Patents

Literature

457 results about "Loading arm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A loading arm permits the transfer of liquid or liquefied gas from one tank to another through an articulated pipe system consisting of rigid piping and swivel joints to obtain flexibility. Transfer to or from a truck transported tank or rail transported tank requires a Top Loading Arm or a Bottom Loading Arm. Transfer to or from a ship or barge requires a marine loading arm.

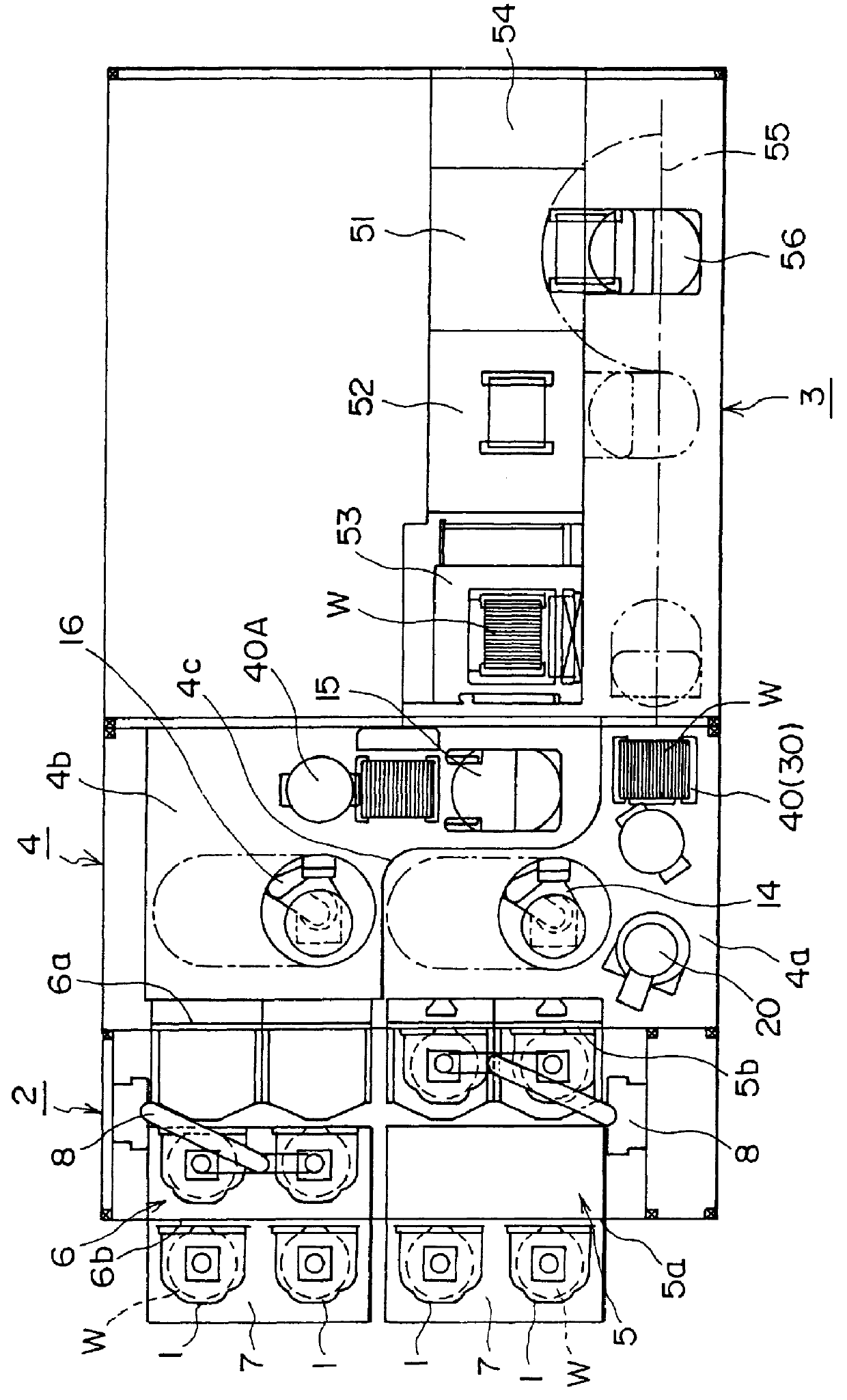

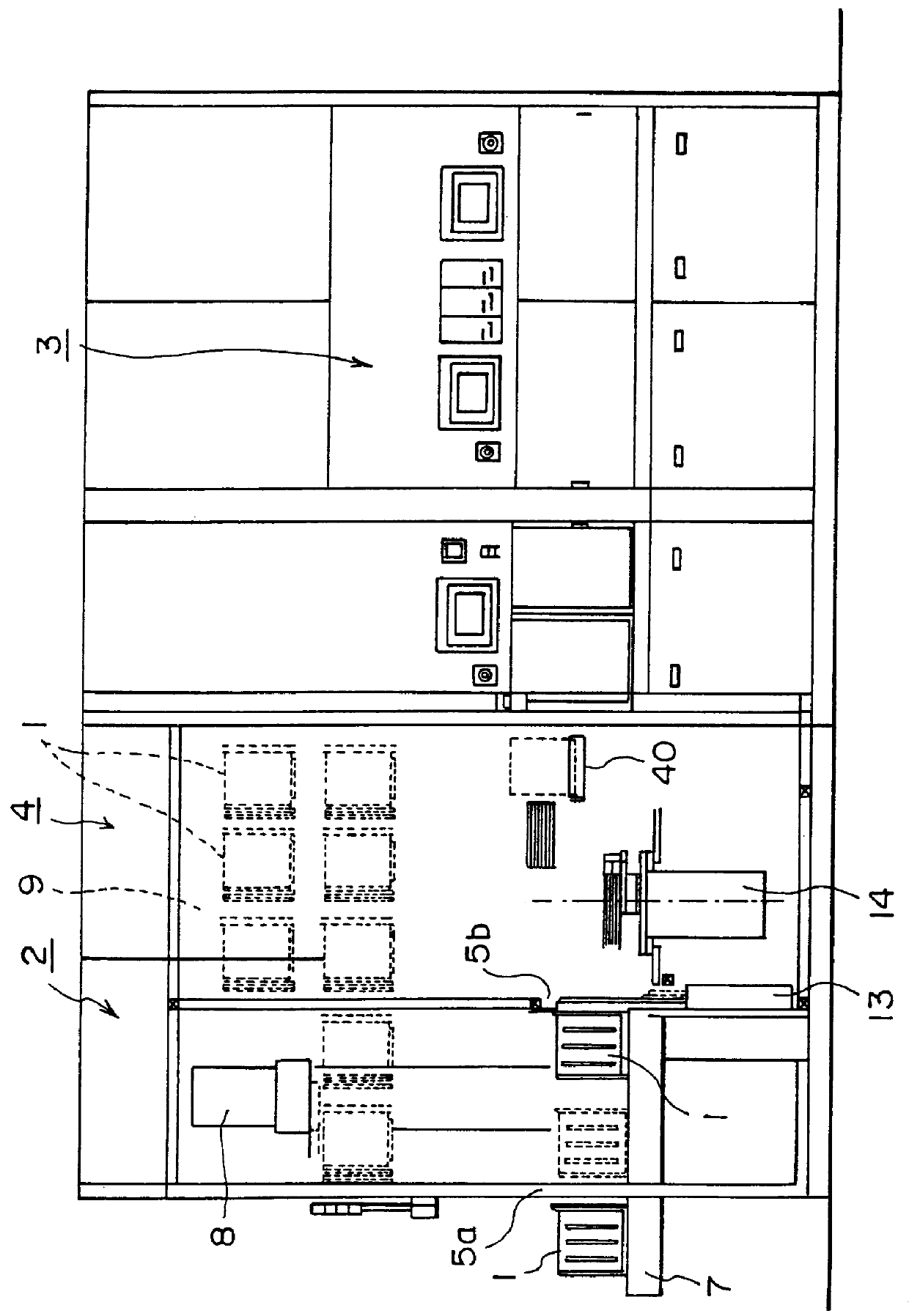

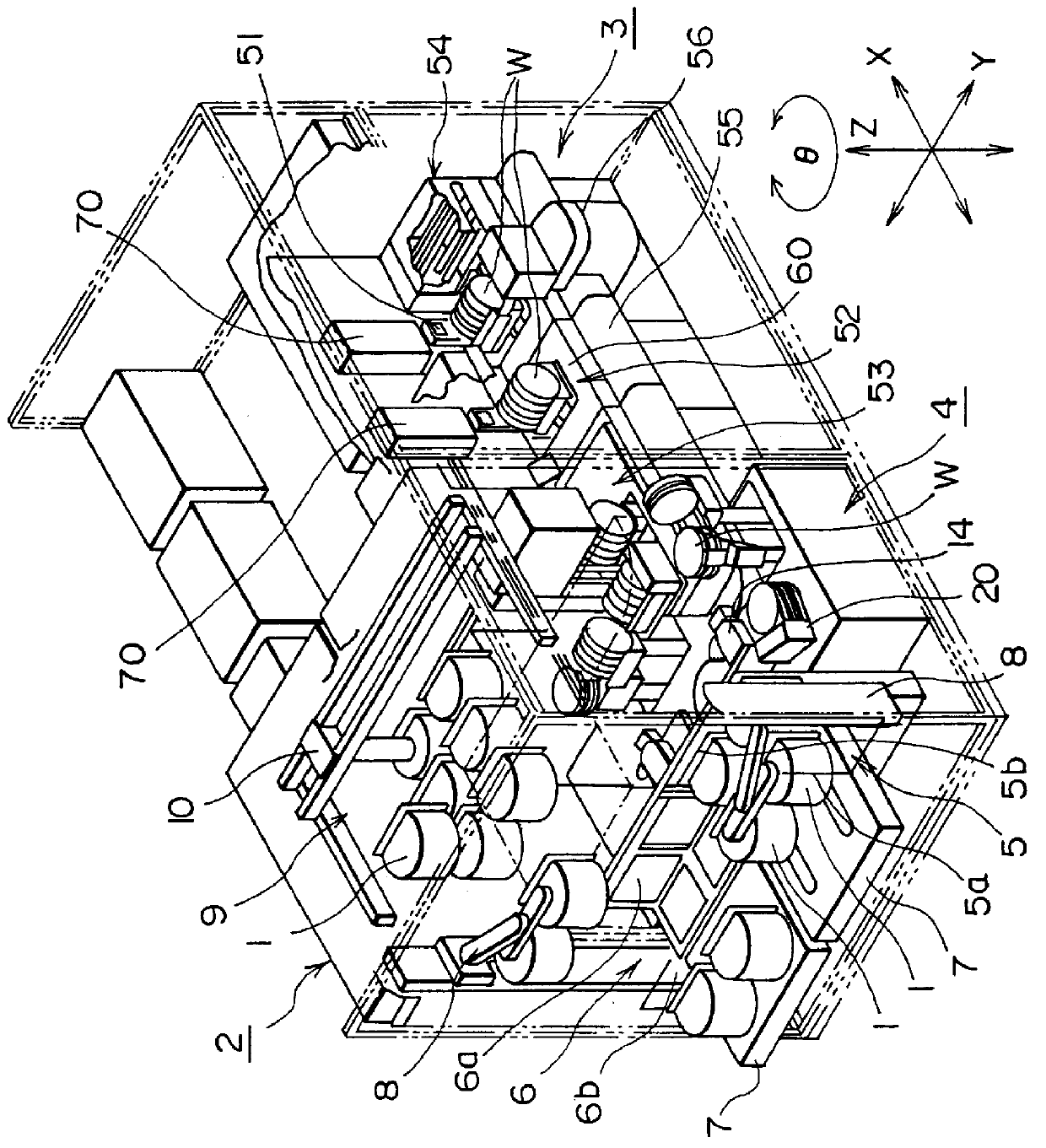

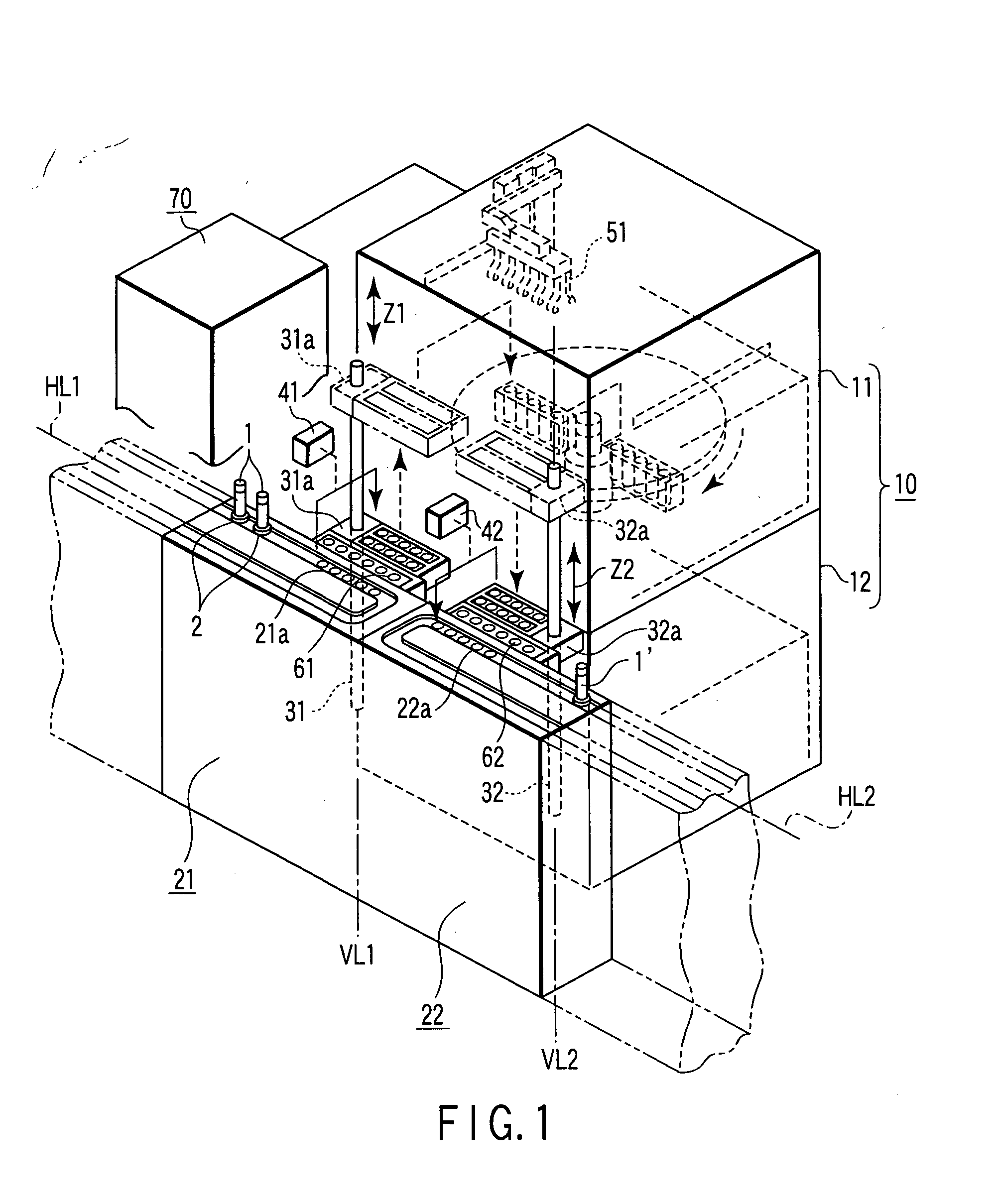

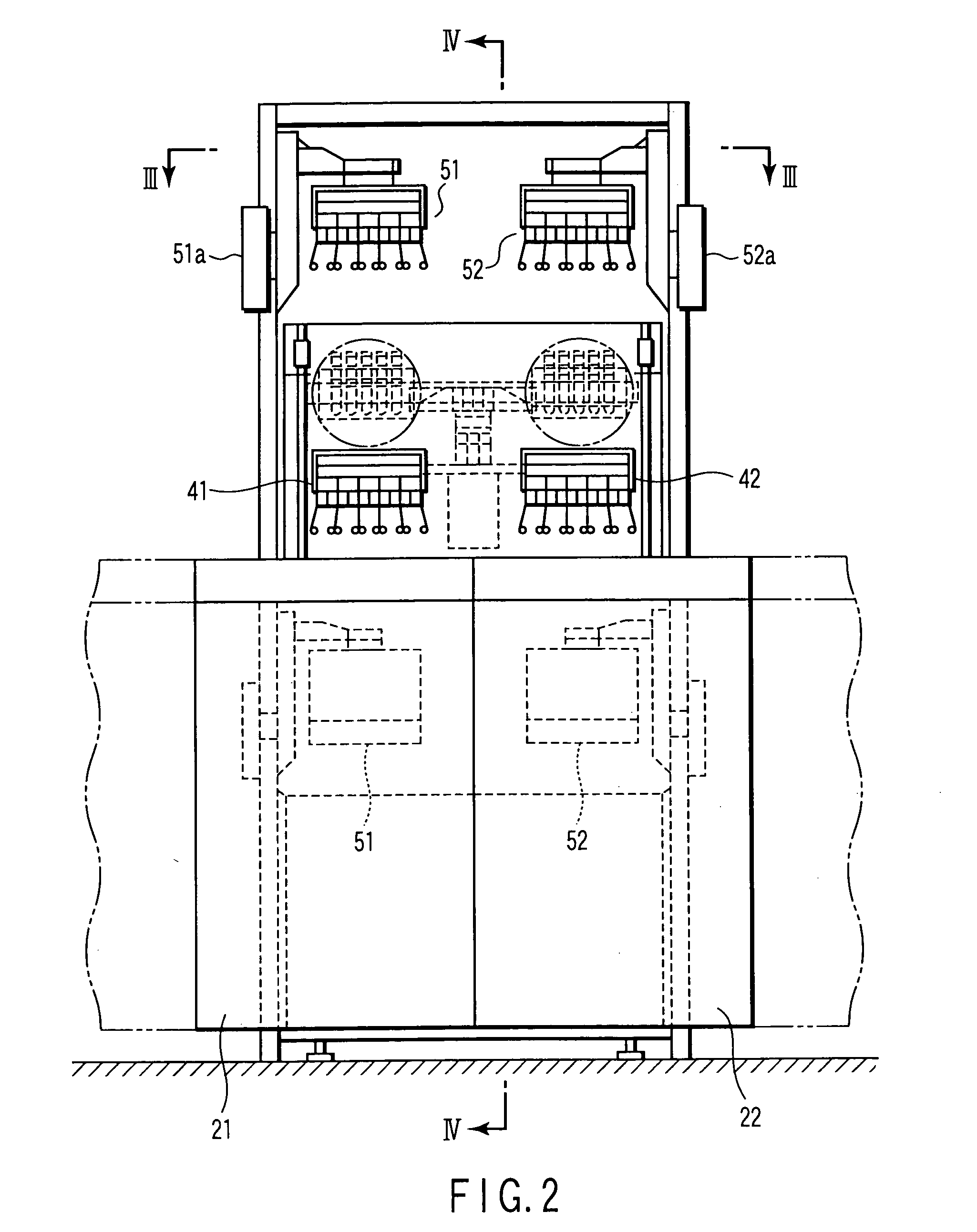

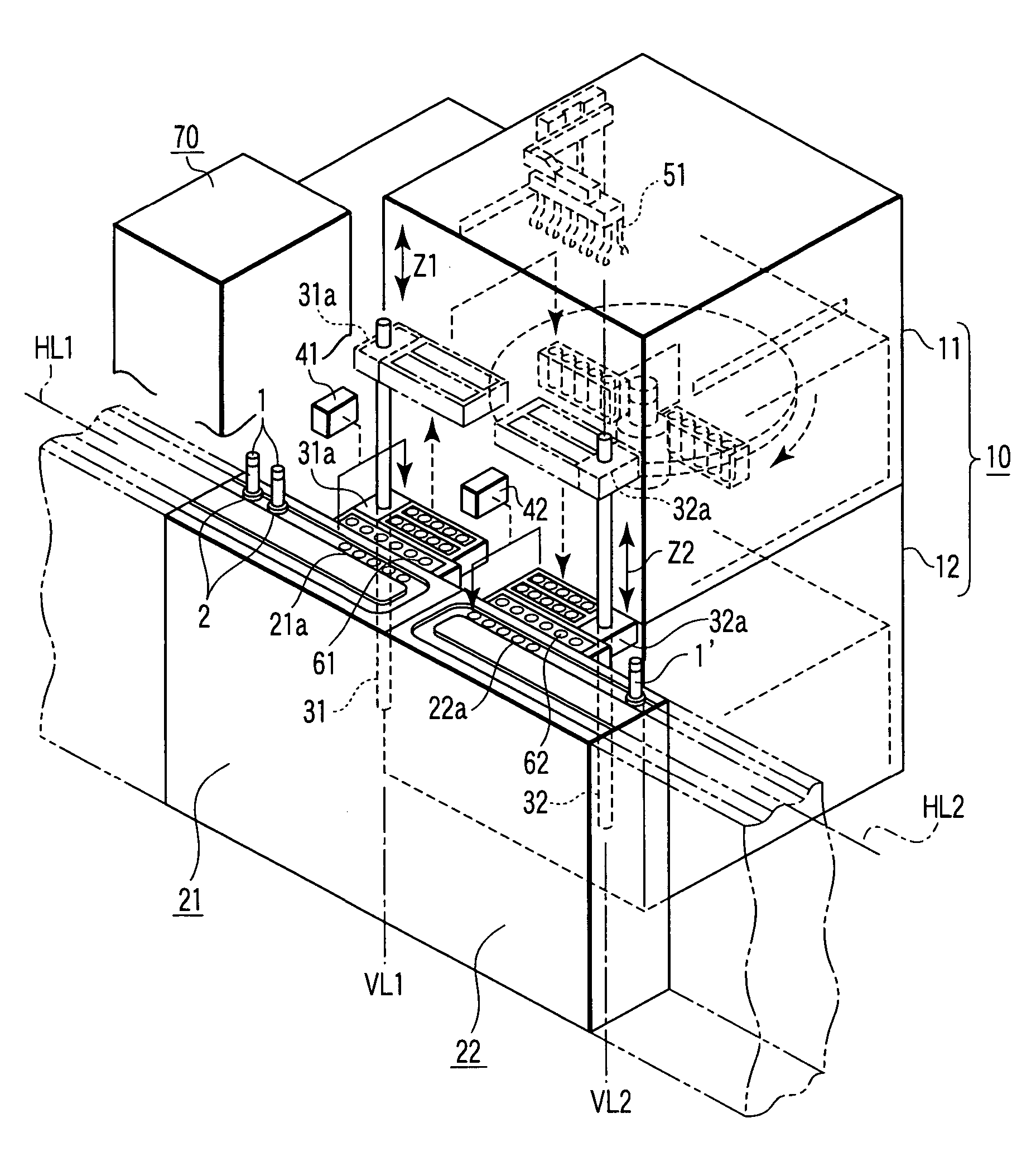

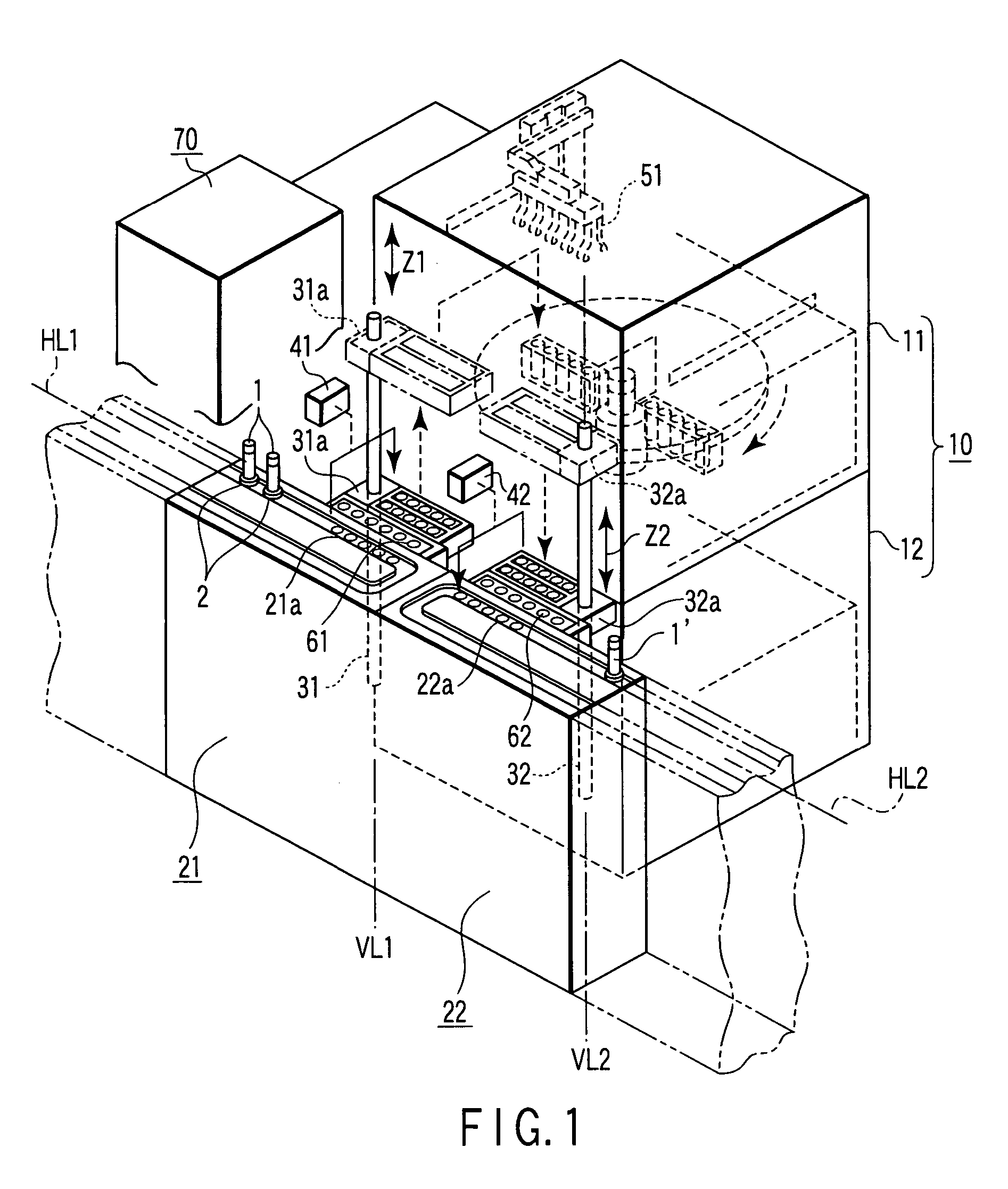

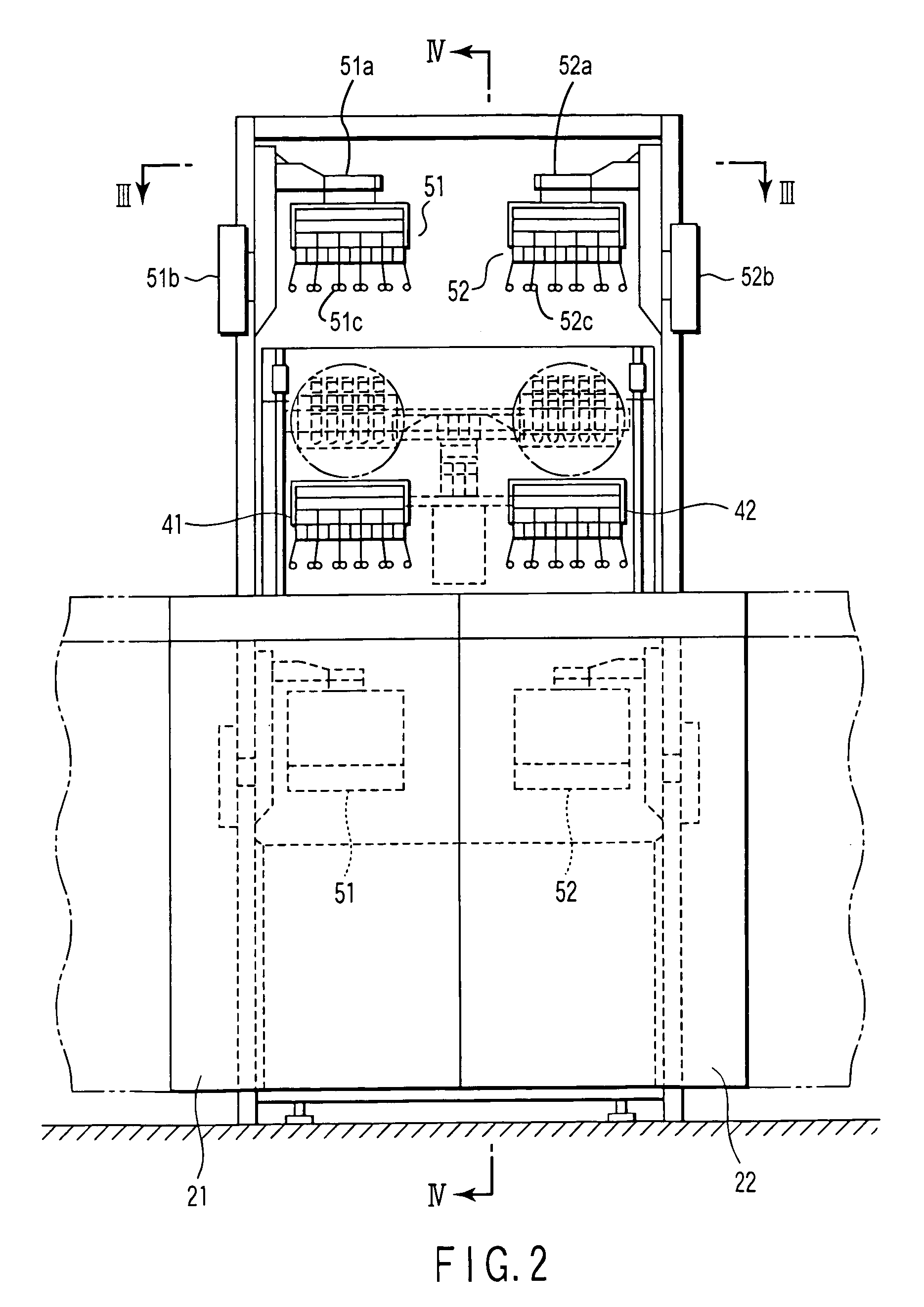

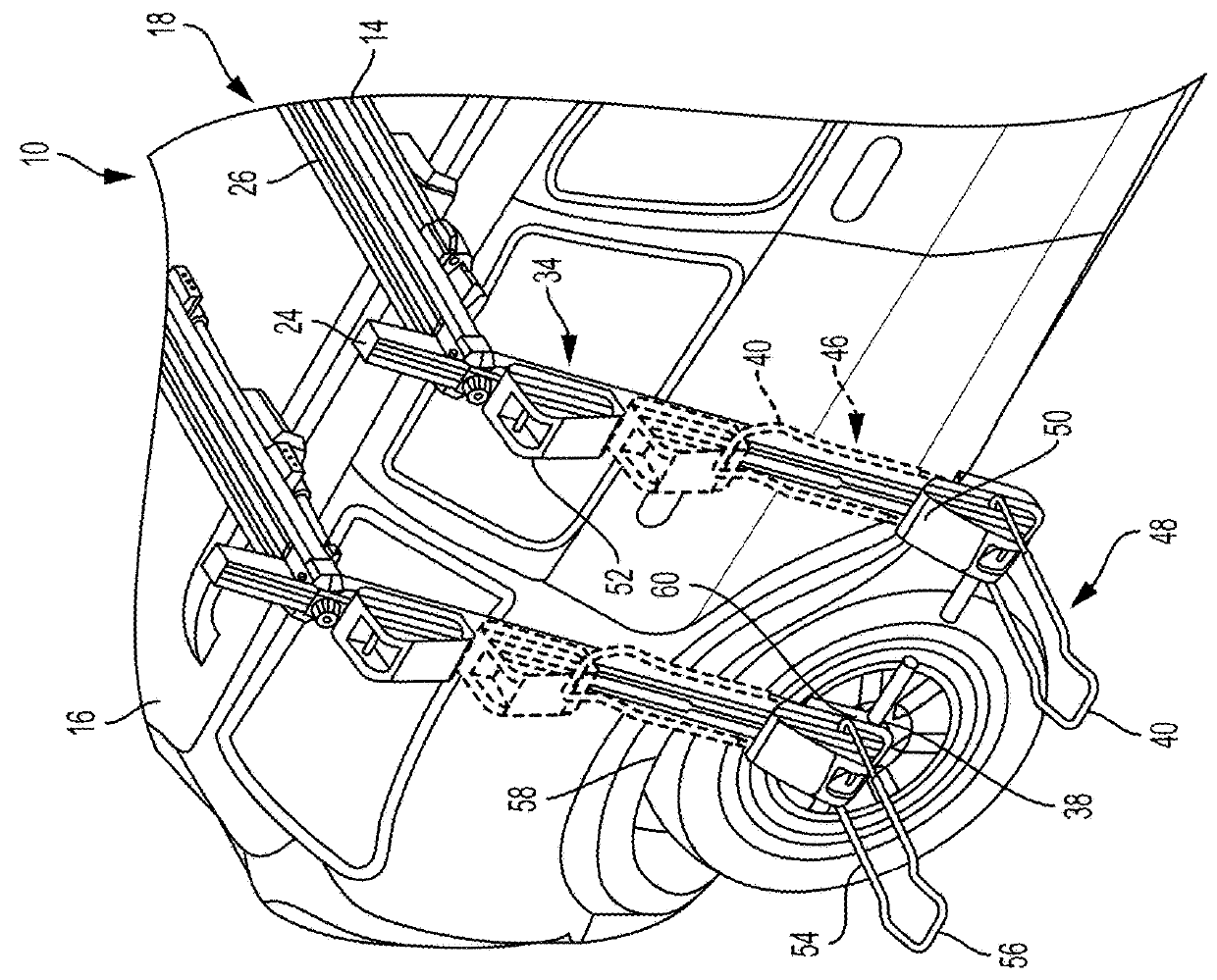

Substrate transporting and processing system

InactiveUS6009890AImprove reliability and operation efficiencyClean evenlySemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringLoading arm

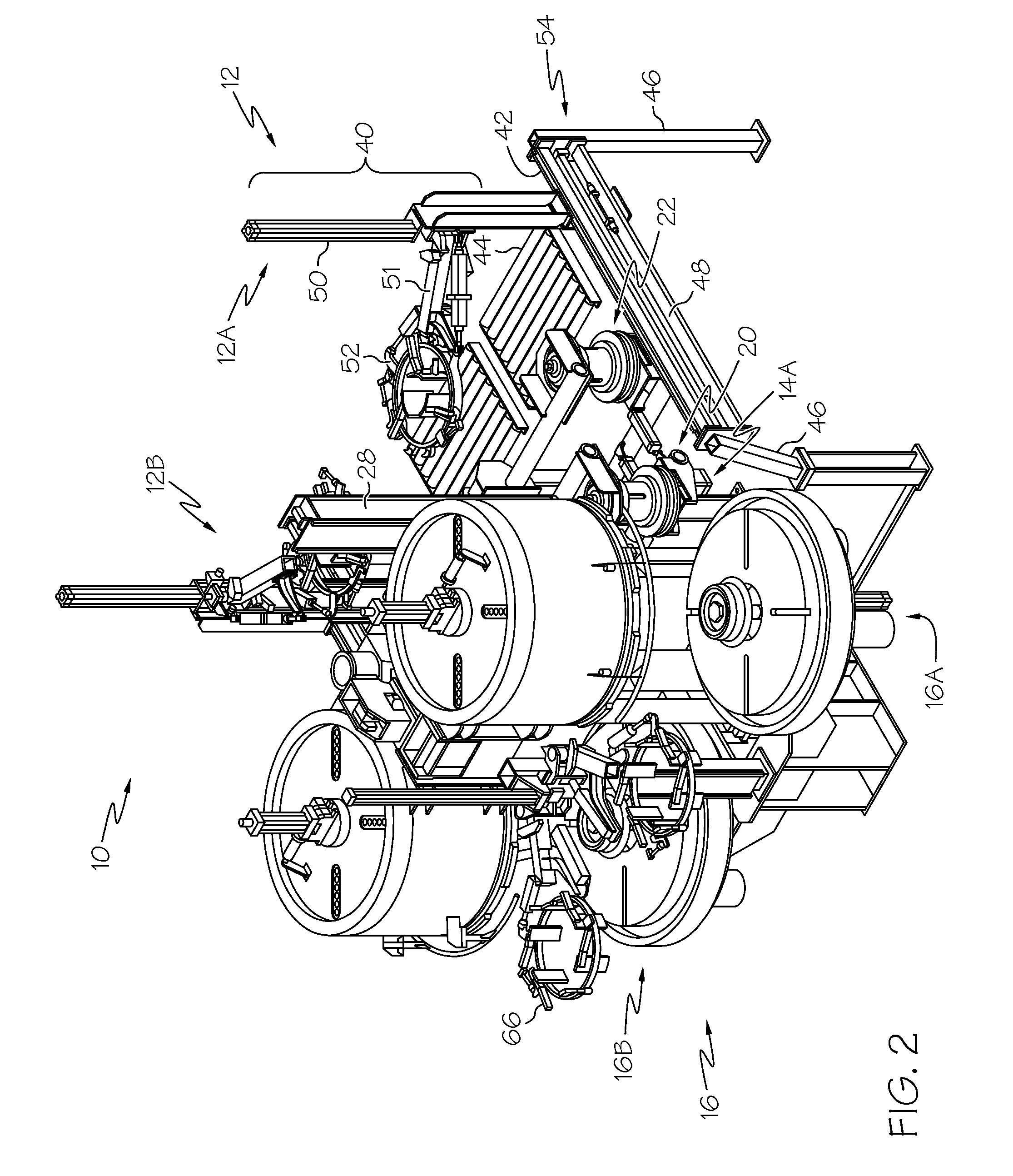

A substrate transporting and processing system generally comprises: a supply section of a carrier 1 for housing therein wafers W to be processed, in a horizontal state; a discharge section of the carrier 1; a wafer unloading arm 14 for unloading the wafers W from said carrier 1; a wafer loading arm 16 for loading the wafers W into the carrier 1; an attitude changing unit 40 for changing the attitude of the wafers W between a horizontal state and a vertical state; a processing section 3 for suitably processing the wafers W; and a wafer transport arm 56 for delivering the wafers W between the attitude changing unit 40 and the processing section 3 and for transporting the wafers W into and from the processing section. Thus, after the wafers W housed in the carrier 1 in the horizontal state are unloaded and the attitude of the wafers W is changed into the vertical state, suitable processes are carried out, and the attitude of the wafers W is changed in the horizontal state after processing, so that the wafers W can be housed in the carrier 1. Thus, it is possible to decrease the size of the whole system to improve the throughput and to improve the yield of products.

