Patents

Literature

168results about How to "Guaranteed filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement-based grouting material used for strengthening repairing as well as preparation method and application thereof

InactiveCN103880372AHigh injectabilityImprove anti-seepage performanceSwelling ratioCompressive strength

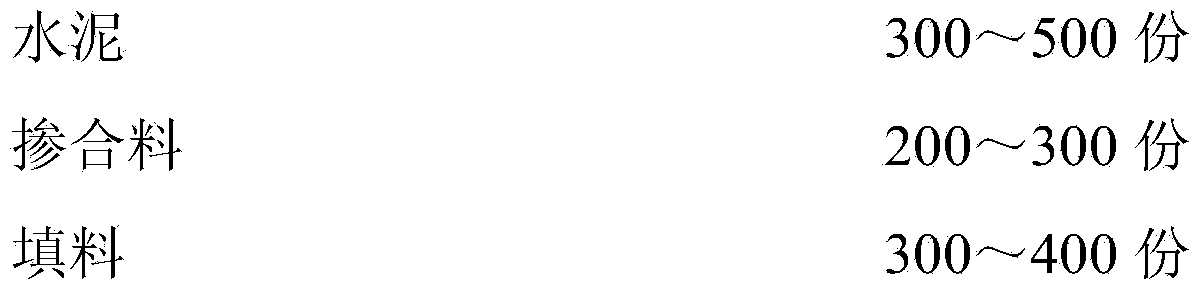

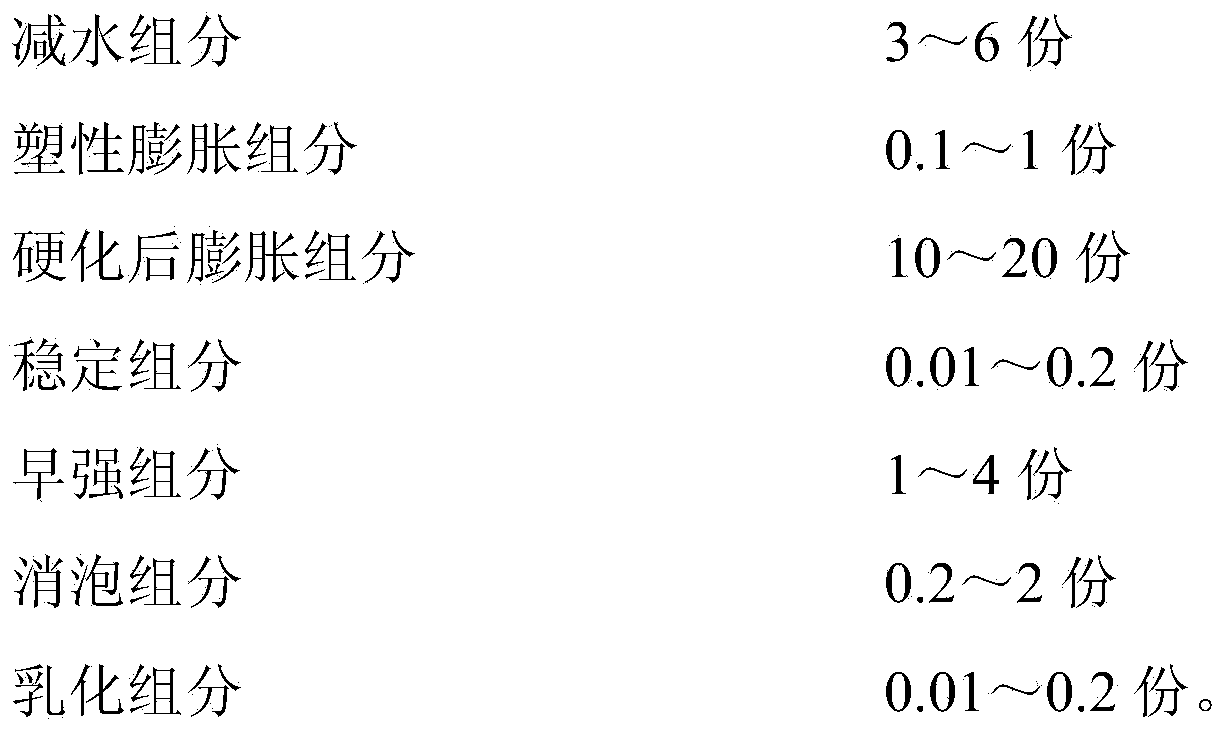

The invention relates to a cement-based grouting material used for strengthening repairing as well as a preparation method and application thereof. The cement-based grouting material comprises the following components in parts by weight: 300-500 parts of cement, 200-300 parts of admixtures, 300-400 parts of fillers, 3-6 parts of water-reducing components, 0.1-1 part of plastic swelling component, 10-20 parts of hardened swelling components, 0.01-0.2 part of stable component, 1-4 parts of early strength components, 0.2-2 parts of defoaming components and 0.01-0.2 parts of emulsifying component. The cement-based grouting material disclosed by the invention has performance advantages such as higher injection-molding performance, initial fluidity not greater than 17s, impermeability not exceeding 1mm, wear resistance not exceeding 10cm<3> / cm<2>, compressive strength within 2 hours not lower than 5MPa, compressive strength within 1 day not lower than 30 MPa, and the like. The cement-based grouting material has composite swelling, the free swelling ratio within 3 hours is 0.02%-2% and grouting is full and dense; the viscosity is low, the volume stability is good and durability is good; the cement-based grouting material does not contain VOC (volatile organic compounds), and is environment-friendly.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH +2

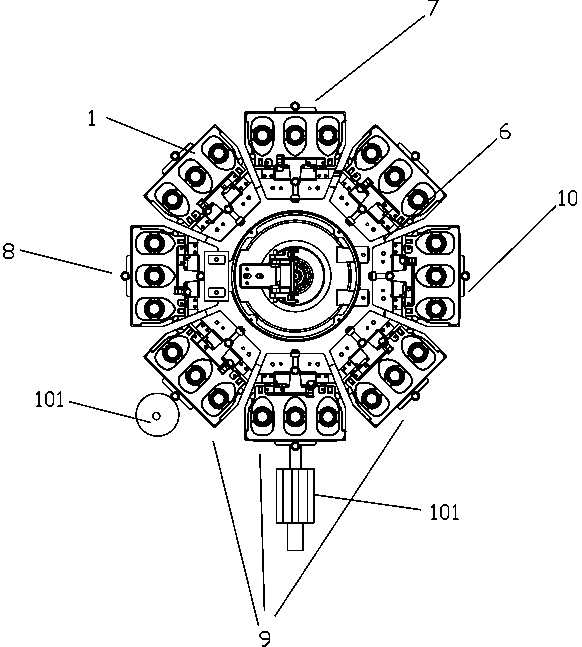

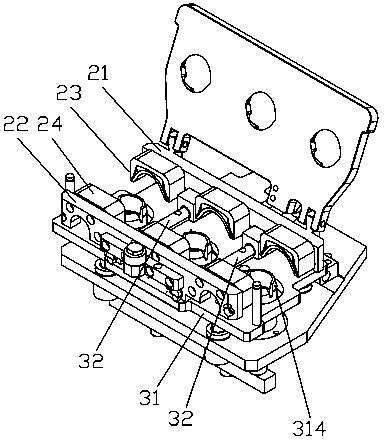

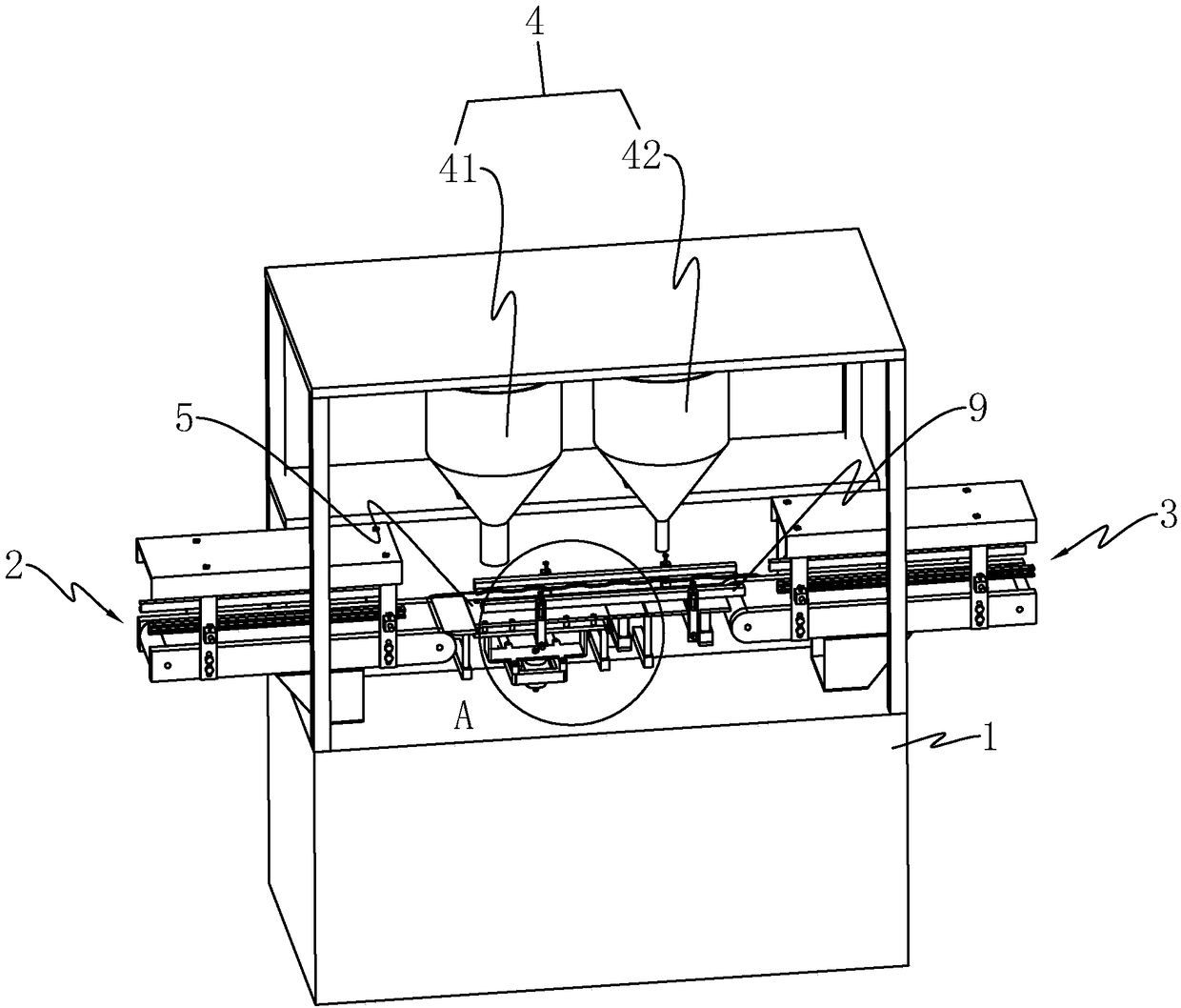

Stuffed food forming method

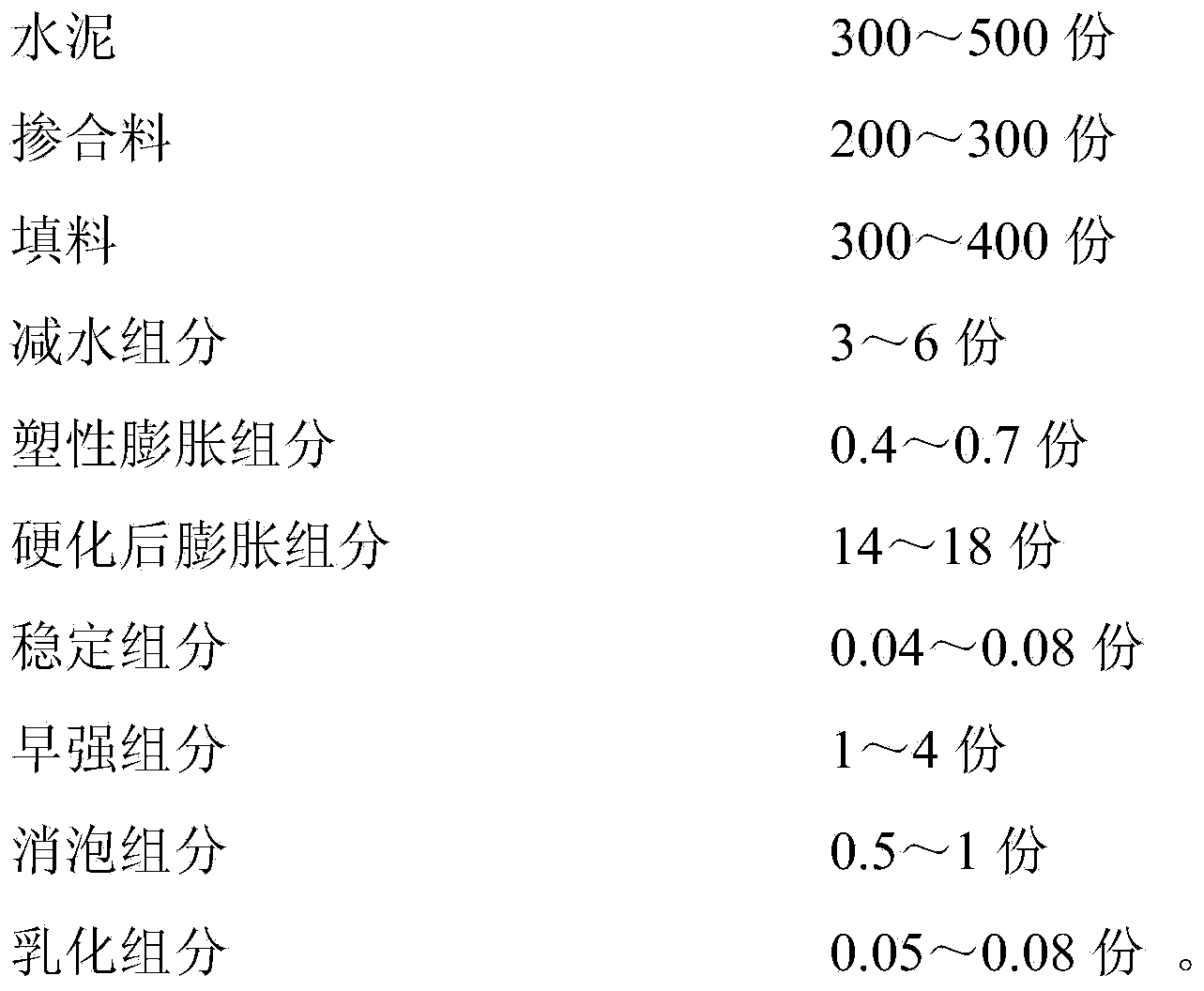

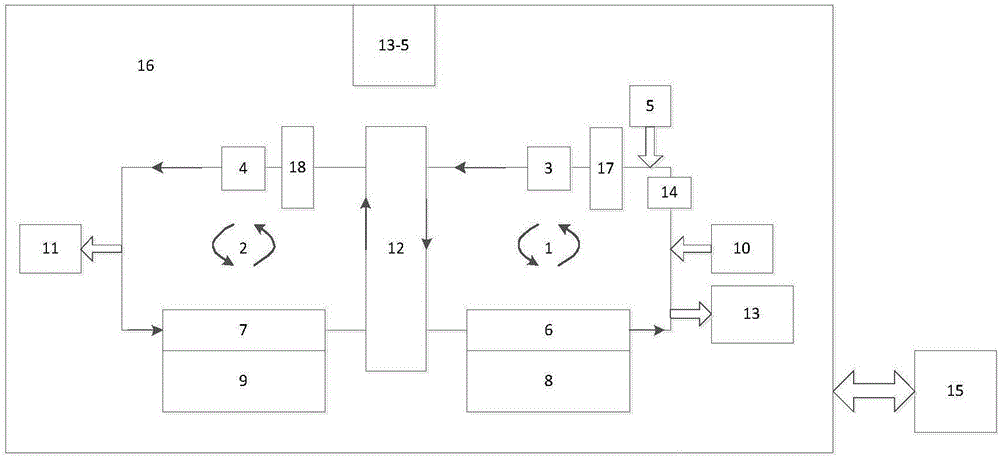

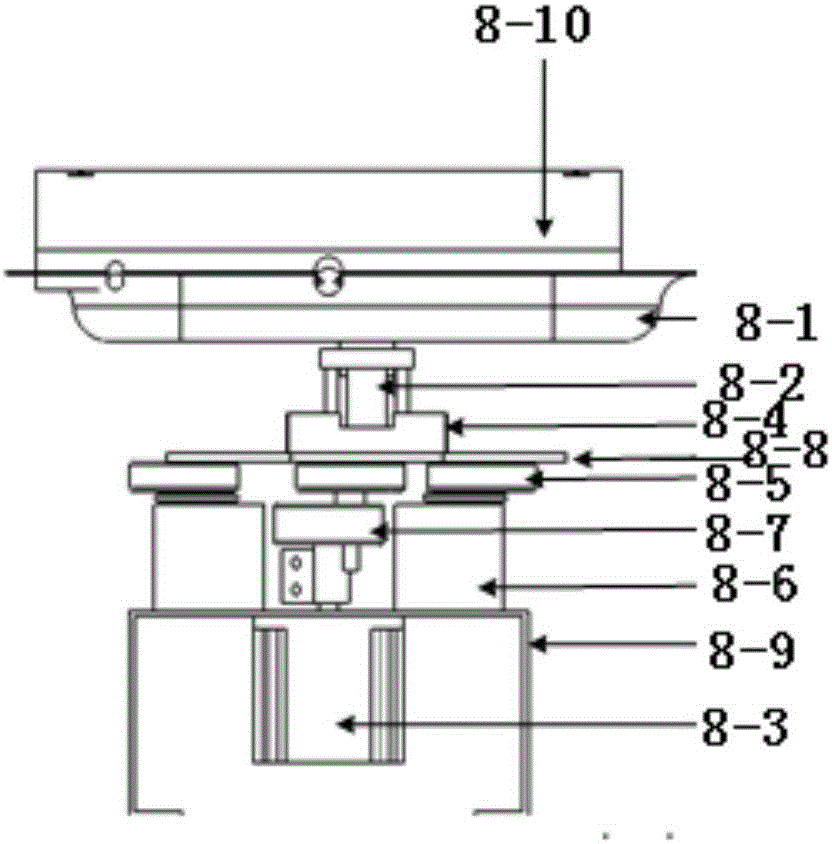

The invention belongs to the technical field of food processing and in particular relates to a stuffed food forming method. The stuffed food forming method comprises the following steps: 1, allowing a wrapper receiving plate to be positioned at a wrapper receiving station of an annular rail, and conveying the wrapper to the wrapper receiving plate at the wrapper receiving station through a wrapper conveying device; 2, moving the wrapper receiving plate and a die assembly device to a stuffing injection station on the annular rail, and injecting the stuffing on the surface of the wrapper through a stuffing injection device; 3, mutually closing die assembly blocks which are positioned on the die assembly device below the wrapper receiving plate and are opposite to each other, coating and forming stuffed foods, and continuously keeping the two closed die assembly blocks be in the state; and 4, simultaneously moving the wrapper receiving plate and the die assembly device to a taken-out station on the annular rail, so that the wrapper receiving plate is opened, and the die assembly blocks which are always positioned in a closed state are separated. According to the die assembly device in the method, continuous pressing force can be provided for the stuffed foods in the processing process, the tightness on the joint part of the wrapper of the stuffed foods can be guaranteed, the wrapper is not open after being pressed for a long time, and the forming rate of the stuffed foods is guaranteed.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

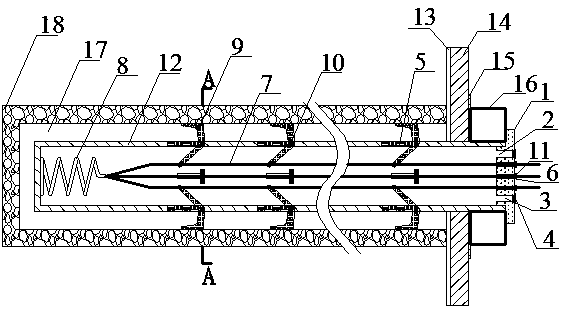

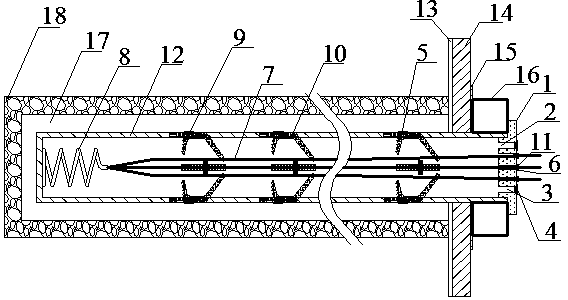

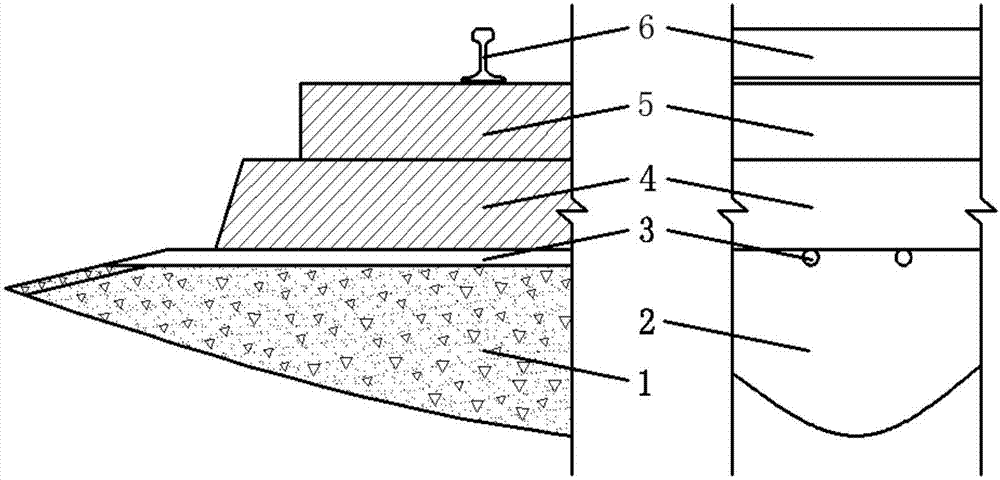

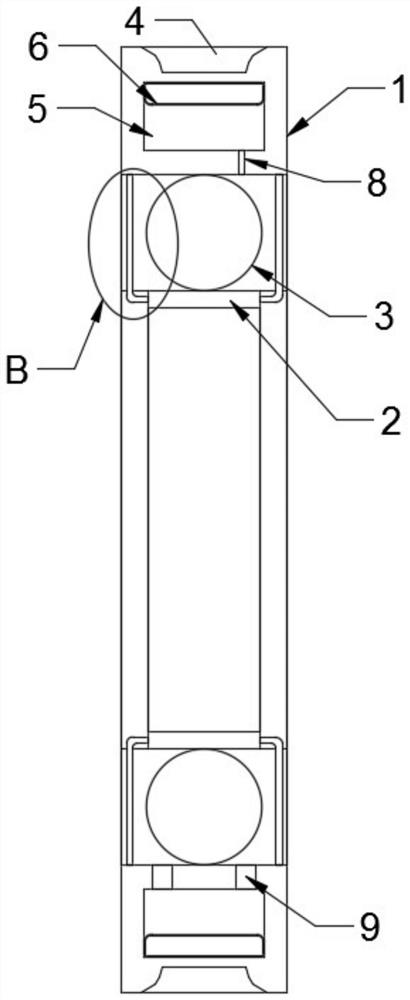

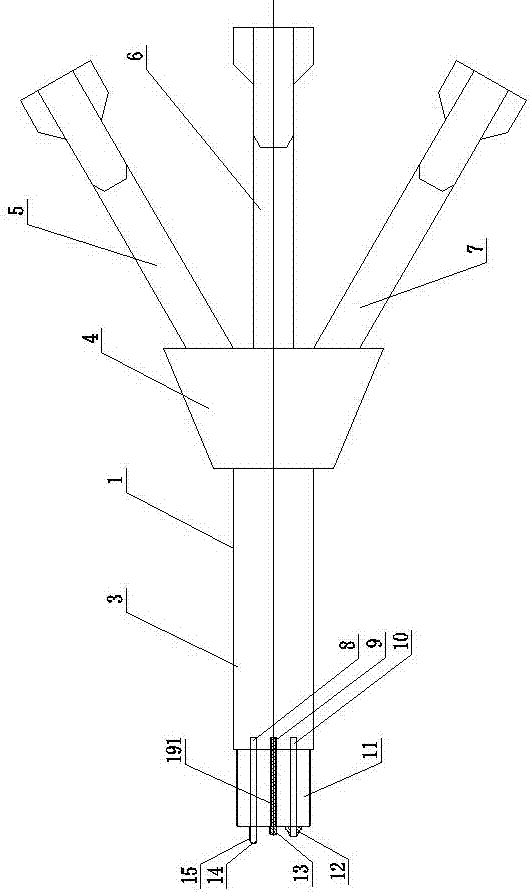

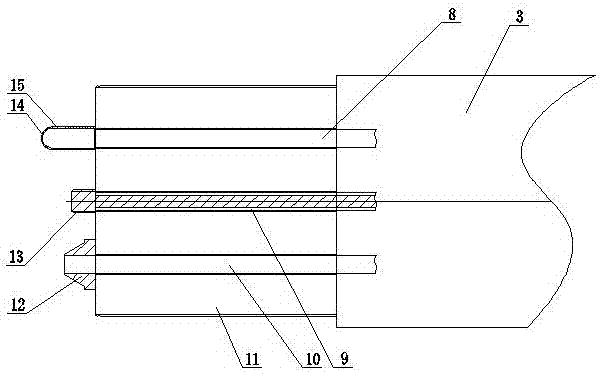

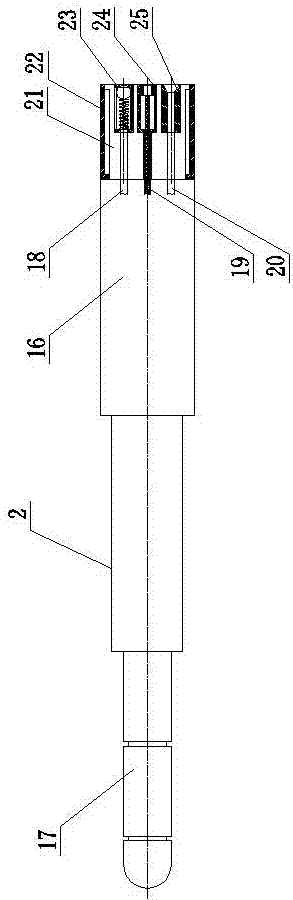

Novel anchoring grouting anchor rod and construction method thereof

ActiveCN108979692ASolve the anchorSolve the problem of insufficient groutingAnchoring boltsClimate change adaptationPre stressPre stressing

