Patents

Literature

116 results about "Pure bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

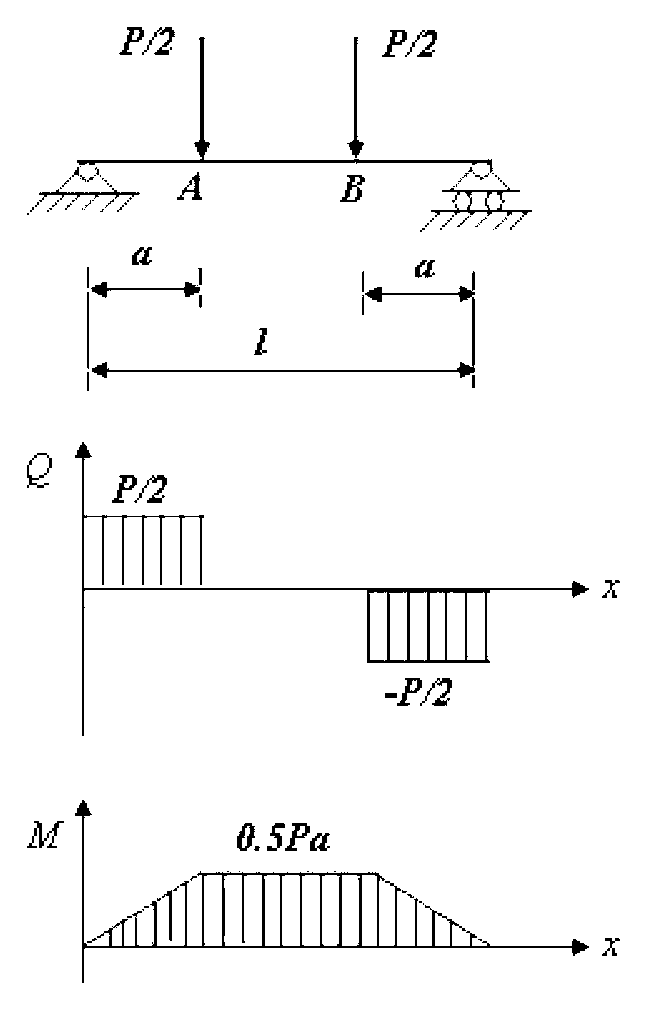

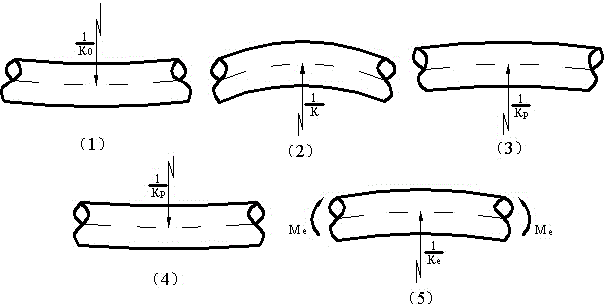

Pure bending is a condition of stress where a bending moment is applied to a beam without the simultaneous presence of axial, shear, or torsional forces. Pure bending occurs only under a constant bending moment (M) since the shear force (V), which is equal to dM/dx=V, has to be equal to zero. In reality, a state of pure bending does not practically exist, because such a state needs an absolutely weightless member.

Material in-situ detection device and method under multi-load multi-physical field coupling service conditions

ActiveCN105223076ANovel structureCompact layoutMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPhysical fieldScientific instrument

