Patents

Literature

287 results about "Interfacial reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

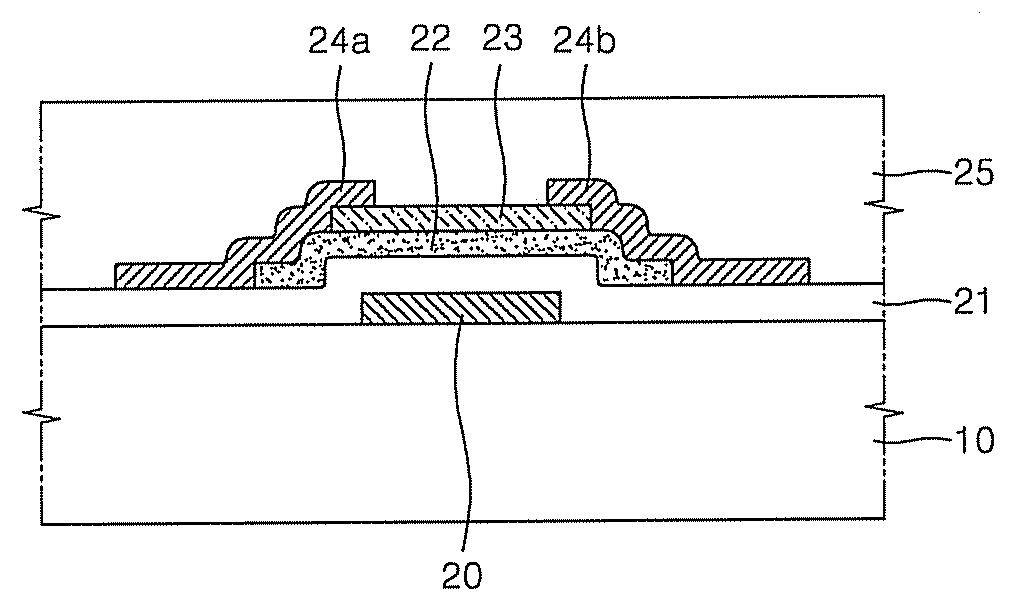

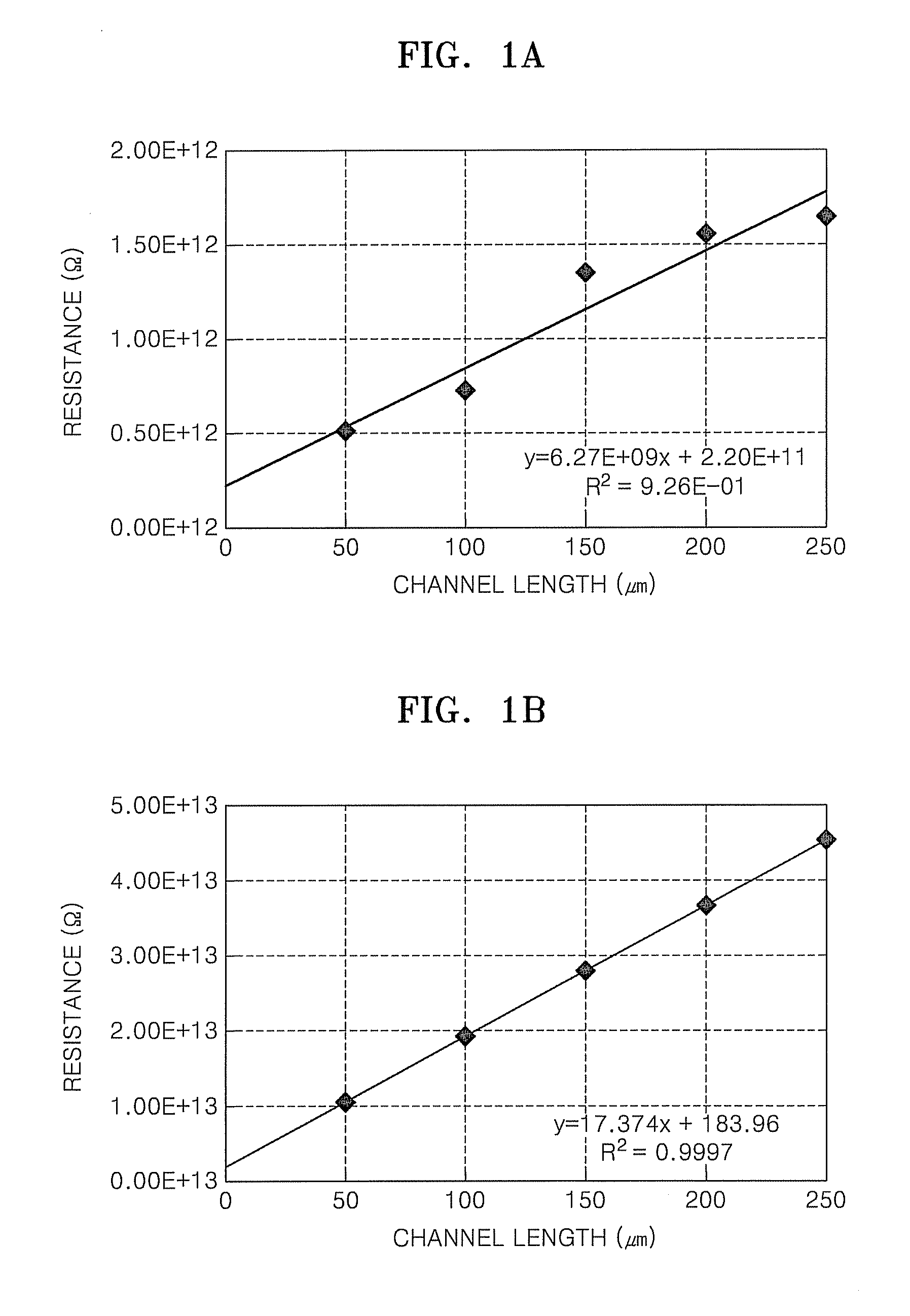

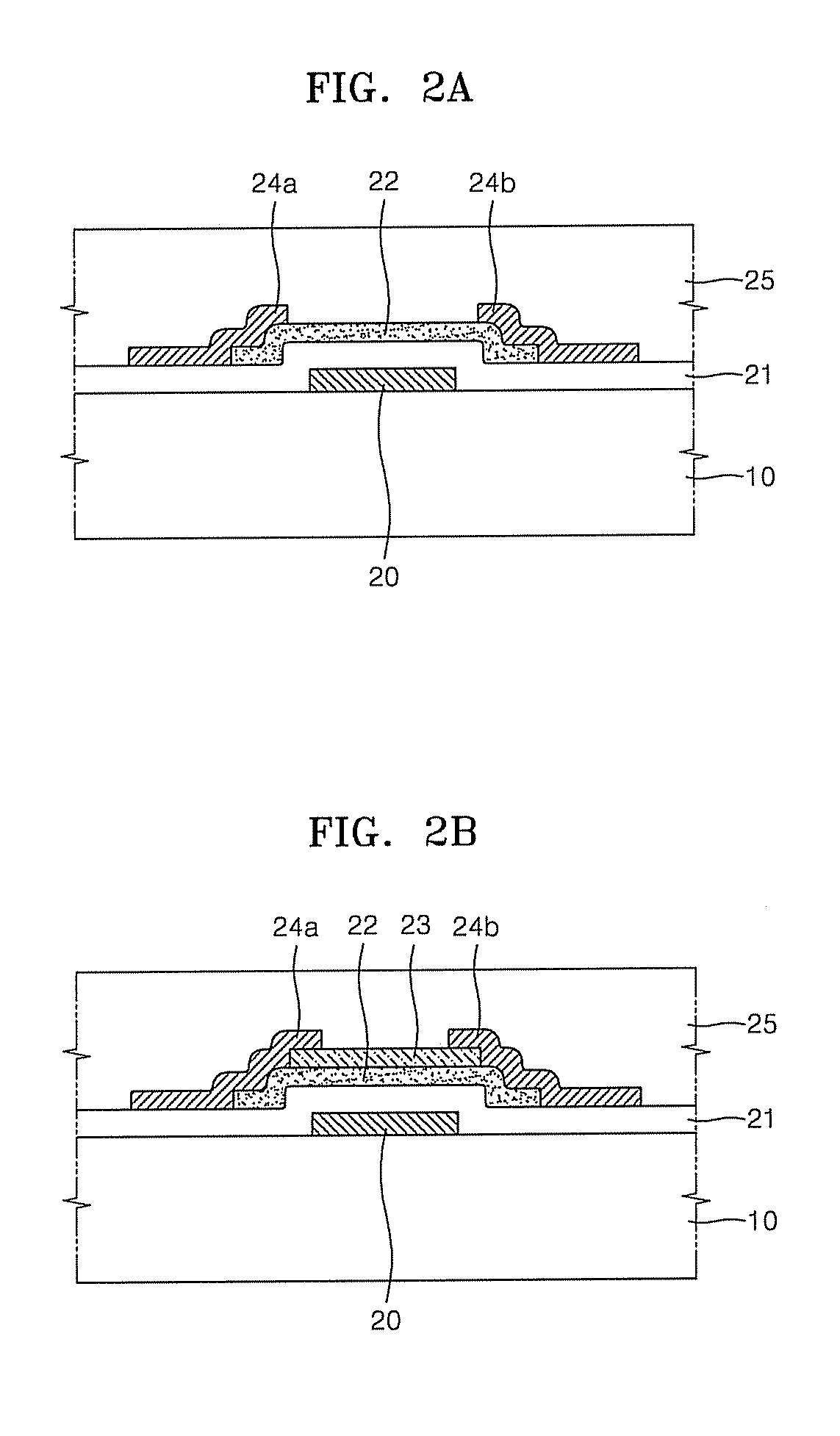

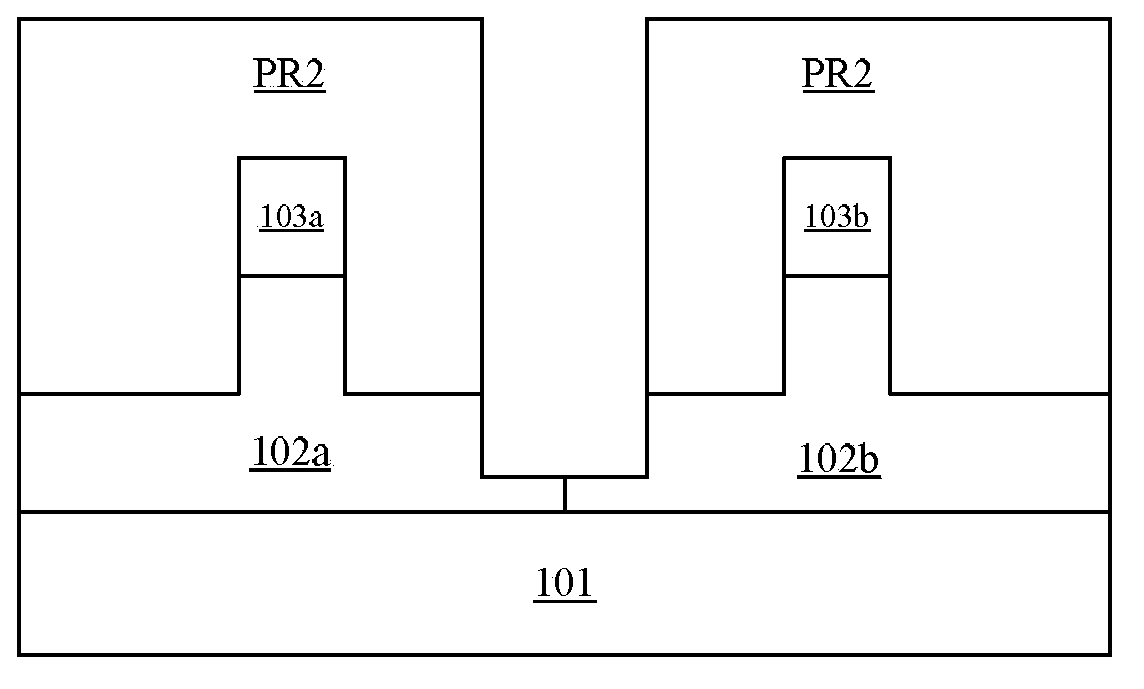

METHOD OF MANUFACTURING ZnO-BASED THIN FILM TRANSISTOR

InactiveUS20080299702A1Reduce carrier concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesInterfacial reactionBottom gate