The invention discloses a novel anchoring grouting anchor rod and a construction method thereof. The novel anchoring grouting anchor rod is formed by a grouting system, an anchoring system and a fastening system. The grouting system comprises a cover, a vent hole, a grouting hole, a slurry plug, and overflow holes and various parts work together to ensure that slurry is full and tightly bonded. The anchoring system is formed by anchoring holes, a steel strand, a high-strength spring, an anchor claw, a rotating shaft and a steel strand clamp, initial anchoring force can be provided for the anchor rod, the anchor claw has barbs and rotates under the traction of the steel strand and closely attaches to a surrounding rock, and anchor removal is effectively prevented. The fastening system is formed by an anchor rod body, a slurry stop pad, a tray, a washer and a high-strength nut. After the slurry is solidified, the pre-stress can be provided for the grouting anchor to control the deformation of the surrounding rock. According to the invention, an anchor claw rotation design is employed, the anchor claw closely attaches to the surrounding rock, sufficient anchoring force is provided toprevent the anchor removal, and vent holes are set to ensure a pouring effect. The application defect of an existing grouting anchor is solved, and the novel anchoring grouting anchor rod and the construction method have the advantages of anchor removal prevention, high adaptability and good grouting effect.

Owner:SHANDONG UNIV OF SCI & TECH

Casting method of magnesium alloy casting

InactiveCN103231016AGuaranteed decompositionGuaranteed fillingFoundry mouldsFoundry coresInterfacial reactionCasting mold

The invention provides a casting method of a magnesium alloy casting. With the method, advantages of different casting methods are utilized, and defects of the methods are overcome. With a special shell preparation method and a method for preventing magnesium alloy-casting mold interfacial reaction, a unique casting technology suitable for thin-wall complex magnesium alloy part production is formed. The method has important significance for developing magnesium alloy performance advantages and satisfying automotive magnesium alloy application requirements.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

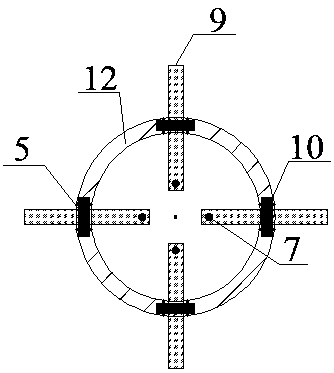

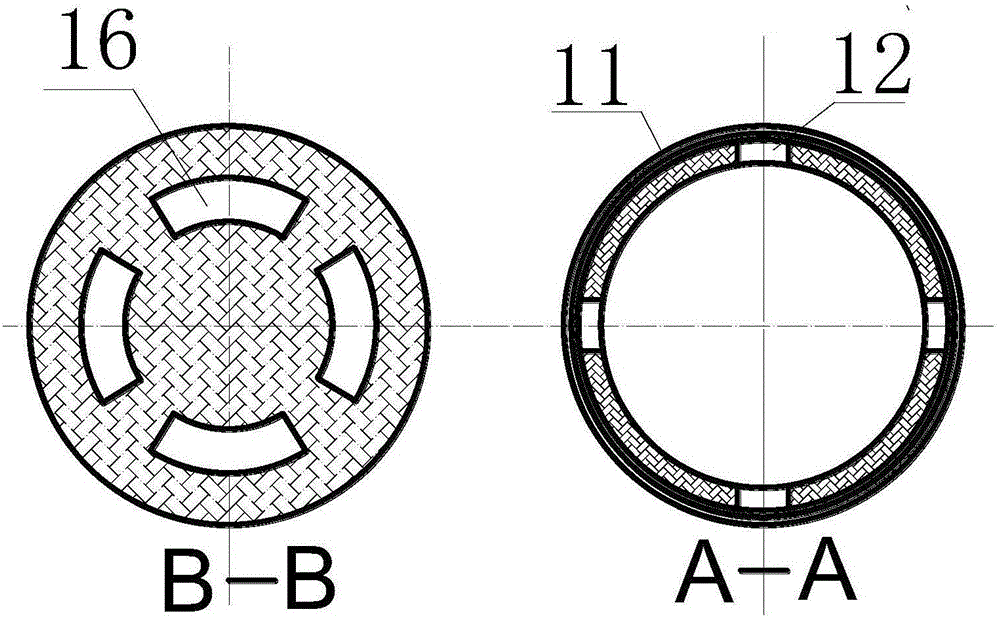

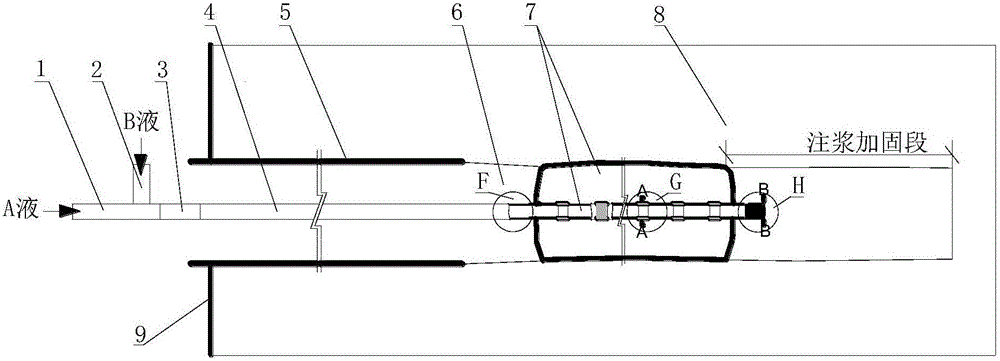

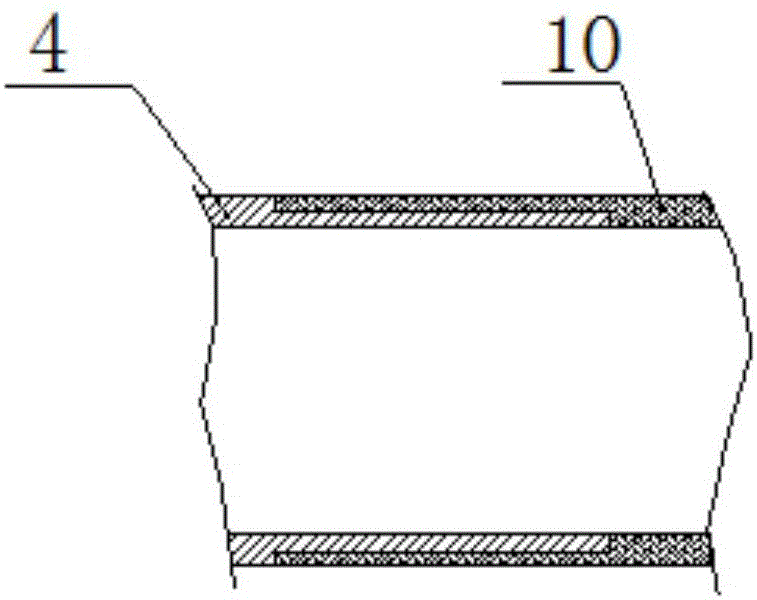

Separated grouting device in drilled hole and sectional grouting operation process

InactiveCN105909257ASolve the problem that it is difficult to be transported to deep surrounding rockSolve difficult problems that cannot be reusedFoundation engineeringSealing/packingSlurryEngineering

The invention discloses a separated grouting device in a drilled hole and a sectional grouting operation process. The device comprises stop-grouting plug assemblies and grouting pipes. A check valve is arranged at one end of one grouting pipe which is provided with multiple stop-grouting plug overflow holes. Pressing belts for blocking the stop-grouting plug overflow holes are arranged on the stop-grouting plug overflow holes outside the corresponding grouting pipe. The pressing belts are flushed open by grout under set pressure, and an expanding non-woven bag outside the corresponding grouting pipe is filled with the grout. The grout can flush open the check valve under set pressure to carry out grouting reinforcement. A grouting lifting tube is detachably mounted at the other end of the corresponding grouting pipe. By means of the separated grouting device in the drilled hole and the sectional grouting operation process, separated grouting can be carried out in irregular loose and weak surrounding rock and even water-rich surrounding rock, the grouting lifting tube can be lifted out after grouting, separated grouting can be carried out in different positions in the same drilled hole, and through separated grouting, the problem that grout is repeatedly injected into shallow surrounding rock and cannot be easily conveyed to deep surrounding rock is solved.

Owner:SHANDONG UNIV

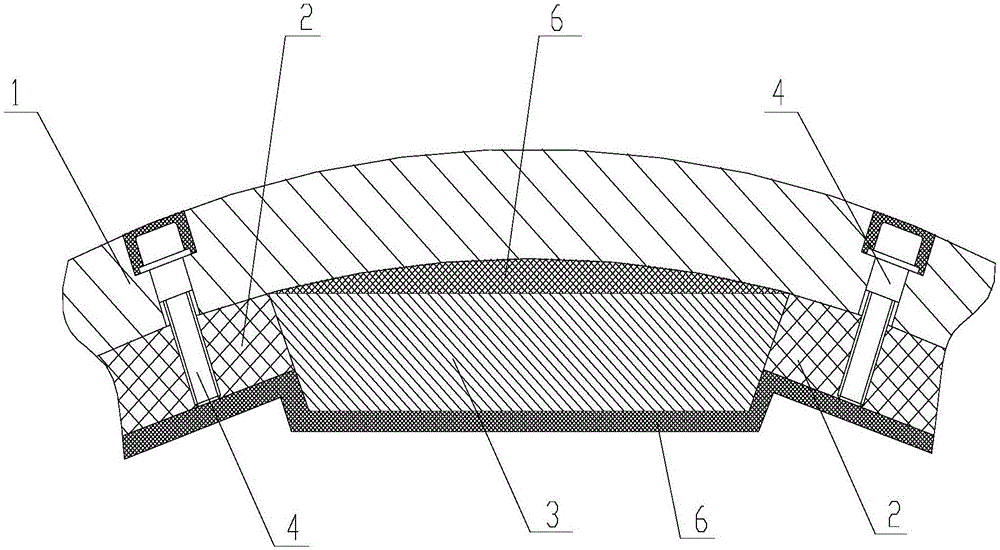

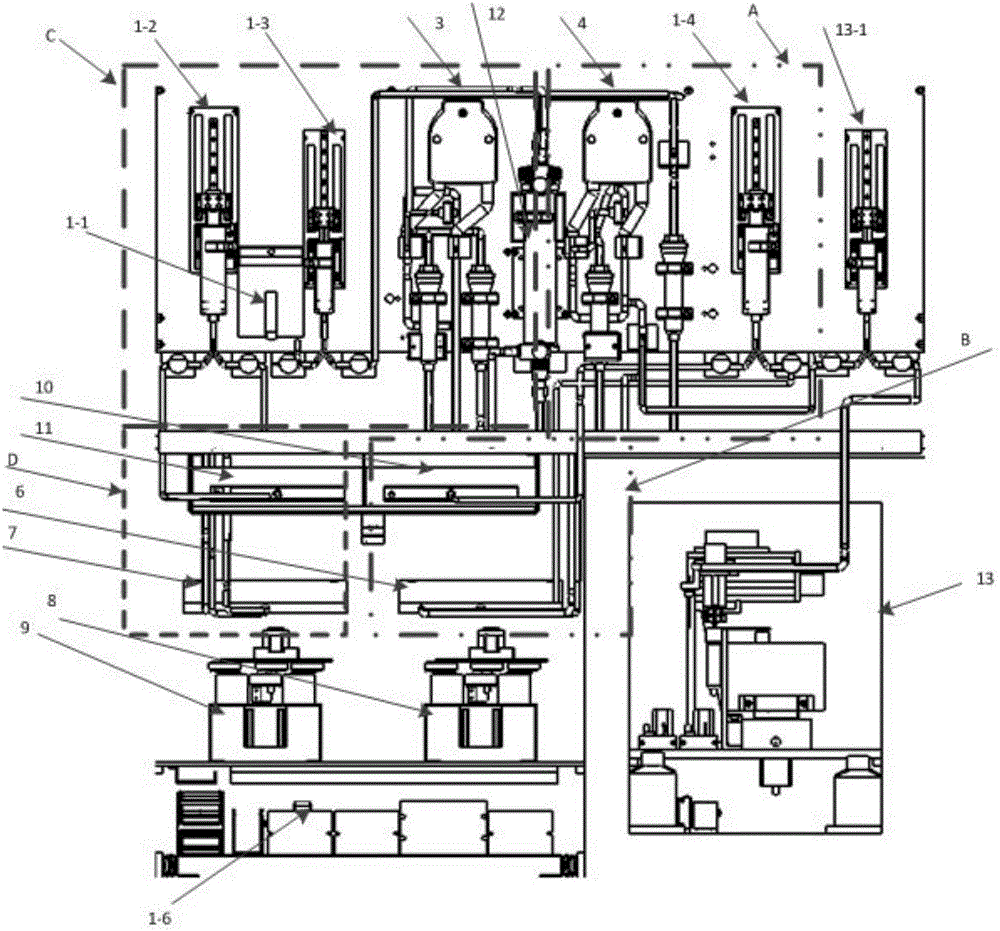

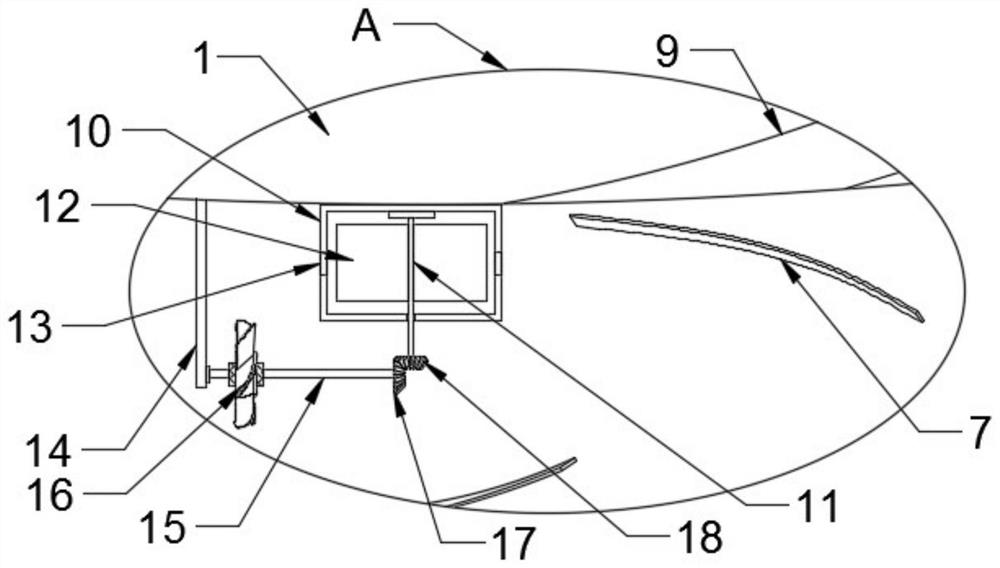

Permanent magnet motor pole protection coating forming process and processing equipment

ActiveCN106469964AAvoid corrosionSuppression temperatureMagnetic circuit rotating partsCooling/ventillation arrangementVacuum pumpingAxial pressure

The invention discloses a permanent magnet motor pole protection coating forming process and auxiliary processing equipment. In the permanent magnet motor pole protection coating forming process, a motor rotor is horizontally placed, positions of an inlet and an outlet operating on a vacuum bag at the current state are controlled to only aligned to an arc section at the bottom part of the motor rotor to perform vacuum pumping and inject an adhesive, the motor rotor is driven to rotate by a predetermined angle after the adhesive of the arc section is preliminarily solidified so as to enable an arc section in which the adhesive is not injected to rotate to the bottom part until all arc sections in the circumferential direction of the motor rotor complete injection of the adhesive. Therefore, a gap between magnetic steel and the magnet yoke wall is dipped in the adhesive of a reinforcing material and simultaneously subjected to a gravity action, a radial pressure gradient action and an axial pressure gradient action, and adhesive filling for the gap between the magnetic steel and the magnet yoke wall and a gap between the magnetic steel and a magnetic steel layer is guaranteed. In addition, a medium used for transferring heat of the running process is arranged between the magnetic steel and the magnet yoke wall, so that the temperature of the magnetic steel can be suppressed, and the performance and the magnetic steel is not damaged by temperature rising and corrosion.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

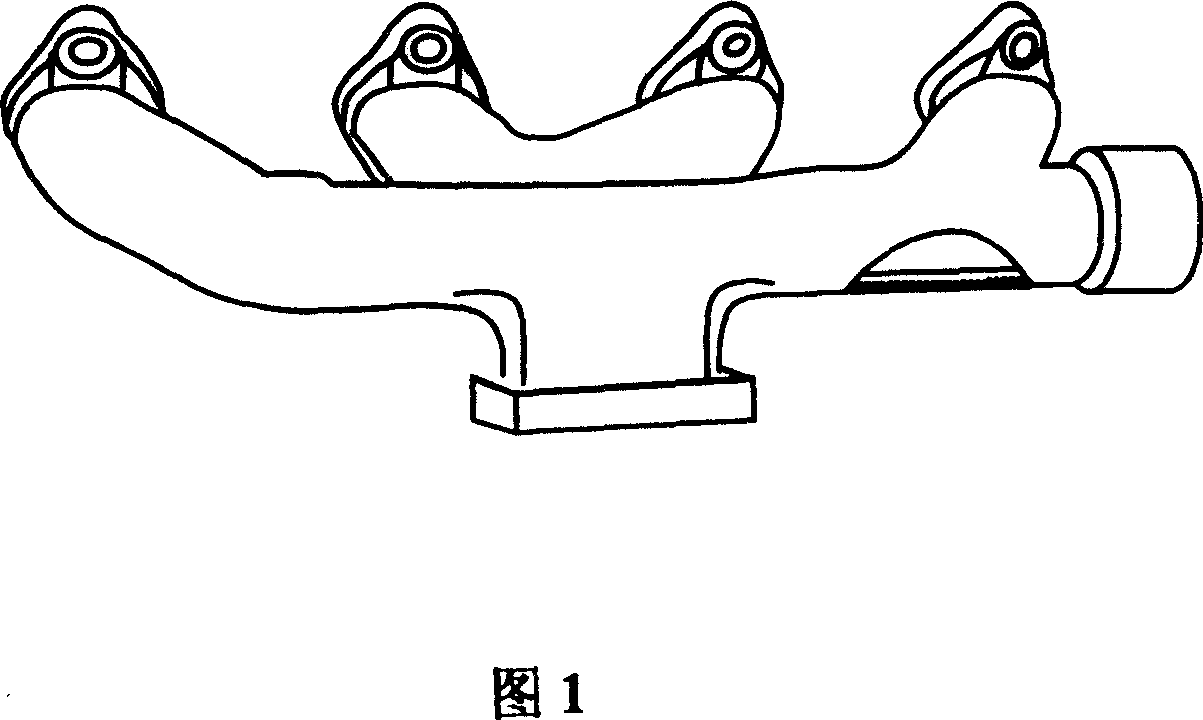

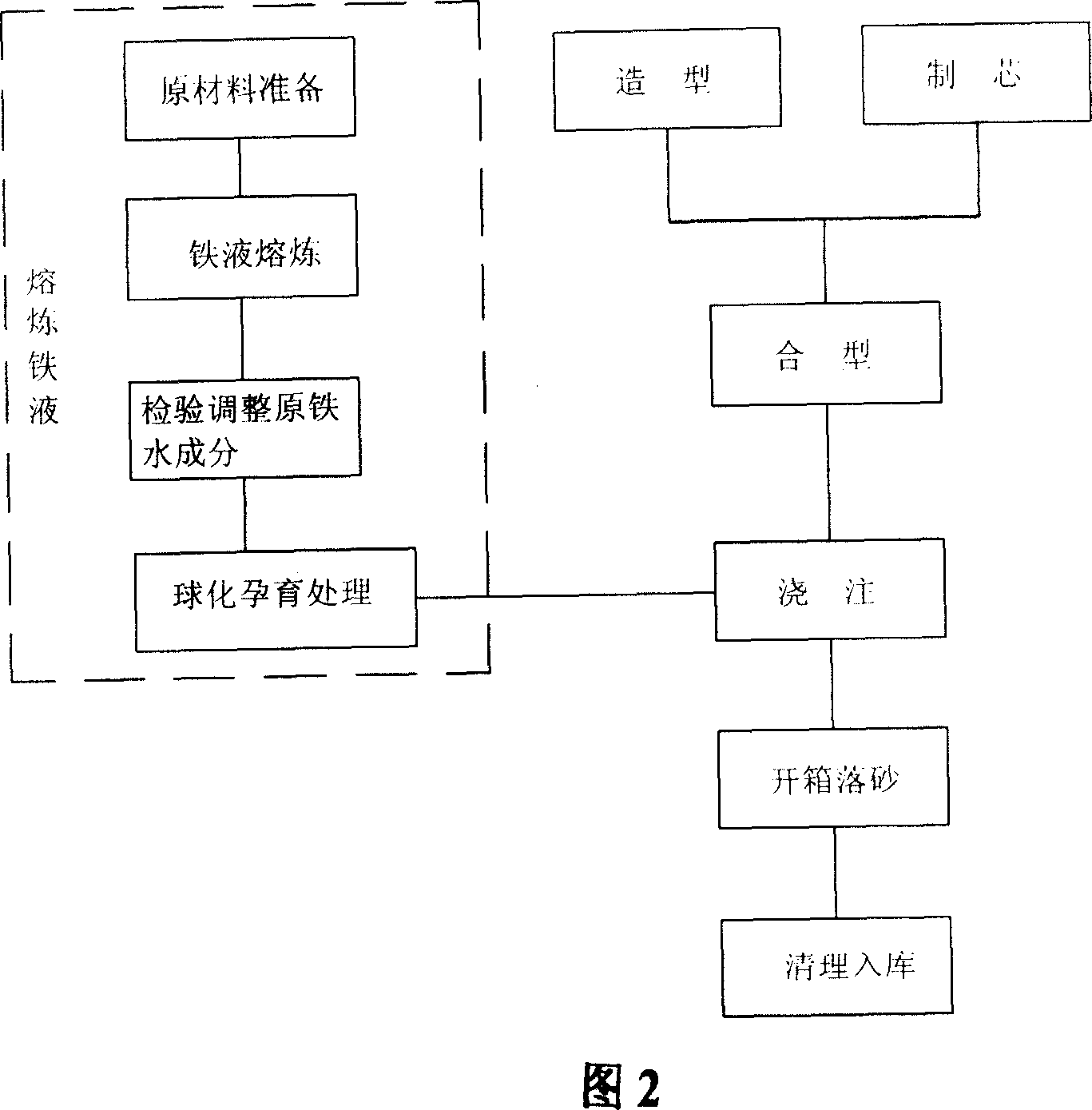

High nickel austenite spheroidal graphite cast iron automobile exhaust branch pipe and casting method

InactiveCN1927505AImprove corrosion resistanceImprove high temperature resistanceExhaust apparatusSilencing apparatusLow nitrogenFerrosilicon

The invention relates to a high-nickel austenite nodular graphite cast iron vehicle discharge branch tube and relative casting method. Wherein, said casting method comprises core production, shaping, combining, smelting, irrigating, dropping sand and cleaning casting; while the core production uses low-nitrogen high-temperature cover sand; the inner sand core of discharge branch tube is internal flow sand core; the outer chamber sand core embeds cold iron at the clamp part between two tubes; and it uses side riser and uses the static compressor in irrigation supplied by wet mound sand; the smelting temperature is 1600-1700Deg. C; and it uses magnetite-silica alloy as nodulizer; and uses ferrosilicon and strontium inoculant to inoculate for two times; and it uses large flux and high temperature irrigation. The inventive branch tube has better corrosion-resistance, high-temperature resistance, and non radiation.