Owner:TOKYO ELECTRON LTD

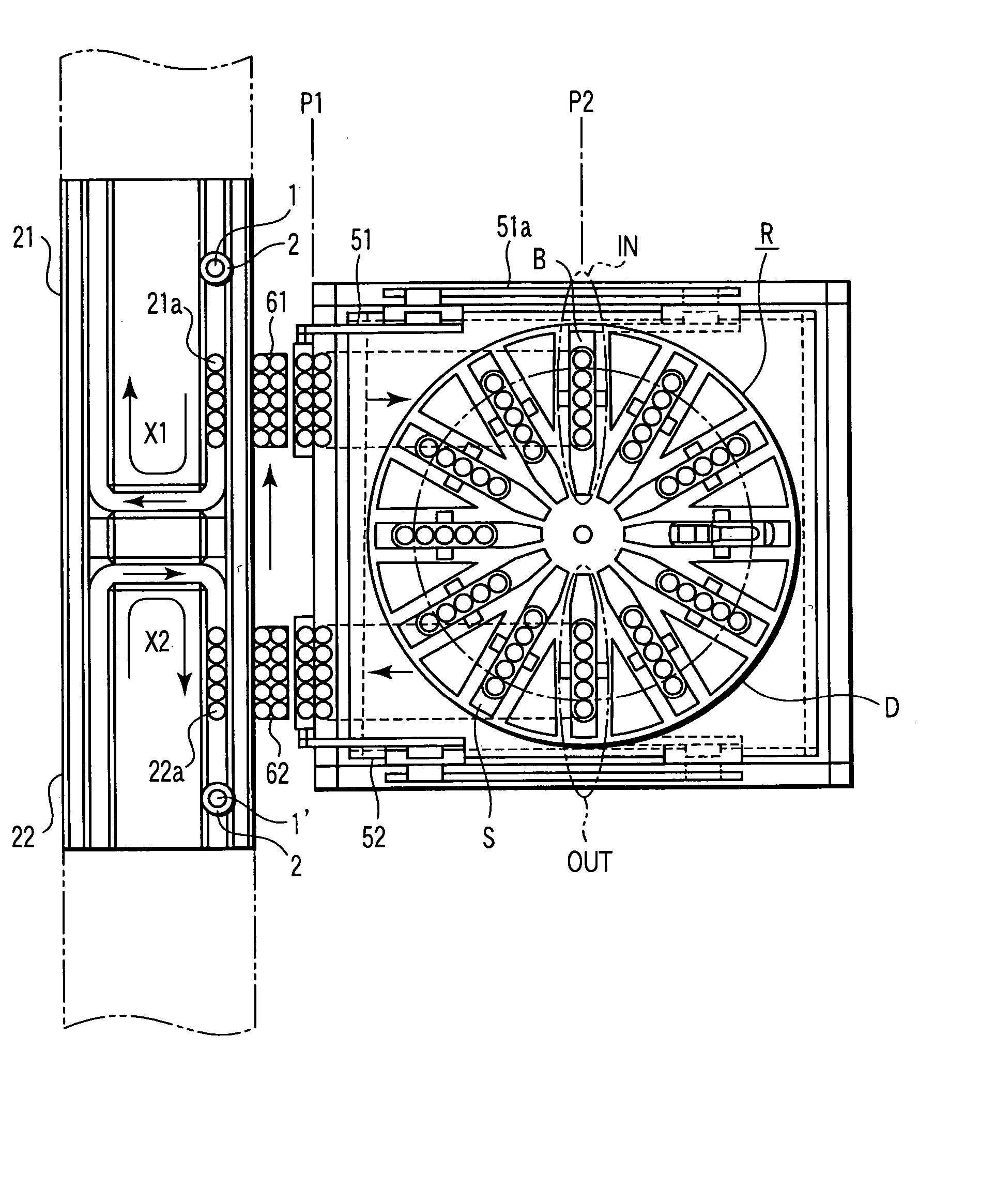

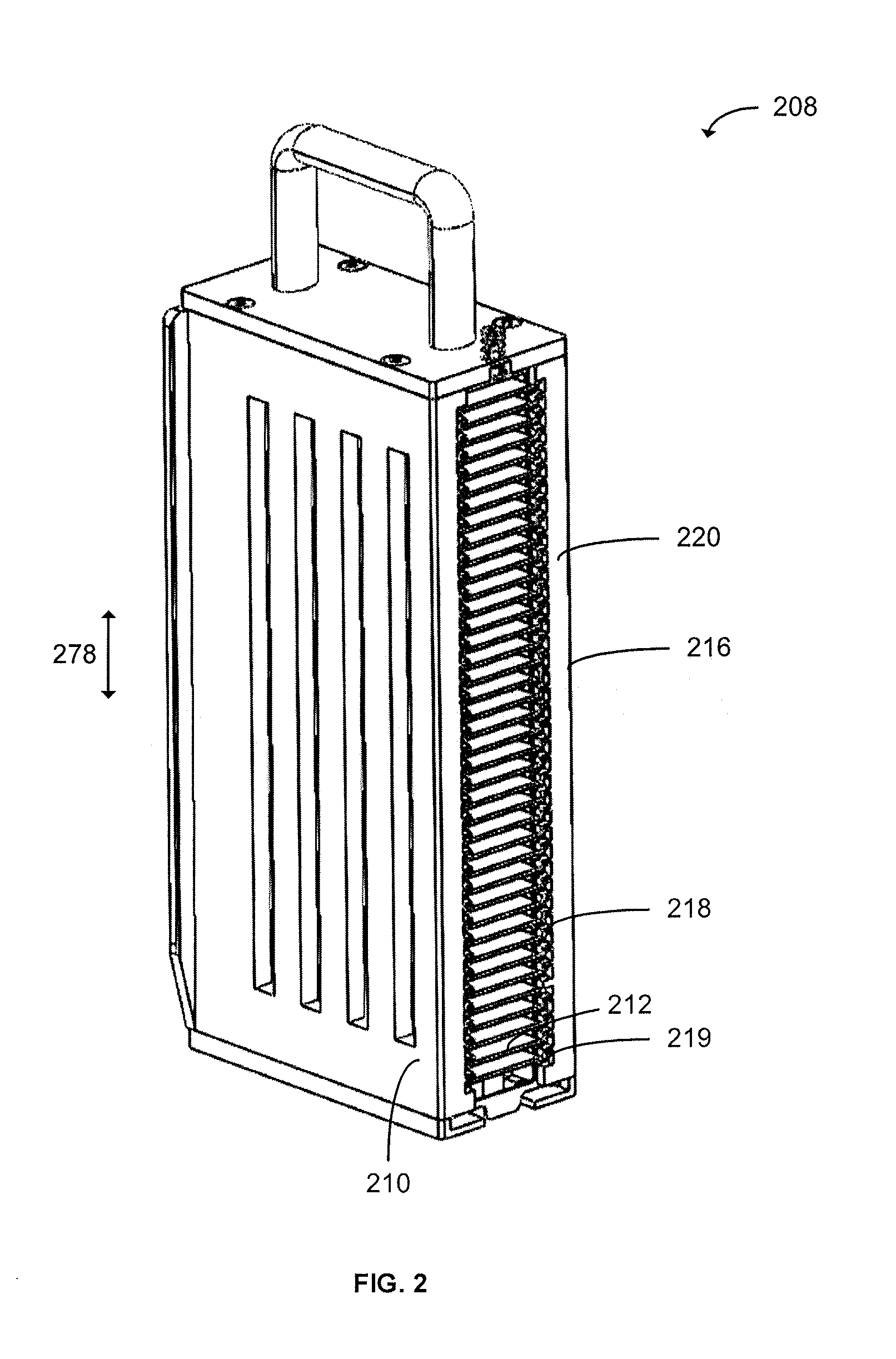

Specimen centrifuge apparatus

ActiveUS20040184959A1Specific gravity using centrifugal effectsMaterial analysis by optical meansEngineeringSpecimen containers

A specimen centrifuge apparatus comprises a specimen container carry-in system and a specimen container carry-out system. The specimen container carry-in system has a specimen container carry-in conveyor for loading pre-processed specimen containers into specimen centrifuge units stacked one on another in a centrifuge device, a carry-in elevator, a carry-in transfer arm, and a loading arm. The specimen container carry-out system has a specimen container carry-out conveyor for unloading the processed specimen containers from the specimen centrifuges, a carry-out elevator, a carry-out transfer arm, and an unloading arm.

Owner:IDS CO LTD

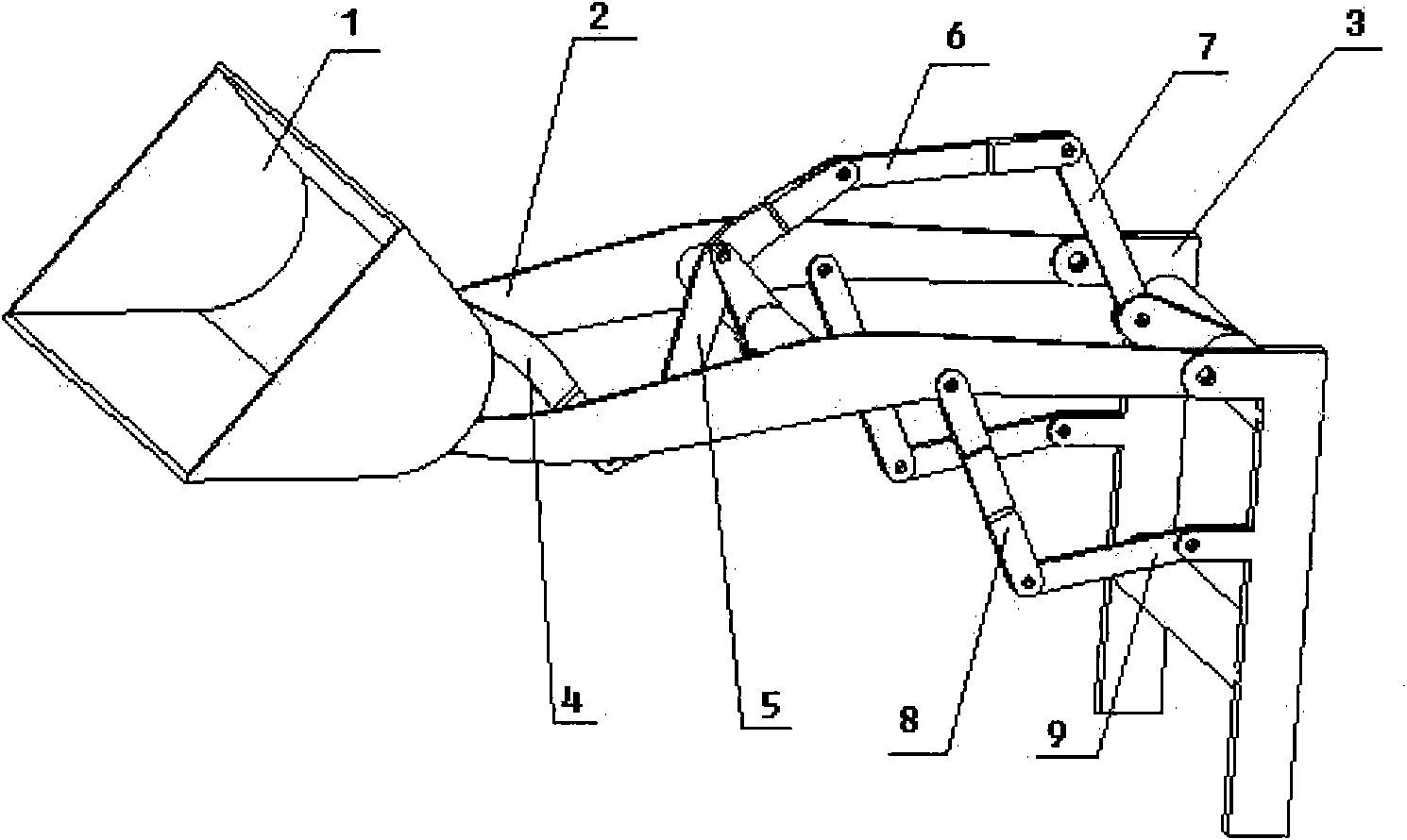

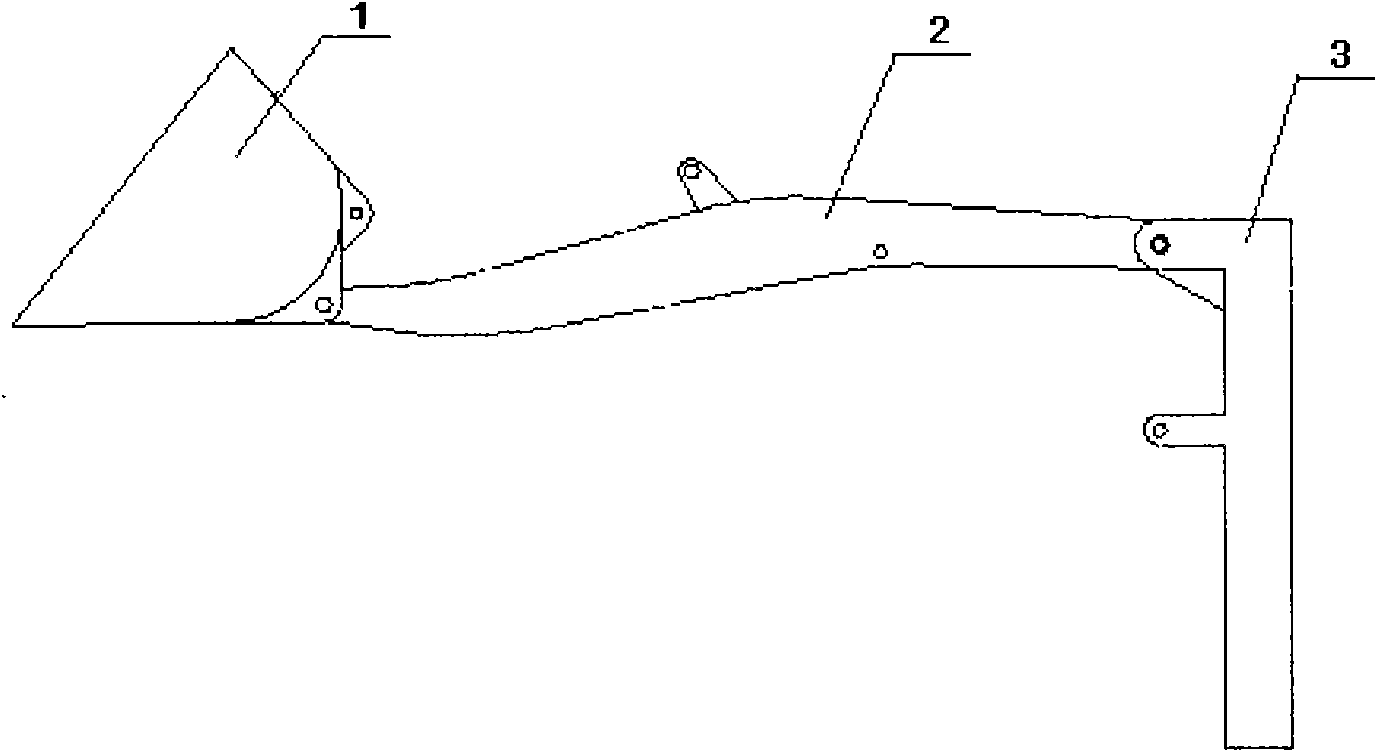

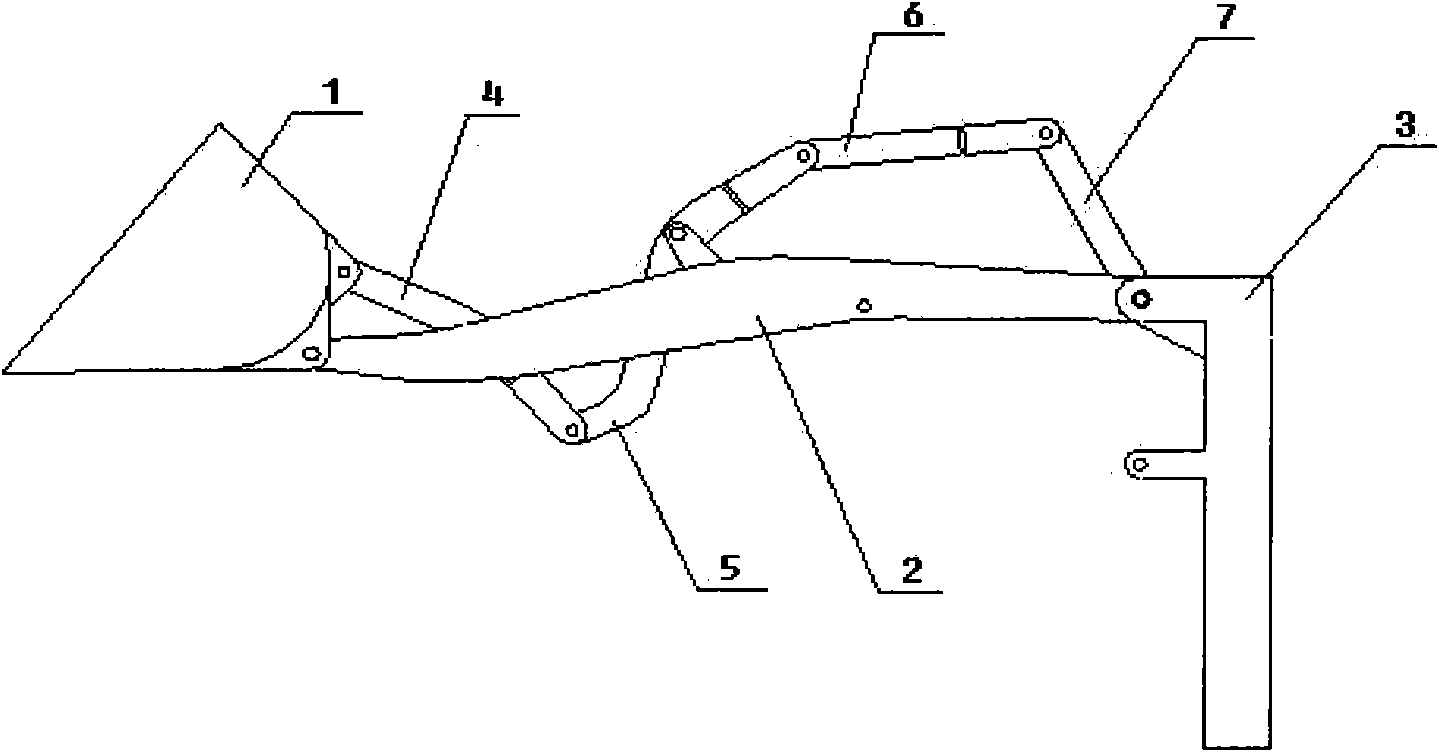

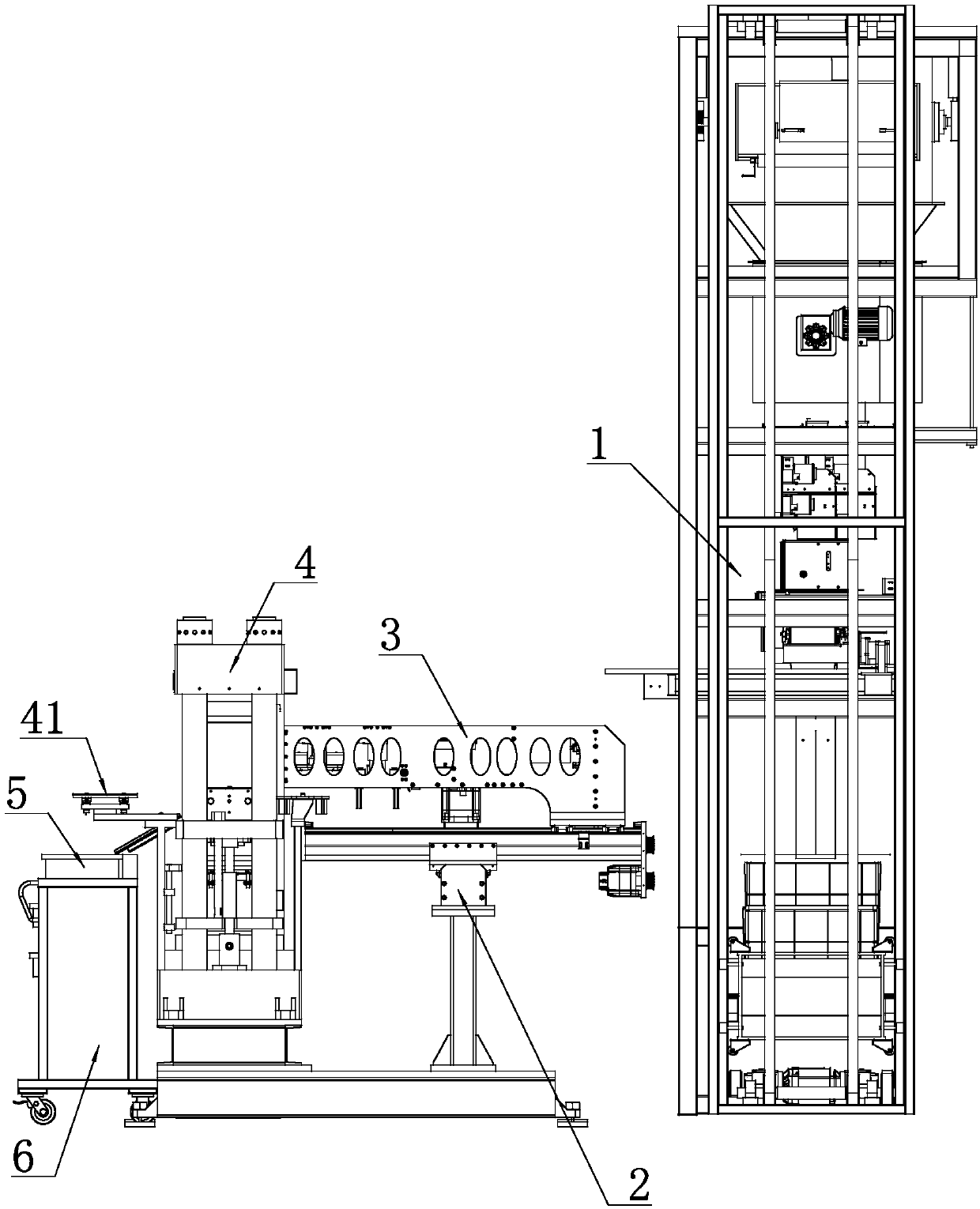

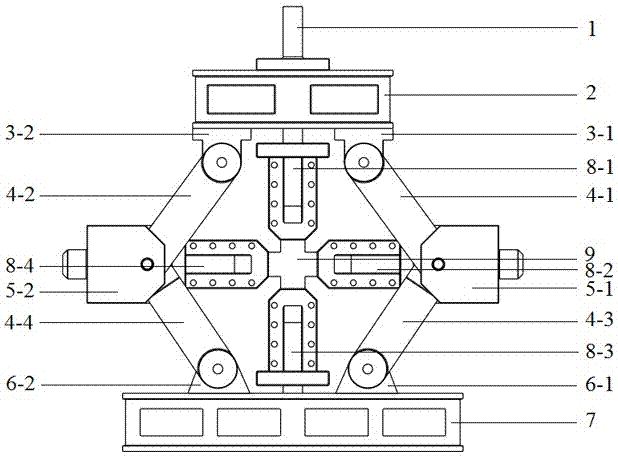

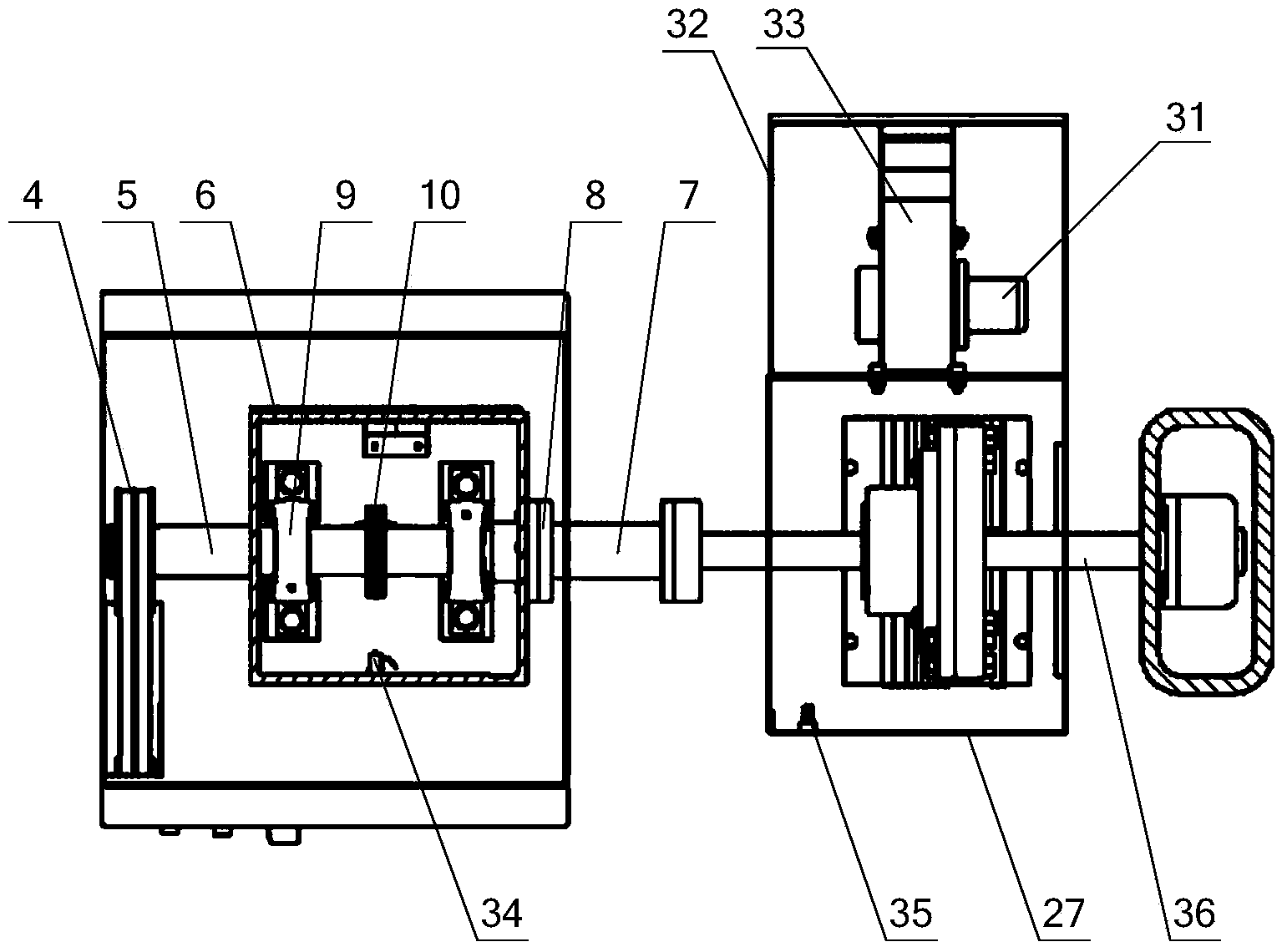

Mechanical two-degree-of-freedom controllable loading machine

InactiveCN101892680AArbitrary outputImplement the loading actionMechanical machines/dredgersEngineeringDegrees of freedom

The invention discloses a mechanical two-degree-of-freedom controllable loading machine. A bucket turning crank-link mechanism consists of two four-bar mechanisms which are connected in series with each other; a loading arm driving mechanism is a crank-rocker mechanism; the three cranks are driven by three controllable motors respectively; any track output of an output end is realized in a working space by programming; and turning of a bucket is matched with lifting of the arm of the loading machine, and actions such as attitude keeping, adjusting and the like are realized by programming a control motor. The mechanical two-degree-of-freedom controllable loading machine can overcome the defects of simple action and difficult control of the traditional mechanical loading machine, and also can overcome the defects of high requirement on a hydraulic element, easy oil leakage, low reliability and the like of the hydraulic loading machine.

