Quaternary Pb-free solder composition incorporating Sn-Ag-Cu-In

a technology of sn-ag-cu-in and pb-free solder, which is applied in the direction of welding/cutting media/materials, manufacturing tools, and soldering apparatus, etc., can solve the problems that the pb-free solder composition does not meet the above conditions, and achieves the effects of reducing the amount of ag, improving reliability, and saving fabrication costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

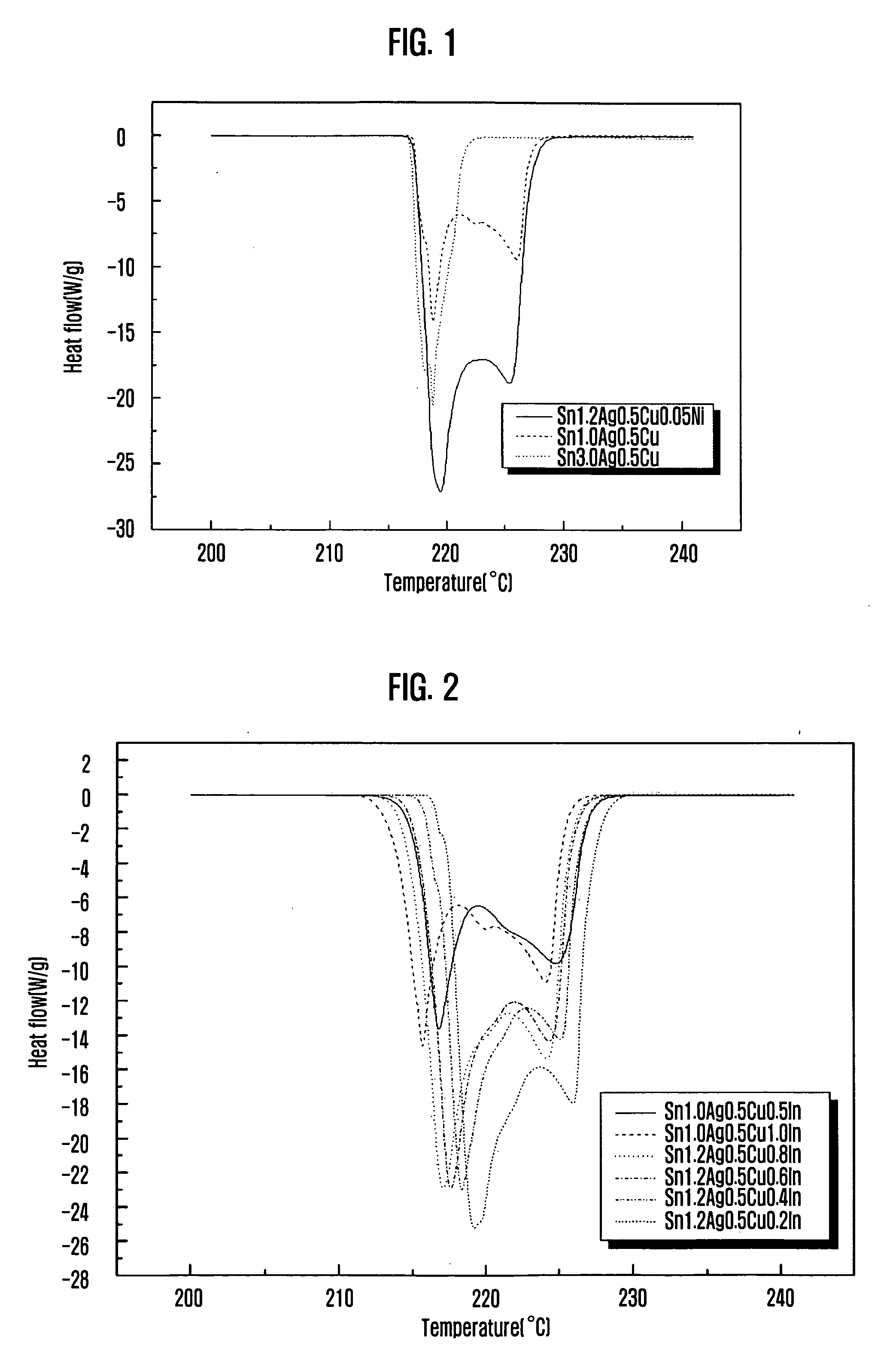

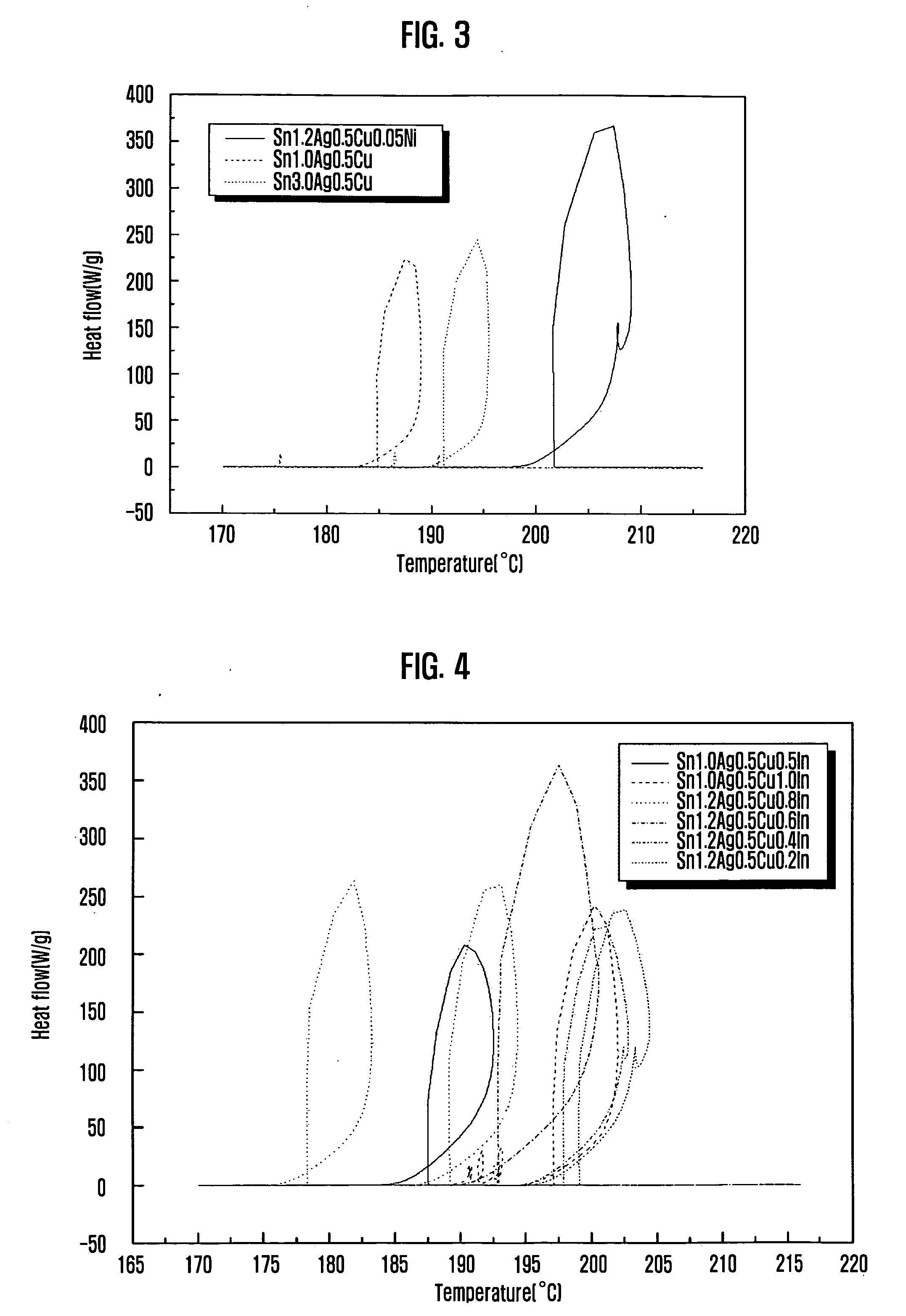

