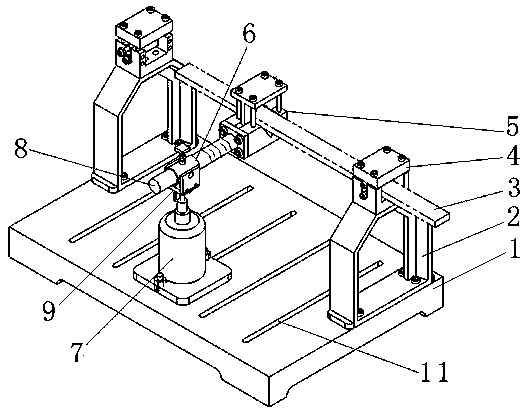

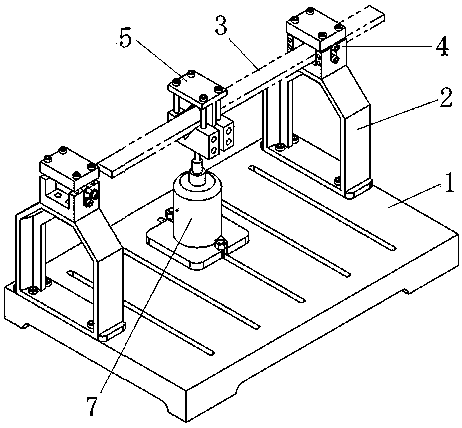

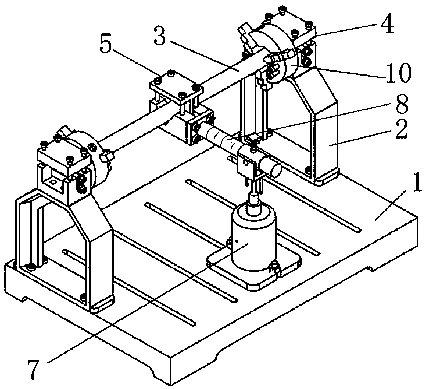

Loading device used for lateral-torsional vibration fatigue experiment and method thereof

A technology of vibration fatigue and loading devices, which is applied in the direction of measuring devices, using stable bending force to test the strength of materials, instruments, etc., to achieve the effect of overcoming single function and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: A preferred embodiment of the present invention is provided below. Take the rectangular section beam specimen as an example:

[0033] First, install the test device, fix the test piece 3 on the fixture 4, and adjust the nuts at both ends of the clamp rod 43. When the screws of the pressure plate 41 are compressed, the end of the test piece 3 can be fixed; adjust the nuts of the pressure plate 41. When the screw of the clamping rod 42 is properly tightened, the end of the specimen can be simply supported. At the same time, it is very convenient to test the fatigue performance of the specimen 3 in the cantilever mode when only one end is fixed. The installation of the loading arm 5 is relatively convenient, and the clamping base 52 and the clamping head 51 are clamped at the position where the test piece 3 is to be loaded, and the fixing screws can be tightened. The hydraulic vibration exciter 7 needs to be installed according to the test mode to be carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com