Owner:GUANGXI UNIV

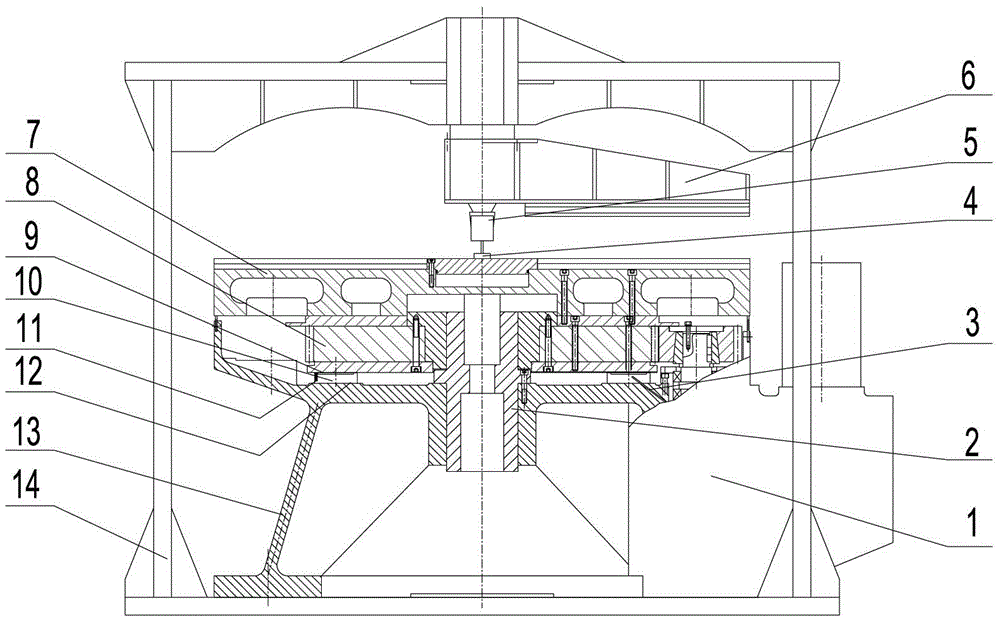

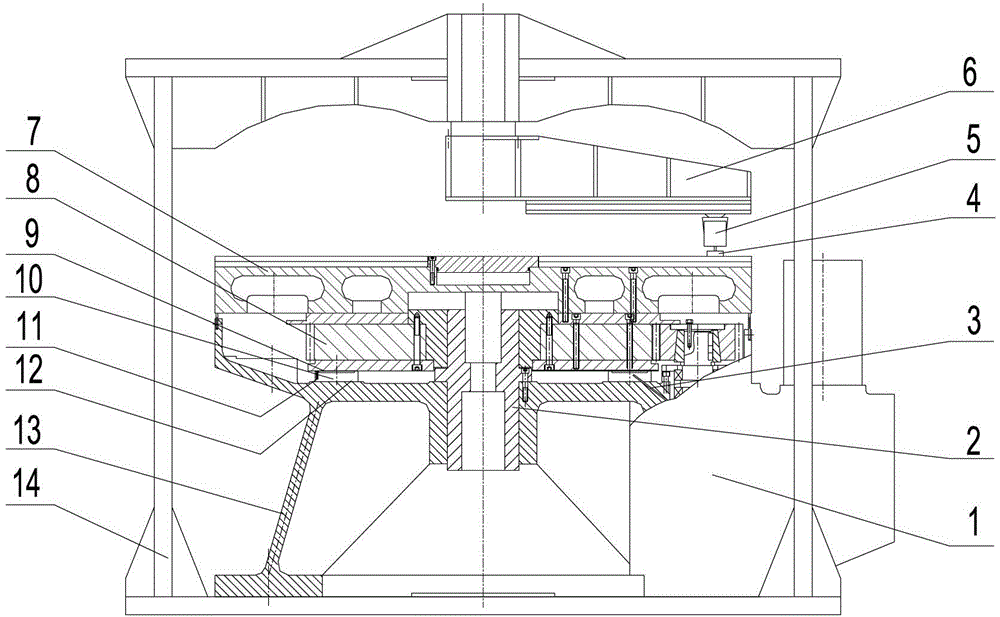

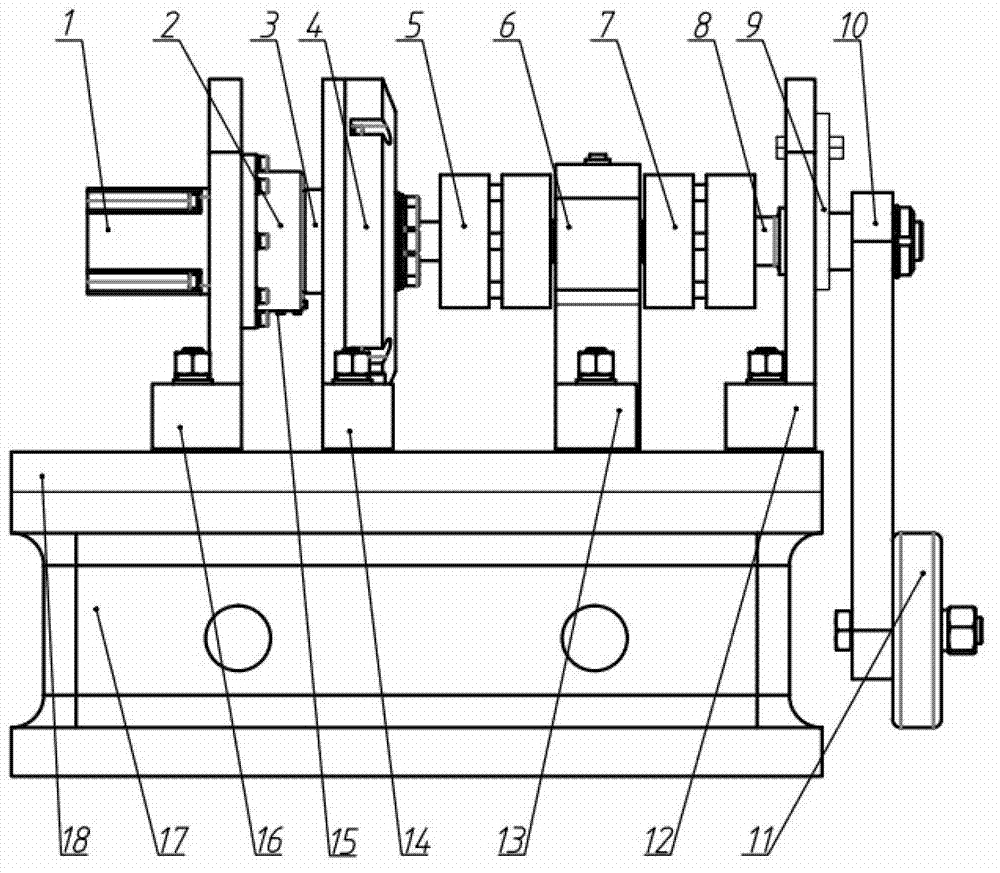

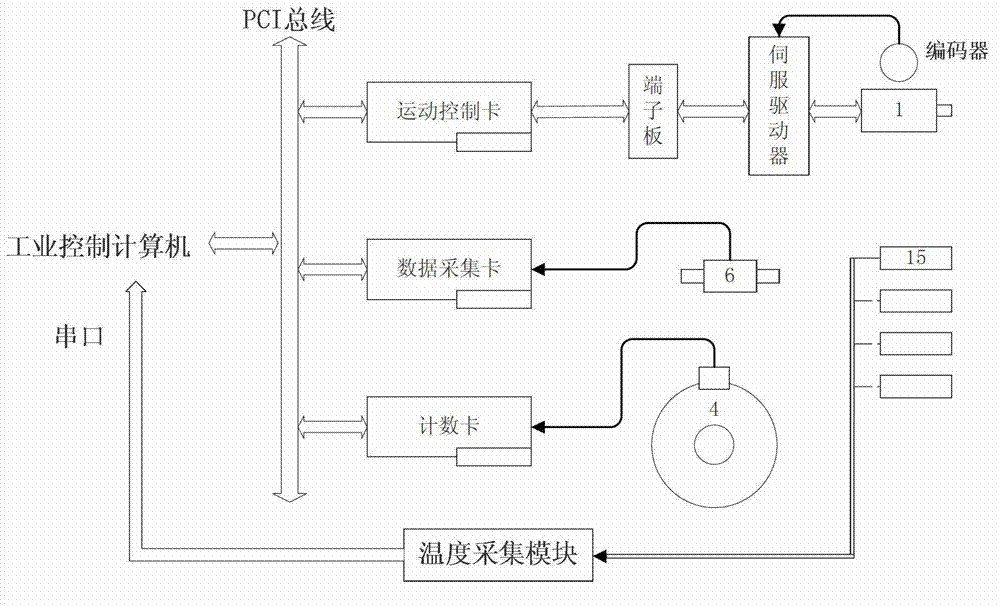

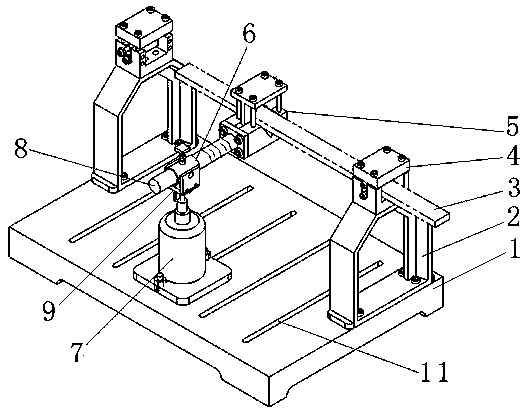

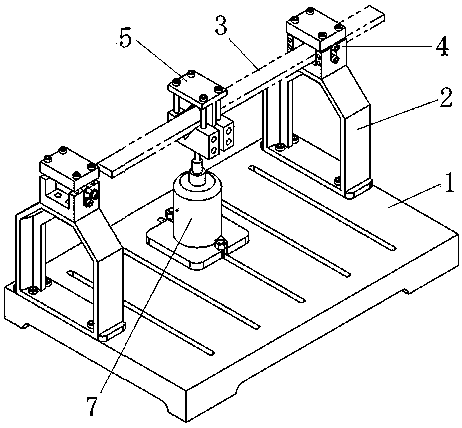

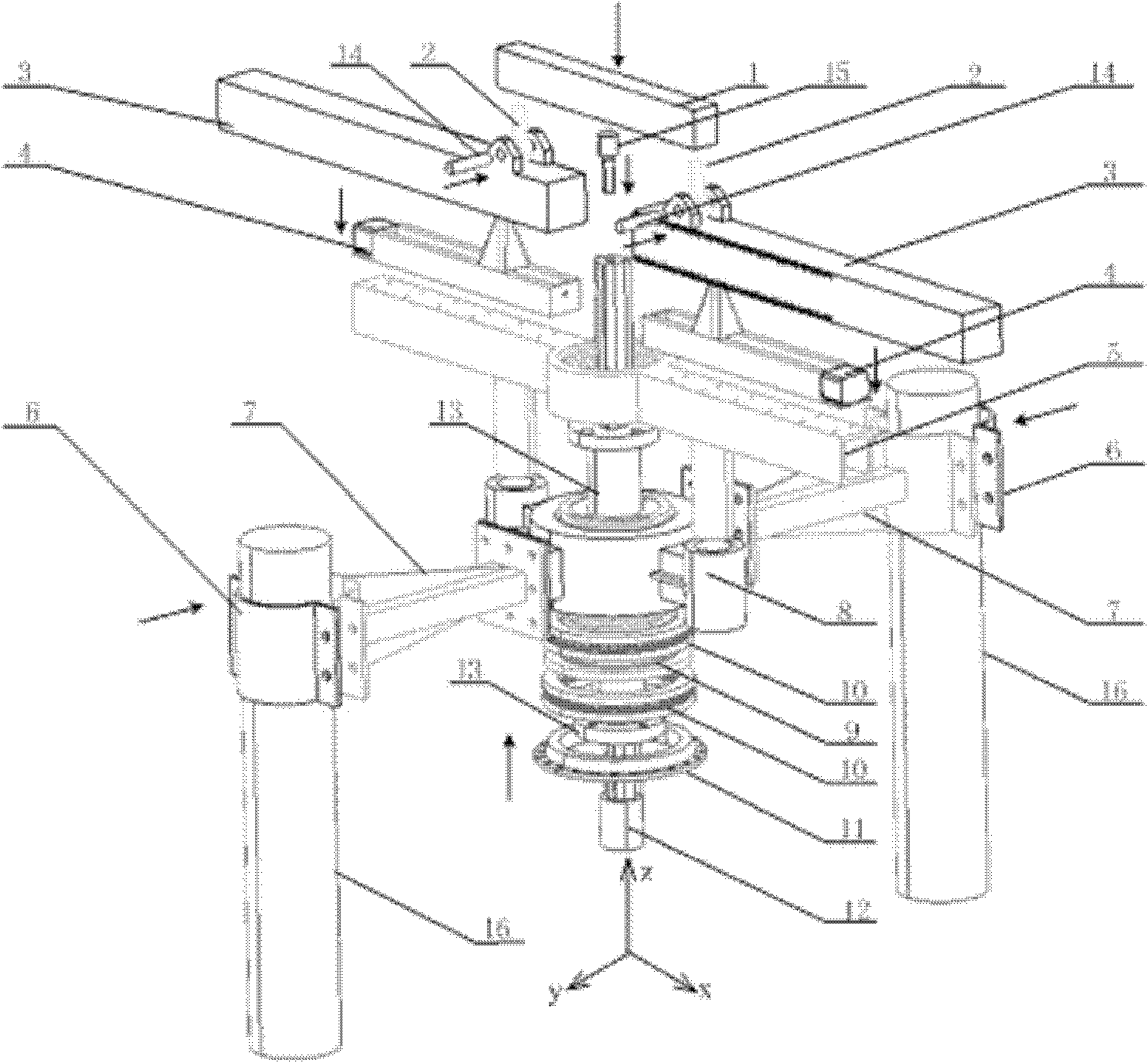

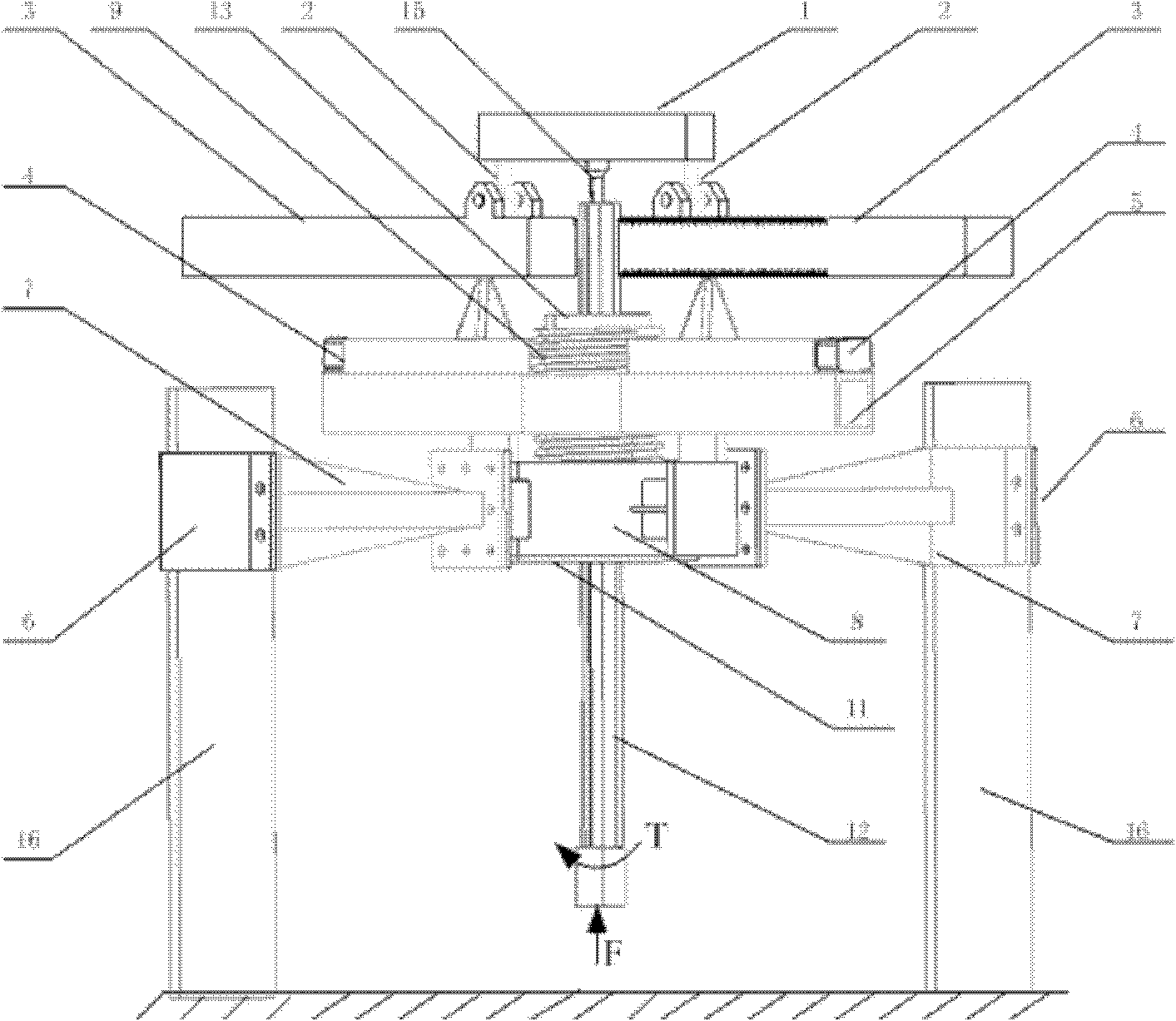

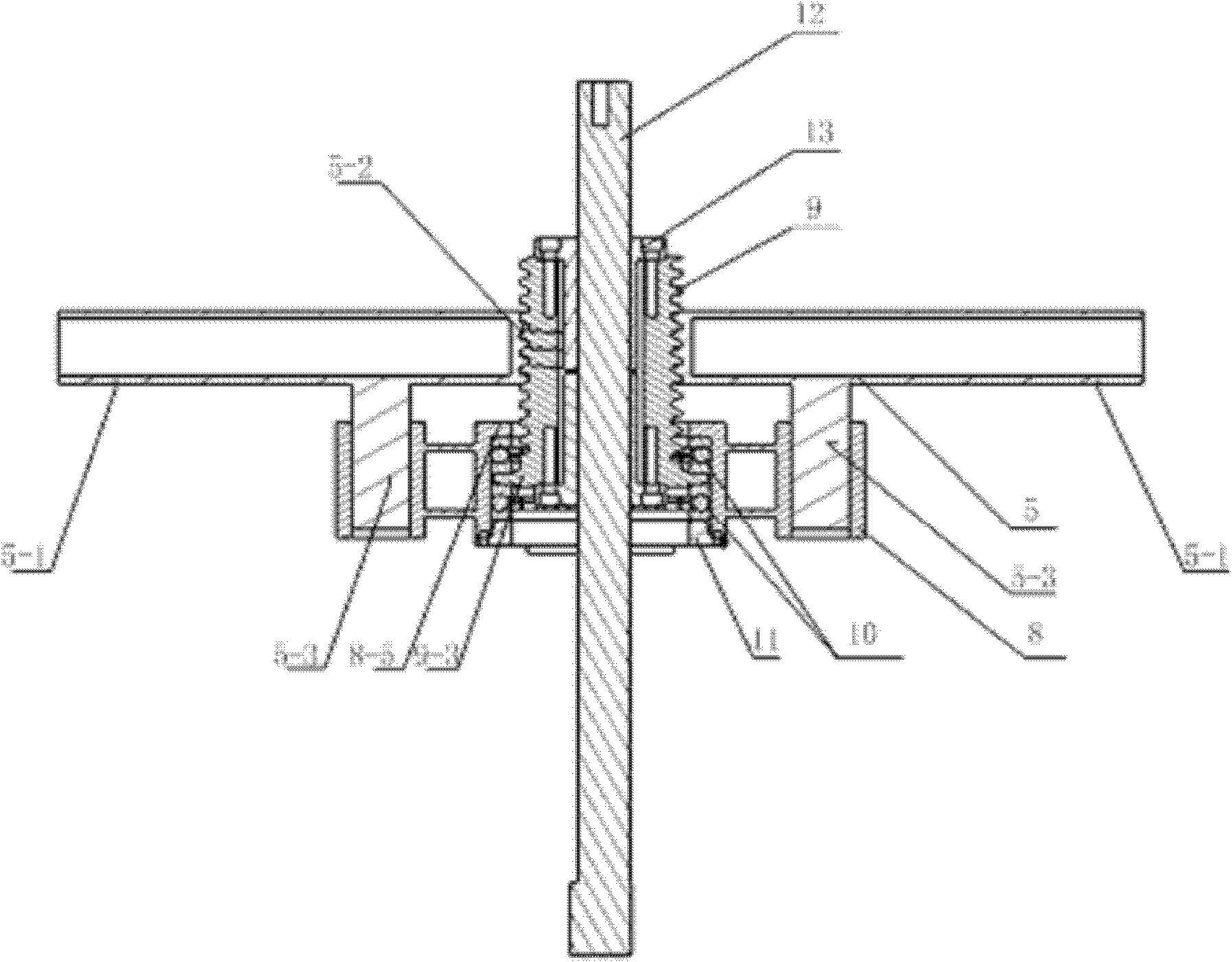

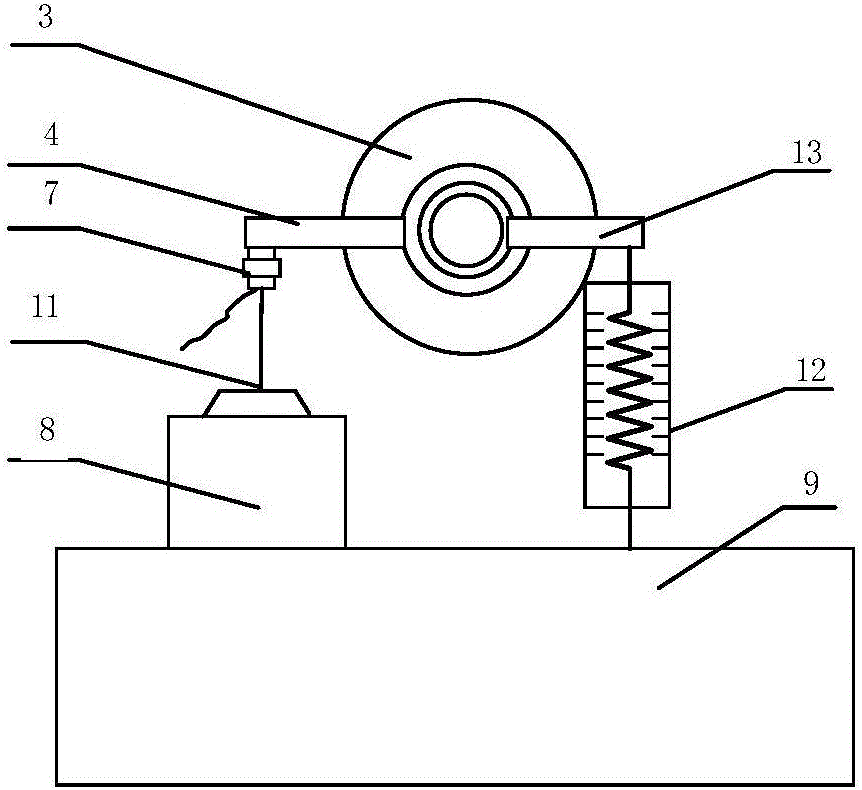

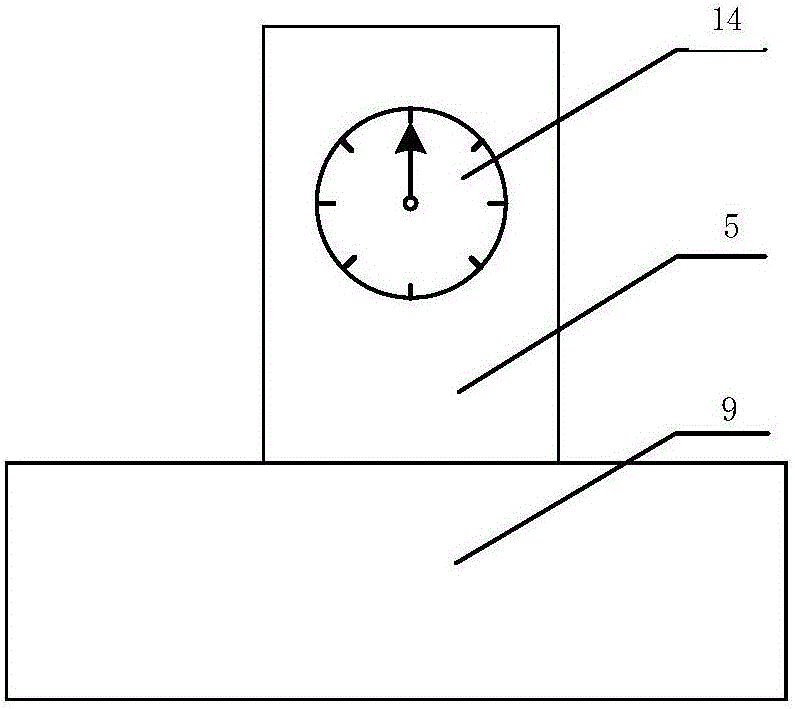

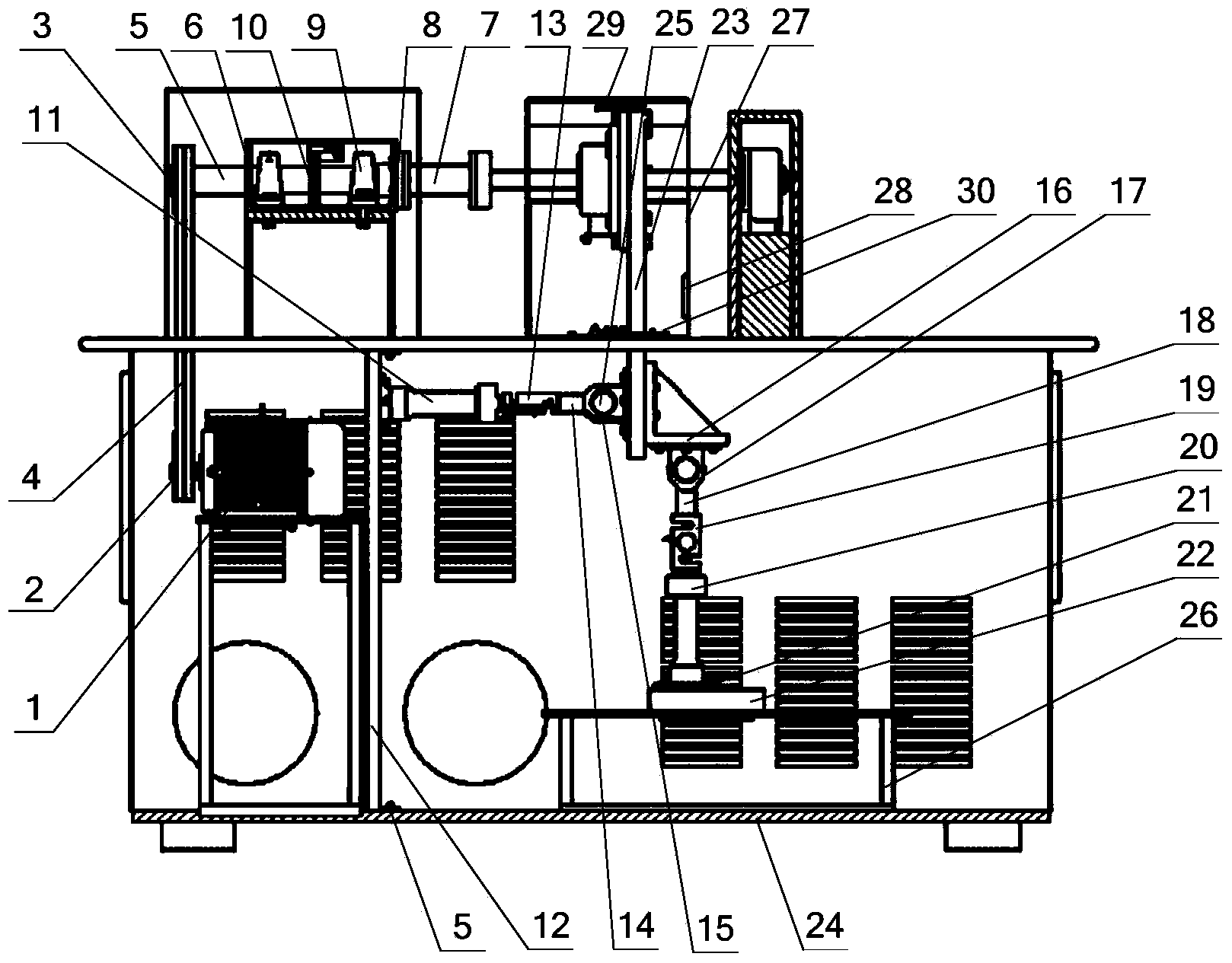

Quantitive type experimental device for dynamic and static performances of static-pressure rotary table

ActiveCN102980755AStructural parameter optimizationImprove machining accuracyMachine part testingElectricityEddy current

The invention provides a quantitive type experimental device for dynamic and static performances of a static-pressure rotary table, and belongs to the field of machinery design and manufacture. According to the experimental device, a loading device (5) and a loading arm (6) are used for changing magnitude of loads or changing oil supply pressure to control the distance between a static-pressure oil cushion (10) and a rotary table disc chuck (7), a pressure sensor (12) is used for measuring pressure in an oil cavity, an eddy current displacement sensor (11) is used for measuring the thickness of an oil film, a thermocouple temperature sensor (3) is used for measuring oil temperature, a force sensor (4) is used for obtaining magnitude of loading force, a pressure gauge a (15) on a multi-head pump at an oil inlet in the oil cavity is used for measuring pressure of the oil inlet of the oil cavity, and a pressure gauge b (16) arranged between an oil pump and the multi-head pump is used for measuring the oil supply pressure of the static-pressure rotary table. By means of the experimental device, a test of the dynamic and static performances of the static-pressure rotary table is carried out under the condition that temperature is between minus 10 DEG C and 60 DEG C and pressure is not more than 100 MPa, and the experimental device provides guarantee for solving problems in engineering, optimizing structural parameters of the rotary table, and improving machining precision of the rotary table.

Owner:BEIJING UNIV OF TECH

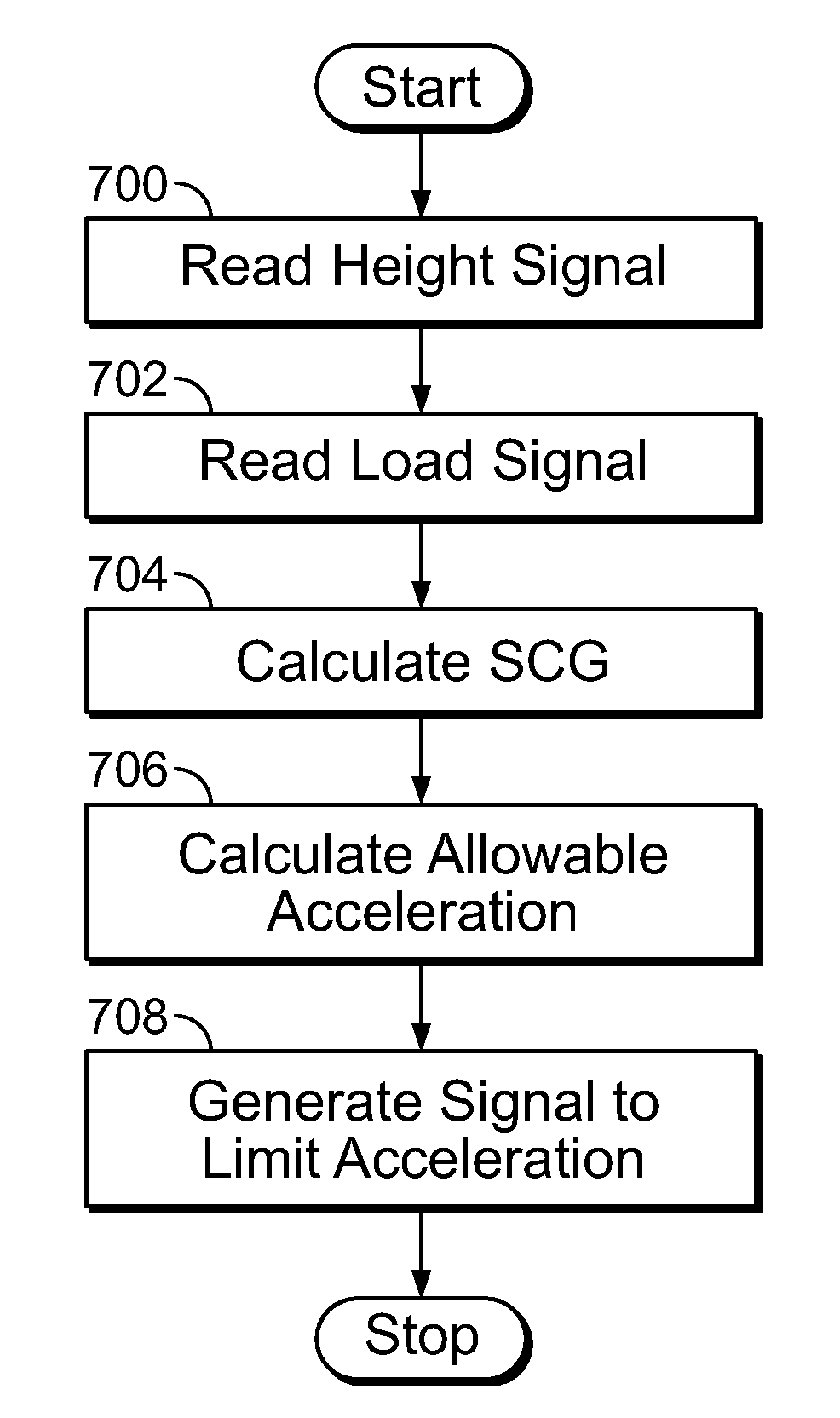

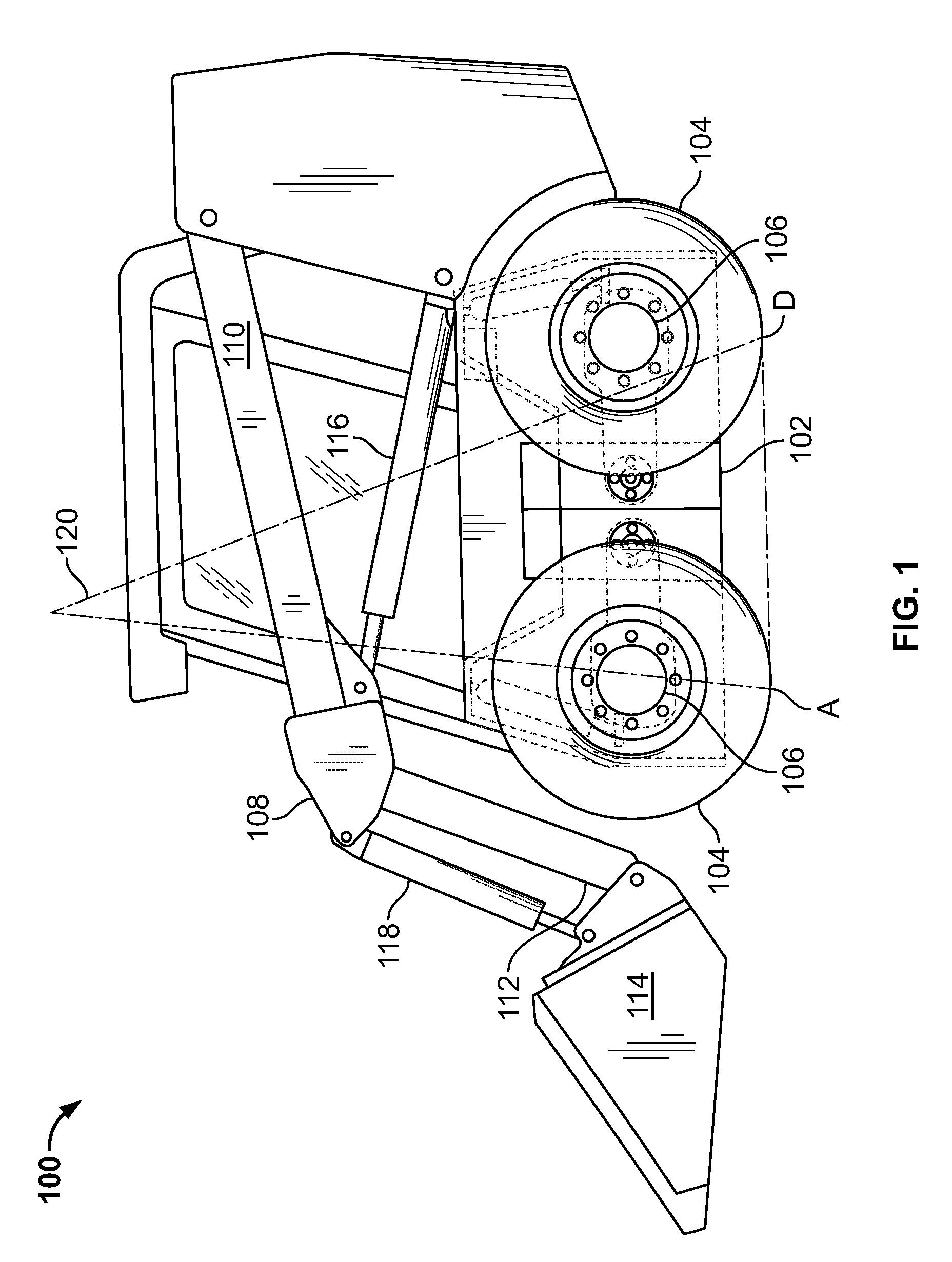

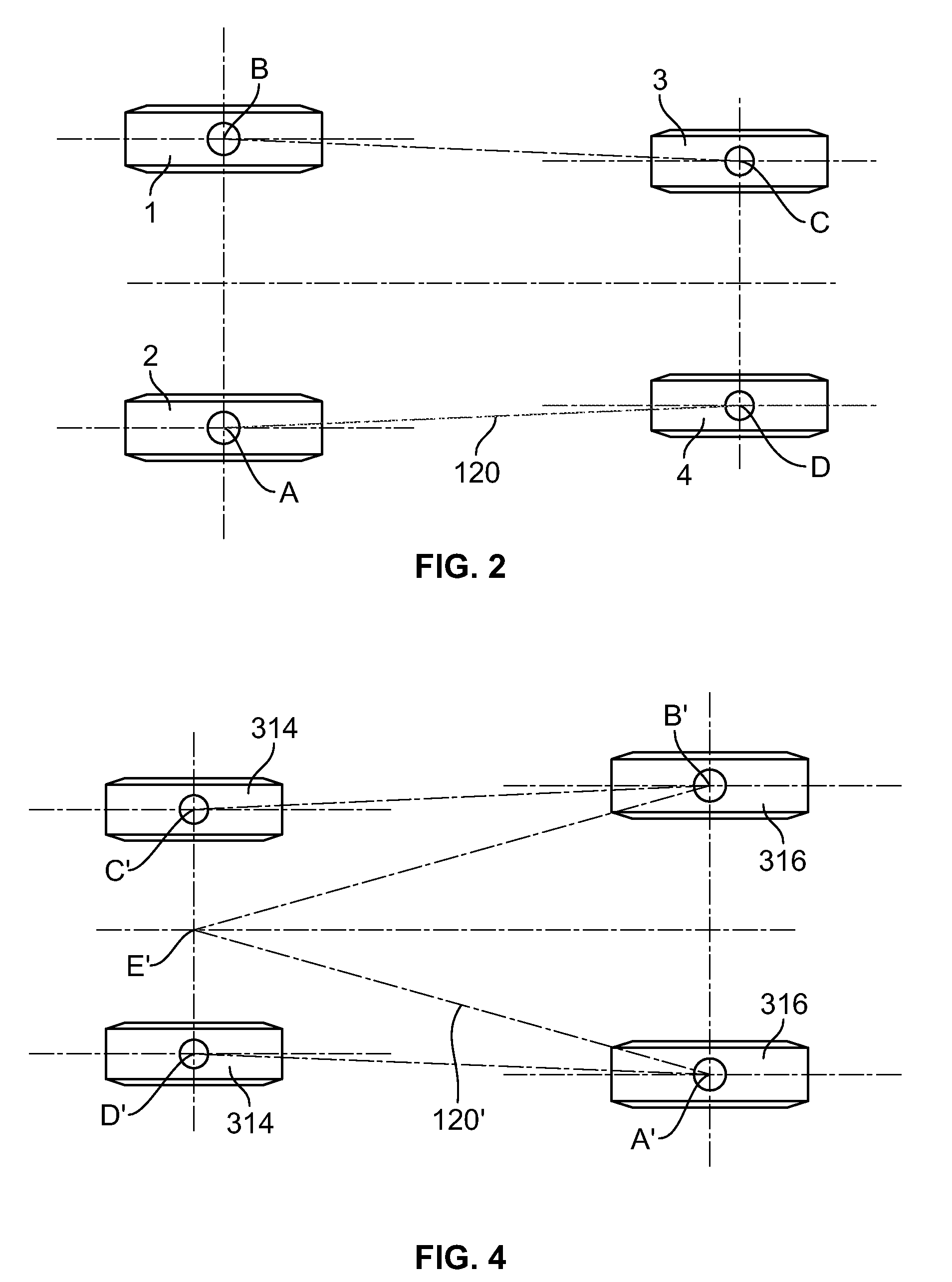

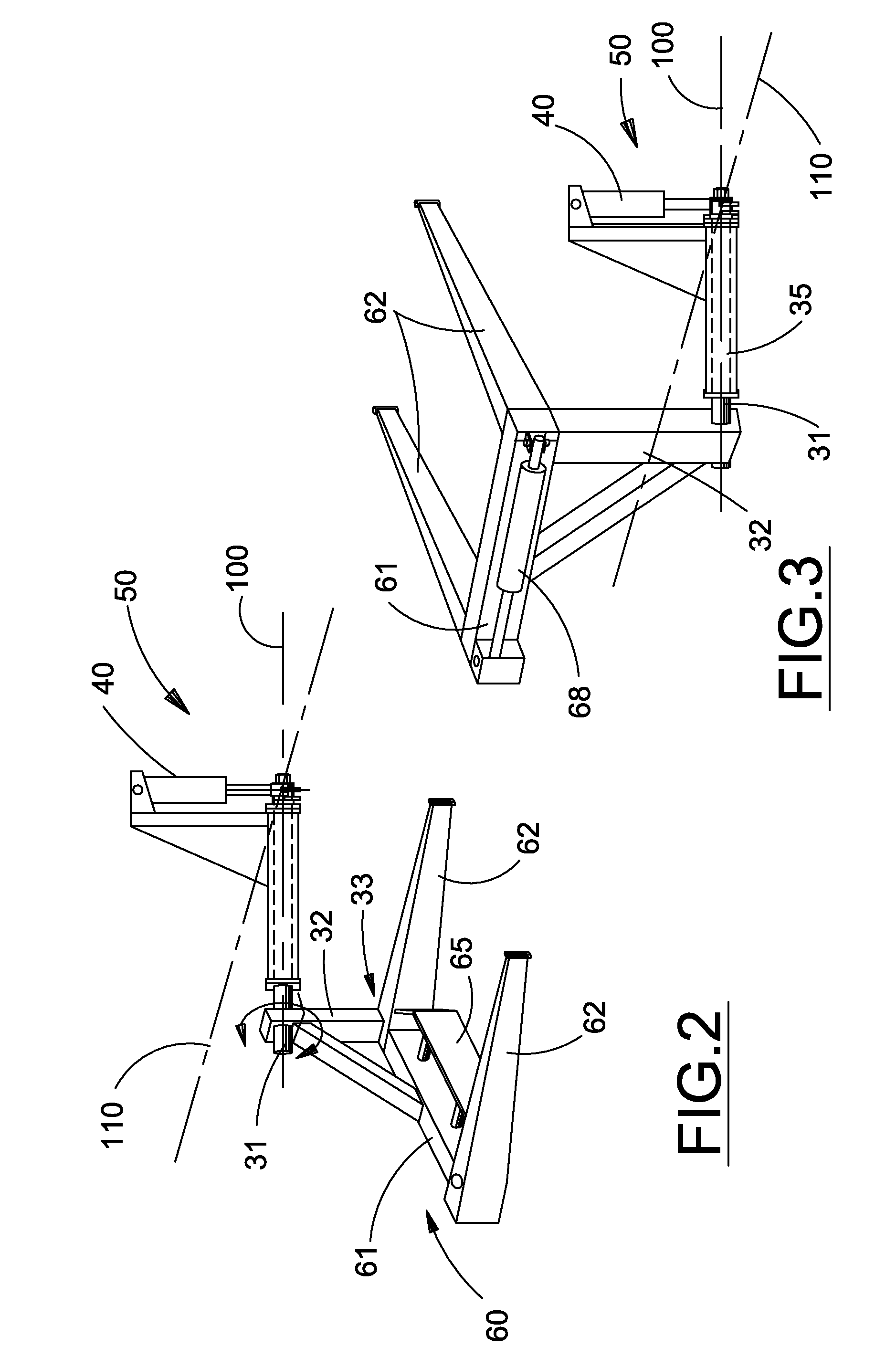

Acceleration control for vehicles having a loader arm

InactiveUS20100204891A1Safety devices for lifting equipmentsAnalogue computers for trafficControl systemLoading arm

A control system for a vehicle having a loader arm, such as a skid steer loader, telescopic handler, wheel loader, backhoe loader or forklift, reads a load height sensor, a load weight sensor; dynamically calculates the static center of gravity of the combined vehicle and load; calculates the acceleration necessary to cause the dynamic center of gravity of the combined vehicle and load to extend exterior of the vehicle's stability polygon; and limits the acceleration of the vehicle to less than the acceleration necessary to cause the dynamic center of gravity of the combined vehicle and load to extend exterior of the vehicle's stability polygon.