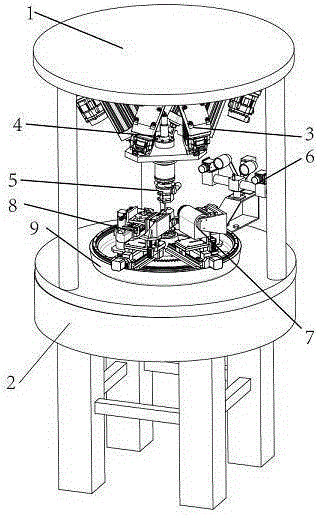

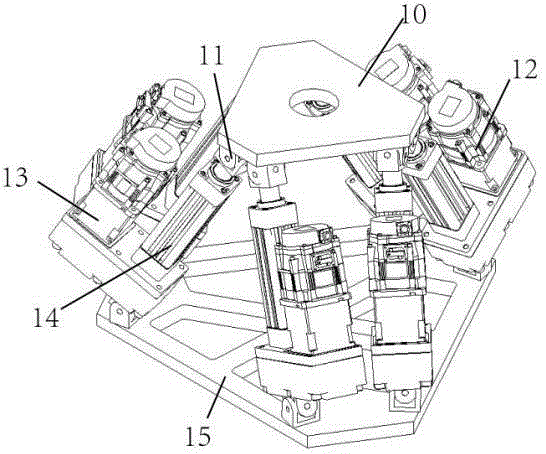

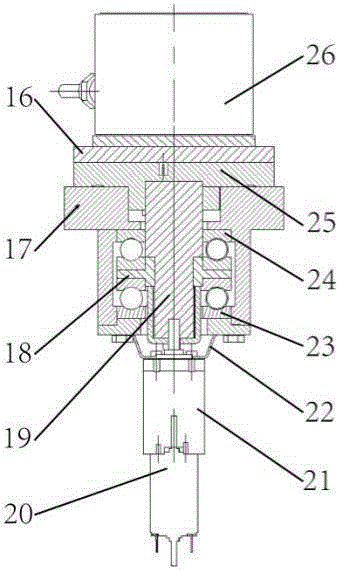

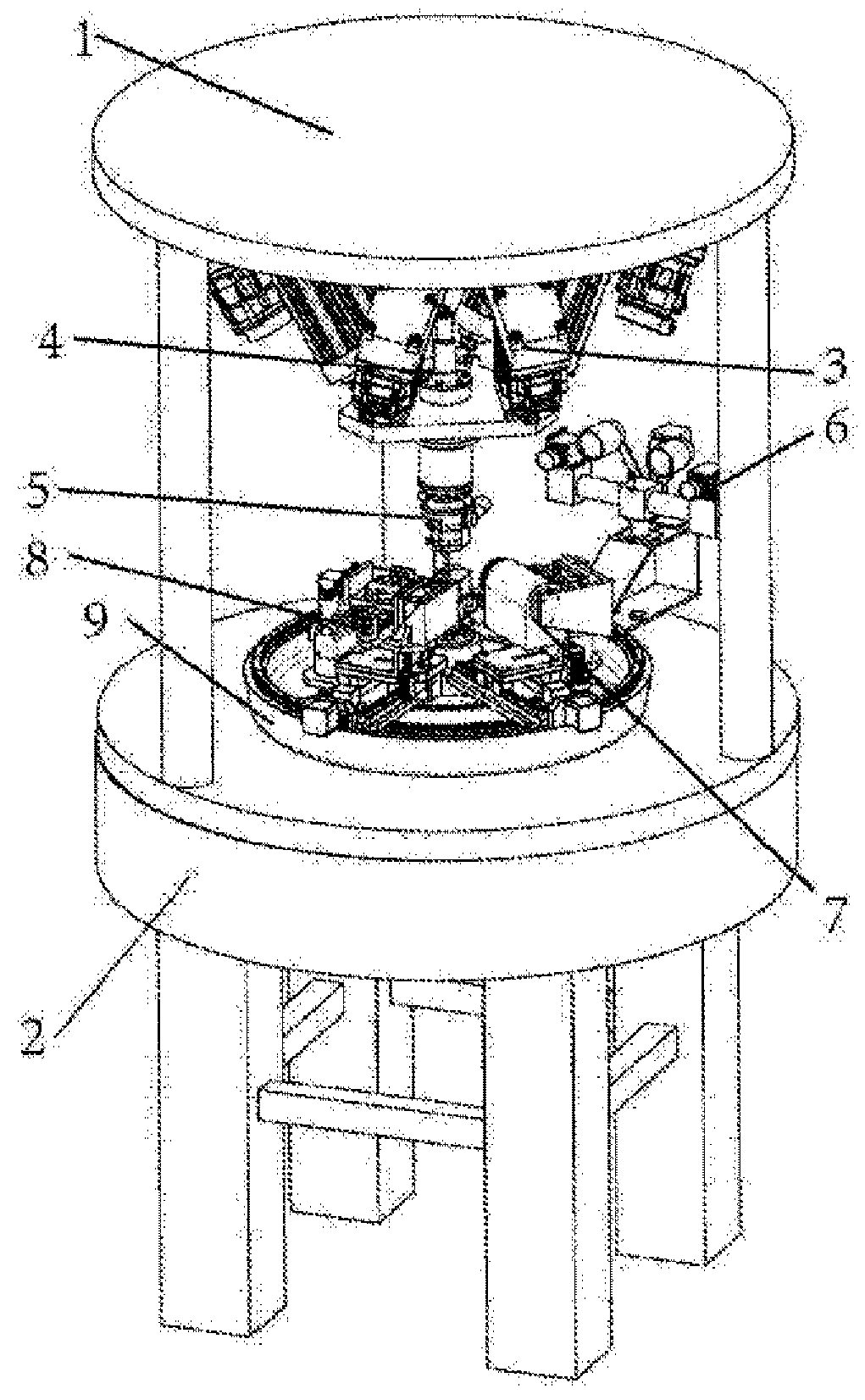

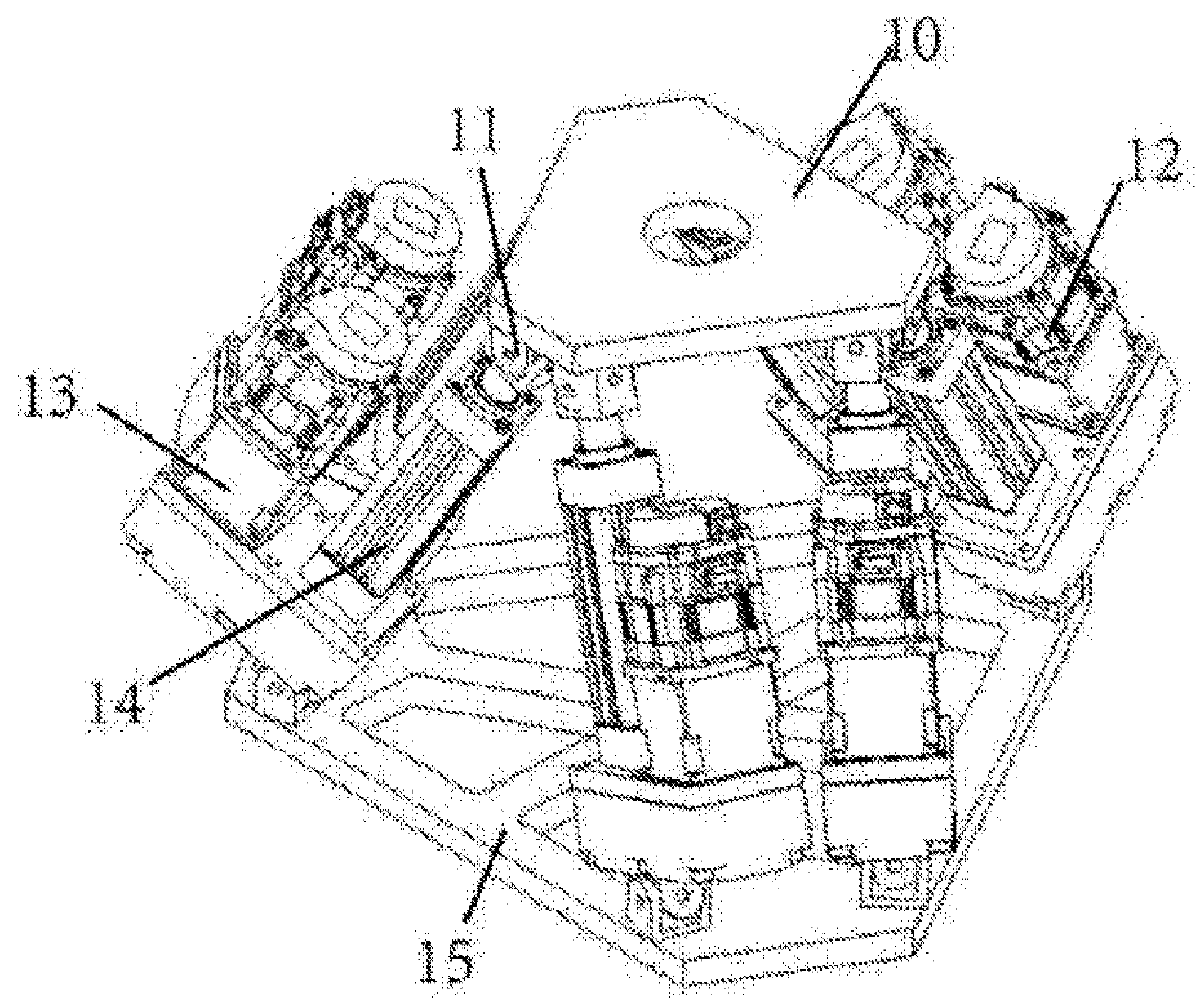

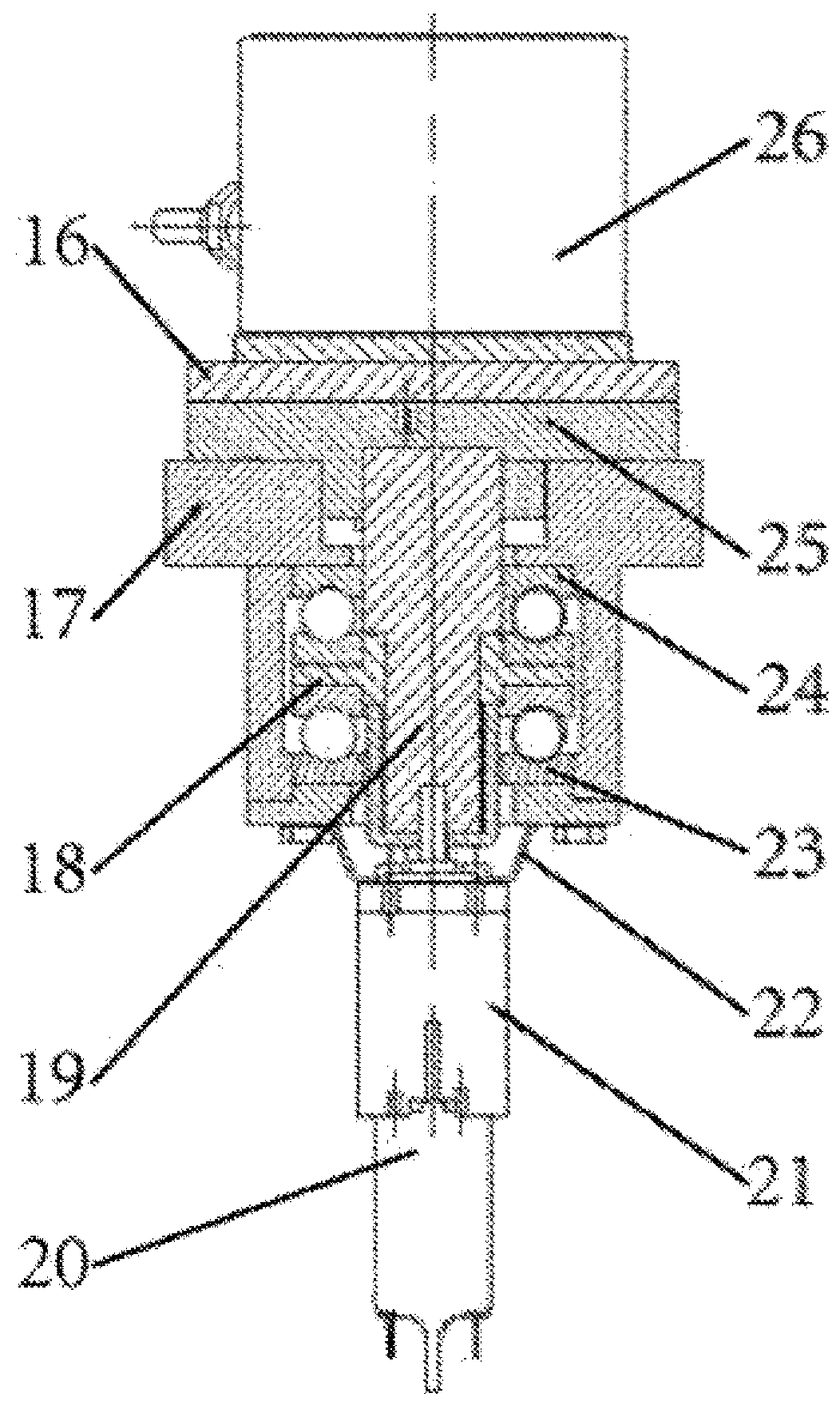

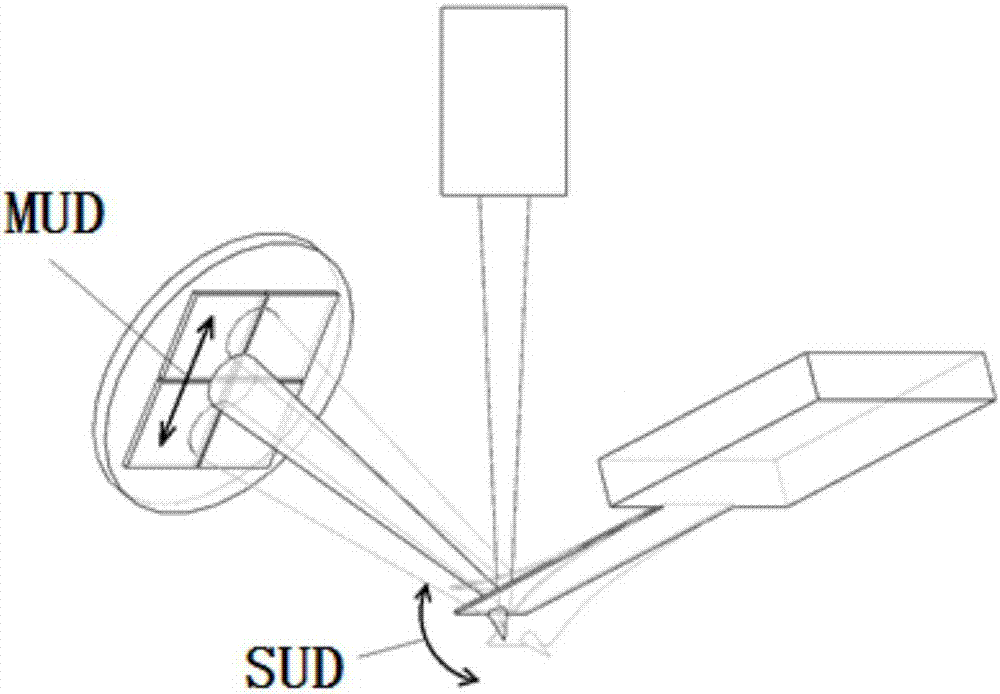

The invention relates to a material in-situ detection device and method under multi-load multi-physical-field coupling service conditions, and belongs to the field of precise scientific instruments. The material in-situ detection device is composed of a precise six-degrees-of-freedom composite load loading module, a precise torsion module, a precise indentation module, a clamp module and a control module which work together to complete a composite-load multi-physical-field coupling experiment, a digital speckle strain measurement and infrared thermal imaging module and a microscope observation module are integrated, and in-situ observation and quantitative characterization are carried out on material deformation behaviors and damage mechanism phenomena in a composite-load multi-physical-field loading process. The device and the method have the advantages that the composite-load loading can be realized, and a novel loading method such as 'cantilever type pure bending, cantilever type tensile / compression-torsion, and cantilever type bending-torsion' is carried out. Silicon nitride ceramic heating sheets, Peltier tiles and current loading are used for achieving simulation of cold / hot-electricity and other multiple physical fields, and an improvement innovative experimental testing method is provided for material micromechanical property tests close to the serving conditions.

