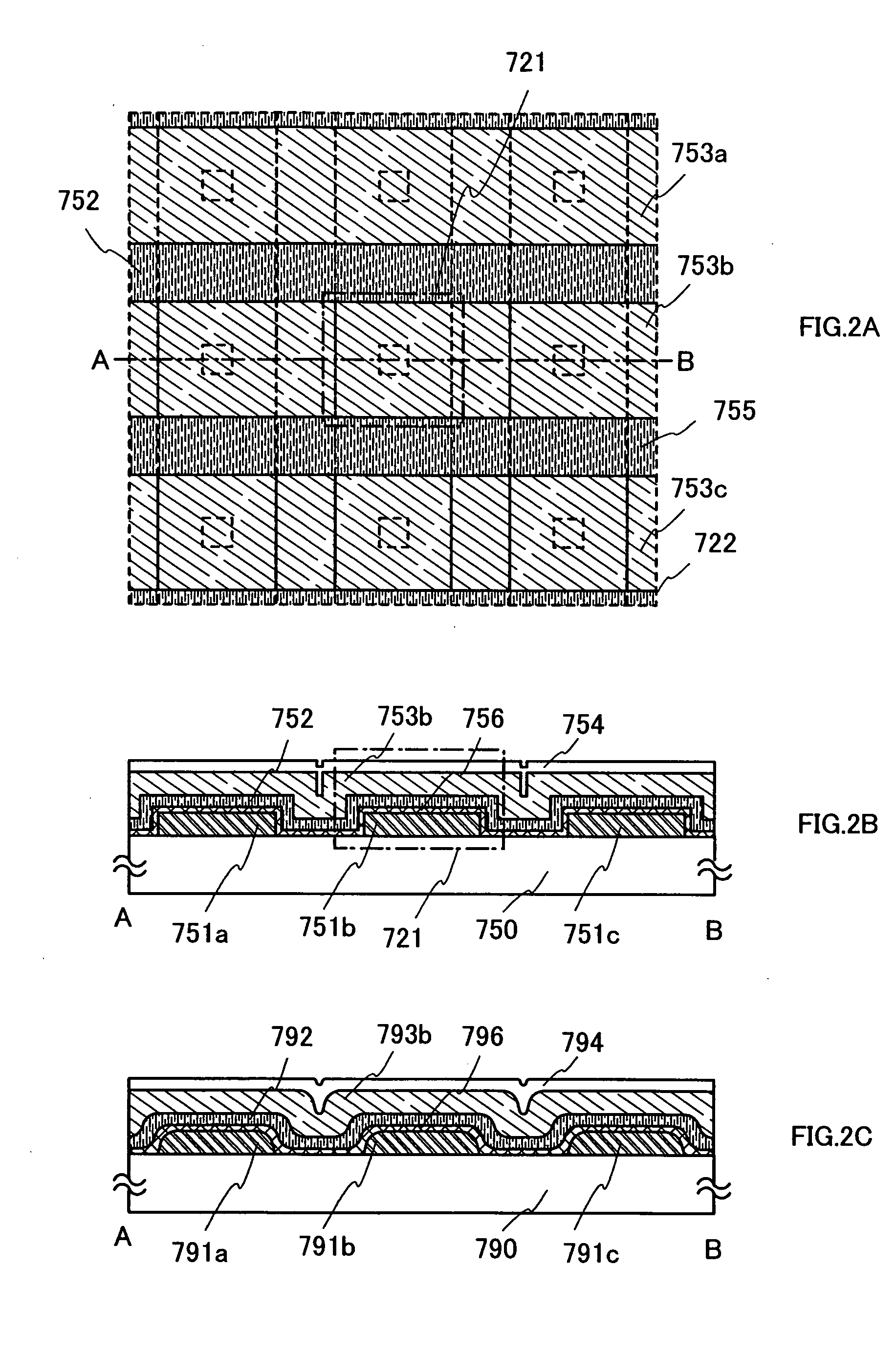

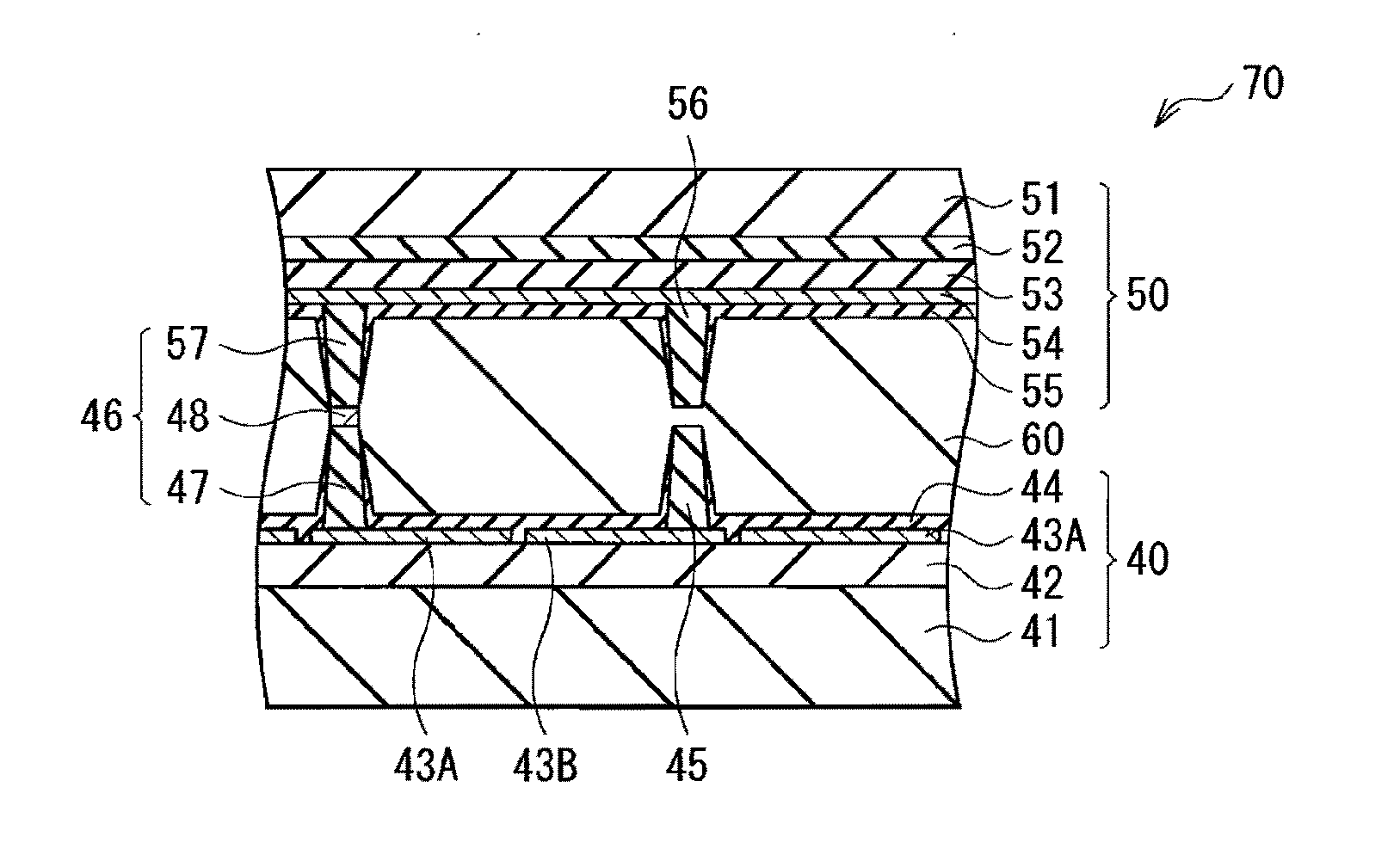

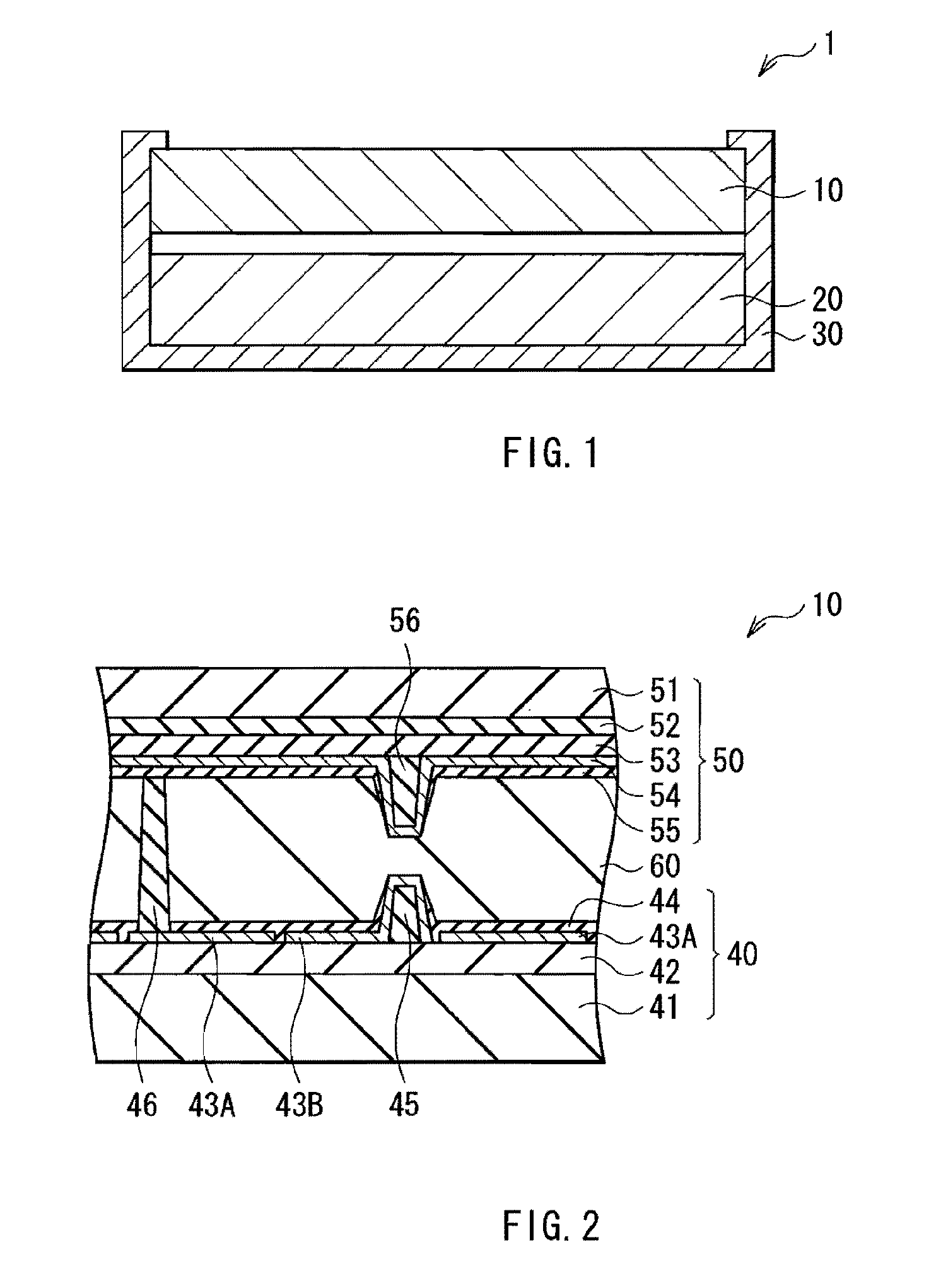

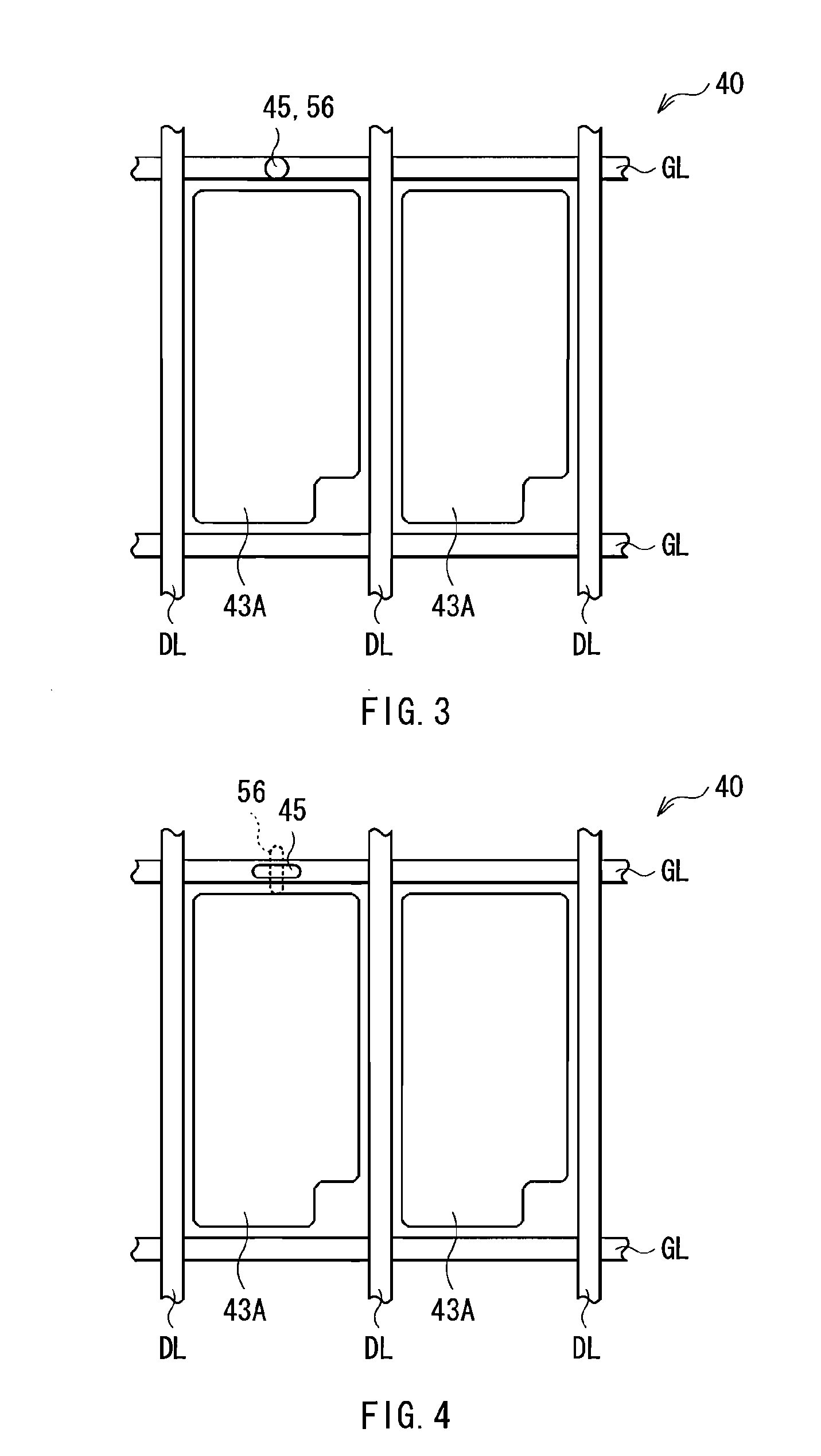

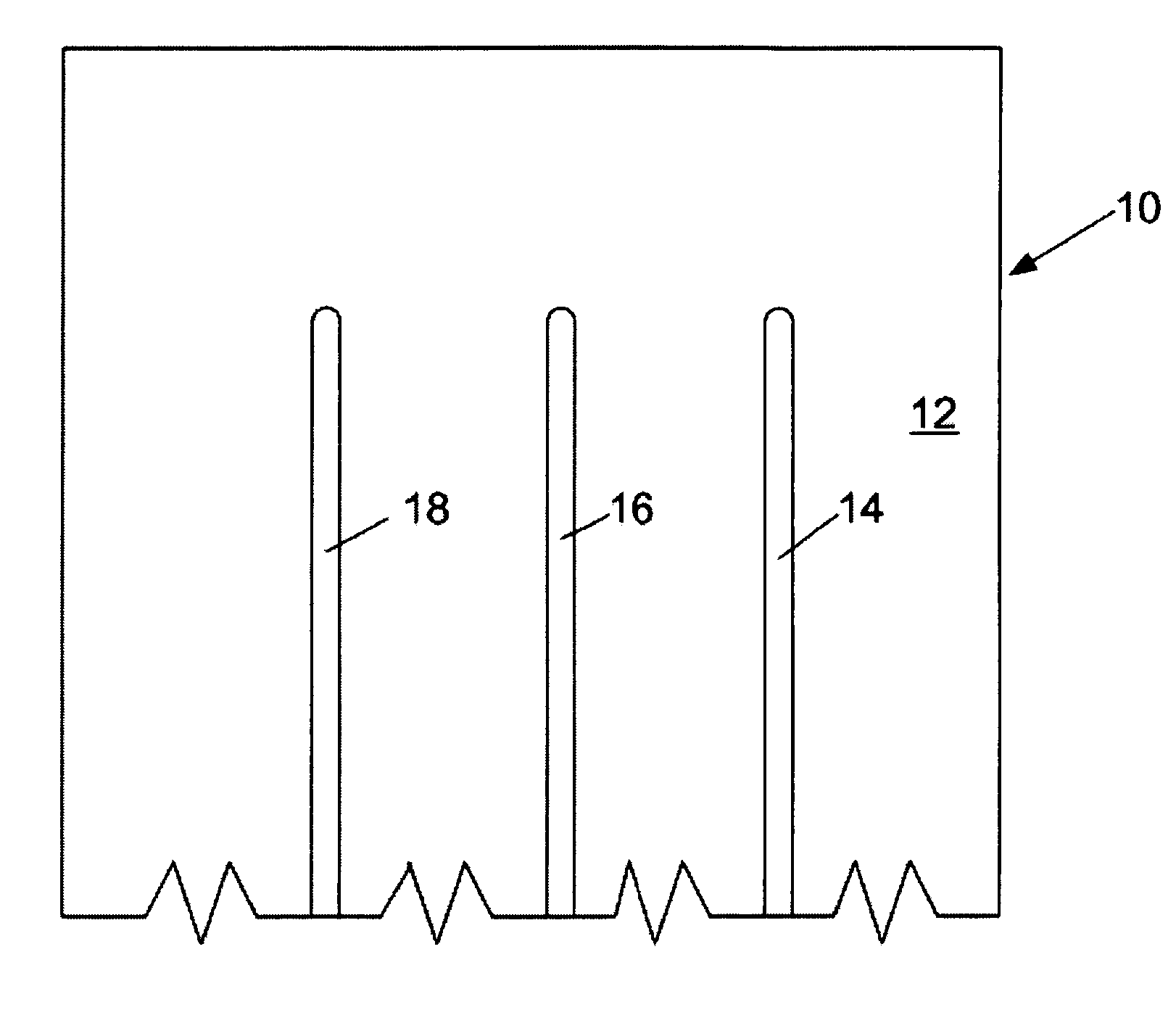

Liquid crystal panel and liquid crystal display device

ActiveUS20100141880A1Maintain durabilityEliminate generationNon-linear opticsLiquid-crystal displayEngineering

The present invention provides a liquid crystal panel and a liquid crystal display device allowing reliability deterioration due to external pressure to be suppressed without yield rate degradation. The liquid crystal panel includes: a pair of substrates facing each other with a space in between; a liquid crystal layer disposed in the space between the pair of substrates; and a plurality of pairs of pillar structures, each pair of pillar structures being arranged on opposing faces of the pair of substrates, respectively, to face each other along a normal to the opposing faces.

