Controlled cooling method for manufacturing fractured connecting rod by using non-quenched and tempered steel

A technology for breaking connecting rods and non-quenched and tempered steel, which is applied in the manufacture of tools, furnaces, furnace types, etc., and can solve problems such as deformation of the cover, high scrapping rate of slag when the connecting rod is broken, and misalignment of the expanding section of the connecting rod. Achieve the effects of simplifying the production process, eliminating the need for quenching and tempering treatment, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

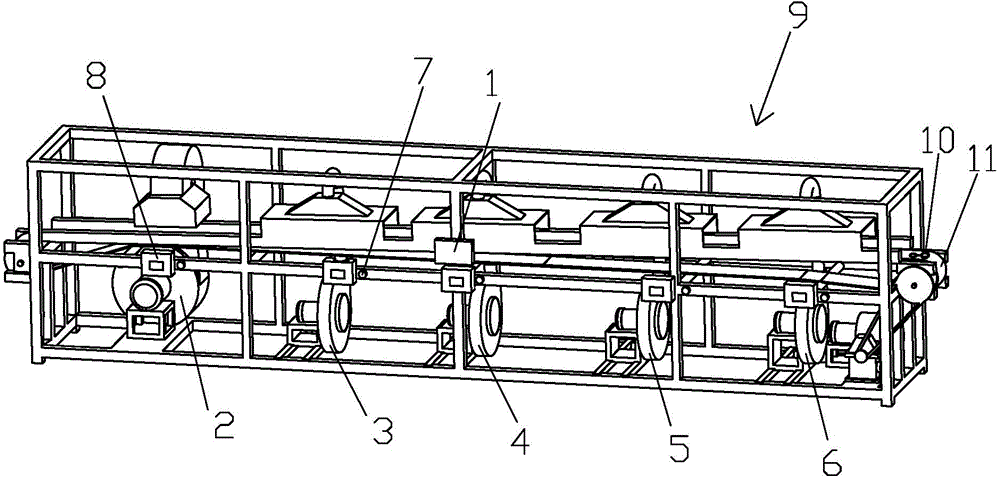

[0018] Embodiment: A controlled cooling method for making expansion and breaking connecting rods with non-quenched and tempered steel. The controlled cooling method mainly uses a controlled cooling device 9, and the endless conveyor chain and various fans are integrated in the controlled cooling device 9. Open the power distribution box 1 of the cooling control device 9, open the independent switch 7 and the independent frequency converter 8 respectively of the first fan 2, the second fan 3, the third fan 4, the fourth fan 5 and the fifth fan 6 to realize The cooling control device 9 is started; the connecting rod 10 is placed on the endless conveyor chain 11, and the connecting rod 10 is sequentially transmitted through the circular conveyor chain 11 through the first fan 2, the second fan 3, the third fan 4, and the fourth fan. The air blower mouth of blower fan 5 and the fifth blower blower 6 is cooled; When being sent to the outlet behind the fifth blower blower 6, the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com