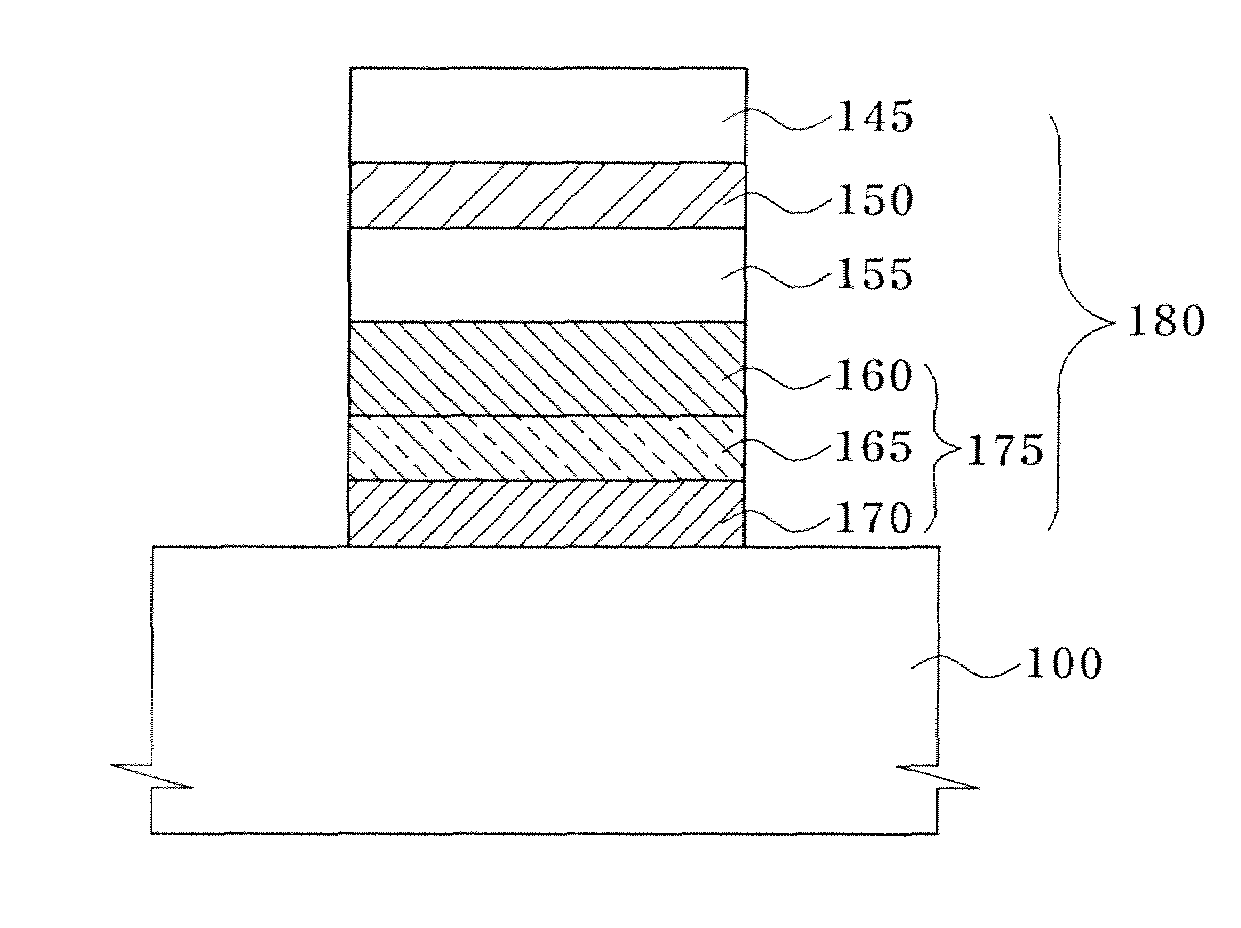

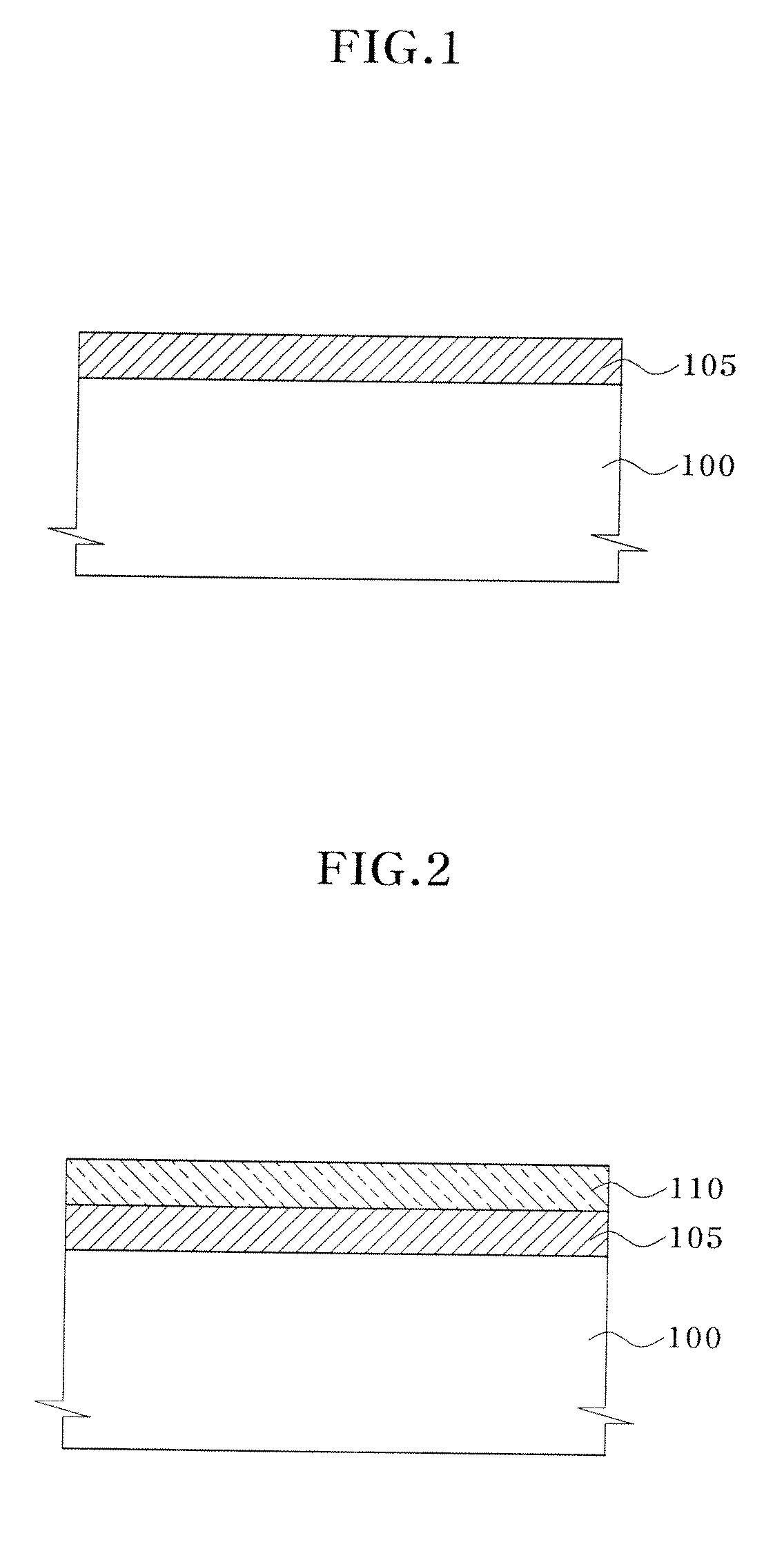

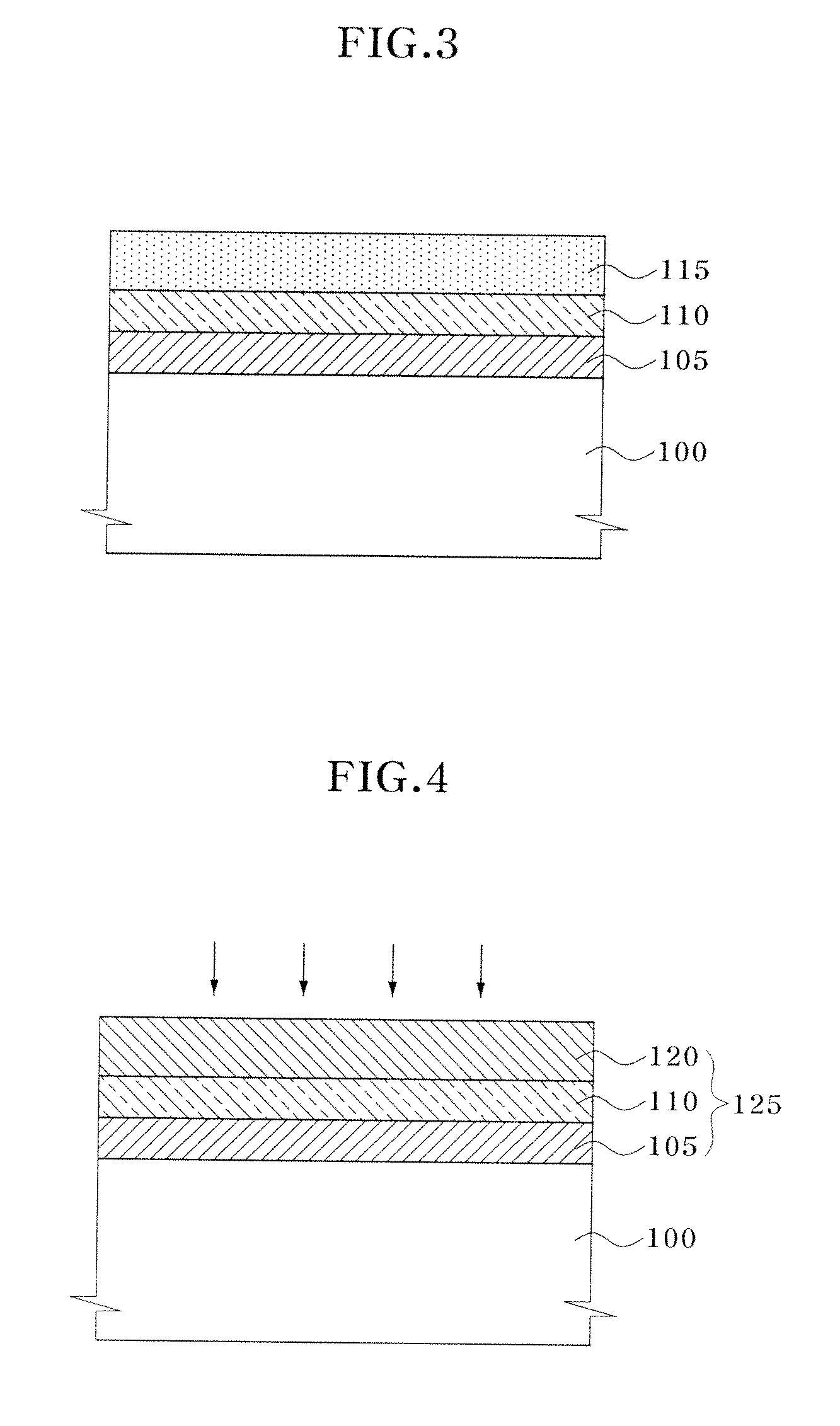

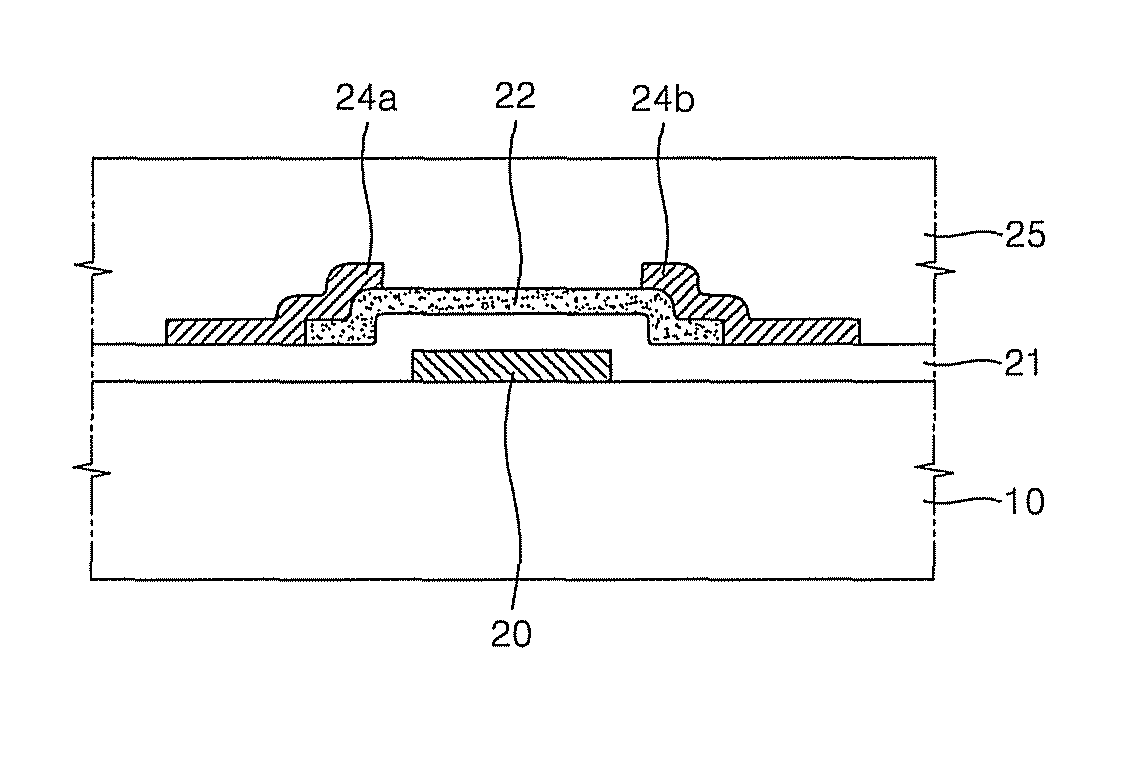

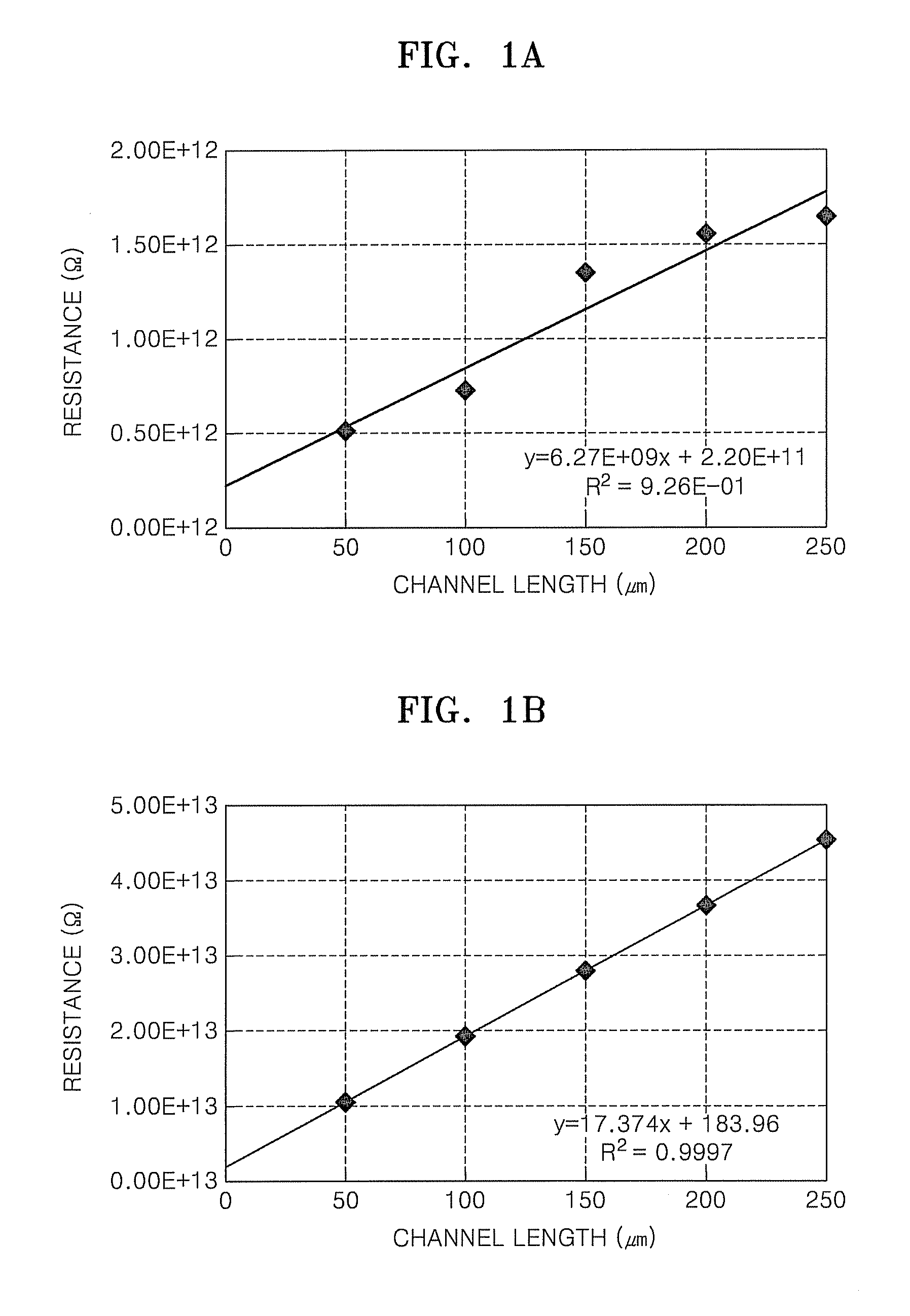

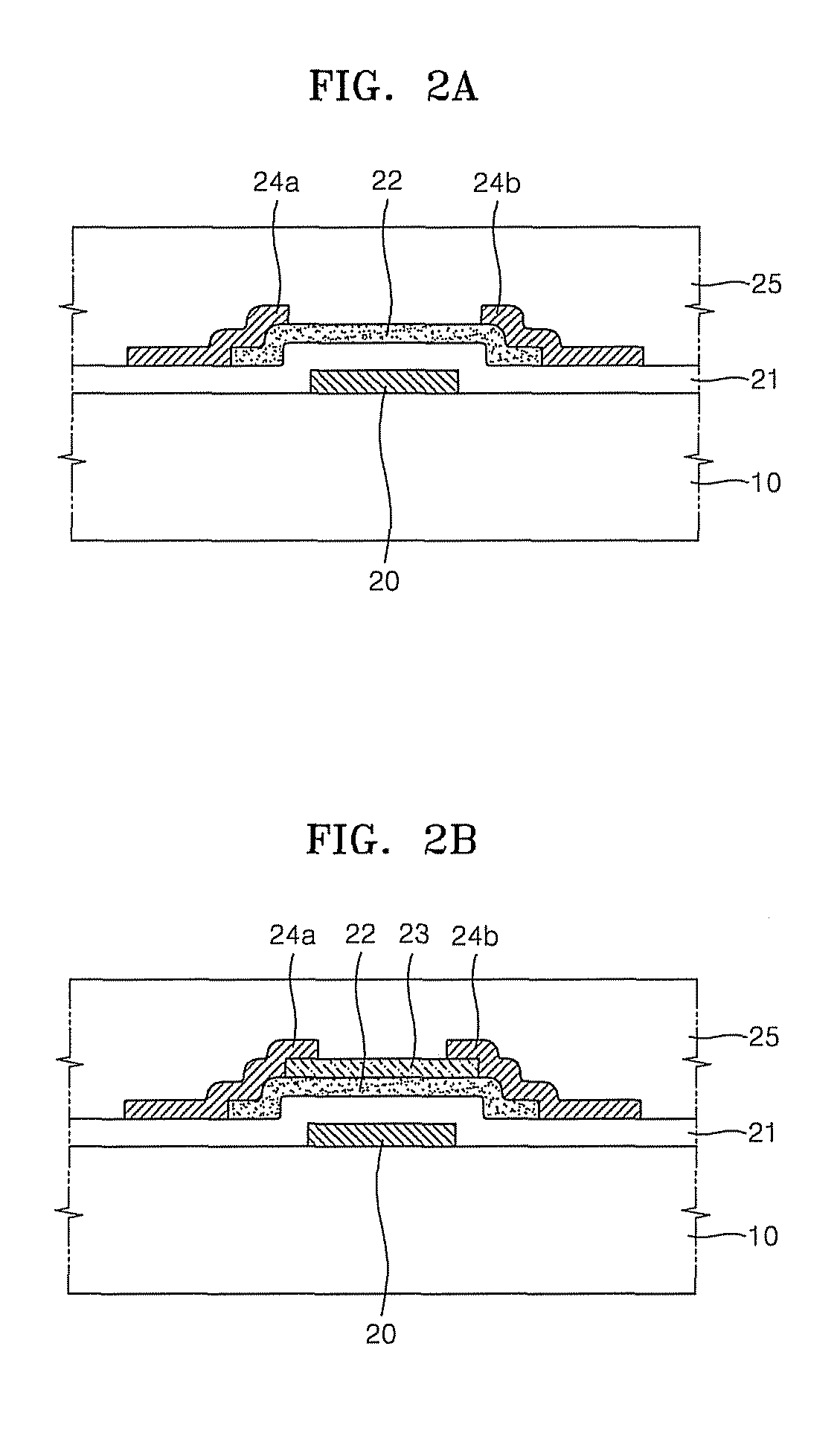

A ZnO-based thin film transistor (TFT) is provided herein. Also provided is a method for manufacturing the TFT. The ZnO-based TFT is very sensitive to the oxygen concentration present in a channel layer. In order to prevent damage to a channel layer of a bottom gate TFT, and to avoid a deep negative threshold voltage resulting from damage to the channel layer, the method for manufacturing the ZnO-based TFT comprises formation of an etch stop layer or a passivation layer comprising unstable or incompletely bonded oxygen, and annealing the layers to induce an interfacial reaction between the oxide layer and the channel layer and to reduce the carrier concentration.

