Composite low-yield-point metal damper with multi-dimensional energy dissipation function

A metal damper, low yield point technology, applied in building types, building components, earthquake resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

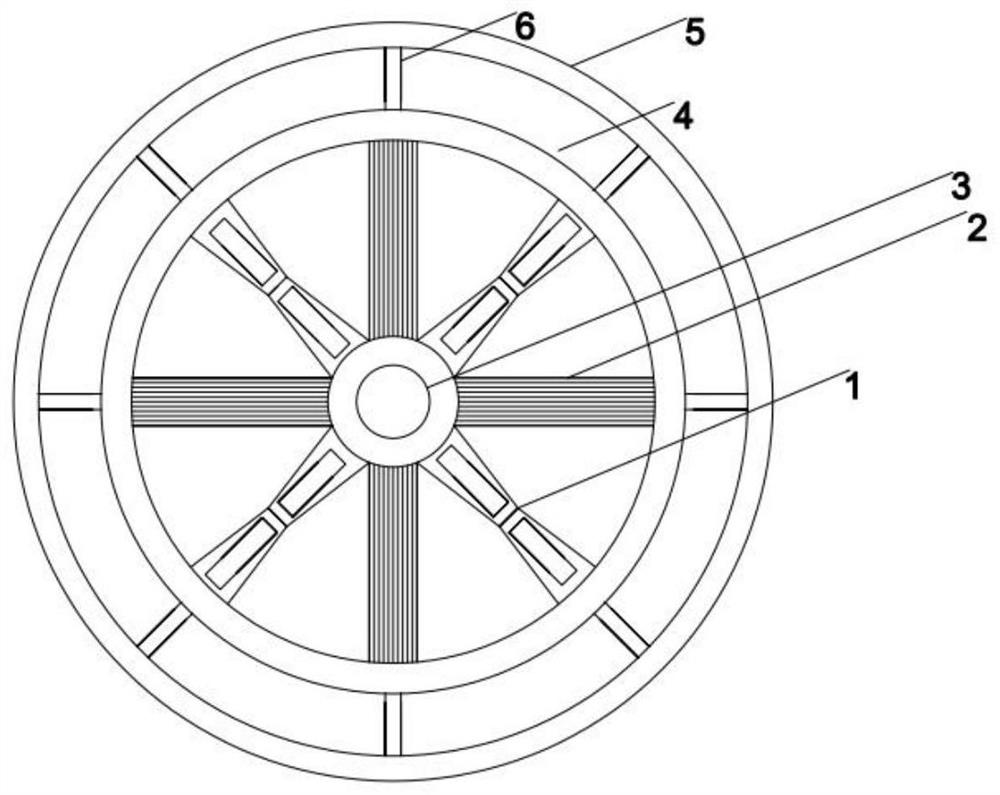

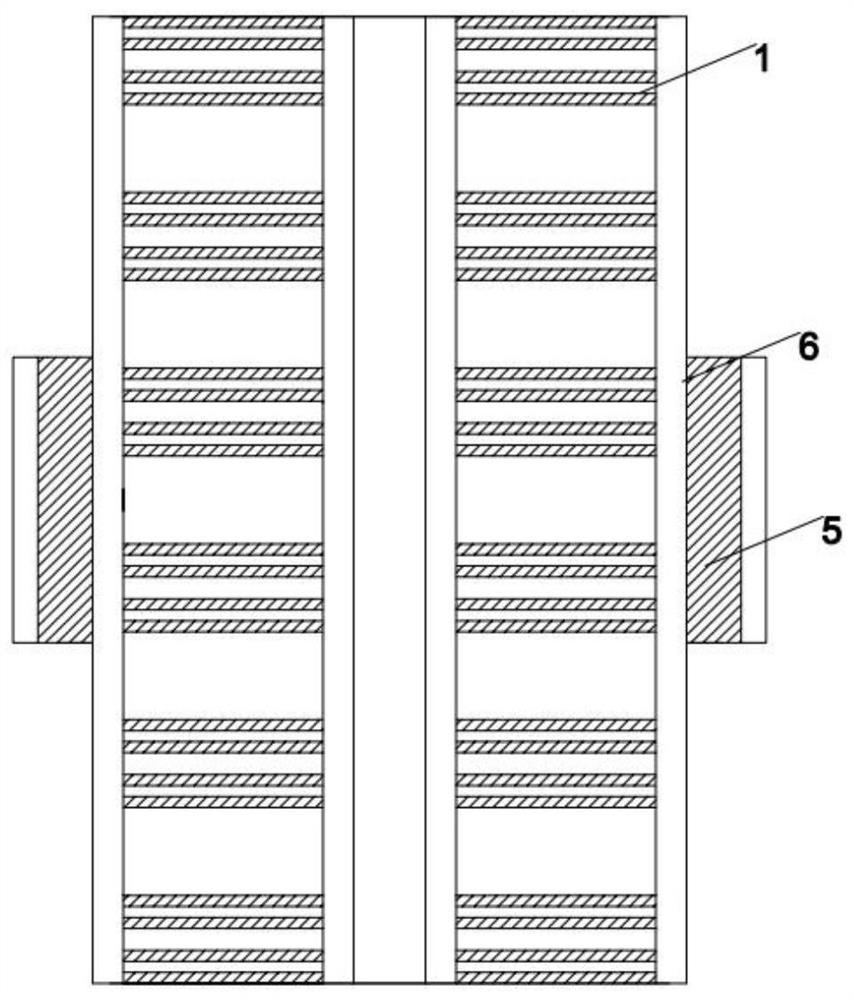

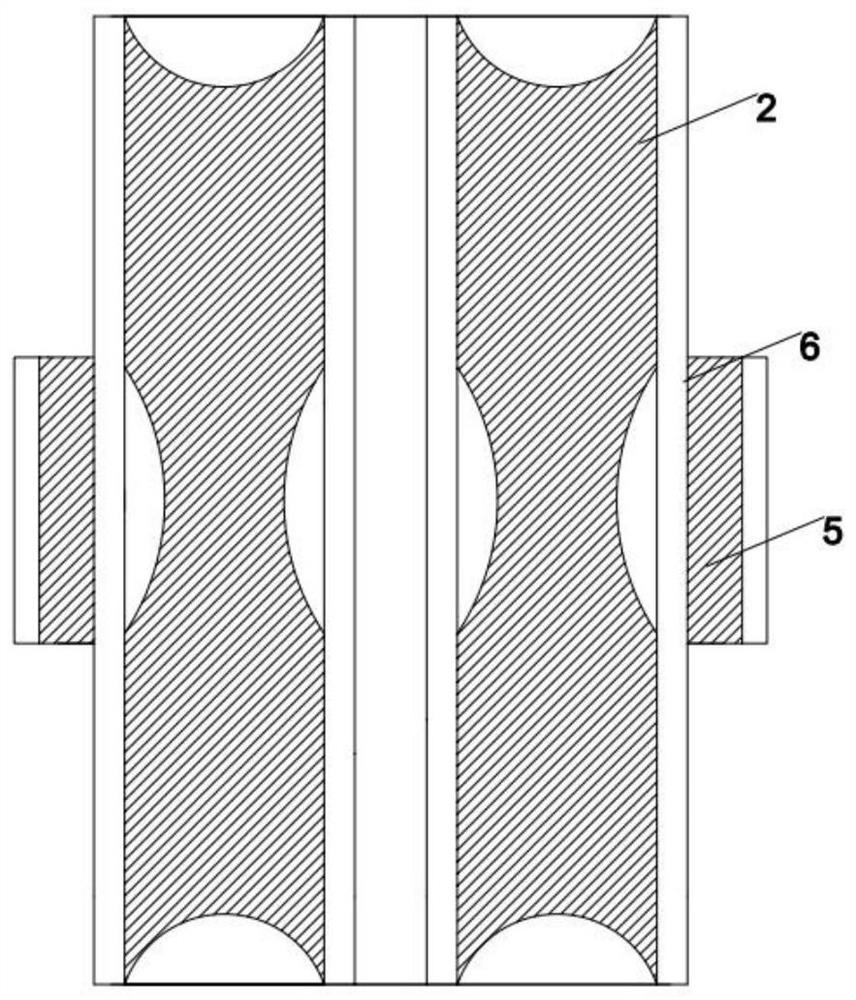

[0029] The proposed composite low-yield point metal damper with multi-dimensional energy dissipation function can play the role of energy dissipation and shock absorption in any direction in the plane, and it is also a damper with vibration damping and reset functions in the vertical and torsional directions . It includes a bending energy dissipation damper (1), a shearing energy dissipation damper (2), an inner steel cylinder (3), an outer steel cylinder (4), an outer steel ring (5) and a steel plate (6).

[0030] The implementation steps are as follows:

[0031] 1) In this example, the applied building is a steel-concrete frame structure with a total of 5 floors and a floor height of 4.2m. For the part of the frame where the damper is installed, the upper end of the damper is fixedly connected to the beam-column node, and the lower end is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com