Owner:西峡飞龙特种铸造有限公司

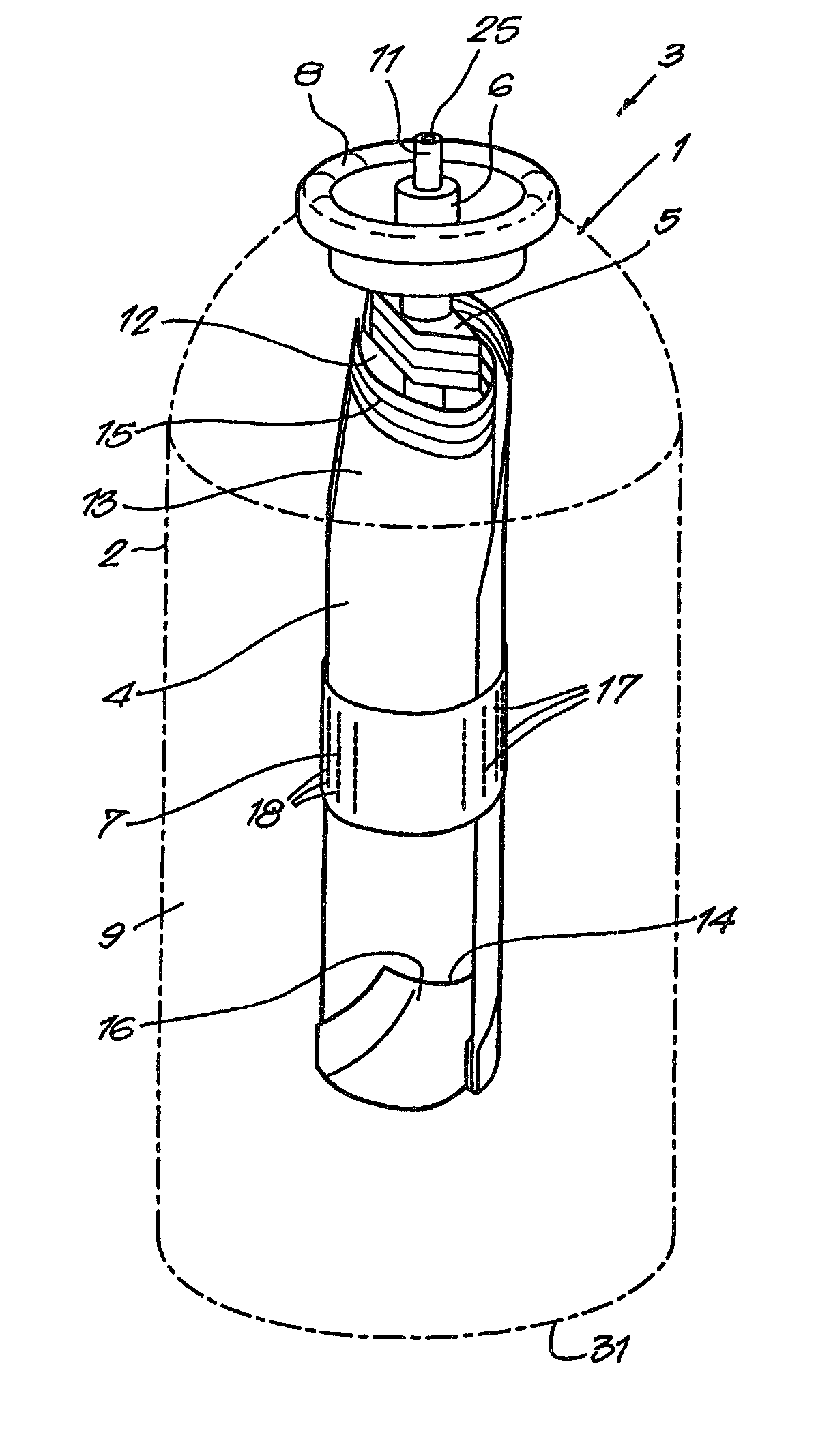

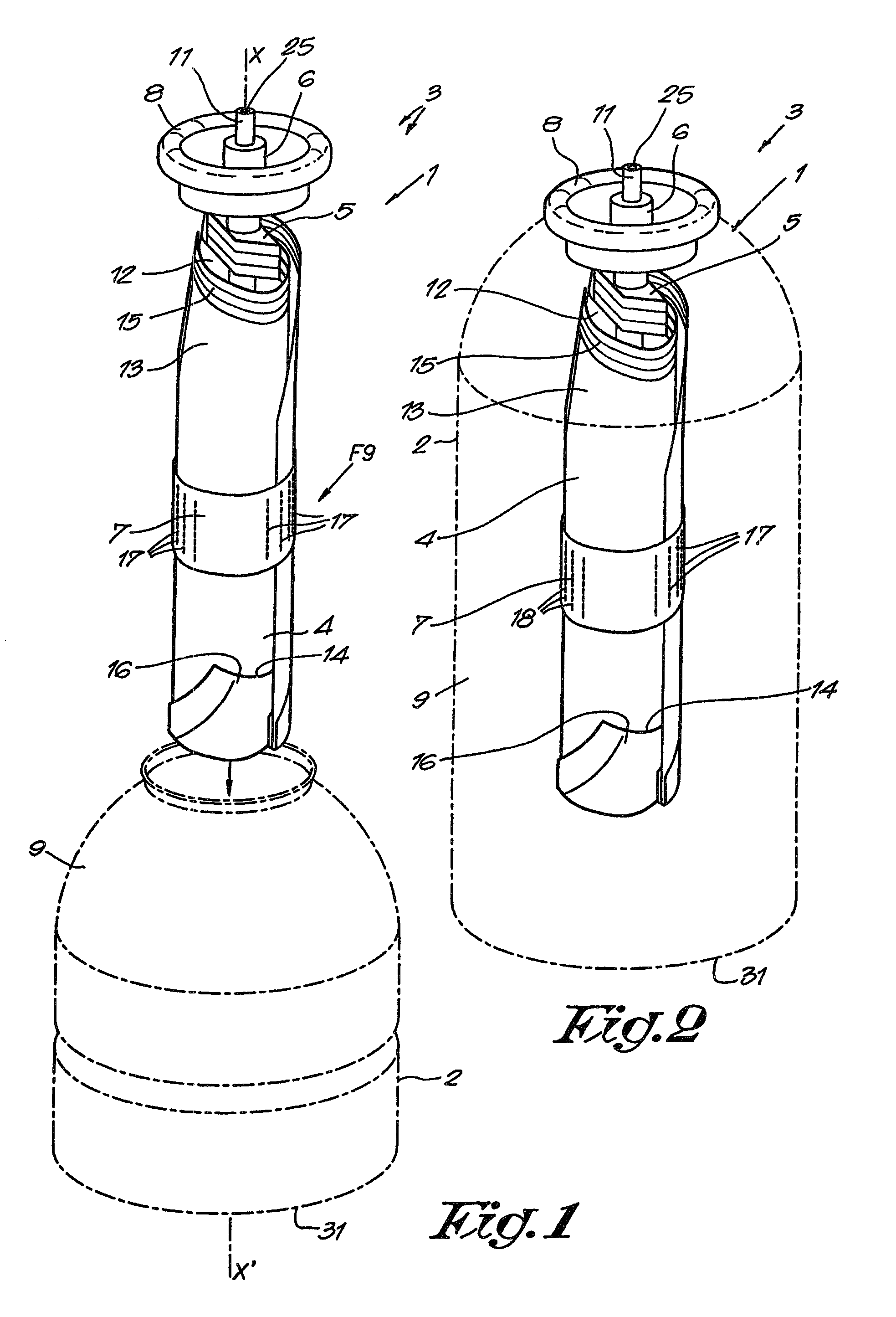

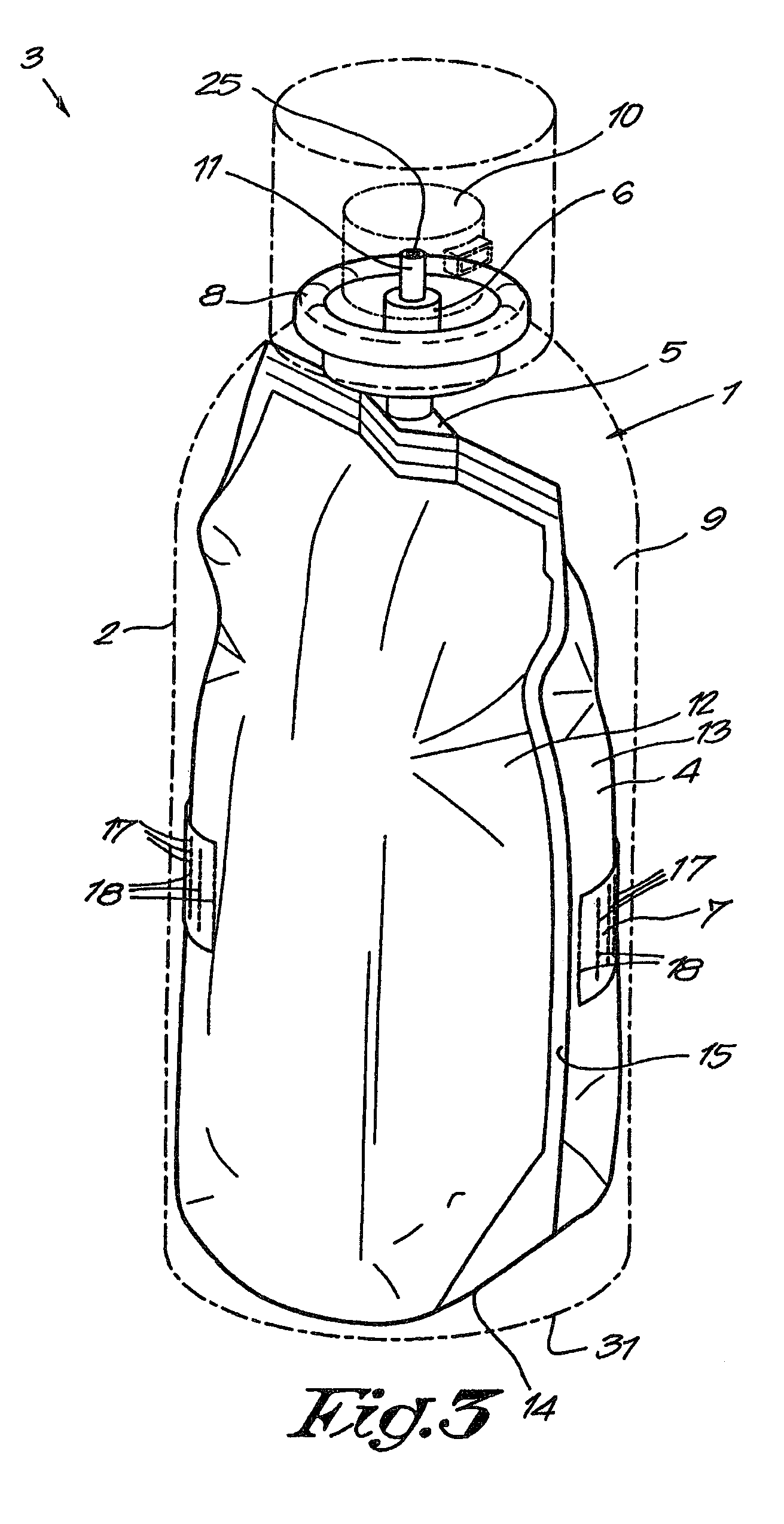

Bag valve

InactiveUS8196620B2Guaranteed fillingReduce riskSolid materialPackaging under special atmospheric conditionsEngineeringMechanical engineering

Owner:ECOPACK FRANCE

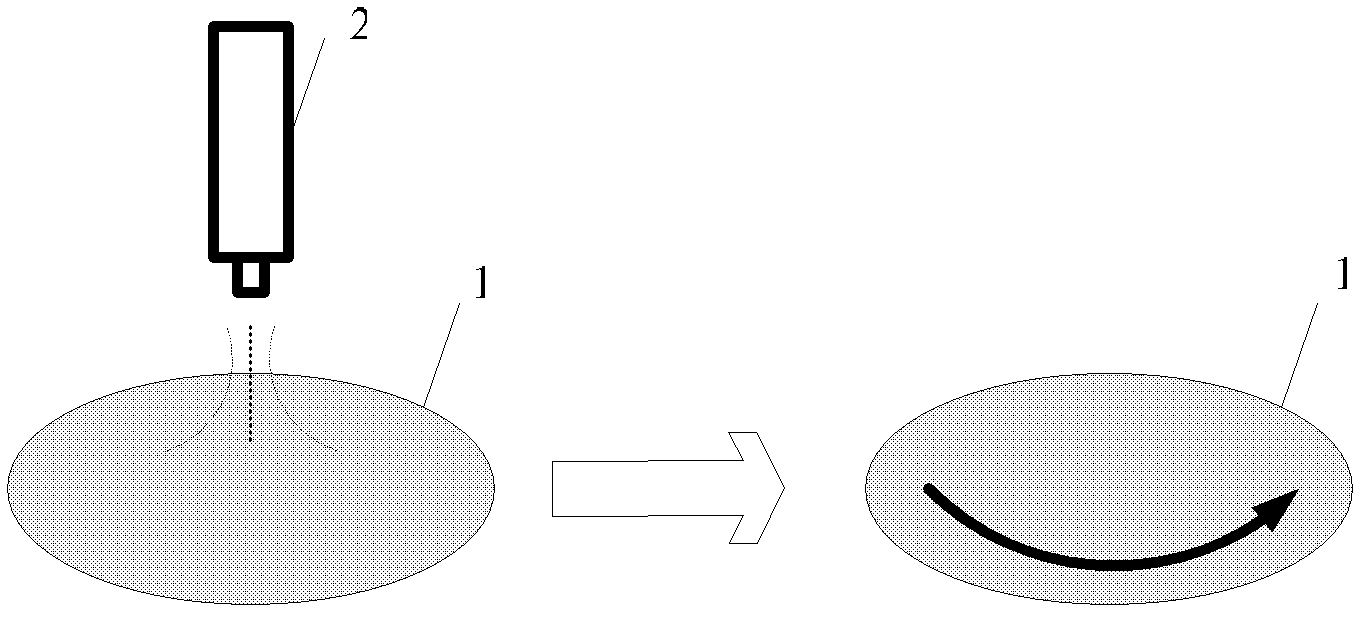

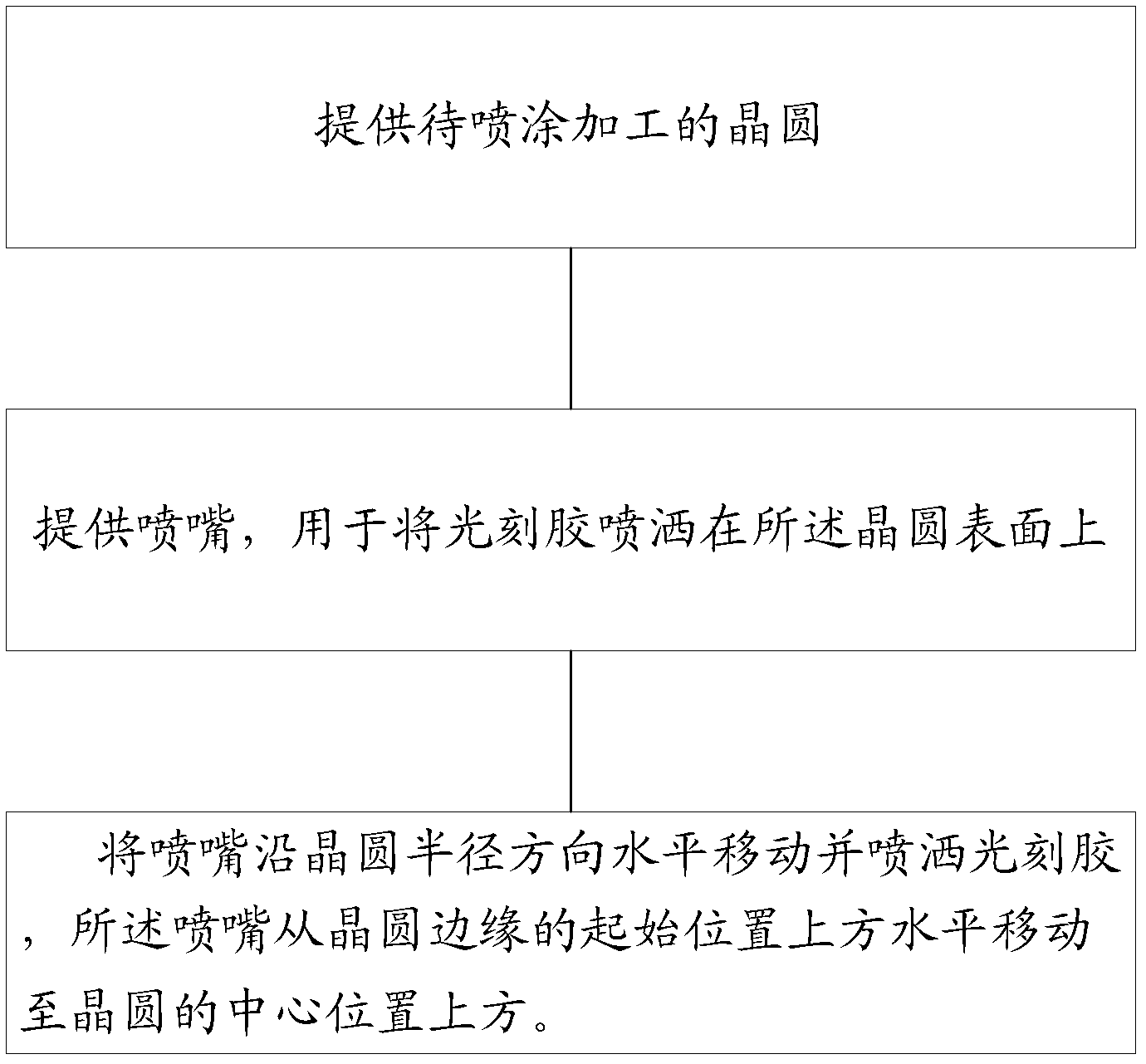

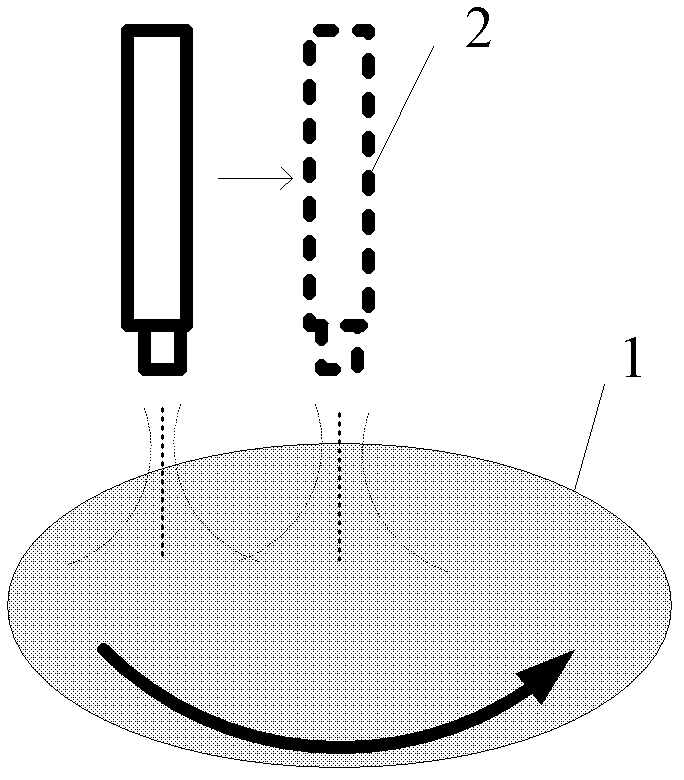

Method for spraying photoresist

InactiveCN102360164AGuaranteed uniformitySolve the problem of incomplete fillingPhotomechanical coating apparatusPhotoresistElectrical and Electronics engineering

The invention provides a method for spraying photoresist. The method is characterized by comprising the following steps: providing a wafer to be sprayed; providing a nozzle used for spraying the photoresist on the surface of the wafer; and horizontally moving the nozzle along the radius direction of the wafer and spraying the photoresist, wherein the nozzle is horizontally moved above the central position of the wafer from the position above the initial position of the wafer edge. The method has the following technical effect: the photoresist-dripping nozzle is horizontally moved along the radius direction of the wafer and sprays photoresist and the rotation speed of the wafer and the horizontal movement speed of the nozzle are executed according to the set technological parameters, thus solving the problem that the patterns on the wafer are not completely filled during photoresist spraying.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

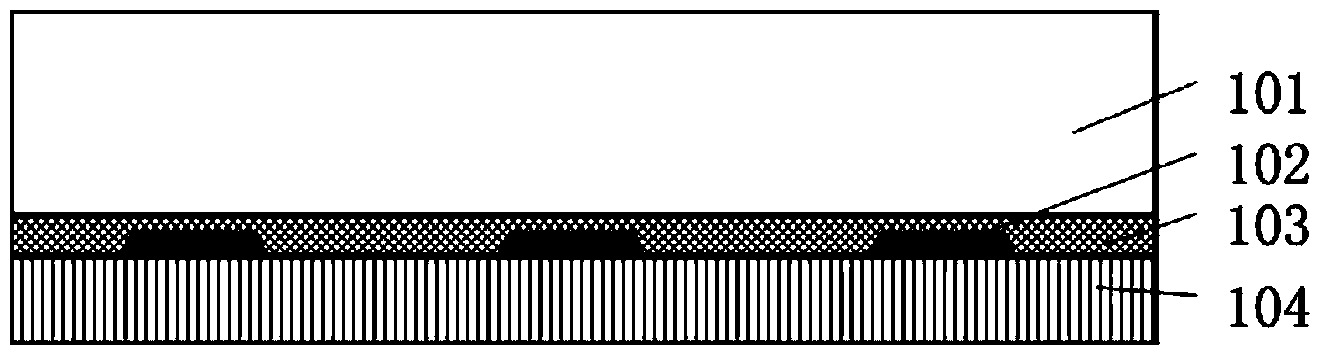

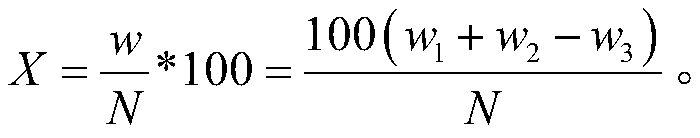

Packaging and interconnecting structure and method for copper protruded points filled up with double layers of underfill