Owner:CNH IND AMERICA LLC

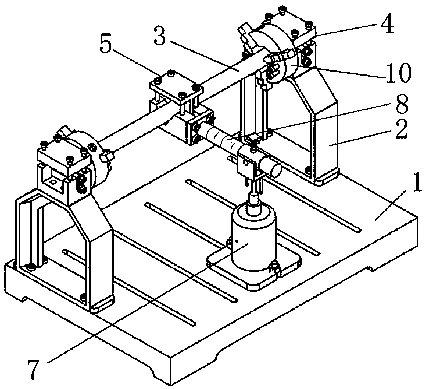

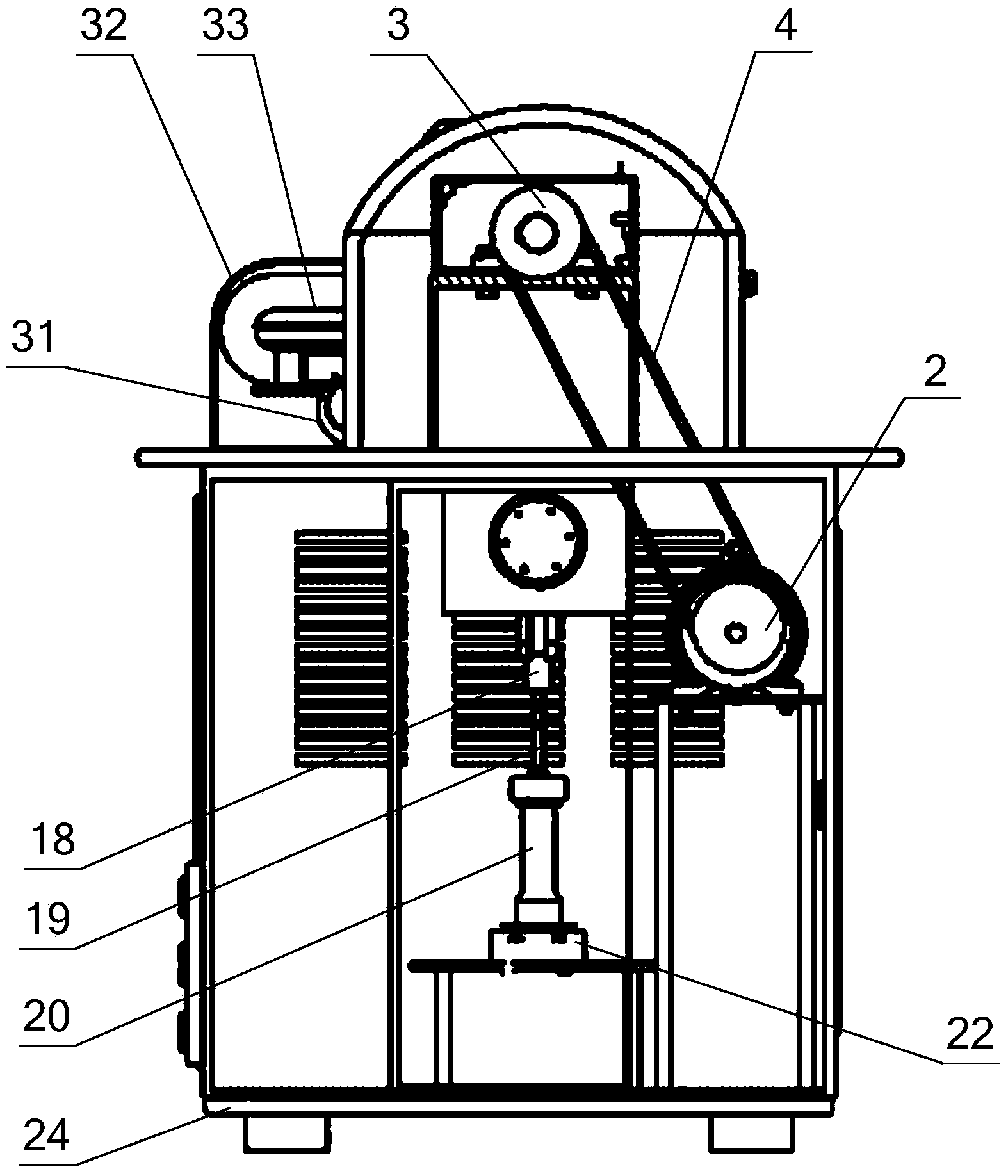

System for testing comprehensive performance of reducer for robot joint

ActiveCN102901625ASimple structureImprove test accuracyMachine gearing/transmission testingReduction driveElectrical control

The invention discloses a system for testing a comprehensive performance of a reducer for a robot joint. The system comprises a mechanical part and an electric control part; the mechanical part comprises a servo motor, a measured reducer, an angle measuring device, a torque sensor and a loading arm coaxially connected in sequence; all the parts are fixed on a horizontal guide rail by a bracket; the measured reducer is provided with a temperature sensor; the electric control part comprises an industrial control computer, a motion control card, a data collecting card, a counting card and a temperature collecting module; the motion control card is connected with the servo motor by a servo driver; the data collecting card is connected with a signal output end of the torque sensor and a torque monitoring end of the servo driver; the counting card is connected with a signal output end of the angle measuring device; and the temperature sensor is connected with a computer serial port by the temperature collecting card. According to the system for testing the comprehensive performance of the reducer for the robot joint, the comprehensive performance of the reducer for the robot joint can be tested; and the system is simple in structure, high in test precision and high in universality.

Owner:XI AN JIAOTONG UNIV

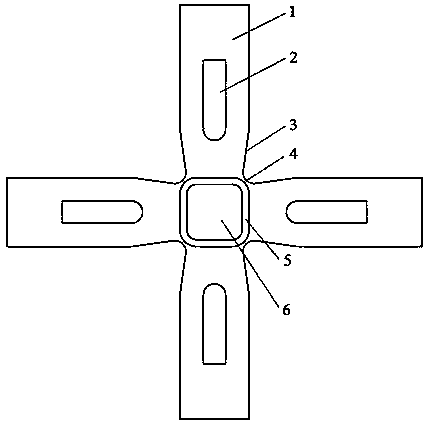

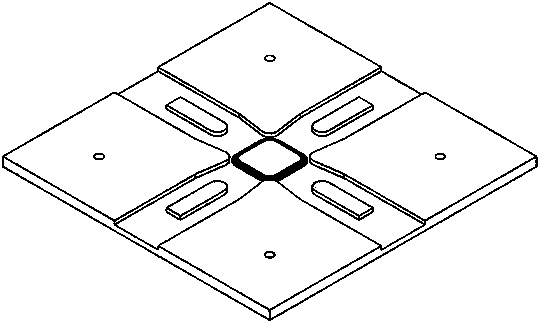

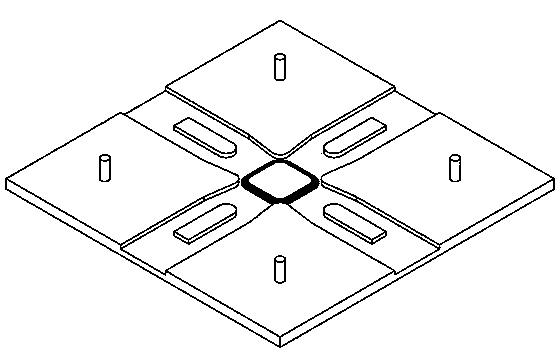

Cross-shaped sample for biaxial mechanical test as well as preparation method and application of cross-shaped sample

InactiveCN104236974AIncreased stress levelsUniform deliveryPreparing sample for investigationMaterial strength using tensile/compressive forcesStress concentrationStress level

The invention relates to a cross-shaped sample for a biaxial mechanical test as well as a preparation method and an application of the cross-shaped sample and belongs to the technical field of composite material biaxial loading tests. The whole sample is cross-shaped and comprises four loading arms, wherein each loading arm is provided with a loading arm hollow area (2), the tail end of each loading arm is a loading arm clamping end (1), and a transition area is arranged between roots of every two adjacent loading arms; a sample center area is arranged among the roots of the four loading arms, the middle area of the sample center area is a central test area (6), and a thinned transition area (5) is arranged between the central test area (6) and the roots of the loading arms. The cross-shaped sample is simple in structure and convenient to realize, stress concentration phenomena in arc transition chamfered positions of the cross-shaped sample are weaker while the central test area is higher and uniform in stress level, the biaxial stress state of the central test area is easier to realize, and initial damage occurs in the central test area.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

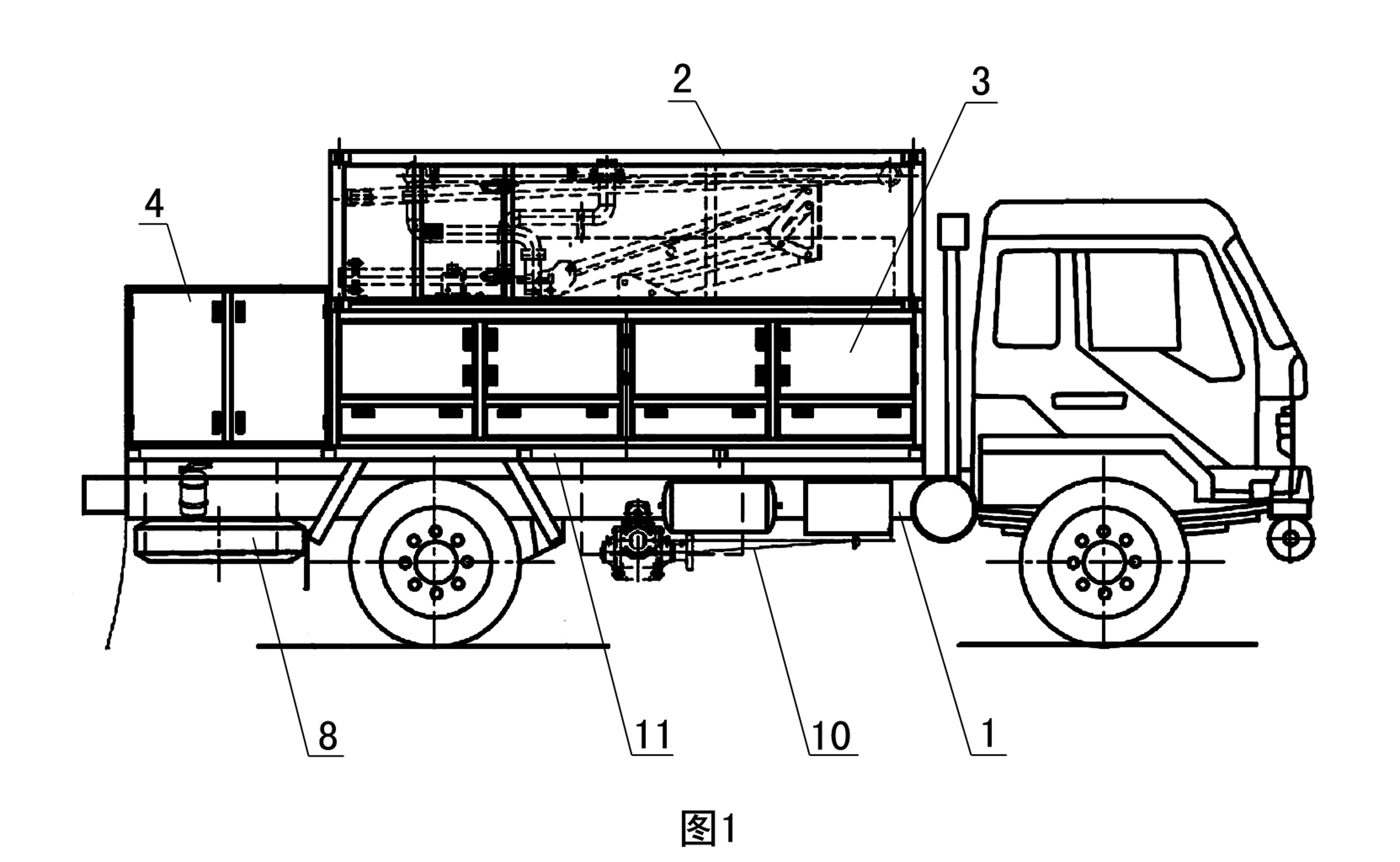

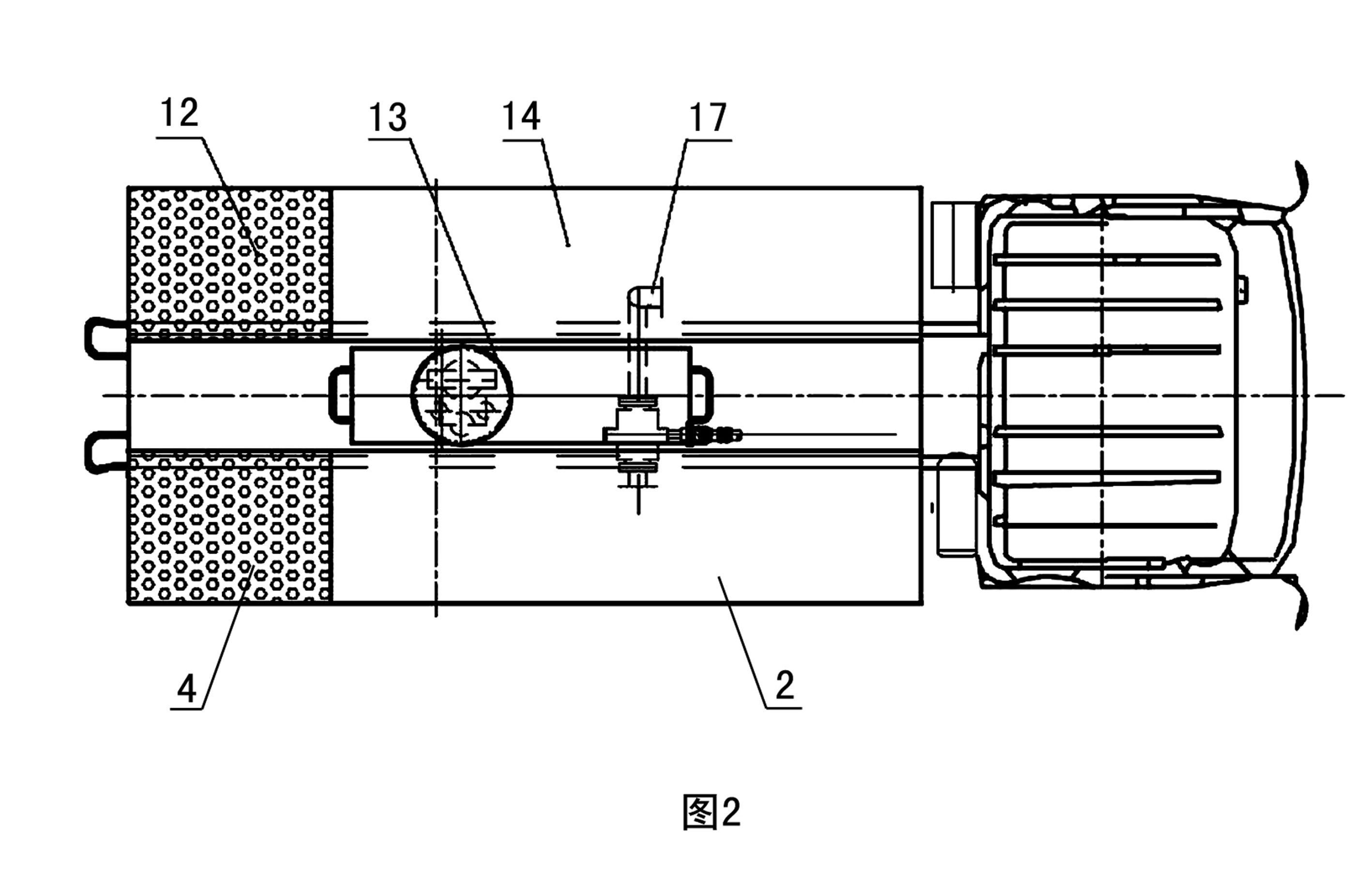

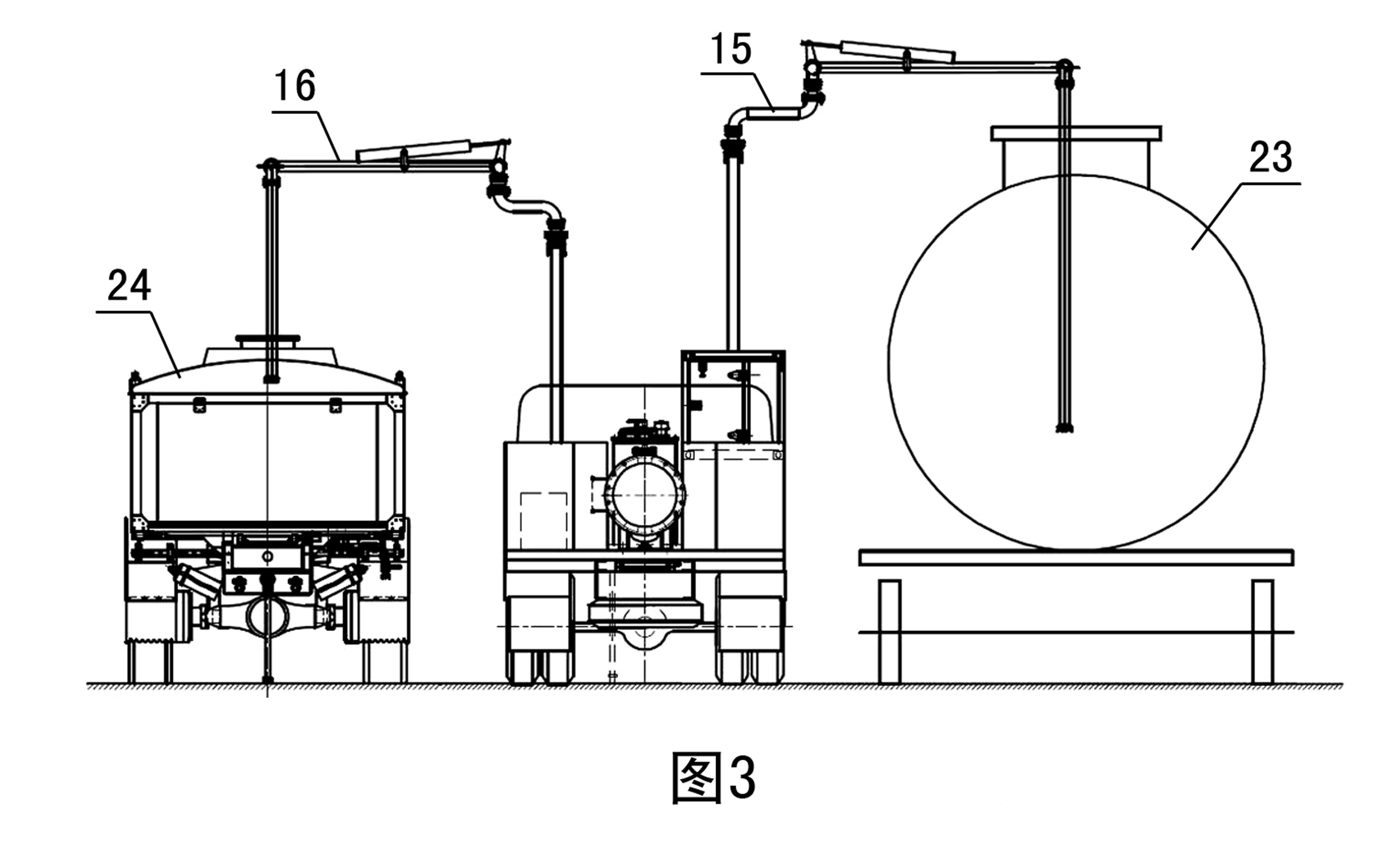

Oil unloading device vehicle for railway oil tank and oil transportation method thereof

InactiveCN101786590AEasy to observeImprove emergency support capabilitiesLiquid transferring devicesDelivery vehicleElectrical control

The invention relates to an oil unloading device vehicle for a railway oil tank and an oil transportation method thereof. A vehicle chassis system is fixedly connected with a platform assembly; the platform assembly is provided with a control box, an electrical control box, an oil return extending-retracting oil tank, an oil pump, a loading arm assembly, a loading arm box and an oil passage control valve; the loading arm assembly comprises a set of railway oil transportation loading arm assembly, a set of vehicle oil transportation loading arm assembly, and one to two sets of bottom filling oil pipe assemblies, wherein the railway oil transportation loading arm assembly is arranged in the an oil absorption loading arm box of the railway oil tank, and the vehicle oil transportation loading arm assembly is arranged in a vehicle oil transportation loading arm box; one side of the vehicle chassis system is provided with the control box; a flow meter, a dry self-sealing joint and the oil passage control valve are arranged in the control box; and the other side of the chassis is provided with the oil passage control valve. The vehicle can complete functions of vacuum pump priming, unloading oil transportation, bottom oil suction, emptying and the like, has the advantages of simple structure, convenient operation, convenient observation of the meter, reasonable layout, high measuring precision, higher explosive-proof grade and the like and is mainly used to suck the flue oil in the railway oil tank and transport the flue oil to the oil delivery vehicle.

Owner:BEIJING SANXING AUTOMOBILE

Loading device used for lateral-torsional vibration fatigue experiment and method thereof

ActiveCN108709793AGuaranteed stabilityMeet needsMaterial strength using steady bending forcesEngineeringLoading arm

The invention discloses a loading device used for a lateral-torsional vibration fatigue experiment and a method thereof. A sliding groove is formed in a base, brackets are installed at the two ends ofthe base, and a vibration exciter is connected to the sliding groove; the base body is connected with the brackets through bolts, rotary shafts are arranged on the two sides of a sliding sleeve, a clamping roller is installed above the sliding sleeve, and the rotary shafts are connected with a sliding seat and a shaft hole of a side plate; a guiding rod is sleeved with the sliding sleeve, and oneend of the guiding rod is connected with a loading arm; a clamping seat and a clamping head of the loading arm are opposite to each other, a V-shaped groove is formed in the clamping seat, and a second coupler is installed below the clamping seat. The loading device has adjustability and enough clamping force to ensure the stability of a platform, can provide pure torsion loading, torsion and transverse bending coupling loading, torsion and longitudinal bending coupling loading, torsion and oblique bending coupling loading and pure bending loading, has the advantages of high accuracy, high efficiency, low cost and multiple functions, and has important practical value regarding the completion of the vibration fatigue performance experiment for experimental piece materials with rectangularcross sections and circular cross sections.

Owner:NANCHANG HANGKONG UNIVERSITY

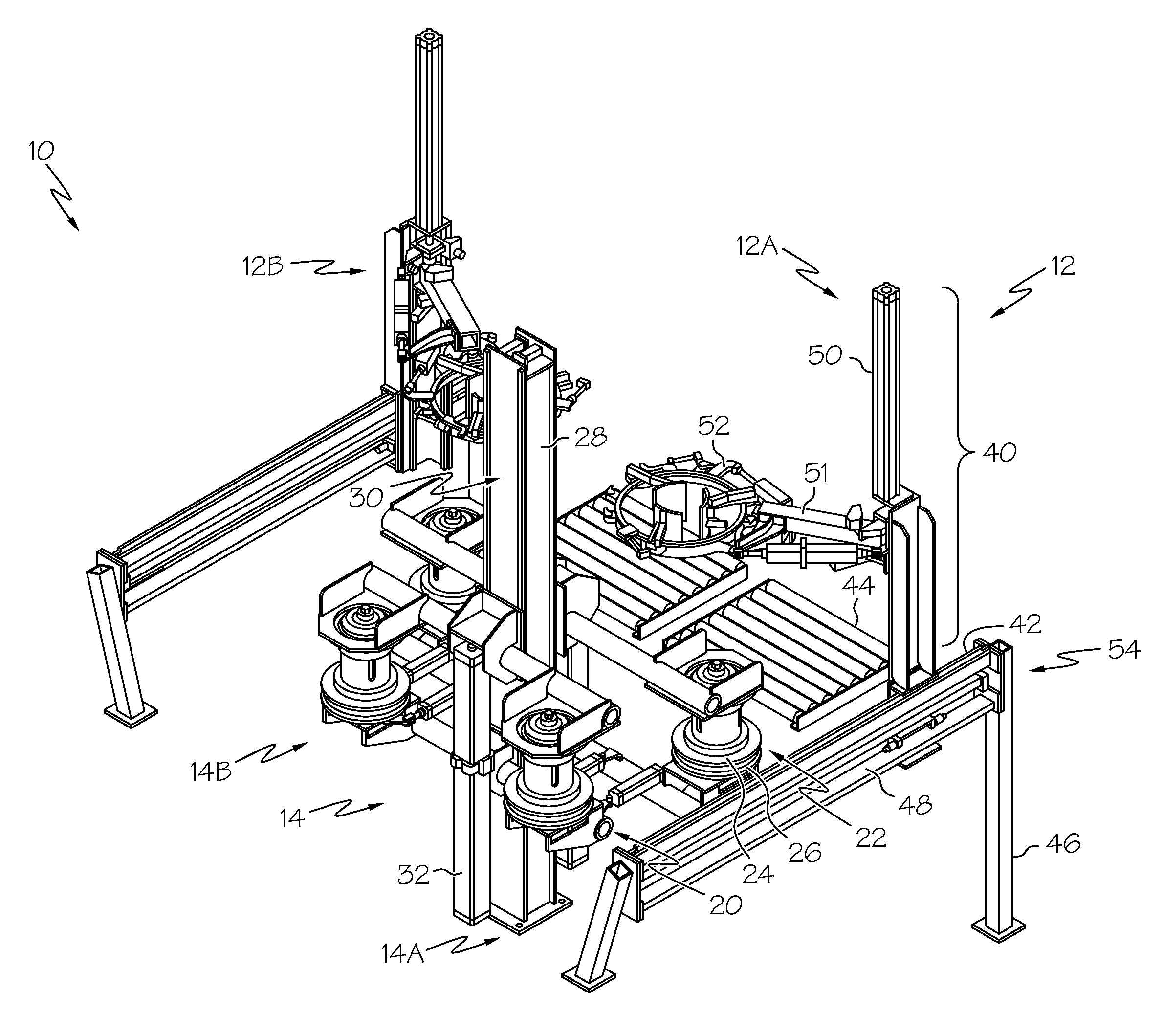

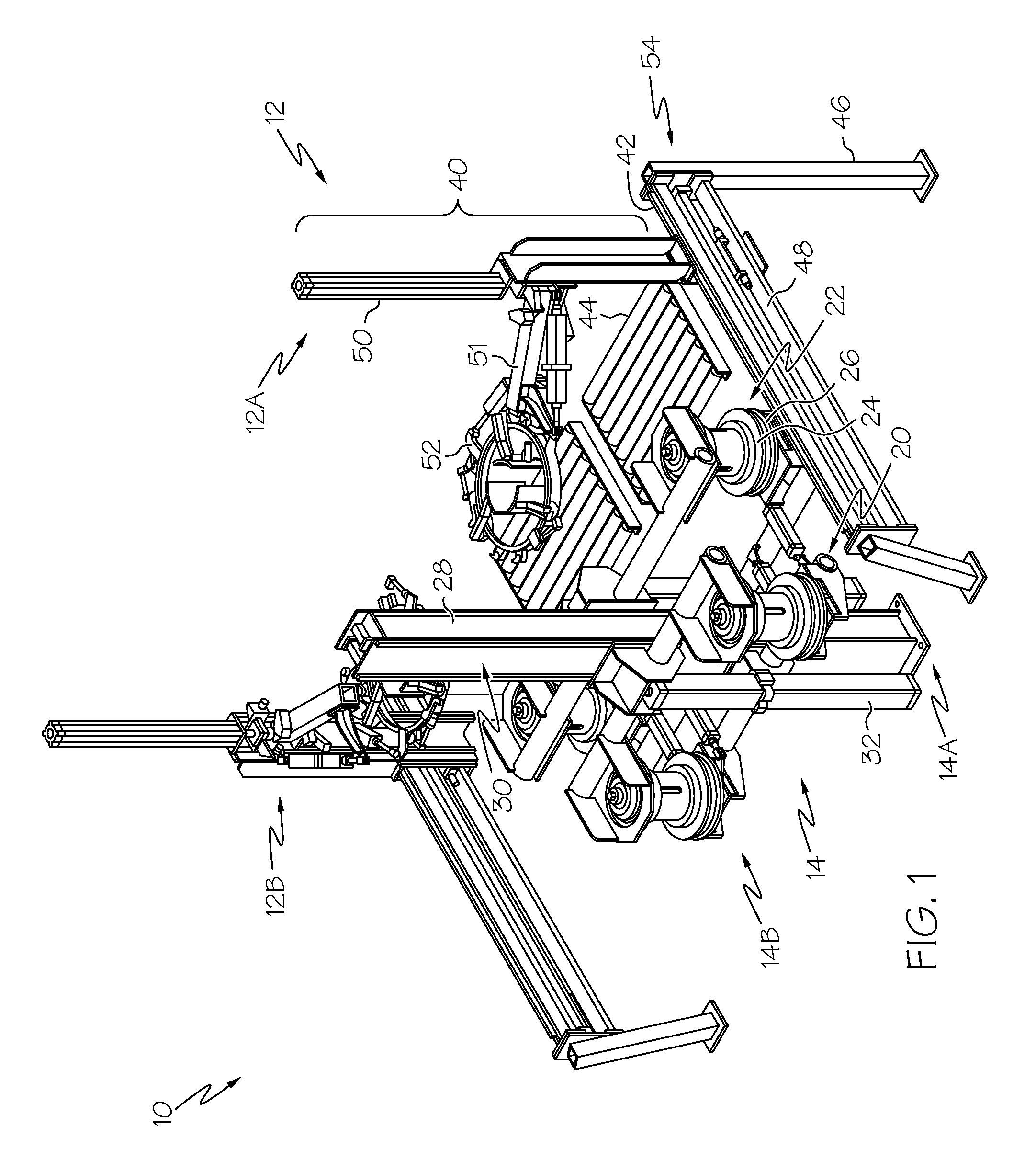

Pipe Handling Apparatus and Method

Owner:AXIS ENERGY SERVICES LLC

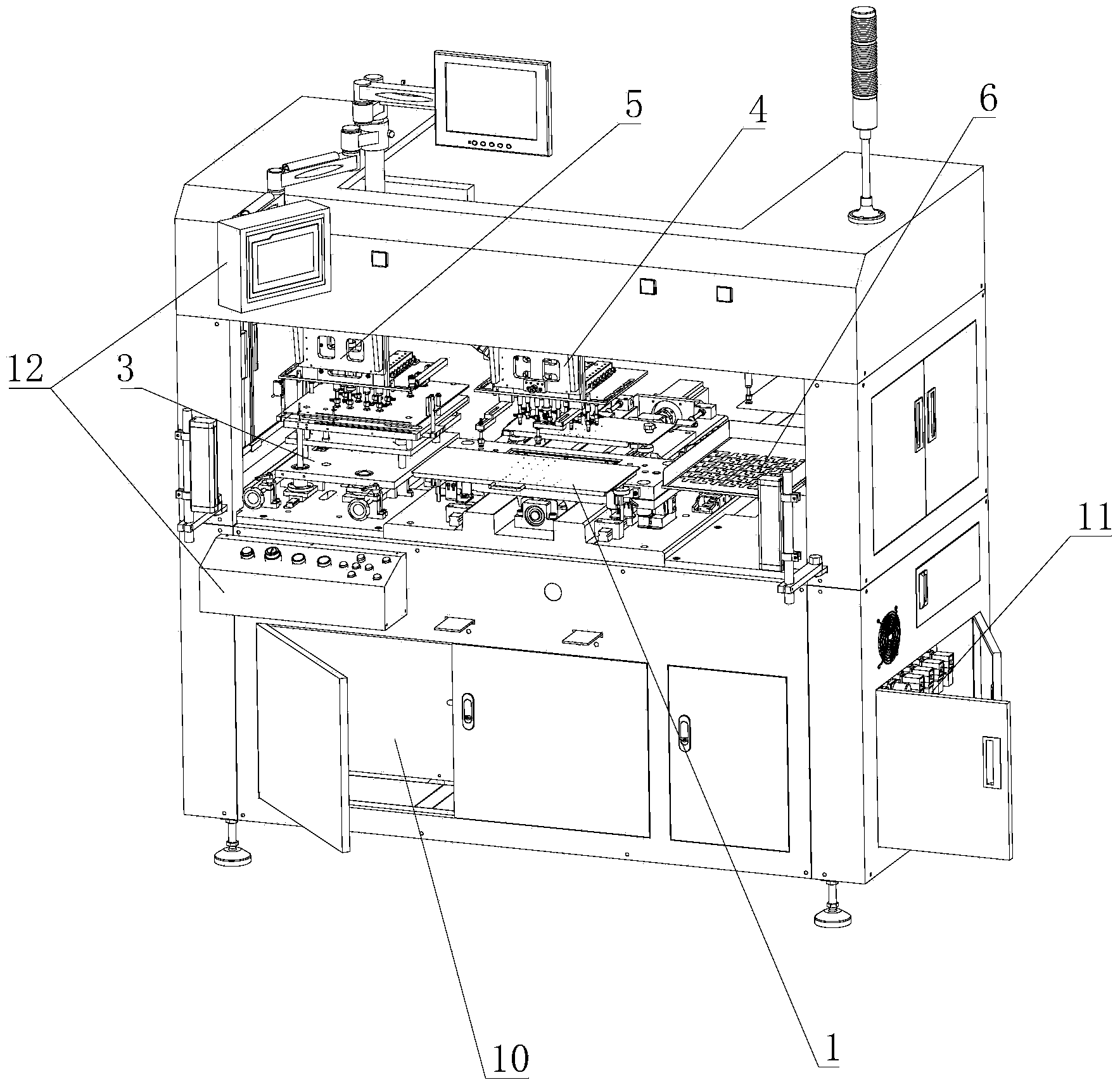

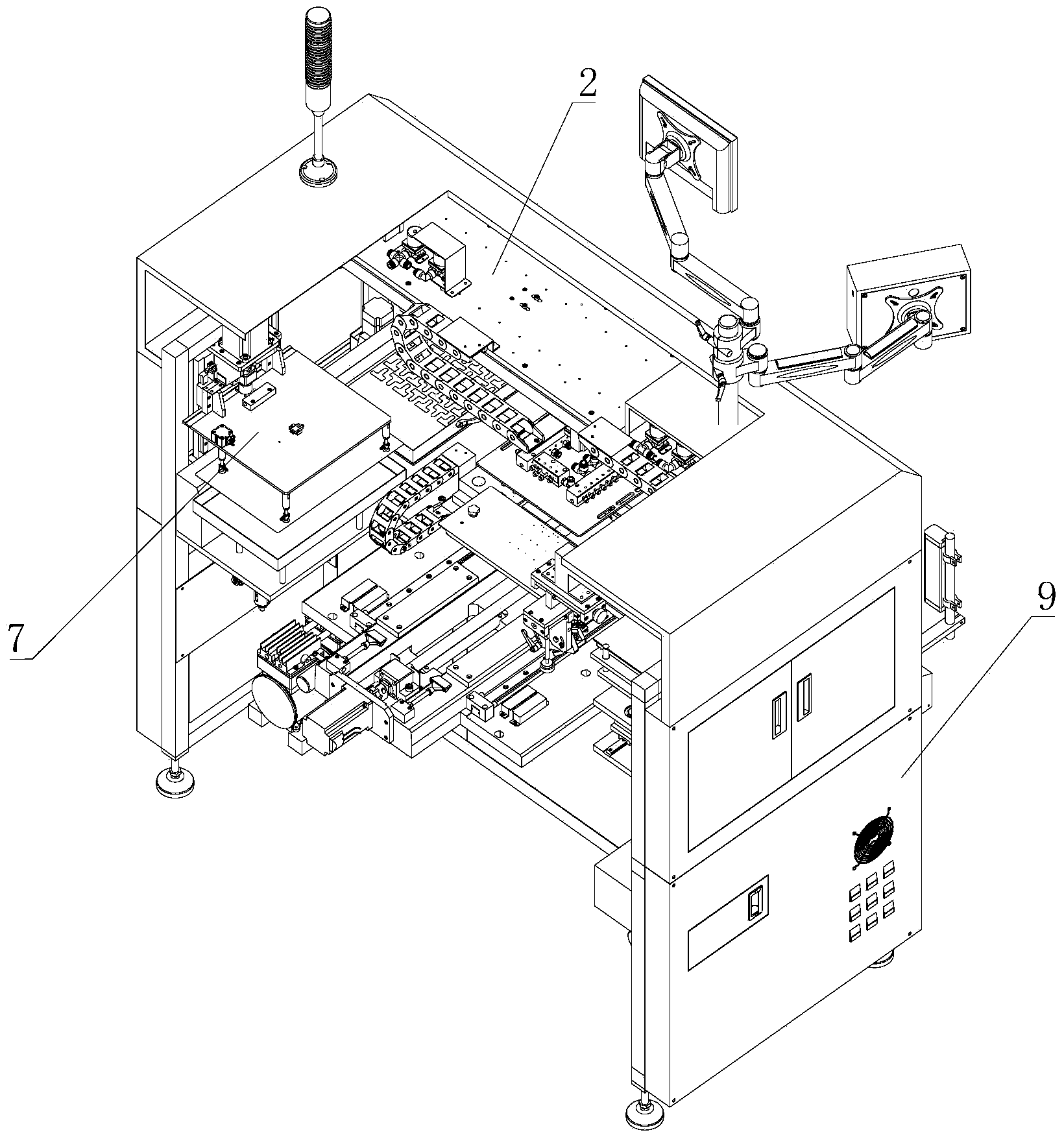

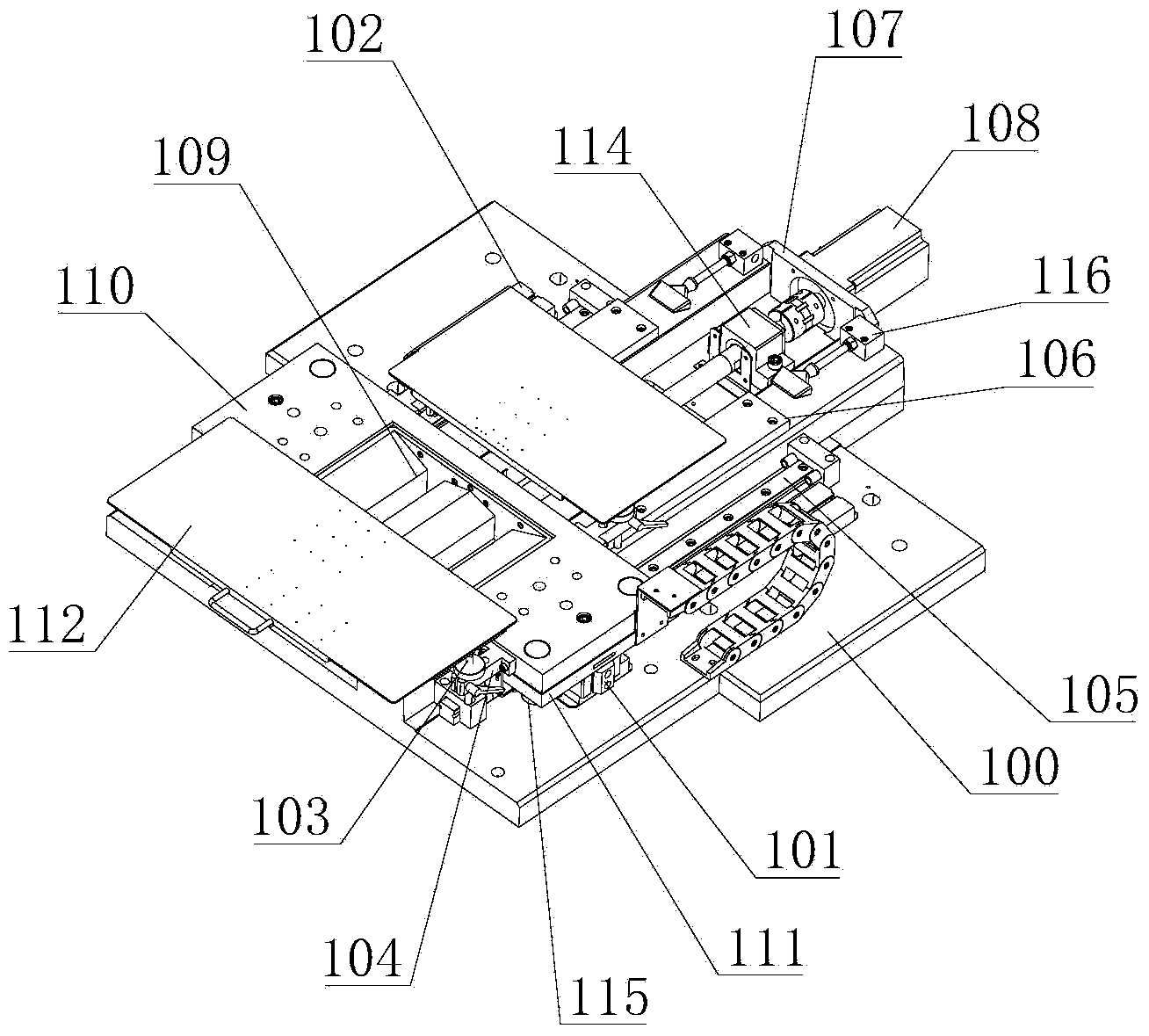

Fully-automatic single blanking mechanical arm

ActiveCN104070558AGet rid of influenceSolve labor intensityMetal working apparatusPunch pressInstability

The invention provides a fully-automatic single blanking mechanical arm. A loading plate device, a loading arm device, a blanking device, a horizontal conveying device, an unloading arm device, an upper partition paper device and a finish product collecting device are mounted on an existing punch press to form an excellent structural design, so that the fully-automatic single blanking mechanical arm can complete operations of loading, conveying, blanking, movement and the like of FPC (flexible printed circuit) boards; the cooperation of all the parts enables the fully-automatic single blanking mechanical arm to meet the requirements of single production, so that the problems existing in the signal production such as high labor intensity, high work-related injury risk, low production efficiency, large worker quantity and personnel instability can be solved.

