Interprocess calibration sample piece design and application method of mechanical steering gear nut

A technology of mechanical steering gear and calibration sample, which is applied in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problems that product quality cannot be well guaranteed, low production efficiency, etc., and achieve convenient and intuitive measurement and detection. Convenience and the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

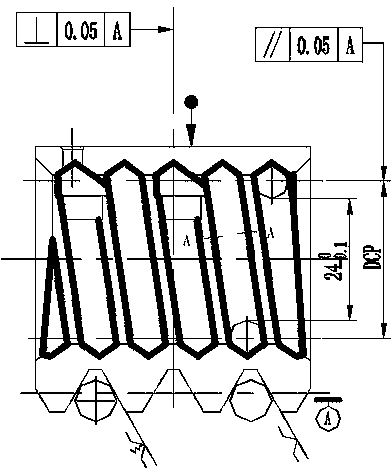

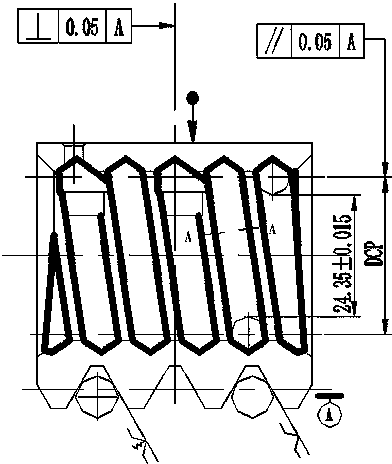

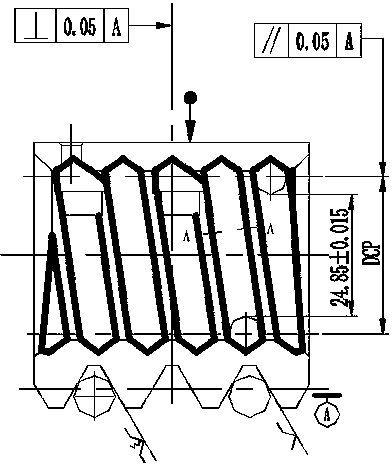

[0012] Figure 5 The design of the inter-process calibration sample of the mechanical steering gear nut shown is an integrated structure, one end of which is a large journal 2, and the other end is a small journal 3, and a long V-shaped block 4 is arranged on the large journal, and the long V The measuring rod 5 is used to position the type block 4; the calibration sample is in the machining of the steering nut. After the tooling is installed, before processing, (1) first install the calibration sample on the tooling of the lathe or grinder and clamp it (where The positioning method of the calibration sample is exactly the same as the positioning method of the steering nut. The long V-shaped block 4 is used for positioning through the measuring rod 5 in the middle, and then the measuring rod 6 is used for auxiliary positioning. The side is one end surface of the calibration sample. Positioning), measure the parallelism between the center line of the calibration sample and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com