ActiveCN104078431AAchieve high densityGuaranteed fillingSemiconductor/solid-state device detailsSolid-state devicesInterconnection densityYoung's modulus

The invention relates to a packaging and interconnecting structure and method for copper protruded points filled up with double layers of underfill. The packing and interconnecting structure is characterized in that the chip end is filled up with the first layer of underfill, the first layer of underfill is manufactured on a wafer through spin coating process, the substrate end is filled up with the second layer of underfill, the substrate end is filled through capillary effects after flip-chip welding is finished, the glass transition temperature and the Young modulus of the first layer of underfill are lower than those of the second layer of the underfill, a chip and a substrate are connected through the copper protruded points and tin-contained solder protruded points to achieve high-density connection, and the copper protruded points are manufactured in twice to guarantee that the first layer underfill is completely filled and the contact between the protruded points and the tin-contained solder is enough. The whole technological process is compatible with existing IC process and has higher vertical interconnection density, better electric connection characteristics and higher mechanical stability. Heating thermal circulation tests show that the service life of chips of the packaging structures is greatly prolonged.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

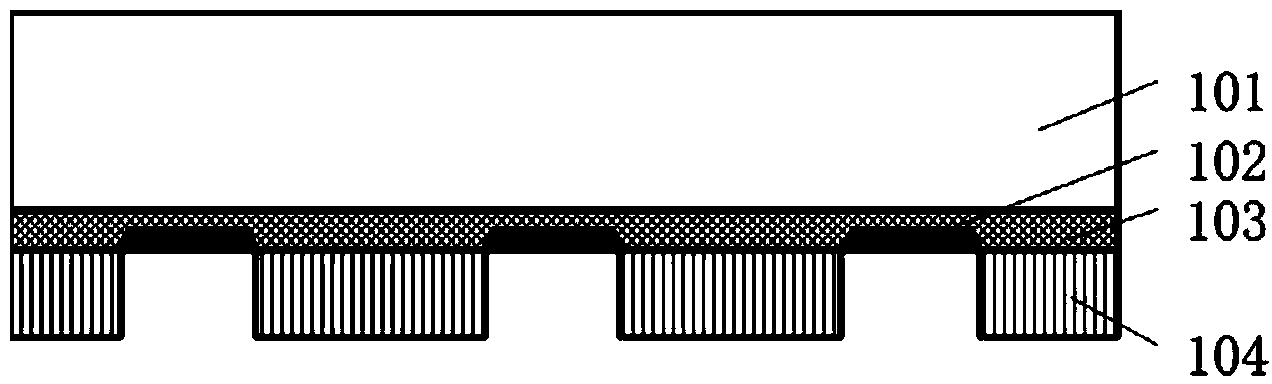

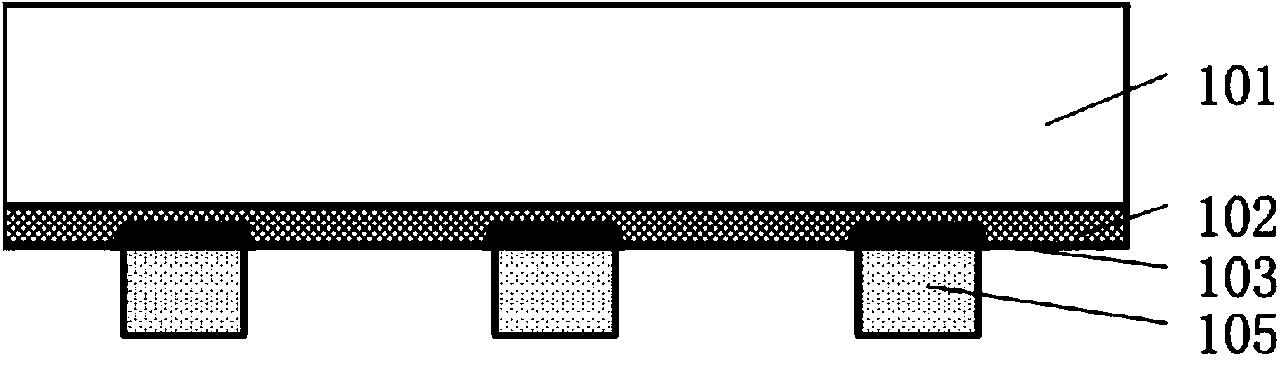

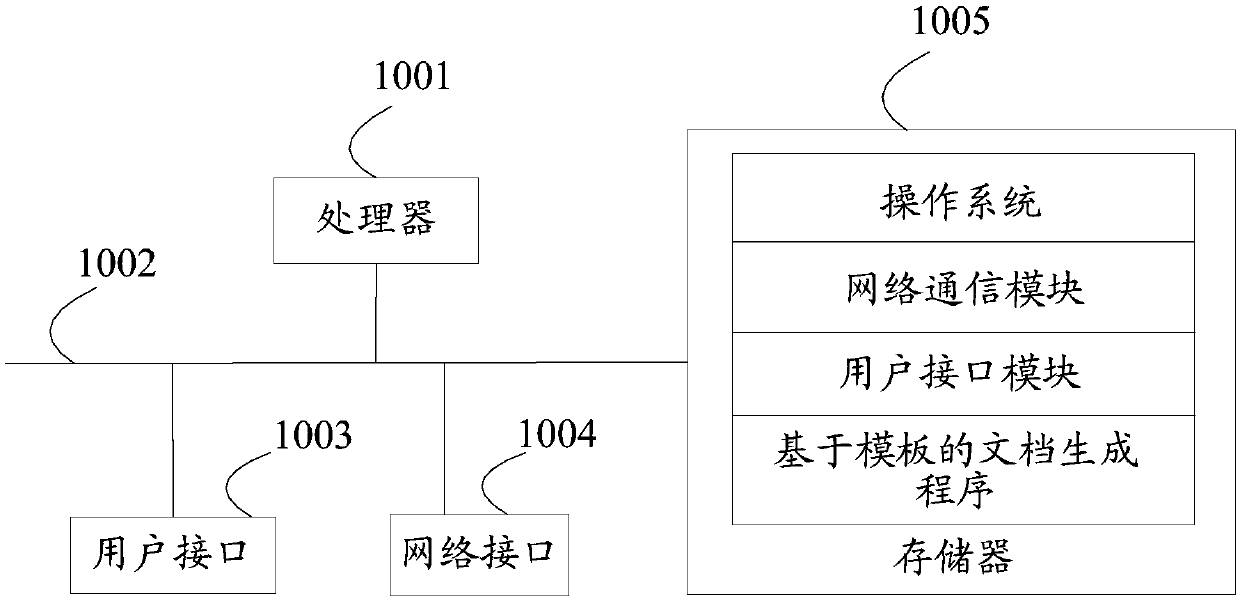

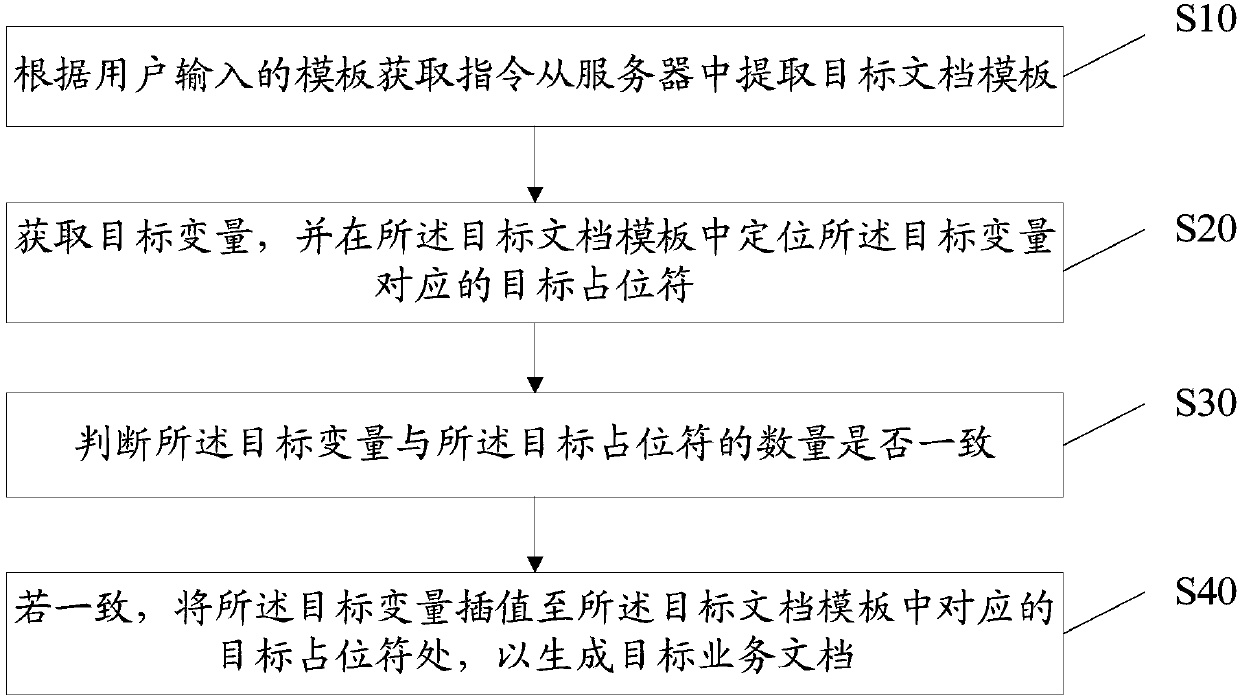

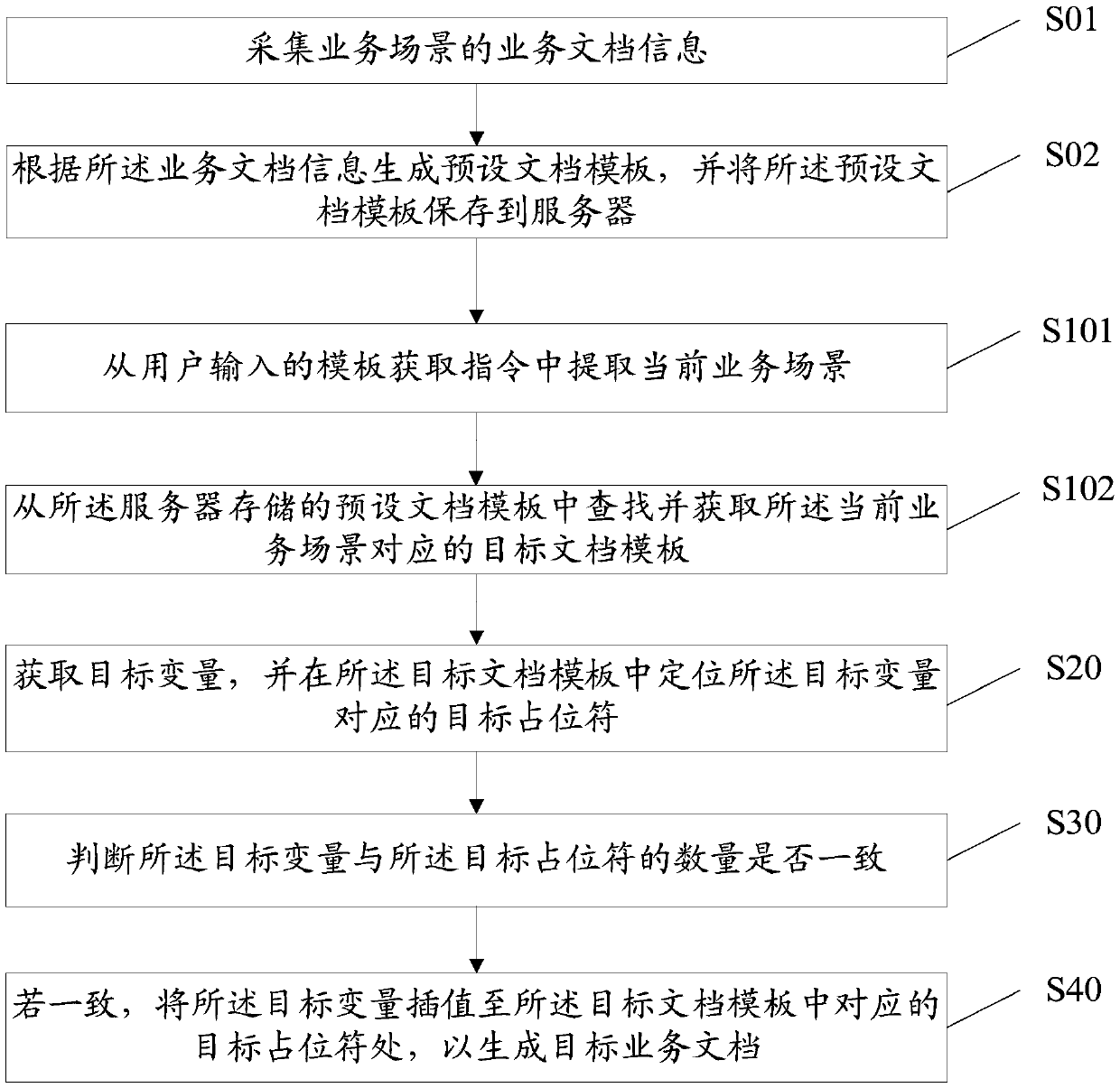

Template-based document generation method and device, storage medium and apparatus

PendingCN109657215AGenerate accuratelyGuaranteed fillingNatural language data processingSpecial data processing applicationsTemplate basedDocumentation

The invention discloses a template-based document generation method and device, a storage medium and an apparatus. The method comprises the steps of generating a preset document template of each business scene and storing the preset document template to a server; Extracting a target document template from the server according to a template acquisition instruction input by a user; Obtaining a target variable, and positioning a target placeholder corresponding to the target variable in the target document template; Judging whether the number of the target variables is consistent with that of thetarget placeholders or not; And if yes, interpolating the target variable to the corresponding target placeholder to generate a target business document. According to the invention, Before the targetvariable is interpolated to the corresponding target placeholder, whether the number of the target variable is consistent with that of the target placeholders or not is judged, if yes, interpolationis carried out, it is guaranteed that the target placeholders are filled with the target variable, the interpolation process is more accurate, and therefore generation of the target business documentis more accurate, and errors are fewer.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

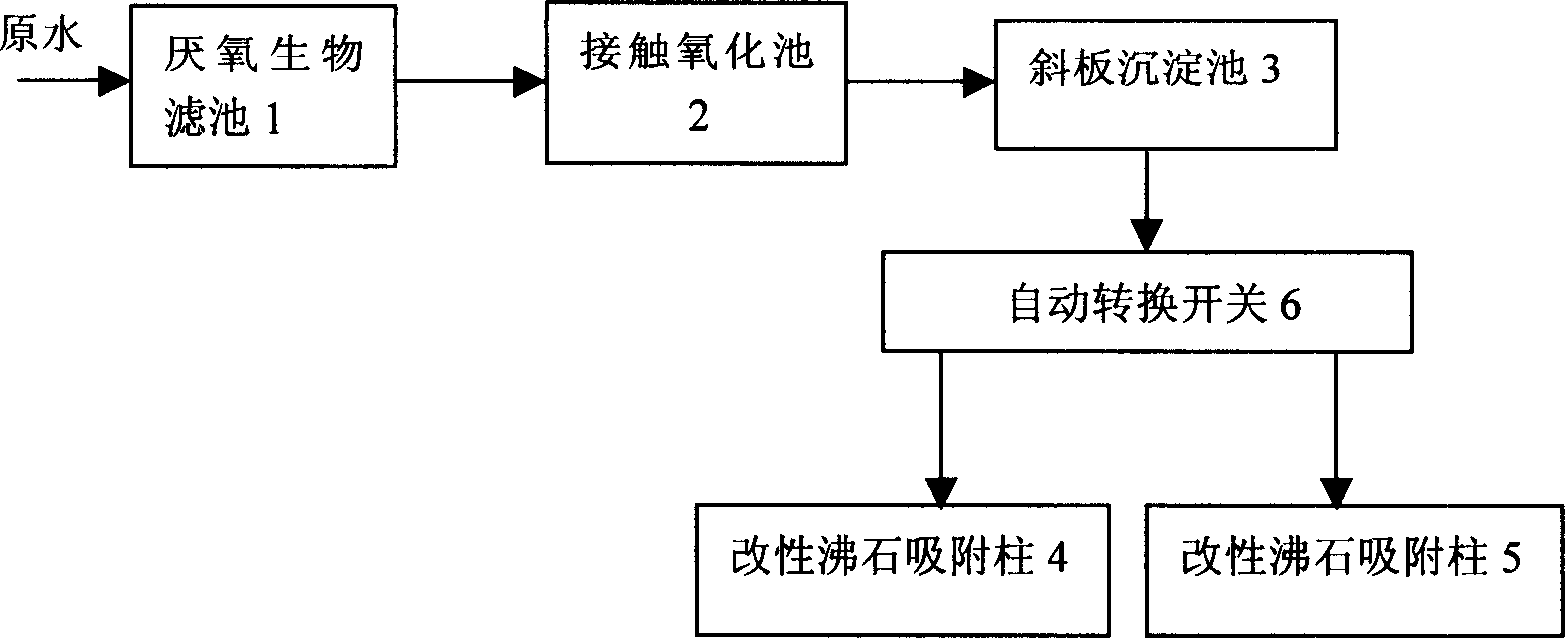

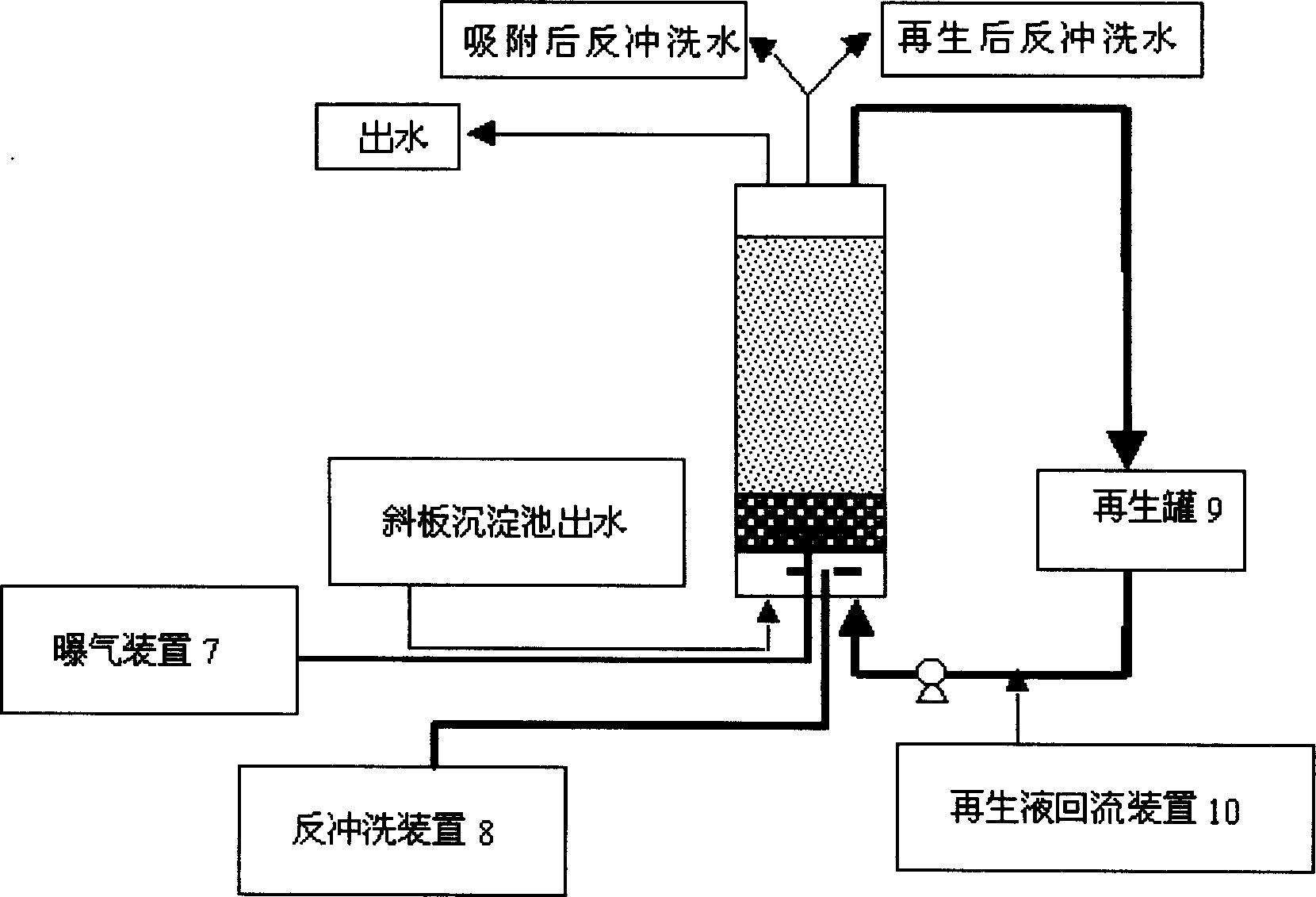

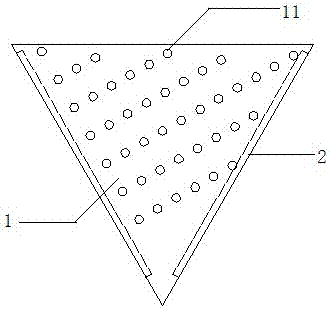

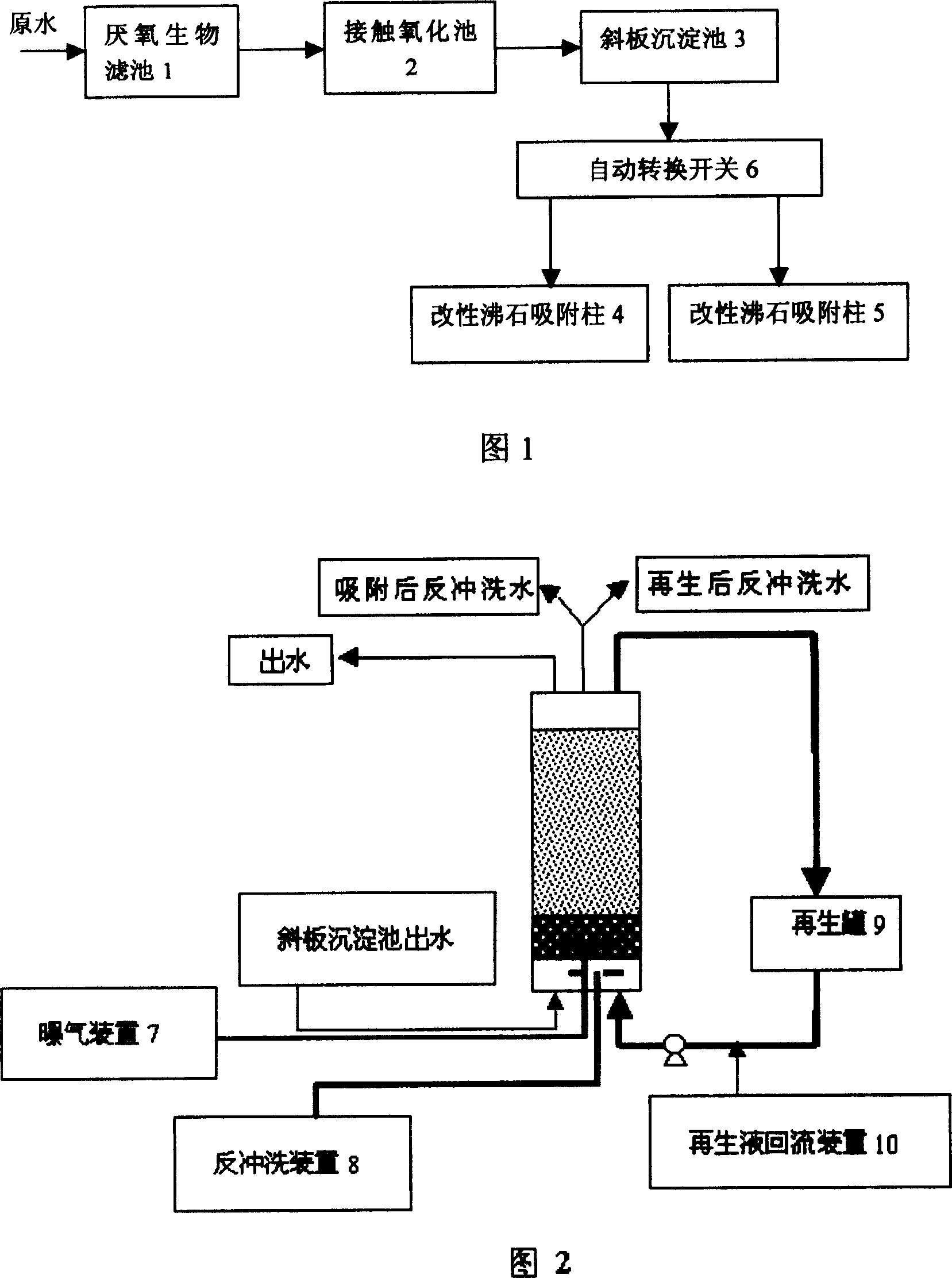

Method for removing ammonia nitrogen from sewage in subzone

InactiveCN1686872AAchieve regenerationContinuous regenerationTreatment with anaerobic digestion processesMultistage water/sewage treatmentAnaerobic filterSewage

The present invention relates to a method for deamination and denitrification of residential quarter sewage, belonging to the field of sewage treatment technology. It is characterized by that after the sewage is passed through anaerobic filter tank, contact oxidation tank and precipitation tank to obtain treatment, then sewage can upwards flow and be fed into two parallel modified zeolite adsorption regeneration columns to implement ammonia and nitrogen adsorption at twice successively, so that said invention can obtain high ammonia and nitrogen treatment efficiency. Said invention also provides the regeneration method of the above-mentioned zeolite adsorption regeneration column by using backflush process.