Owner:SHENZHEN MAKEN M & E

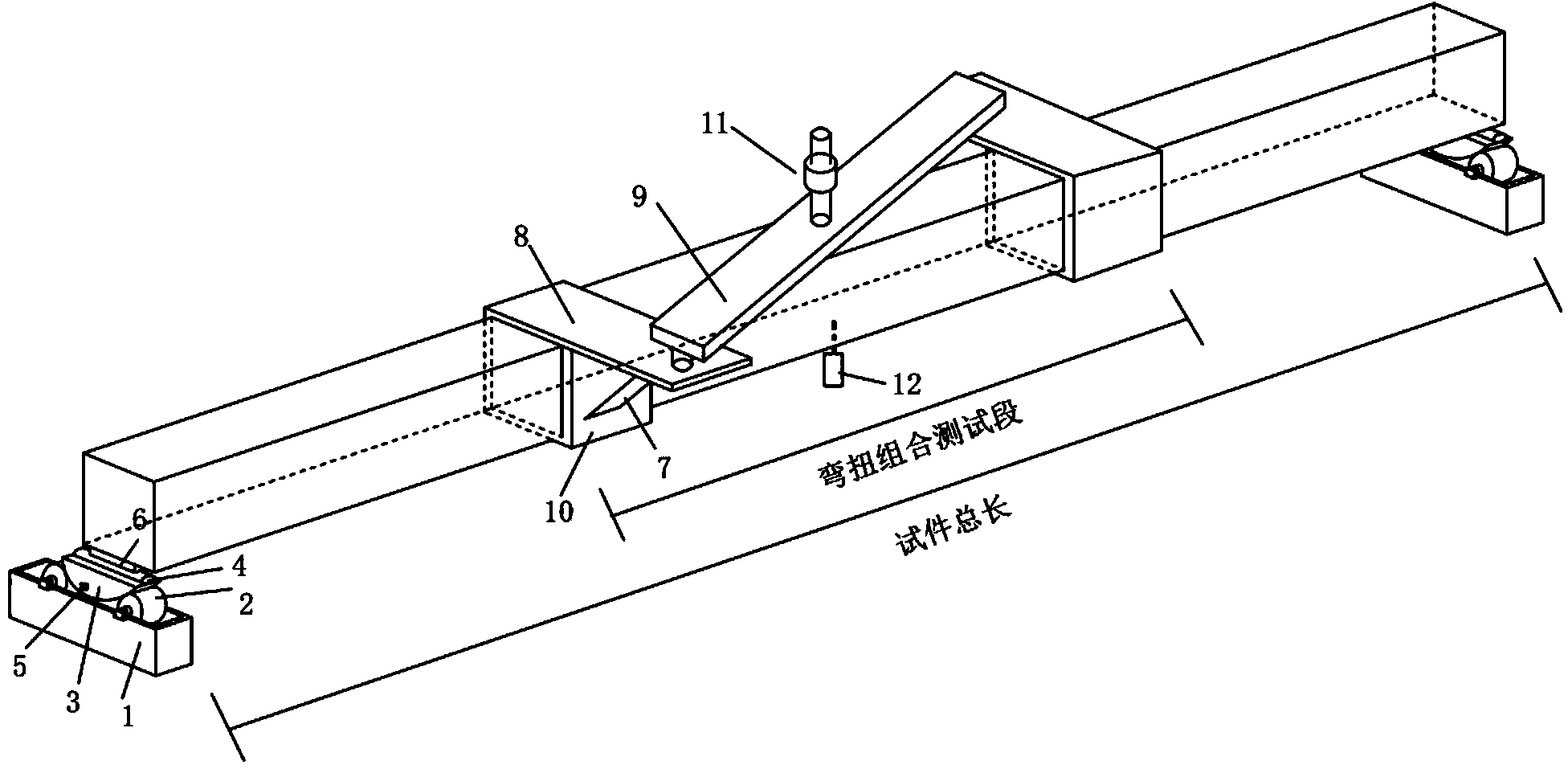

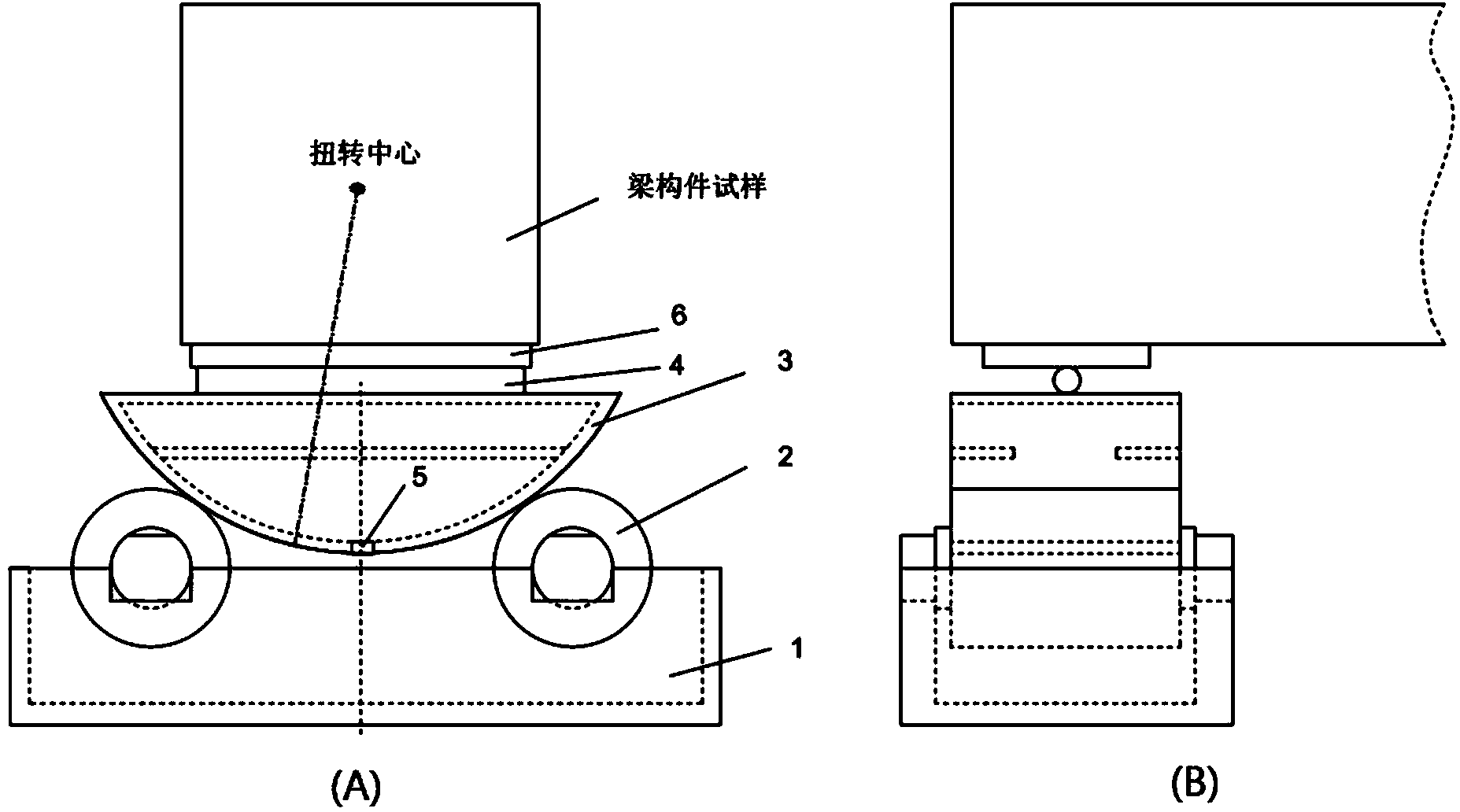

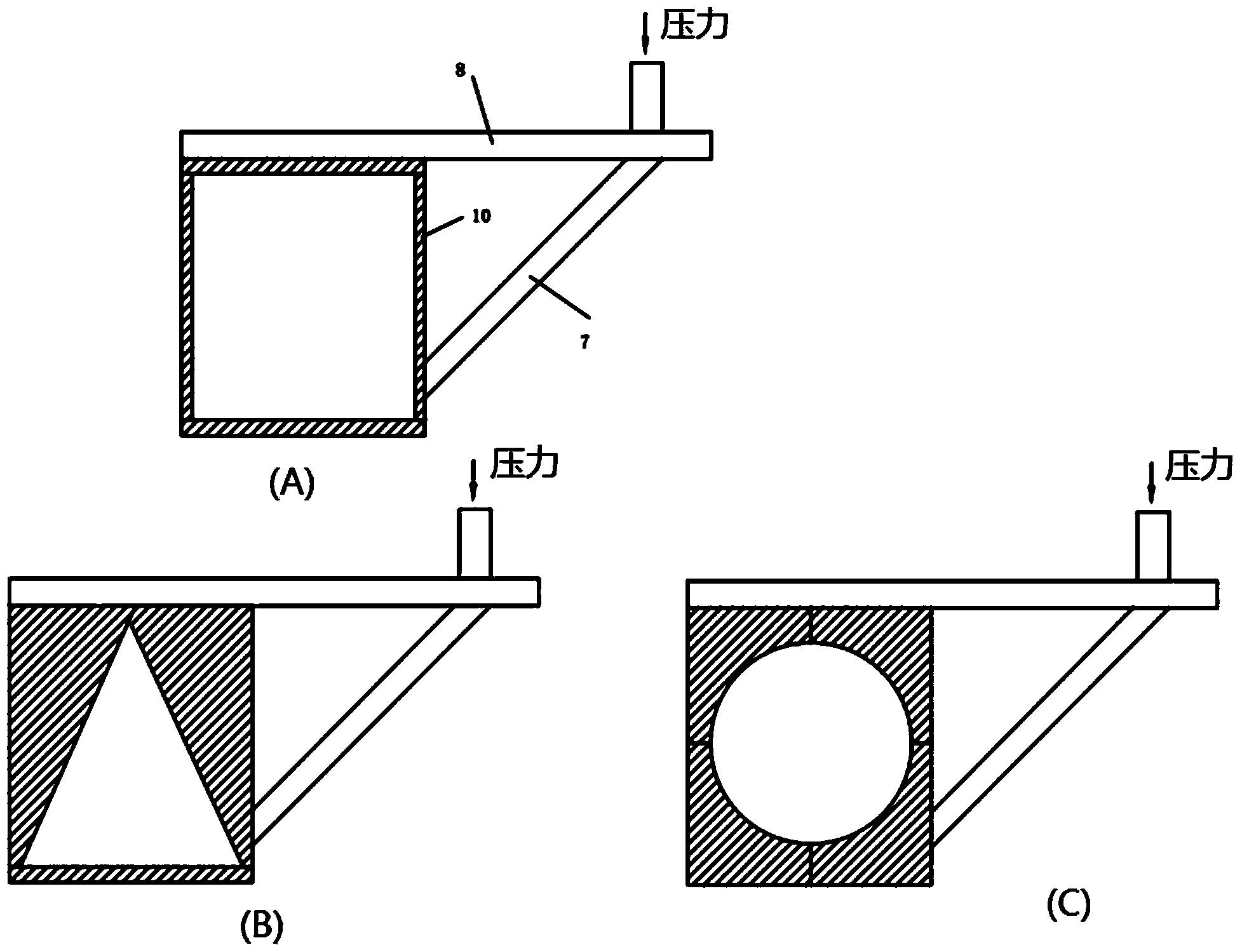

Beam component bending and torsion combined load test device and method

ActiveCN104359754AIntuitive and convenient measurementSmart and reasonable setting of boundary conditionsMaterial strength using steady bending forcesTurn angleTest segment

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

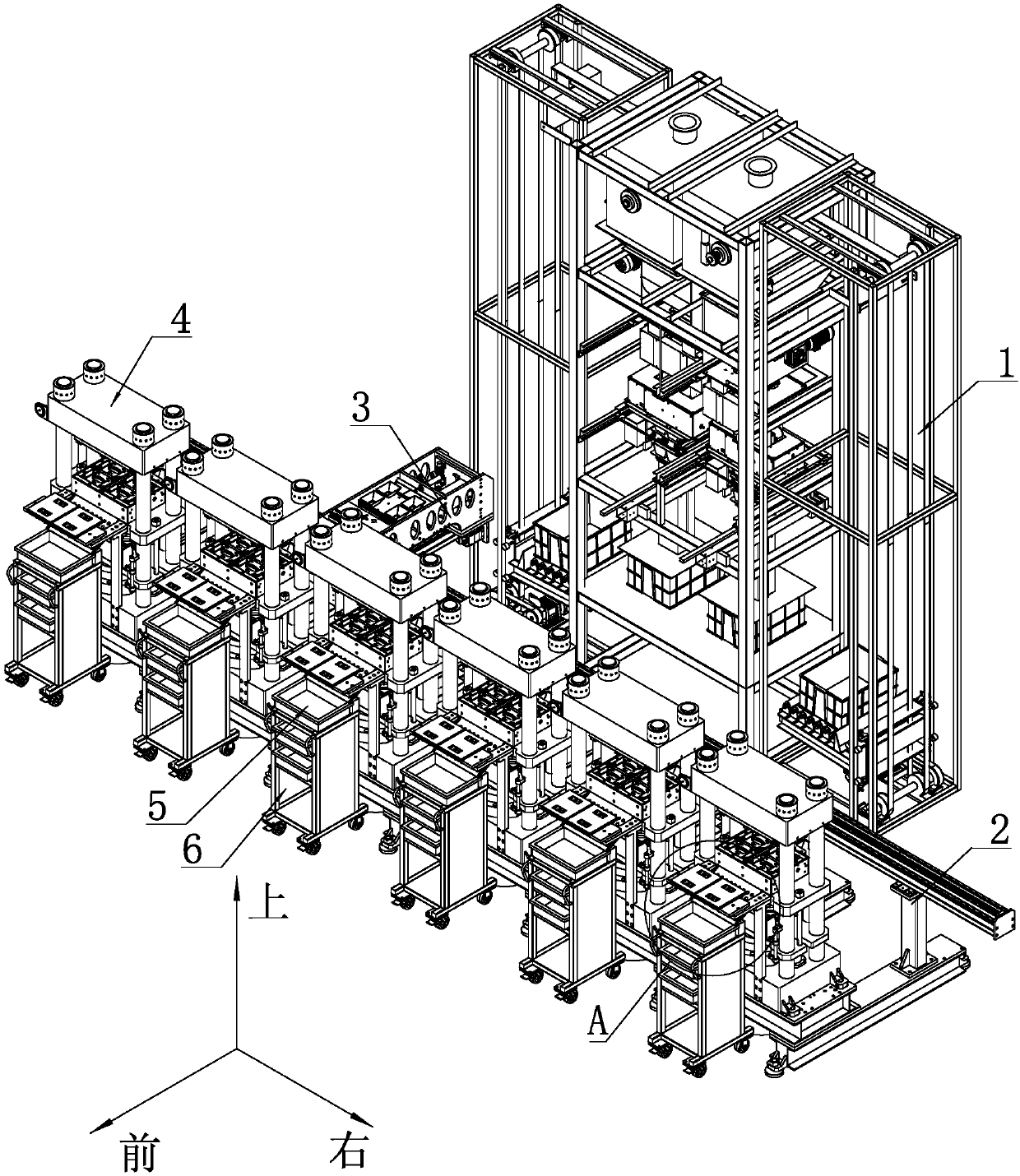

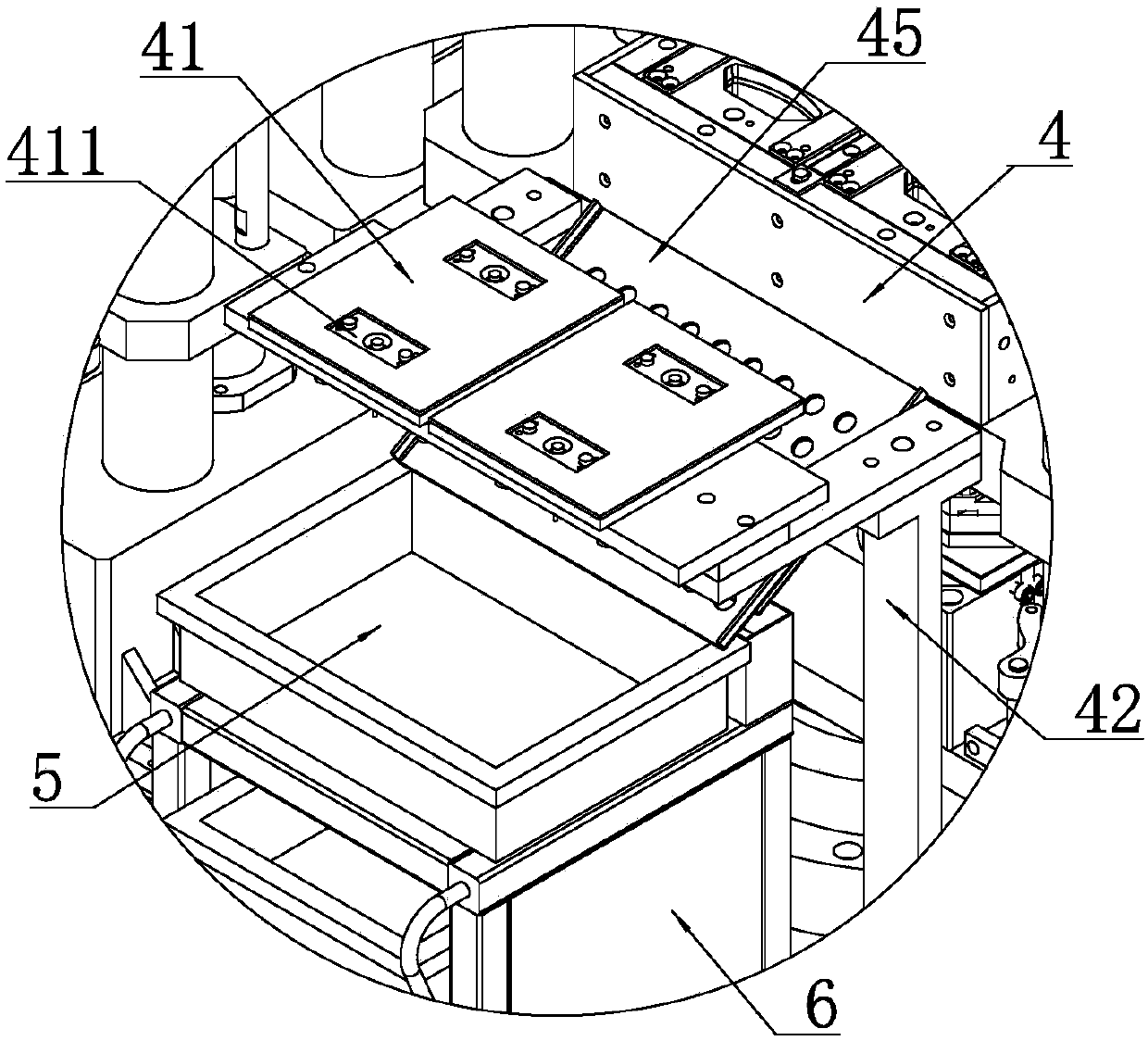

Fully-automatic production line applied to brake pad production

The invention discloses a fully-automatic production line applied to brake pad production. The production line sequentially comprises a weighing device, a loading device and a plurality of hot presseswhich are arranged in a straight mode from front to rear, wherein a material receiving box is separately arranged at the front side of each hot press; the loading device comprises a cross sliding table which is composed of a beam and a longitudinal beam in sliding connection with the beam; a loading arm is arranged on the longitudinal beam in a sliding mode; a transverse drive mechanism is arranged between the beam and the longitudinal beam; a longitudinal drive mechanism is arranged between the longitudinal beam and the loading arm; the loading arm comprises a loading arm frame body; and a loading mechanism, a spraying mechanism, a flattening mechanism, a cleaning mechanism and a taking-placing mechanism are sequentially arranged in the loading arm frame body from rear to front. The production line can realize automatic production of a brake pad, does not need manual operation throughout the process, and greatly improves production efficiency.

Owner:济南悦创液压机械制造有限公司

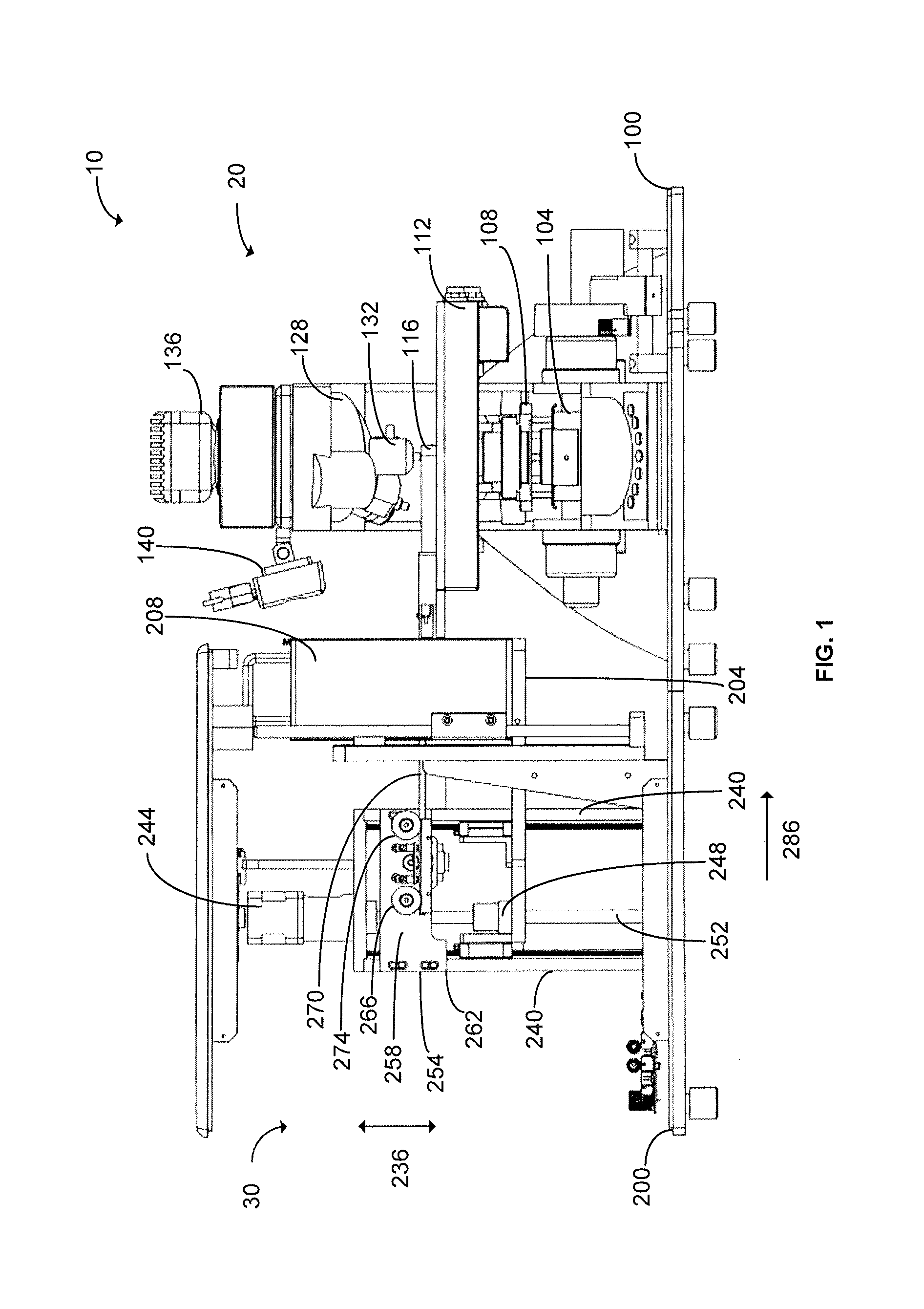

Automatic slide loading system and method

A microscopy slide loading system includes a motorized cassette having a plurality of stacked slots for supporting microscopy slides and a motorized loading arm being displaceable between a retracted position and a loading position. The loading arm projects through a slide slot of the cassette to push a slide positioned therein, eject the slide from the cassette and load the slide onto a slot of a slide holder of a microscope. Loading of the slide into the slide holder allows analysis of the slide by the microscope. After analyzing the slide, a front portion of the loading arm having gripping fingers grip the slide and pulls the slide from the slide holder back into the cassette in order to reload the slide into the cassette. Another slide of the cassette can be loaded and unloaded in a similar manner.