Owner:JAPAN DISPLAY WEST

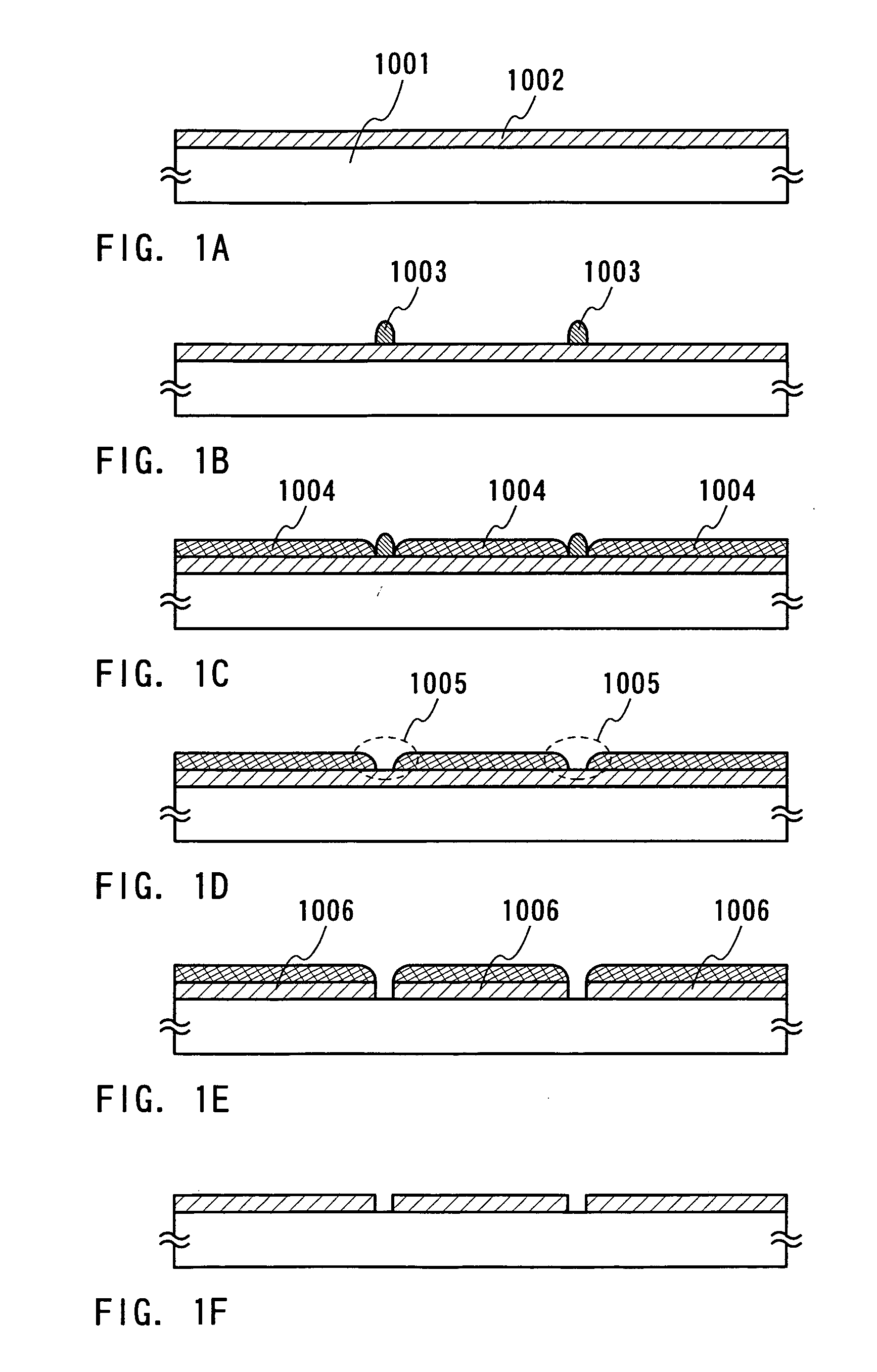

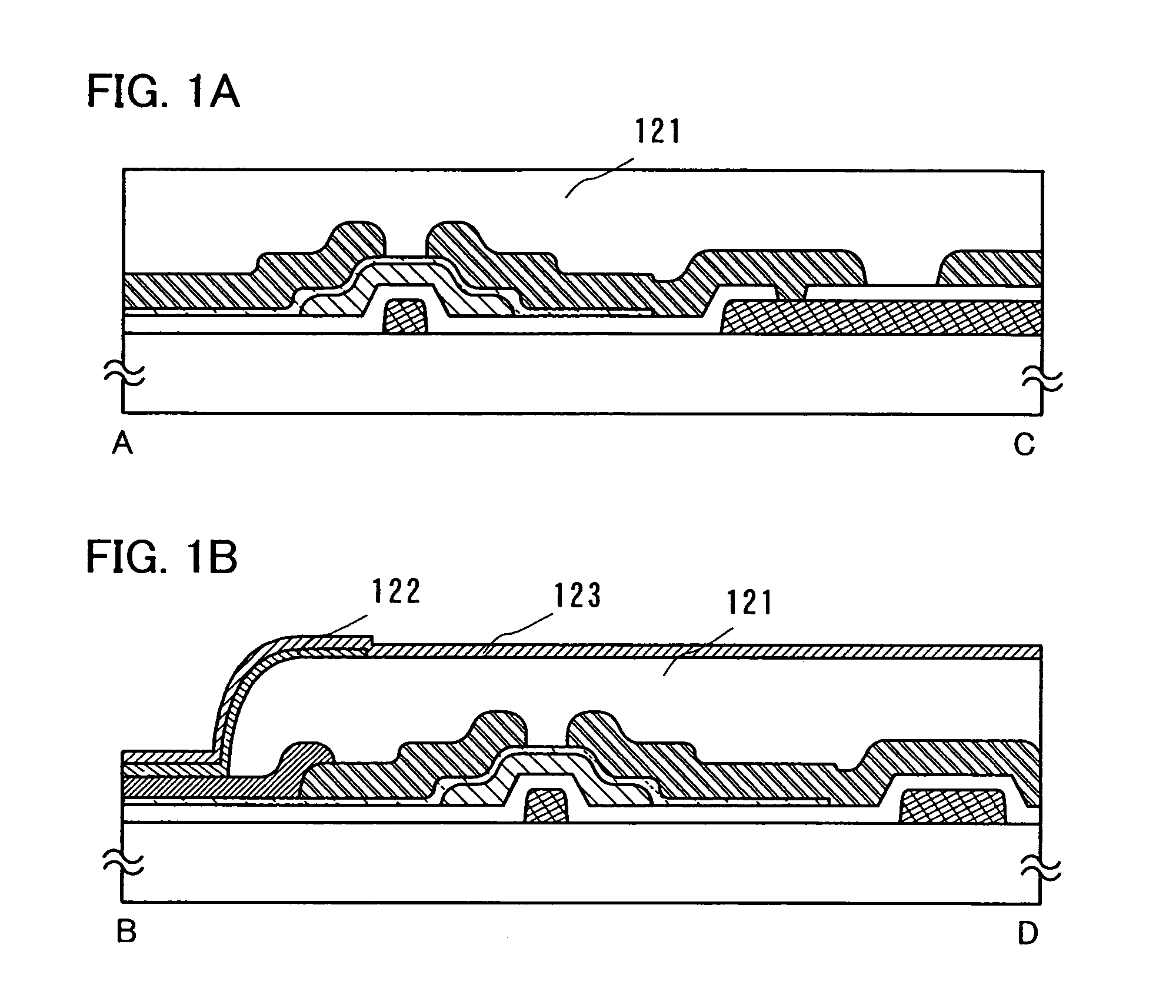

Method for manufacturing display device, liquid crystal telvision, and EL television

InactiveUS20050244995A1Increase productionImprove wettabilitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLCD television

An object of the present invention is to provide a method for manufacturing a display device with few steps and high yield. One feature of the invention is to form a first mask pattern having low wettability over a conductive layer, form a second mask pattern having high wettability over the conductive layer using the first mask pattern as a mask, and form a mask pattern for etching the conductive layer by removing the first mask pattern. Another feature is to form a pixel electrode by etching the conductive layer.