Owner:SAMSUNG ELECTRONICS CO LTD

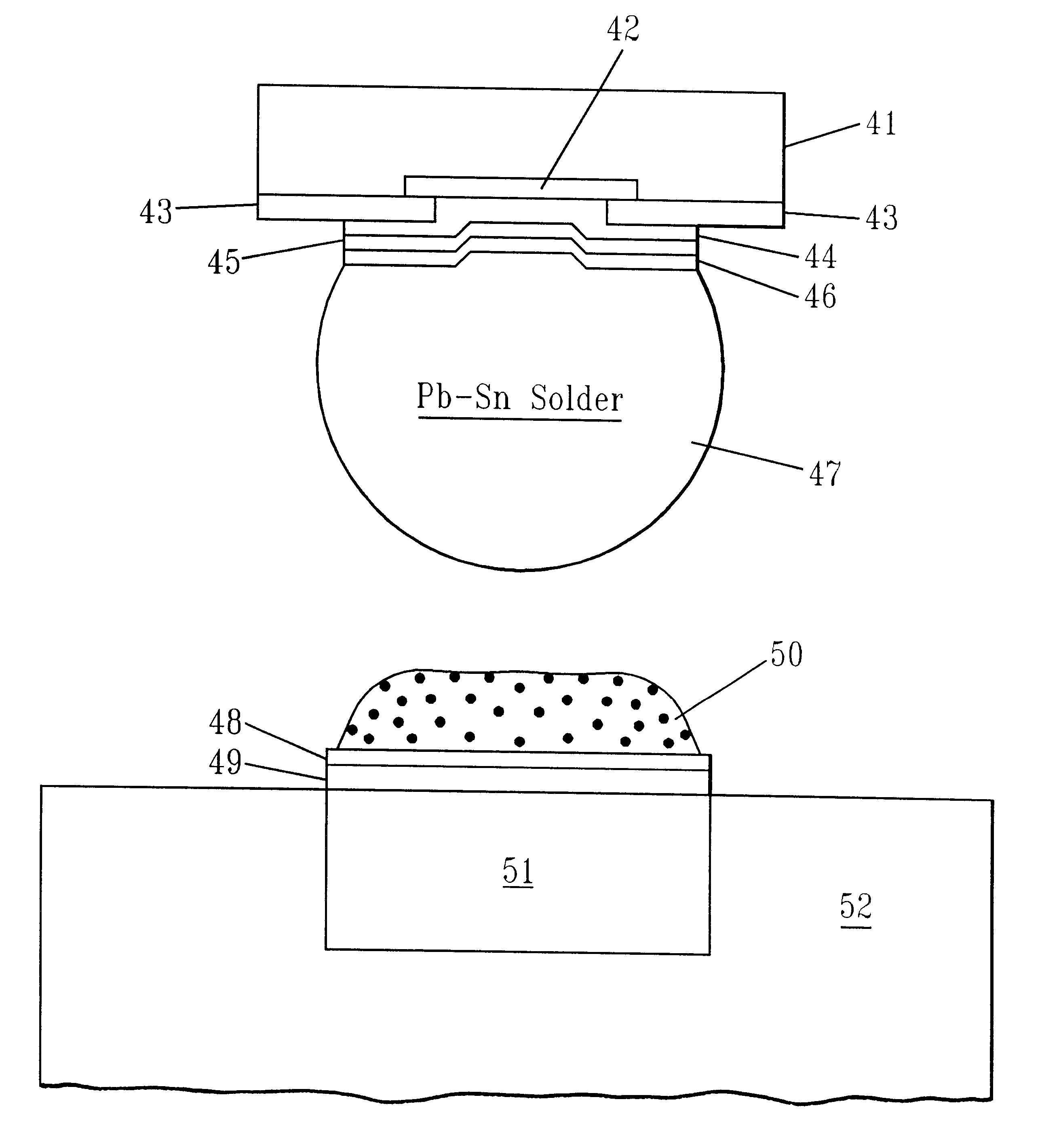

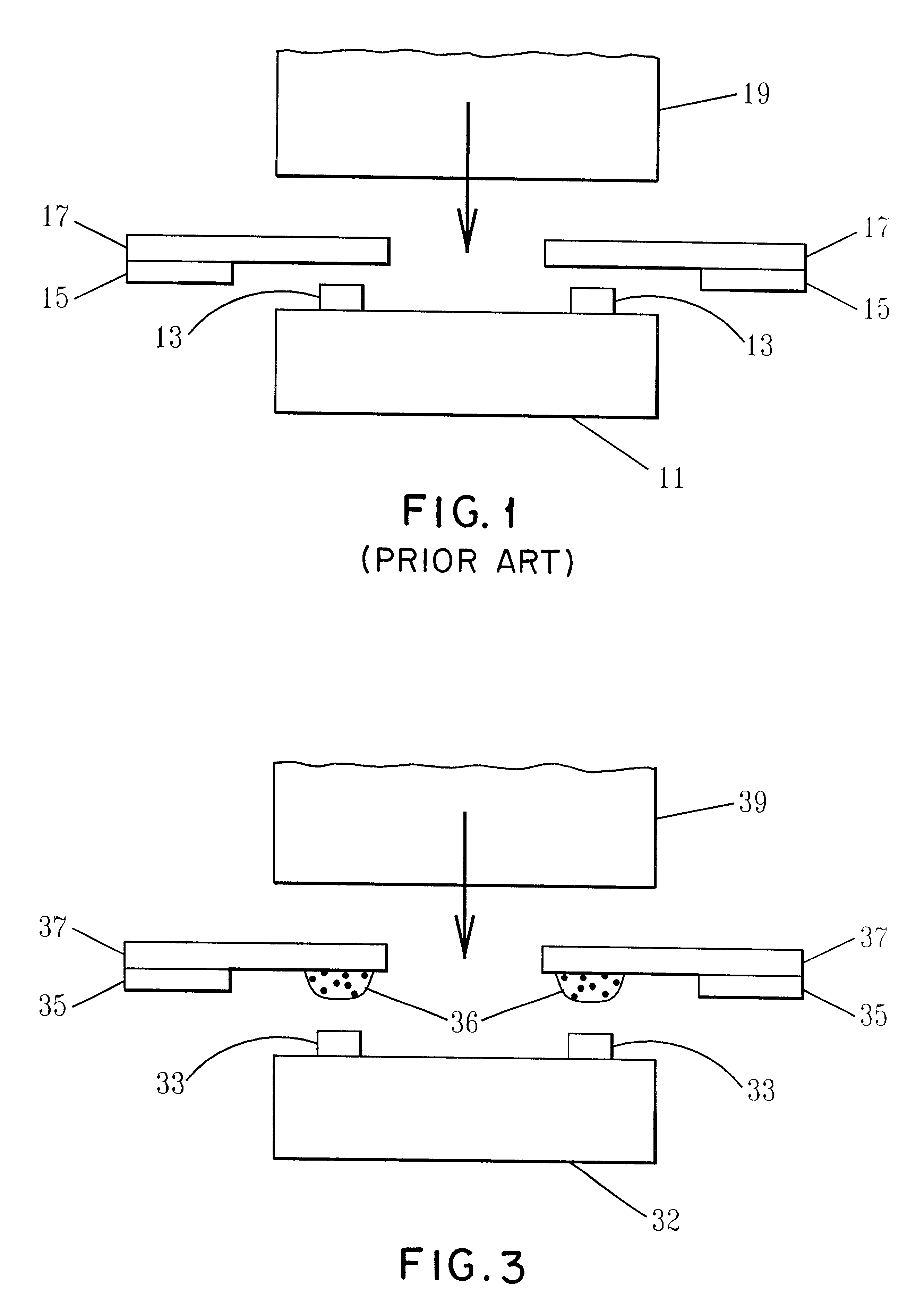

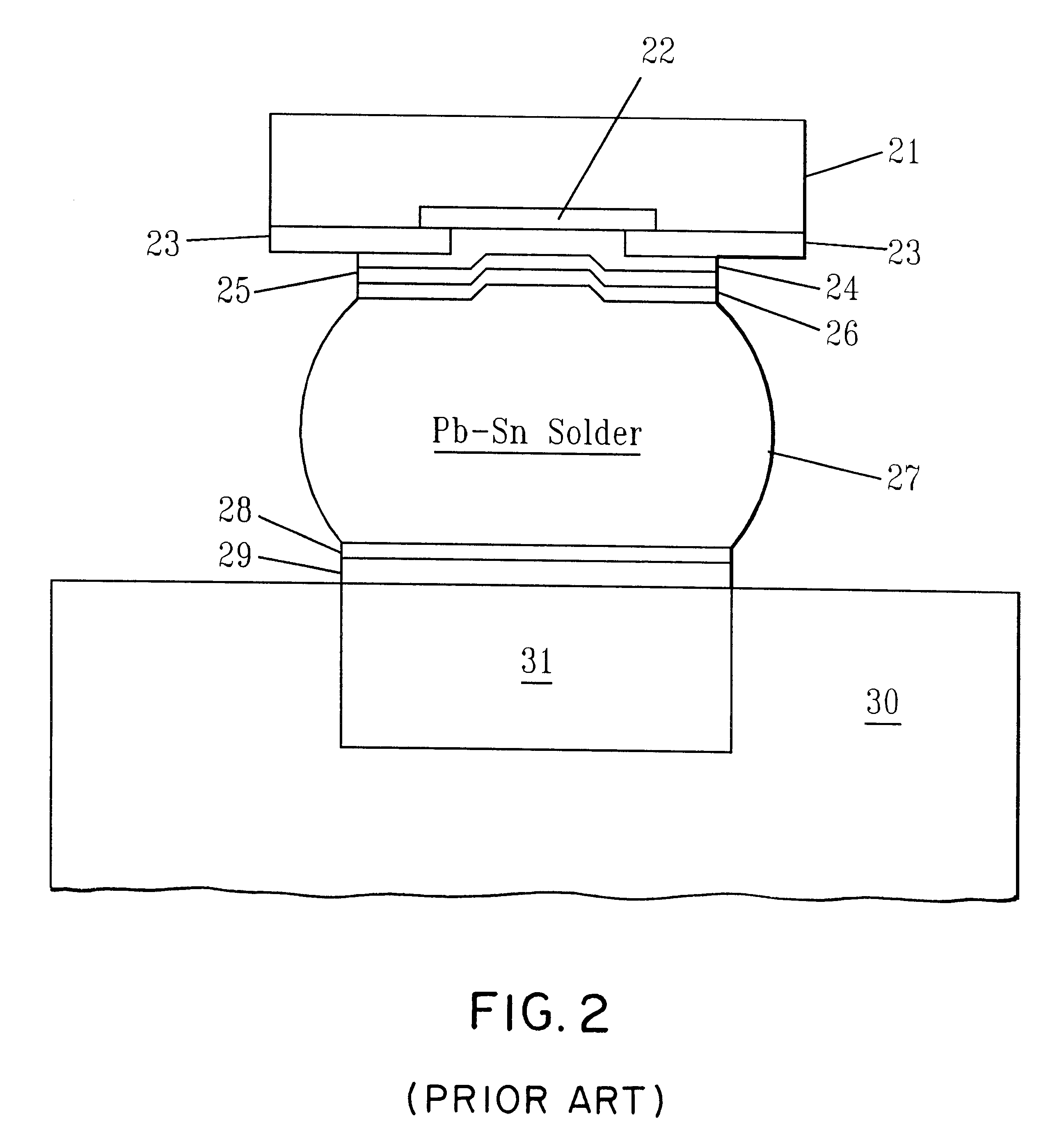

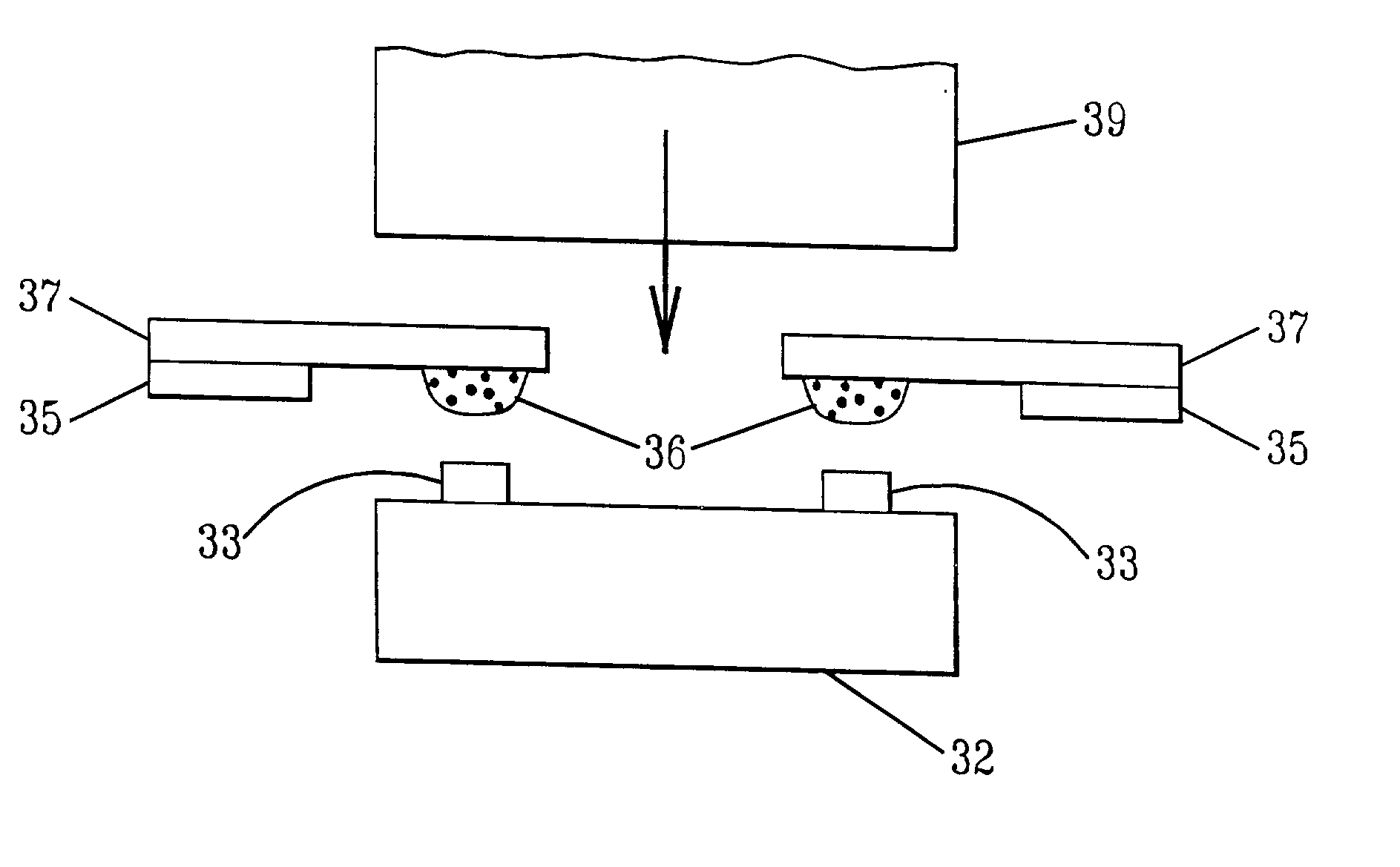

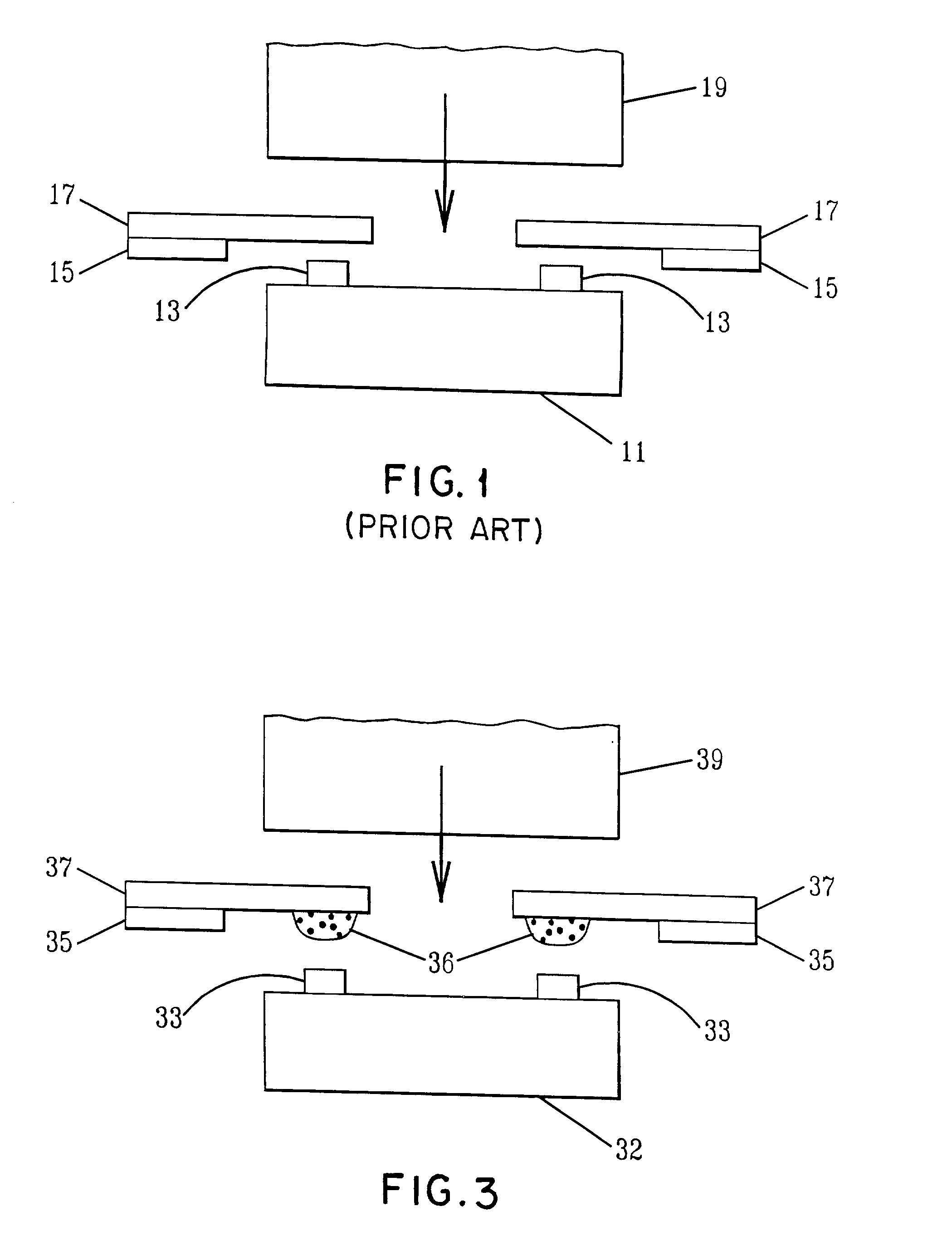

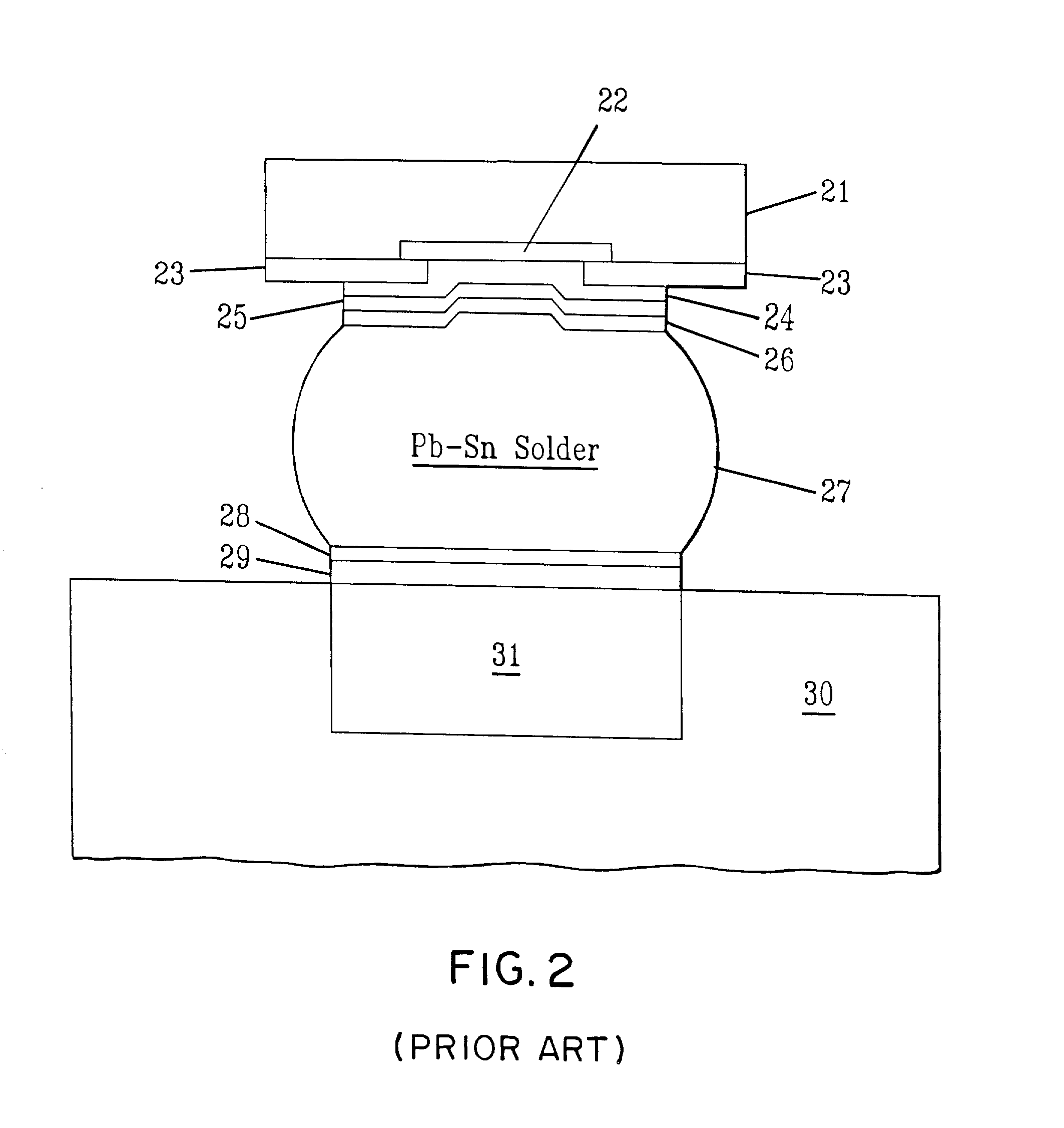

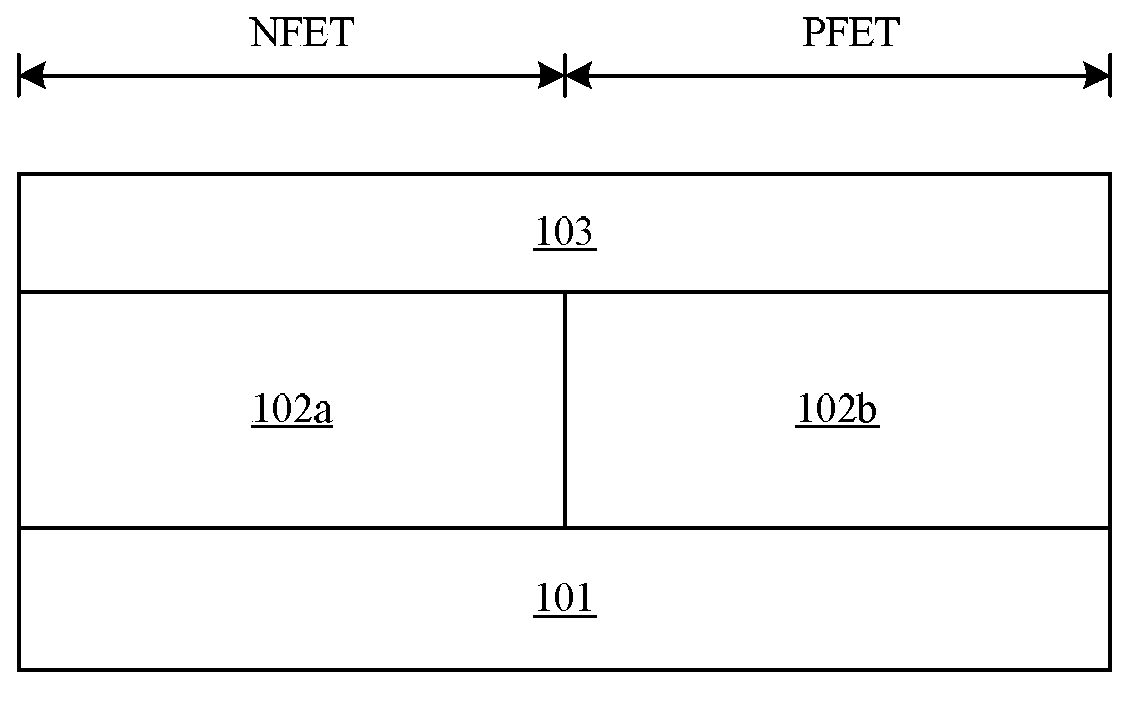

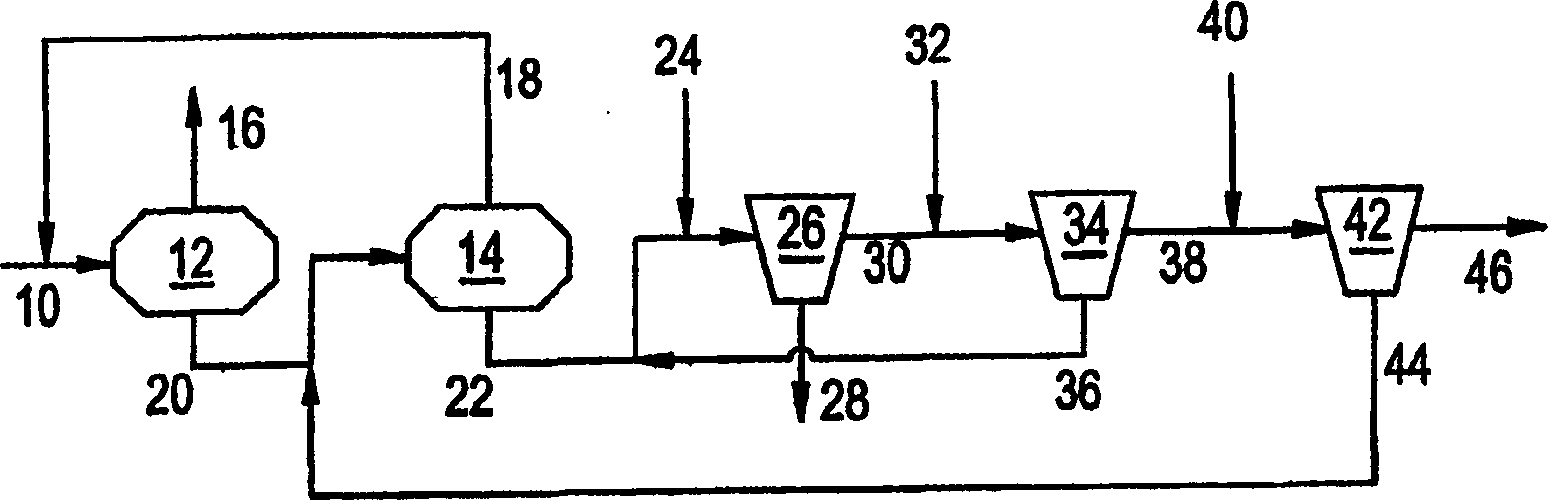

Structure employing electrically conductive adhesives

InactiveUS6337522B1Stable TAB joint structureImprove fatigue lifePrinted circuit assemblingLayered productsInterfacial reactionActive-matrix liquid-crystal display

A new interconnection scheme is disclosed for a tape automated bonding (TAB) package, a flip chip package and an active matrix liquid crystal display (AMLCD) panel, where an electrically conducting adhesive is used to form an electrical interconnection between an active electronic device and its components. The electrically conducting adhesive can be a mixture comprising a polymer resin, a no-clean solder flux, a plurality of electrically conducting particles with an electrically conducting fusible coating which provides a metallurgical bond between the conducting particles as well as to the substrates. The advantages of using the electrically conducting adhesives include reduction in bonding pressure and / or bonding temperature, control of interfacial reactions, promotion of stable metallurgical bonds, enhanced reliability of the joints, and others.

Owner:AU OPTRONICS CORP

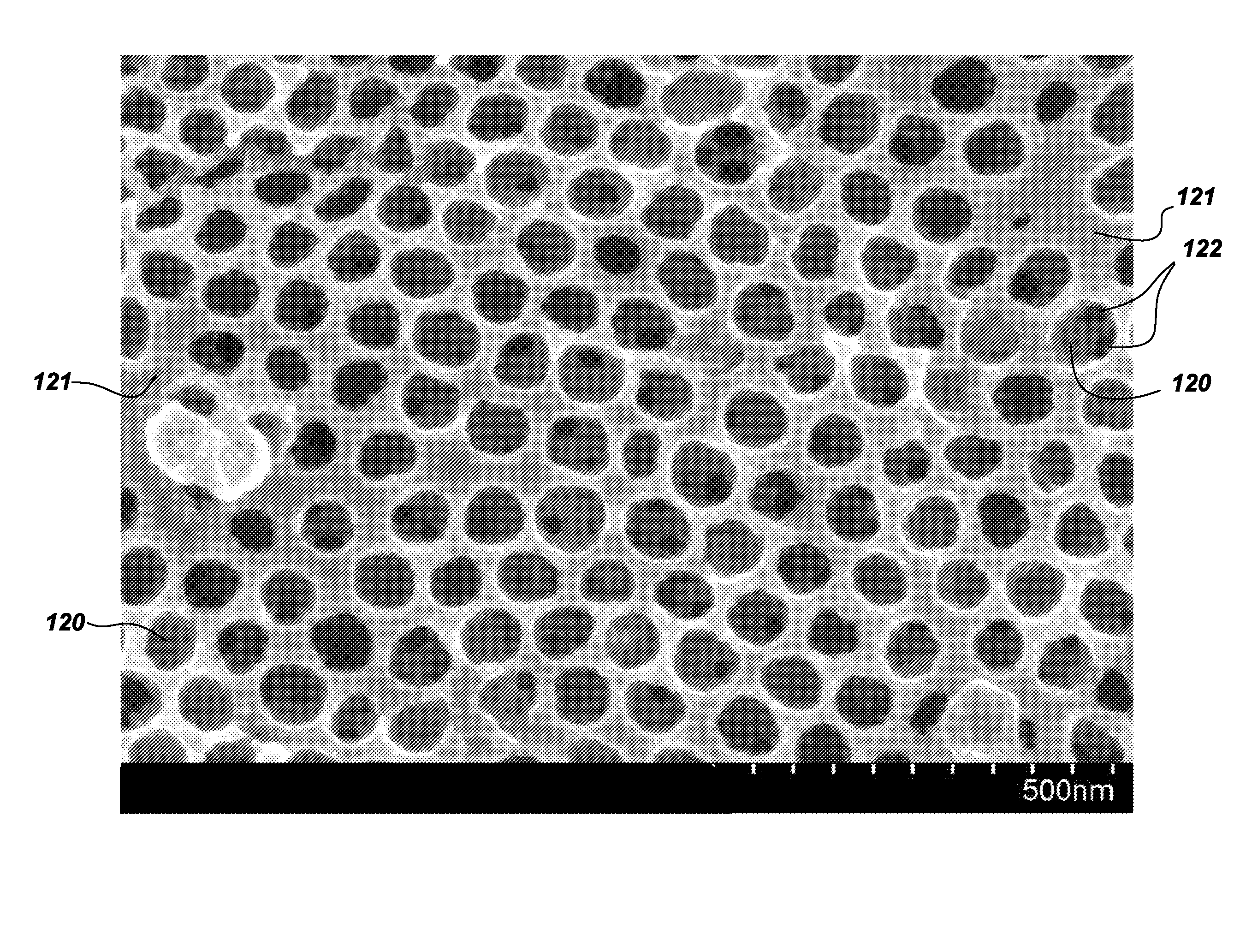

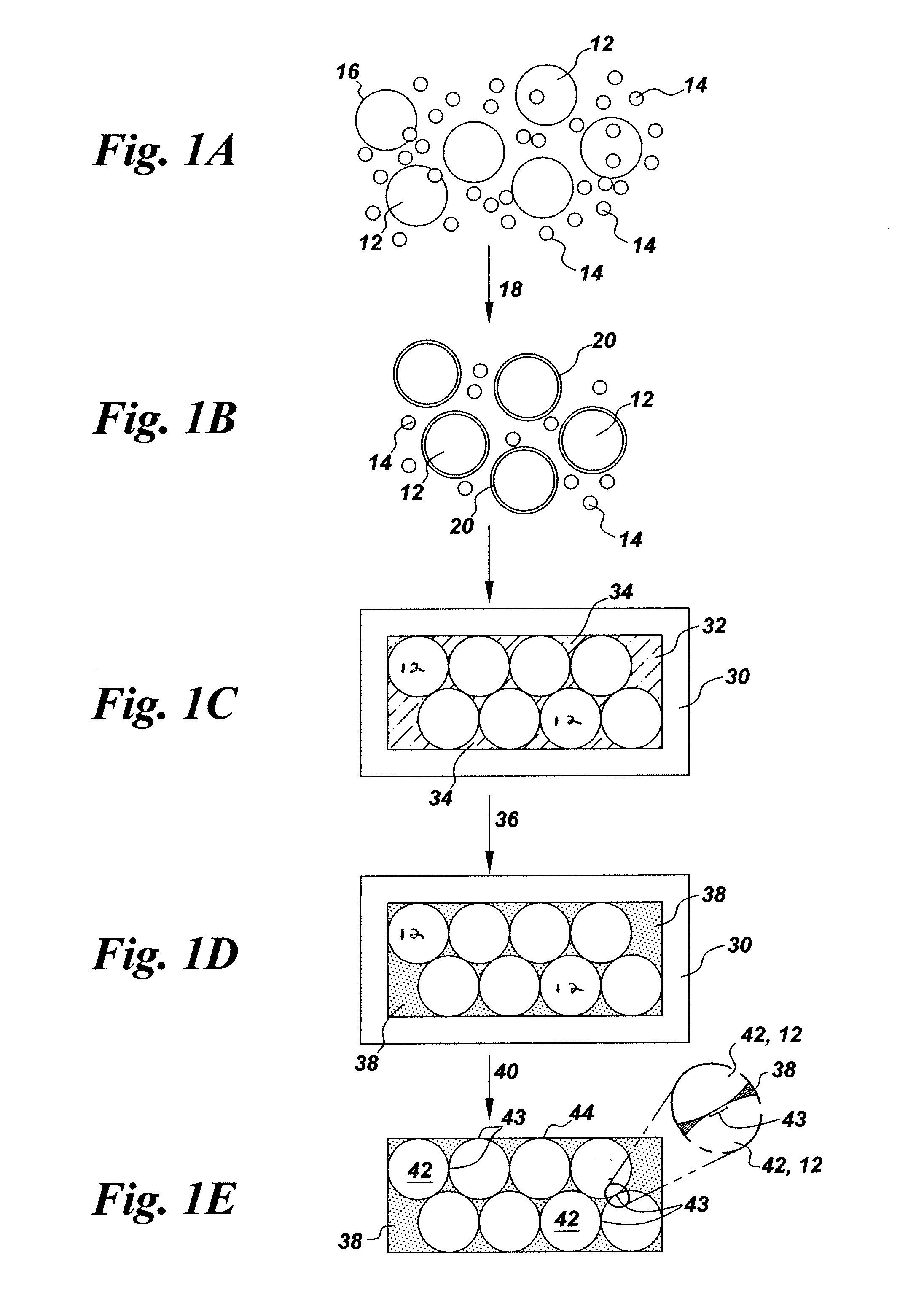

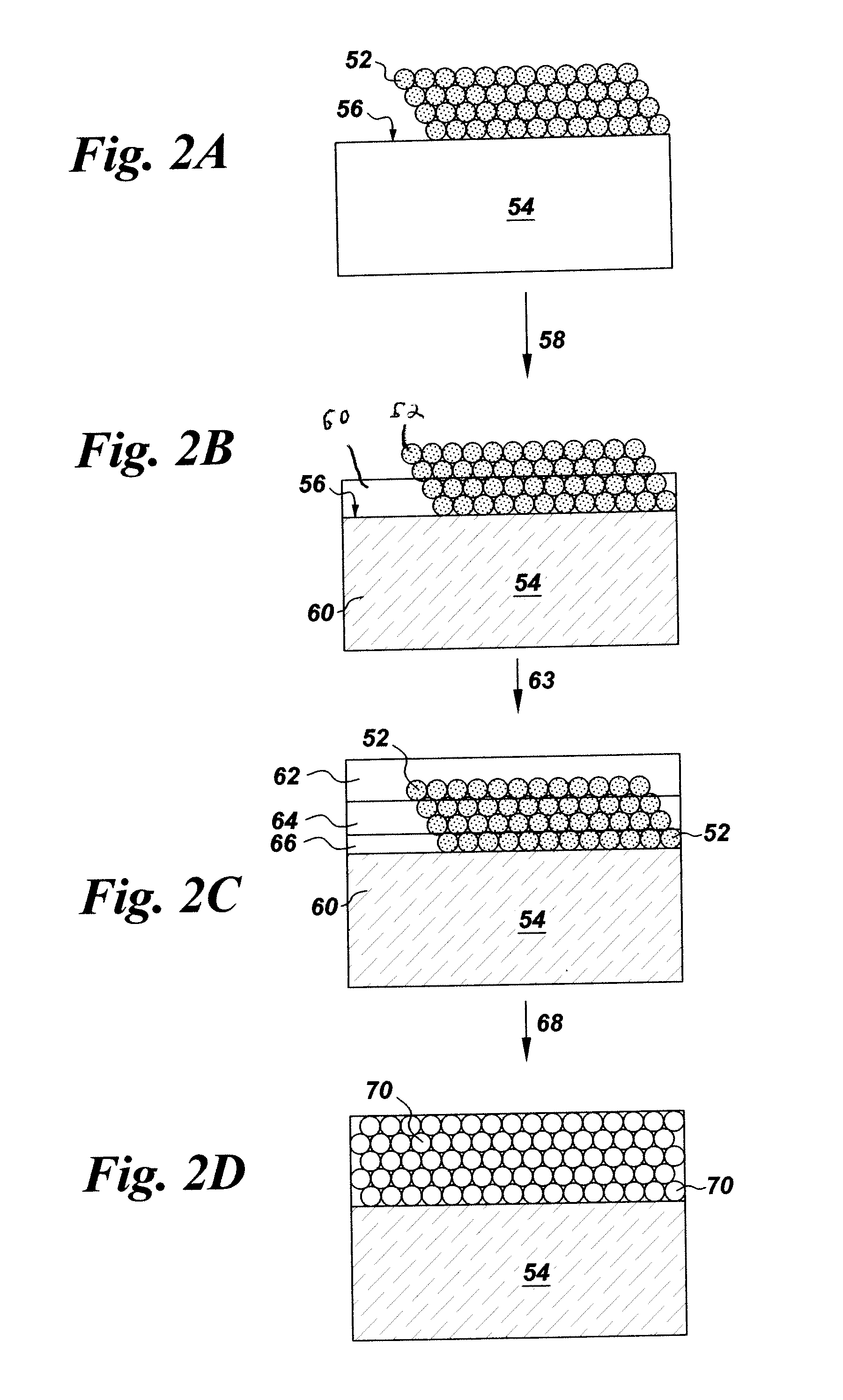

Particle-templated membranes, and related processes for their preparation

InactiveUS20100155325A1Small sizeSemi-permeable membranesMembranesInterfacial reactionFiltration membrane

A method for the formation of a membrane is described. A collection of substantially spherical particles formed from a selected material is contacted with at least one reactive material. The reactive material is cured or otherwise polymerized by various techniques, so that it forms a matrix that substantially surrounds and contains the particles. A portion of the particle material is then removed, so that the matrix contains a pattern of pores that are permeable to selected substances in solution. In some instances, the matrix is formed by an interfacial reaction between at least two reactive materials. Related filtration membranes are also described.

Owner:GENERAL ELECTRIC CO

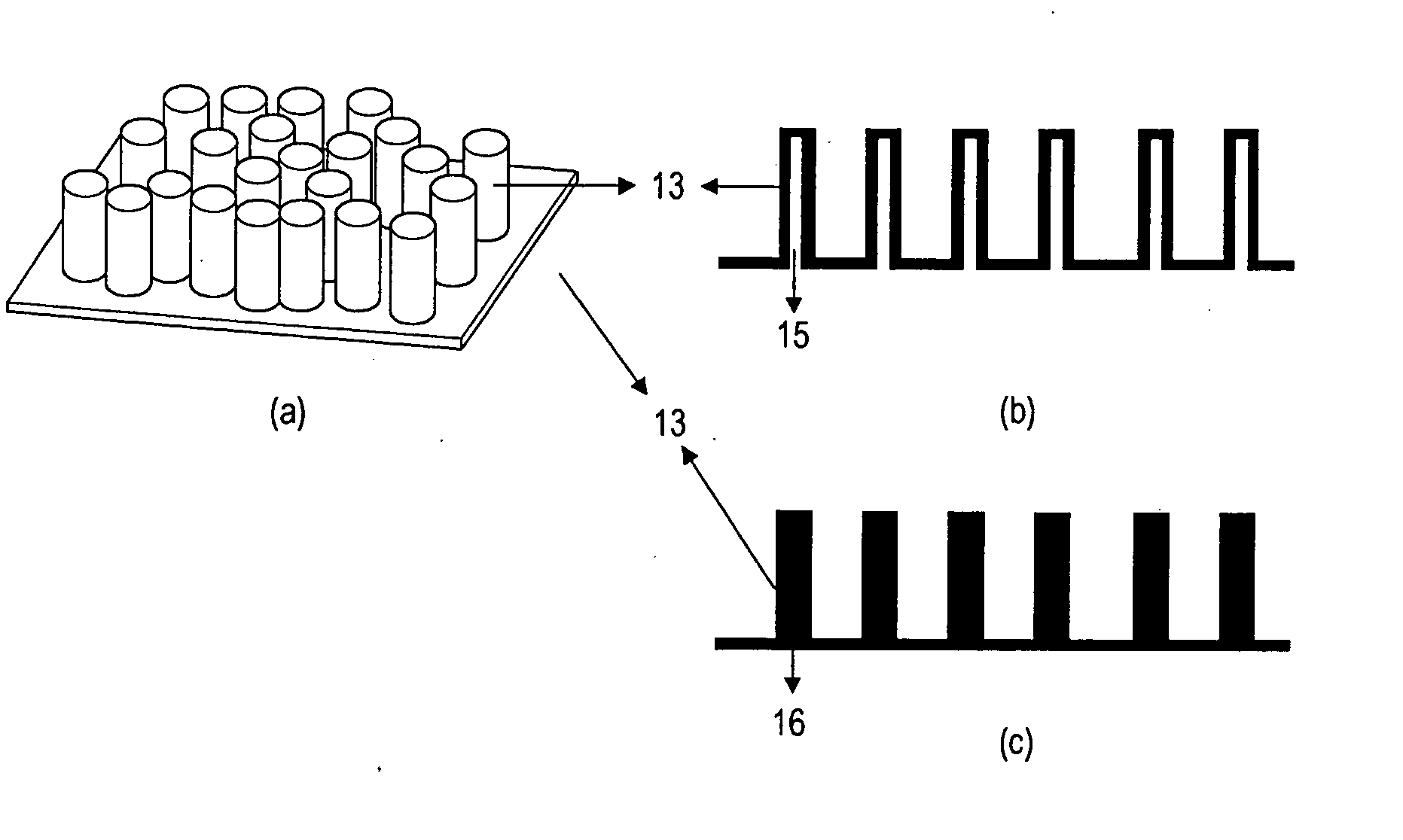

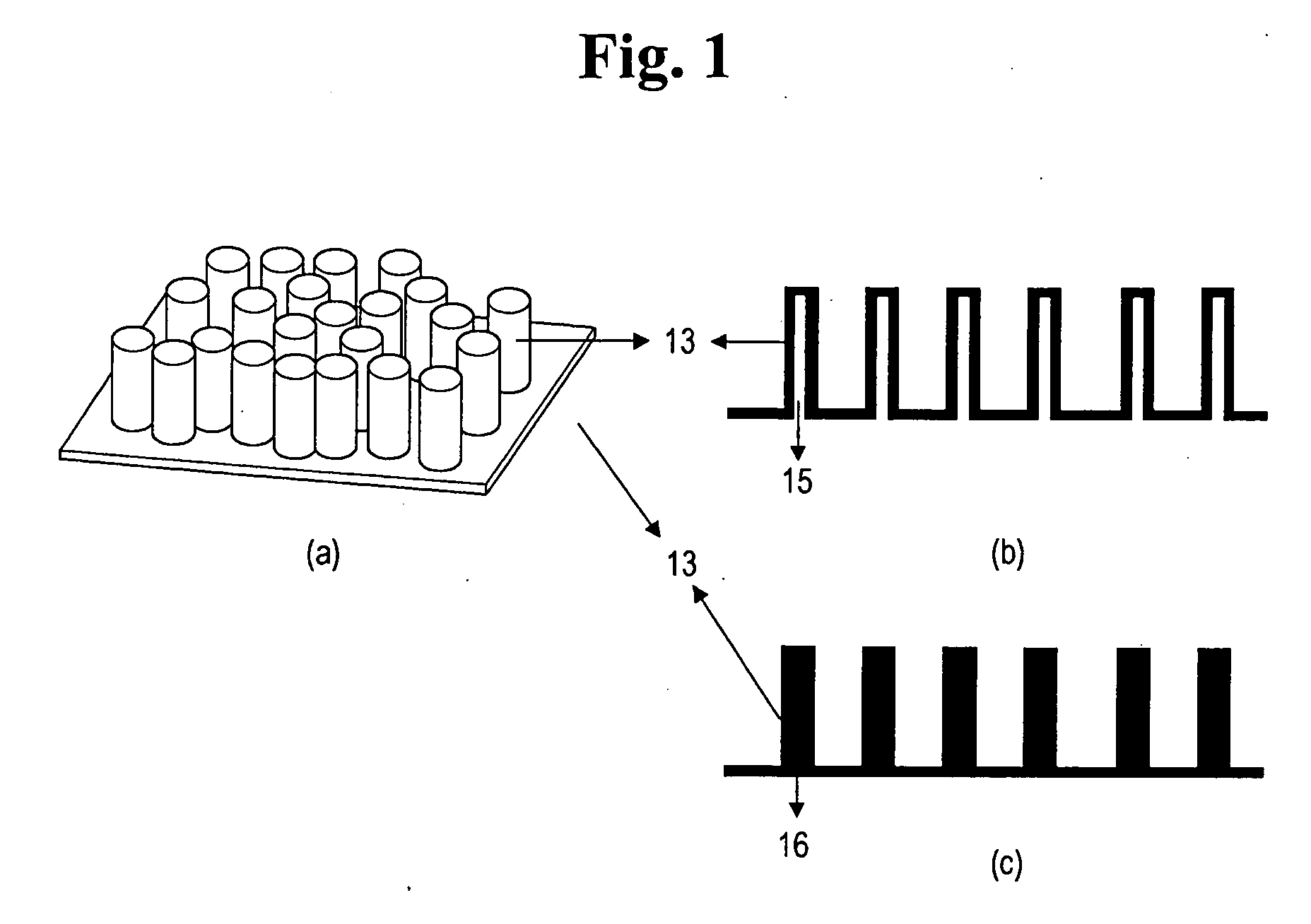

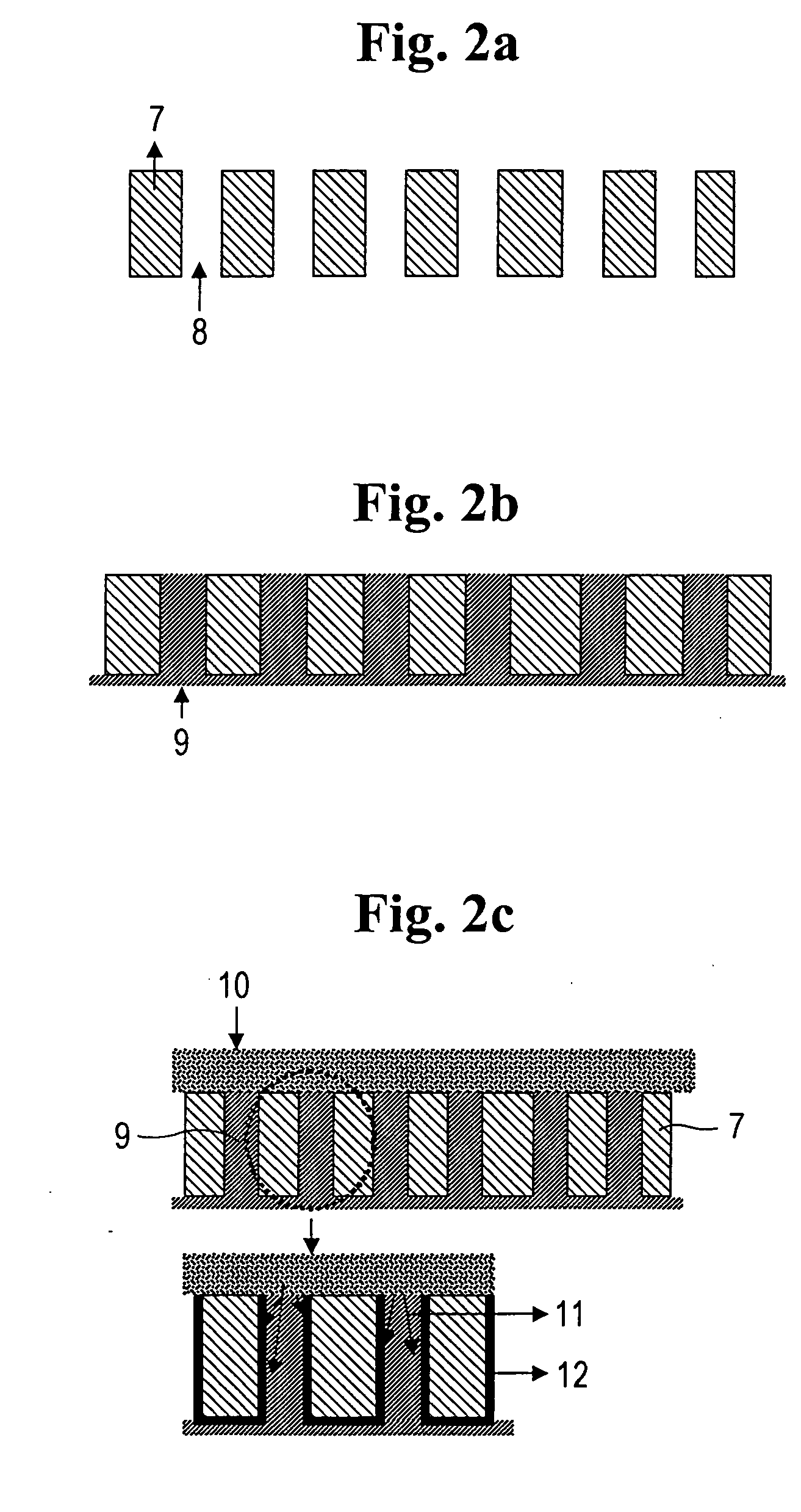

Method of fabricating a three-dimensional nanostructure

InactiveUS20070100086A1Rapid and reliable mannerManufactured rapidly and reliablyMaterial nanotechnologyNanostructure manufactureInterfacial reactionMicrometer

There is provided a rapid and reliable method of fabricating a three-dimensional organic / inorganic nanostructure of a well-arranged shape wherein tubes or fibers of several nanometer to several micrometer size have horizontal and vertical orientations. The method of the present invention comprises the following steps: A) forming a tube- or fiber-type structure of an organic or inorganic nanometer / micrometer size by an interfacial polymerization method or interfacial reaction method; and B) obtaining the organic / inorganic composite three-dimensional nanostructure.