Owner:CLEMEX TECH

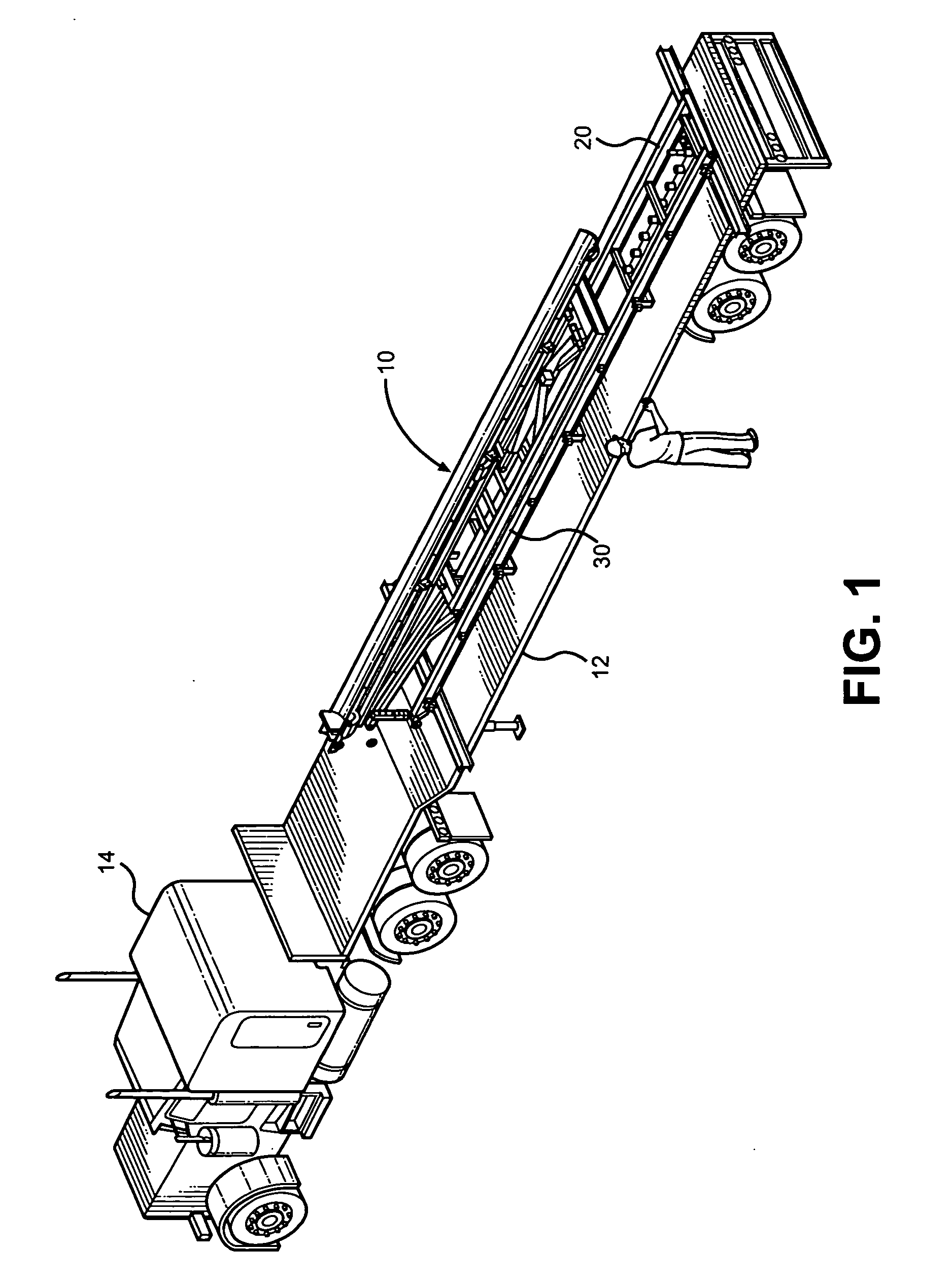

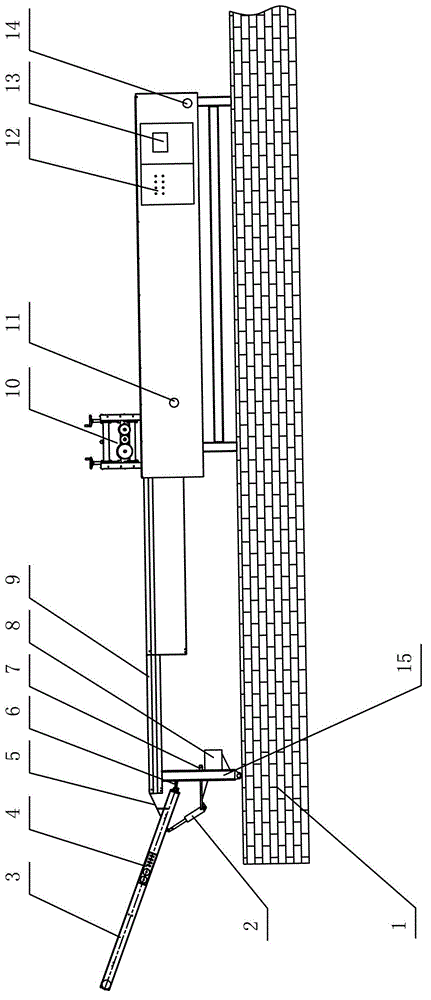

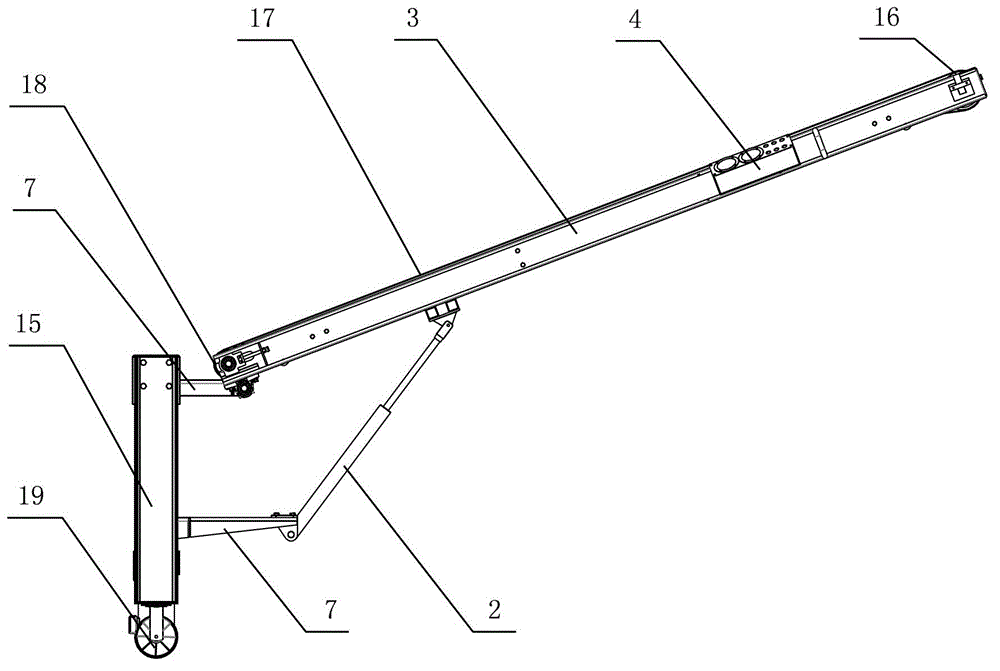

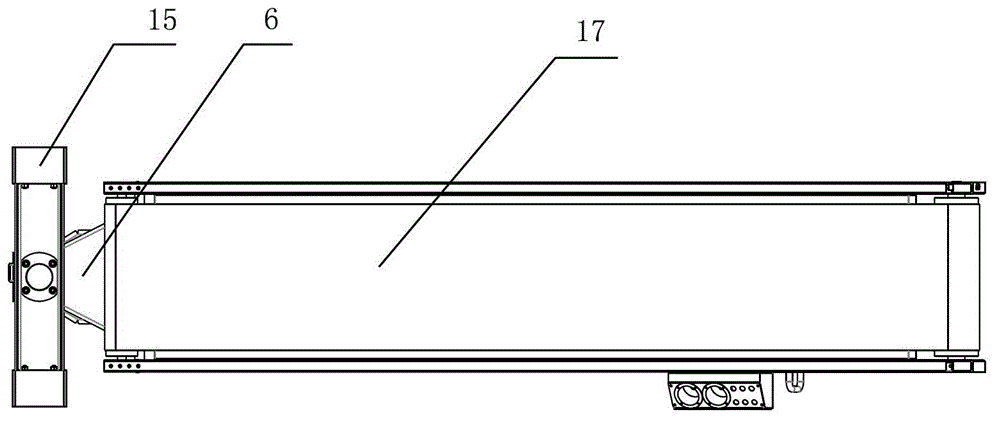

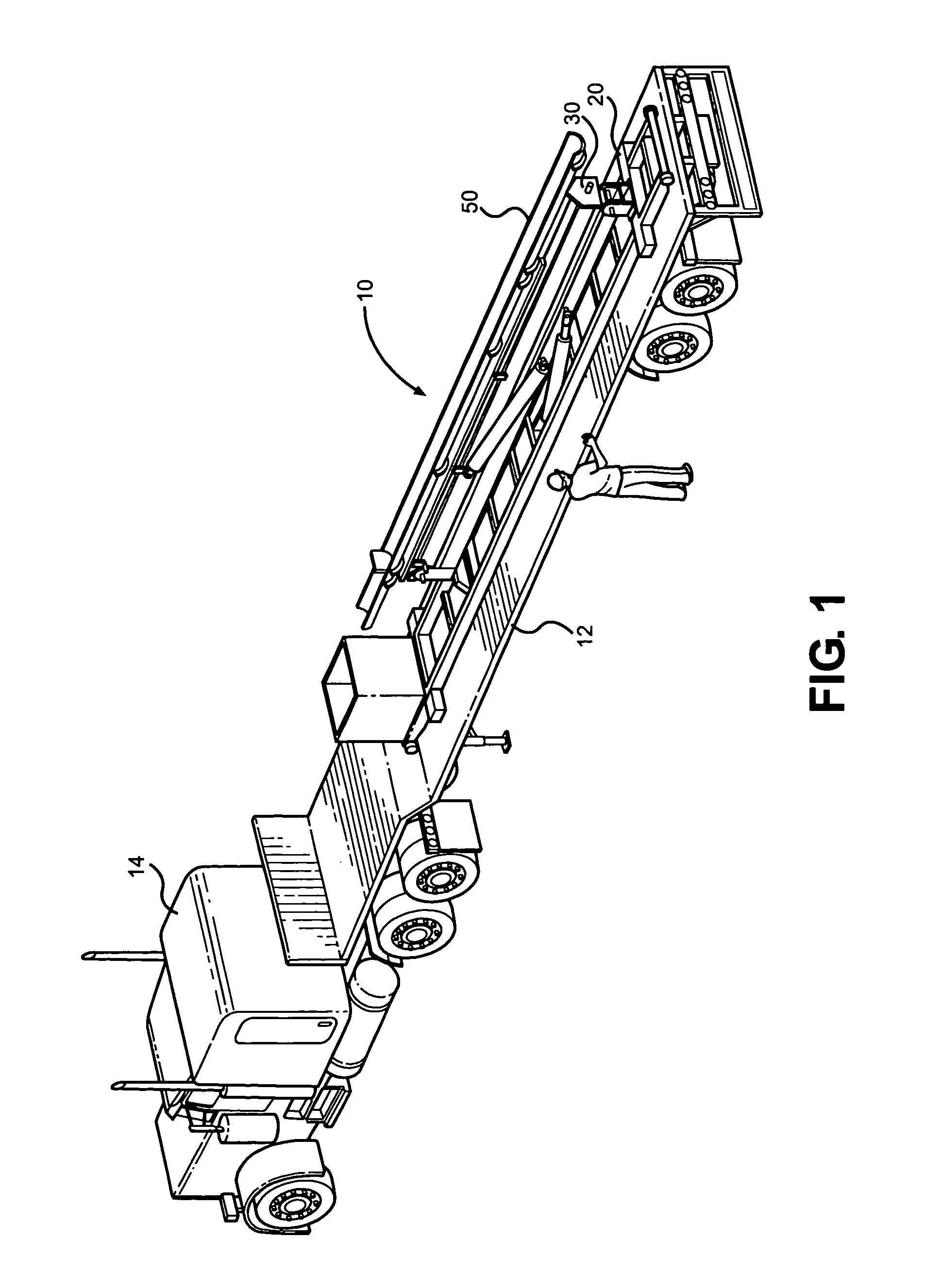

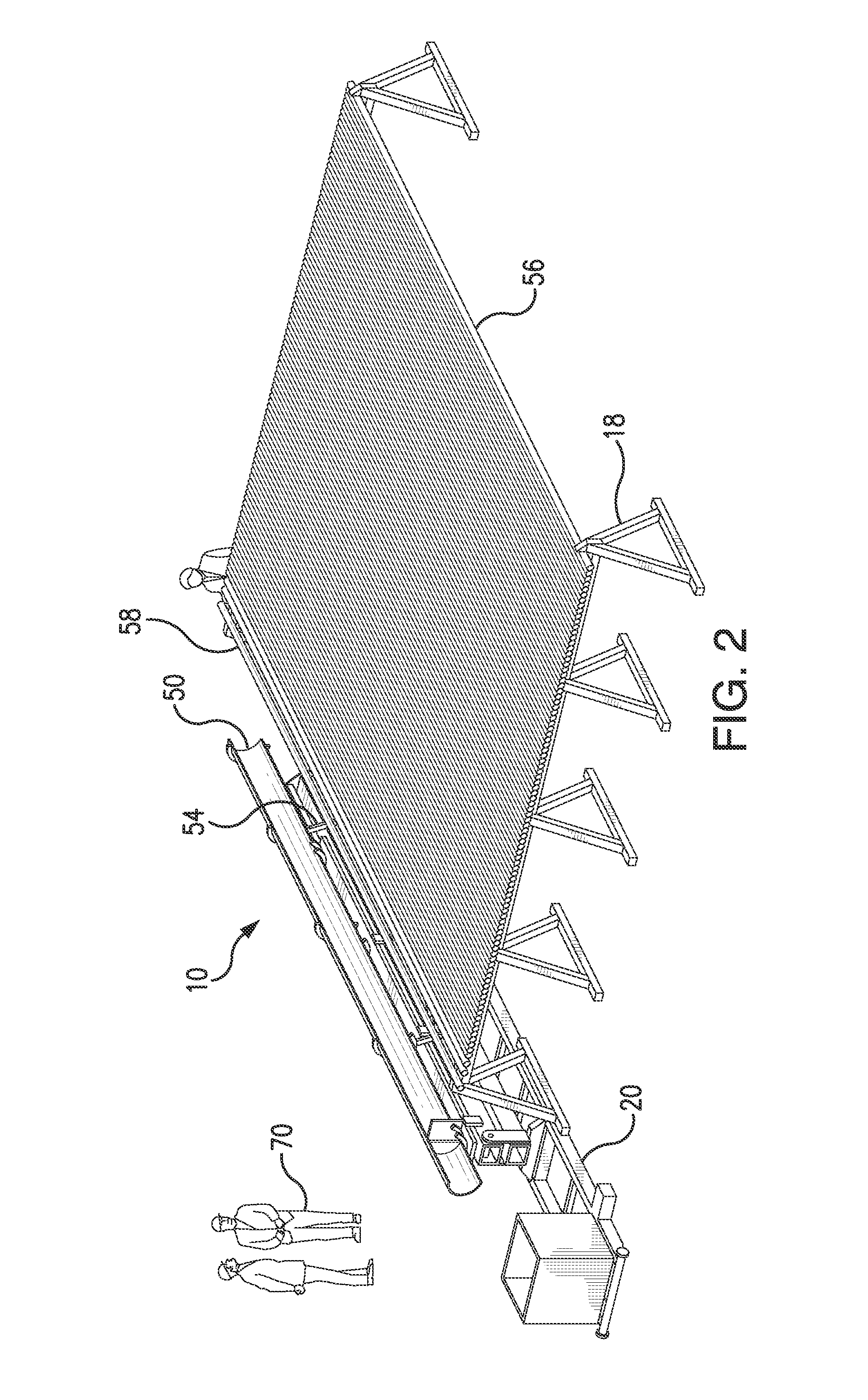

Full-automatic telescopic type car loader

The invention relates to a car loader, in particular to a full-automatic telescopic type car loader, is suitable for the stacking and car loading of materials which are packed in bags and cases, and belongs to the field of warehousing and logistic machinery equipment. The car loader comprises a feeding and conveying device, wherein the front end of the feeding and conveying device is movably connected with a car loading arm, the car loading arm is provided with a climbing conveyor, the part, near the feeding and conveying device, of the car loading arm is connected with a lifting driving device, the lifting driving device is connected with a swinging driving device, and the swinging driving device is arranged on the feeding and conveying device. The car loader has the advantages that the problem of slipping or being over-tight of a belt of the conveyor caused by the integral lifting of the traditional conveyor is solved, the running is stable, and the service life is prolonged; through the vertical and transverse omnibearing movement of the car loading arm, the car loader is suitable for the automatic car loading and stacking of carriages different in types; and the conveyor can extend and retract to any position, the car loader is suitable for different working environments, and the flexibility in use is realized.

Owner:山东聚阳智能装备有限公司

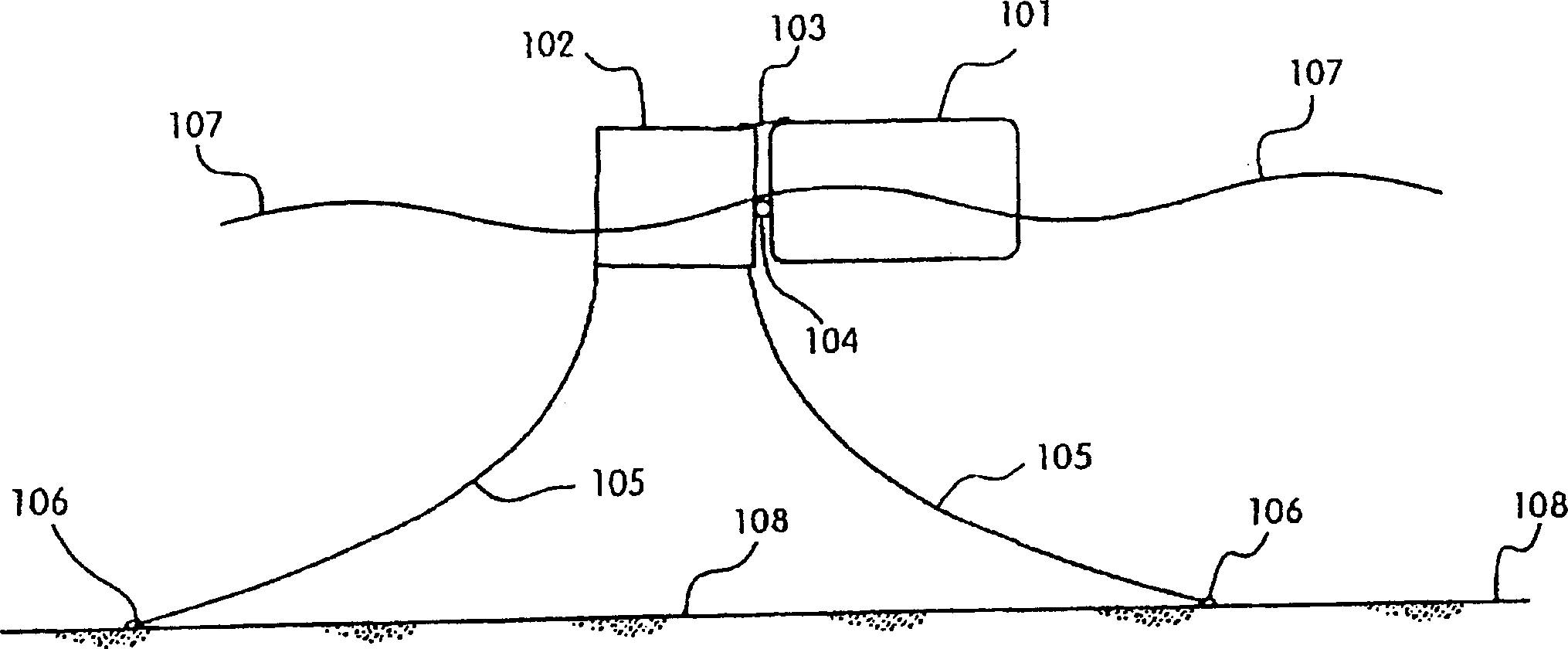

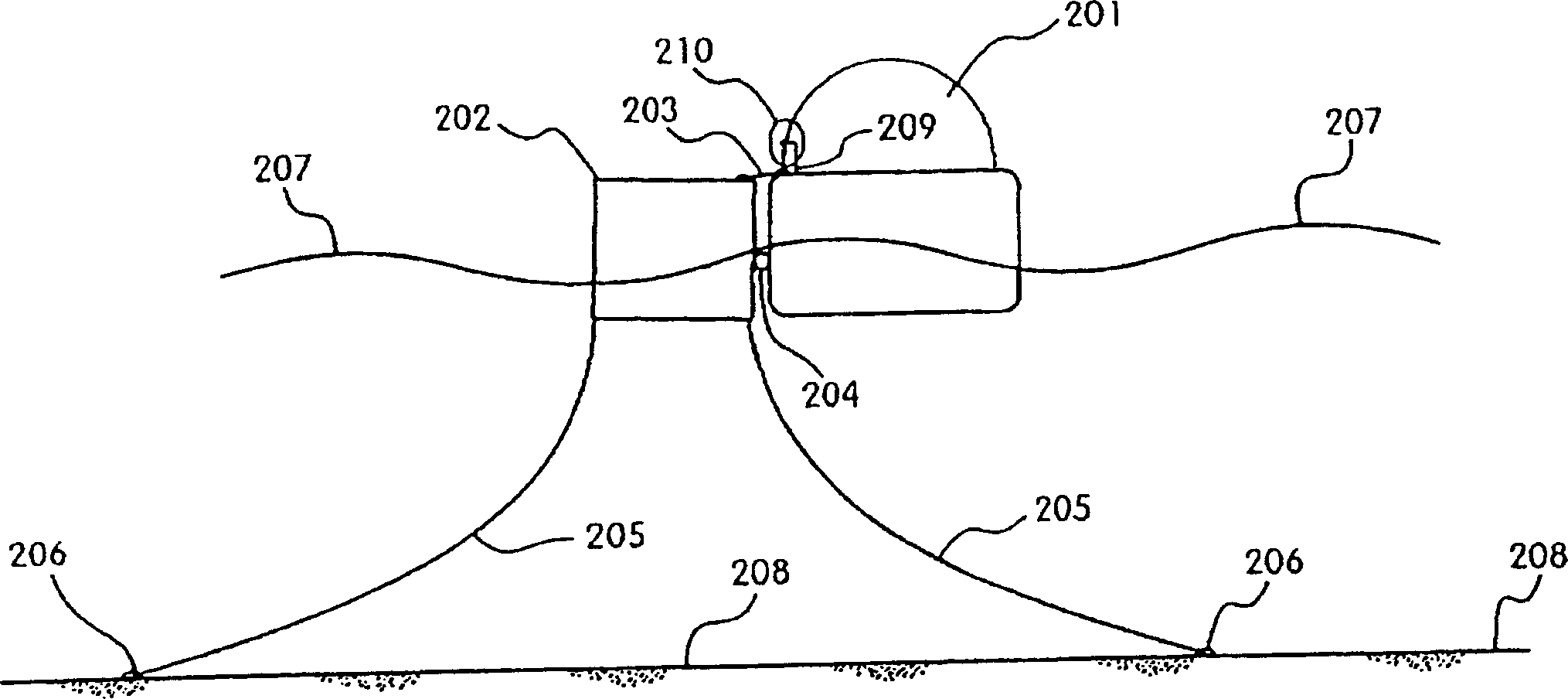

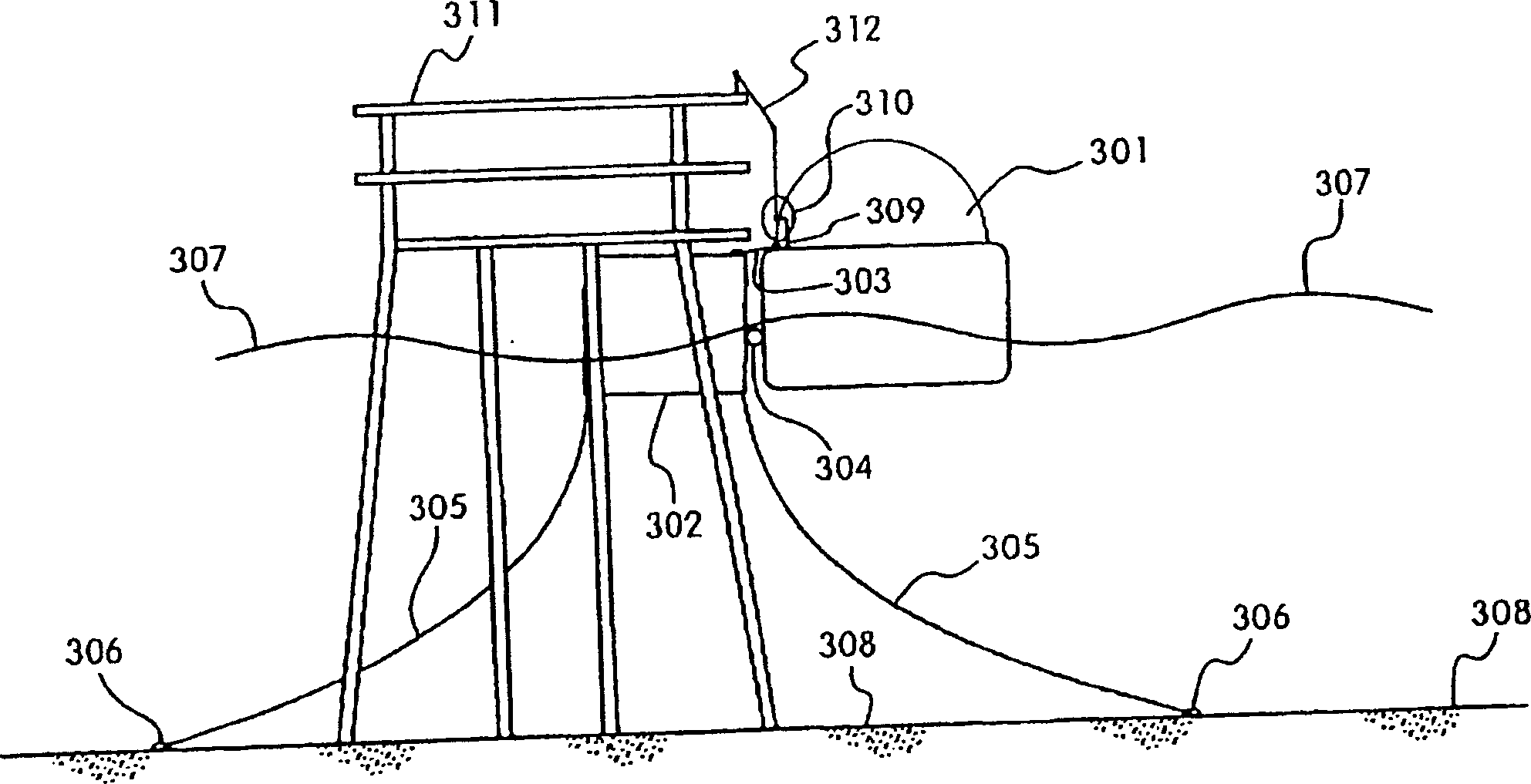

Berthing method and system

A method and a system are provided for safely mooring seagoing vessels on the high seas and in other unprotected waters. The present invention allows a large vessel to berth close enough to a marine structure side-by-side that the vessel can be loaded and unloaded in most environmental conditions using conventional loading arm equipment. Vessels may be moored side by side to the marine structure using one or more floating bollards anchored to the sea floor and provided with guards. The preferred type of floating bollard is a triangular semi-submerged anchored buoy structure comprising three buoy sections or "caissons" arranged in a vertical fashion, three buoy shell sections or "pontoons" which support and separate the buoyancy The column member provides movement damping to the anchored buoy structure, and three horizontal support members hold the top of the buoyant column member in place.

Owner:大卫·查尔斯·兰德瑞 +1

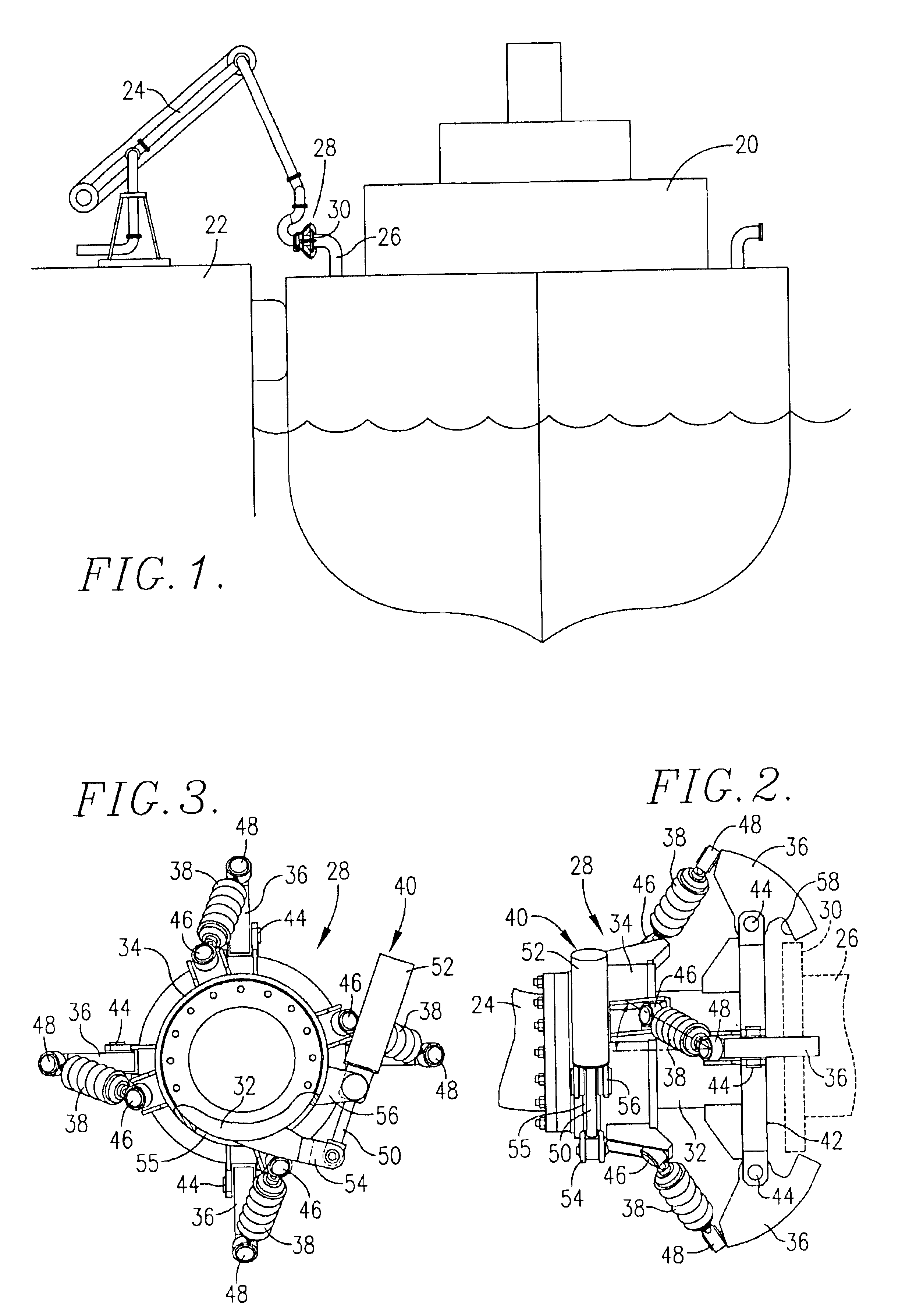

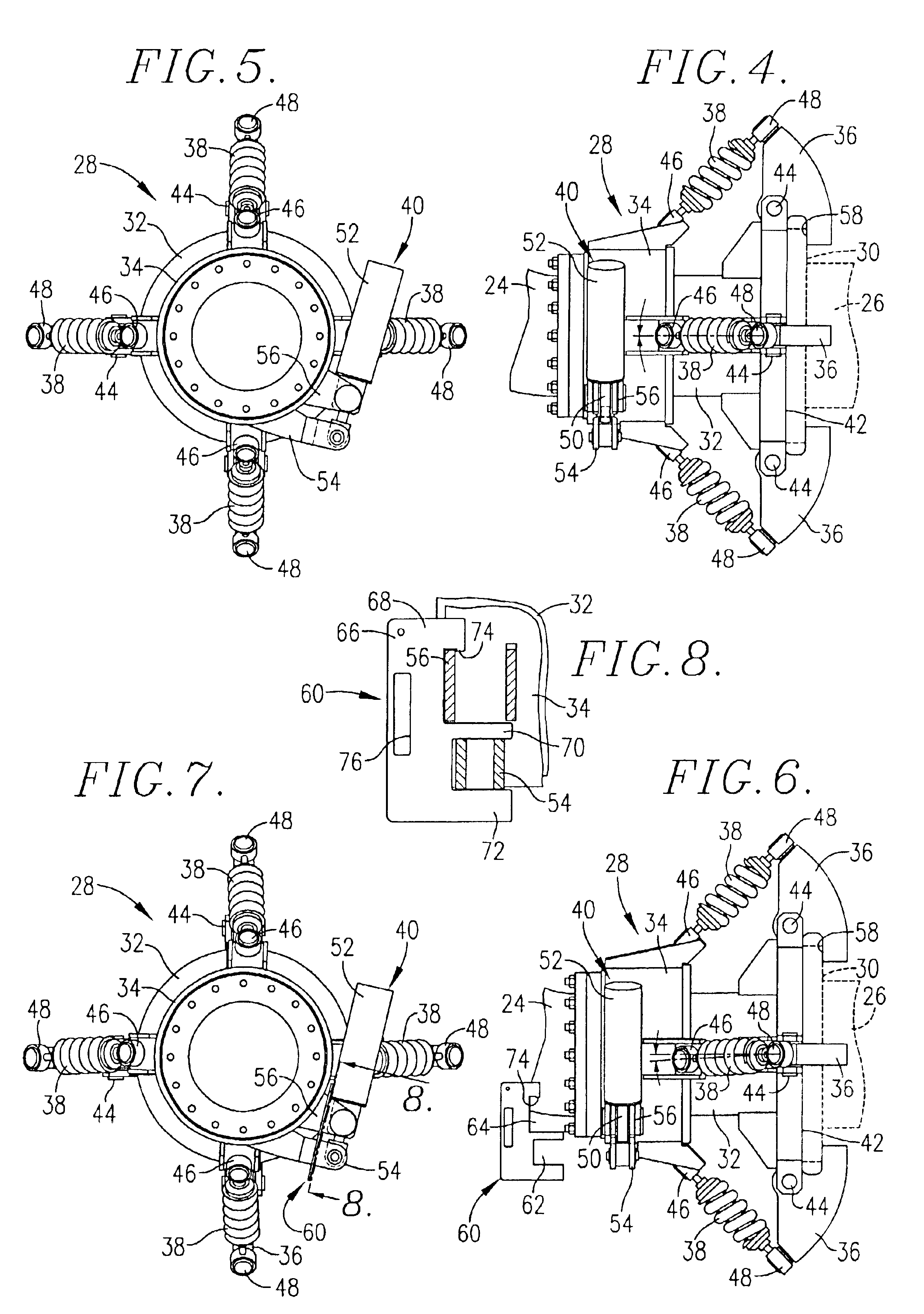

Mechanical locking system for marine loading arm coupler

InactiveUS6843511B2Prevent rotationSleeve/socket jointsCargo handling apparatusMarine engineeringLoading arm

Mechanical lock system for preventing disengagement of a marine loading arm from an inlet / outlet port of a marine tanker by physically restraining rotation of a collar of a quick-connect coupler relative to a main body of the quick-connect coupler.

Owner:PHILLIPS 66 CO

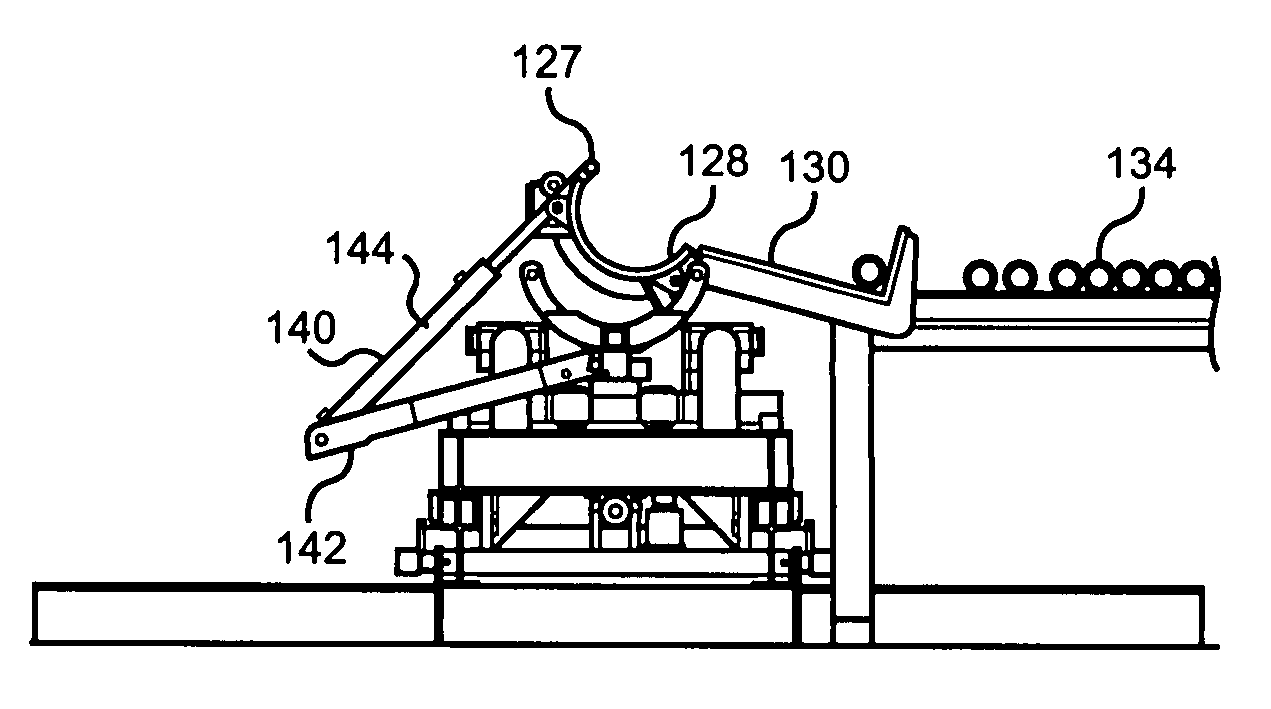

Combination loader and post cure inflator

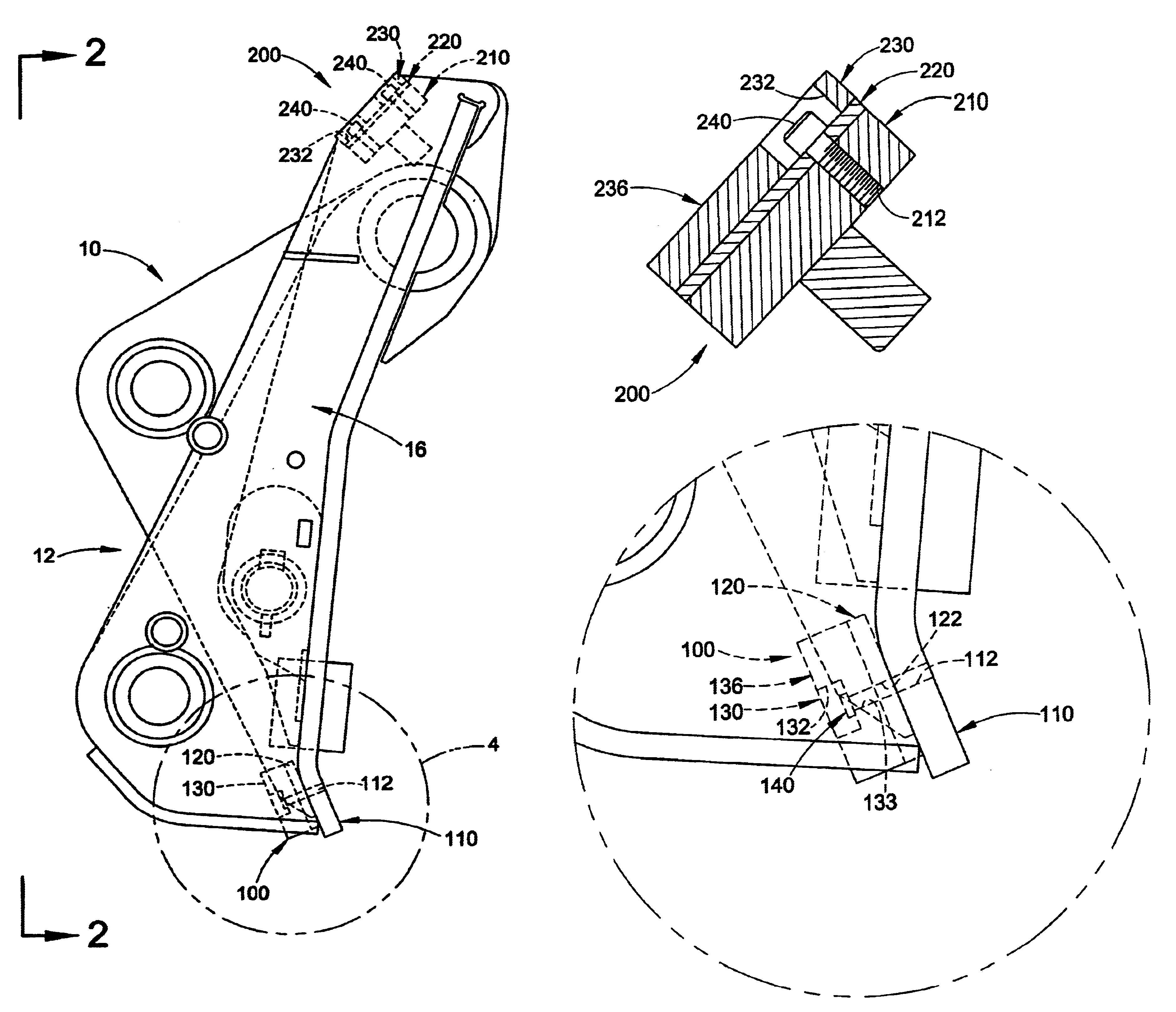

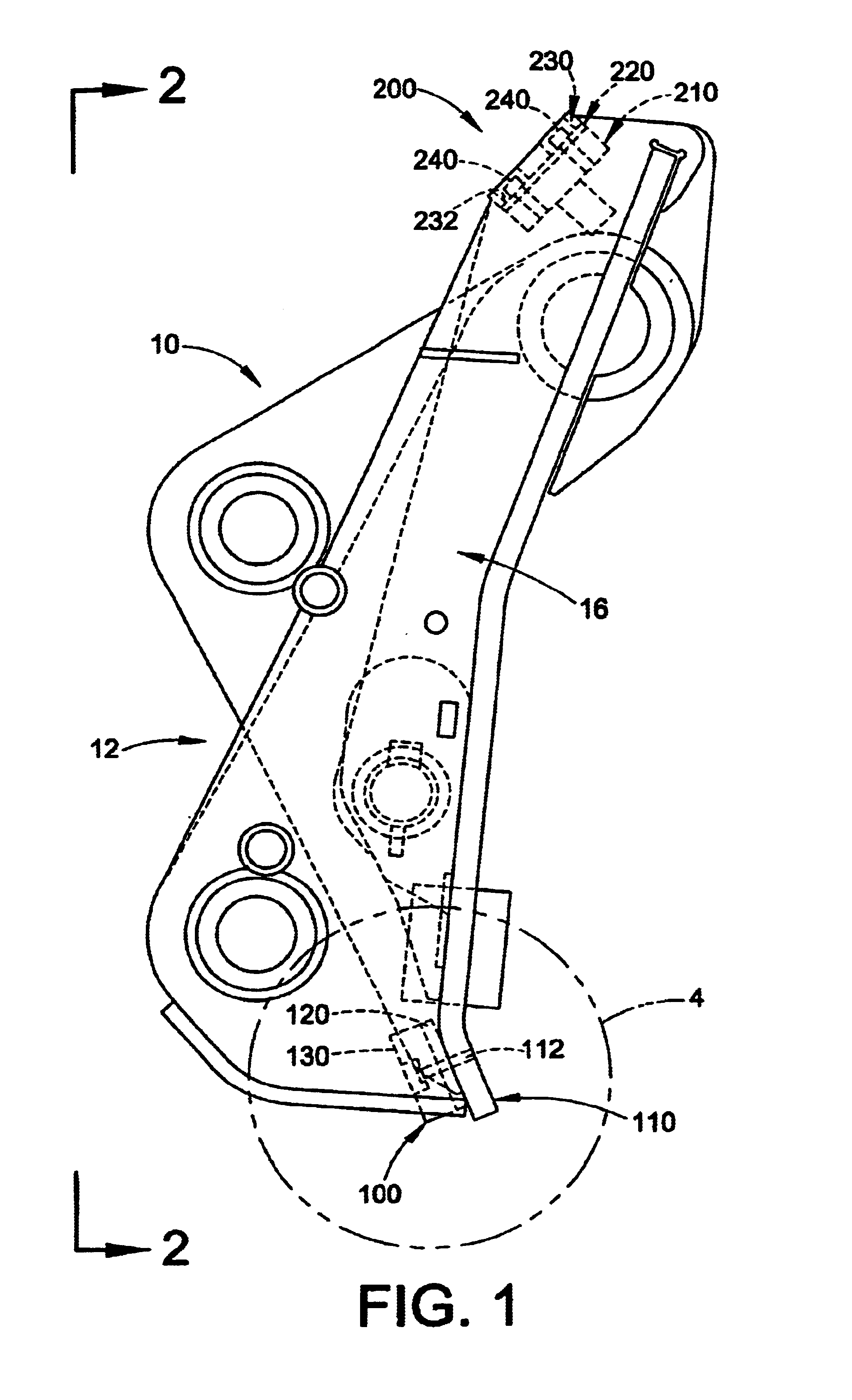

A combination loader and post cure tire inflator for use with a tire press is provided. A post cure inflator for inflating and curing vulcanized tires includes a plurality of inflator stations with each inflator station including a pair of axially aligned, vertically separable tire inflating chuck rings. A loading apparatus includes a loading arm movable along a linear track relative to the plurality of inflator stations to load and unload each vulcanized tire in a selected one of the plurality of inflator stations without rotating the vulcanized tires in a turnover operation.

