Cross-shaped sample for biaxial mechanical test as well as preparation method and application of cross-shaped sample

A biaxial mechanics and cross-shaped technology, which is applied in the preparation of test samples and the use of stable tension/compression to test the strength of materials, etc., can solve the problem that the cross-shaped sample and its production and test methods have not made good progress. Development, the problem of biaxial loading has not been researched much, and the results of biaxial testing are not ideal, etc., to achieve the effect of simple and easy molding process, stable test performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, by way of embodiment, the present invention is described in detail:

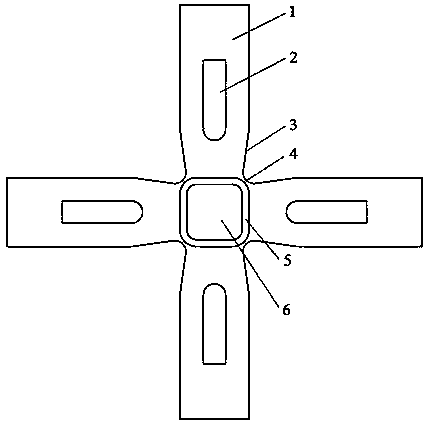

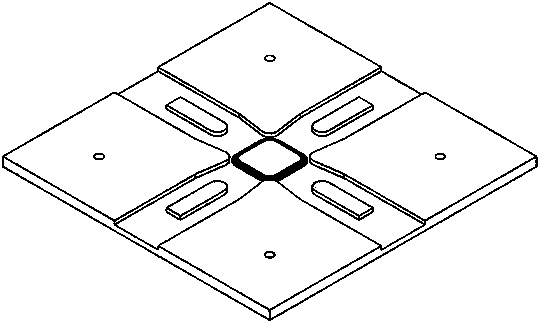

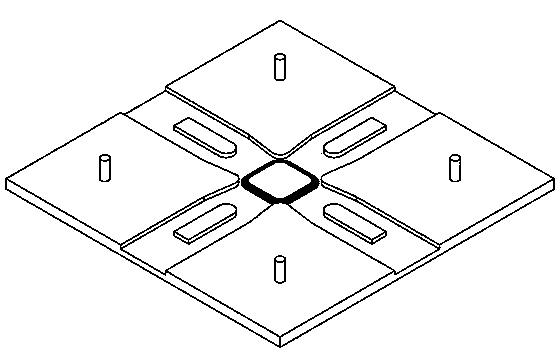

[0029] A cross-shaped sample for biaxial mechanical testing, characterized in that the sample is in the shape of a cross as a whole and has four loading arms, each loading arm is provided with a loading arm hollow area 2, and the end of the loading arm is a loading arm The arm clamping end 1 is provided with a transition area between the roots of adjacent loading arms, and the transition area is composed of a tapered transition area 3 and a circular arc transition chamfer 4;

[0030] Between the roots of the four loading arms is the central area of the sample, the middle area of the central area of the sample is the central test area 6, and a thinning transition area 5 is provided between the central test area 6 and the root of the loading arm.

[0031] There are four loading arms, which form a cross-shaped symmetrical structure, including the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com