Owner:SEMICON ENERGY LAB CO LTD

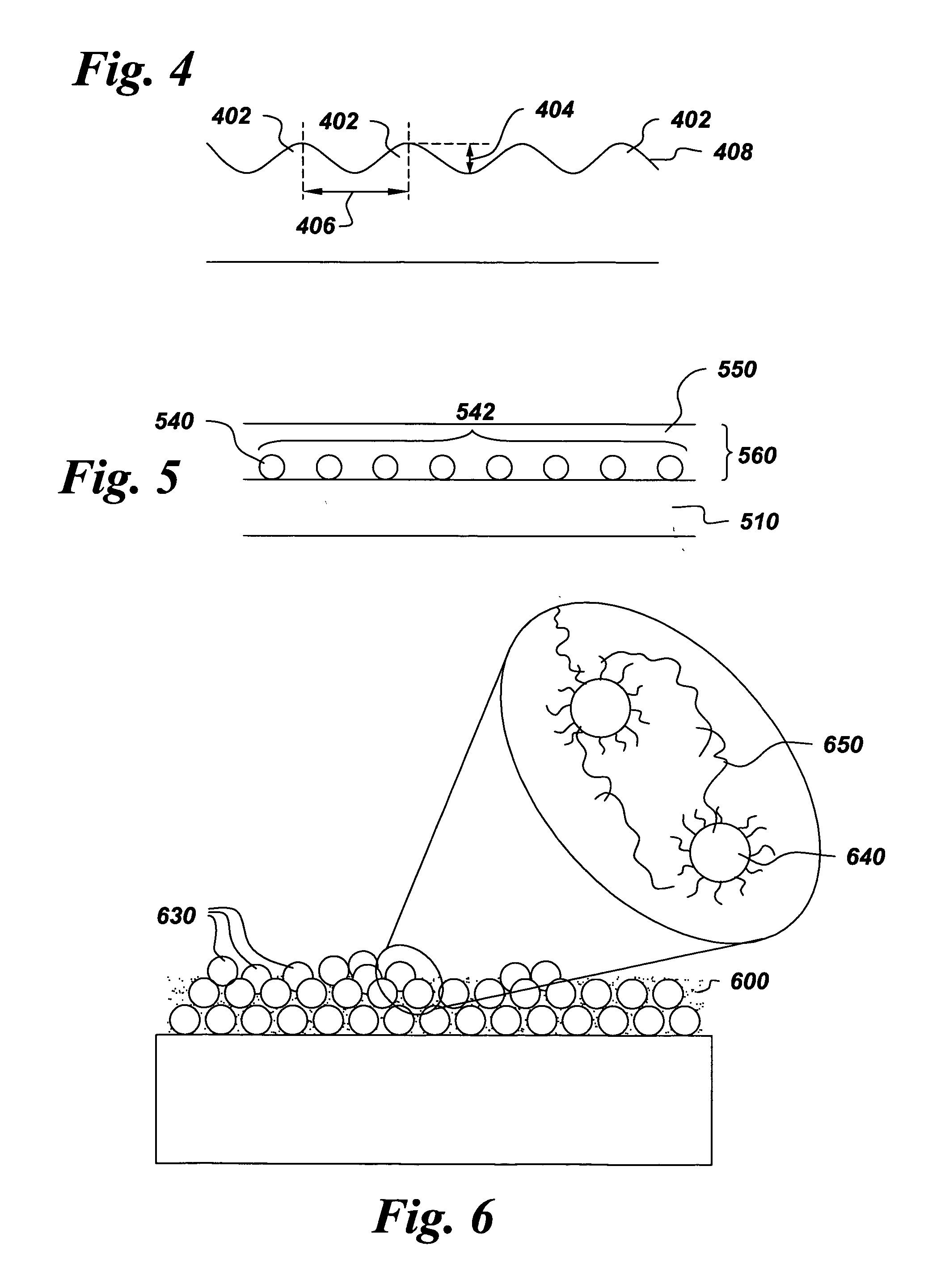

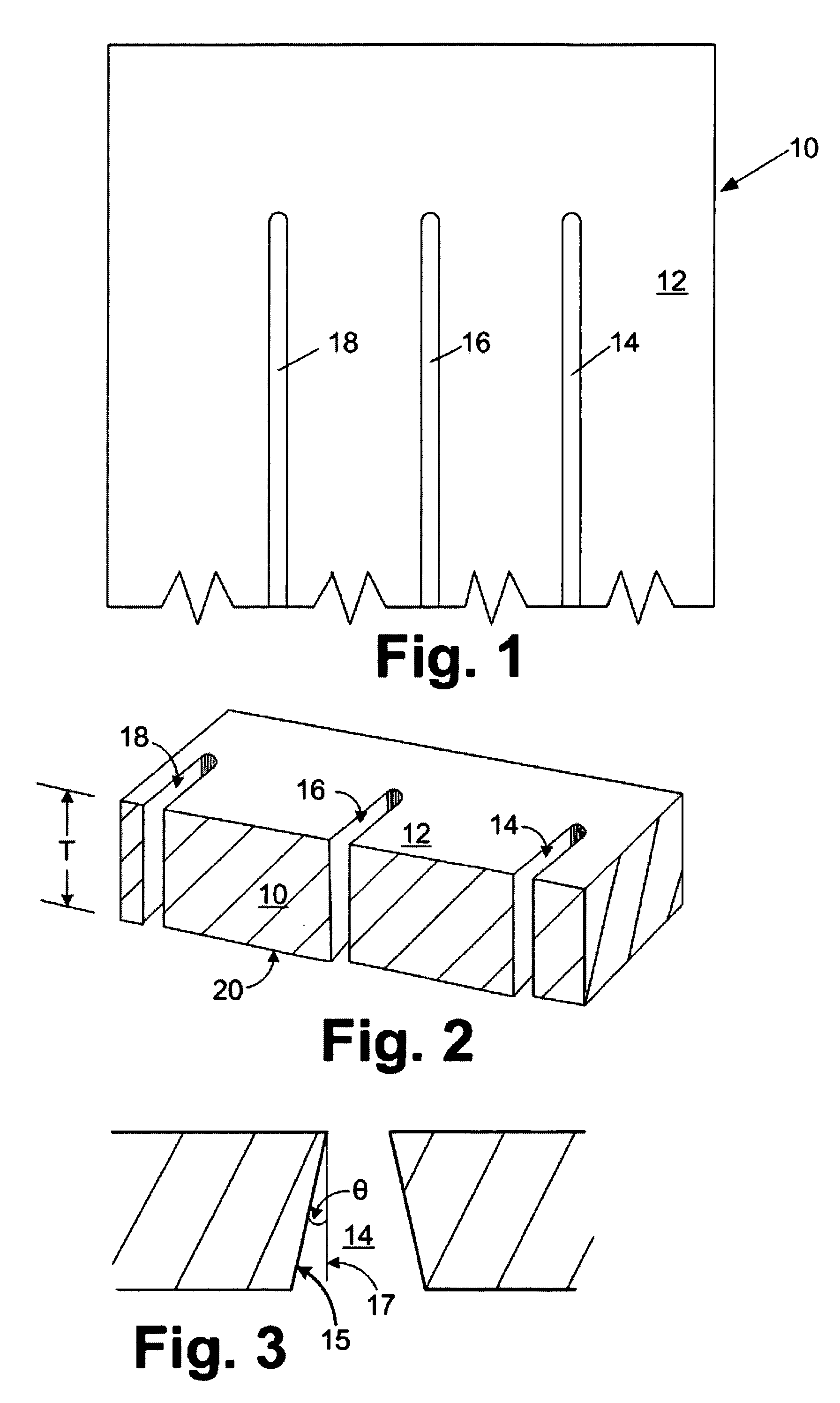

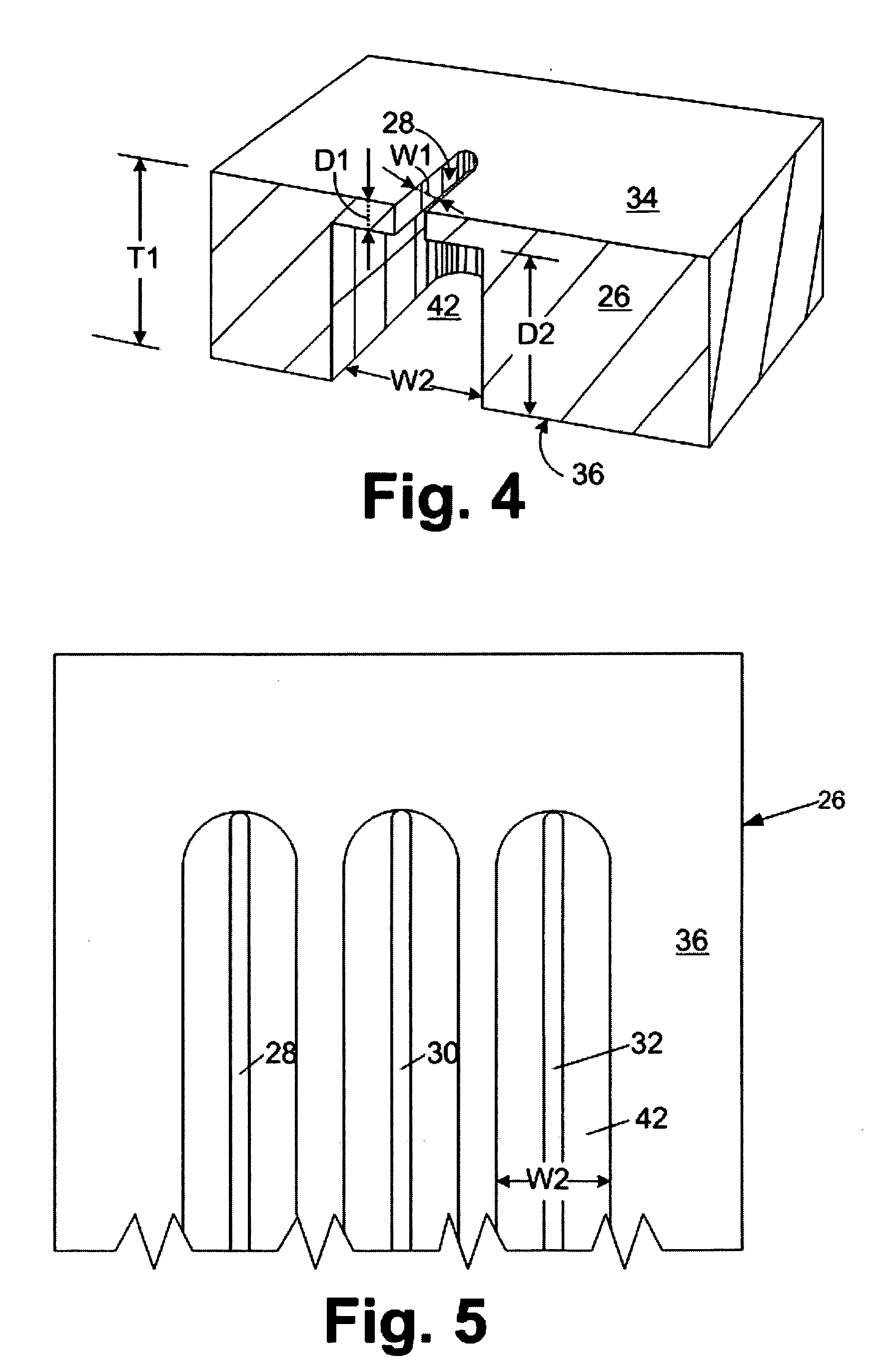

Microfluidic substrates having improved fluidic channels

ActiveUS20060077221A1Lower surface energyLow wettabilitySemiconductor/solid-state device manufacturingPrintingChemical treatmentEngineering

A method for improving fluidic flow for a microfluidic device having a through hole or slot therein. The method includes the steps of forming one or more openings through at least part of a thickness of a substrate from a first surface to an opposite second surface using a reactive ion etching process whereby an etch stop layer is applied to side wall surfaces in the one or more openings during alternating etching and passivating steps as the openings are etched through at least a portion of the substrate. Substantially all of the etch stop layer coating is removed from the side wall surfaces by treating the side wall surfaces using a method selected from chemical treatment and mechanical treatment, whereby a surface energy of the treated side wall surfaces is increased relative to a surface energy of the side wall surfaces containing the etch stop layer coating.

Owner:FUNAI ELECTRIC CO LTD

Lead-free solder with low copper dissolution

InactiveUS20070172381A1Minimize formation of oxideAdvantageously producedWelding/cutting media/materialsSoldering mediaDissolutionImpurity

Lead-free solder compositions suitable for joining electronic devices to printed wiring boards, which comprises by weight 0.2 to 0.9% copper, 0.006 to 0.07% nickel, 0.03 to 0.08% bismuth, less than 0.5% silver, less than 0.010% phosphorus, and a balance of tin and inevitable impurities. A solder composition embodying this invention finds particular application in automated wave-soldering machines where conventional lead-free solders dissolve excessive copper from printed wiring circuitry and component terminations.

Owner:KESTER

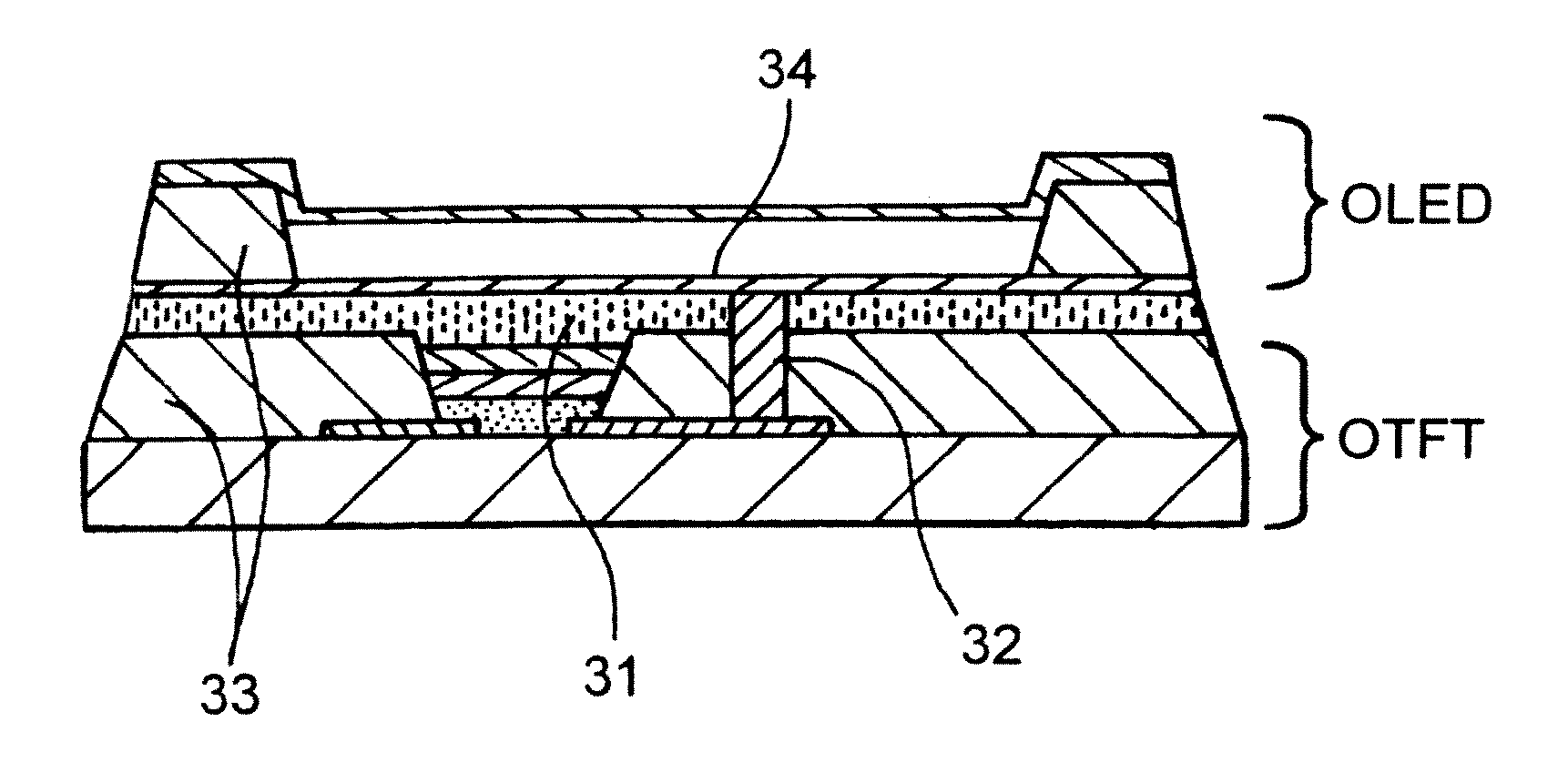

Organic Electronic Devices and Methods of Making the Same Using Solution Processing Techniques