Owner:HARBIN INST OF TECH

Biological culture device based on hemodialyzer

ActiveCN106190838AGet weight in real timeEasy to manufactureBioreactor/fermenter combinationsBiological substance pretreatmentsHemodialysisMicrobiology

The invention provides a biological culture device based on a hemodialyzer. The biological culture device comprises the hemodialyzer, a circulating pump, a swing weighing device, a sample collecting and storing device, a medicine-dosing device and a culture bag. The culture bag comprises a main culture bag and an auxiliary culture bag. The main culture bag is connected with the two ends inside a hemodialyzer main body to form a main circulation loop, and the auxiliary culture bag is connected with the two ends outside the hemodialyzer main body to form an auxiliary circulation loop. The sample collecting and storing device and the medicine-dosing device are connected with a pipe between the main culture bag and the hemodialyzer. The biological culture device is a cell or bacterium culture device which can monitor culture conditions, keep the monitor culture conditions stable, perform automatic liquid adding and sample, can simulate medicine concentration changes and is based on the hemodialyzer.

Owner:NANJING NORMAN BIOLOGICAL TECH

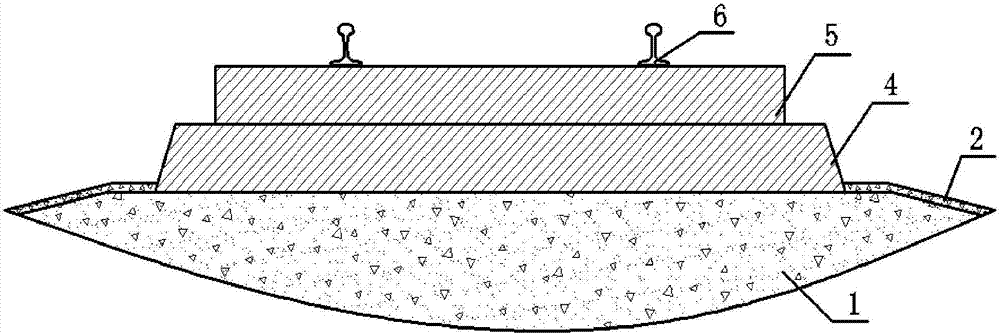

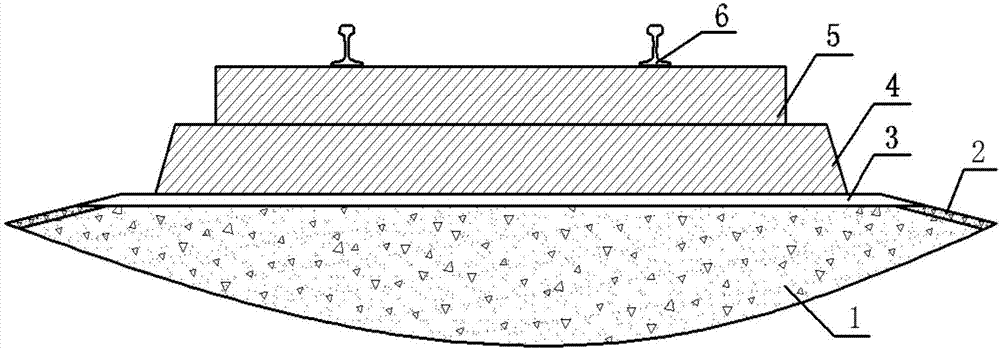

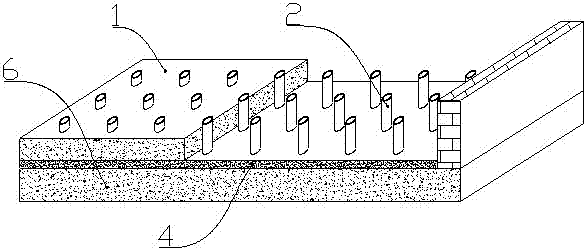

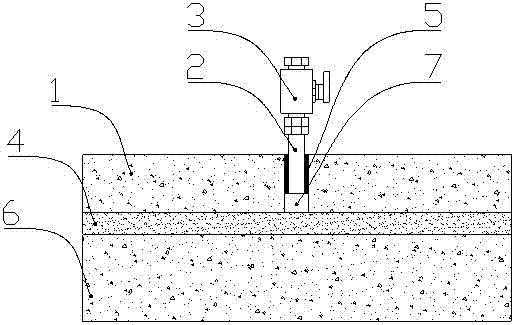

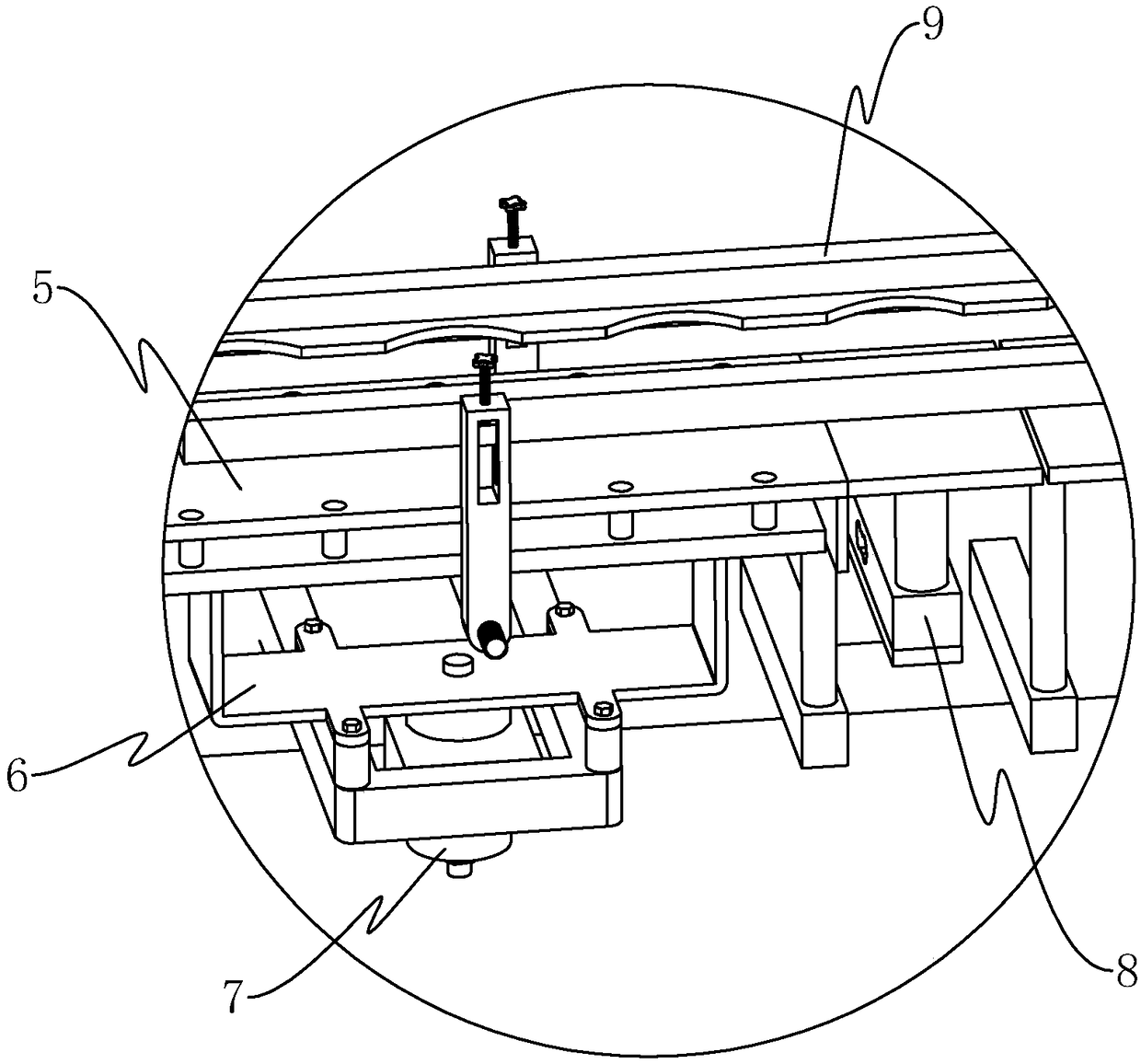

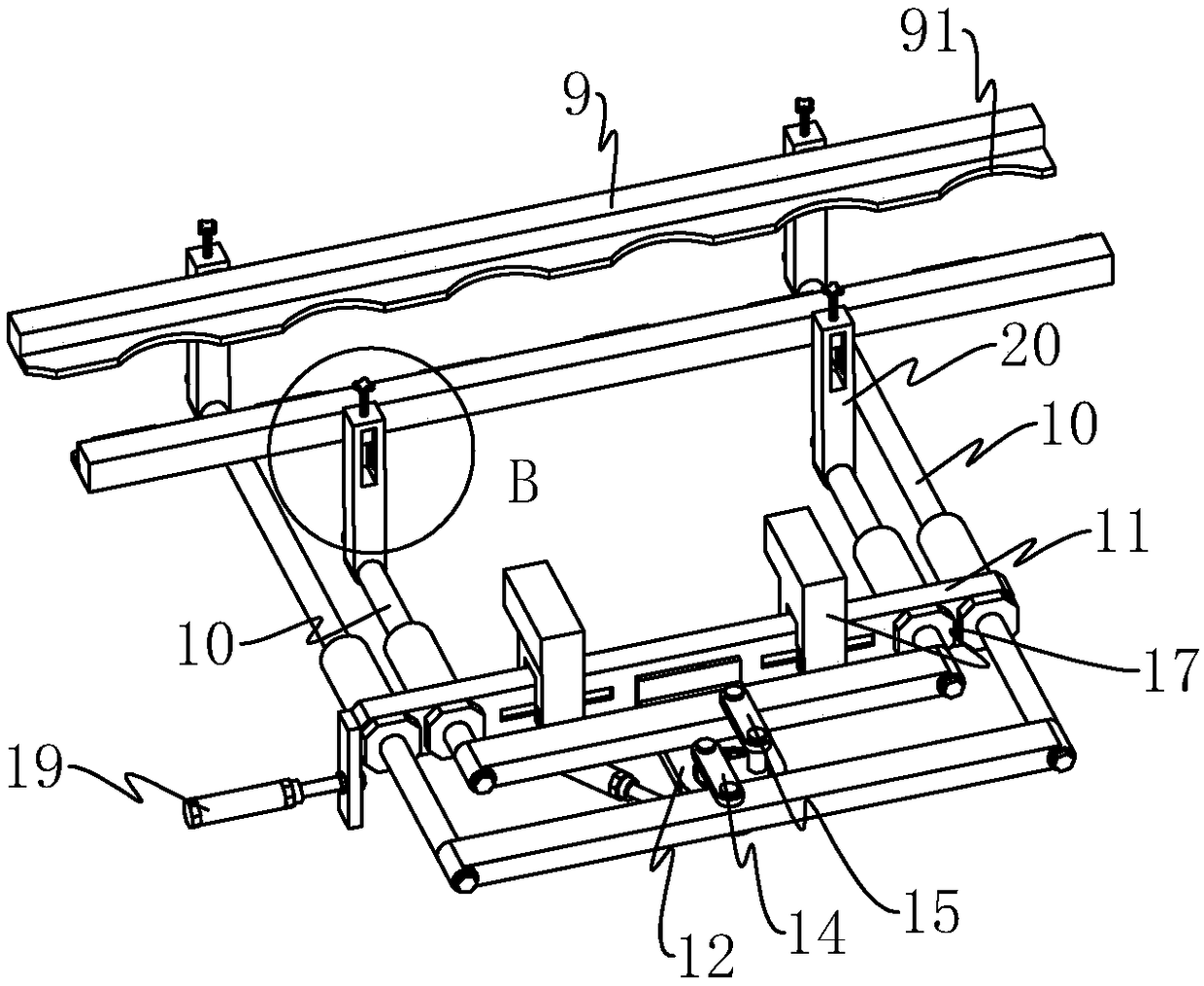

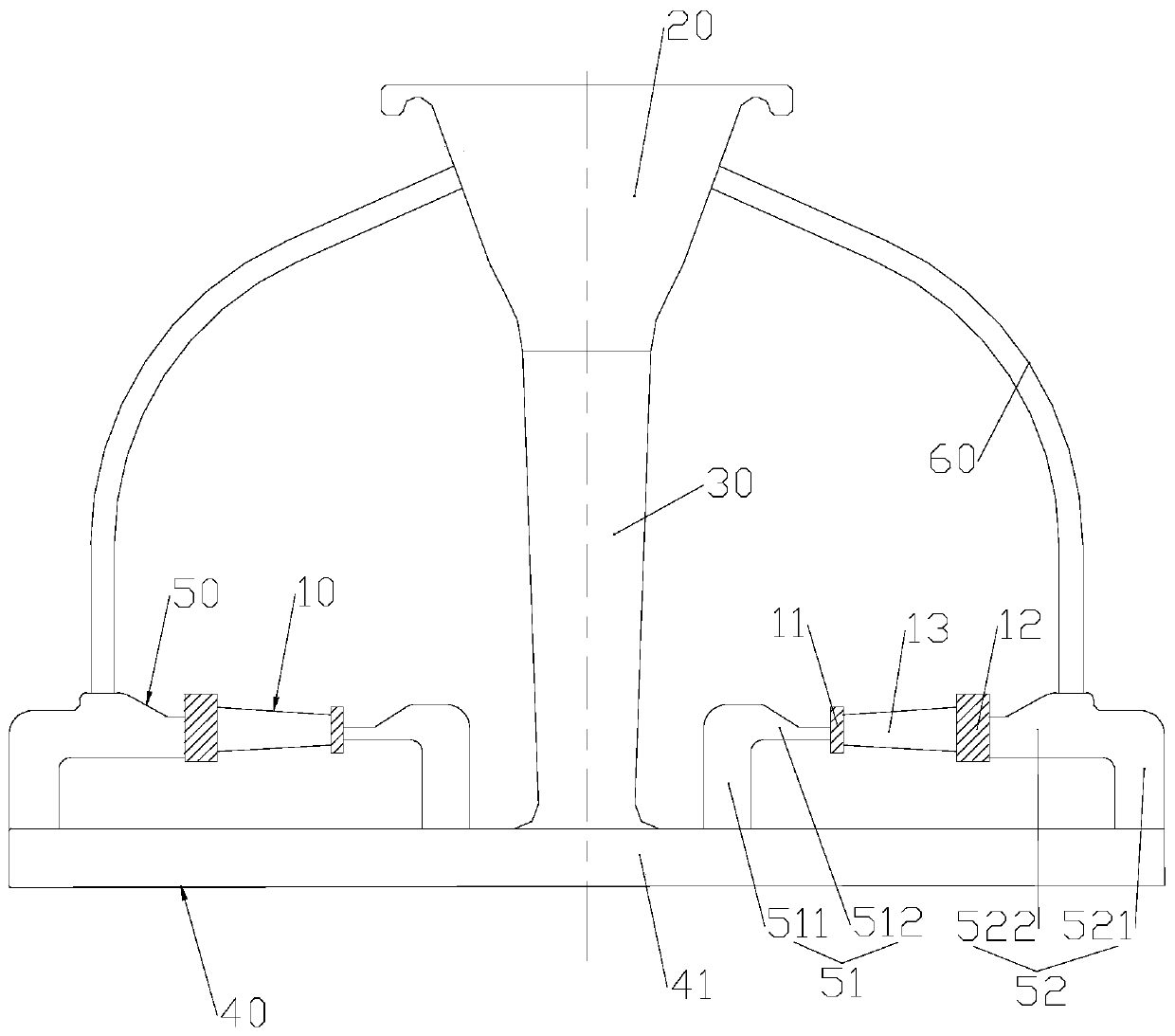

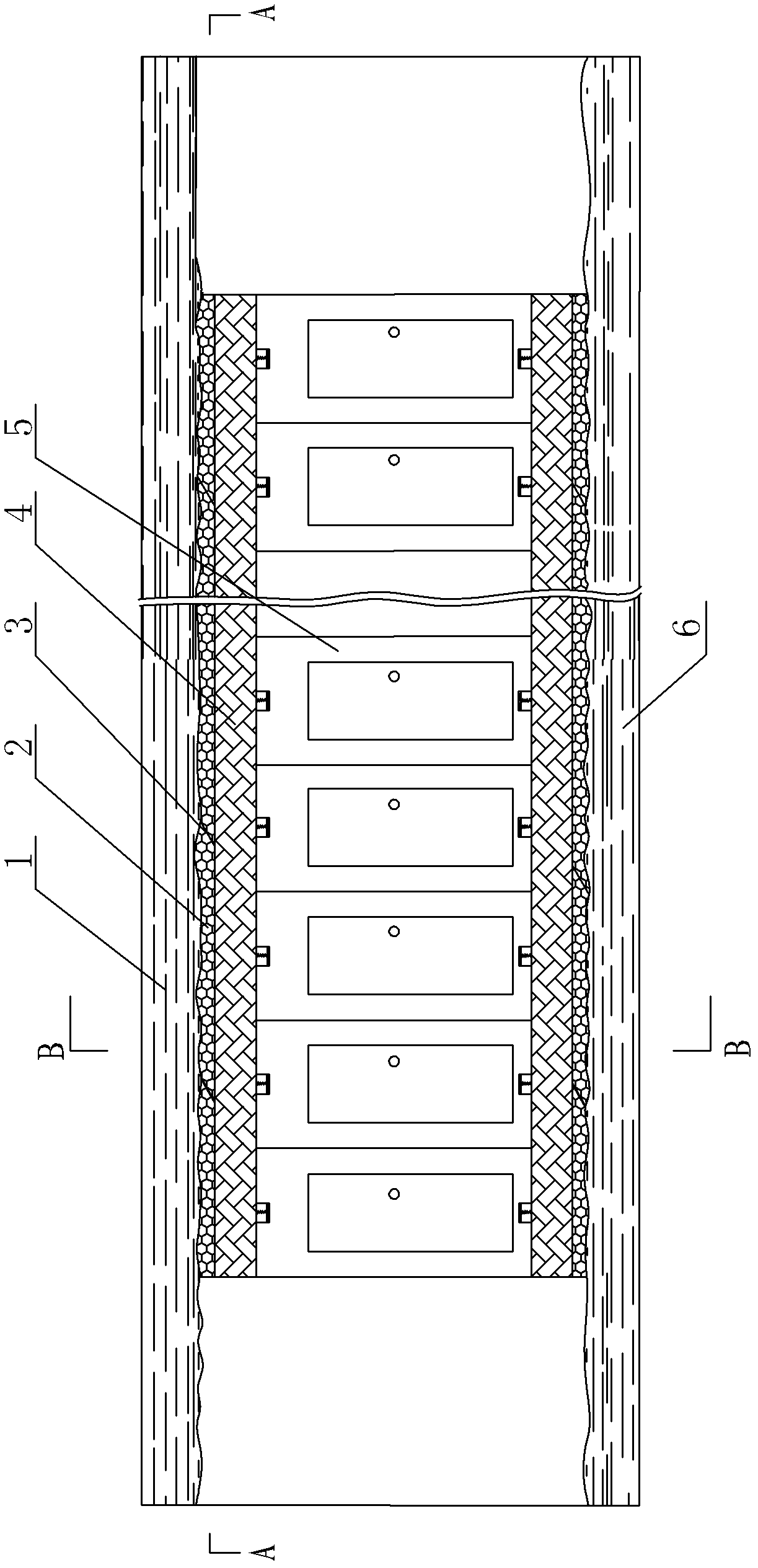

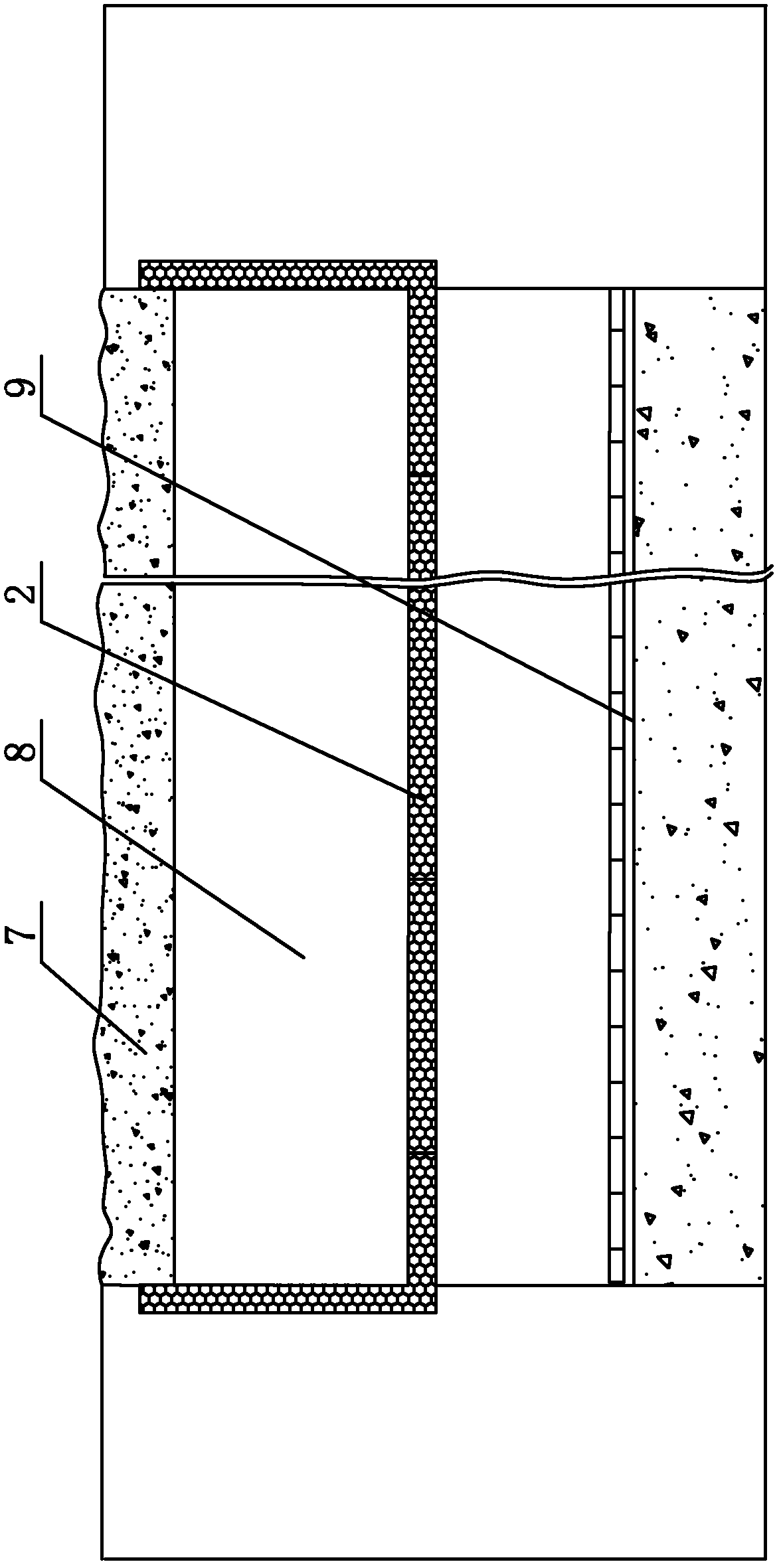

Renovation method for treating mud pumping of plate-type ballastless track railway roadbed

The invention discloses a renovation method for treating mud pumping of a plate-type ballastless track railway roadbed. Drilling is conducted on the surface layer of a foundation bed through a special horizontal drilling machine, and then the method that hot air is injected into grouting hole passageways is adopted; accumulated water in a mud pumping disease area is subjected to treatment, and grouting is conducted in grouting holes after accumulated water treatment is completed; before grouting, telescopic seams of a base plate, cracks of the side edges and orifices of the opposite sides of the grouting holes are subjected to sealing treatment, and then grouting is successively conducted in the hole passageways according to a certain sequence; a uniform and compact water insulation layer with the certain strength is formed between the base plate and the surface layer of the foundation bed after grouting is completed; and the water insulation layer can obstruct water of cracks on the upper portion from invading into the surface layer of the foundation bed and can also block fine particle soil in the surface layer of the foundation bed on the lower portion to move upwards. According to the novel renovation method for treating mud pumping of the plate-type ballastless track railway roadbed, the mud pumping disease of the plate-type ballastless track railway roadbed can be well governed.