Owner:KOREA INST OF SCI & TECH

Method for Manufacturing Non-Volatile Memory Device having Charge Trap Layer

InactiveUS20090227116A1Semiconductor/solid-state device manufacturingSemiconductor devicesInterfacial reactionCharge layer

A method for manufacturing a non-volatile memory device having a charge trap layer comprises in one embodiment: forming a first dielectric layer over a semiconductor substrate; forming a second dielectric layer having a higher dielectric constant than that of the first dielectric layer over the first dielectric layer; forming a nitride buffer layer for preventing an interfacial reaction over the second dielectric layer; forming a third dielectric layer by supplying a radical oxidation source onto the nitride buffer layer to oxidize the nitride buffer layer, thereby forming a tunneling layer comprising the first, second, and third dielectric layers; and forming a charge trap layer, a shielding layer, and a control gate electrode layer over the tunneling layer.

Owner:SK HYNIX INC

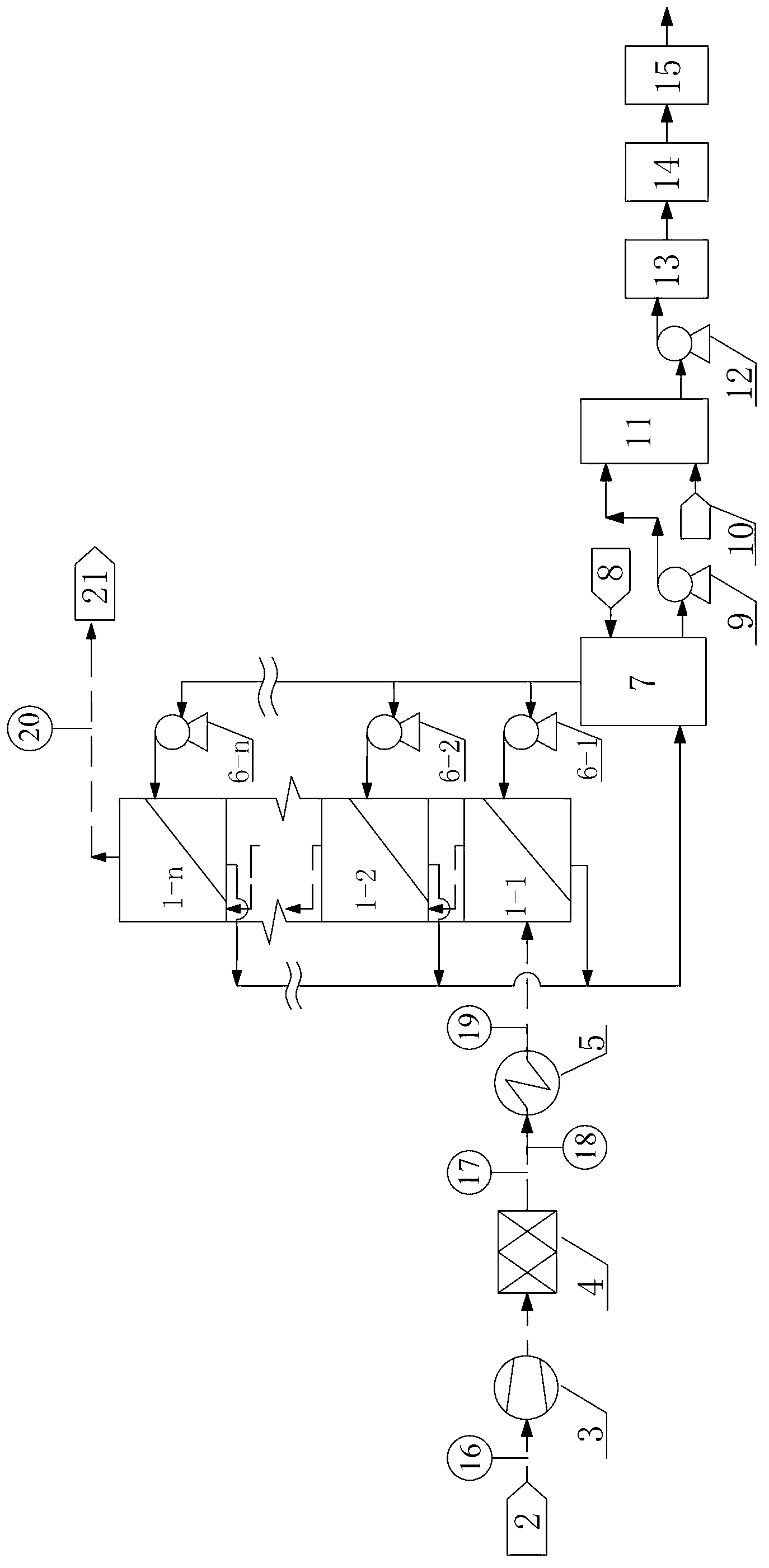

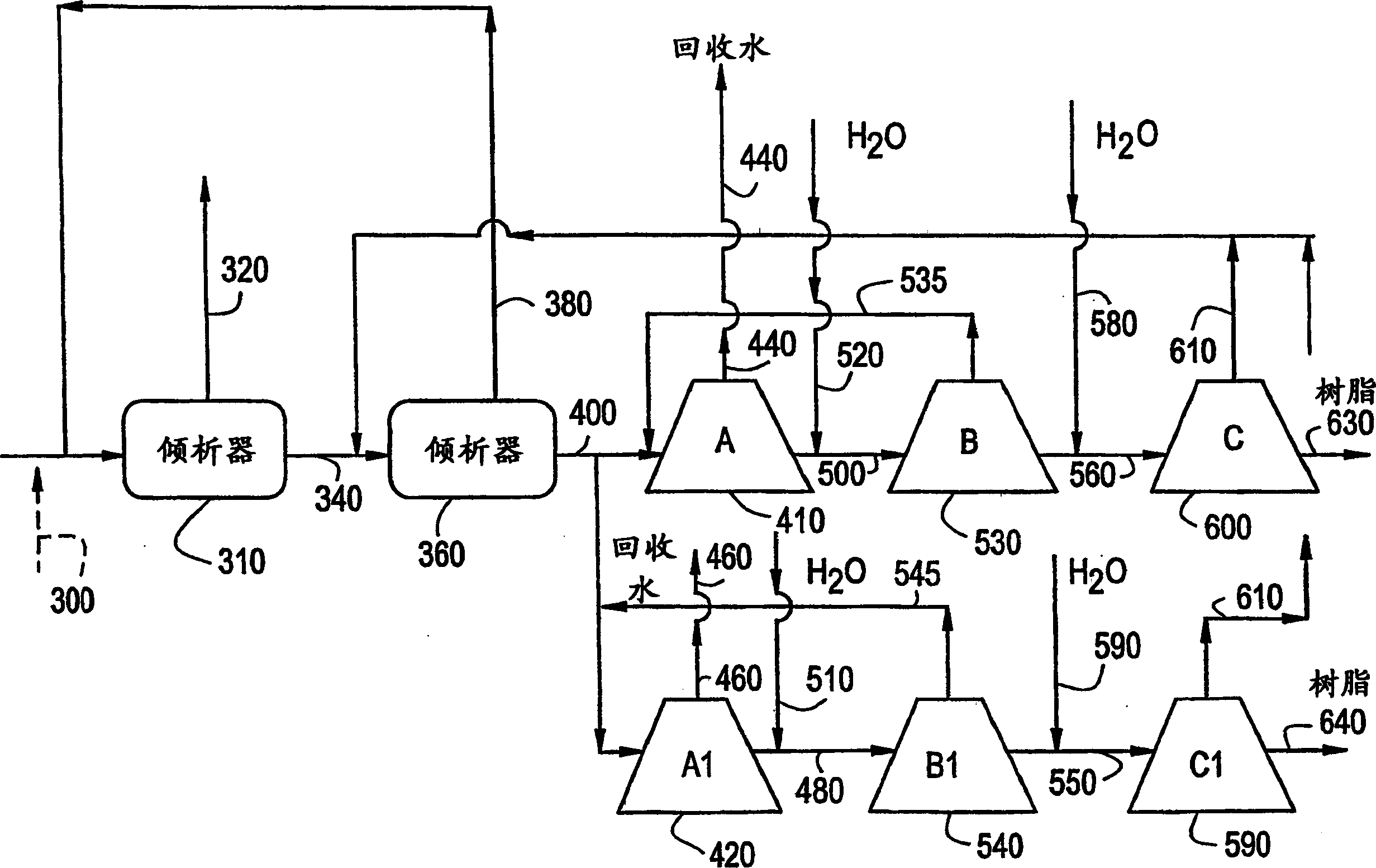

Resource reclamation type membrane flue gas desulphurization and denitration device and its technology

ActiveCN103316573ANo poisoningLarge adjustment rangeDispersed particle separationAir quality improvementInterfacial reactionHigh concentration

The invention discloses a resource reclamation type membrane flue gas desulphurization and denitration device which comprises at least one hydrophobic hollow fiber membrane absorber. A technology of the device is as follows: nitric oxide in flue gas is firstly subjected to an oxidation reaction to generate nitrogen dioxide, and the flue gas and an alkaline absorbent respectively enter a shell side and a tube side of the hydrophobic hollow fiber membrane absorber; SO2 and NOX in the flue gas permeate membrane wall micropores and undergo a rapid interfacial reaction with the alkaline absorbent so as to realize purification of the flue gas; and the alkaline absorbent is recycled to form a high-concentration salt-making mother liquor which is processed to prepare sulfate and nitrate. According to the technology, flow velocity of gas-liquid two-phase is independently controlled, and operating range is wide; non-direct contact between the flue gas and the absorbent can avoid heavy metal in flue dust and flue gas from entering the absorbent, resource recycling of pollutants in the flue gas is realized, and a high-purity by-product with high added value is obtained; and the technological process has high degree of automation, is economic and highly efficient and causes no secondary pollution.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Method of manufacturing ZnO-based thin film transistor

InactiveUS8735229B2Reduce carrier concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesInterfacial reactionBottom gate

A ZnO-based thin film transistor (TFT) is provided herein. Also provided is a method for manufacturing the TFT. The ZnO-based TFT is very sensitive to the oxygen concentration present in a channel layer. In order to prevent damage to a channel layer of a bottom gate TFT, and to avoid a deep negative threshold voltage resulting from damage to the channel layer, the method for manufacturing the ZnO-based TFT comprises formation of an etch stop layer or a passivation layer comprising unstable or incompletely bonded oxygen, and annealing the layers to induce an interfacial reaction between the oxide layer and the channel layer and to reduce the carrier concentration.

Owner:SAMSUNG ELECTRONICS CO LTD

Interconnections with electrically conductive adhesives: structures, materials, method and their applications

InactiveUS20020056925A1Stable structureImprove fatigue lifePrinted circuit assemblingSemiconductor/solid-state device detailsInterfacial reactionElectrically conductive adhesive

A new interconnection scheme is disclosed for a tape automated bonding (TAB) package, a flip chip package and an active matrix liquid crystal display (AMLCD) panel, where an electrically conducting adhesive is used to form an electrical interconnection between an active electronic device and its components. The electrically conducting adhesive can be a mixture comprising a polymer resin, a no-clean solder flux, a plurality of electrically conducting particles with an electrically conducting fusible coating which provides a metallurgical bond between the conducting particles as well as to the substrates. The advantages of using the electrically conducting adhesives include reduction in bonding pressure and / or bonding temperature, control of interfacial reactions, promotion of stable metallurgical bonds, enhanced reliability of the joints, and others.

Owner:AU OPTRONICS CORP

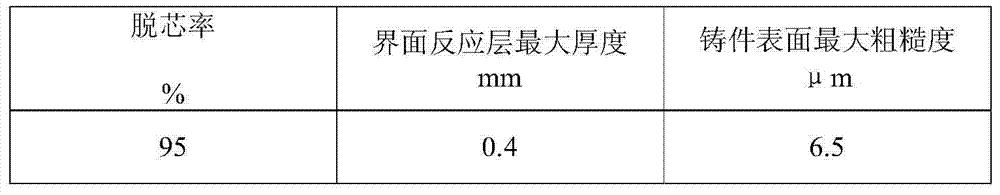

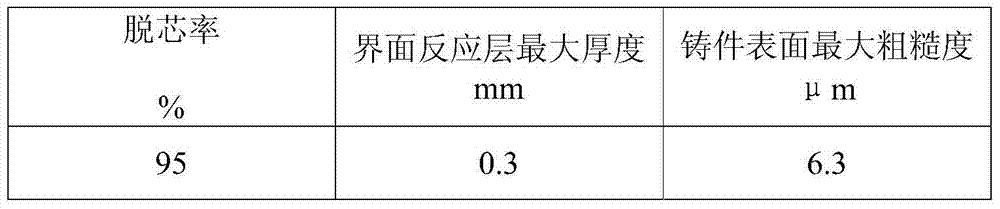

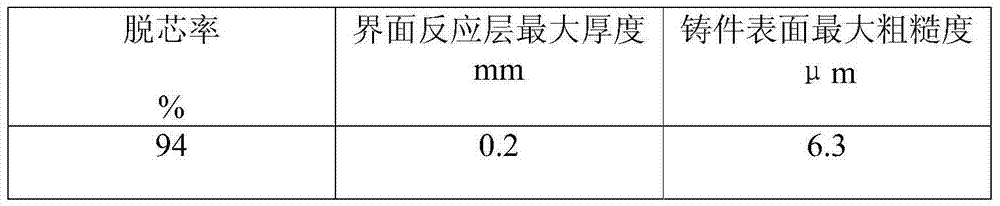

Casting method of magnesium alloy casting

InactiveCN103231016AGuaranteed decompositionGuaranteed fillingFoundry mouldsFoundry coresInterfacial reactionCasting mold

The invention provides a casting method of a magnesium alloy casting. With the method, advantages of different casting methods are utilized, and defects of the methods are overcome. With a special shell preparation method and a method for preventing magnesium alloy-casting mold interfacial reaction, a unique casting technology suitable for thin-wall complex magnesium alloy part production is formed. The method has important significance for developing magnesium alloy performance advantages and satisfying automotive magnesium alloy application requirements.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

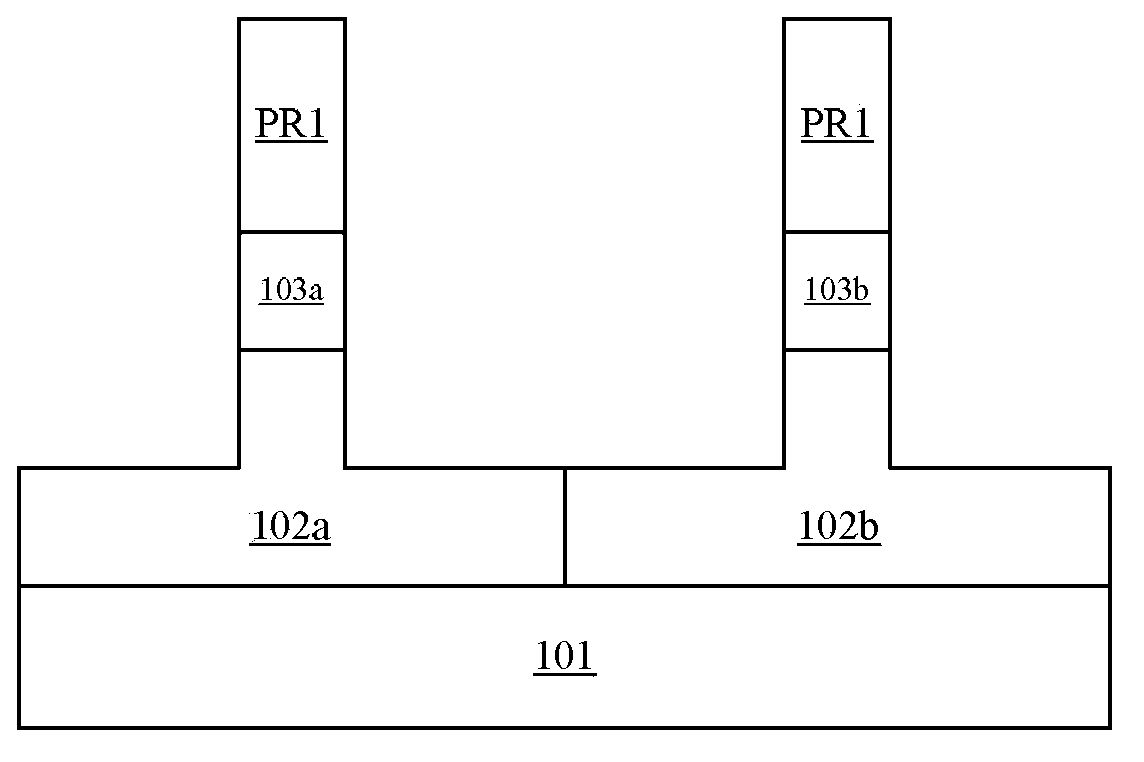

Semiconductor device and manufacturing method thereof

ActiveCN103855093AImprove distribution uniformityAdjust the effective work functionTransistorSolid-state devicesInterfacial reactionInterfacial oxide

The invention discloses a semiconductor device and a manufacturing method thereof. The manufacturing method of the semiconductor device includes the following steps that: semiconductor fins are formed on a semiconductor substrate; interfacial oxide layers are formed on the surfaces of the tops and side walls of the semiconductor fins; high K gate dielectrics are formed on the interfacial oxide layers; first metal gate layers are formed on the high K gate dielectrics; and doping agents are implanted into the first metal gate layers through conformal doping; and annealing is performed, so that the doping agents can be diffused and accumulated at upper interfaces between the high K gate dielectrics and the first metal gate layers and lower interfaces between the high K gate dielectrics and the interfacial oxide layers, and electric dipoles can be generated at the lower interfaces between the high K gate dielectrics and interfacial oxides through interfacial reaction.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

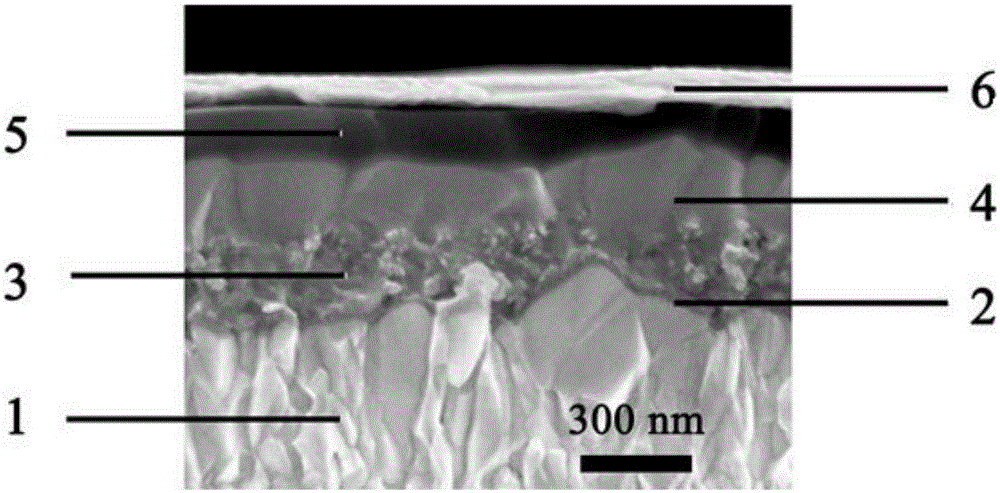

Method for preparing perovskite layer of perovskite solar cell by using solid-mist interfacial reaction

InactiveCN105006524AHigh crystallinityIncrease coverageSolid-state devicesSemiconductor/solid-state device manufacturingInterfacial reactionState of art

The invention provides a method for preparing a perovskite layer of a perovskite solar cell by using solid-mist interfacial reaction and belongs to the technical field of organic metal halide perovskite solar cells. In view of disadvantages of poor perovskite coverage rate and poor repeatability of an organic metal halide perovskite solar cell prepared by the prior art, the method prepares a lead iodide solid-phase membrane by means of a spin-coating method, and then enables an organic halide solution to be atomized to form solution mist to react with solid-mist-phase interface, thereby forming an organic metal halide layer with perovskite structure. The perovskite layer prepared through the method is good in crystallinity and high in coverage rate, and may improve the photoelectric conversion efficiency of the perovskite solar cell. The method is short in reaction time, easy to control in reaction condition, simple in equipment, good in maneuverability, good in repeatability, suitable for being popularized and applied in real production.

Owner:JILIN UNIV

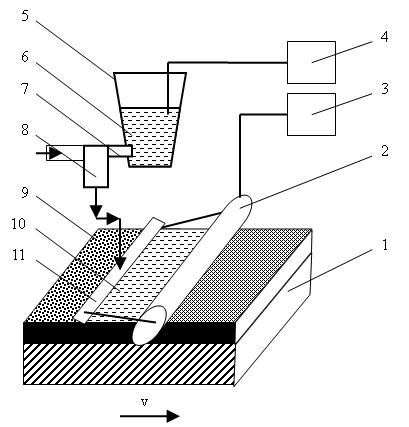

Brazing filler metal for brazing W-Cu composite and Fe-based alloy, method and brazing technique

ActiveCN105081597AModerate melting temperatureFacilitated Diffusion and Interfacial ReactionsWelding/cutting media/materialsWelding/soldering/cutting articlesAlloy elementMicrometer

The invention discloses brazing filler metal for brazing a W-Cu composite and Fe-based alloy, a method and a brazing technique. The brazing filler metal is in a foil piece strip shape. The thickness of the brazing filler metal ranges from 50 micrometers to 100 micrometers. The brazing filler metal comprises, by weight, 6.0%-9.0% of Mn, 3.5%-5% of Co, 0.3%-1.7% of Ni, 2.0%-5.0% of Zr, 1.2%-2.8% of Ti, and the balance Cu. The brazing temperature of the brazing filler metal ranges from 1000 DEG C to 1050 DEG C, the melting temperature of the brazing filler metal is moderate, and the brazing filler metal is uniformly melted; diffusion and the interface reaction of alloy elements in the brazed connection process can be promoted through a brazing filler metal foil piece, and the wetting and spreading capacity of the brazing filler metal on the surfaces of the W-Cu composite and the Fe-based sintered alloy is improved; crystal particles are refined, residual stress is reduced, and the mechanical performance of joints is improved; the brazing technique for connecting the W-Cu composite and the Fe-based sintered alloy through the brazing filler metal is stable and reliable, vacuum brazed connection is used, a component is in a vacuum state in the heating process, the whole component does not deform, the defects such as microscopic cracks, air holes and inclusions are avoided, and the wetting and spreading capacity of the surface of the brazing filler metal is good.