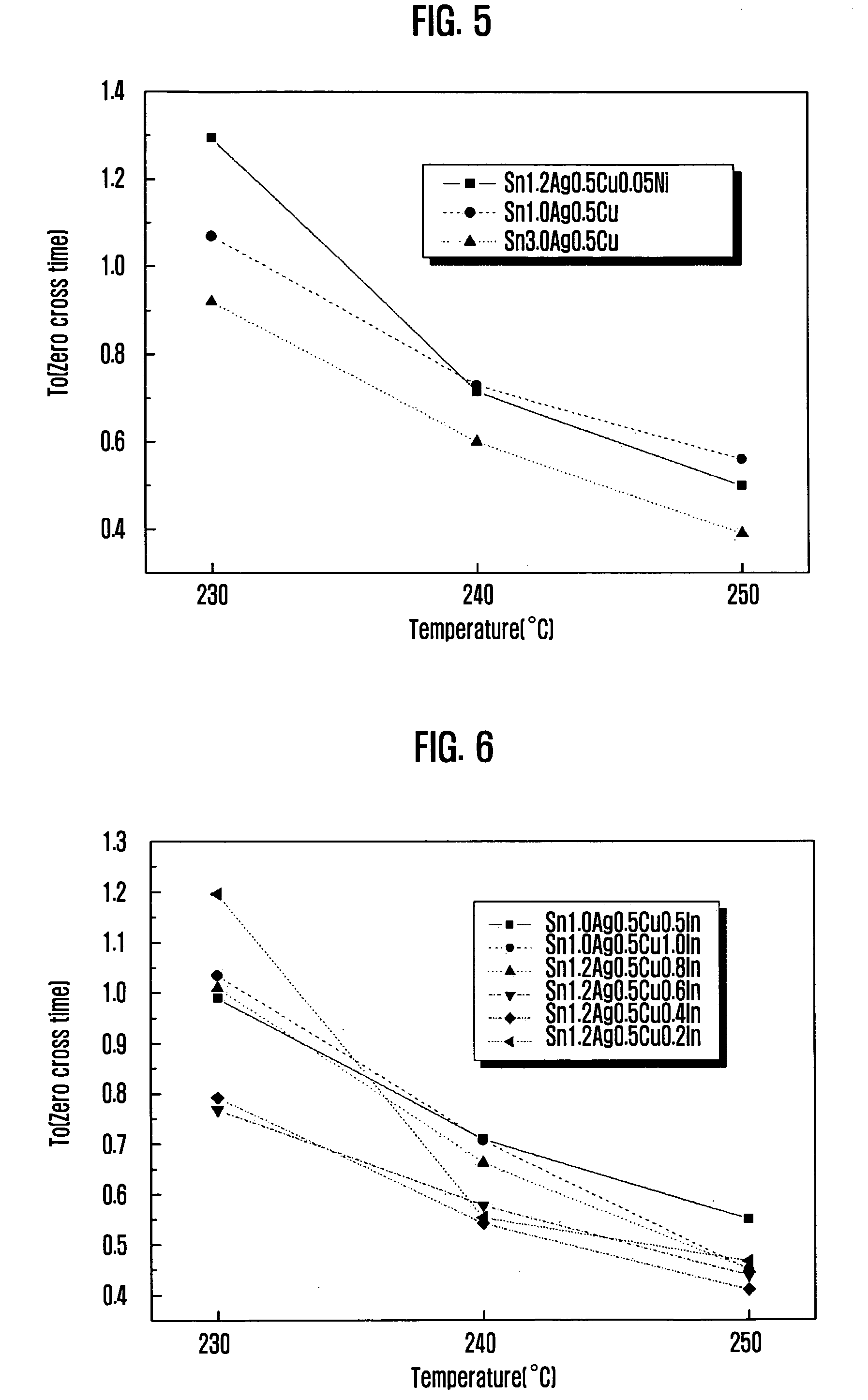

[0032]Hereinafter, a quaternary lead (Pb)-free composition incorporating tin-silver-copper-indium (Sn—Ag—Cu—In) in accordance with the present invention will be described in detail with reference to the accompanying drawings. Herebelow, specific descriptions for a related well-known function or construction will be omitted when it is deemed that they make the gist of the present invention vague unnecessarily.

[0033]In a Pb-free solder composition of the present invention, the weight percent of Ag is less than about 2.5 wt. % but not less than about 0.3 wt. %. If the weight percent of Ag is less than 0.3 wt. %, a liquidus temperature hardly drops, leading to an increase in a melting point of a solder and a packaging process temperature. On the contrary, if the weight percent of Ag is 2.5 wt. % or more, the fabrication cost increases unfavorably. Consequently, the weight percent of Ag should be less than about 2.5 wt. % but not less than about 0.3 wt. %, preferably about 1.2 wt. %.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Mechanical properties | aaaaa | aaaaa |

| Interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com