Owner:ZHEJIANG UNIV

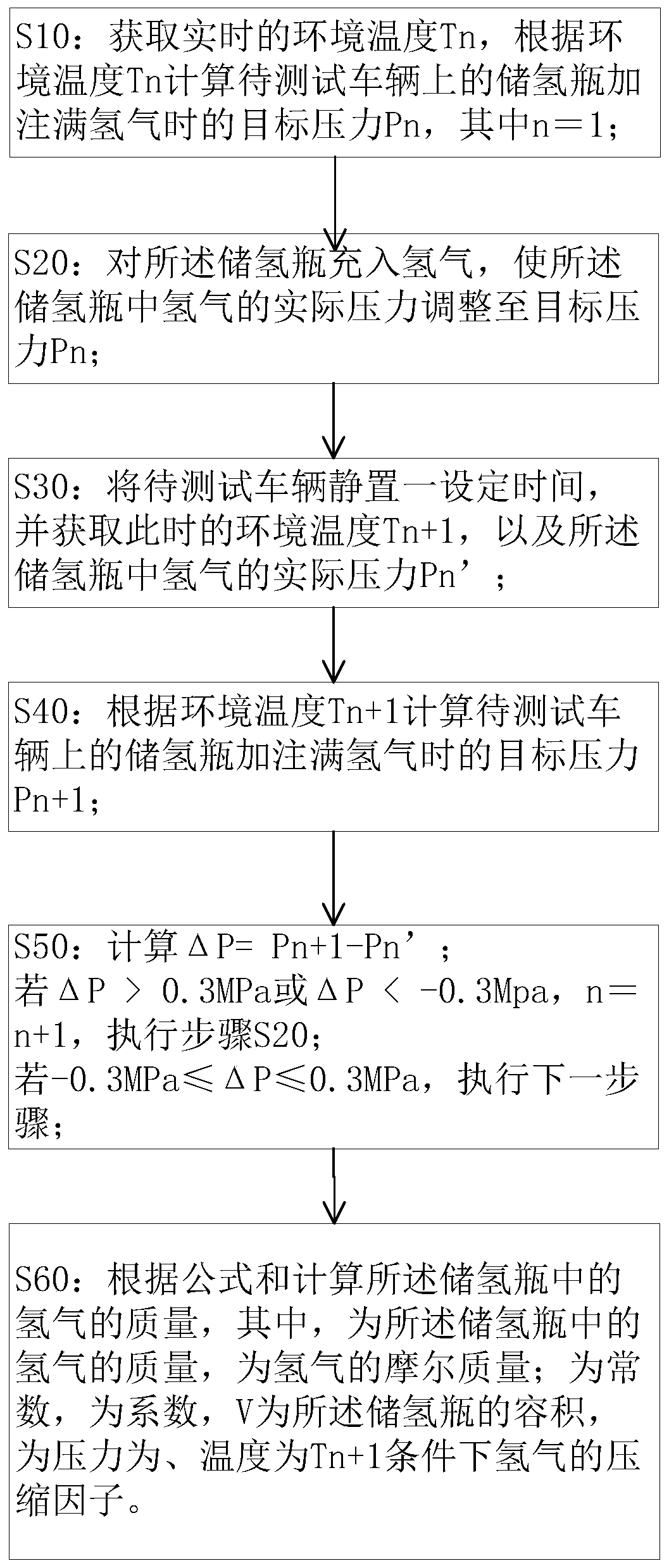

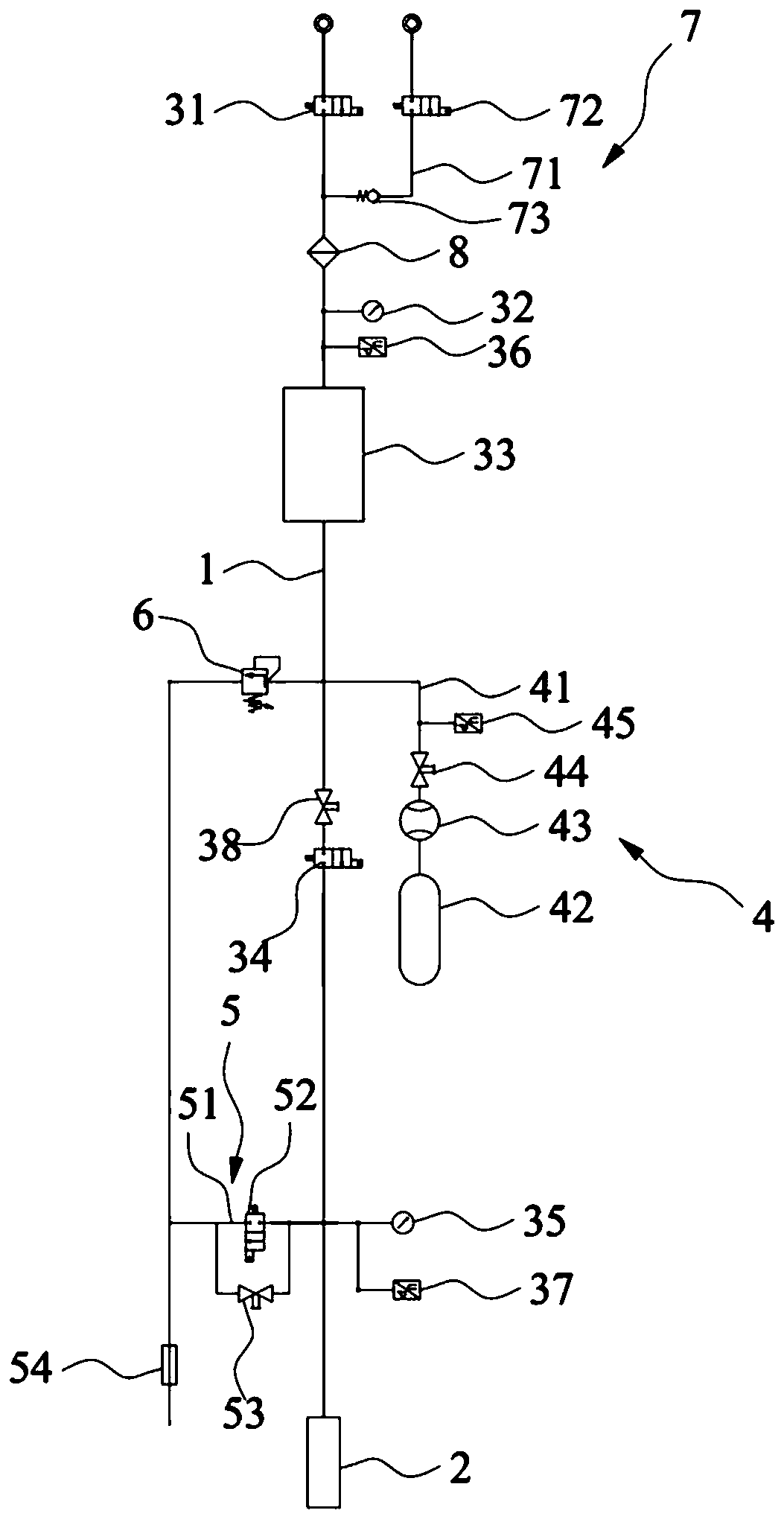

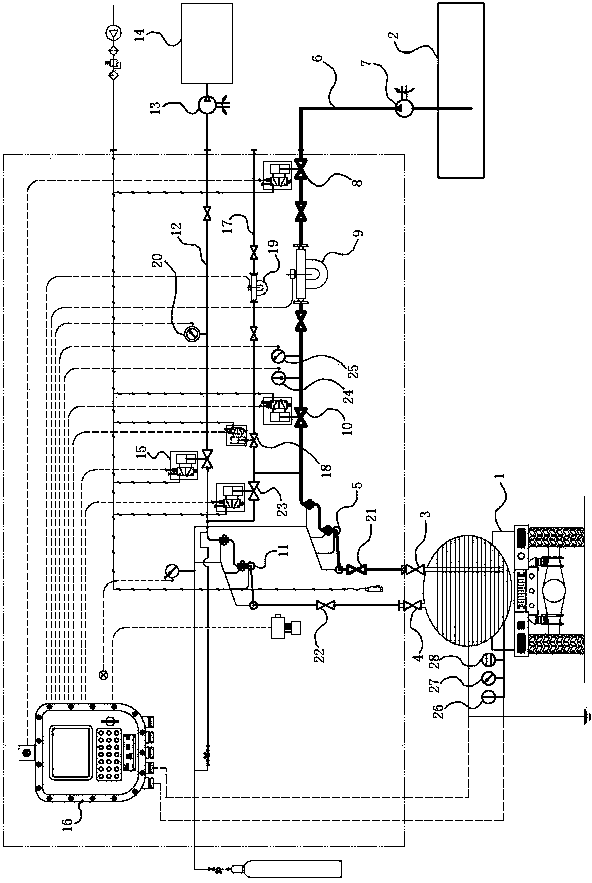

Hydrogenation device and hydrogenation method

PendingCN110848566AGuaranteed fillingThe hydrogenation method was successfully realizedFluid handledRoad vehiclesEngineeringMechanical engineering

The invention particularly discloses a hydrogenation device and a hydrogenation method. The hydrogenation method comprises the steps that S10, the real-time environment temperature Tn is acquired, thetarget pressure Pn obtained when a hydrogen storage bottle on a to-be-tested vehicle is full of hydrogen through filling is calculated according to the environment temperature Tn, and n=1; S20, the hydrogen storage bottle is filled with hydrogen, and the actual pressure of hydrogen in the hydrogen storage bottle is adjusted to the target pressure Pn; S30, the to-be-tested vehicle is subjected tostanding for a set time, and the environment temperature Tn+1 at this moment and the actual pressure Pn' of hydrogen in the hydrogen storage bottle are acquired; and S40, according to the environmenttemperature Tn+1, the target pressure Pn+1 generated when the hydrogen storage bottle on the to-be-tested vehicle is full of hydrogen through filling is calculated. According to the hydrogenation device and the hydrogenation method, the temperature factor is fully considered, and through constant calculation and hydrogenation adjusting, it can be guaranteed that the hydrogen storage bottle is fullof hydrogen through filling.

Owner:SHANGHAI MOTOR VEHICLE INSPECTION CERTIFICATION & TECH INNOVATION CENT CO LTD +1

Construction technology for reconstructing durable waterproof layer by using minimally invasive method

InactiveCN107448008AImprove adhesionSolve the leakBuilding repairsProtective foundationSurface layerEngineering

The invention discloses a construction technology for reconstructing a durable waterproof layer by using a minimally invasive method. Firstly, defects of a construction surface are treated; 2-8 grouting holes are formed per square meter of the construction surface, and hollow needles connected with feed valves are embedded in the grouting holes in a connection mode; secondly, epoxy acrylate is injected in the grouting holes to serve as a back-surface filling agent to reinforce a back-surface layer, and an AHA turbine sealant is injected in the grouting holes; after the AHA turbine sealant overflows from the hollow needles in every two adjacent grouting holes, the feed valve on the previous hollow needle is closed, and then the AHA turbine sealant is injected again in the hollow needles where the AHA turbine sealant overflows until all the feed valves are in a closed state; after the AHA turbine sealant is cured for 24 hours, the hollow needles are removed, and the grouting holes are blocked off. The construction technology has the following advantages that the process is simple, labor is saved, energy conservation and environmental protection are achieved, and resources are saved.

Owner:韩旭 +1

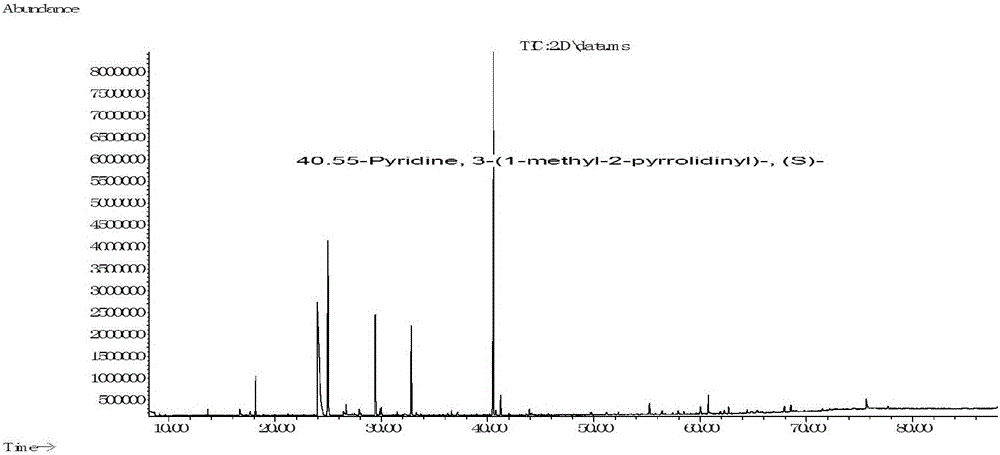

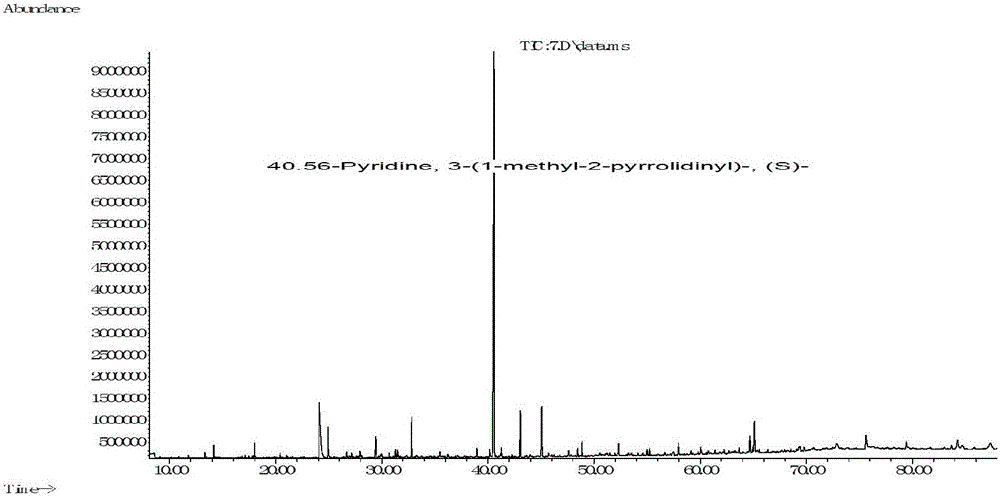

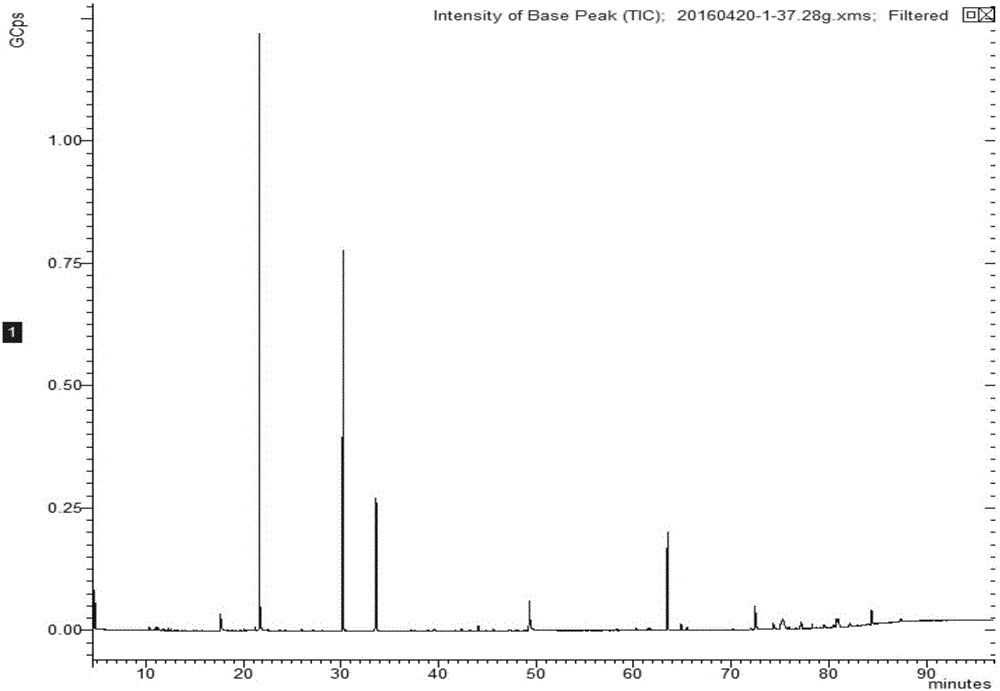

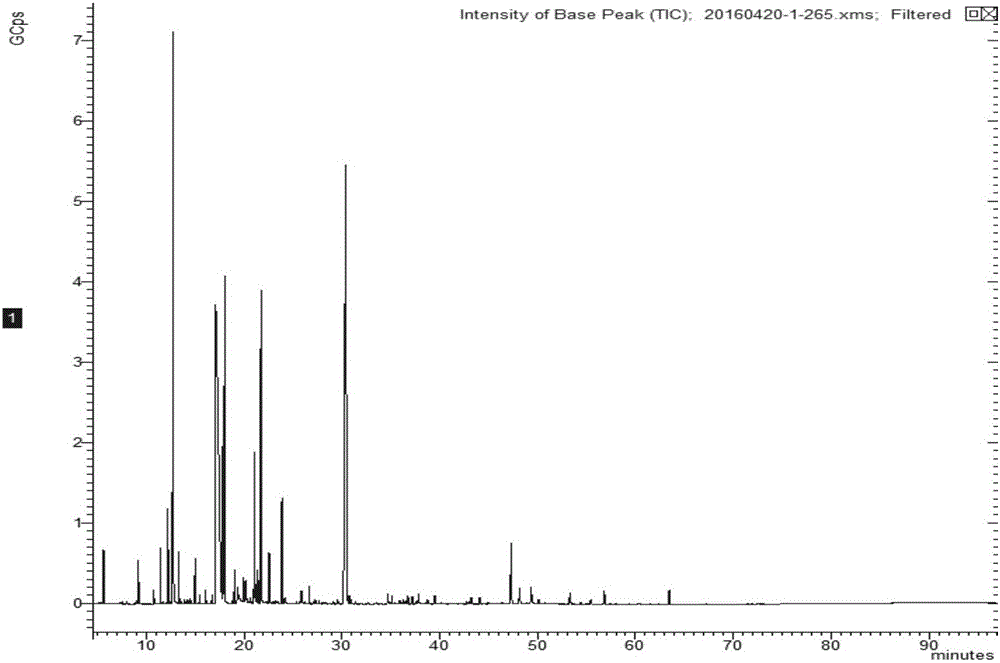

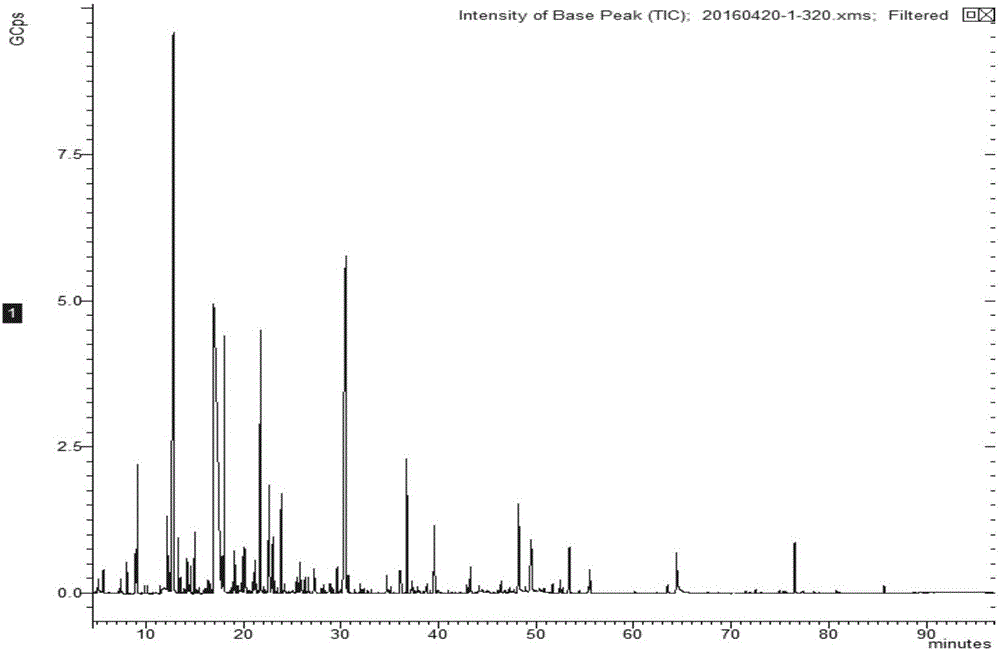

Preparation method of tobacco-sourced basic cigarette-smell raw material

InactiveCN105852200AStrong smoky aromaRealistic traditional cigarette smoking experienceTobacco treatmentTobacco productDry distillation

The invention discloses a preparation method of tobacco-derived basic smoke flavor raw material. The technical solution of the present invention is to carry out dry distillation and pyrolysis of tobacco raw materials; cool and collect the material produced by dry distillation and pyrolysis to obtain dry distillation pyrolysis liquid; extract the tobacco residue after dry distillation and pyrolysis to obtain extract; dry distillation pyrolysis liquid and extraction The tobacco-derived basic smoke taste raw material can be obtained after mixing the substances in any proportion. The raw material is applied to new tobacco products directly or after further processing, which can significantly increase / enhance the aroma characteristics of smoke, burnt, and roasted aroma of new tobacco products, making it closer to traditional cigarettes. The raw material can also be used for flavoring traditional cigarettes. The invention has the advantages of simple process, economic safety, obvious and unique use effect, and broad application prospect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Preparation method of copper/graphite film multi-layer laminated blocky composite material

ActiveCN107791616AHigh in-plane thermal conductivityHigh strengthMetal layered productsPolyvinyl butyralElectrolysis

The invention provides a preparation method of a copper / graphite film multi-layer laminated blocky composite material, which can be applied in the field of electronic packaging of an integrated circuit industry. The raw materials of the composite material adopt an anisotropic high-thermal-conductivity net-shaped graphite film and electrolytic pure copper powder. The preparation method comprises the following steps: adding the copper powder into a uniformly mixed solution of an adhesive prepared from polyvinyl butyral and an ethanol solution as well as dimethyl phthalate serving as a plasticizer, completely stirring to obtain uniform slurry with high flowability, spreading the slurry on the net-shaped graphite film uniformly, drying, cutting, degumming, superposing layer by layer, and performing bidirectional pressurizing and sintering to prepare the compact multi-layer laminated blocky composite material with the graphite film and metal copper which are arranged alternately in a layered mode. The heat conductivity of the composite material along the plane direction of the graphite film is 1.5 to 2 times higher than that of pure copper, the density can be reduced to be 65 to 80 percent of the density of the pure copper, and the composite material can be used for replacing the traditional copper tungsten metal heat-conducting material.

