Super-thick non-hardening plastic mold steel and method for manufacturing the same

A plastic mold steel and manufacturing method technology, applied in the direction of manufacturing tools, heat treatment process control, heat treatment equipment, etc., can solve the problems of high quenching crack sensitivity, small thickness of rolling forming, high manufacturing cost, etc., achieve high hardenability, Effect of improving hardenability and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1, first heat the steel ingot to 1170°C for 3 hours and then press the pliers, then return to the furnace and heat it to 1170°C for 170 minutes and then upsetting. After upsetting, one steel ingot is returned to the furnace for heating, and the other continues to be drawn. To the finished product specification of 300mm×790mm×5000mm; a steel ingot returned to the furnace is held at 1170°C for 120 minutes, then upsetting and elongated to the finished product specification of 450mm×790mm×3500mm; after the module is forged, it is air-cooled to room temperature and carried out at 600°C Tempering treatment.

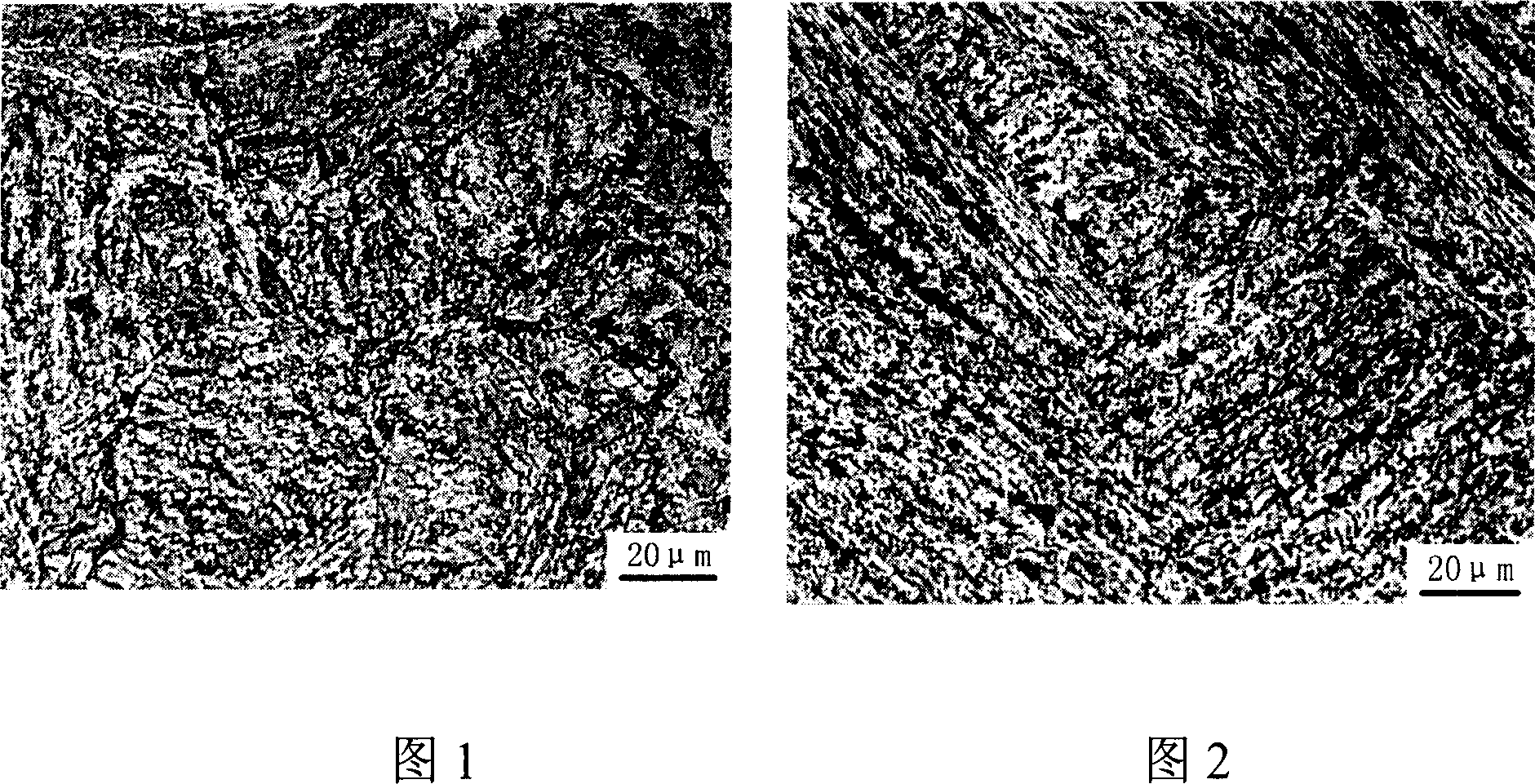

[0049] The final hardness of the module is: HRC32~34, the hardness is uniform, the surface layer and the core of the module with a thickness of up to 450mm are all bainite structures, and the structure is very uniform, see pictures of the structure in Figure 1 and Figure 2.

[0050] The above results show that micro-alloying technology has made a breakthrough in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com