Beam component bending and torsion combined load test device and method

A loading device and combined loading technology, used in measuring devices, using stable bending force to test material strength, instruments, etc., can solve the problem that the bending moment boundary conditions are not ideal simply supported, the beam members are not ideal rotation, and the loading device is difficult to achieve and other problems, to achieve the effect of ingenious and reasonable setting of boundary conditions, intuitive and convenient measurement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

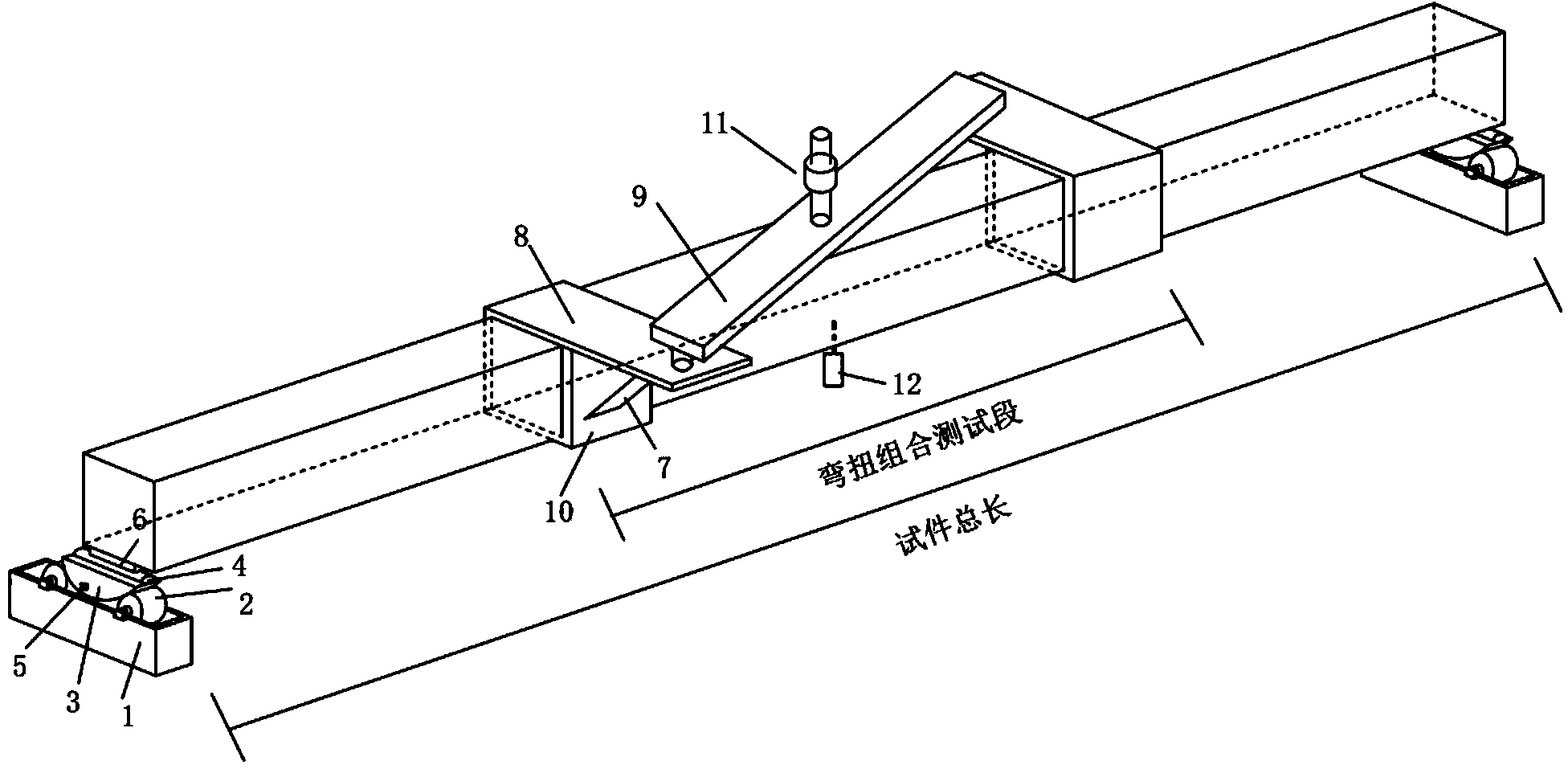

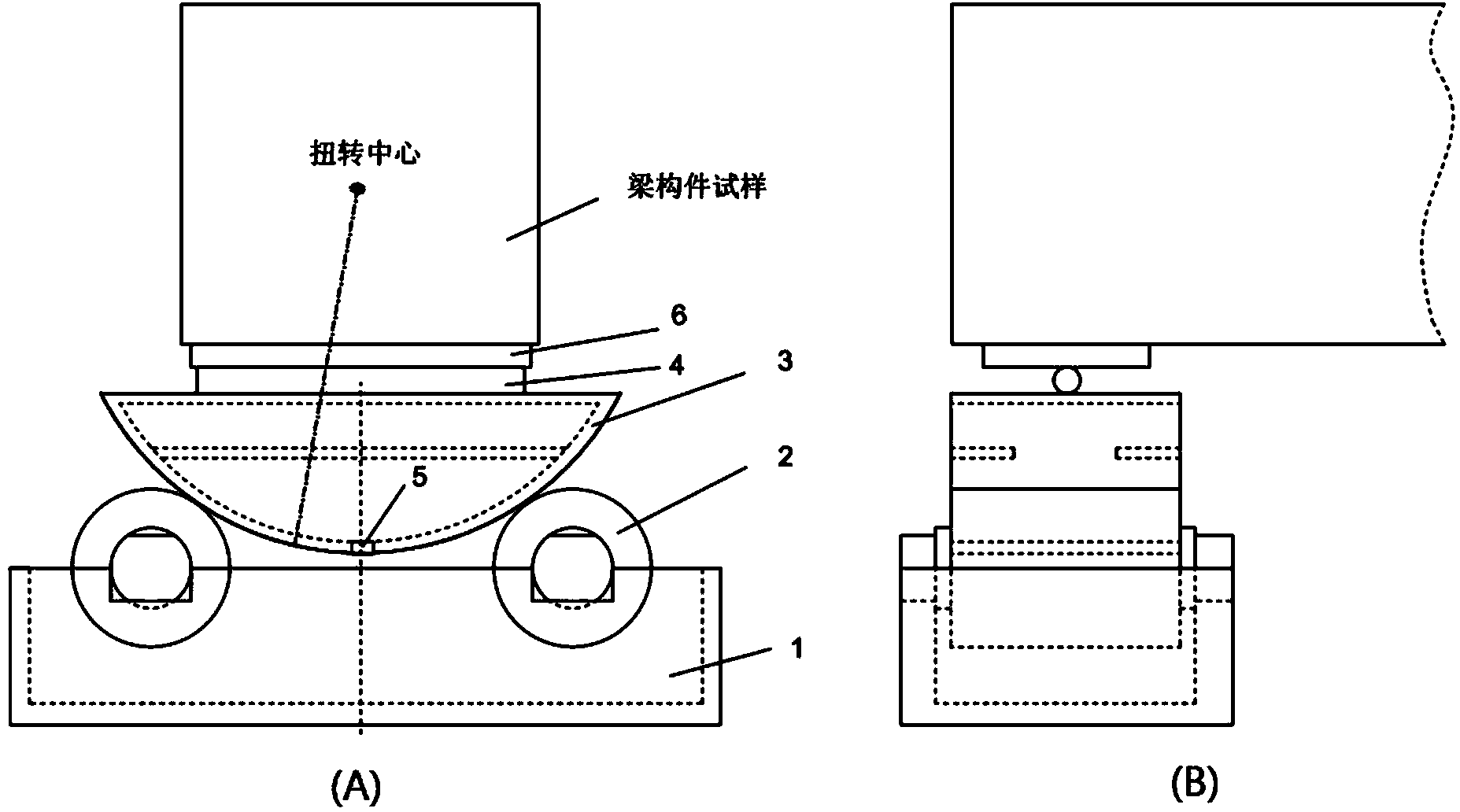

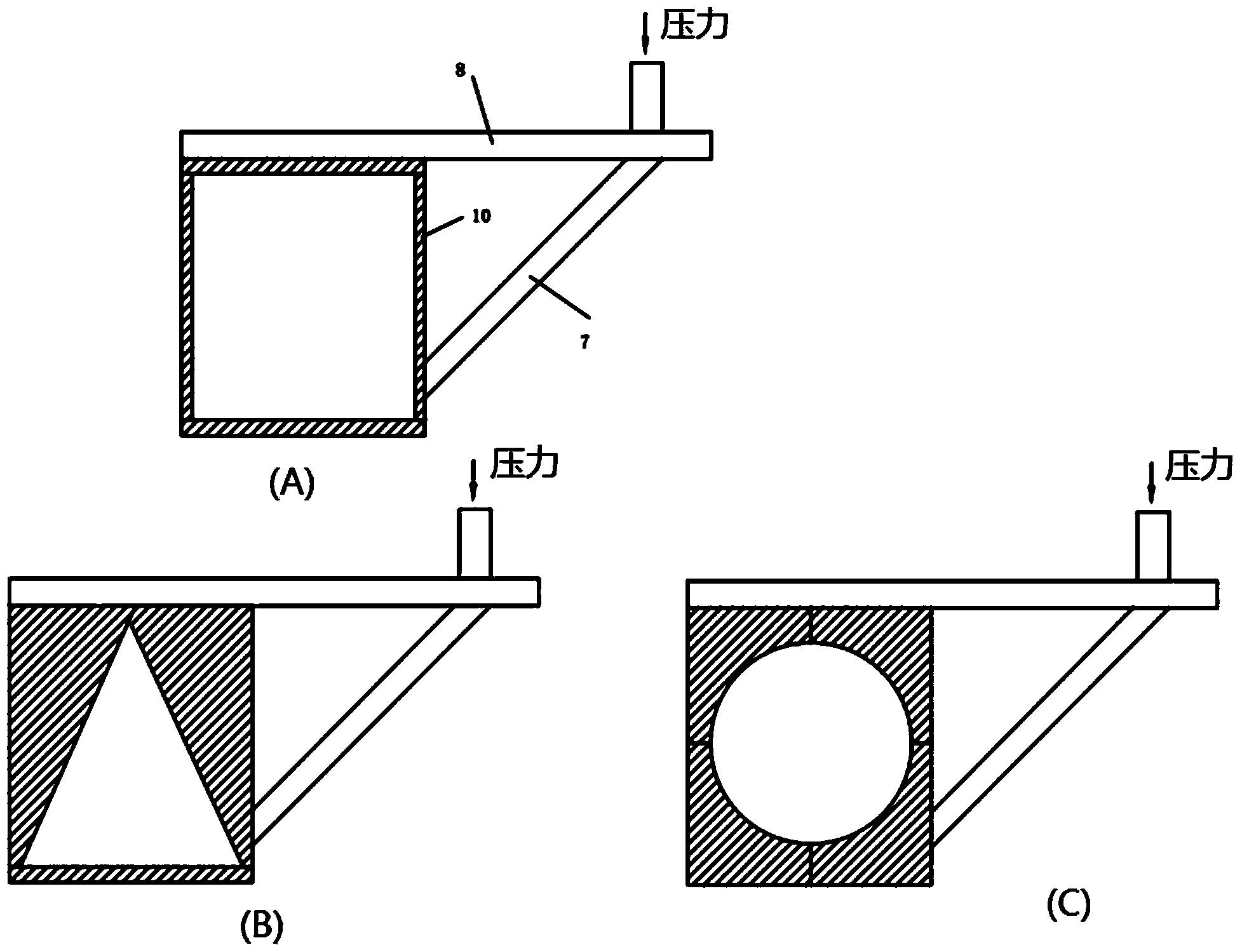

[0025] Such as Figure 1~2 As shown, the beam member bending-torsion combined loading test device of the present invention includes two parts, a simply supported-torsion combined support and a combined loading component. The simply supported-torsion combined support includes a fixed base 1, a roller 2, a torsion support 3, a simply supported support 4, an electronic torsion angle meter 5, and a backing plate 6. A simply supported-torsion combined support is fixed at both ends of the sample to support the sample and control the boundary conditions. Specifically: a number of rollers 2 are placed on the fixed base 1, the rollers 2 support the torsion support 3, and an electronic torsion angle meter 5 is installed. This part of the structural combination i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com