Owner:UNIV OF SCI & TECH BEIJING

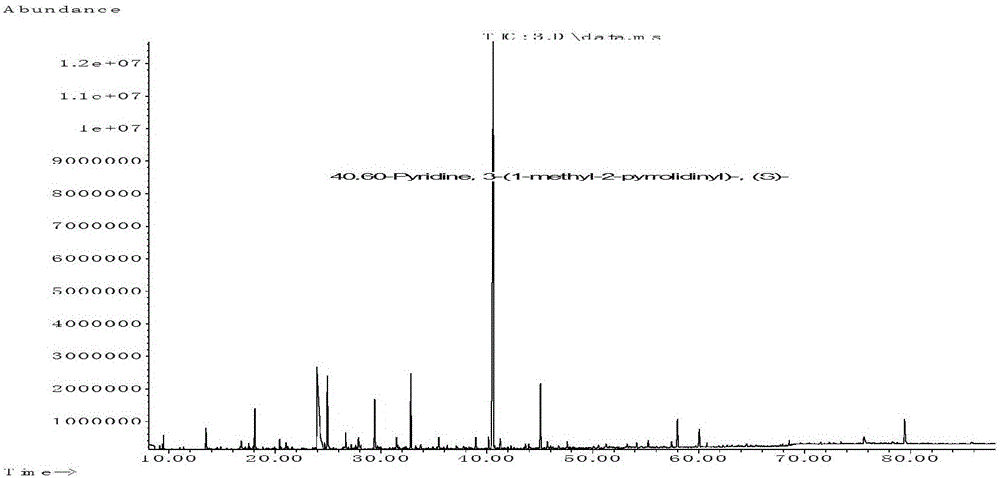

Preparation method for tobacco source raw material with basic cigarette smell

InactiveCN105686070AAffect the number of suction portsAffect the atomization effectTobacco treatmentTobacco productDry distillation

The invention discloses a preparation method for a tobacco source raw material with a basic cigarette smell. According to the technical scheme, the preparation method comprises the steps of extracting a tobacco raw material to obtain extract; performing dry distillation and pyrolysis on tobacco residues after extraction to obtain a dry distillation and pyrolysis solution; and combining the extract with the dry distillation and pyrolysis solution in any ratio (the usage amount of the extract is less than 100%) to obtain the tobacco source raw material with the basic cigarette smell. The tobacco source raw material with the basic cigarette smell is applied to a novel tobacco product, and not only has good tobacco aroma but also can remarkably improve the aromatic characteristics of the smoky aroma, scorch aroma, baking aroma and the like of the novel tobacco product to enable the novel tobacco product to be closer to a conventional cigarette. Meanwhile, the raw material also can be applied to the conventional cigarette. The preparation method is simple in process, economic and safe, thereby having wide application prospects; and the raw material has a good use effect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

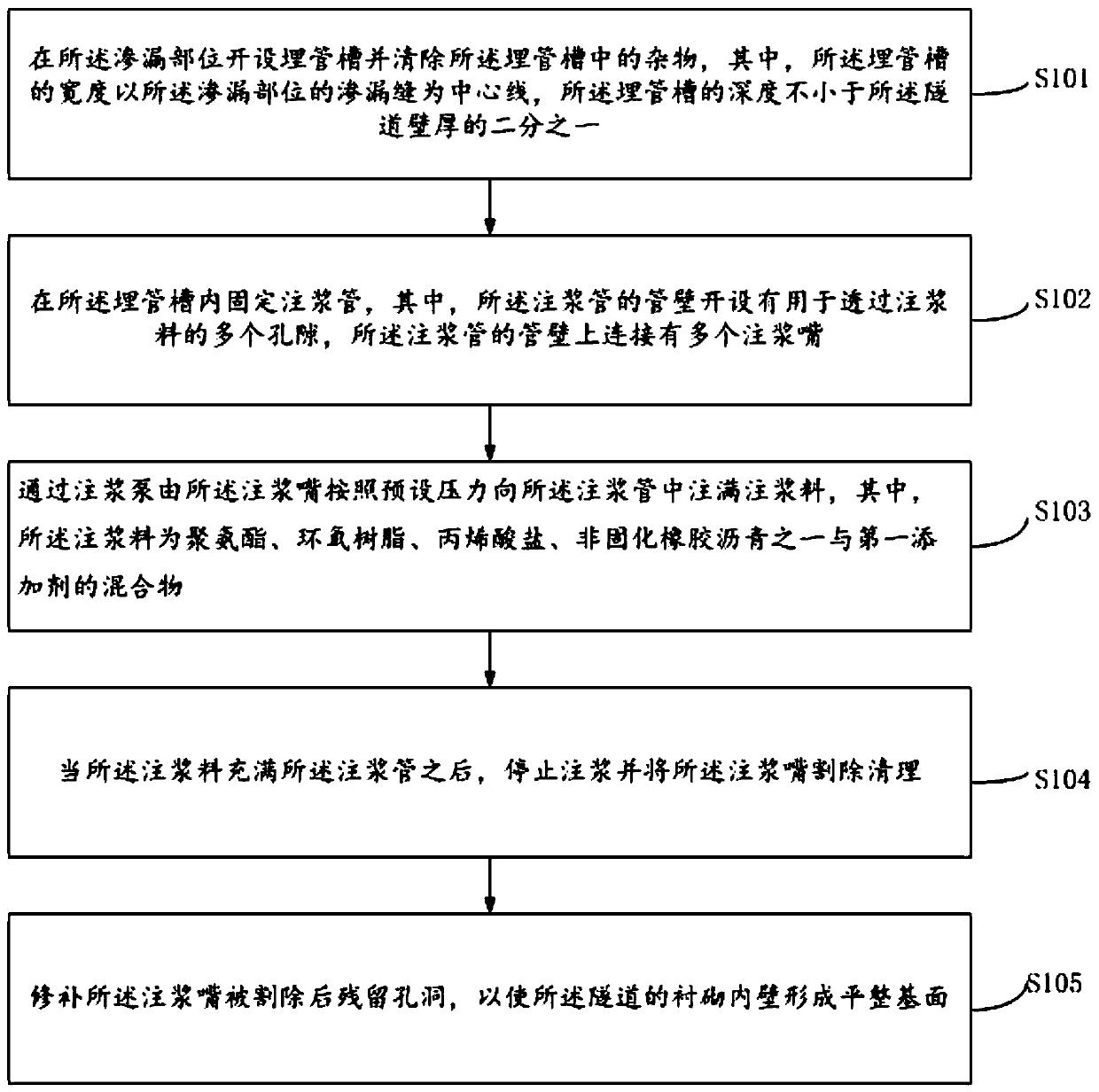

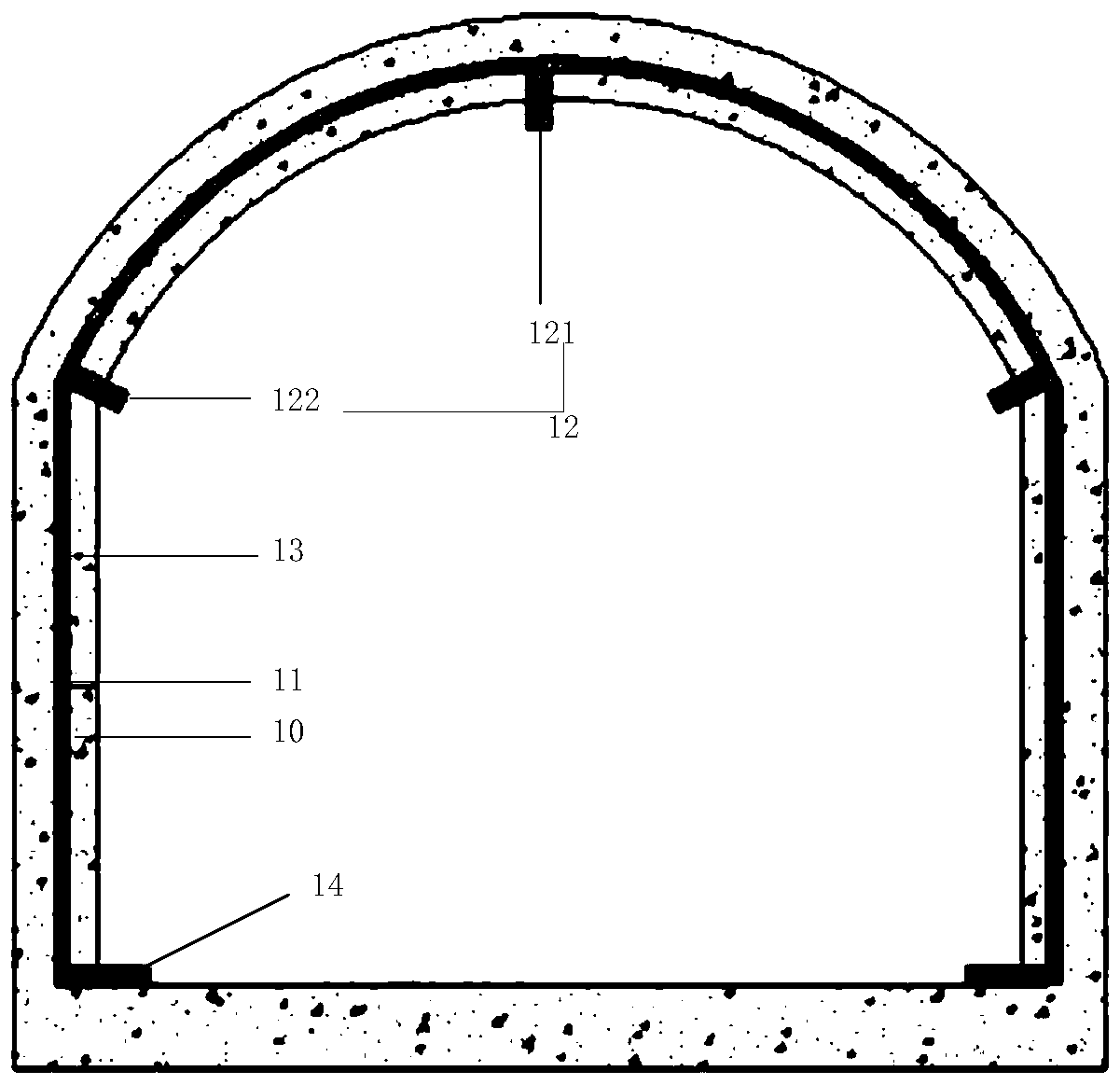

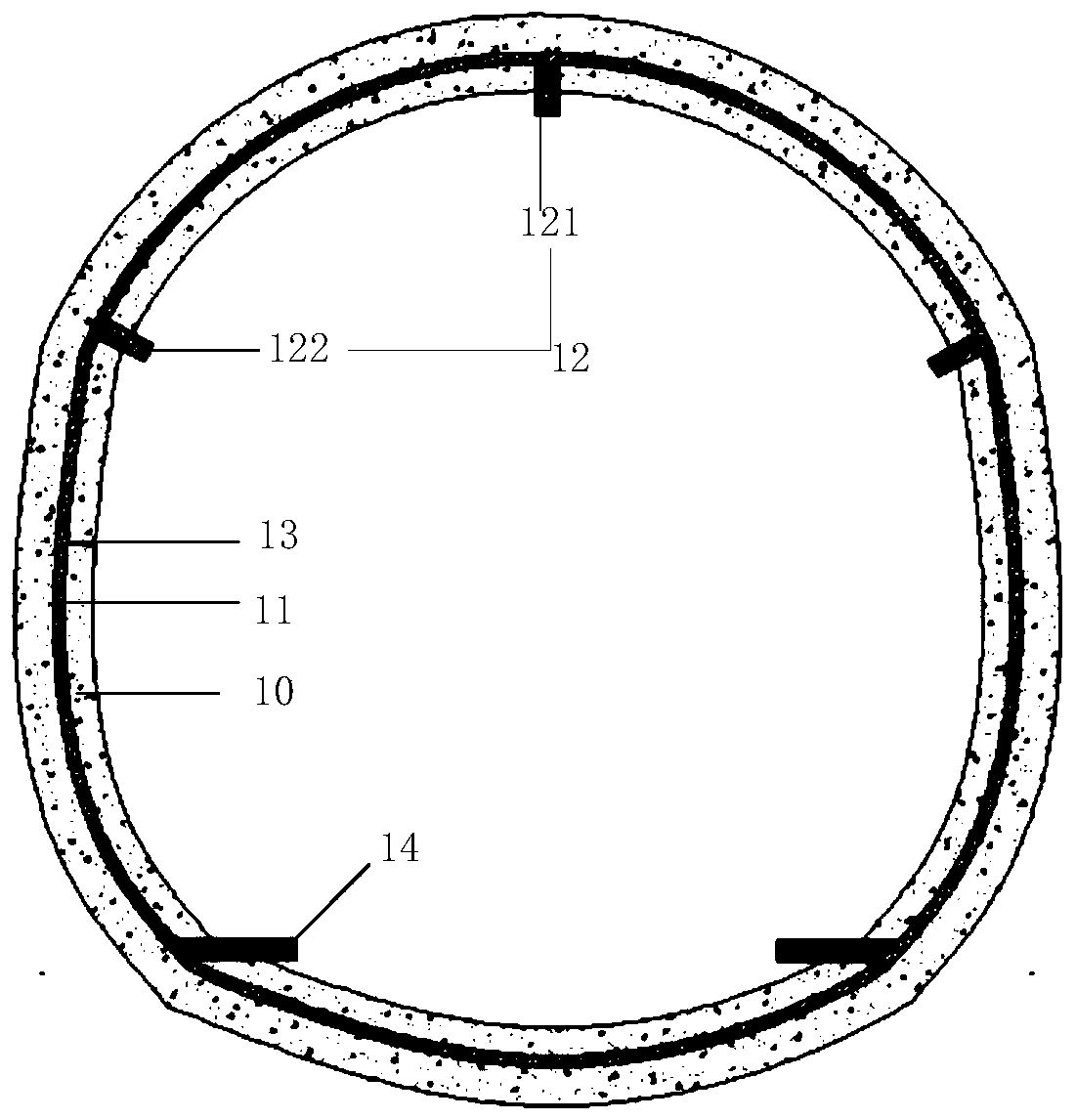

Waterproof construction method for engineering joint of tunnel

InactiveCN110410112AGuaranteed fillingImprove waterproof reliabilityUnderground chambersTunnel liningArchitectural engineeringProcess innovation

The embodiment of the invention provides a waterproof construction method for an engineering joint of a tunnel. The waterproof construction method is applied to a leakage part of a circumferential construction joint or a deformation joint of the tunnel. The waterproof construction method comprises the following steps: forming a pipe laying groove in the leakage part and eliminating sundries in thepipe laying groove; fixing a grouting pipe in the pipe laying groove; filling the grouting pipe full with a grouting material by a grouting nozzle by a grouting pump according to a preset pressure; when the grouting pipe is filled with the grouting material, stopping grouting and cutting and cleaning the grouting nozzle; and repairing residual holes after the grouting nozzle is cut so as to forma smooth basal plane on the lining inner wall of the tunnel. According to the waterproof construction method for the engineering joint of the tunnel, by means of process innovation, for example, groove removing, pipe laying, grouting and etc, in the leakage part of the engineering joint, the grouting material in the gap is full, and the waterproof reliability of the circumferential construction joint and the deformation joint of the tunnel is improved.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

Filling machine

ActiveCN108382657AAvoid interferenceGuaranteed normal fillingLiquid materialMechanical equipmentPower component

The invention discloses a filling machine and belongs to the field of packaging mechanical equipment. The filling machine comprises a rack, a hopper, a conveyor belt group and a weighing device; the conveyor belt group comprises a front conveyor belt and a back conveyor belt; a supporting plate is erected between the front conveyor belt and the back conveyor belt; clamping plates are arranged on the two sides of the supporting plate in a width direction respectively; the rack is provided with a clamping power component and a feeding power component; the clamping power component comprises a moving bracket, a rotation bracket, a first transmission rod, a second transmission rod and a clamping cylinder; the feeding power component comprises a linkage frame, a supporting frame and a feeding cylinder; the hopper comprises a first hopper and a second hopper; and the first hopper and the second hopper are arranged in a length direction of the supporting plate at an interval. The invention provides the filling machine which is fully automatic and is stable in work, convenient and rapid to operate and very high in both filling efficiency and filling accuracy of a product.

Owner:上海达和荣艺包装机械有限公司

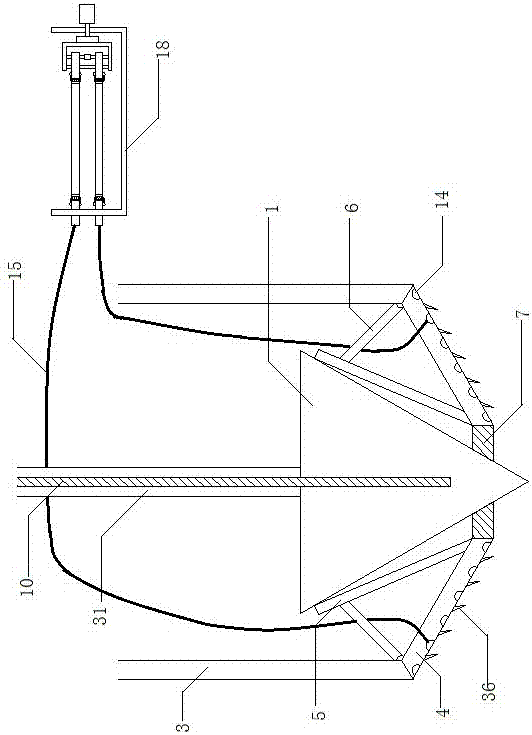

Bottom gating system for guider

ActiveCN110883315AAct as scumPlay the role of slag blockingFoundry mouldsFoundry coresMold fillingEngineering

The invention discloses a bottom gating system for a guider. The bottom gating system comprises a sprue cup, wherein the lower end of the sprue cup communicates with a sprue which is vertically arranged; the bottom end of the sprue communicates with a cross gate assembly which is horizontally arranged; the cross gate assembly is used for carrying out diversion and slag stopping on mold filling liquid filled by the sprue in order to remain slag inclusion mixed in the mold filling liquid in the cross gate assembly; and the cross gate assembly is further used for rectifying the mold filling liquid in order to enable the mold filling liquid to be injected stably. The cross gate assembly communicates with mold filling pouring gate assemblies; the mold filling pouring gate assemblies are arranged above the cross gate assembly; and each mold filling pouring gate assembly is separately arranged on the inner side of an inner ring mold shell and the outer side of an outer ring mold shell of a guider mold shell and respectively communicates with the inner ring mold shell and the outer ring mold shell, so that the mold filling liquid after slag stopping and rectifying in the cross gate assembly is stably injected into the inner ring mold shell and the outer ring mold shell through the mold filling pouring gate assembly.

Owner:CHINA HANGFA SOUTH IND CO LTD

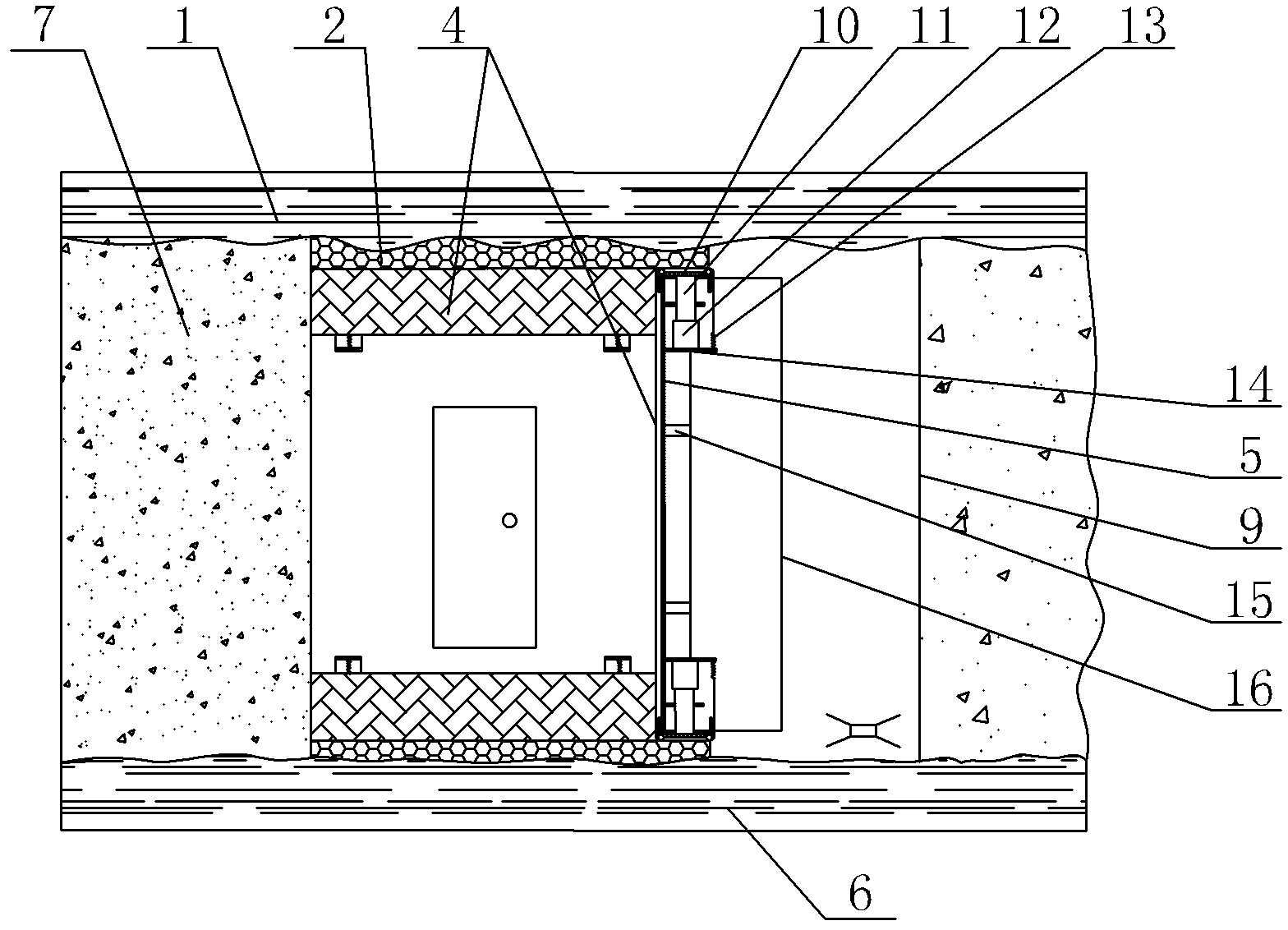

Mobile type hydraulic airtight filling device

InactiveCN102619543AAvoid pollutionAvoid damageMaterial fill-upMine roof supportsHydraulic cylinderEngineering

The invention relates to a mobile type hydraulic airtight filling device which comprises a plurality of groups of hydraulic supports arranged in parallel, the rear ends of each group of hydraulic supports are connected with vertical retaining walls made of hard plates via cross beams, and an upper and a lower opposite hydraulic cylinders are fixedly installed on the hydraulic supports respectively via supporting plates; adjusting plates are fixed at the top ends of piston rods of the hydraulic cylinders, the adjusting plates comprise one horizontal pressing plate perpendicular to the piston rods and two vertical plates welded on both ends of the horizontal pressing plate and parallel to the piston rods, and the horizontal pressing plate is fixed at the top ends of the piston rods; the vertical plates are located at the inner side of the vertical retaining walls, an integral waterproof cloth curtain is arranged at the outer side of a plurality of vertical retaining walls, and the upper and lower ends of the cloth curtain respectively wind around the upper and lower horizontal pressing plates and are connected with the supporting plates via the adjusting plates, a macromolecular elastic sealing block is arranged above the cloth curtain above the horizontal pressing plates, and the sealing block is connected with the cloth curtain via a positioning device. When the device is used for filling, the sealing effect is good, and top plate collapse and surface subsidence can be well inhibited by filling while mining.