InactiveUS20110180907A1Low wettabilityIncreasing time and complexity and expenseElectroluminescent light sourcesSolid-state devicesSemiconductor materialsConductive materials

Owner:CAMBRIDGE DISPLAY TECH LTD

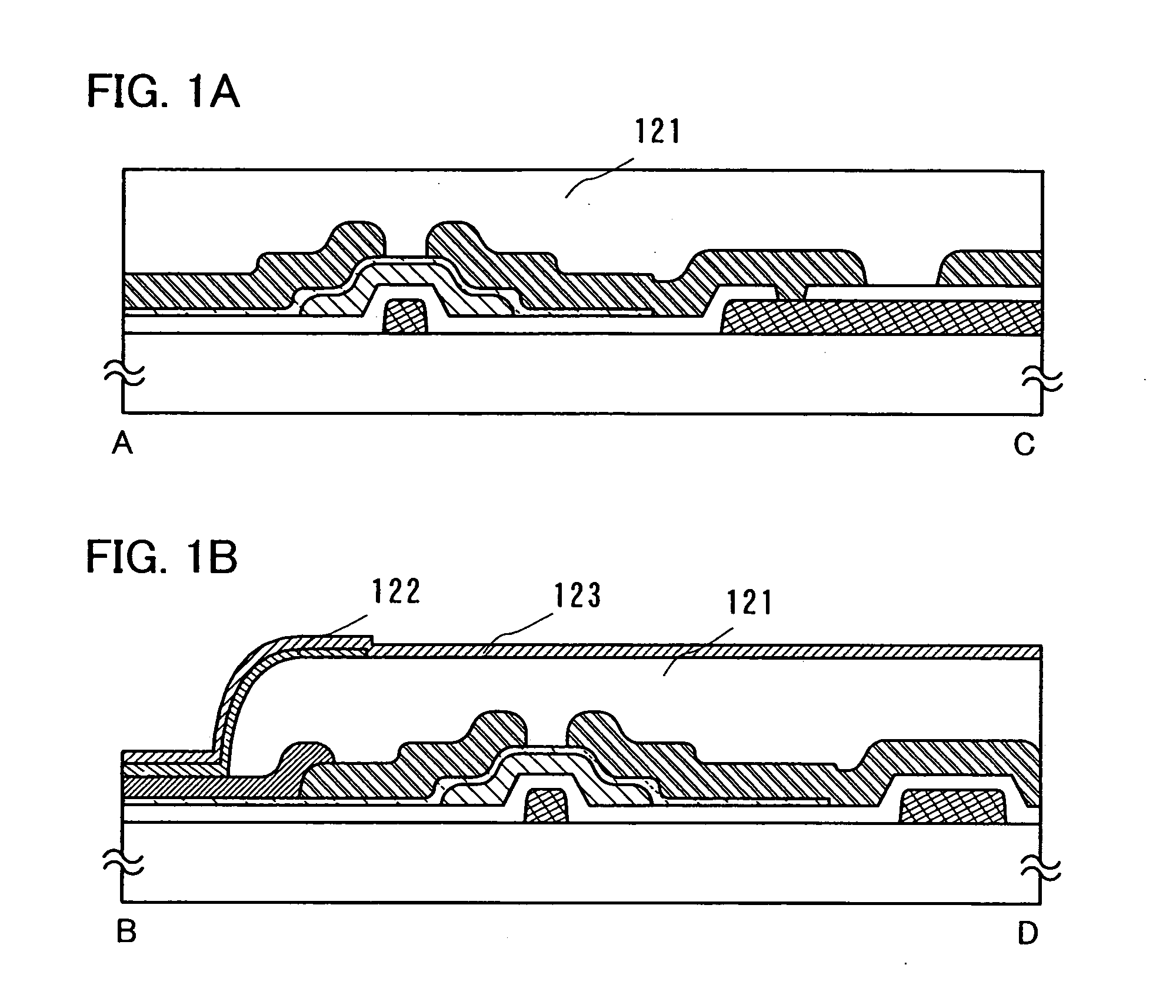

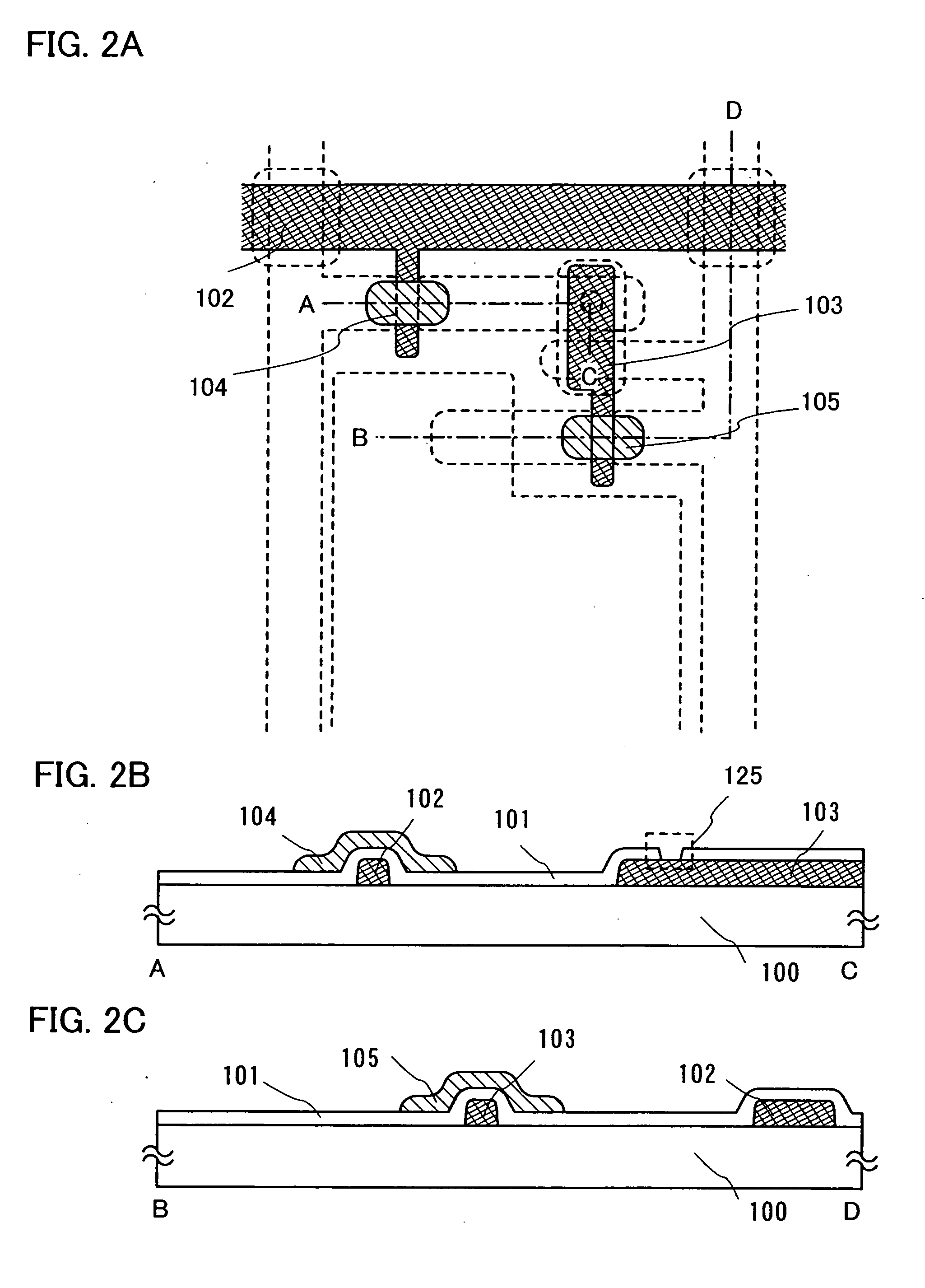

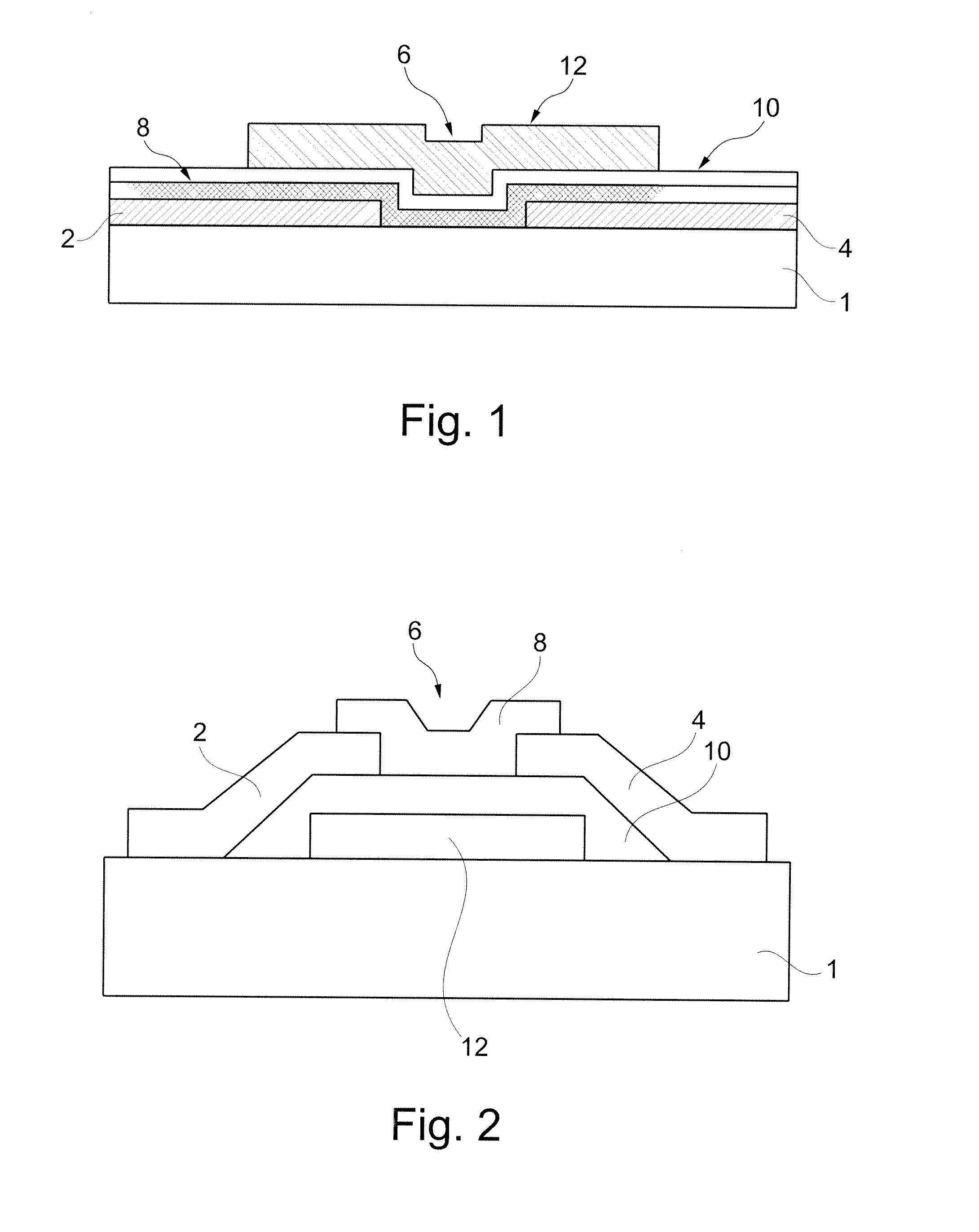

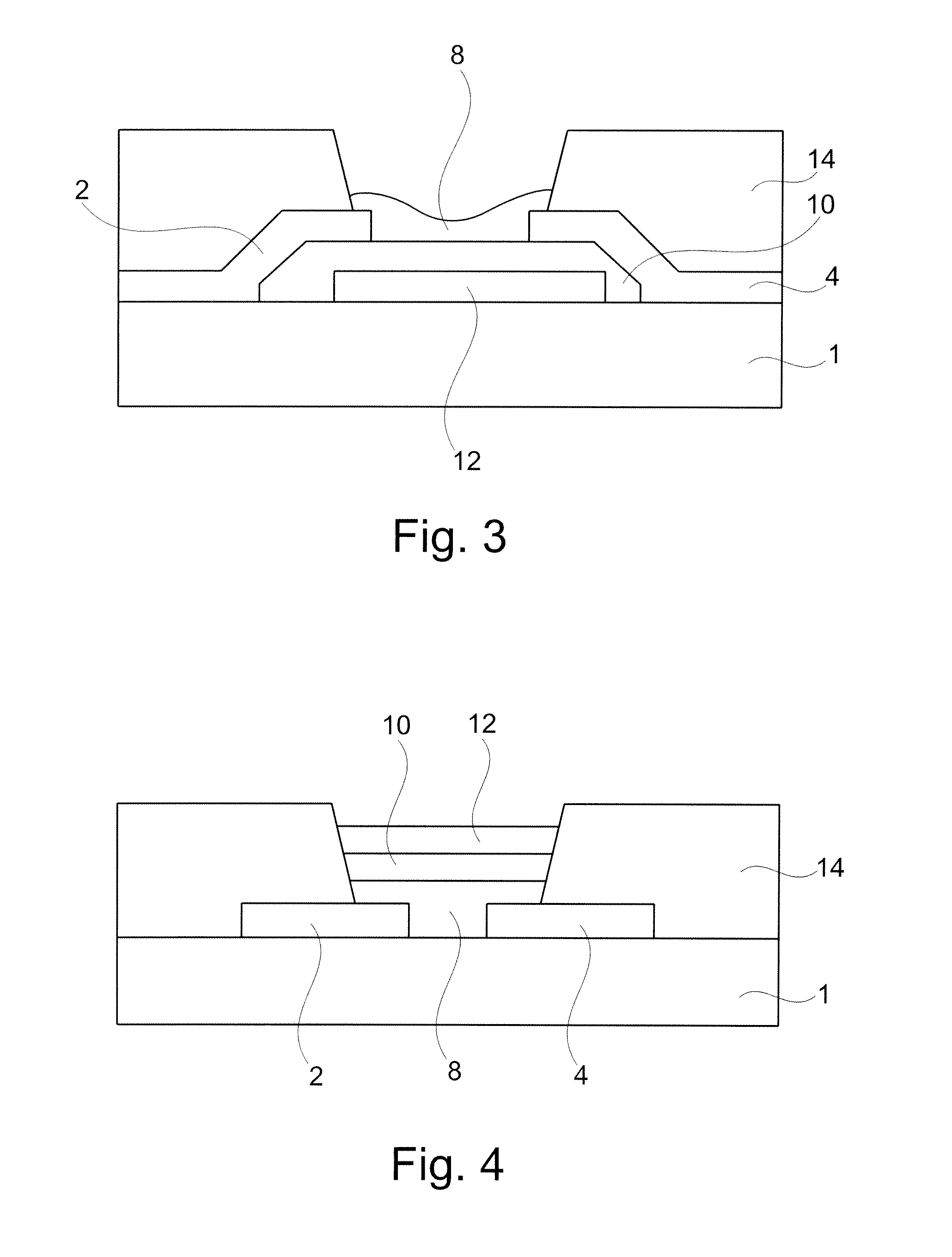

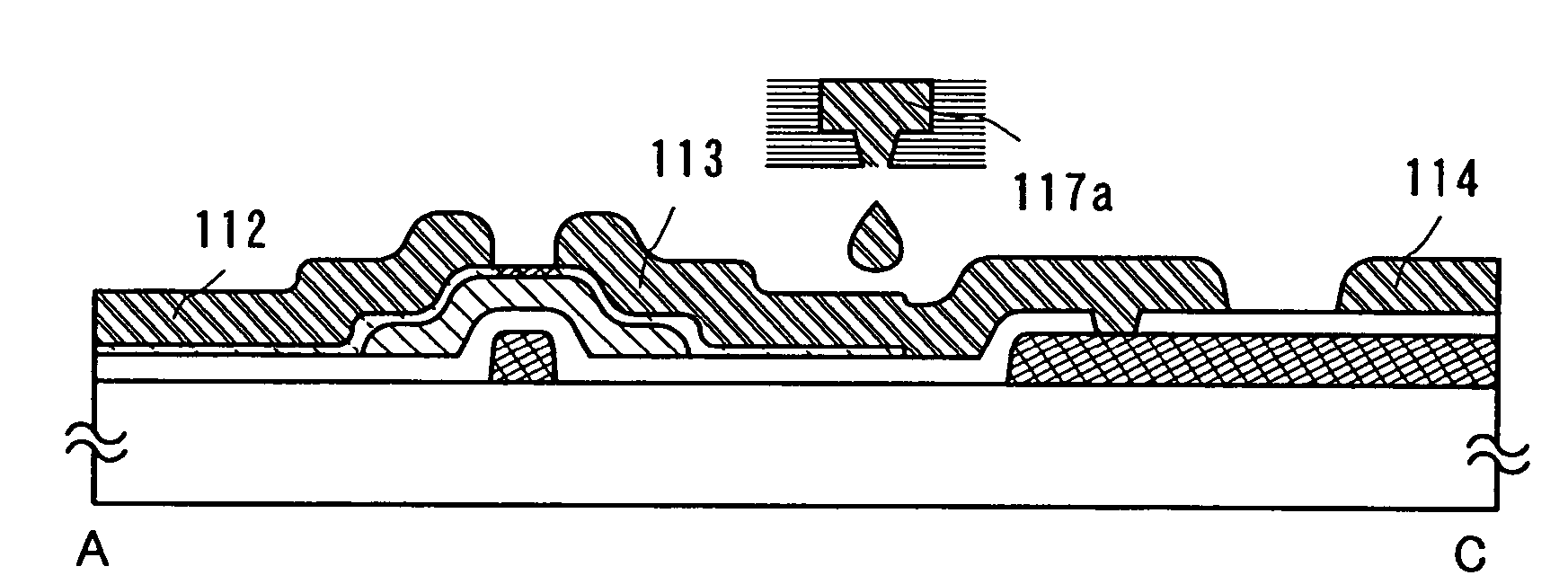

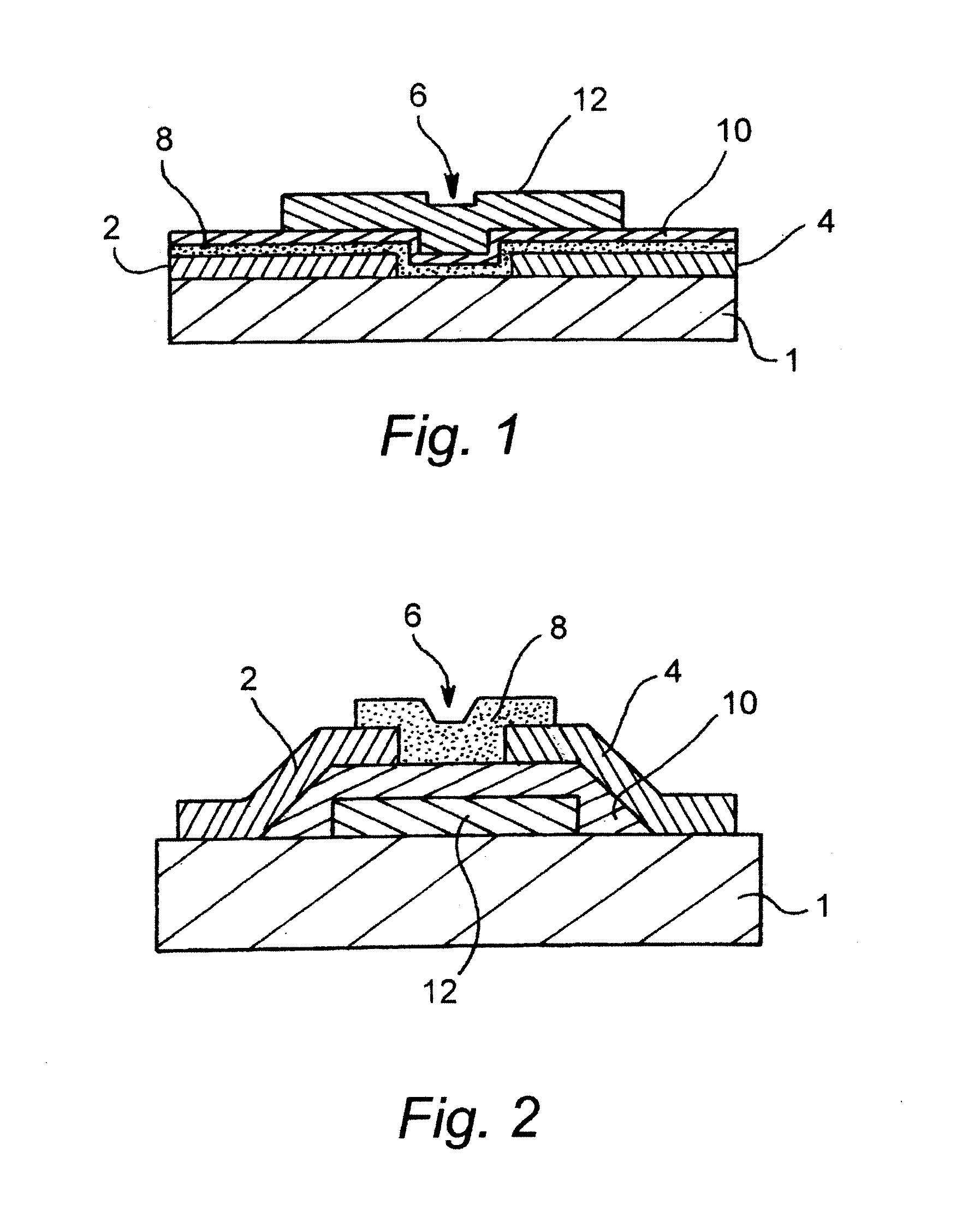

Thin Film Transistor and Display Device, and Method for Manufacturing Thereof

InactiveUS20080315428A1Low wettabilityLow related substancesTransistorLiquid surface applicatorsDisplay deviceEngineering

The present invention discloses a display device and a manufacturing method thereof by which a manufacturing process can be simplified. Further, the present invention discloses technique for manufacturing a pattern such as a wiring into a desired shape with good controllability. A method for forming a pattern for constituting the display device according to the present invention comprises the steps of forming a first region and a second region; discharging a composition containing a pattern formation material to a region across the second region and the first region; and flowing a part of the composition discharged to the first region into the second region; wherein wettability with respect to the composition of the first region is lower than that of the second composition.