Owner:JIANGSU UNIV OF SCI & TECH

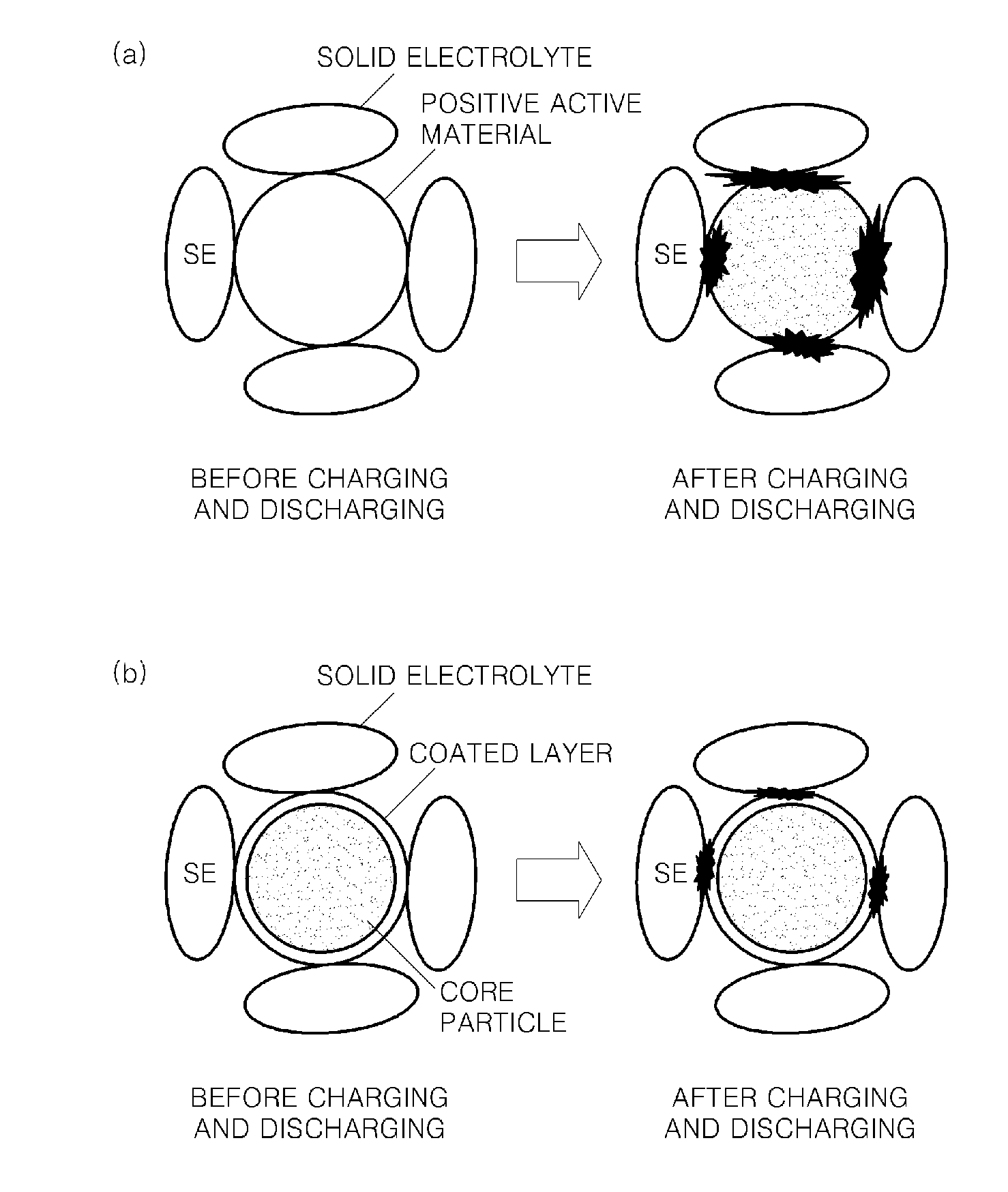

All-solid lithium ion secondary battery and electrode therefor

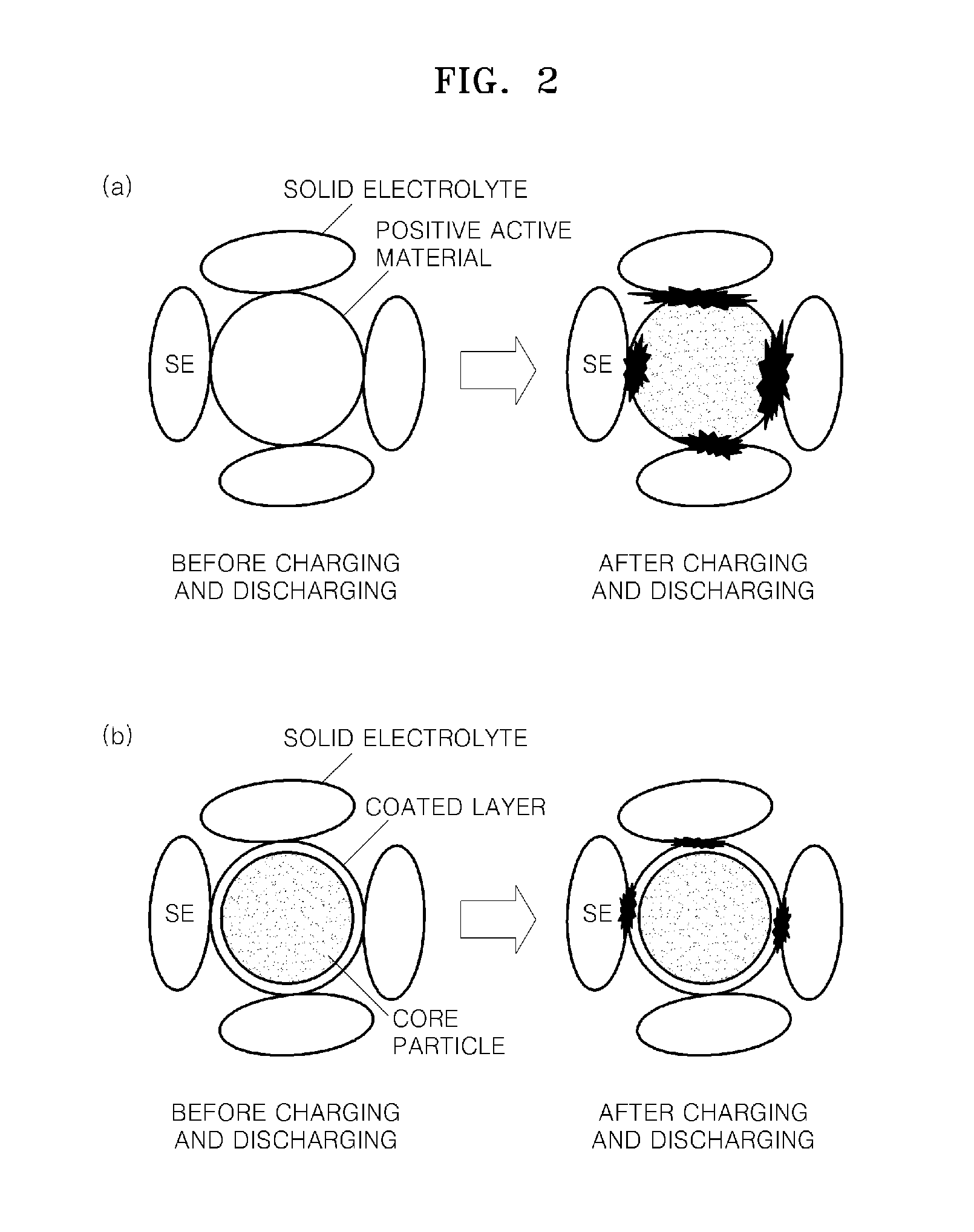

InactiveUS20120021298A1Suppressed opportunityAvoid HierarchySolid electrolytesCell electrodesInterfacial reactionCompound (substance)

The positive electrode of a solid lithium ion secondary battery including a solid electrolyte and a positive active material that includes core particles and a coated layer at least partially covering the surfaces of the core particles. The core particles comprise a layered lithium composite oxide including a metal element having an oxidation number that remains constant during charging and discharging within a voltage range from about 2 V to about 5 V. The coated layer comprises a metal compound including a metal element having an oxidation number that remains constant during charging and discharging within a voltage range from about 2 V to about 5 V. The structure of the positive active material is stable over repeated charge and discharge cycles. Interfacial reaction between the positive active material and the solid electrolyte is suppressed. The solid lithium ion secondary battery has high output power and a long lifetime.

Owner:SAMSUNG ELECTRONICS CO LTD

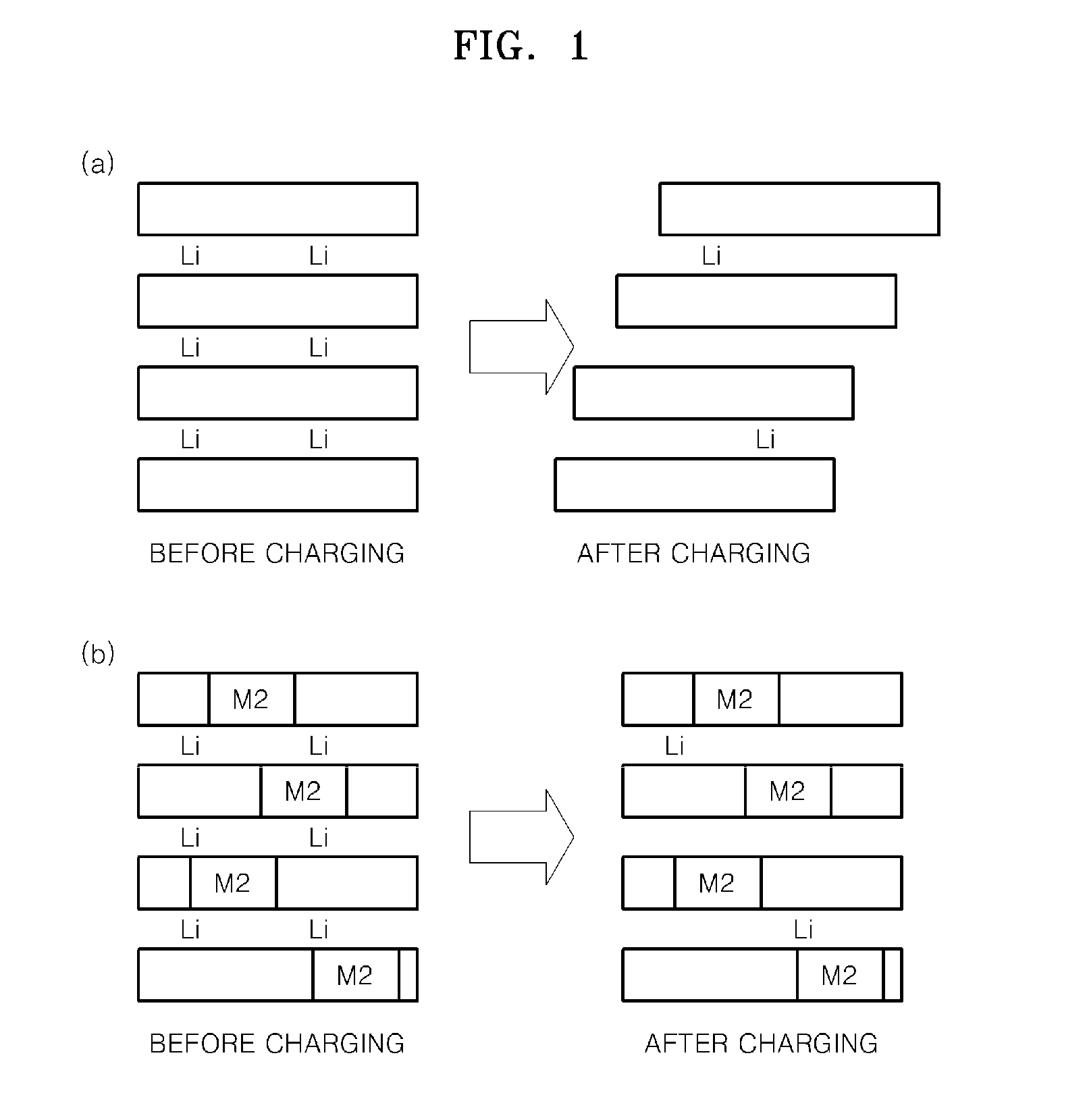

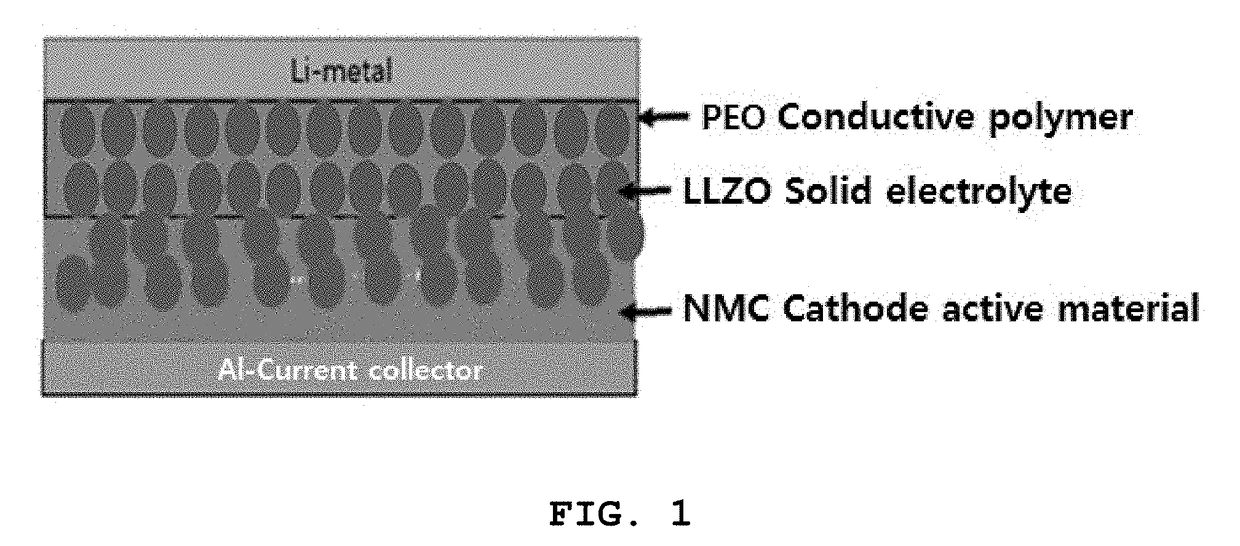

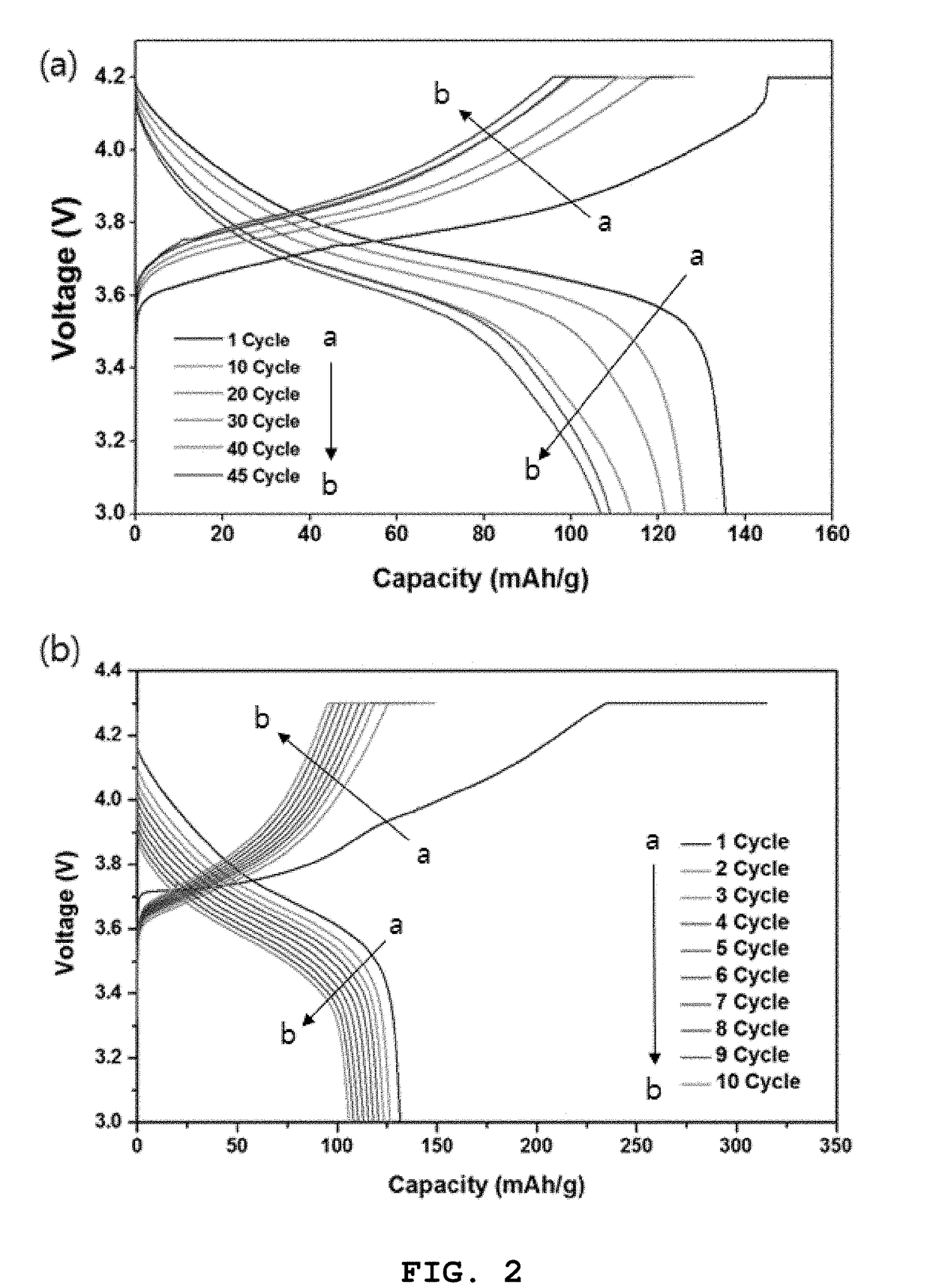

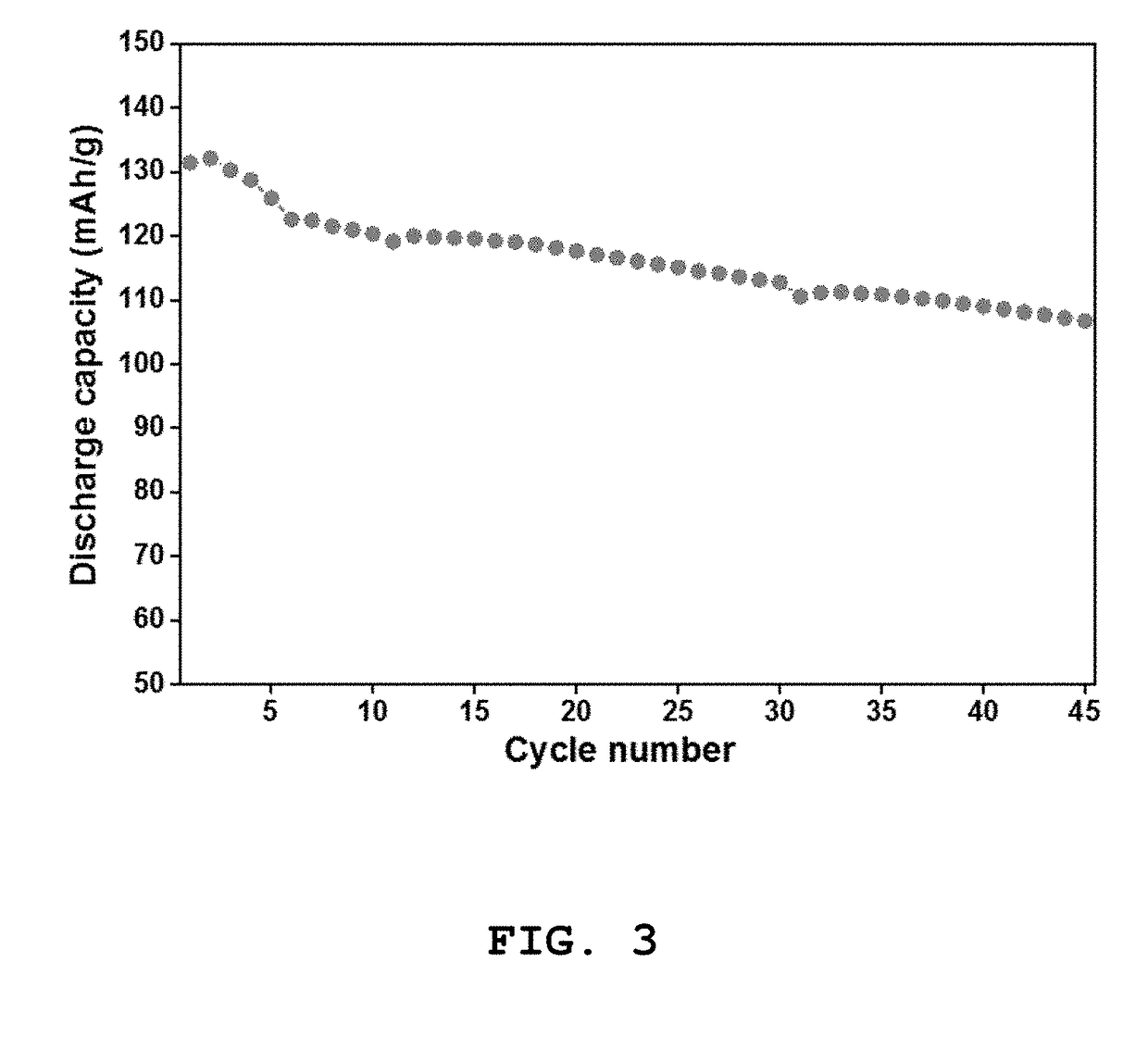

All-solid-state lithium secondary battery containing llzo solid electrolyte and method for preparing same

ActiveUS20190051934A1Improve discharge capacityExcellent cycle characteristicsSolid electrolytesFinal product manufactureInterfacial reactionManufacturing cost reduction

The present invention relates to an all-solid-state lithium secondary battery and a method of manufacturing the same. The all-solid-state lithium secondary battery includes a cathode, an anode, and a composite solid electrolyte layer between the cathode and the anode, wherein first and second LLZOs contained respectively in the cathode and the composite solid electrolyte layer are each independently aluminum-doped or undoped LLZO, and the battery of the invention can exhibit improved discharge capacity and cycle characteristics because both the cathode and the composite solid electrolyte layer contain a conductive polymer, a lithium salt and an inorganic ceramic solid electrolyte. The method of the invention enables the all-solid-state lithium secondary battery to be manufactured in a non-sintering manner, thus reducing manufacturing costs and controlling interfacial reactions between active materials, between solid electrolyte particles, and between an electrolyte and an electrode, thereby further reducing the internal resistance of the battery.

Owner:KOREA INST OF IND TECH

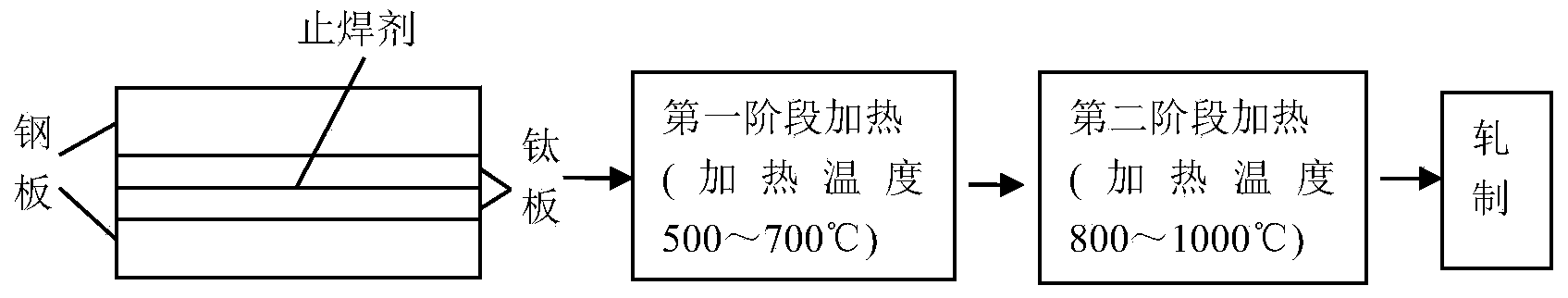

Manufacturing method of titanium rolled composite plate

InactiveCN104001719AImprove the bonding strength of the interfaceReduce spreadAuxillary arrangementsMetal rolling arrangementsInterfacial reactionTitanium

The invention provides a manufacturing method of a titanium rolled composite plate and belongs to the material processing field. The method is characterized in that a titanium plate-steel plate combined blank manufactured by use of a common method is heated at two stages: firstly, the titanium plate-steel plate combined blank is put in a heating furnace and heated to the range of 500-700 DEG C; after heat preservation of 50-90 minutes, the titanium plate-steel plate combined blank is further heated to the range of 800-1000 DEG C, and then heat is preserved for 10-20 minutes so that the temperature of the internal titanium layer is lower than that of the external steel layer. The heating at the first stage is carried out at a low temperature and thus capable of reducing the degree of element diffusion between the titanium plate and the steel plate, while the heating at the second stage is carried out at a higher temperature and thus advantageous for hot rolling. In addition, the short-time high-temperature heating at the second stage aims at enabling the temperature of the internal titanium layer is lower than that of the external steel layer. Due to the adoption of the manufacturing method, element diffusion between the steel plate and the titanium plate can be retarded and the degree of an interfacial reaction can be reduced, and therefore, the titanium composite plate with higher bonding strength can be manufactured.