Owner:ZIBO WANGZHUANG COAL MINE

Automatic loading system and loading method of leakage-free loading arms of liquefied chlorine tank truck

ActiveCN103939735AGuaranteed fillingAvoid the danger of overdoseContainer discharging methodsContainer filling under pressureLiquid stateGas phase

The invention discloses an automatic loading system of leakage-free loading arms of a liquefied chlorine tank truck. The automatic loading system is connected with a liquefied chlorine tank of the tank truck and a liquefied chlorine storage tank of a user to carry out liquefied chlorine loading operation; a liquid phase filling opening and a gas phase pumpback opening are formed in the top of the liquefied chlorine tank of the tank truck; the liquid phase filling opening is communicated with the liquefied chlorine storage tank through a liquid phase leakage-free loading arm of the liquefied chlorine and the gas phase pumpback opening is communicated with a chlorine recycling treatment device through a gas phase leakage-free loading arm of the liquefied chlorine. The automatic loading system is mainly applied when the liquefied chlorine is filled into the tank truck through the leakage-free loading arms; an explosion separation batch controller is used for switching each pneumatic stop valve to realize liquefied chlorine filling and excess pumping back and for measuring the pressures, temperatures and flow rates of liquefied chlorine and gasified chlorine in each pipeline, so that the purpose of automatic metering, quantitative control, safe measuring and interlocking during filling is realized.

Owner:CHINA CHENGDA ENG +1

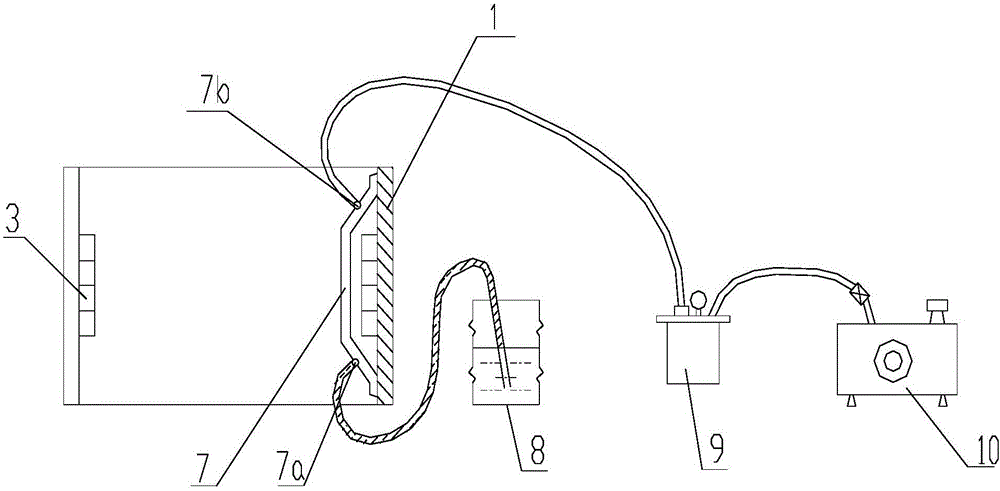

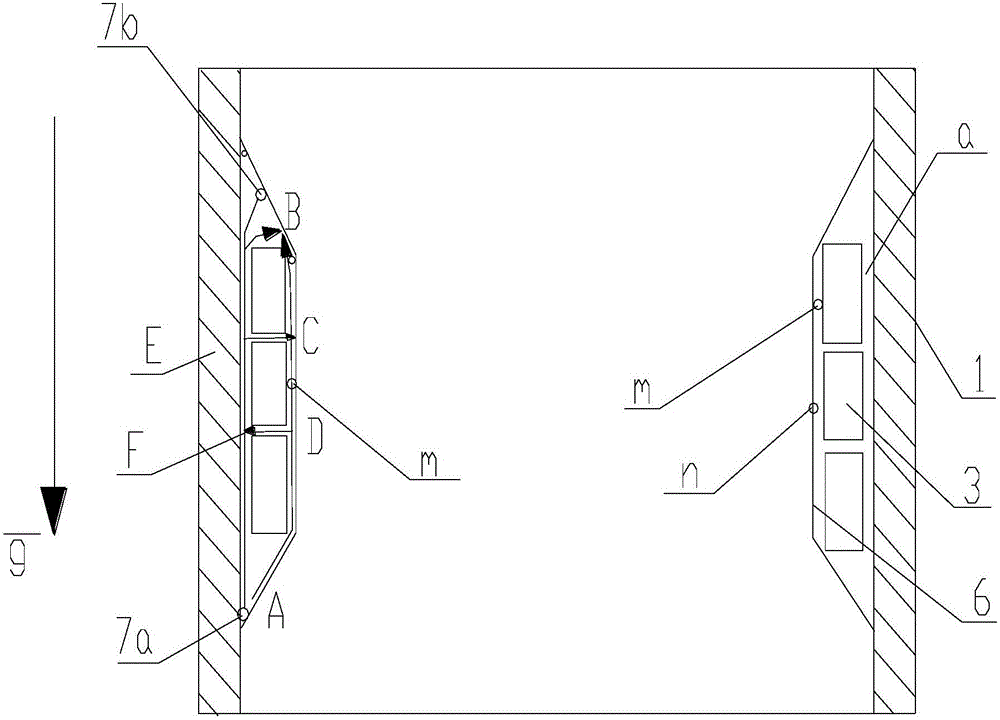

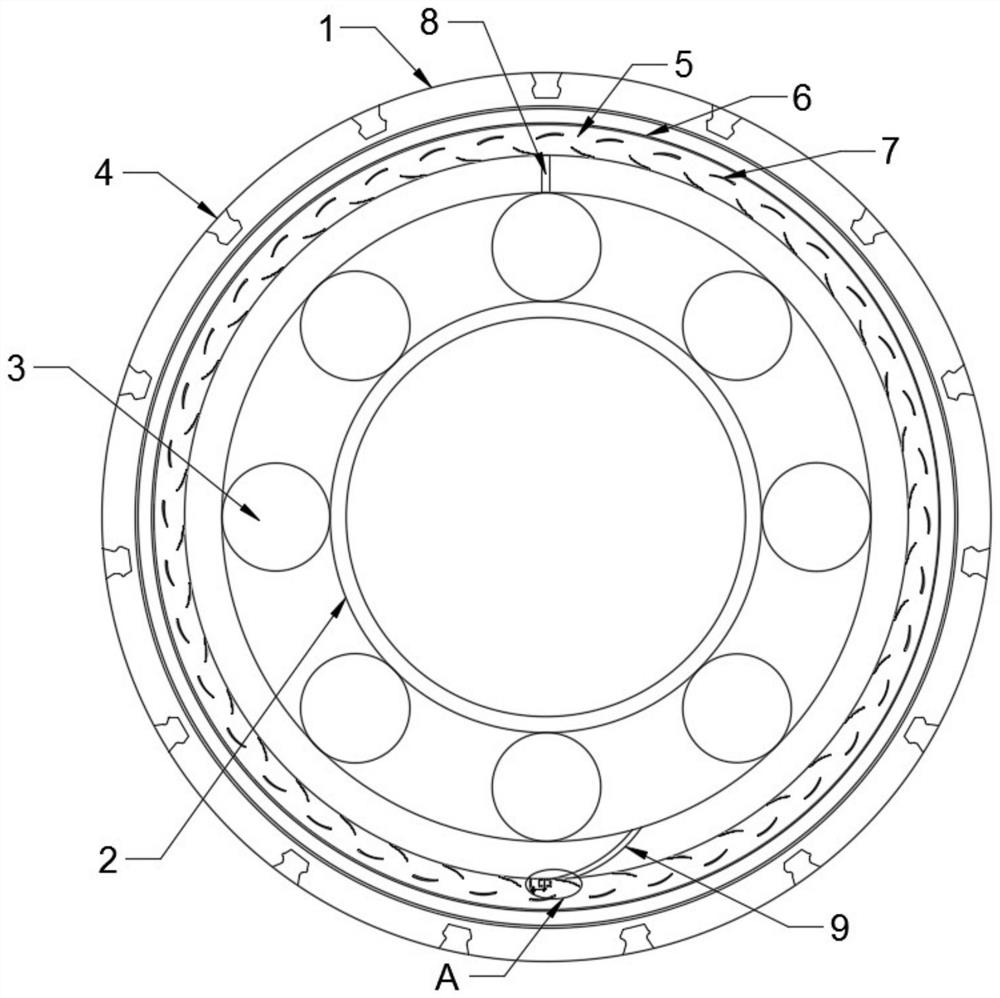

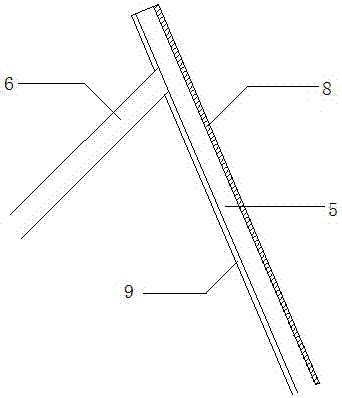

Self-sealing lubricating high-temperature rolling bearing and manufacturing method thereof

ActiveCN113027925ARealize high temperature self-lubricationGuaranteed fillingShaftsBearing componentsImpellerRolling-element bearing

The invention discloses a self-sealing lubricating high-temperature rolling bearing and a manufacturing method thereof. The self-sealing lubricating high-temperature rolling bearing comprises a bearing main body, wherein a lubricating mechanism and a flow guide mechanism are arranged in the bearing main body, and a sealing mechanism is arranged on the side wall of the bearing main body. The flow guide mechanism comprises a driving assembly and a flow guide assembly which are arranged in the bearing body, wherein the driving assembly and the flow guide assembly are meshed with each other. The flow guide assembly comprises a driving rod, wherein the driving rod is driven by the driving assembly, an impeller is fixedly installed on the side wall of the driving rod, and a first bevel gear is fixedly connected to the end of the driving rod. The sealing mechanism comprises sealing plates which are oppositely arranged on the side wall of the bearing main body, and sealing teeth are arranged on the side walls of the two sealing plates. Lubricating oil is discharged through connecting grooves, circulation of the lubricating oil between an outer ring and an inner ring is achieved in the process, the heat dissipation area of the outer ring can be effectively increased through heat dissipation grooves, and therefore the temperature of the lubricating oil is reduced, the protection function on a bearing is achieved, and the service life of the bearing is prolonged.

Owner:NANCHANG INST OF TECH

Slurry direct cyclic rotation drilling punching and slurry return device of ground source heat pump

ActiveCN106968606AGuaranteed pouring effectGuaranteed fillingDrill bitsConstructionsReturn functionDrill bit

The invention provides a slurry direct cyclic rotation drilling punching and slurry return device of a ground source heat pump. The drilling punching and slurry return device comprises a drilling punching part and a slurry return part. The drilling punching part comprises a drill bit body and a drill bit substrate. The slurry return part comprises an injecting mechanism and a discharging mechanism. The injecting mechanism comprises an injecting pipe and an injecting spray hole. The discharging mechanism comprises a discharging hole and a discharging pipe. The drilling punching and slurry return device is a combination of the drilling punching and slurry return functions, injection of clean water and slurry discharging are ensured while the drilling punching quality is ensured, slurry generated during drilling punching is effectively utilized, the drilling punching cost is effectively reduced, and the drilling punching and slurry return device is suitable for being applied and popularized.

Owner:JIANGSU SHENGSHI ELECTROMECHANICAL ENG CO LTD

Cosmetic containing stigma croci liquid extract

InactiveCN106821932AEffective absorptionPromote blood microcirculationCosmetic preparationsToilet preparationsFritillaria thunbergiiAllergy

The invention belongs to the field of cosmetics, and relates to a cosmetic containing stigma croci liquid extract. The cosmetic comprises the stigma croci liquid extract, fritillaria thunbergii extract, pomegranate extract, sodium hyaluronate, fish collagen, rye seed extract, fine euglena extract, cetearyl olivate, Sorbitan olivate, macadamia integrifolia seed oil, vitamin E, shea butter, butylene glycol, whey protein, glyceryl stearate, palmitoyl tetrapeptide and deionized water. The cosmetic is extracted from specific natural raw materials, by rational compounding, the cosmetic can achieve the effect of reducing skin wrinkles and moisturizing by synergistic effects of improving microcirculation, enhancing activity, restoring support and moisturizing and filling and the like. At the same time, traditional Chinese medicines are introduced into the cosmetic for resisting wrinkles and beautifying, and the disadvantages of easy allergy and insecurity caused by excessive addition of chemical components in similar products sold in the market can be overcome.

Owner:宁波君瑞生物科技有限公司

Method for removing ammonia nitrogen from sewage in subzone

InactiveCN1312063CAchieve regenerationContinuous regenerationTreatment with anaerobic digestion processesMultistage water/sewage treatmentAnaerobic filterSewage

The present invention relates to a method for deamination and denitrification of residential quarter sewage, belonging to the field of sewage treatment technology. It is characterized by that after the sewage is passed through anaerobic filter tank, contact oxidation tank and precipitation tank to obtain treatment, then sewage can upwards flow and be fed into two parallel modified zeolite adsorption regeneration columns to implement ammonia and nitrogen adsorption at twice successively, so that said invention can obtain high ammonia and nitrogen treatment efficiency. Said invention also provides the regeneration method of the above-mentioned zeolite adsorption regeneration column by using backflush process.

Owner:HARBIN INST OF TECH

Special dismountable ERCP multifunctional biliarystone removal saccule

PendingCN107157545AGuaranteed sealingGuaranteed fillingSurgeryAgainst vector-borne diseasesAirflowSaccule

The invention provides a special dismountable ERCP (Endoscopic Retrograde Cholangiopancreatography) multifunctional biliarystone removal saccule, and relates to the technical field of a medical tool. The special dismountable ERCP multifunctional biliarystone removal saccule comprises a pipe body, a connector and a saccule, wherein a first saccule cavity, a first guide wire cavity and a first injection cavity are arranged in a first pipe fitting; a second saccule cavity, a second guide wire cavity and a second injection cavity are arranged in a second pipe fitting; a first connecting element is arranged at one end of the first pipe fitting; a second connecting element is arranged at one end of the second pipe fitting; a hollow saccule post, a hollow guide wire post and a hollow injection post are connected into the second connecting element; an air flow inlet and an air flow outlet are formed in the saccule post; a one-way valve is connected into the saccule post; the second connecting element and the first connecting element are detachably connected; and after the connection, the first saccule cavity, the first guide wire cavity and the first injection cavity are arranged in a way of being in one-to-one correspondence to the one-way valve, the guide wire post and the injection post. The special dismountable ERCP multifunctional biliarystone removal saccule has the stone removal function of an ordinary biliarystone removal saccule, and can also be used as a guide device; the ERCP operation risk is reduced; and the work efficiency is improved.

Owner:YANGZHOU NO 1 PEOPLES HOSPITAL

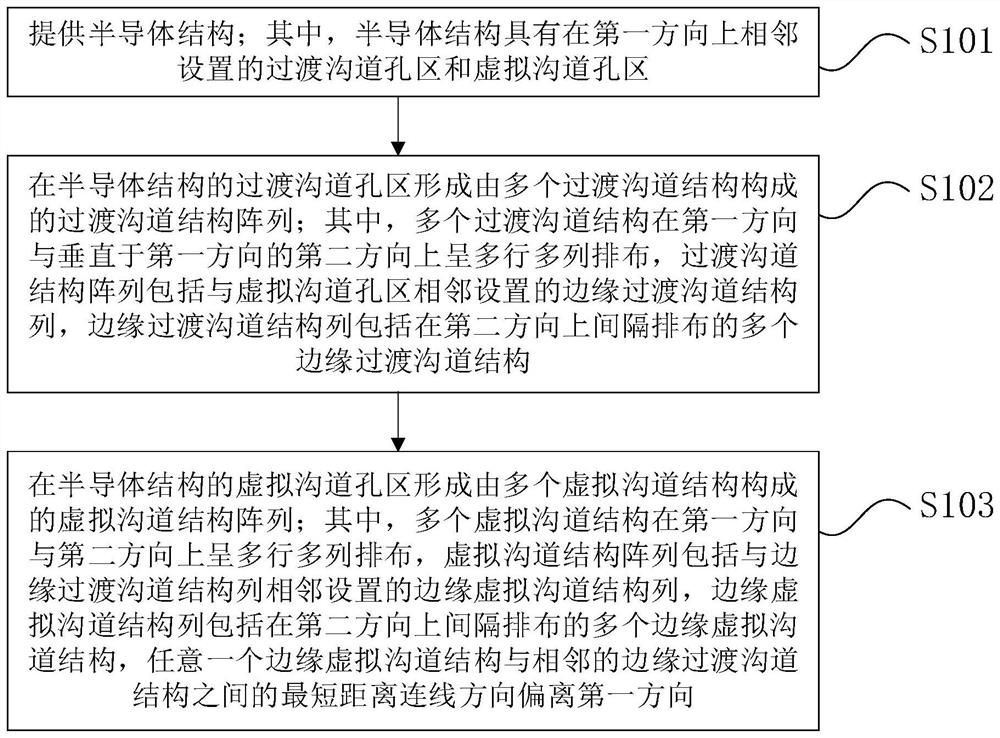

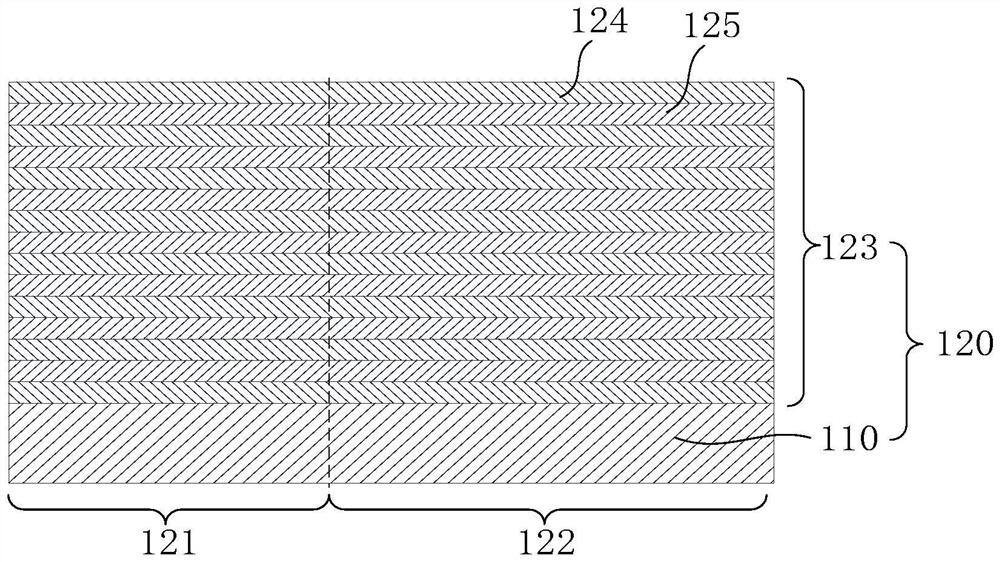

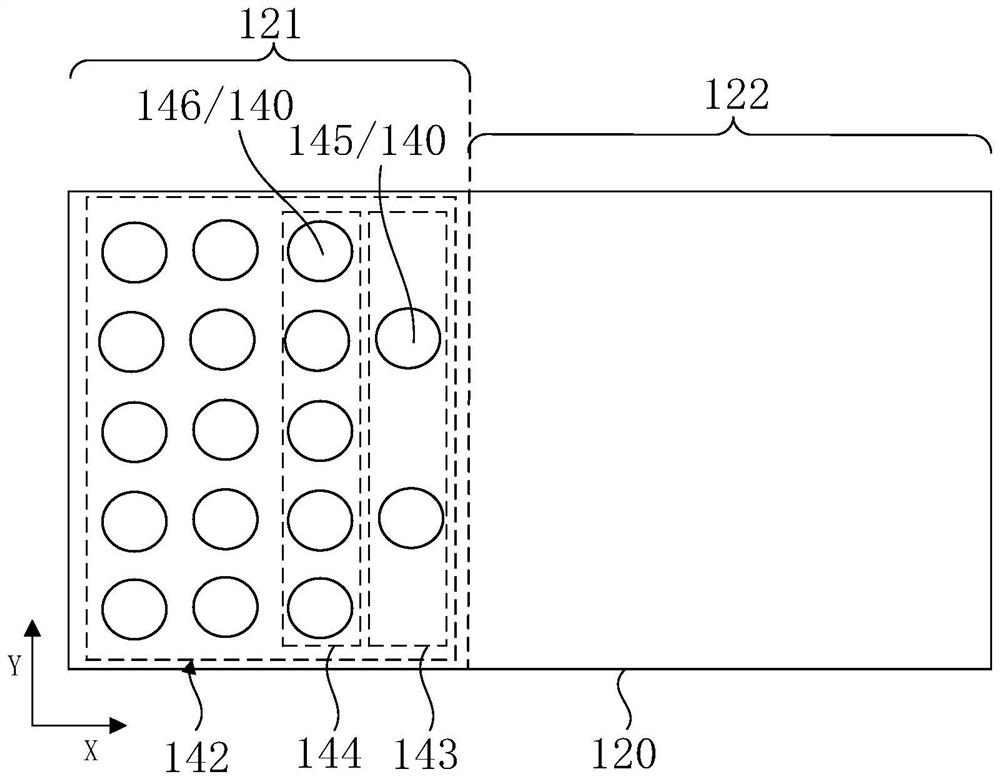

Semiconductor device and manufacturing method thereof

ActiveCN112397521AAvoid connectionPrevent leakageSolid-state devicesSemiconductor devicesSemiconductor structureDevice material

The invention discloses a semiconductor device and a manufacturing method thereof. The semiconductor device comprises a semiconductor structure, a transition channel structure array and a virtual channel structure array, wherein the transition channel structure array and the virtual channel structure array are arranged in the semiconductor structure and are adjacently arranged in a first direction; the transition channel structure array comprises an edge transition channel structure column adjacent to the virtual channel structure array, the edge transition channel structure column comprises aplurality of edge transition channel structures arranged at intervals in the second direction, and the second direction is perpendicular to the first direction; the virtual channel structure array comprises an edge virtual channel structure column adjacent to the edge transition channel structure column, and the edge virtual channel structure column comprises a plurality of edge virtual channel structures arranged at intervals in the second direction; the shortest distance connecting line direction between any edge virtual channel structure and the adjacent edge transition channel structure deviates from the first direction. The problem of sharp corners of the edge virtual channel holes can be avoided, and therefore electric leakage of the three-dimensional storage device is avoided.

Owner:YANGTZE MEMORY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com