Owner:MCNEIL & NRM

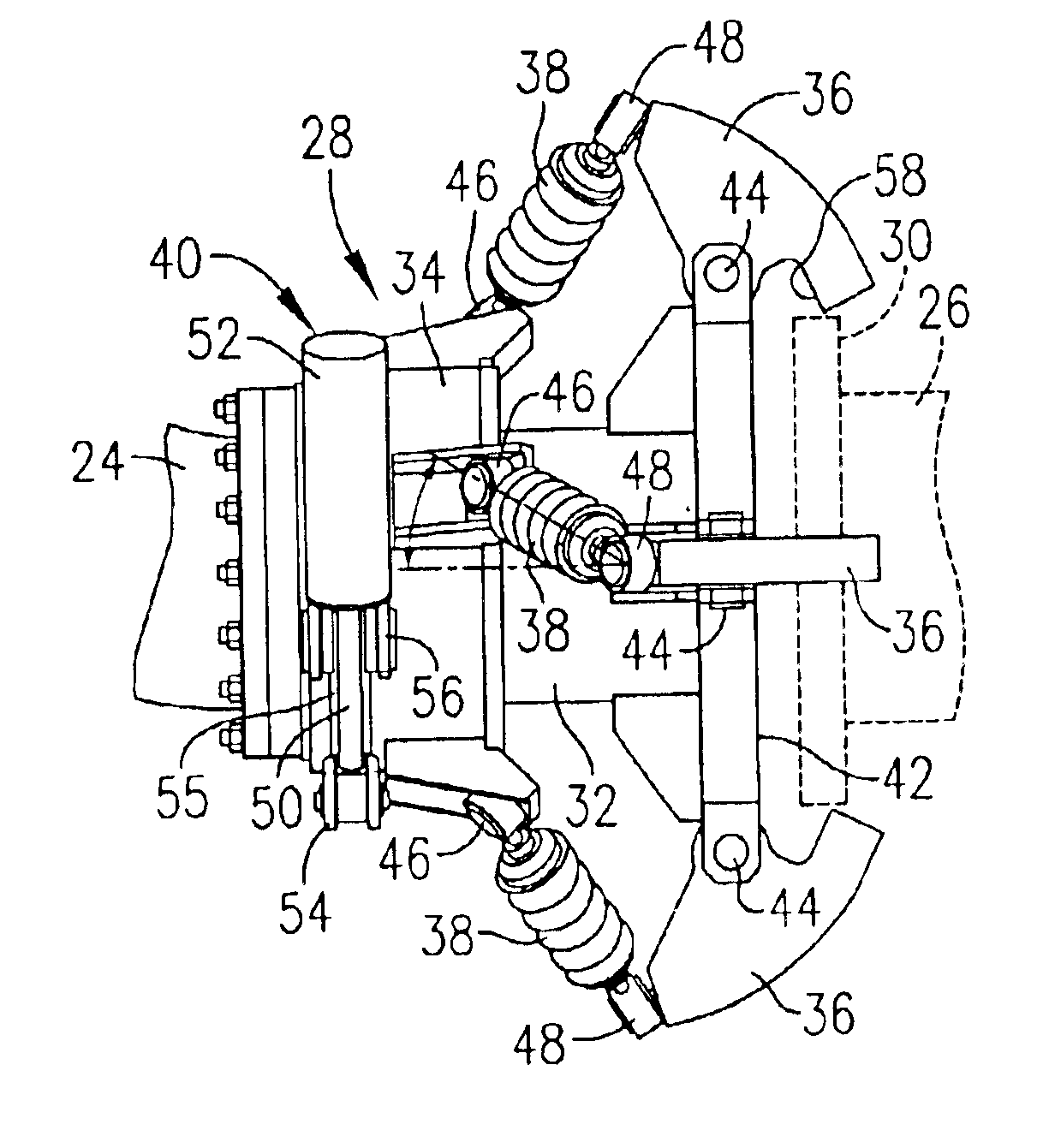

Loader coupler with adjustable dump and roll-back stops

A loader coupler includes first and second dump stops located on opposite lateral sides of the coupler and first and second roll-back stops located on opposite lateral sides of the coupler. Each of the dump and roll-back stops includes a base connected to or formed as a part of the coupler; at least one shim located adjacent the base; and, a cover releasably connected to the base and located adjacent the at least one shim. Accordingly, the at least one shim is located between the cover and the base. The outer face of the cover can be angled to ensure flush contact between it and an associated arm of a loader to which the coupler is connected. The adjustable stops are used by locating at least one shim adjacent the base and securing the a cover to the base member and adjacent the shim, with the shim located between the cover and the base member. Thereafter, it is determined if the cover contacts the associated loader arm in a desired stop position. If the cover does not contact the associated loader arm in the desired stop position, the position of the cover relative to the base is adjusted by changing the number of shims located between the cover and the base and / or changing the thickness of the shim. An angle of contact between an outer face of the cover and the associated loader arm can also be adjusted.

Owner:JRB ATTACHMENTS

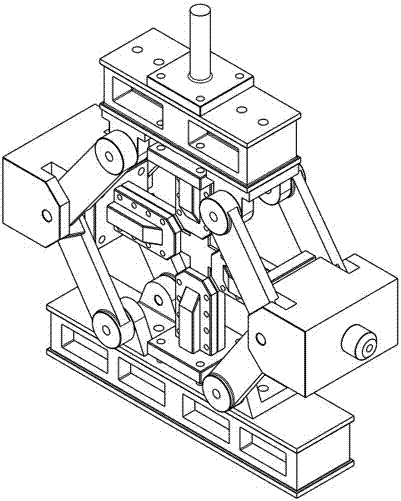

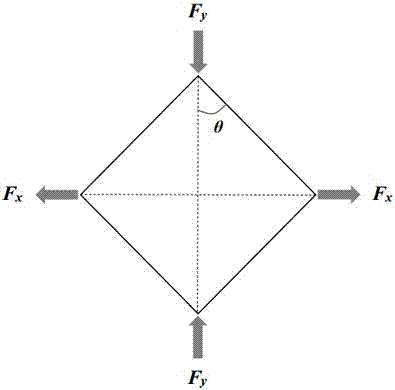

Device and method for biaxial pull-press loading test device of material

InactiveCN106932274AEasy to completeSimple structureMaterial strength using tensile/compressive forcesEngineeringLoading arm

The invention provides a device for a biaxial pull-press loading test device of a material. The device consists of a clamping end (1), a loading press block (2), four inclined loading arms (4-1, 4-2, 4-3 and 4-4), two eudipleural stretching supporting seats (5-1 and 5-2), four chucks (8-1, 8-2, 8-3 and 8-4) and a base (7), wherein the two adjacent inclined loading arms on the left side are connected with a stretching supporting seat (5-1), the two adjacent inclined loading arms on the right side are connected with a stretching supporting seat (5-2), the two stretching supporting seats (5-1 and 5-2) are eudipleural, the inclined loading arms are upward connected with the loading press block (2) through top hinged supports (3-1 and 3-2) and are downward connected with the base through bottom hinged supports (6-1 and 6-2); the four chucks (8-1, 8-2, 8-3 and 8-4) are separately arranged on the loading press block (2), the two stretching supporting seats (5-1 and 5-2) and the base (7). Compared with the prior art, the device disclosed by the invention has the advantages that the structure is simple and convenient to maintain; the device can be conveniently matched with an uniaxial testing machine to realize a biaxial pull-press loading test, so that the test cost is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

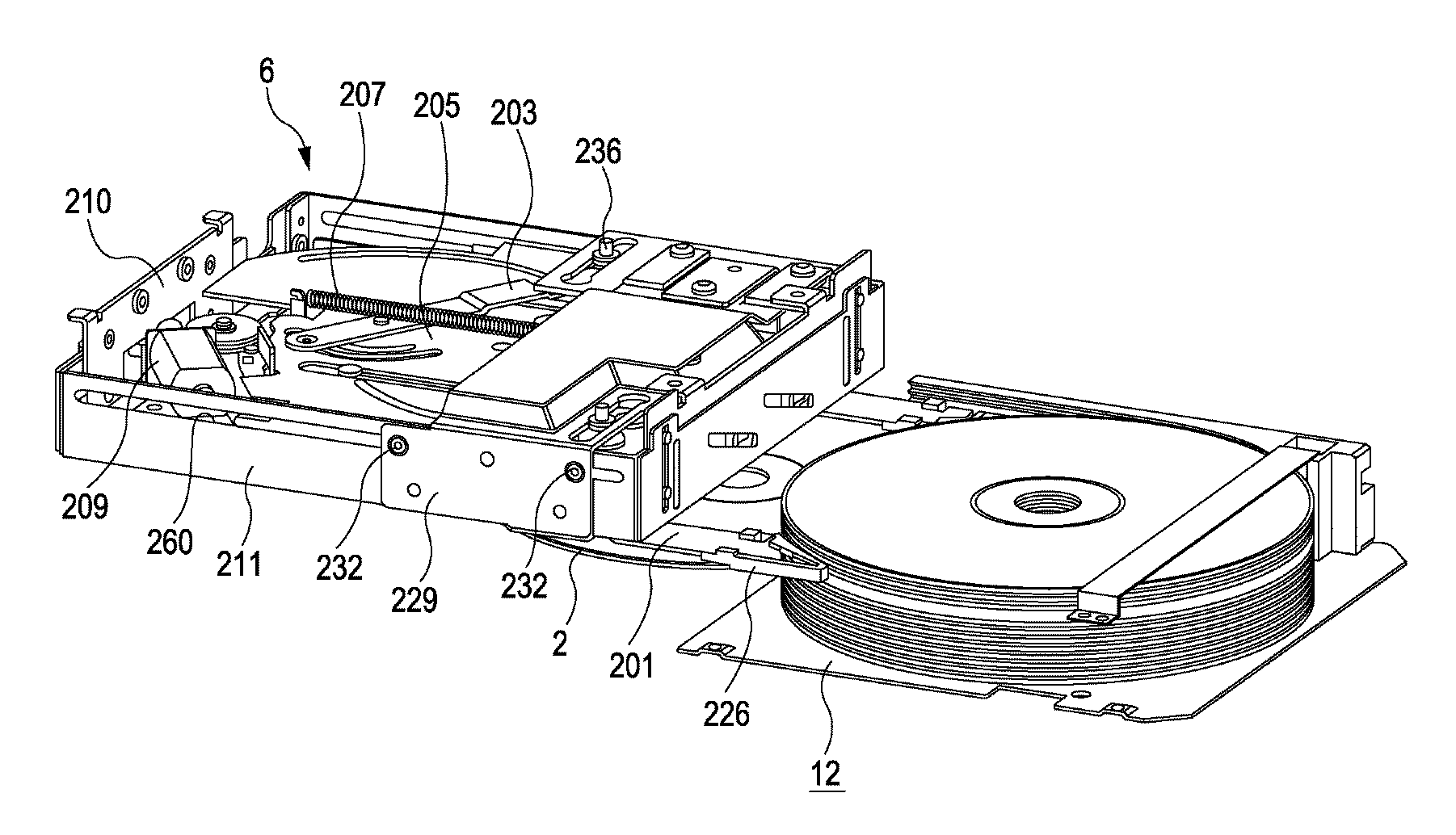

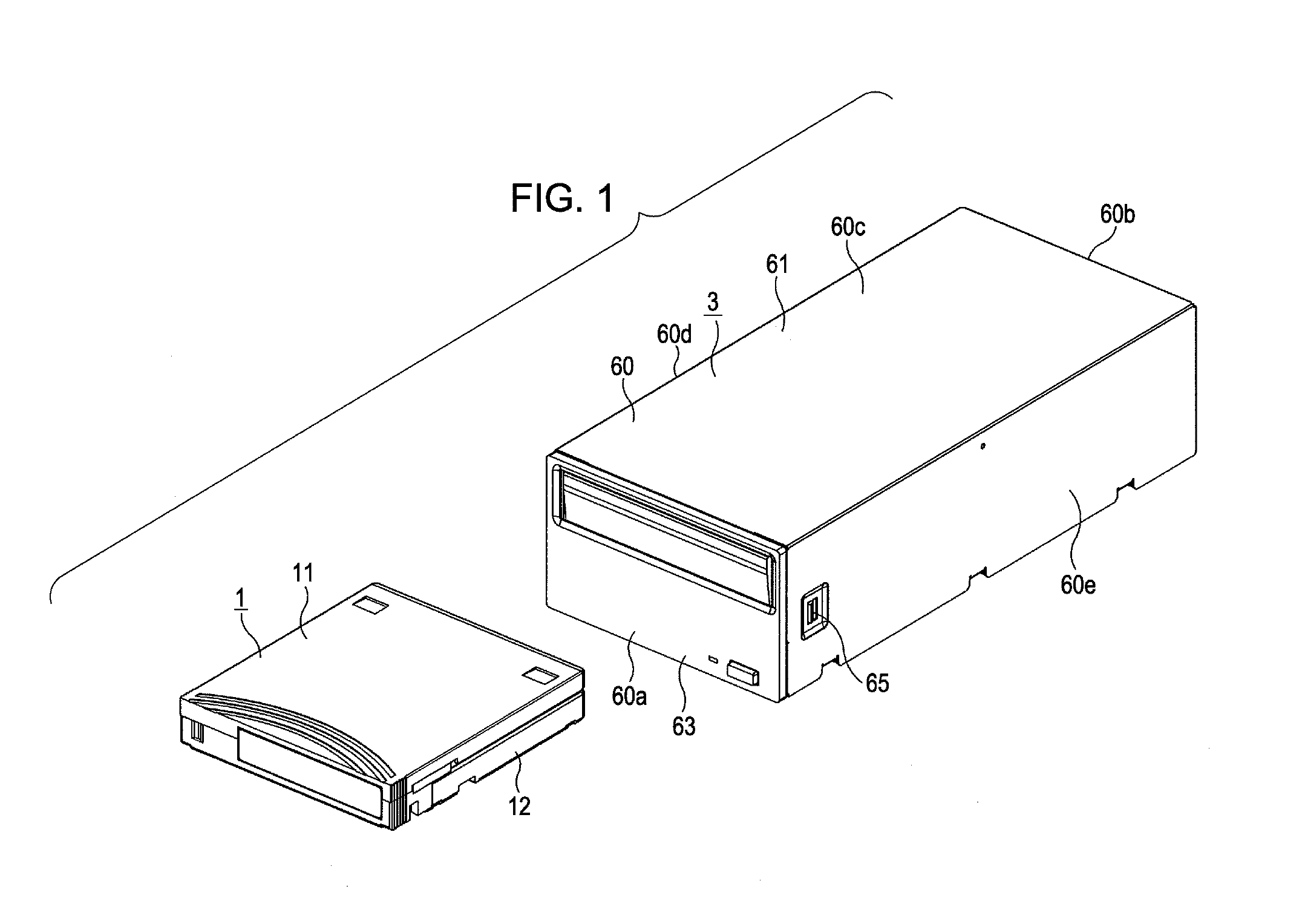

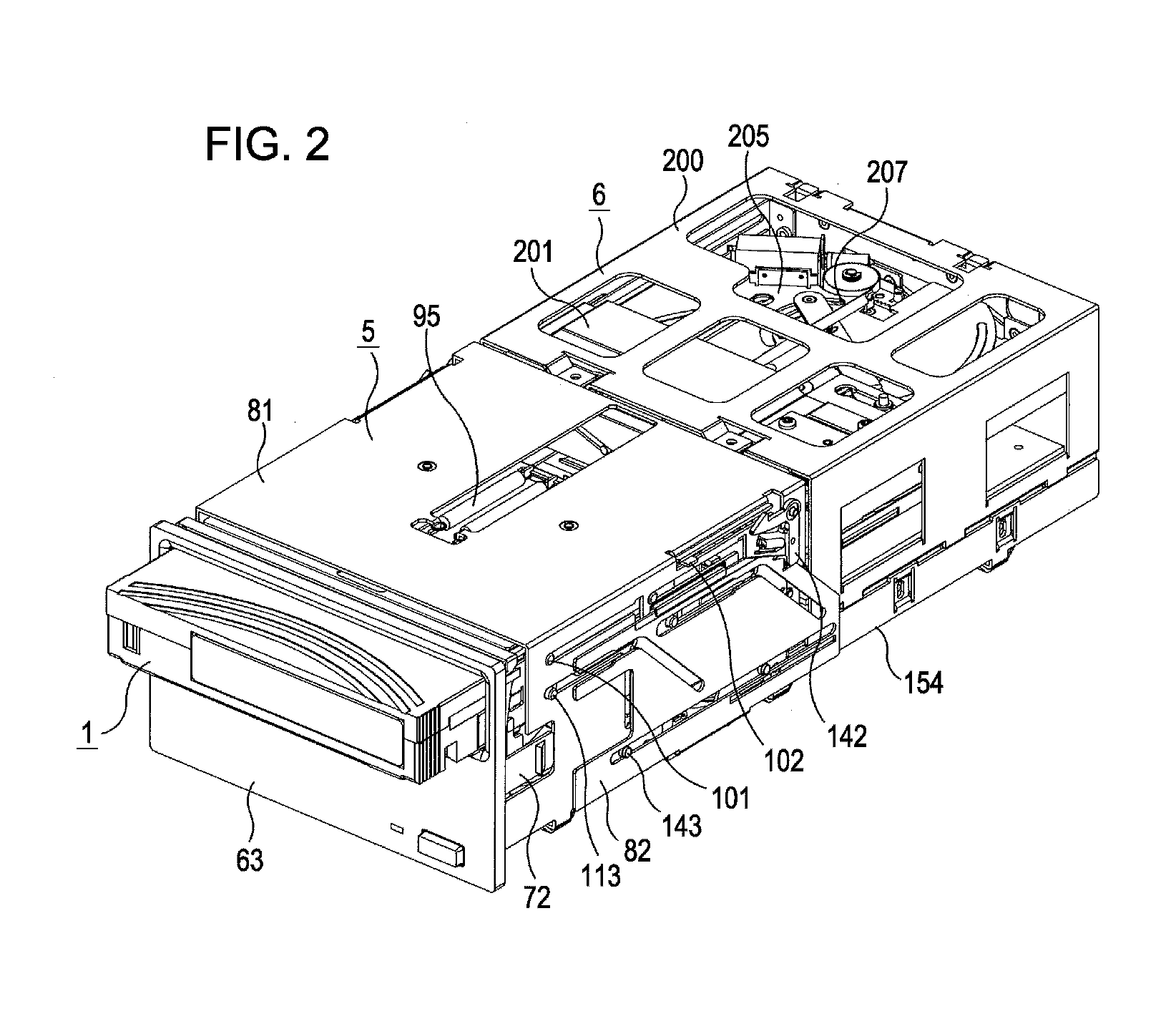

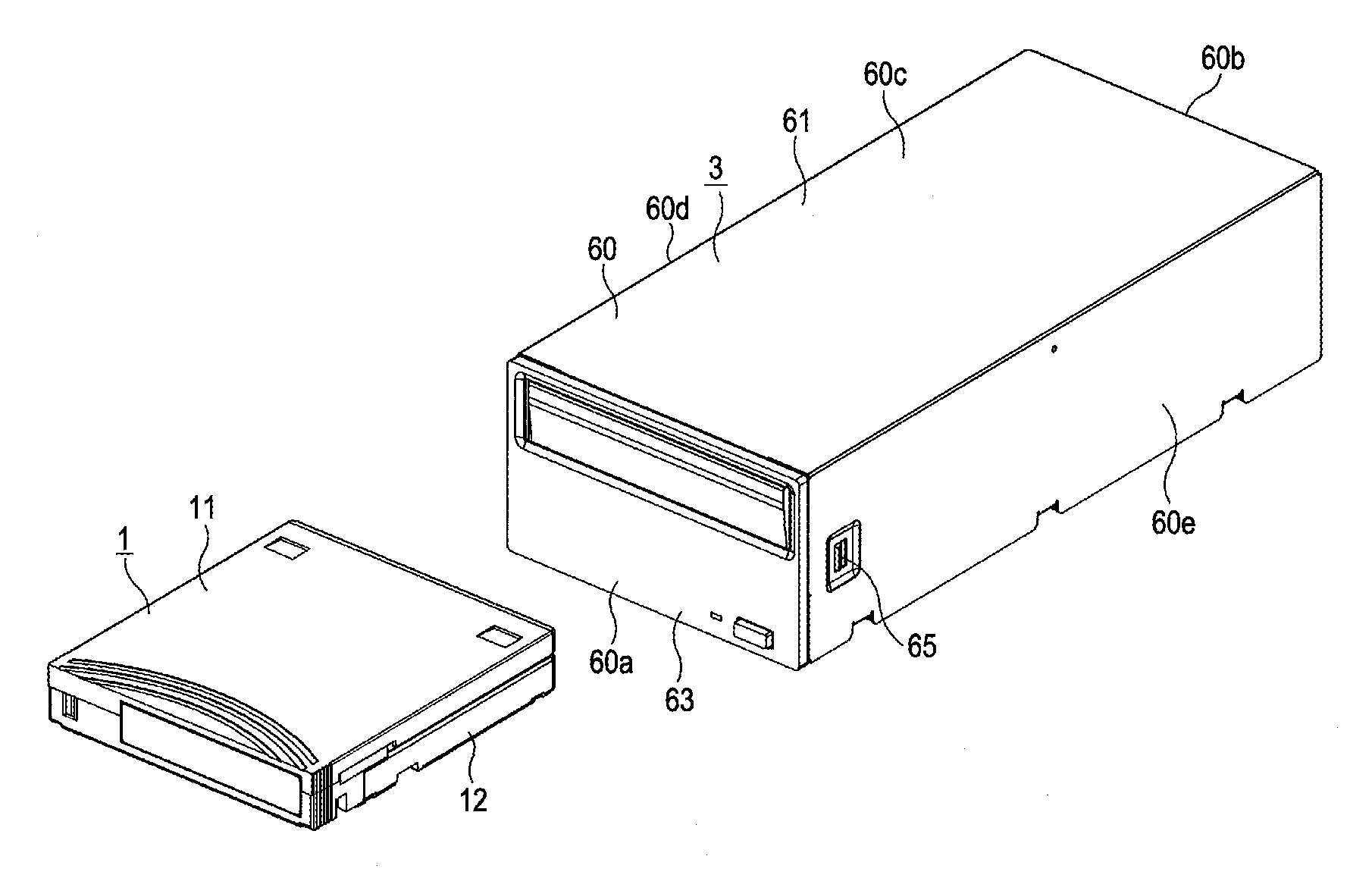

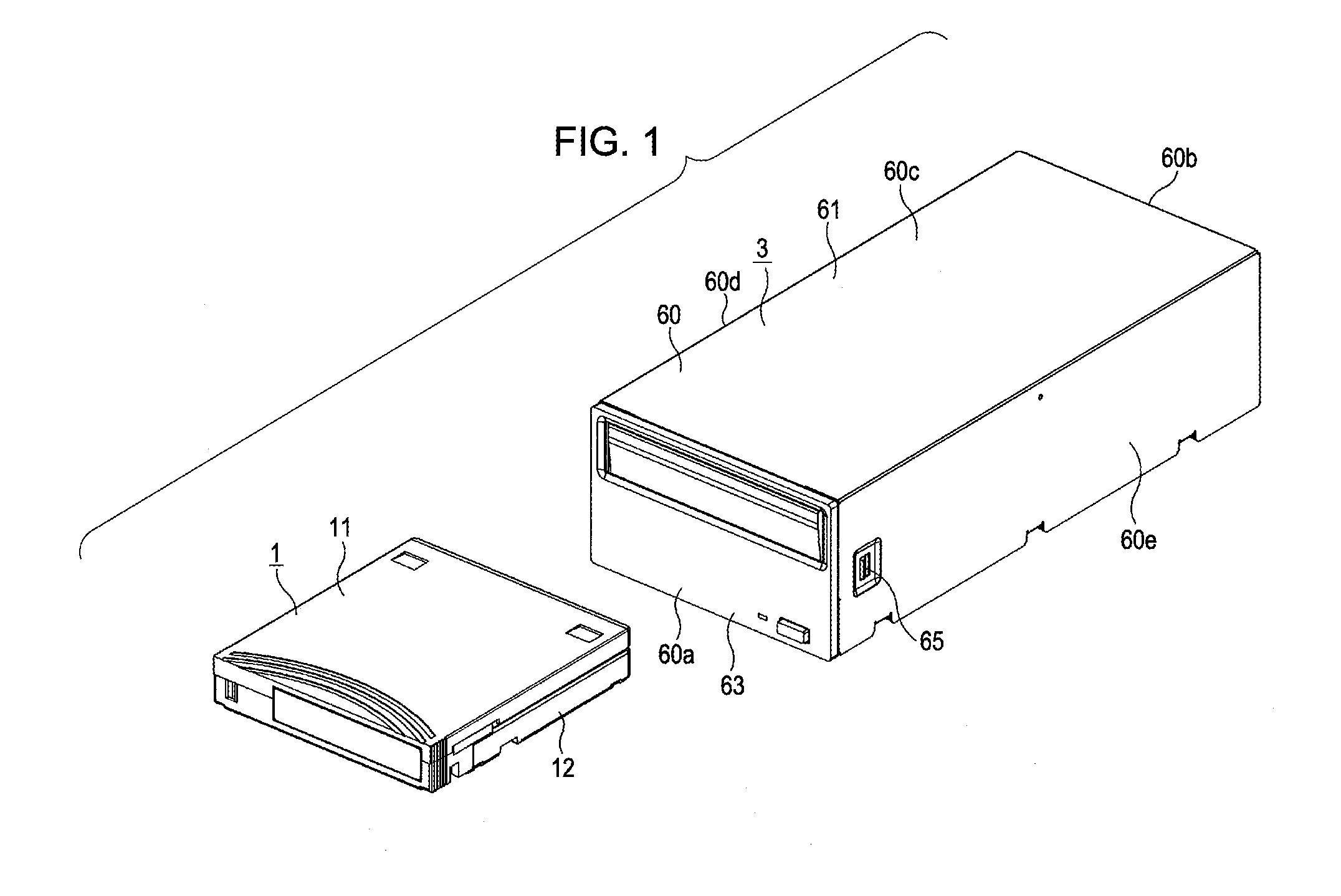

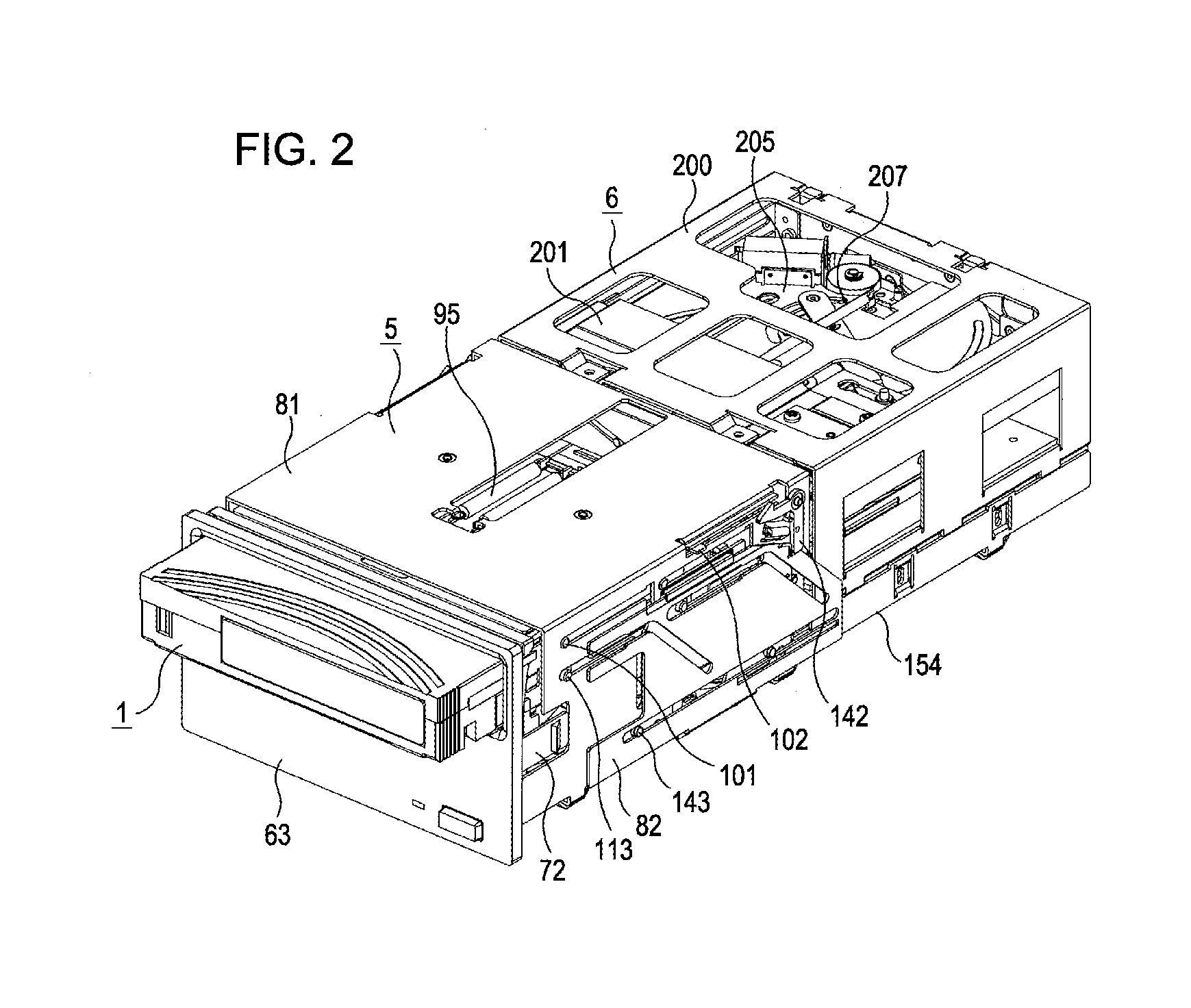

Mechanism to load disc from cartridge to recording apparatus

InactiveUS8281327B2Simple configurationRecord information storageRecord carrier contruction detailsEngineeringContact position

A disc loading mechanism transporting a disc between a disc cartridge and a recording and reproducing apparatus includes: a loading arm having at a leading end thereof claw members which comes into contact with an outer circumference of the disc and performs drawing of the disc into the recording and reproducing apparatus and insertion of the disc into the disc cartridge; an arm driving mechanism which slides the loading arm in a disc transport direction; a disc extruding lever which extrudes the disc up to a contact position with the claw members when discharging the disc; and a lever driving mechanism which drives the extrusion lever, wherein each of the claw members includes a draw-in surface portion and an insertion surface portion provided at the opposite side to the draw-in surface portion.

Owner:SONY CORP

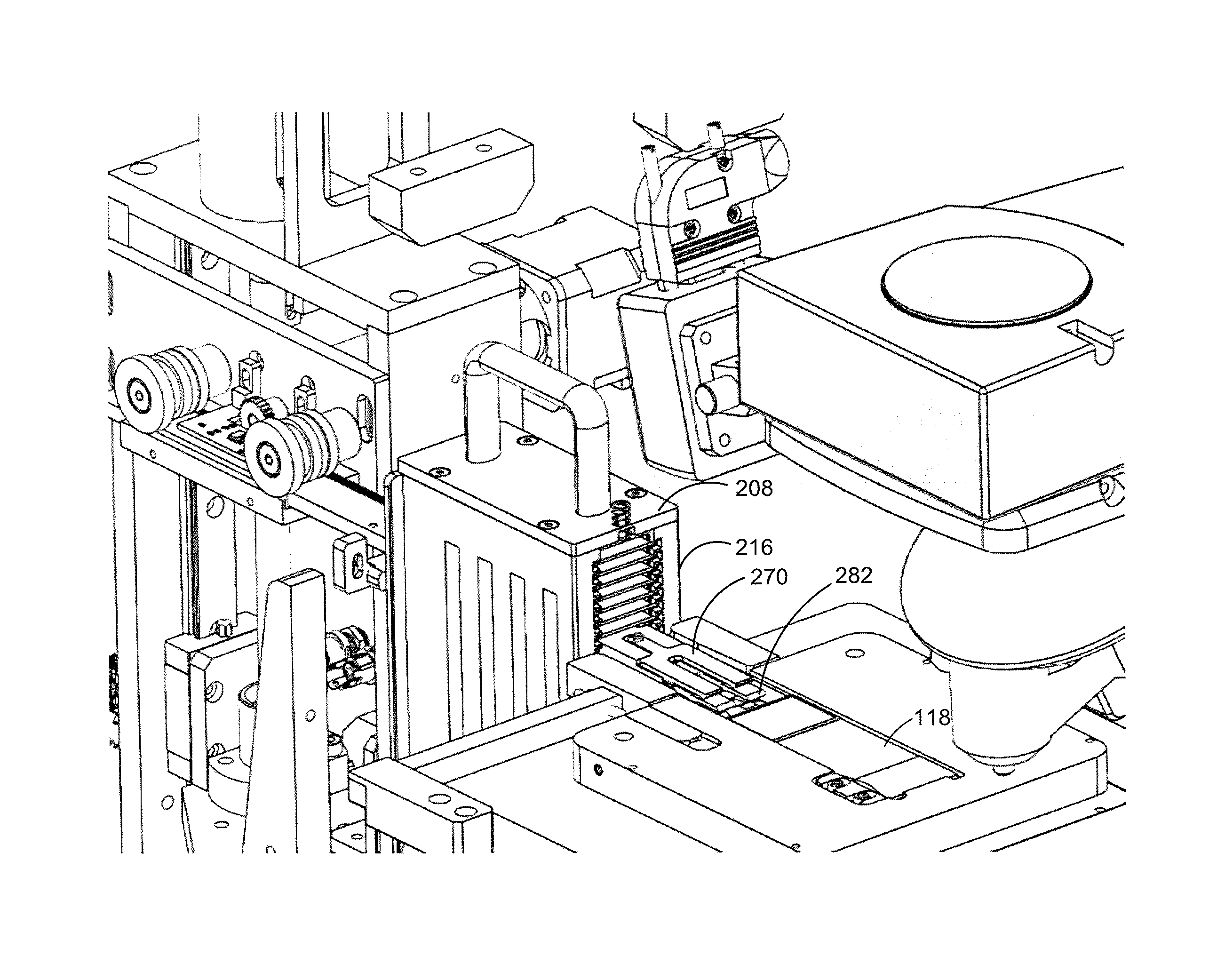

Specimen centrifuge apparatus

ActiveUS7112303B2Specific gravity using centrifugal effectsMaterial analysis by optical meansEngineeringLoading arm

A specimen centrifuge apparatus includes a specimen container carry-in system and a specimen container carry-out system. The specimen container carry-in system has a specimen container carry-in conveyor for loading pre-processed specimen containers into specimen centrifuge units stacked one on another in a centrifuge device, a carry-in elevator, a carry-in transfer arm, and a loading arm. The specimen container carry-out system has a specimen container carry-out conveyor for unloading the processed specimen containers from the specimen centrifuges, a carry-out elevator, a carry-out transfer arm, and an unloading arm.

Owner:IDS CO LTD

Disc loading mechanism

InactiveUS20110119691A1Simple configurationRecord information storageRecord carrier contruction detailsCompact discLoading arm

A disc loading mechanism transporting a disc between a disc cartridge and a recording and reproducing apparatus includes: a loading arm having at a leading end thereof claw members which comes into contact with an outer circumference of the disc and performs drawing of the disc into the recording and reproducing apparatus and insertion of the disc into the disc cartridge; an arm driving mechanism which slides the loading arm in a disc transport direction; a disc extruding lever which extrudes the disc up to a contact position with the claw members when discharging the disc; and a lever driving mechanism which drives the extrusion lever, wherein each of the claw members includes a draw-in surface portion and an insertion surface portion provided at the opposite side to the draw-in surface portion.

Owner:SONY CORP

Impact loading mechanism

InactiveCN102156081AImprove applicabilityGuaranteed continuous gradientMaterial strength using repeated/pulsating forcesBall bearingThrust bearing

The invention relates to an impact loading mechanism comprising two sets of bracket arms, two bracket arm splints, an installation barrel, a seal cover, two sets of thrust force bearings, two sets of movable loading cones, a threaded sleeve, a spline shaft, two flange splines, two loading arms, two rod end joint ball bearings, two support columns, two impact loading rods and a joint ball bearing.The impact loading mechanism can convert the torque of the load input end of the spline shaft into the thrust force of the movable loading cones and apply the thrust force of the movable loading cones to the impact loading rods, and the impact loading mechanism can directly apply the thrust force or pull force of the load input end of the spline shaft to the impact loading rods through the first loading arm. Because mobile blocks on the movable loading cones can be movable or static, the distance between two loading points on a single impact loading rod can change along with time or keep unchanged. Thus, the dynamic synchronous multi-point movement simulation impact loading of the impact loading rods can be realized, and random dynamic or static shearing force and torque can be obtained at the roots of the impact loading rods.

Owner:BEIHANG UNIV

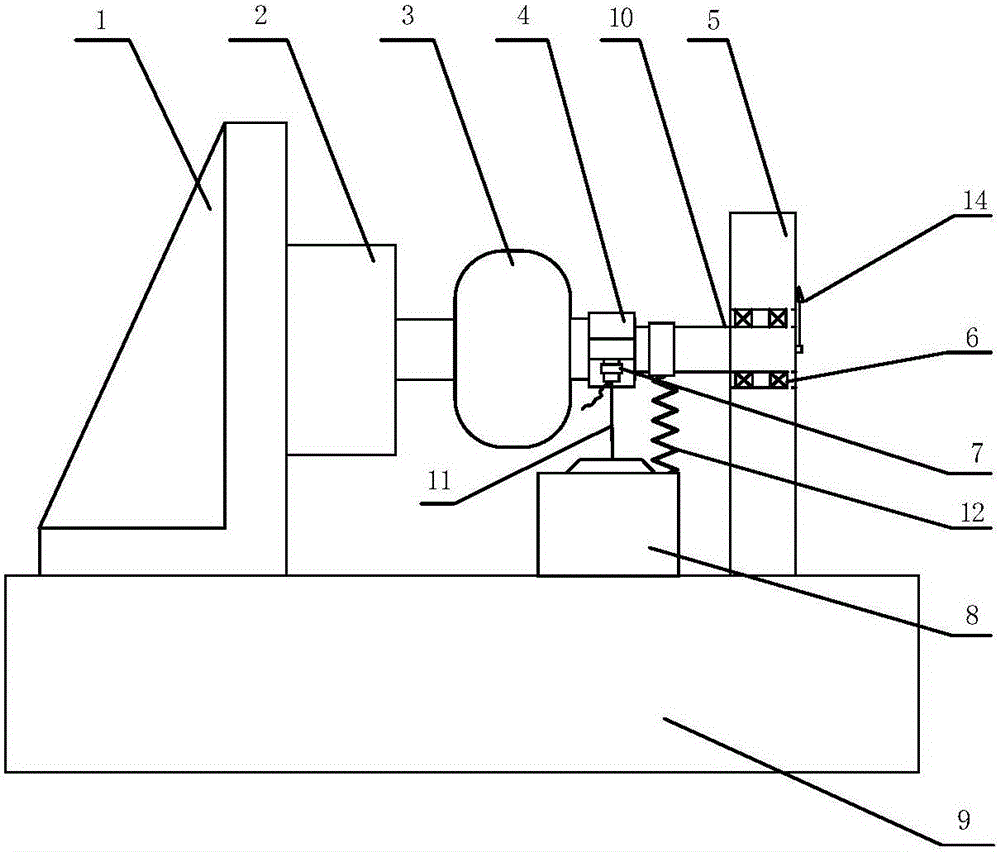

Elastic coupling dynamic and static torsion rigidity simple testing device and method

ActiveCN106052983AAvoid Bending-Torsion CouplingEasy to install and adjustElasticity measurementTurn angleCoupling

The invention provides an elastic coupling dynamic and static torsion rigidity simple testing device and method. One end of an elastic coupling is fixed, and a loading arm and a torque preloading device are arranged on the other end. The torque preloading device is used to preload torque of a certain degree, a turning angle indicating gauge measures a static angular displacement of the coupling, a preload force is converted into preload static torque, and the static torsion rigidity of the coupling is obtained; and the loading arm is excited by a vibration exciter, an impedance head is utilized to measure the dynamic force and dynamic acceleration of an excited point of the loading arm, the force and acceleration are converted into the torque and dynamic angular displacement, and finally the dynamic torsion rigidity of the coupling is obtained. According to the invention, a special test table is not needed, the installation and adjustment are convenient, both the static torsion rigidity and the dynamic torsion rigidity can be measured, the vibration exciter is used for dynamic loading, the exciting frequency and amplitude can be conveniently adjusted on line, and the torsion rigidity under different working frequencies can be conveniently tested; in addition, dual-bearing constraint is adopted, bending-torsional coupling generated when the coupling is excited is avoided, and the measuring result is more precise.

