Device and method for biaxial pull-press loading test device of material

A technology of loading test and axial pulling, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems of small size of test piece and loading limit, complex actual implementation, and complex structure of test equipment, etc., to achieve convenient biaxial Tension-compression loading ratio, uniform load transmission and distribution, easy processing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

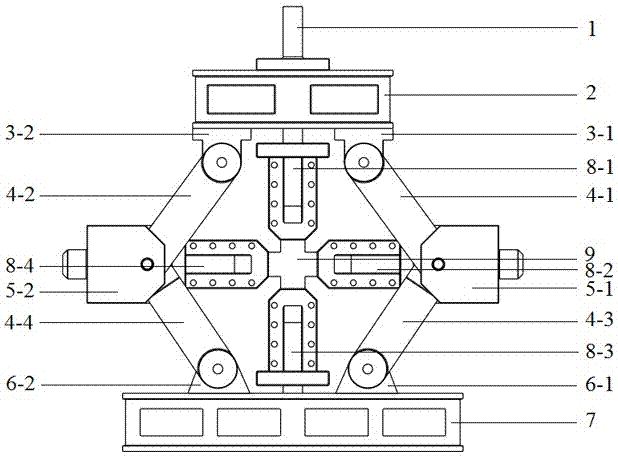

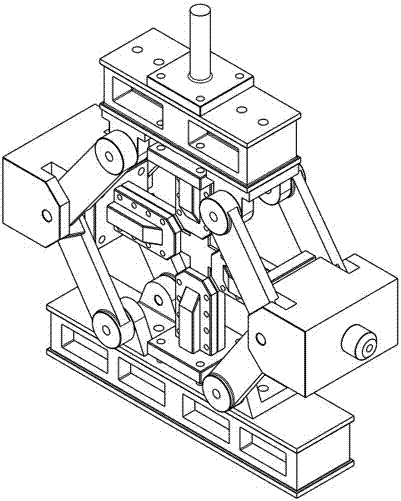

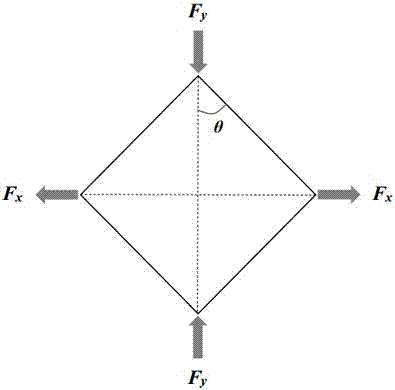

[0034] A device for biaxial tension-compression loading test of materials, its structure is as follows figure 1 , figure 2 As shown, the device consists of a clamping end 1, a loading press block 2, four inclined loading arms 4-1, 4-2, 4-3, 4-4, two left and right symmetrical stretching supports 5-1, 5-2, composed of four chucks 8-1, 8-2, 8-3, 8-4 and base 7;

[0035] Wherein the two adjacent inclined loading arms on the left and right sides are respectively connected with two left and right symmetrical tensile supports 5-1, 5-2, and are upwardly connected with the loading press block 2 through the top hinge supports 3-1, 3-2, Connect to the base through bottom hinge supports 6-1 and 6-2 downward;

[0036] Four chucks 8-1, 8-2, 8-3, 8-4 are respectively installed on the loading press block 2, the two tensile supports 5-1, 5-2 and the base 7.

[0037] The clamping end 1 is connected with the loading pressure block 2 through bolts, and the clamping end 1 can be connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com