Owner:SEMICON ENERGY LAB CO LTD

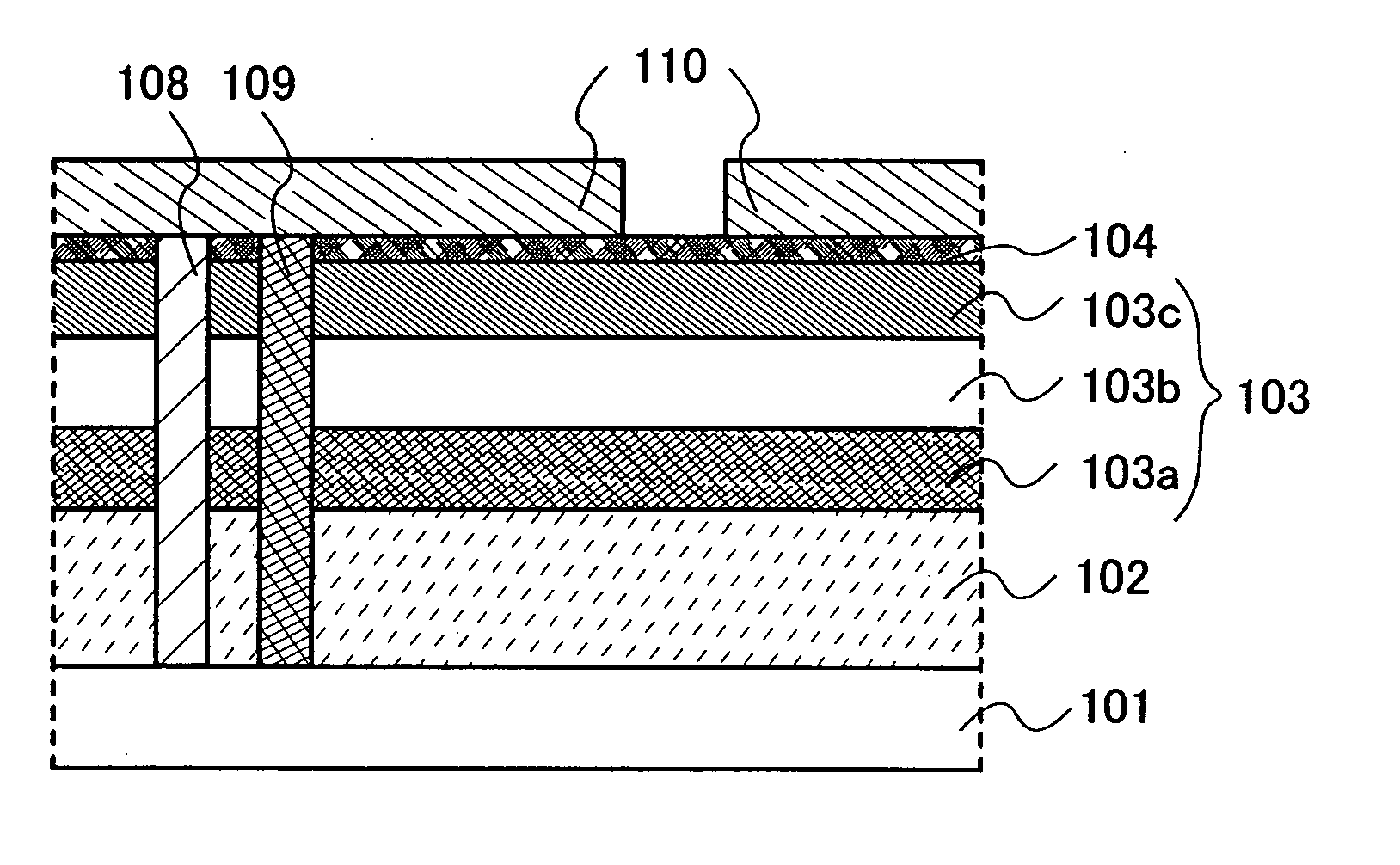

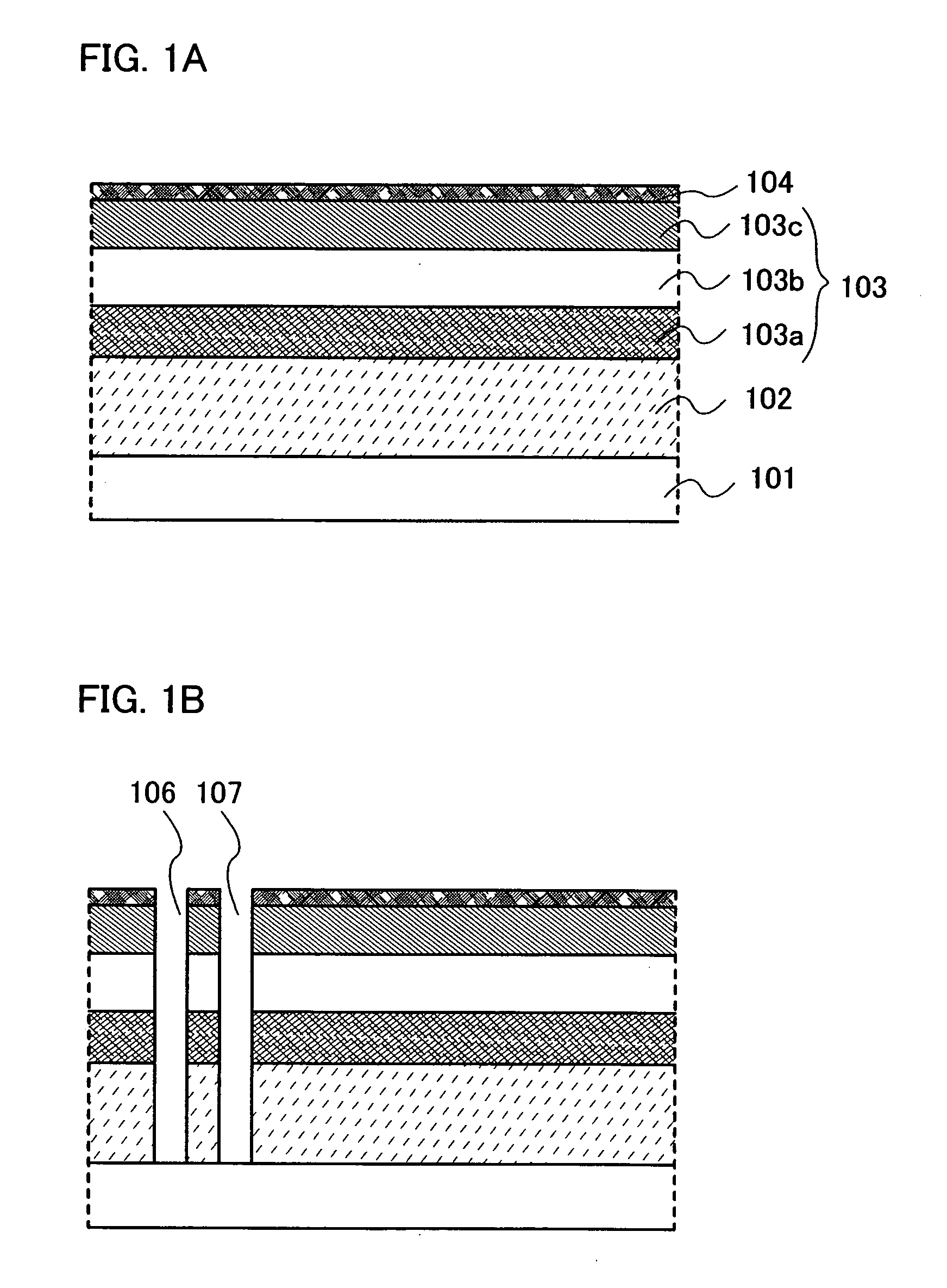

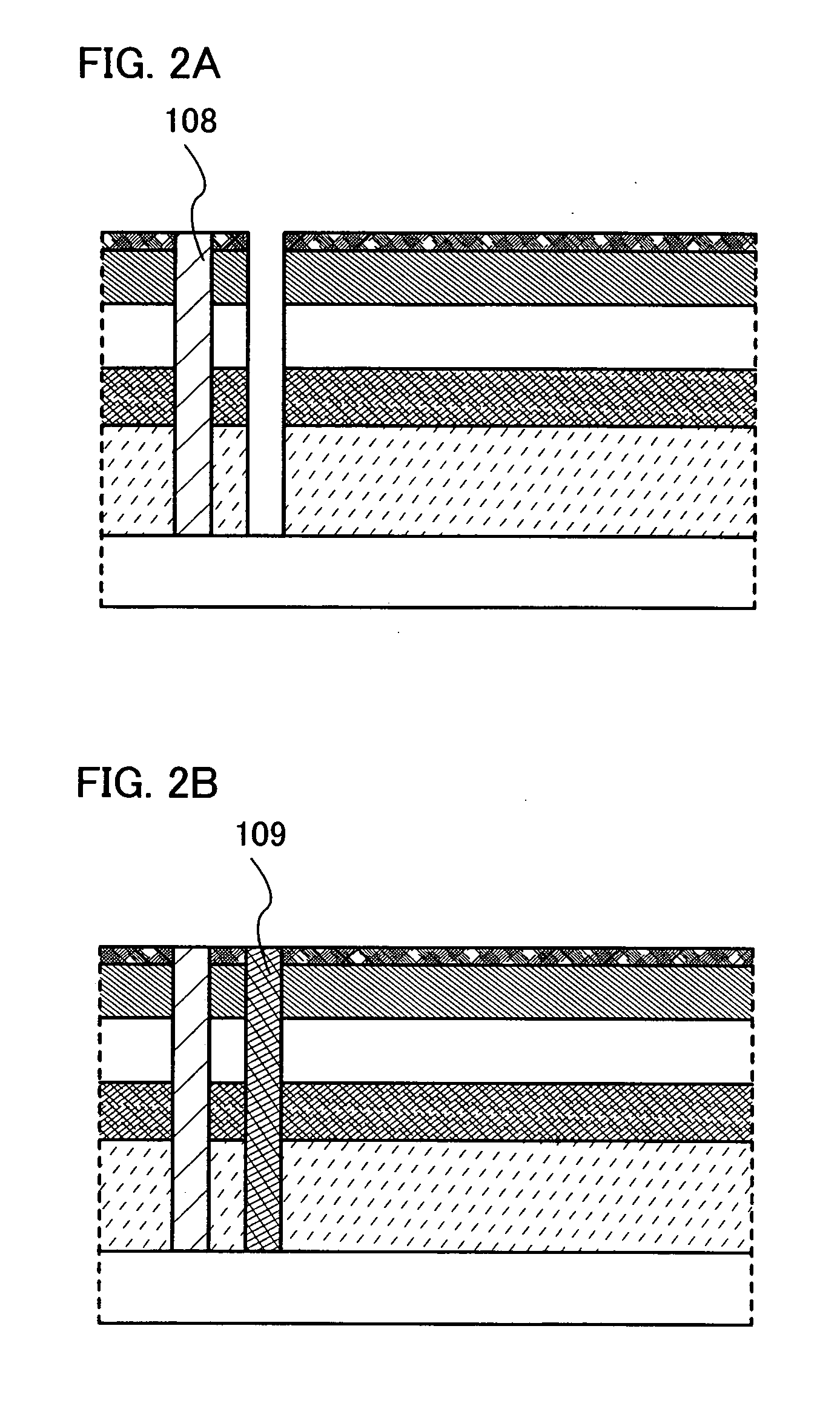

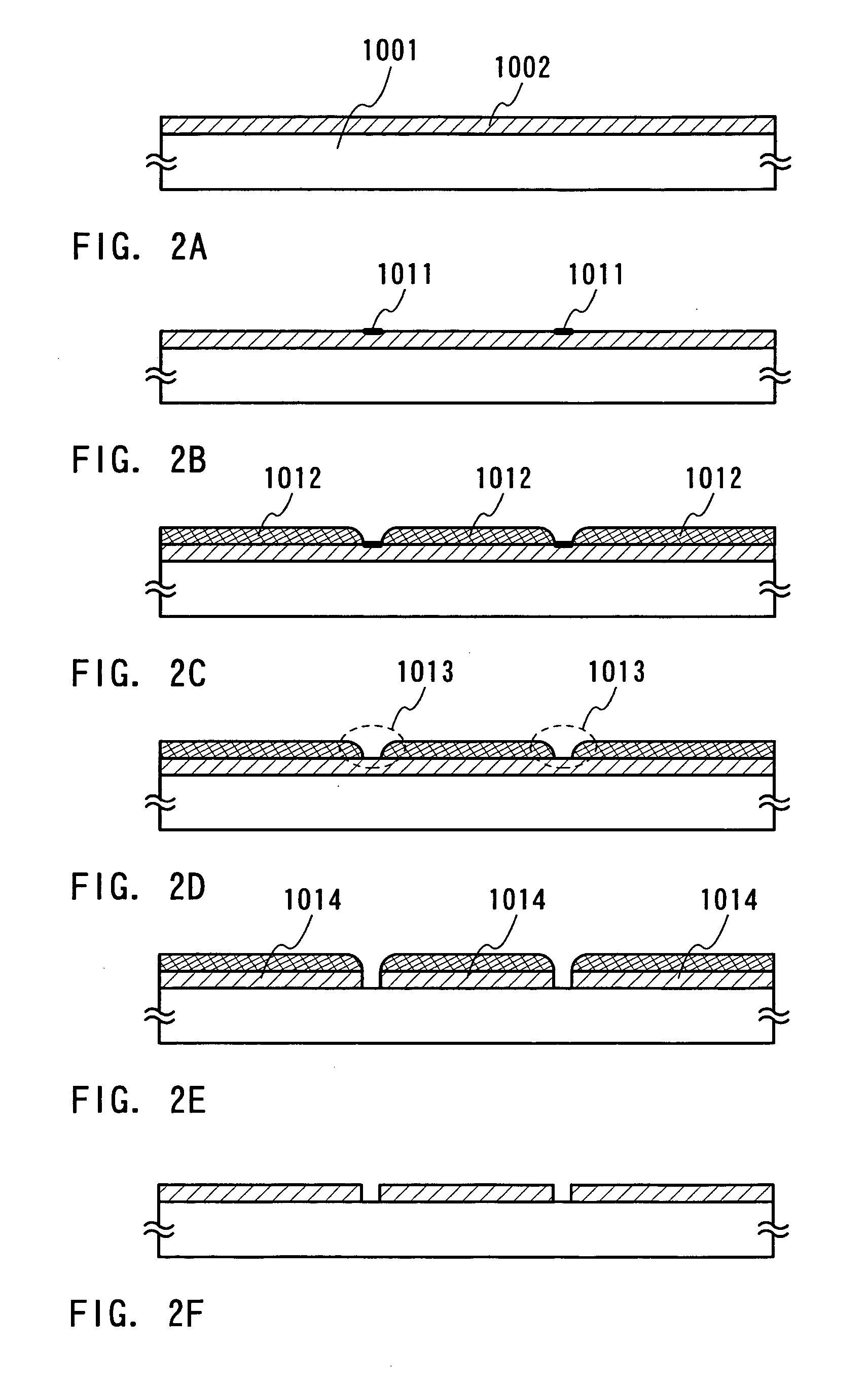

Method for manufacturing display device

InactiveUS7470604B2Reduce in quantitySimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingLight irradiationDisplay device

The present invention, the quality of the surface of a substrate is improved and the wettability thereof is controlled by light irradiation from the reverse side with respect to the substrate having the conductive layer. A conductive material or an insulating material is adhered on the modified surface by discharging it (including jetting, etc.), or the like to form a conductive layer and an insulating layer. The processing efficiency by the light can be enhanced by function of the light absorption and energy radiation of the photocatalytic substance. Furthermore, the mask layer is formed selectively on the conductive layer and the wettability of the region on the conductive layer that is a non-irradiation region is also controlled.