Owner:UNIV OF SCI & TECH BEIJING

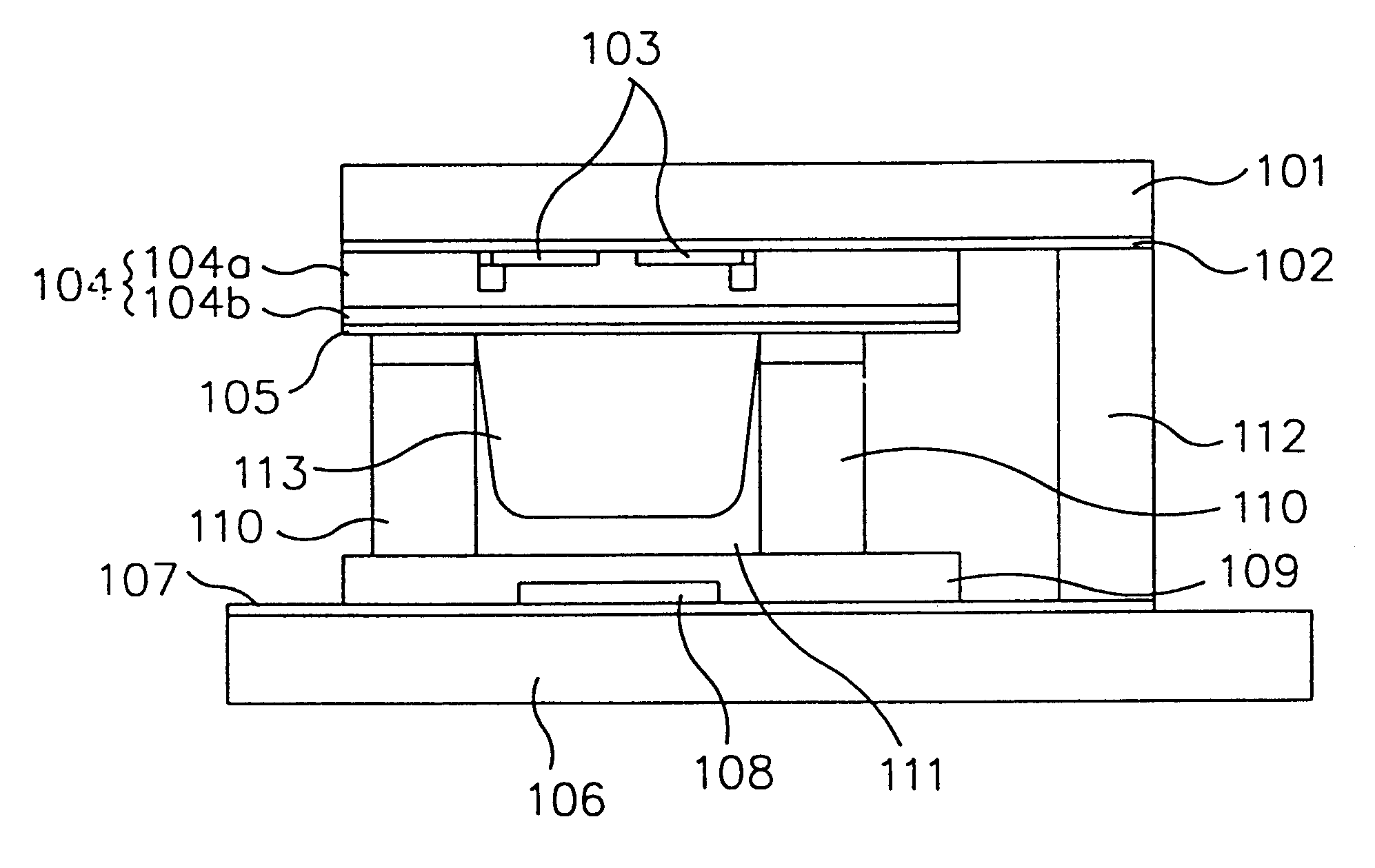

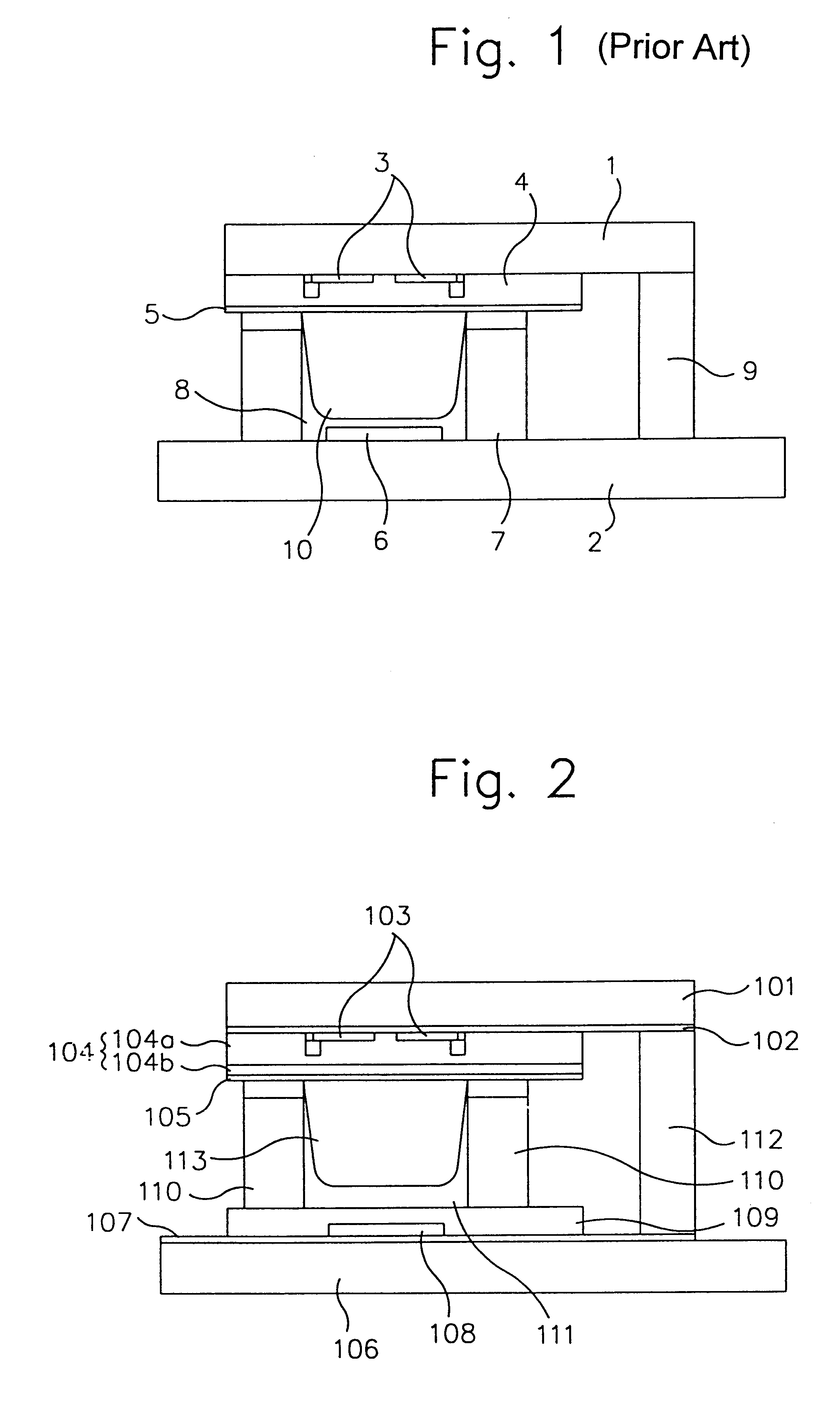

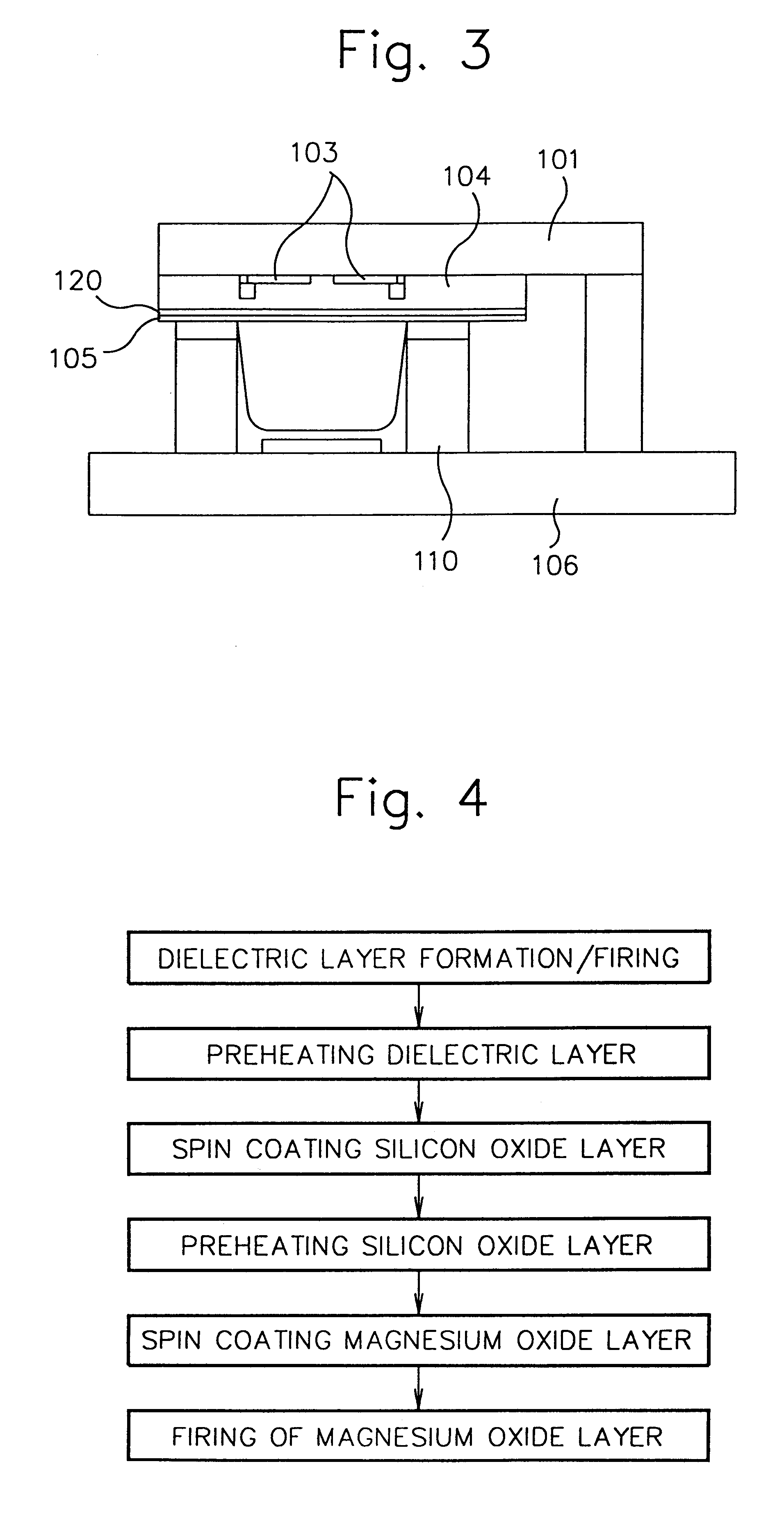

Substrate structure of plasma display panel and its fabricating method

InactiveUS6215246B1Prevent short-circuitingAlternating current plasma display panelsCold-cathode tubesInterfacial reactionPhosphor

An electrode structure of a PDP (plasma display panel) and its manufacturing method, where the production cost is curtailed with the extension of life by forming a protection layer of excellent properties and low cost on an insulating substrate during the manufacture of the panel. The structure comprises two substrates coupled in parallel with each other by frit glass. One of the two substrates has sustain electrodes. One or more dielectric layers are formed over the sustain electrodes, and an interfacial reaction preventive layer and a protection layer are formed over the dielectric layers. The other substrate has address electrodes arranged thereon. A lower dielectric layer is formed over the address electrodes. Barriers coated with phosphor are formed between the upper and lower substrates. The protection layer may be deposited in a multilayered form by a spin coating method.

Owner:LG ELECTRONICS INC

All-solid-state lithium battery and preparation method thereof

ActiveCN108511786ASolve the problem of interdiffusionFinal product manufactureElectrolyte accumulators manufactureInterfacial reactionSolid state electrolyte

The invention relates to an all-solid-state lithium battery and a preparation method thereof. The all-solid-state lithium battery comprises a positive plate, a negative plate and a solid electrolyte layer, wherein the positive plate comprises a positive active substance, and the positive active substance comprises positive material particles and a fluorine-containing lithium titanate layer coatingthe surfaces of the positive material particles. According to the method for preparing the positive active substance with a positive material coated by the fluorine-containing lithium titanate layerfrom the positive material, titanium tetrafluoride and a lithium salt through mixing and sintering, the surface of the positive material can be uniformly modified so as to obtain the positive materialwith controllable fluorine content and fluorine-containing lithium titanate layer thickness on its surface. When the positive material is used in the all-solid lithium battery, the structure of a coating can be stabilized, interfacial reaction or element diffusion between the positive material and the solid electrolyte can be avoided, and interface impedance is reduced.

Owner:BYD CO LTD

Method for preparing silicon oxide-based ceramic core for titanium and titanium alloy casting

The invention relates to a method for preparing a silicon oxide-based ceramic core for titanium and titanium alloy casting. The method comprises steps of preparing a blank of the silicon oxide-based ceramic core, preparing a ZrO2 or Y2O3 coating on the surface of the blank of the silicon oxide-based ceramic core through a surface coating technology, and intensively sintering the ceramic core. The silicon oxide-based ceramic core prepared by the method can effectively overcome the defect that the zirconia or yttria-based ceramic core has high cost and is difficult to remove as well as the defect that conventional silicon oxide ceramic core cannot be used due to strong interfacial reaction in solidification of the titanium alloy.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

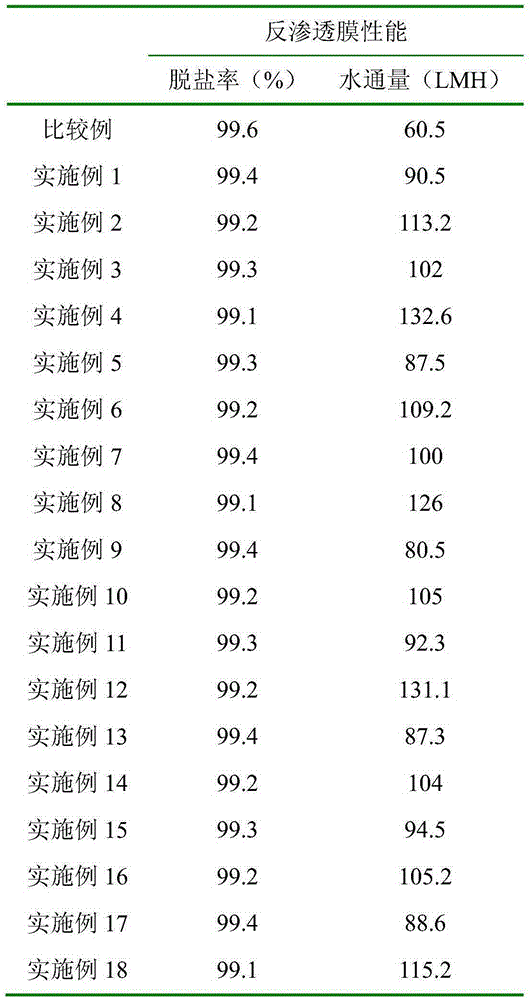

Preparation method of high water flux reverse osmosis membrane

InactiveCN105396471AHigh desalination rateGood reproducibilitySemi-permeable membranesInterfacial reactionDesalination

The invention belongs to the technical field of reverse osmosis composite membrane, and specifically refers to a high water flux reverse osmosis membrane and a preparation method thereof. An interfacial reaction of an aqueous solution of aromatic polyamine with polybasic acyl chloride solution is carried out on a porous support film, wherein the aqueous phase or organic phase solution for interfacial polymerization is supplemented with a polar aprotic additive; and certain subsequent treatment is carried out. The present invention has the advantage that the provided a preparation method is simple, and low in operating pressure; and the prepared polyamide reverse osmosis composite membrane has high water flux without significant reduction in the rate of desalination. The high water flux polyamide composite reverse osmosis membrane of the present invention has broad application prospects.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

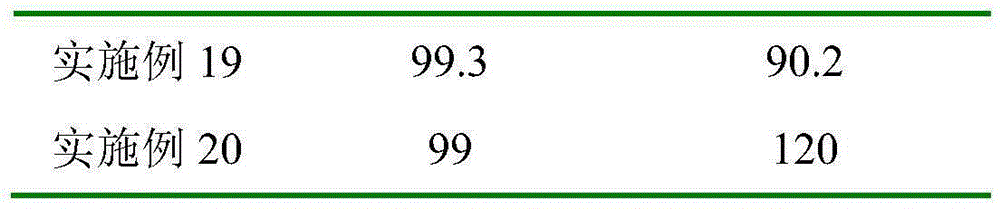

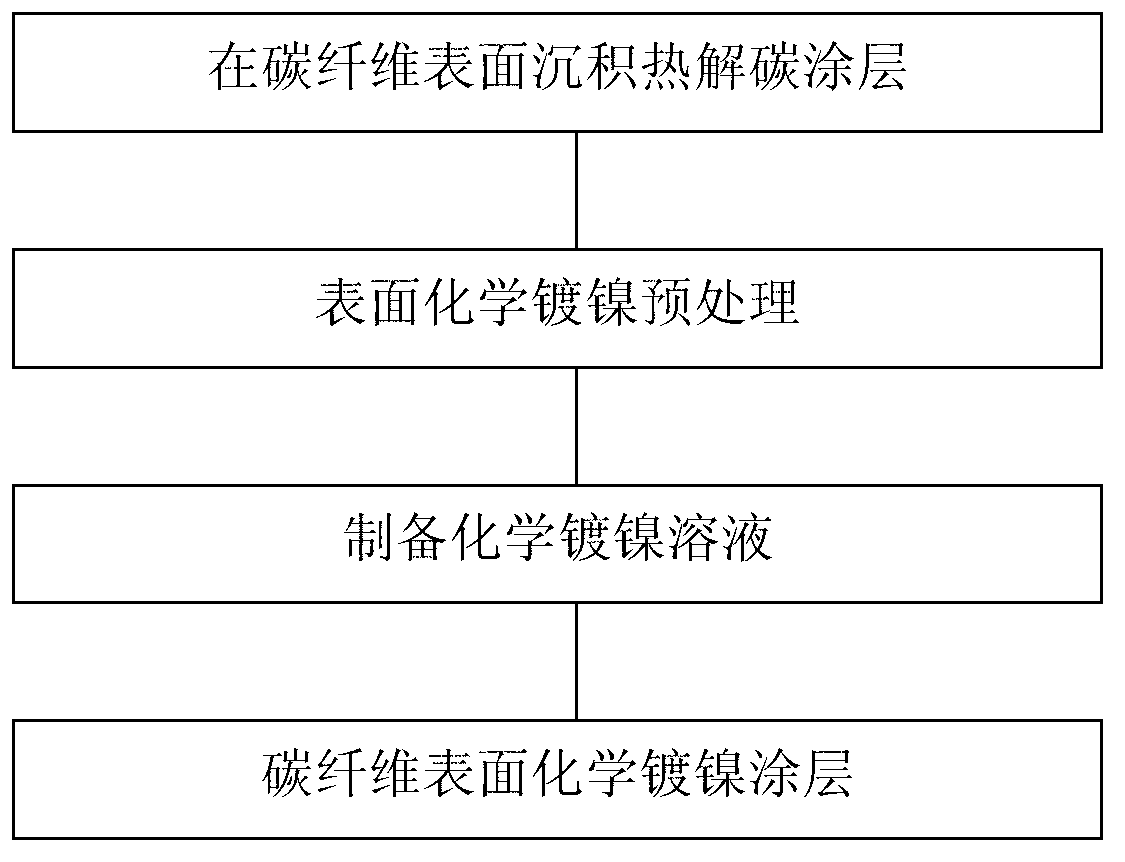

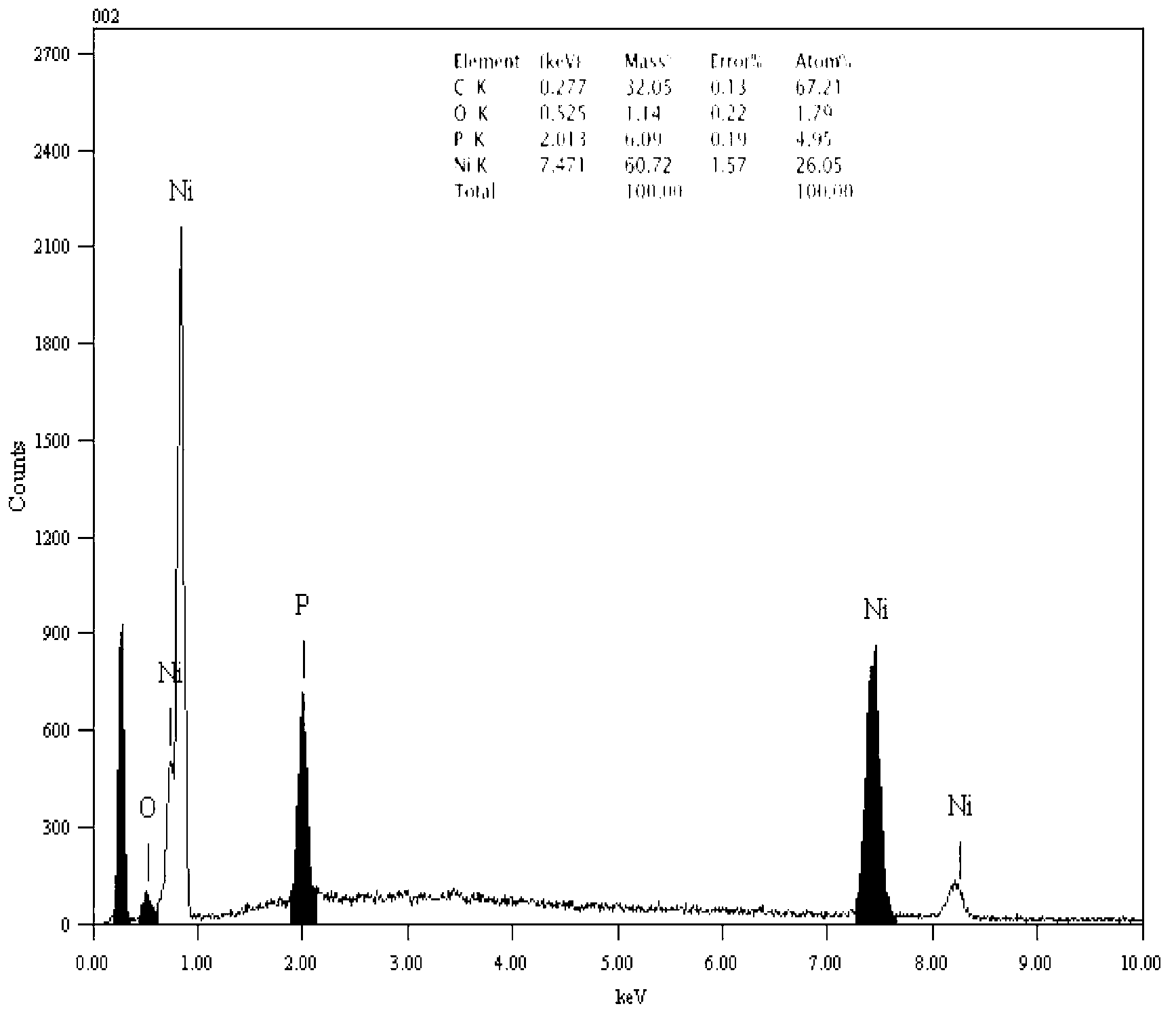

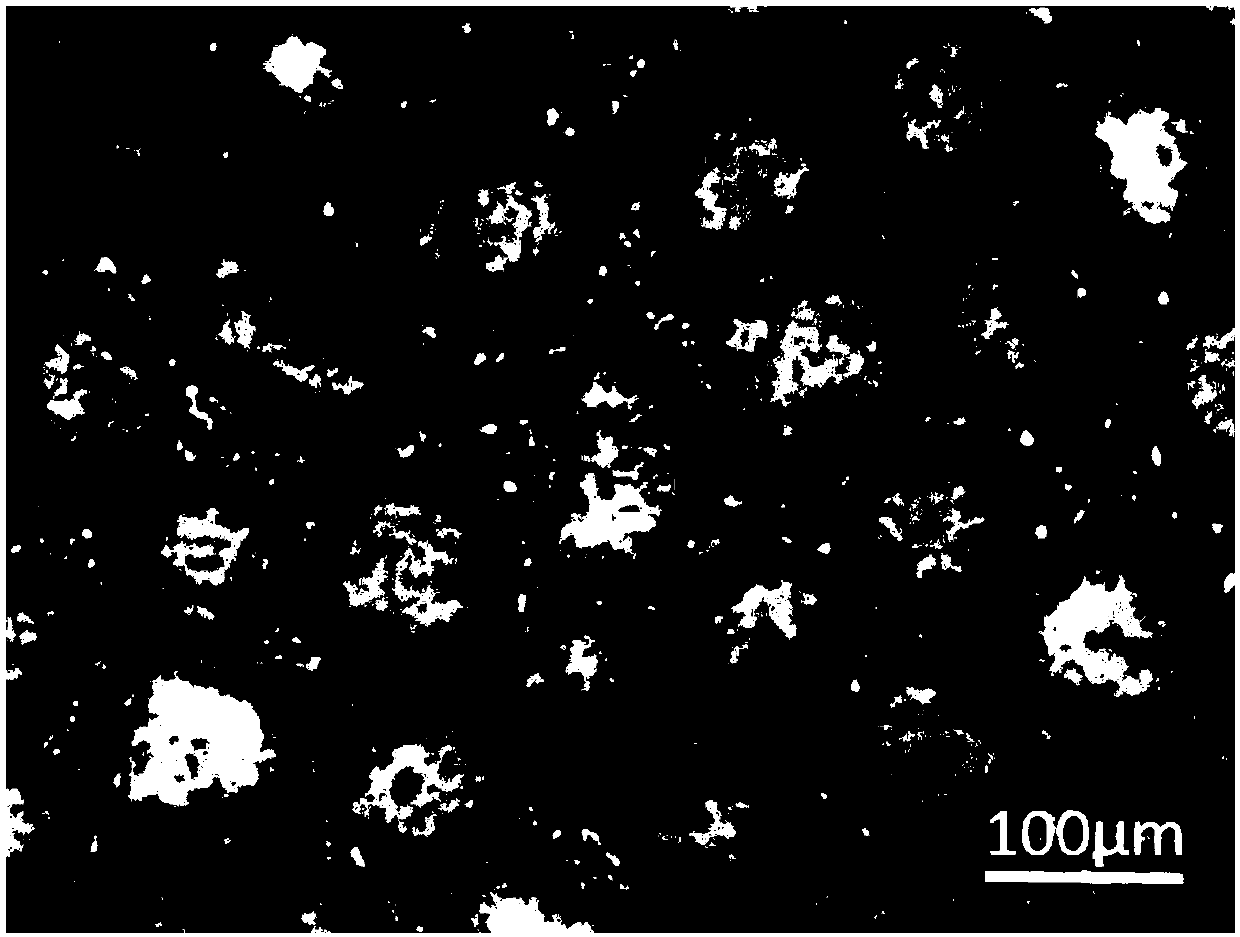

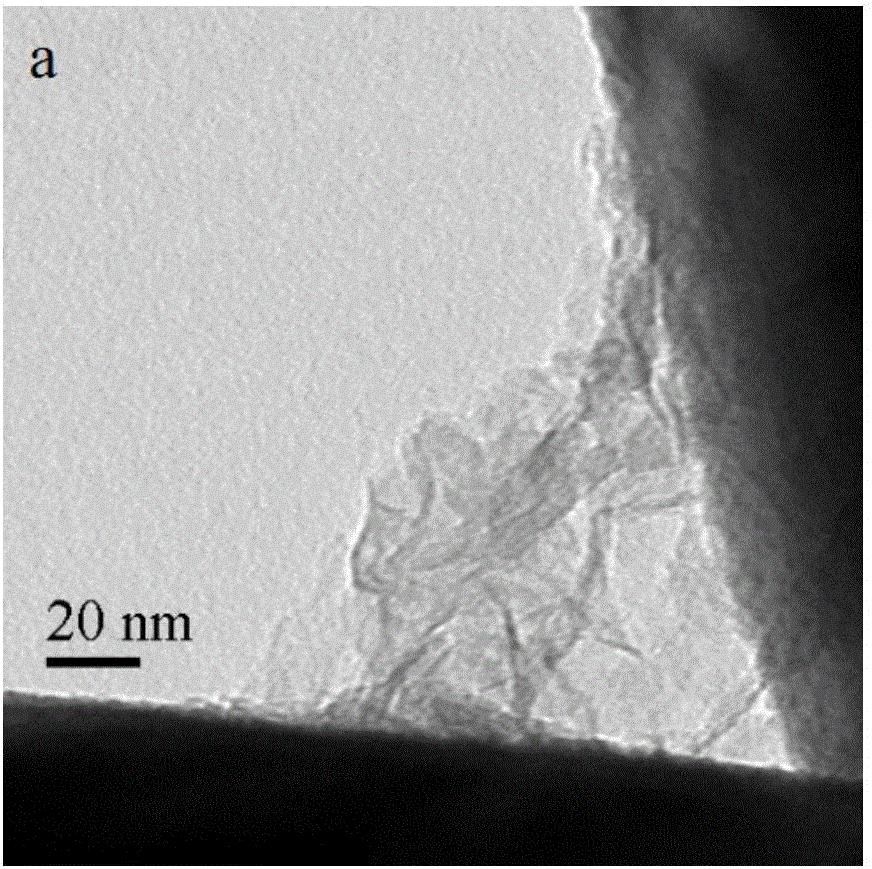

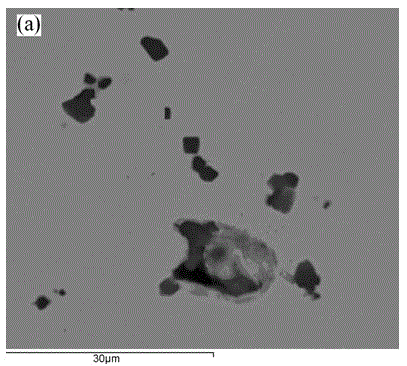

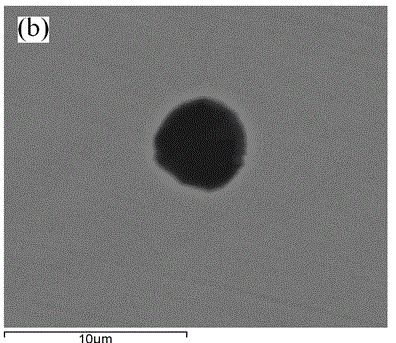

Preparation method of continuous carbon fiber surface pyrolytic carbon/nickel composite coating