Owner:HARBIN ENG UNIV

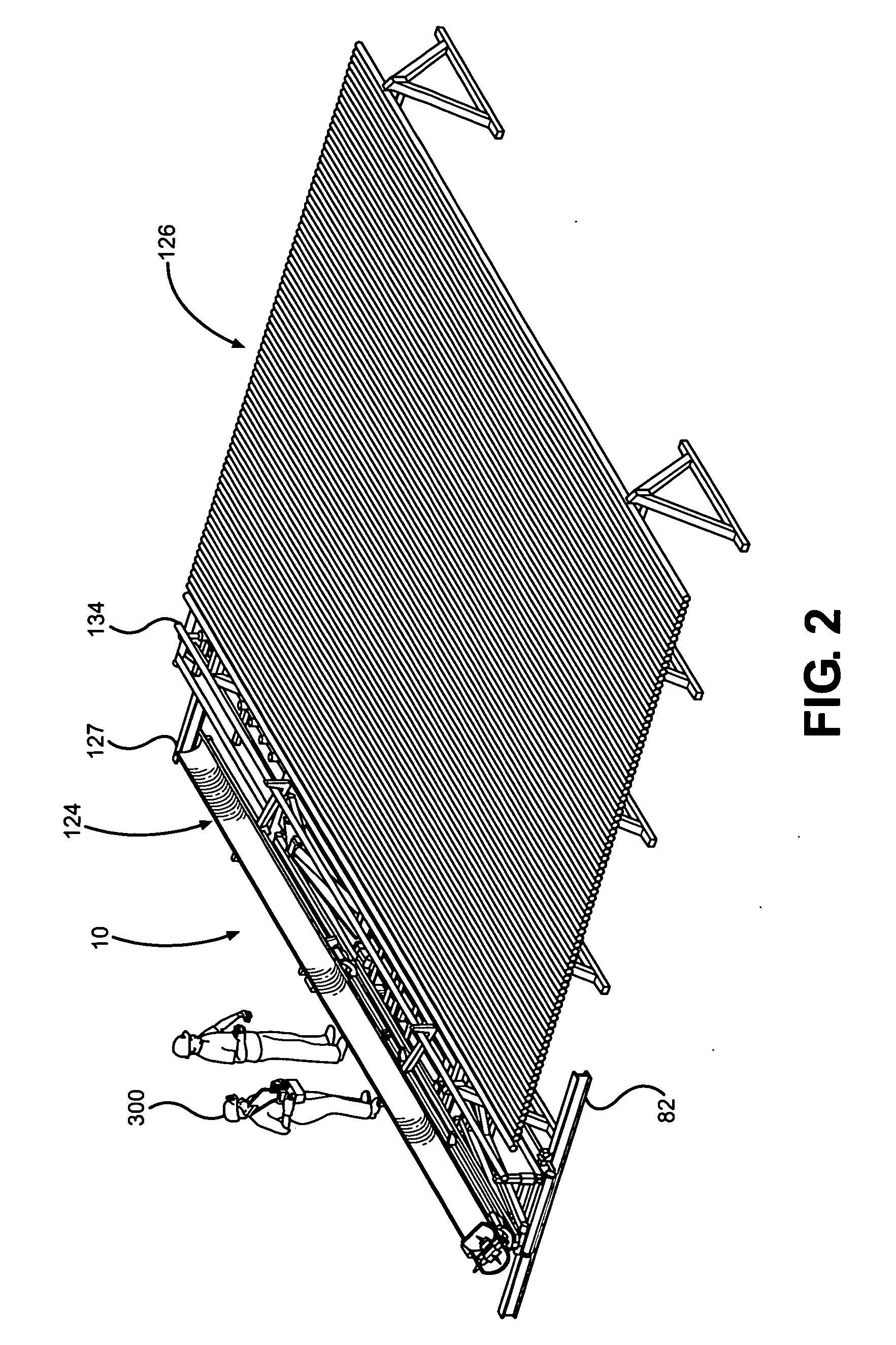

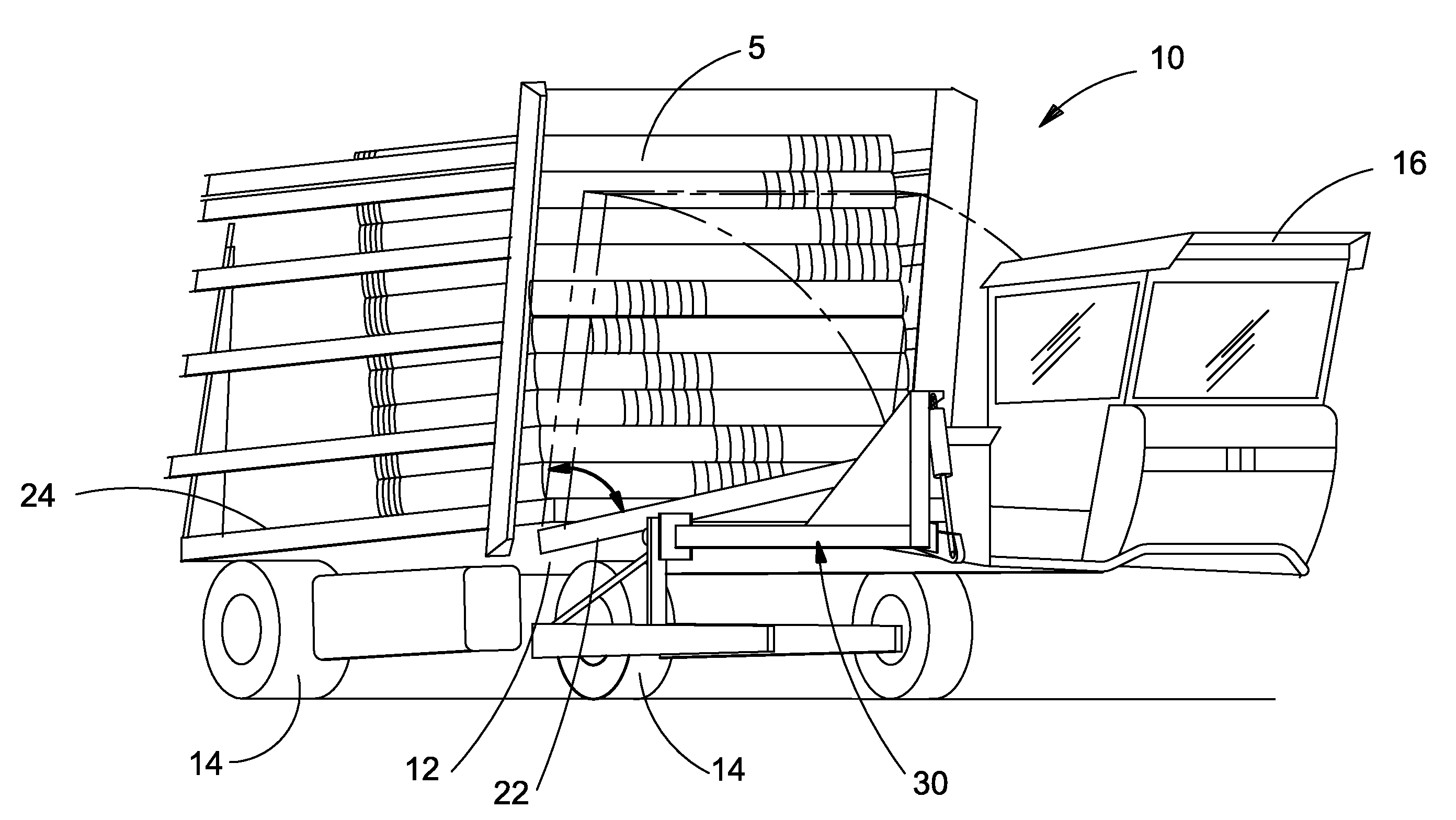

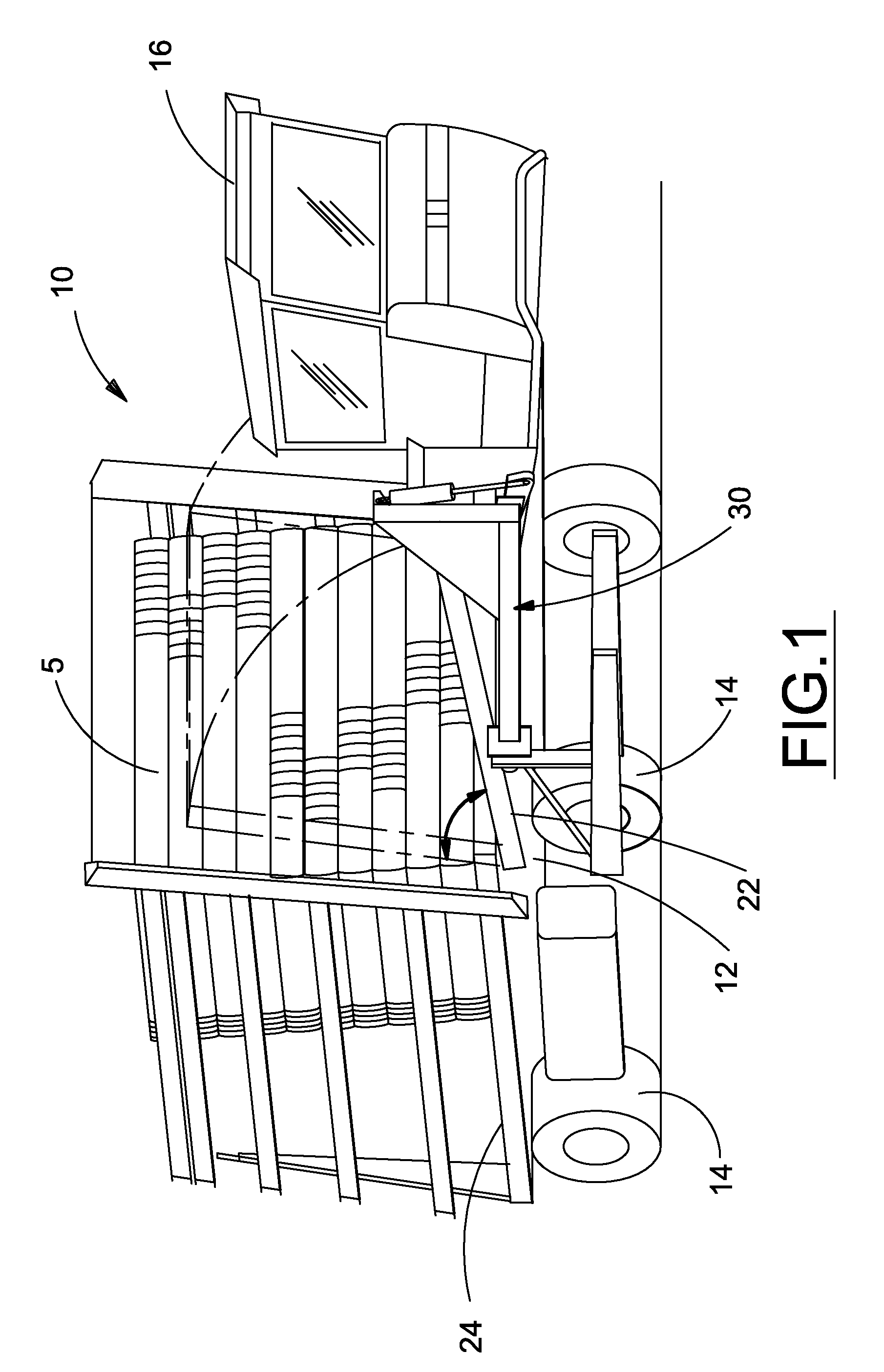

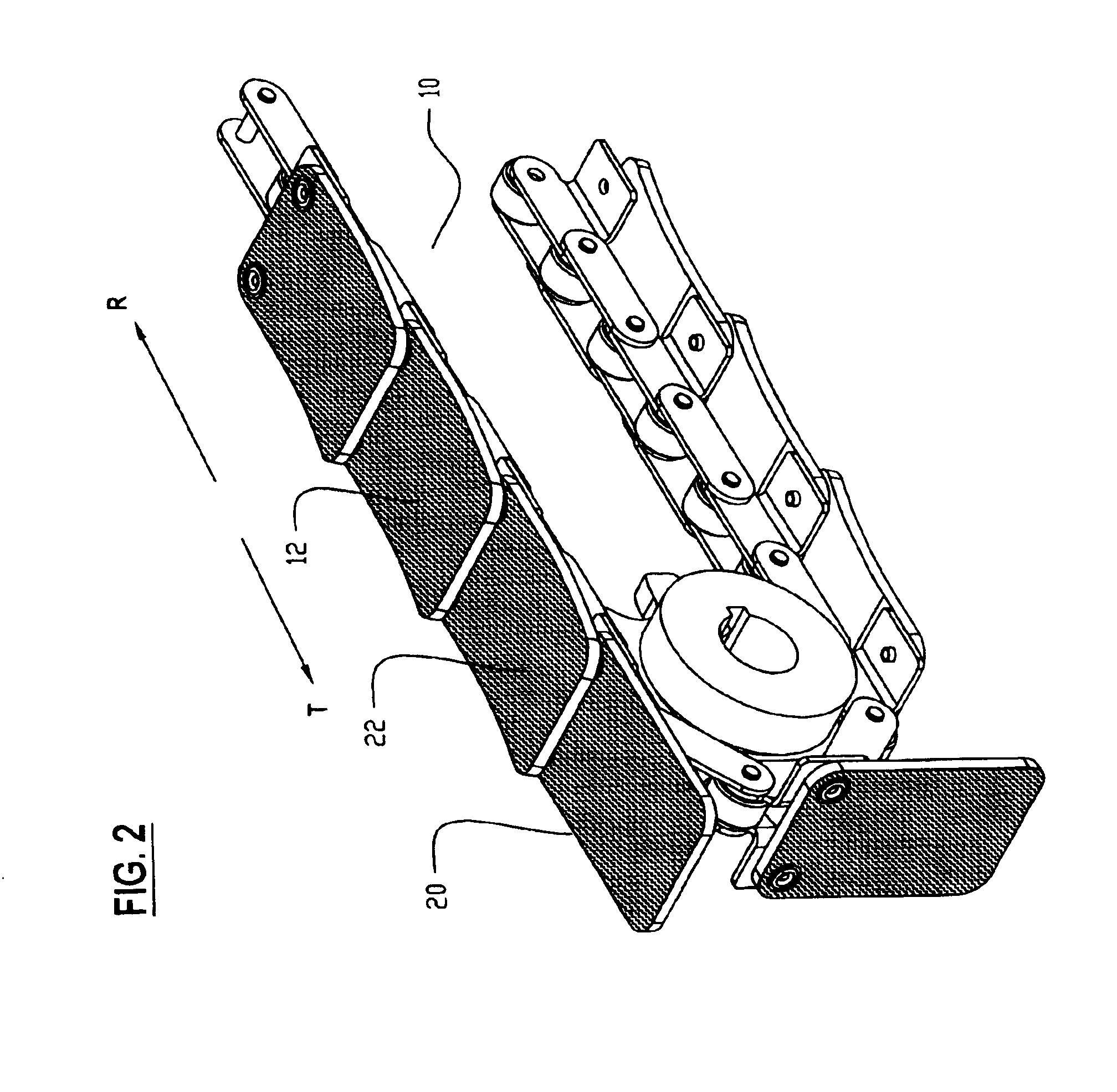

Automatic control of a large bale loading apparatus

A control system for managing rotation of a bale loading arm in a bale loader in which a pair of sensors combined with a purposefully designed sensor target enable loading arm position to be efficiently derived by a controller in order to direct the actuator movements based upon loading arm position necessary for automated operation of a bale loading cycle. Additional inputs to the controller enable initiation of a bale loading cycle to be automatically initiated. The controller may also determine when a complete bale wagon load is achieved and automatically direct loading arm motions necessary to configure the bale wagon for transport.

Owner:BLUE LEAF I P INC

Dustproof performance simulation test machine for automobile hub bearing unit

The invention discloses a dustproof performance simulation test machine for an automobile hub bearing unit, wherein automobile hub bearings mainly are third-generation in China, and the traditional dustproof performance test machine is incapable of simulating the sealing dustproof working conditions during an actual vehicle running process. The dustproof performance simulation test machine disclosed by the invention comprises a drive mechanism, a transmission mechanism, a loading mechanism, a dust box component, a fan component, a control system and a test component, wherein a main shaft is driven by the drive mechanism, and a buffering shaft is fixed with the main shaft; the piston of an axial loading oil cylinder is fixed with a first knuckle bearing by virtue of a first tension and pressure sensor; the first knuckle bearing is hinged with a first joint sleeve by virtue of a pin shaft; the first joint sleeve and a loading arm are fixed with a load loading plate, the loading arm is fixed with a second joint sleeve, and the second joint sleeve is hinged with a second knuckle bearing by virtue of a pin shaft; one end of a second tension and pressure sensor is fixed with the second knuckle bearing, and the other end of the second tension and pressure sensor is fixed with the piston of a radial loading oil cylinder. The dustproof performance simulation test machine disclosed by the invention is suitable for various automobile hub bearings, and capable of simulating the complex loaded conditions of the hub bearings.

Owner:HANGZHOU DIANZI UNIV

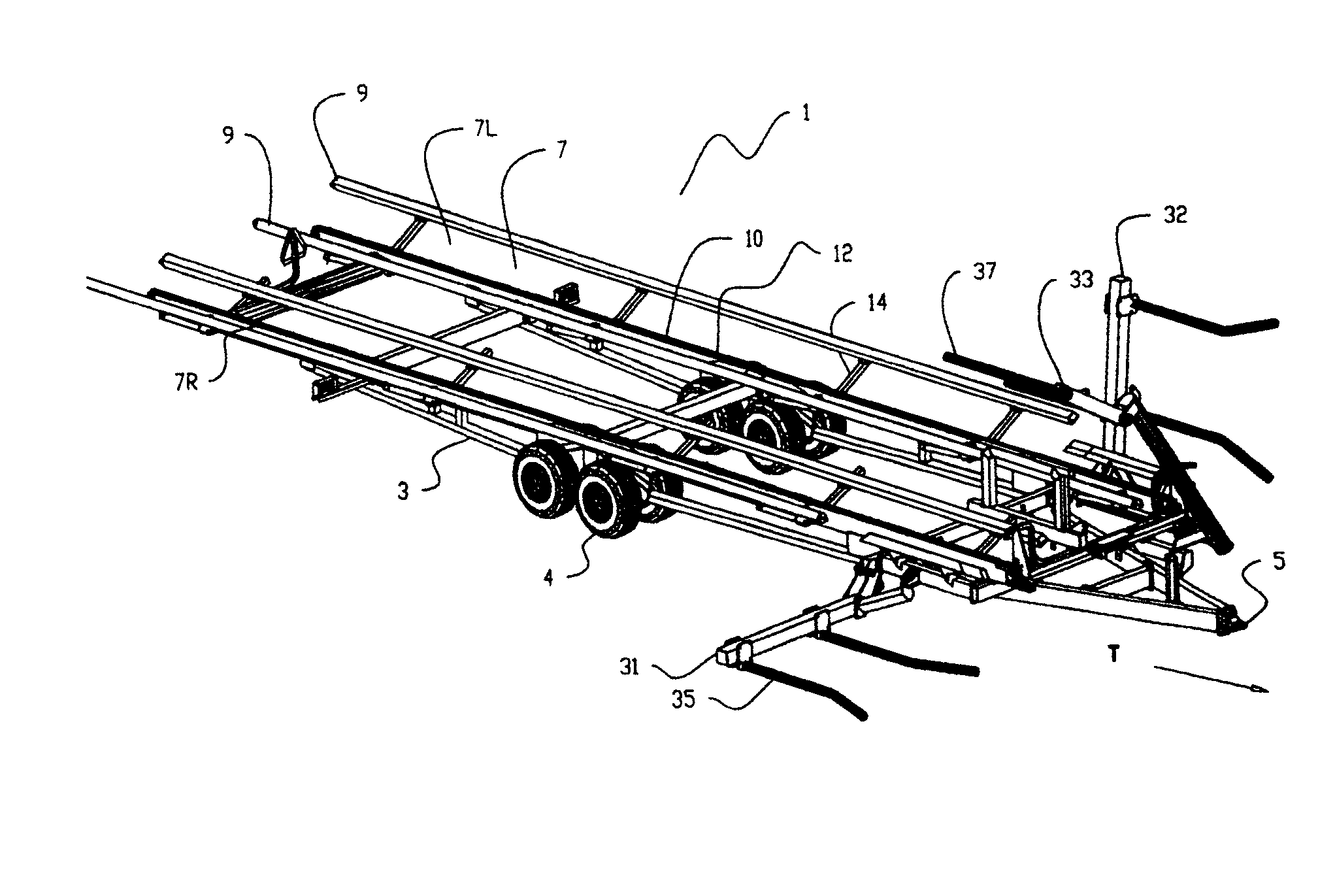

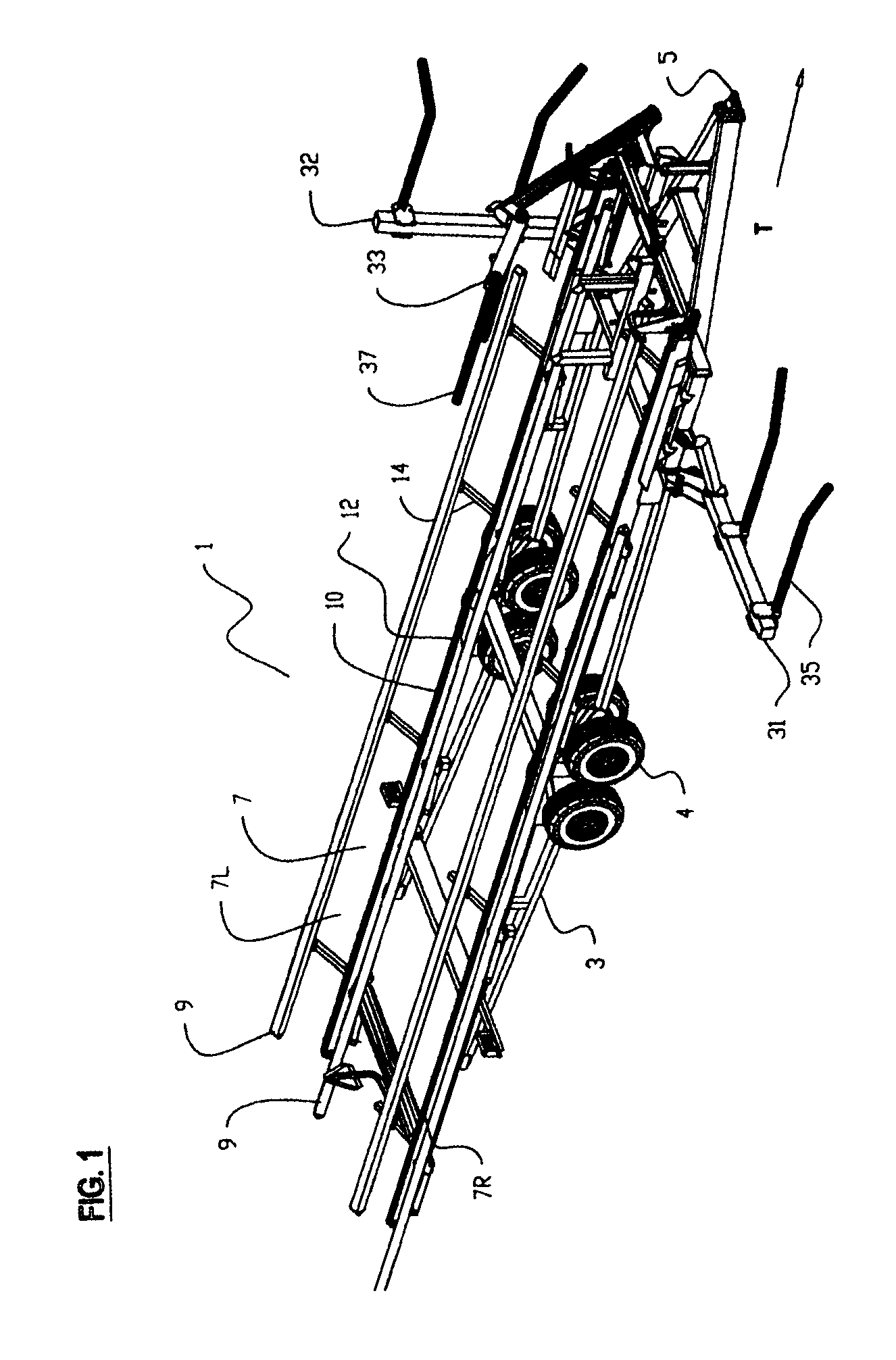

Round bale trailer

InactiveUS6935827B2Reduce harmCheap manufacturingVehicle with pivoted armsLoadersEngineeringLoading arm

A trailer for transporting cylindrical bales comprises a pair of rails and a conveyor chain located between and below the rails such that a bale is maintained in position on the conveyor chain by the rails. The load engaging face of the conveyor chain comprises a plurality of resilient pads having a roughened surface to increase friction between the pads and the bale without protruding into the bale. The load engaging face can slide with respect to the bale. First and second loading arms are operative to raise first and second bales onto corresponding conveyors. A third loading arm raises the first bale from the first conveyor to allow the first loading arm to raise a third bale from the ground and position it on the first conveyor, and then lowers the first bale to rest on the second and third bales.

Owner:BOURGAULT INDS

Pipe handling apparatus and method

ActiveUS8899901B2Promote sportsDrilling rodsSemiconductor/solid-state device manufacturingEngineeringLoading arm

Owner:AXIS ENERGY SERVICES LLC

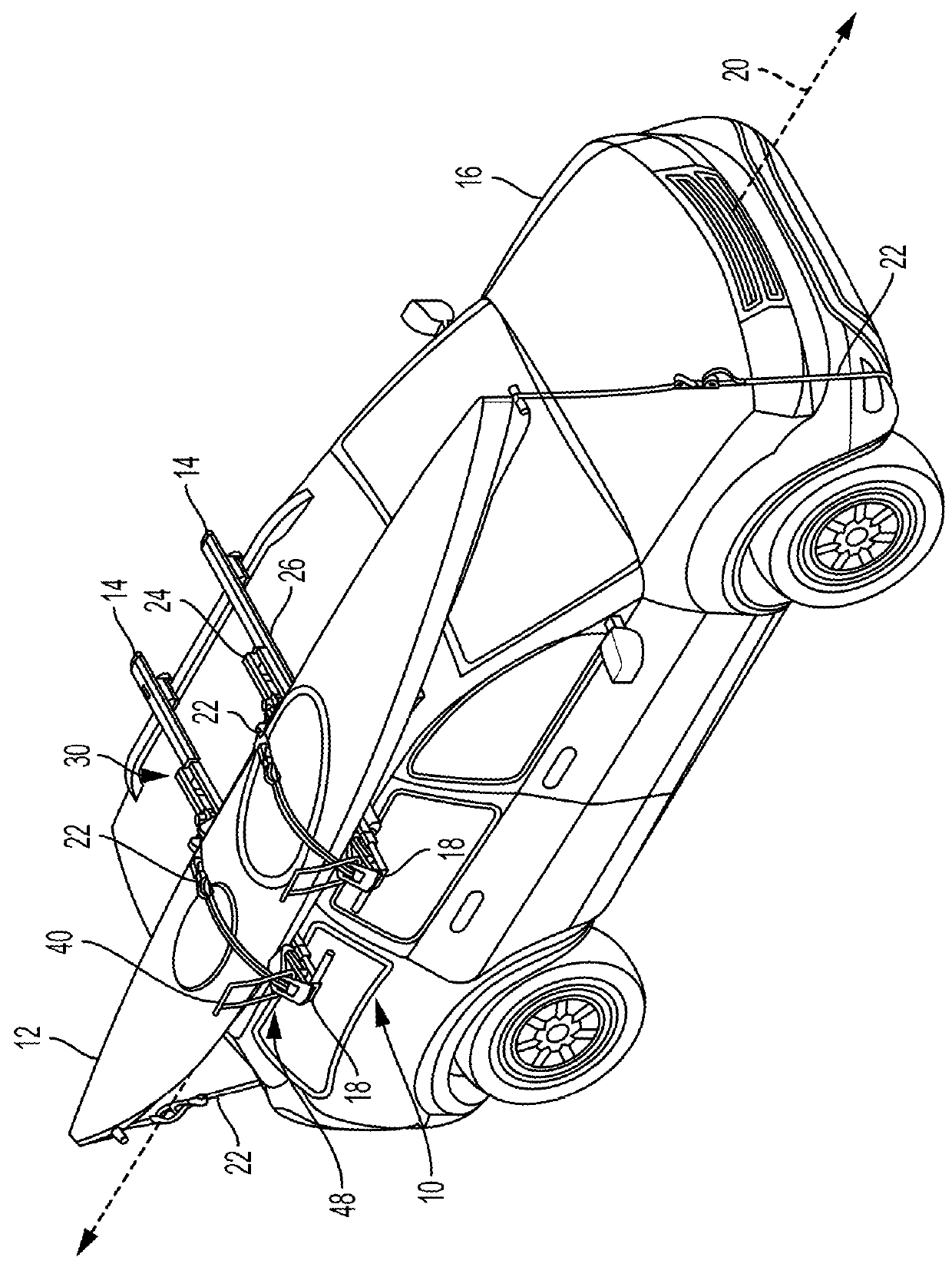

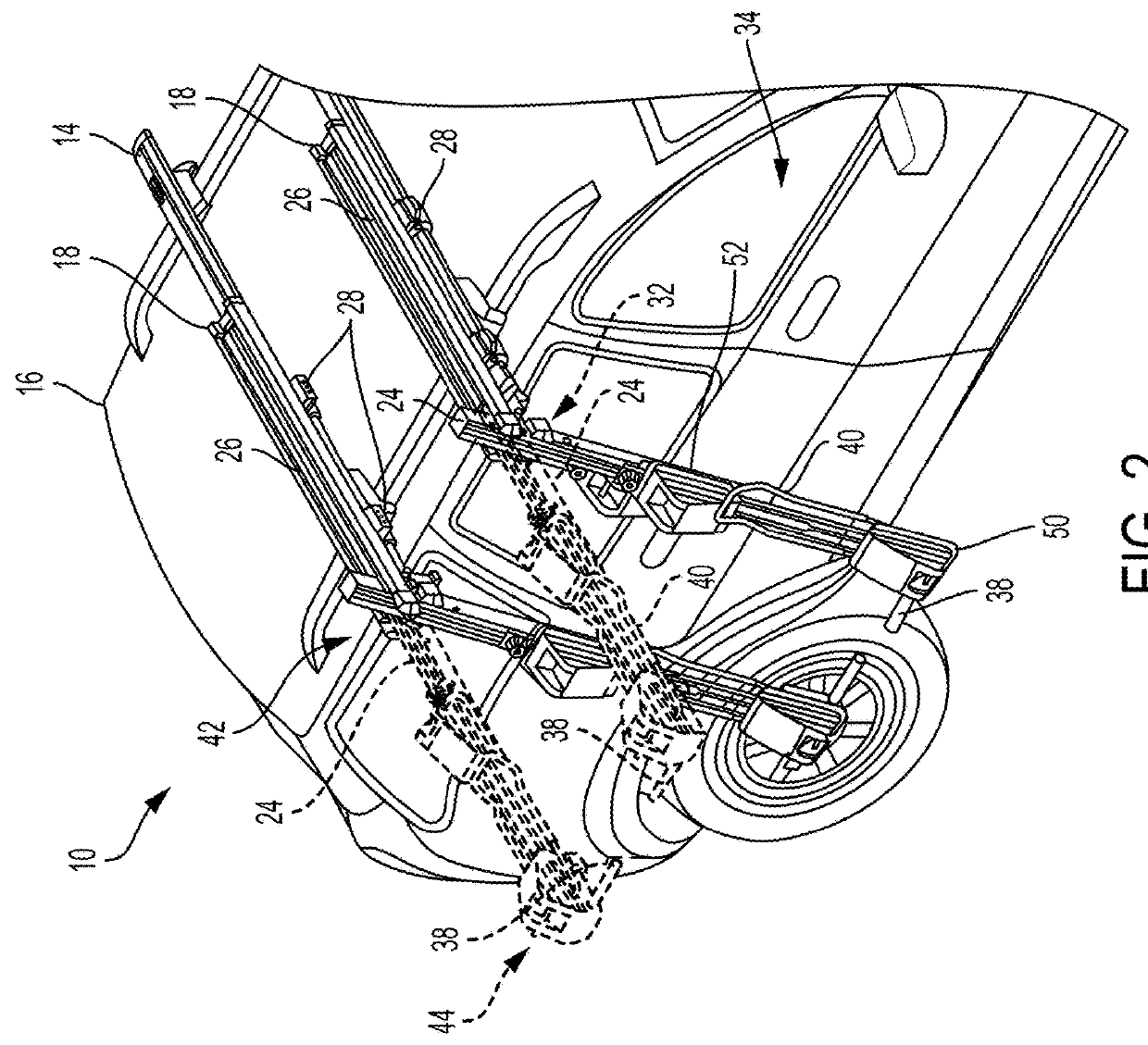

Vehicle rack with loading apparatus

ActiveUS20180162288A1Assist in loadingSupplementary fittingsItem transportation vehiclesVehicle frameEngineering

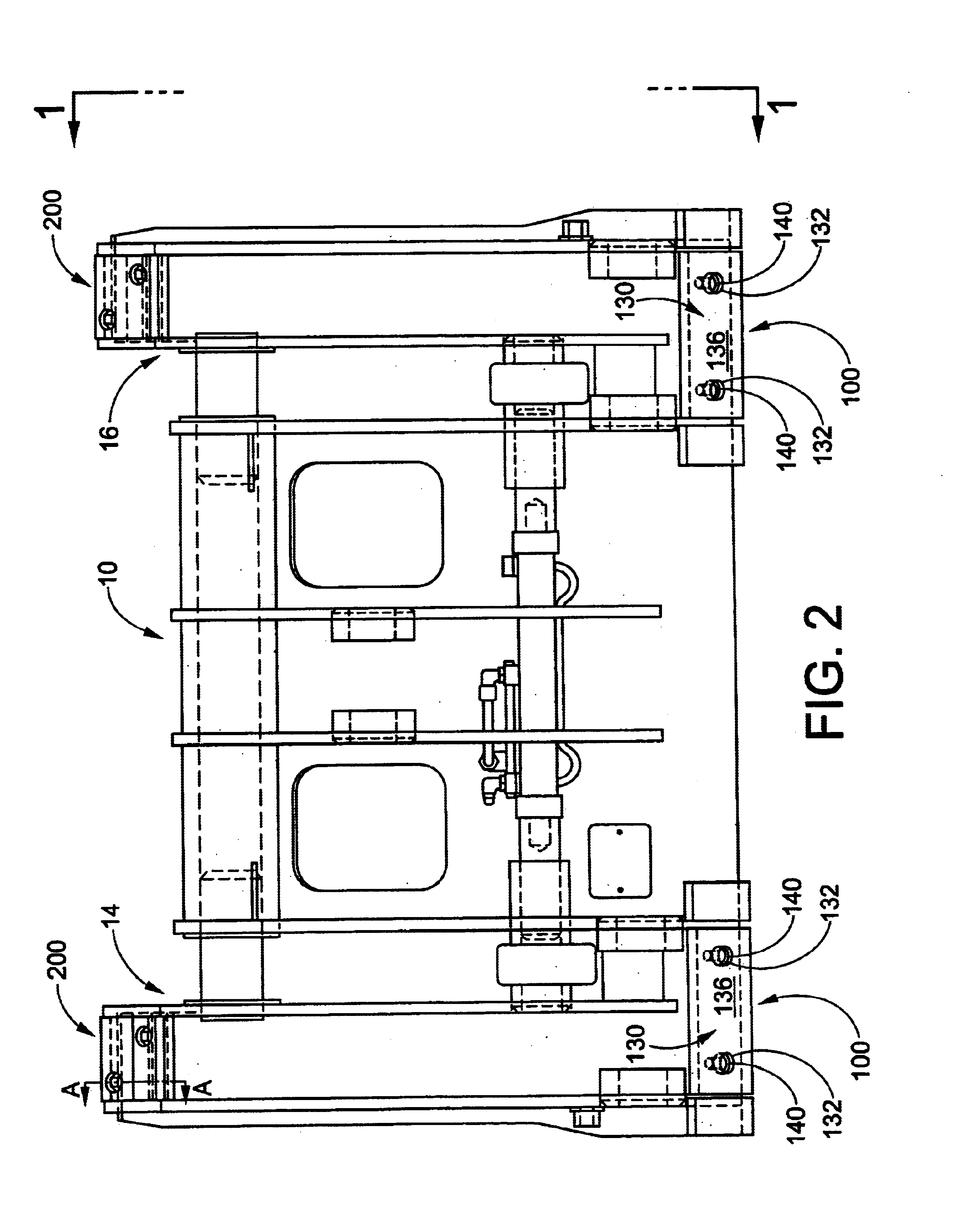

A rack for carrying cargo on top of a vehicle is disclosed, comprising a pair of longitudinal support assemblies. Each support assembly is configured for mounting on a crossbar secured across the roof of a vehicle, and includes a stationary base and an extendable rail. Each rail is moveable between a first position in which the rail is substantially coextensive with the base, a second position in which the rail extends significantly beyond the end of the base, and a third position in which the rail pivots downward adjacent a side of the vehicle. Each rail also has a proximal end portion and a distal end portion, with a loading arm pivotably connected to the distal end portion. The loading arm is moveable between a collapsed position parallel the rail and an extended loading position.

Owner:YAKIMA PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com