Owner:SEMICON ENERGY LAB CO LTD

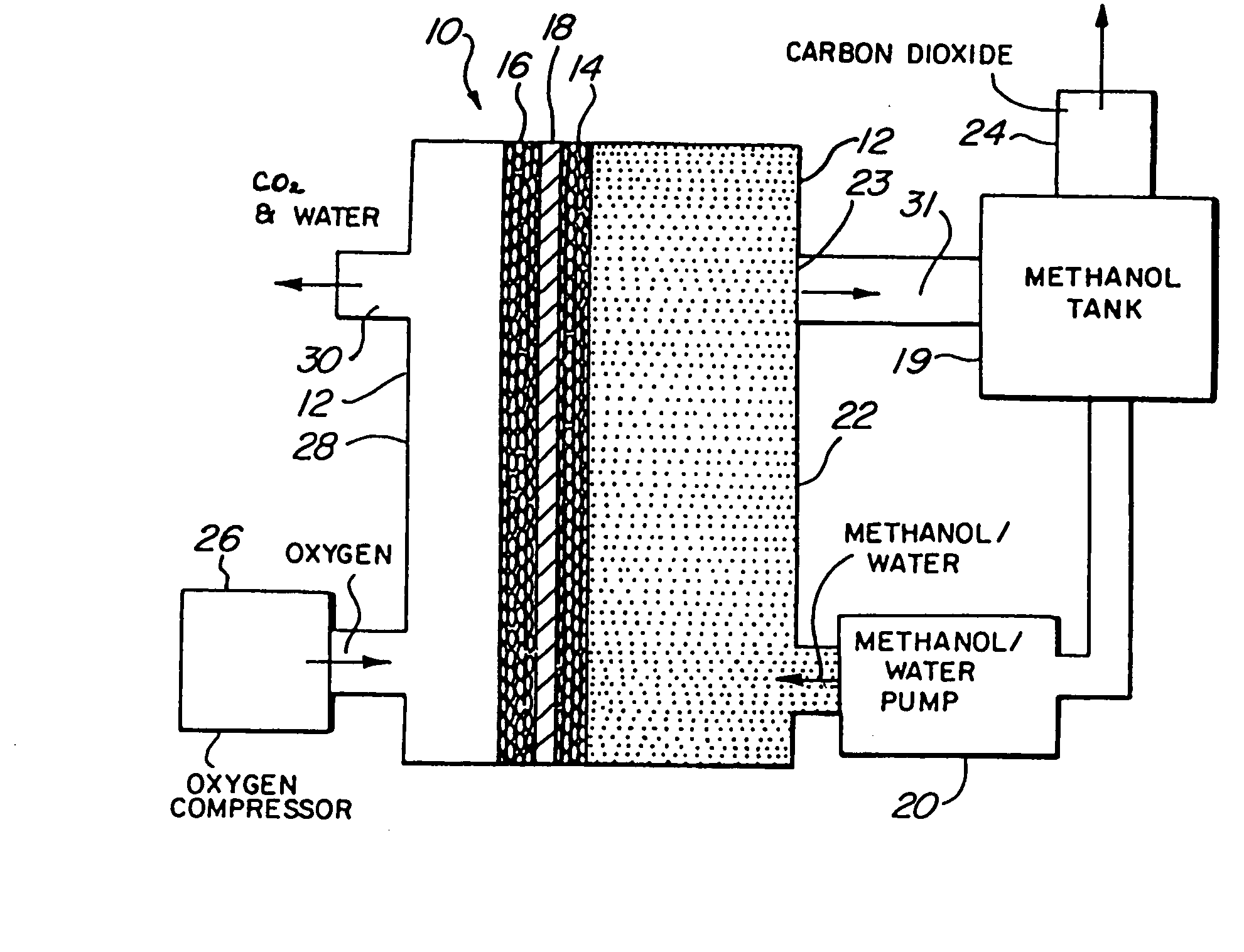

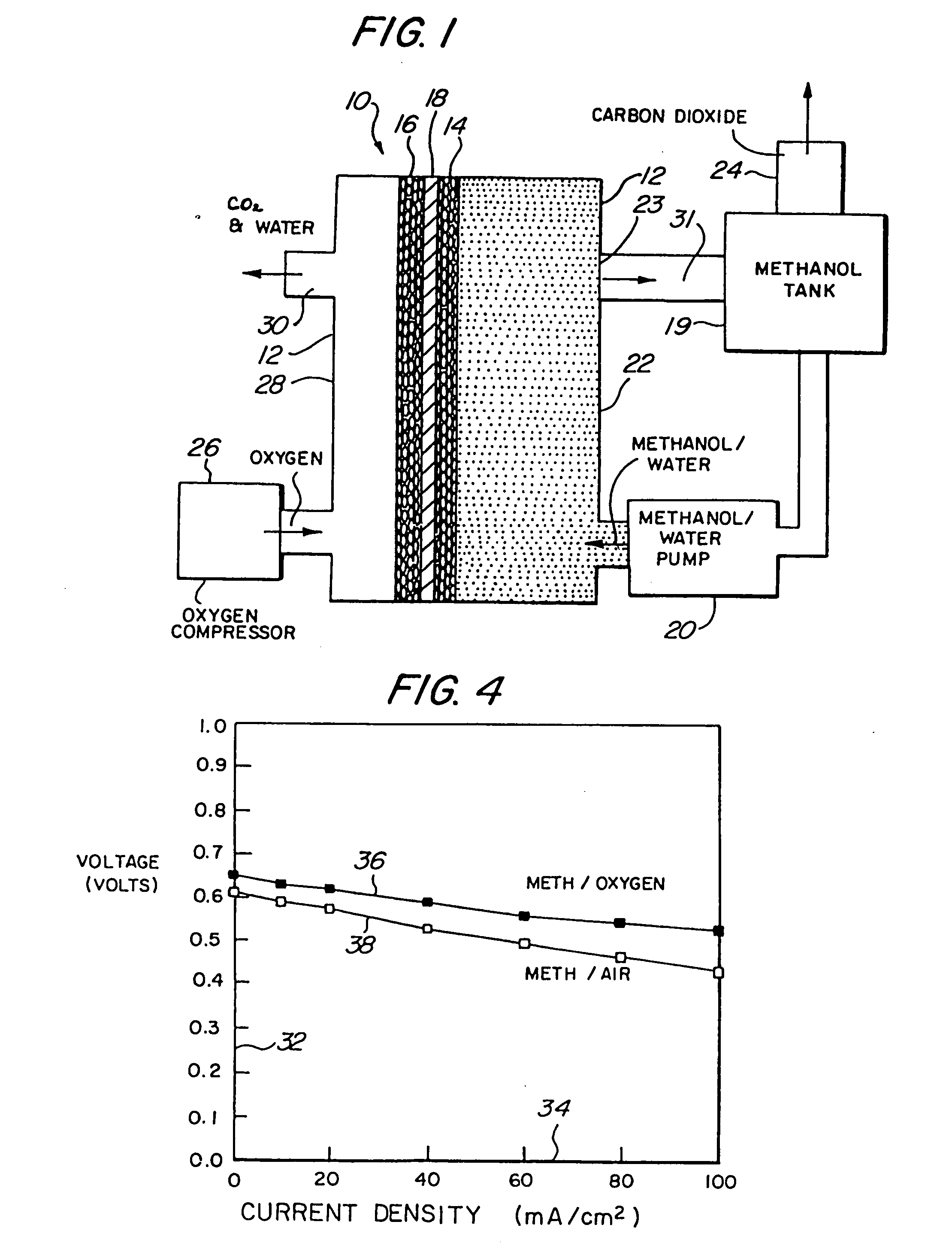

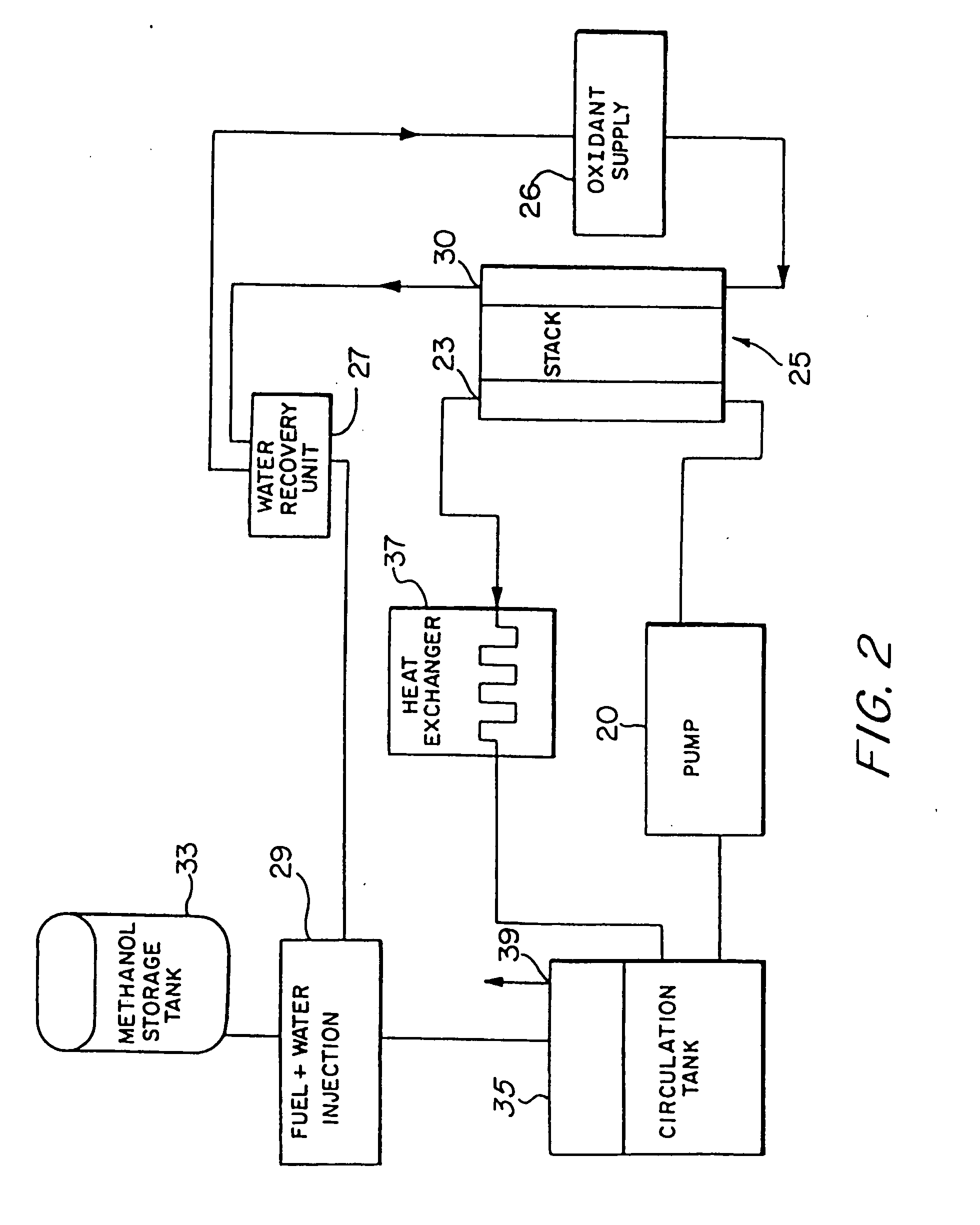

Organic fuel cell methods and apparatus

InactiveUS20060204810A1Poor fuel wetting propertyImprove wettabilitySolid electrolytesFuel cells groupingElectrical batteryOrganic fuel

A liquid organic, fuel cell is provided which employs a solid electrolyte membrane. An organic fuel, such as a methanol / water mixture, is circulated past an anode of a cell while oxygen or air is circulated past a cathode of the cell. The cell solid electrolyte membrane is preferably fabricated from Nafion™. Additionally, a method for improving the performance of carbon electrode structures for use in organic fuel cells is provided wherein a high surface-area carbon particle / Teflon™-binder structure is immersed within a Nafion™ / methanol bath to impregnate the electrode with Nafion™. A method for fabricating an anode for use in a organic fuel cell is described wherein metal alloys are deposited onto the electrode in an electro-deposition solution containing perfluorooctanesulfonic acid. A fuel additive containing perfluorooctanesulfonic acid for use with fuel cells employing a sulfuric acid electrolyte is also disclosed. New organic fuels, namely, trimethoxymethane, dimethoxymethane, and trioxane are also described for use with either conventional or improved fuel cells.

Owner:CALIFORNIA INST OF TECH +1

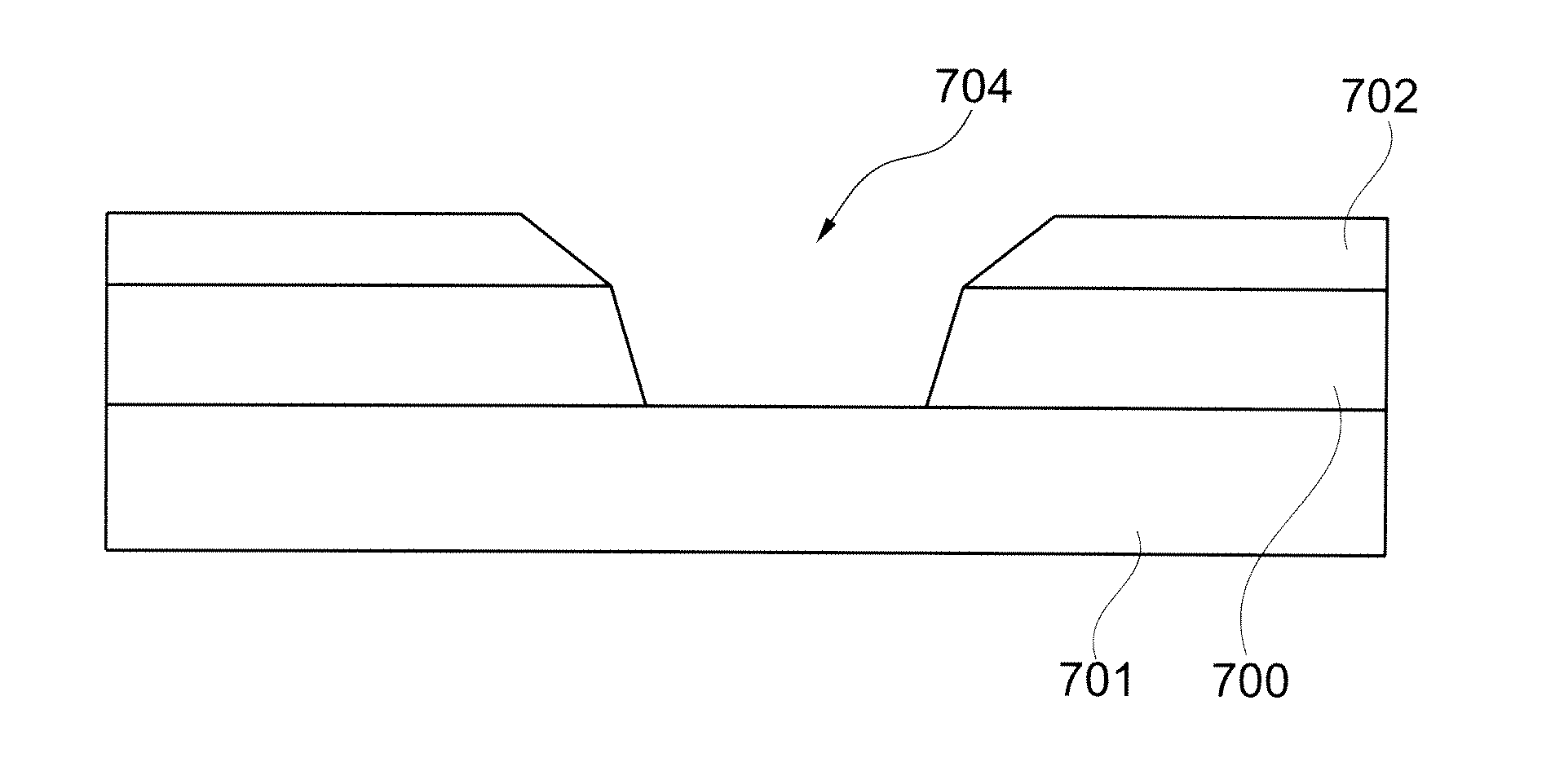

Electronic Devices and Methods of Making the Same Using Solution Processing Techniques

ActiveUS20110042656A1Cheap and effective method of formDecrease wettabilityTransistorSolid-state devicesEngineeringOrganic semiconductor

An electronic device comprising: an electronic substrate comprising circuit elements; a double bank well-defining structure disposed over the electronic substrate, the double bank well-defining structure comprising a first layer of insulating material and a second layer of insulating material thereover, the second layer of insulating material having a lower wettability than the first layer of insulating material; and organic semiconductive material disposed in wells defined by the double bank well-defining structure.

Owner:CAMBRIDGE DISPLAY TECH LTD

Electronic Devices and Methods of Making Them Using Solution Processing Techniques

InactiveUS20110101317A1Low wettabilityImprove surface wettabilityElectroluminescent light sourcesSolid-state devicesEngineeringElectron

A method of manufacturing an electronic device comprises: providing a base comprising circuit elements; forming a double bank well-defining structure over the base, comprising a first layer of insulating material and a second layer of insulating material thereover; and depositing a solution of organic material in the well defined by the double bank structure. The double bank well-defining structure is formed by removing material from the first and second layers in a single processing step to form the well. The first layer is made of a material which is removed at a faster rate than material of the second layer to form an overhanging step structure in which the second layer protrudes out over an edge of the first layer.