ActiveCN103160826AAvoid Hole DefectsImprove the preparation effectLiquid/solution decomposition chemical coatingChemical vapor deposition coatingFiberInterfacial reaction

The invention discloses a preparation method of a continuous carbon fiber surface pyrolytic carbon / nickel composite coating. According to the invention, a pyrolytic carbon coating is prepared on the surface of a carbon fiber in weftless carbon fiber cloth through a chemical vapor deposition method, and the thickness of the pyrolytic carbon coating is 0.03-0.1 micrometer. A nickel coating is prepared on the surface of the carbon fiber with the pyrolytic carbon coating through a chemical plating method. By controlling the reaction time of the carbon fiber in a chemical nickel-plating solution, the thickness of the nickel coating is controlled to 0.02-0.1 micrometer, so that the carbon fiber containing a pyrolytic carbon / nickel composite coating which is 0.05-0.2 micrometers in thickness is acquired. According to the preparation method, the carbon fiber can be well prevented from being oxidized and is effectively prevented from being damaged and destroyed; and the occurrence of too many interfacial reactions between the carbon fiber and aluminum alloy can be reduced because the microstructure of pyrolytic carbon tends to be graphitized so that the interface combinability between the carbon fiber and the aluminum alloy can be adjusted.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

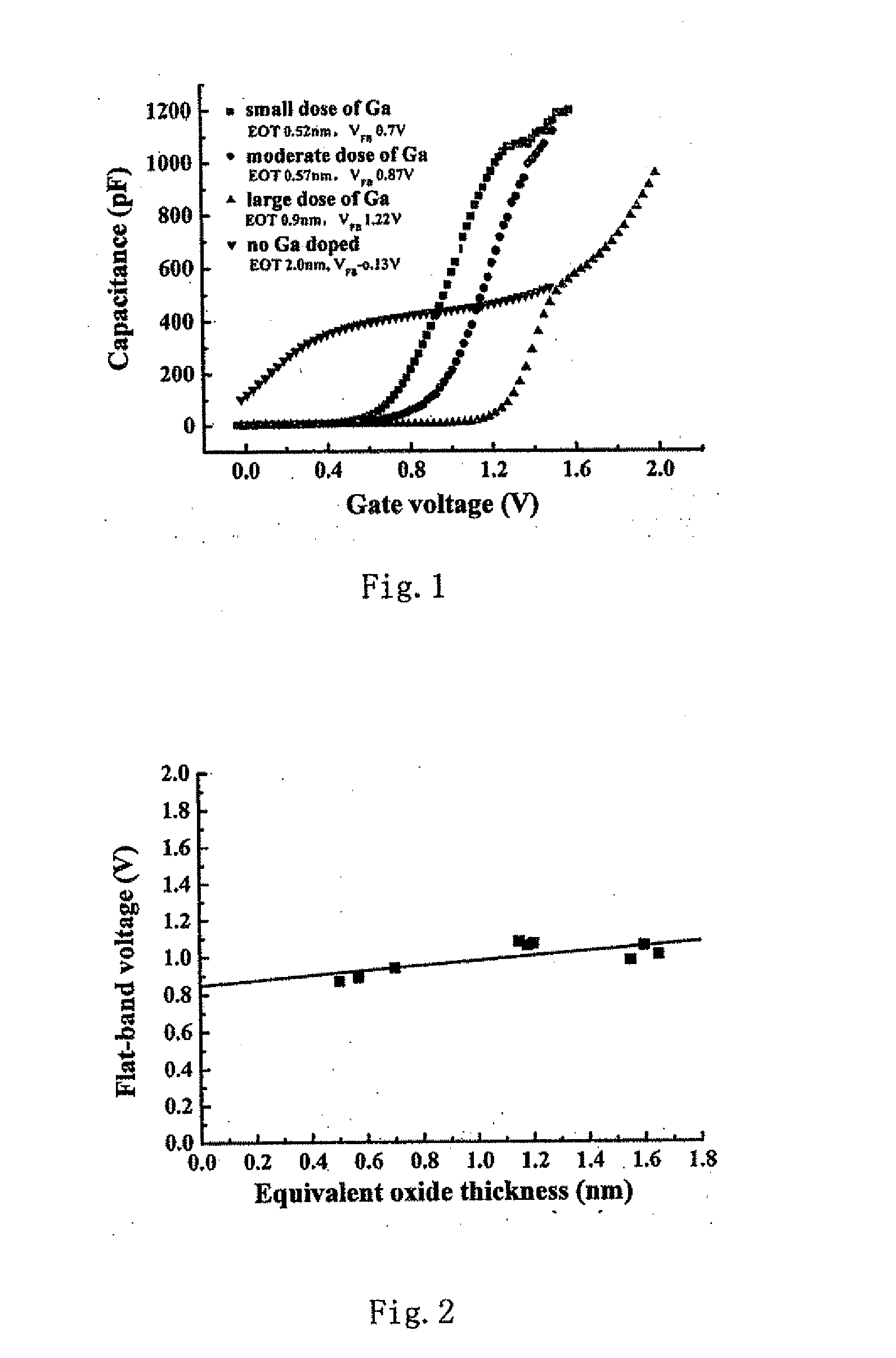

Method for tuning the work function of a metal gate of the pmos device

ActiveUS20110256701A1The process is simple and convenientImprove thermal stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesInterfacial reactionGate dielectric

The present application discloses a method for tuning the work function of a metal gate of the PMOS device, comprising the steps of depositing a layer of metal nitride or a metal on a layer of high-k gate dielectric by physical vapor deposition (PVD), as a metal gate; doping the metal gate with dopants such as Al, Pt, Ru, Ga, Ir by ion implantation; and driving the doped metal ions to the interface between the high-k gate dielectric and interfacial SiO2 by high-temperature annealing so that the doped metal ions accumulate at the interface or generate dipoles by interfacial reaction, which in turn tunes the work function of the metal gate. The inventive method can be widely used and its process is simple and convenient, has a better ability of tuning the work function of the metal gate, and is compatible with the conventional CMOS process.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

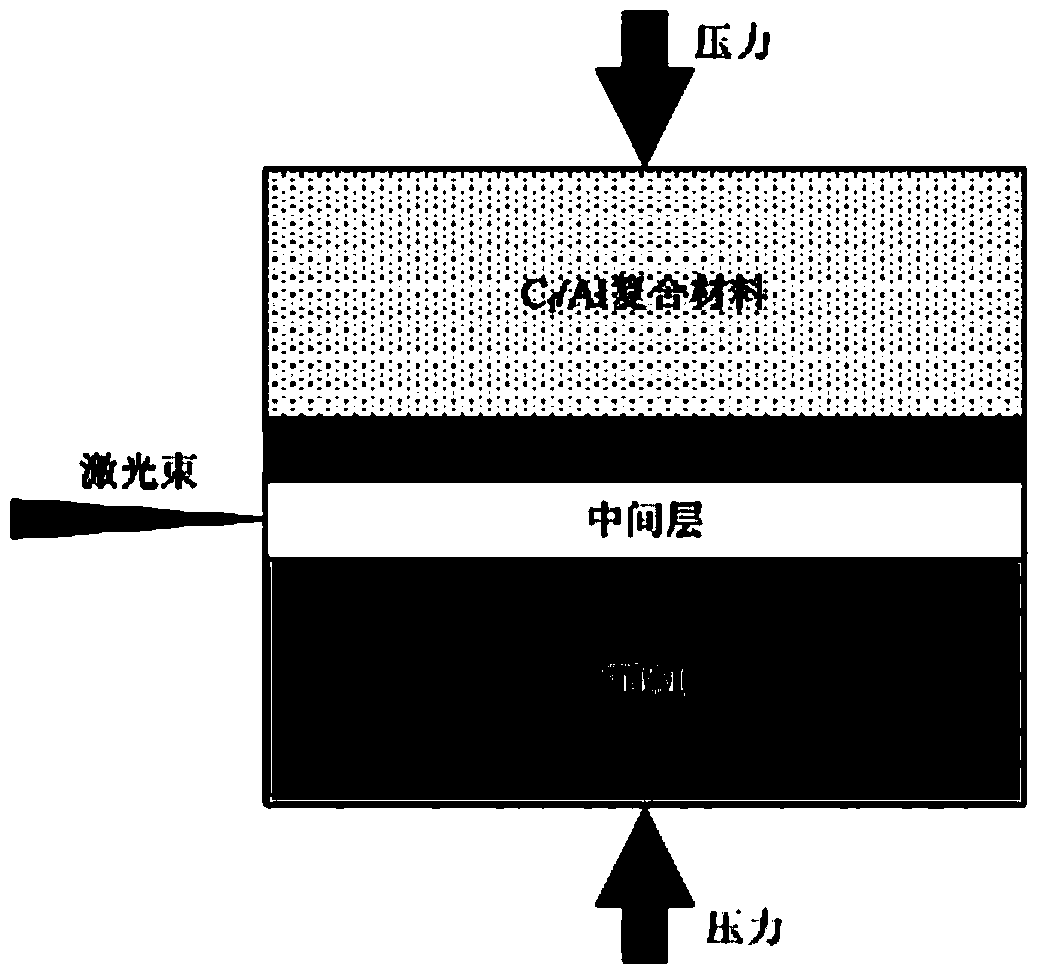

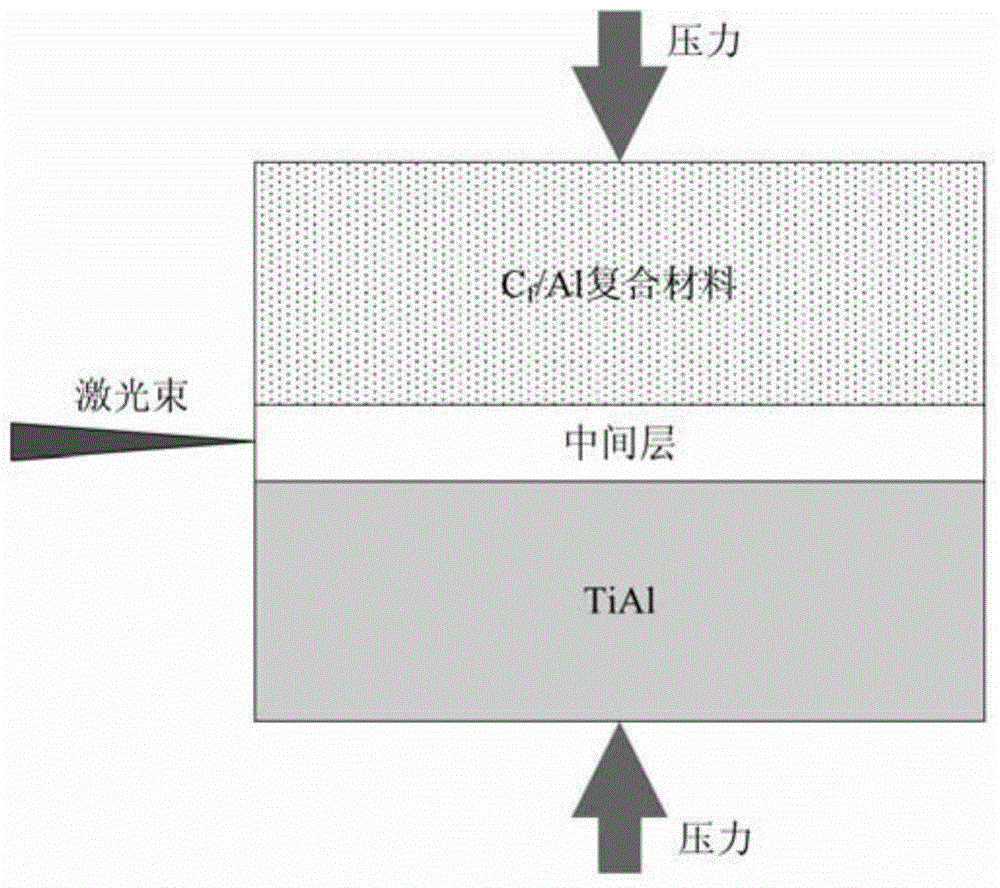

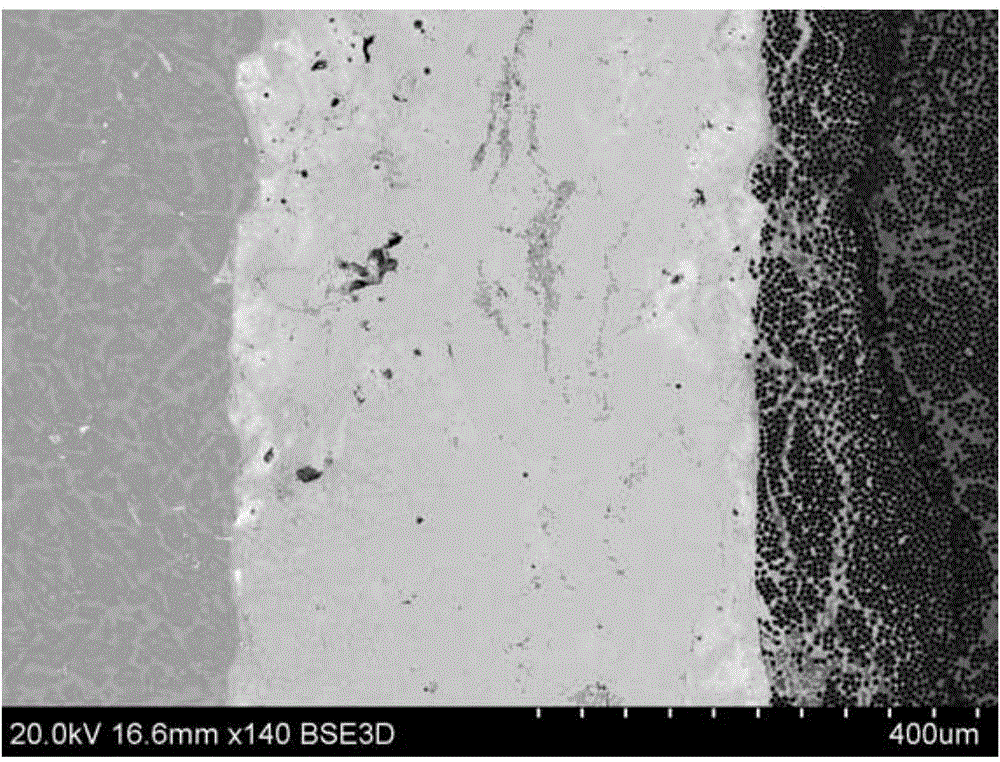

Method for connecting Cf/Al composite materials and TiAl through laser ignition self-propagating reaction auxiliary brazing

InactiveCN103586582APerformance is not affectedImprove performanceSoldering apparatusWelding/soldering/cutting articlesInterfacial reactionAl powder

Owner:HARBIN INST OF TECH

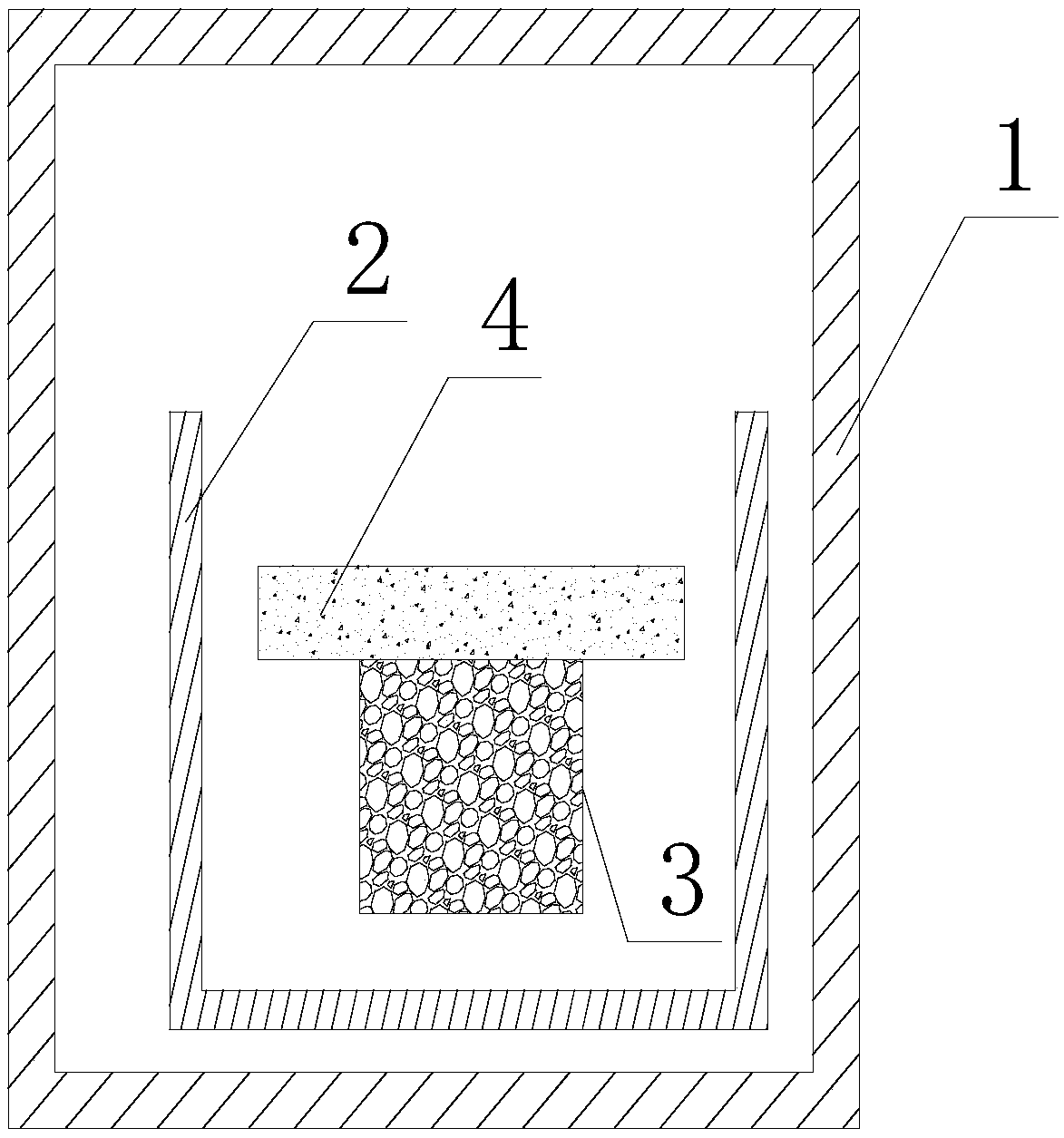

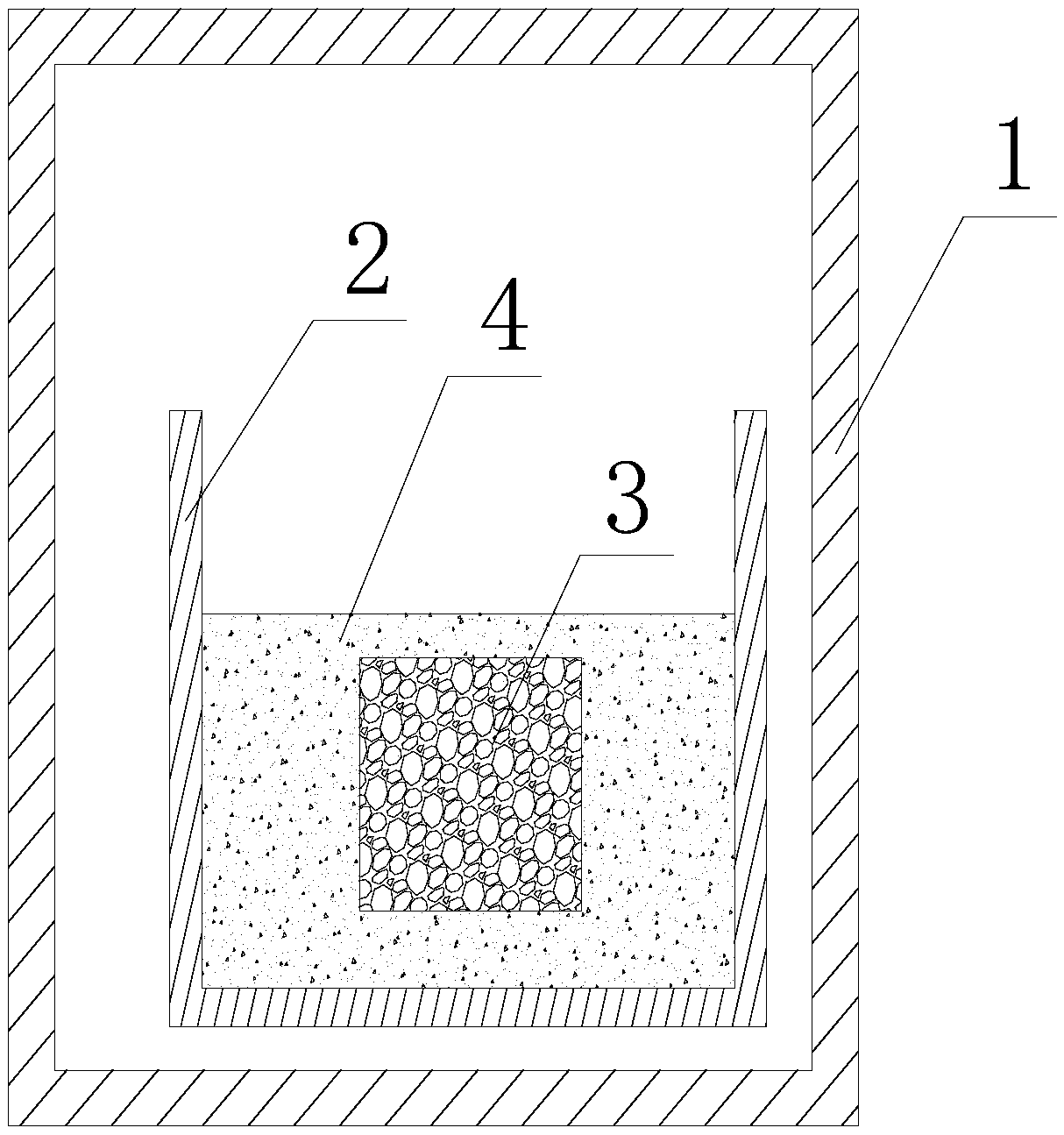

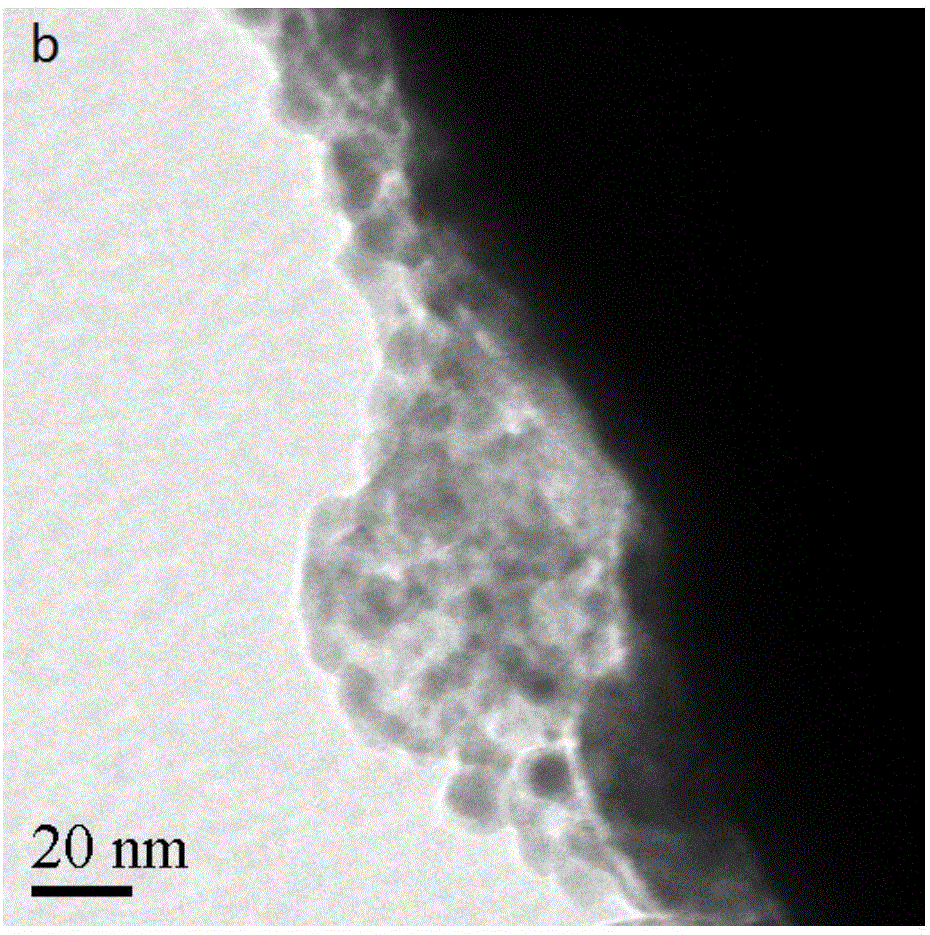

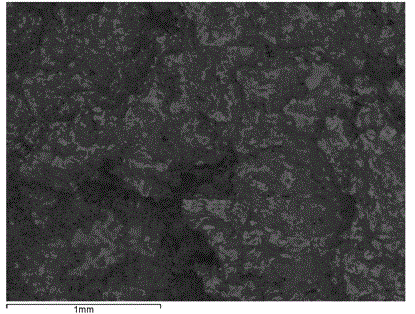

Diamond/aluminum composite and efficient preparation method thereof

ActiveCN107739948ALow density solutionImprove thermal conductivityInterfacial reactionAluminum metal

The invention relates to diamond / aluminum composites and preparation methods of the diamond / aluminum composites, in particular to a diamond / aluminum composite and an efficient preparation method of the diamond / aluminum composite. The diamond / aluminum composite and the efficient preparation method of the diamond / aluminum composite aim to solve the problems that a diamond / aluminum composite preparedin the prior art is poor in interface bonding strength and low in heat conductivity, infiltration efficiency and density, and the interfacial reaction of diamond and aluminum is insufficient. The diamond / aluminum composite is composed of aluminum metal and diamond powder with a coating film layer, and intervals of the diamond powder with the coating film layer are filled with the aluminum metal.The efficient preparation method of the diamond / aluminum composite comprises the steps of firstly, preparing a near-net forming mold; secondly, coating the surface of the diamond powder with the film;thirdly, conducting pressure infiltration preparation, fourthly, conducting pressure infiltration and fifthly conducting demolding. The density of the diamond / aluminum composite reaches 99.8% or over, the production efficiency is improved, the raw material cost is reduced, and the interface bonding strength and the heat conductivity are improved. The efficient preparation method is suitable for preparation of the diamond / aluminum composite.

Owner:HARBIN INST OF TECH

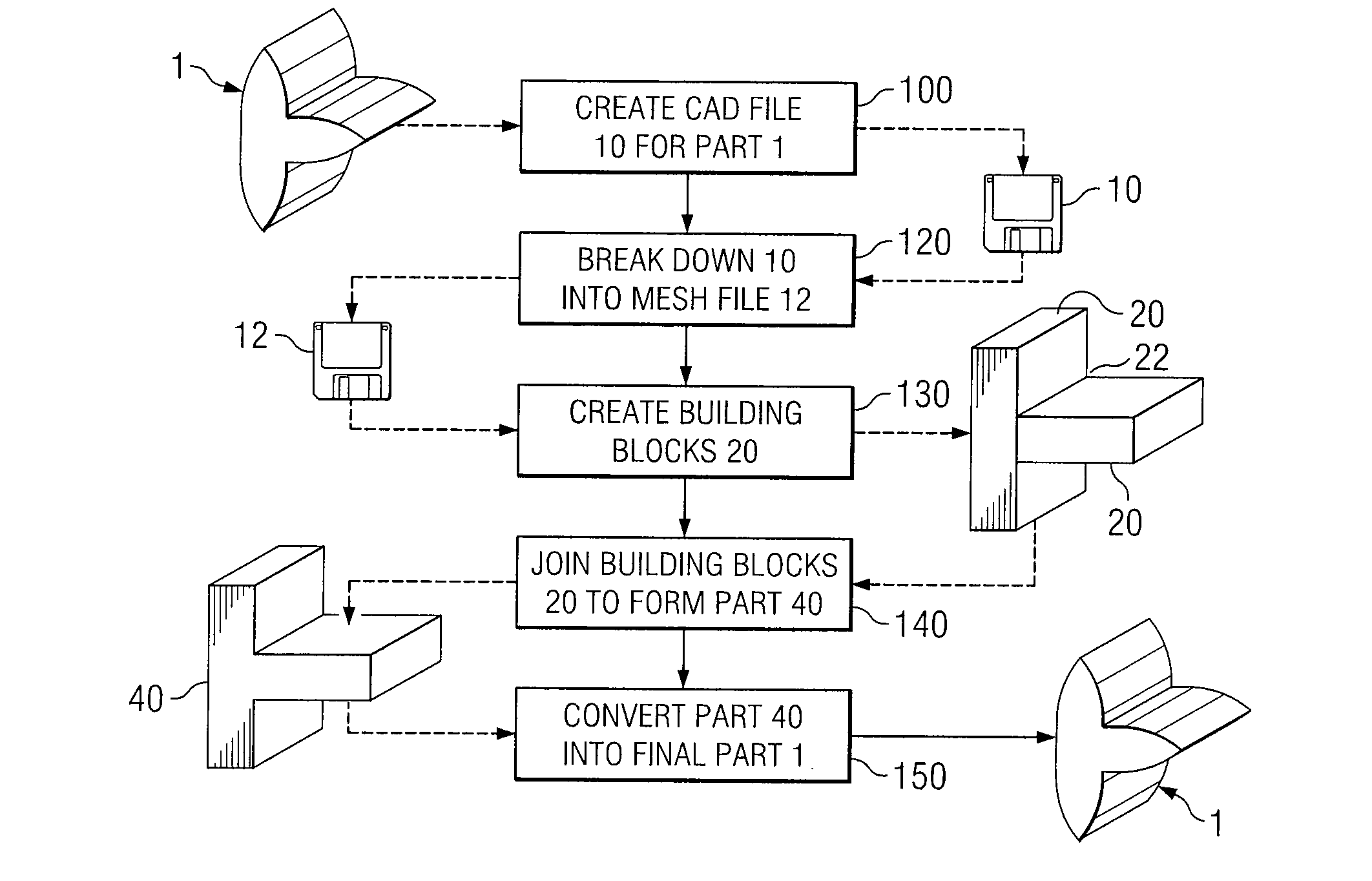

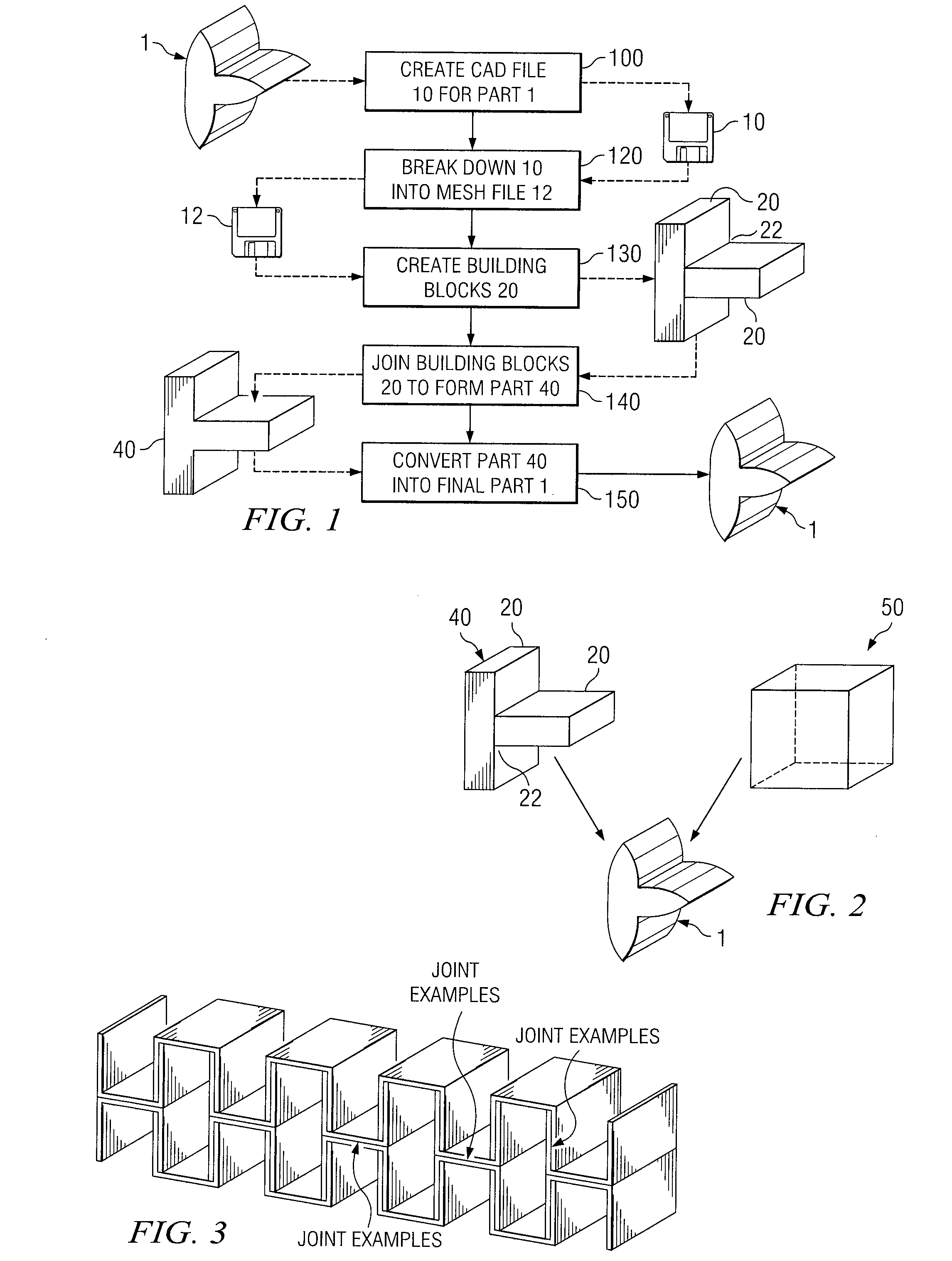

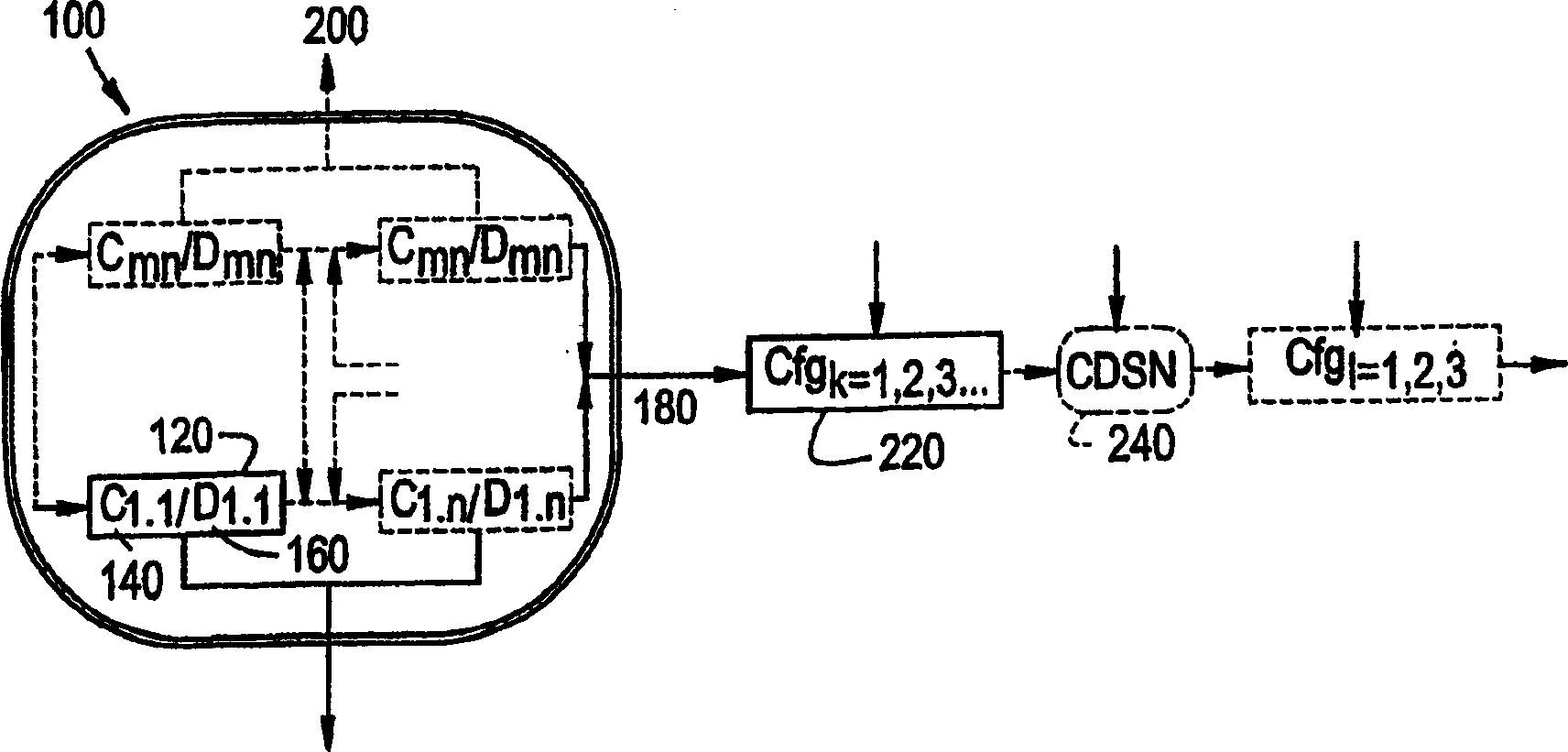

Method to construct and physically join building blocks into a near-net shaped part using an interfacial reaction-activation mechanism

The disclosure provides a method to construct and physically join near-net shaped structural building blocks into a composite part using an interfacial reaction-activation mechanism.

Owner:SOUTHWEST RES INST

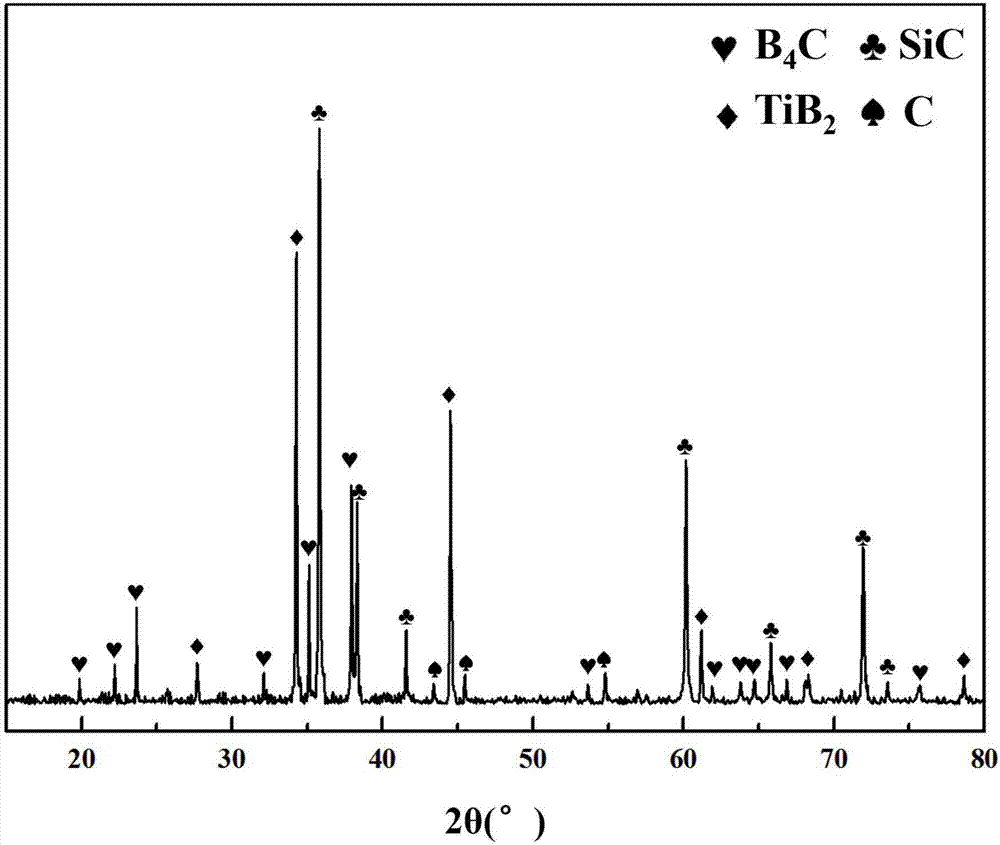

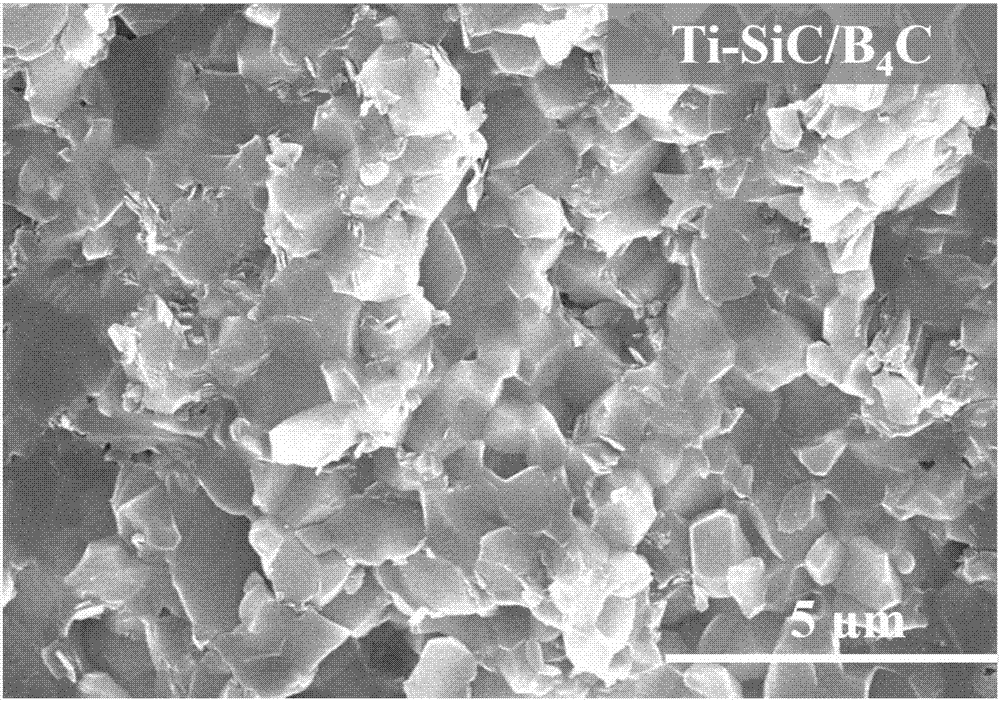

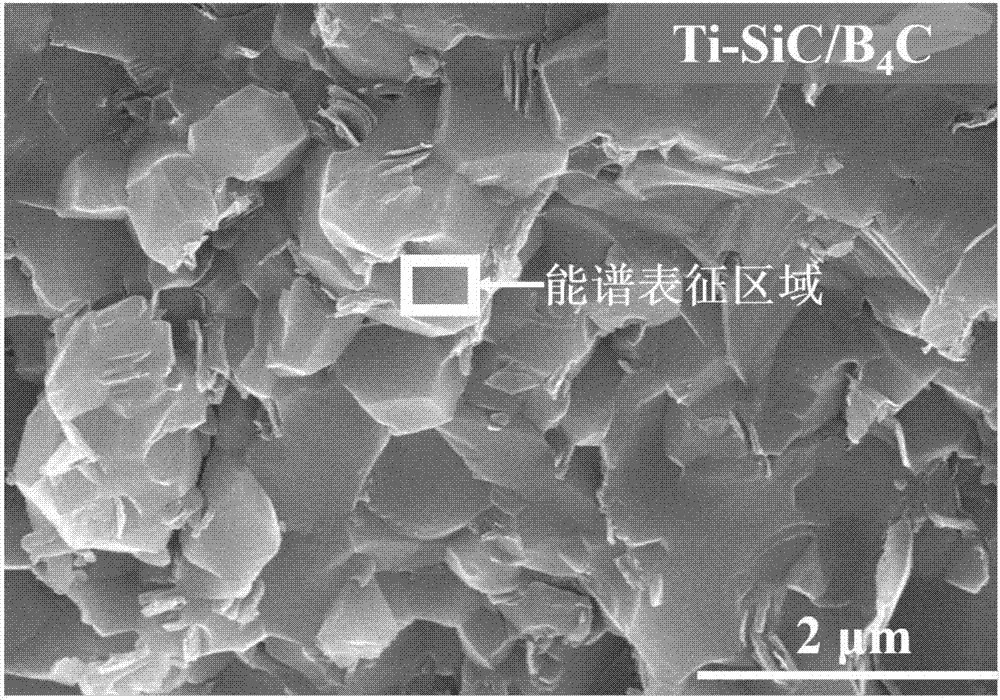

Ti-enhanced B4C/SiC multiphase ceramic

InactiveCN107043261AImprove mechanical propertiesPromote sinteringCeramic compositeTransgranular fracture

The invention relates to a Ti-enhanced B4C / SiC multiphase ceramic, which belongs to the technical field of a metal particles-enhanced ceramic composite material. In the Ti-enhanced B4C / SiC multiphase ceramic, Ti and B4C are subjected to an interface reaction to generate a TiB2 phase, optimization of object phase composition is realized, crystal grain refinement effect is realized, and mechanical properties of the multiphase ceramic can be increased; a lot of liquid phase is generated during a vacuum hot pressed sintering of Ti, sintering and densifying processes of the multiphase ceramic can be promoted, the microstructure of the prepared multiphase ceramic is compact; in addition, the multiphase ceramic has a transgranular fracture and intergranular fracture-coexisted mixing fracture mode, so that the fracture toughness property of the multiphase ceramic is increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for connecting Cf/Al composite with TiAl based on laser ignition and self-propagating reaction

InactiveCN103600169APerformance is not affectedUniform performanceWelding/cutting auxillary devicesAuxillary welding devicesFiberInterfacial reaction

Owner:HARBIN INST OF TECH

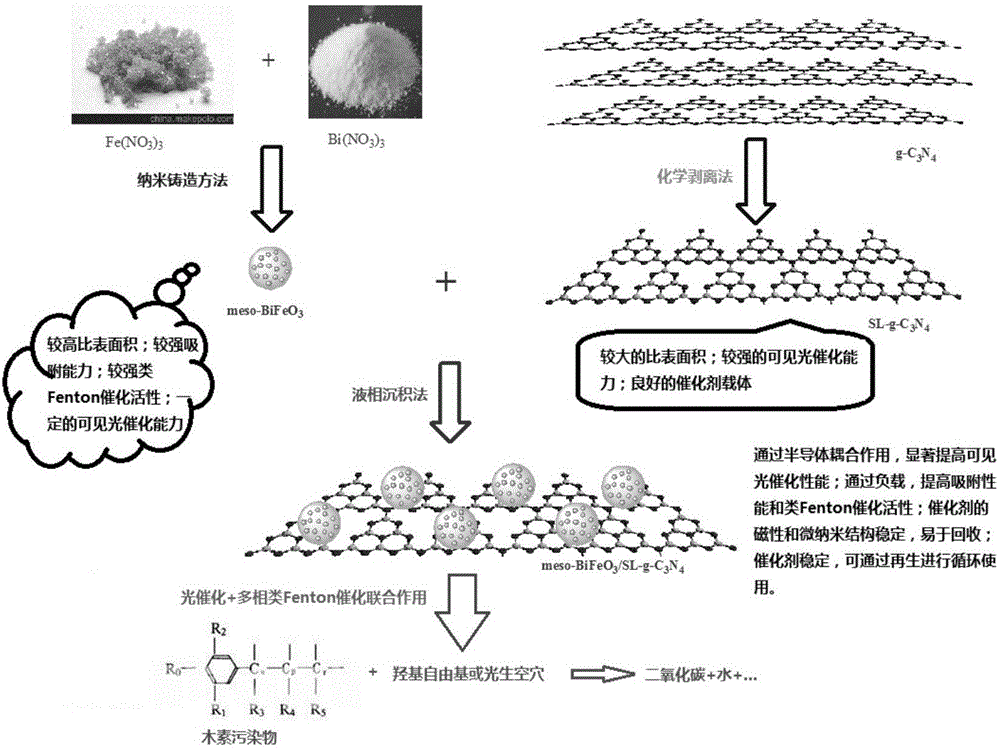

Bifunctional porous material efficient in adsorptively degrading lignin and preparation method thereof

InactiveCN106179171AImprove adsorption capacityHighly selective adsorptionWater/sewage treatment by irradiationOther chemical processesCouplingCarbon nitride

A bifunctional porous material efficient in adsorptively degrading lignin and a preparation method thereof are characterized in that the bifunctional porous material is made by compounding bismuth ferrite and carbon nitride nanosheets, the bismuth ferrite is of highly-ordered mesoporous structure, and a mol ratio of the mesoporous bismuth ferrite meso-BiFeO3 to the carbon nitride nanosheets g-C3N4 NS is (1-11):1; a composite catalyst uses the mesoporous nano bismuth ferrite as a main catalyst and ultrathin carbon nitride nanosheet carrier as a surface adsorbing modifying layer is provided, affinity between carbon nitride and a substrate is enhanced through Pi-Pi action and hydrophobic action between the carbon nitride and the substrate, adsorption is significantly enhanced for lignin, and interfacial reacting capacity is improved; semiconductor coupling action between the bismuth ferrite and carbon nitride promotes the separation and migration of photo-induced carriers in a heterophase interface, and visible light catalytic activity of the composite catalyst is improved; finally, in a reaction system of visible light and H2O2, highly oxidative materials such as hydroxyl radicals produced by catalysis of the catalyst attack lignin molecules and causes structural loop opening to the molecules, and efficient degradation is implemented; the material and the preparation method thereof are of important scientific significance and environmental benefit.

Owner:HUBEI UNIV OF TECH

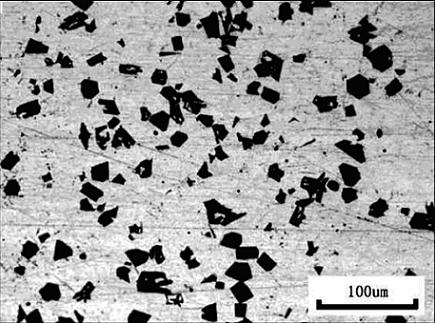

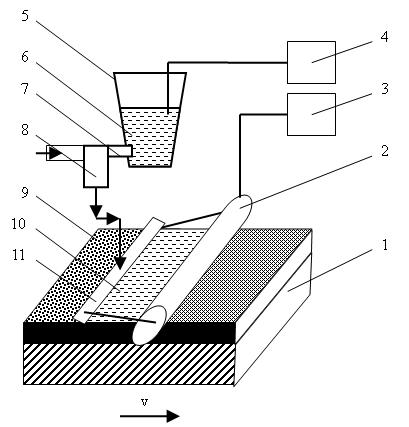

Method for preparing particle-enhanced metal matrix composite

InactiveCN102021357AImprove performanceReduce interface reactionInterfacial reactionMetal matrix composite

The invention relates to a method for preparing a metal matrix composite, in particular to a method for preparing a particle-enhanced metal matrix composite by laminating technology. In the method, a metal matrix in the metastable state such as a fine-grained, even amorphous state and the like obtained by combining quick cooling technology and the enhancement of ceramic particles is combined with the ceramic particles to achieve higher material performance; molten metal is blown onto surfaces of the ceramic particles under the protection of inert gases, and the ceramic particles are combined with the matrix firmly by rolling compaction; the molten metal blown later is compounded with a metal layer blown earlier, so that the combination of the ceramic particles and the metal matrix during the rolling compaction is improved further; and the processes are performed repeatedly until the particle-enhanced metal matrix composite with specified thickness is obtained. The method is easy and convenient to operate, and the large-scale industrial production is easy to realize; and due to high cooling rate, the matrix metal has high performance, and an interface reaction between the particles and the metal matrix is relieved simultaneously.

Owner:JIANGSU UNIV

Refined slag control method

ActiveCN102943150AImprove interface responsivenessAchieve transformationProcess efficiency improvementInterfacial reactionSlag

The invention provides a refined slag control method for improving castability of small square billet killed steel and belongs to steelmaking refinement control technologies. Aluminum wires are ensured not to be fed into a ladle furnace (LF) by adding sufficient aluminum alloy to perform deoxidization and adding an appropriate amount of synthesized slag to perform washing, simultaneously CaO, CaF2 and Al2O3 are adopted in the LF refining process to perform slag formation, slag charges are added in a batch mode, aluminum particles are scattered on the slag surface in the refining process according to the slag situations to ensure the slag reducibility, and finally final slag components are controlled as follows: CaO=45-55%, Al2O3=35-40%, MgO=5-10%, and SiO2<=5%. Therefore, the flowability of a slag system is good, steel slag interfacial reaction is facilitated, absorption of oxide inclusion in molten steel is facilitated, accordingly conversion and removal of aluminum deoxidized inclusion in the molten steel are promoted, the feeding amount of Ca wires can be decreased, even the Ca wires are not fed, the castability of the molten steel is good, and the liquid level of a crystallizer is stable.

Owner:YANGCHUN NEW STEEL CO LTD

Process for purification of polycarbonate-containing solutions by plate decantation

InactiveCN1461322AEfficient and economical separationEfficient and economical purificationCentrifugal force sediment separationSedimentation settling tanksInterfacial reactionCentrifugation

This invention relates to an economical and efficient process for purifying a reaction mixture obtained in a two-phase interfacial reaction for the preparation of polycarbonate. More particularly, the method of the invention provides for separating the reaction mixture into an organic phase, which includes the desired polycarbonate and undesirable impurities, and an aqueous phase. The organic phase is further purified by using a plate decanter in combination with coalescence and centrifugation.

Owner:SABIC GLOBAL TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com