Owner:CAMBRIDGE DISPLAY TECH LTD

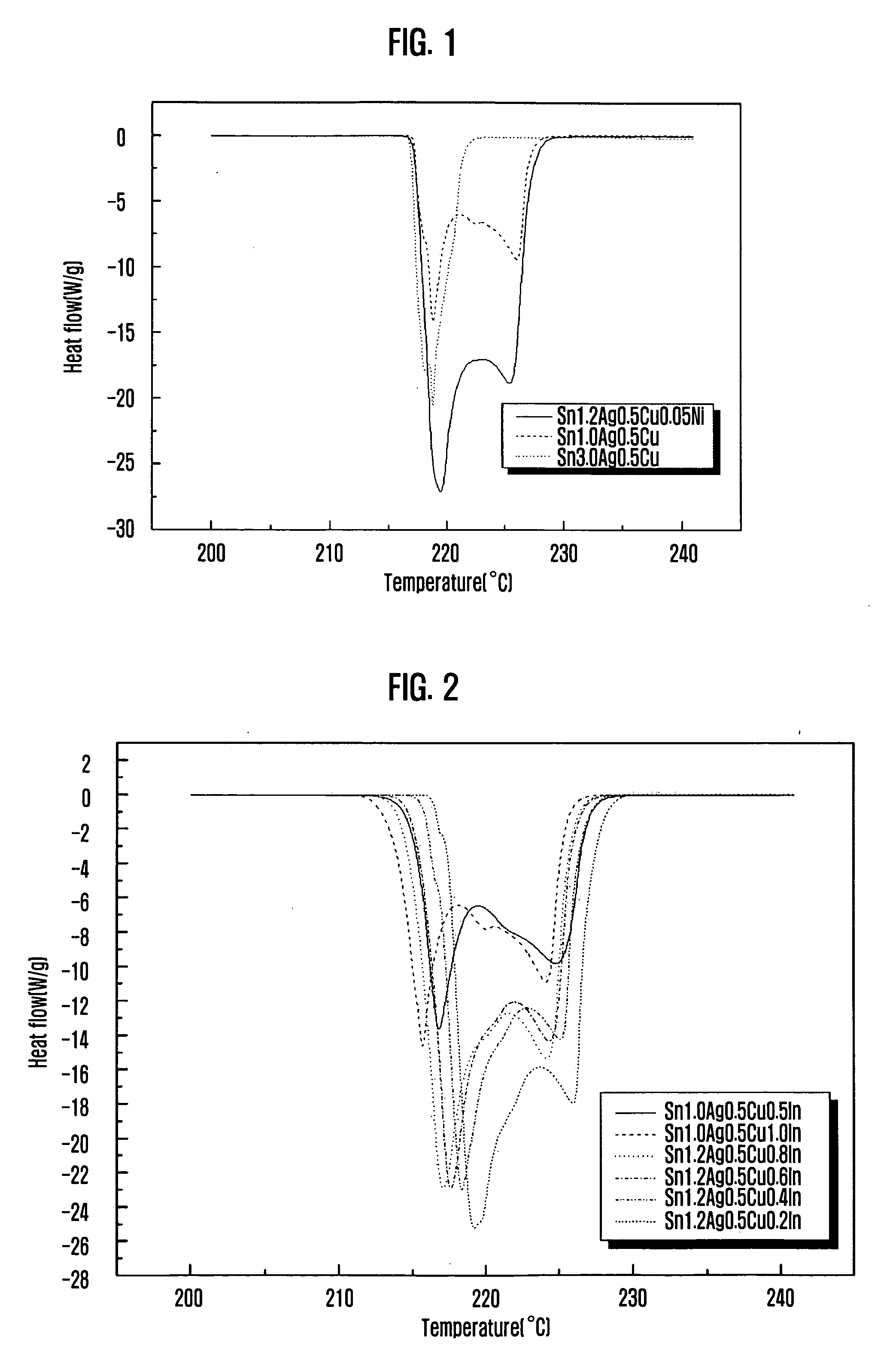

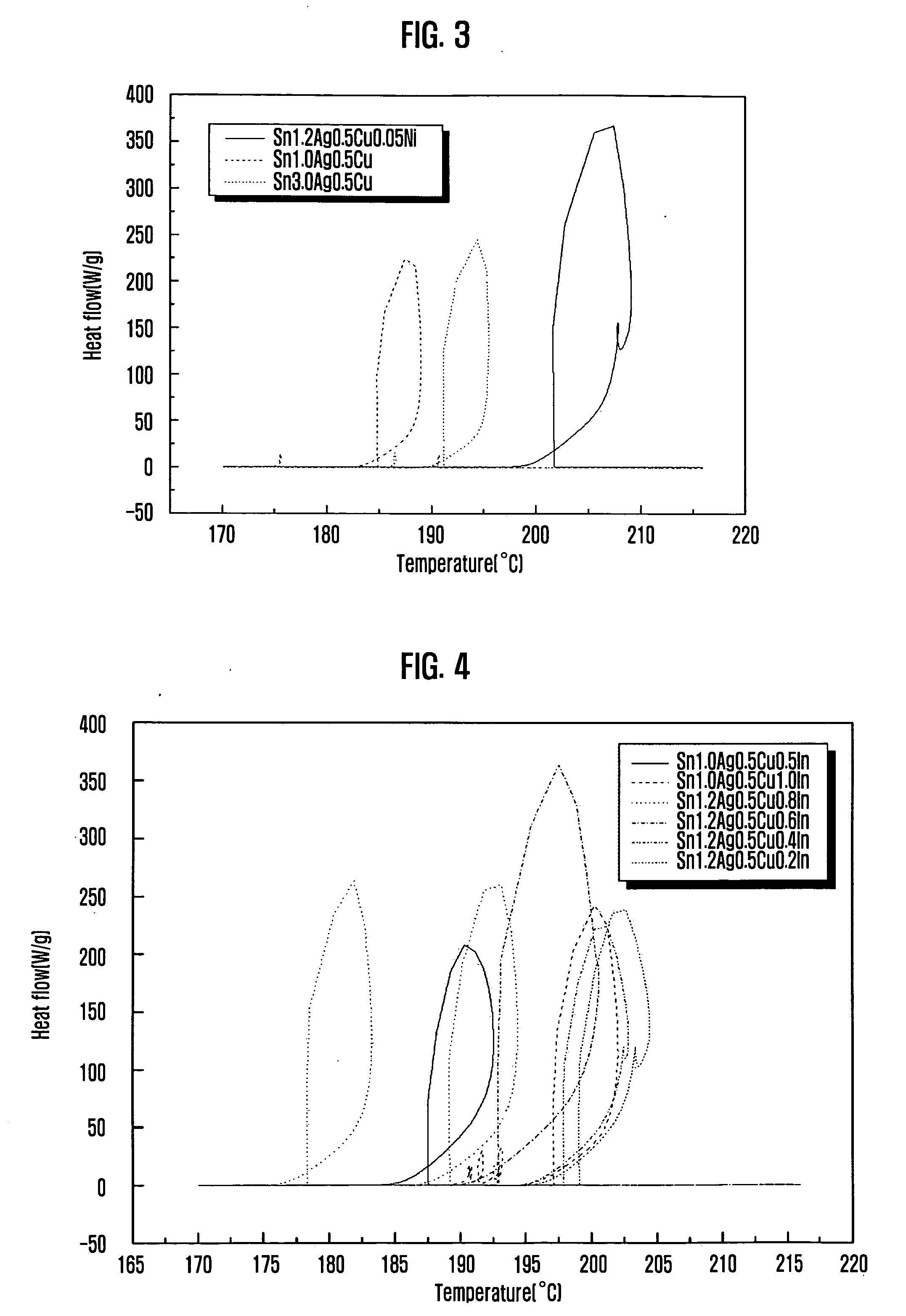

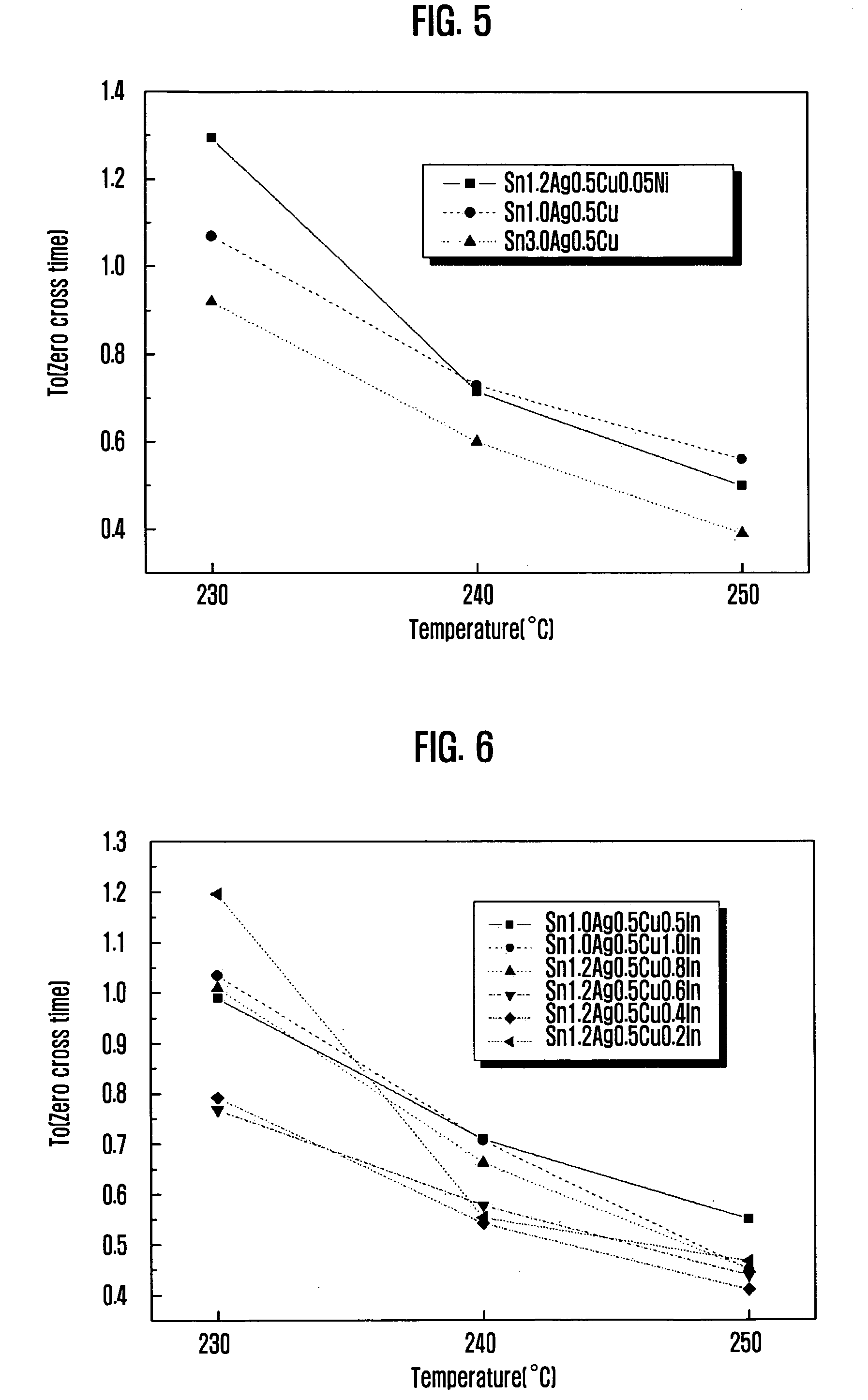

Quaternary Pb-free solder composition incorporating Sn-Ag-Cu-In

InactiveUS20080292493A1Reduce manufacturing costImprove reliabilityWelding/cutting media/materialsSoldering mediaIndiumMechanical impact

Provided is a quaternary Pb-free solder composition incorporating Sn—Ag—Cu—In, which can prevent a cost increase and sufficiently ensure proccessability and mechanical property as a solder material. To this end, indium (In) with appropriate amount is added into the Pb-free solder composition, and the addition amount of Ag is optimized, thus preventing a decrease in wettability caused by a decrease in the amount of Ag and improving resistance to a thermal cycling and a mechanical impact. The quaternary Pb-free solder composition includes silver (Ag) of about 0.3 wt. % or more, and less than about 2.5 wt. %, copper (Cu) of about 0.2 wt. % or more, and less than about 2.0 wt. %, indium (In) of about 0.2 wt. % or more, and less than about 1.0 wt. % or less, and a balance of tin (Sn).

Owner:KOREA INST OF IND TECH

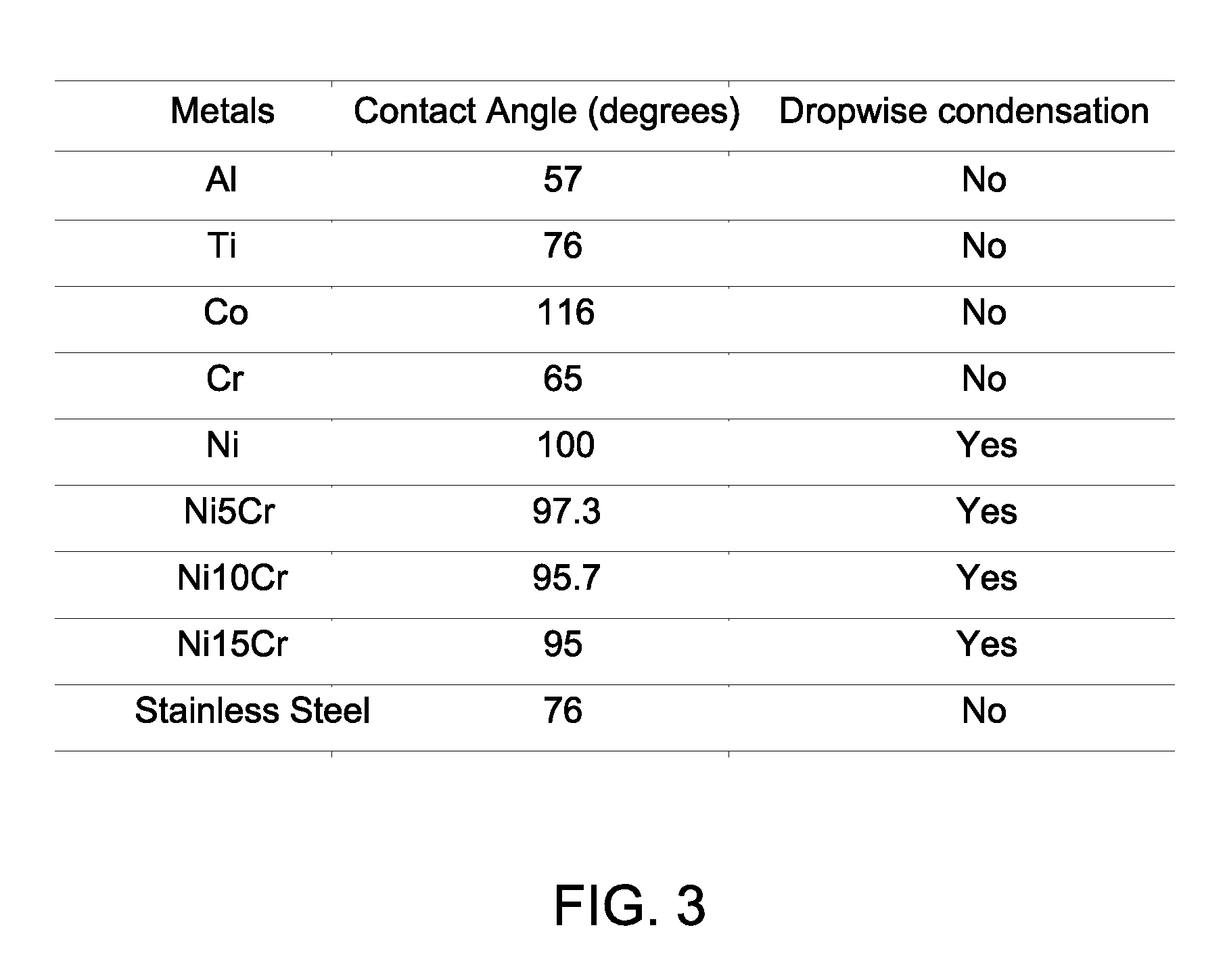

Wetting resistant material and articles made therewith

ActiveUS20100143620A1Increased durabilityLow liquid wettabilityTurbinesRecord information storageNiobiumNitrogen

An article coated with a highly durable, wetting resistant coating is provided. The article comprises a coating that comprises a cermet material. The cermet material includes a nickel-bearing metal matrix and a phase disposed within the matrix. The phase includes an anion moiety, for example nitrogen, carbon, or boron; and a cation moiety, for example chromium, zirconium, titanium, vanadium, hafnium, niobium, or tantalum. The phase is present in the cermet at a level of at least about 5 volume %.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com