Owner:JILIN UNIV

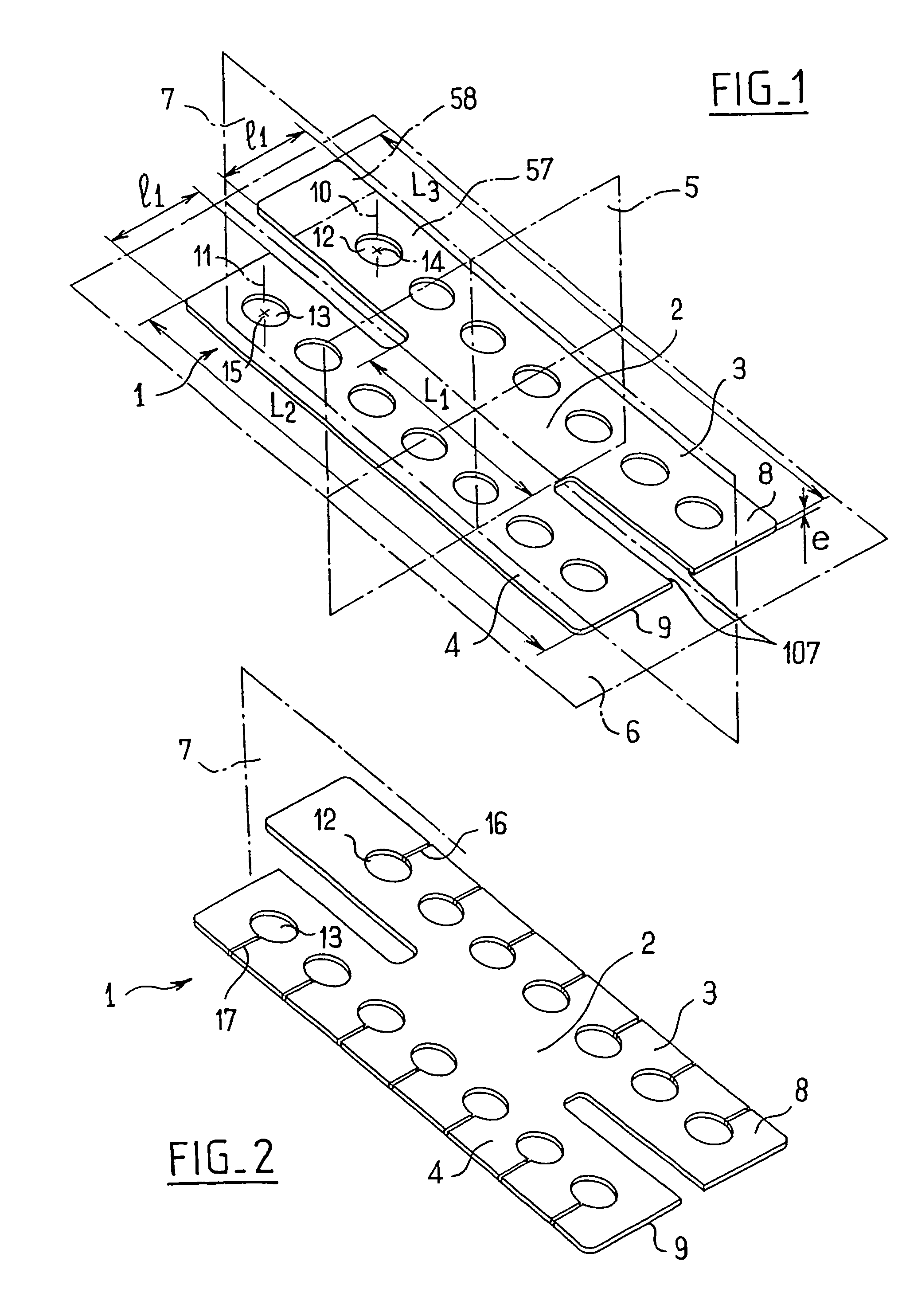

Device for testing thin specimens in pure bending

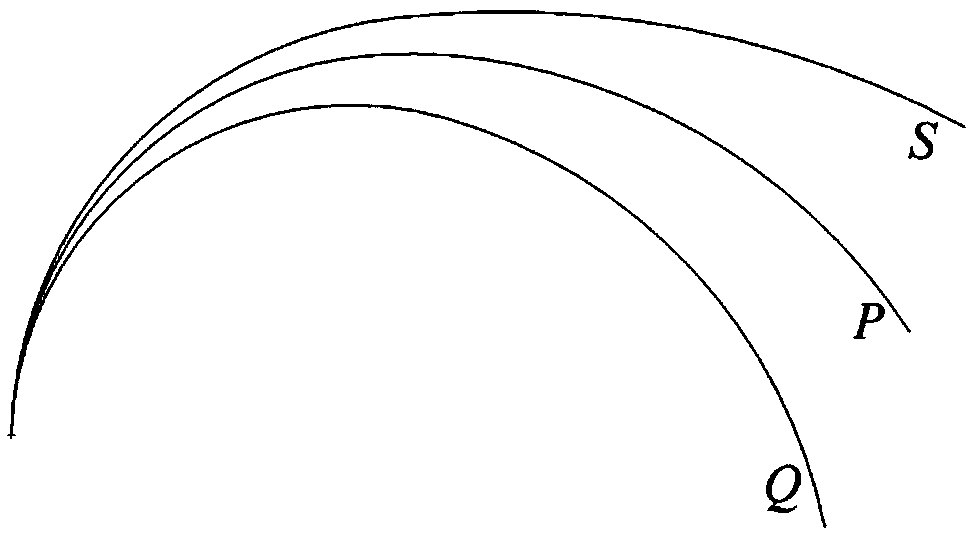

An improved test fixture to evaluate thin composite laminates commonly used in deployable space structures. The fixture is designed to impart a pure moment into the coupon, a necessary improvement to prior test methods where results are obtained by fitting material properties in a nonlinear structural analysis of the test. Fixture mechanics allow for direct calculation of the coupon flexural modulus and allowable flexural strain based on two key measurements, fixture displacement and applied load.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Loading device used for lateral-torsional vibration fatigue experiment and method thereof

ActiveCN108709793AGuaranteed stabilityMeet needsMaterial strength using steady bending forcesEngineeringLoading arm

The invention discloses a loading device used for a lateral-torsional vibration fatigue experiment and a method thereof. A sliding groove is formed in a base, brackets are installed at the two ends ofthe base, and a vibration exciter is connected to the sliding groove; the base body is connected with the brackets through bolts, rotary shafts are arranged on the two sides of a sliding sleeve, a clamping roller is installed above the sliding sleeve, and the rotary shafts are connected with a sliding seat and a shaft hole of a side plate; a guiding rod is sleeved with the sliding sleeve, and oneend of the guiding rod is connected with a loading arm; a clamping seat and a clamping head of the loading arm are opposite to each other, a V-shaped groove is formed in the clamping seat, and a second coupler is installed below the clamping seat. The loading device has adjustability and enough clamping force to ensure the stability of a platform, can provide pure torsion loading, torsion and transverse bending coupling loading, torsion and longitudinal bending coupling loading, torsion and oblique bending coupling loading and pure bending loading, has the advantages of high accuracy, high efficiency, low cost and multiple functions, and has important practical value regarding the completion of the vibration fatigue performance experiment for experimental piece materials with rectangularcross sections and circular cross sections.

Owner:NANCHANG HANGKONG UNIVERSITY

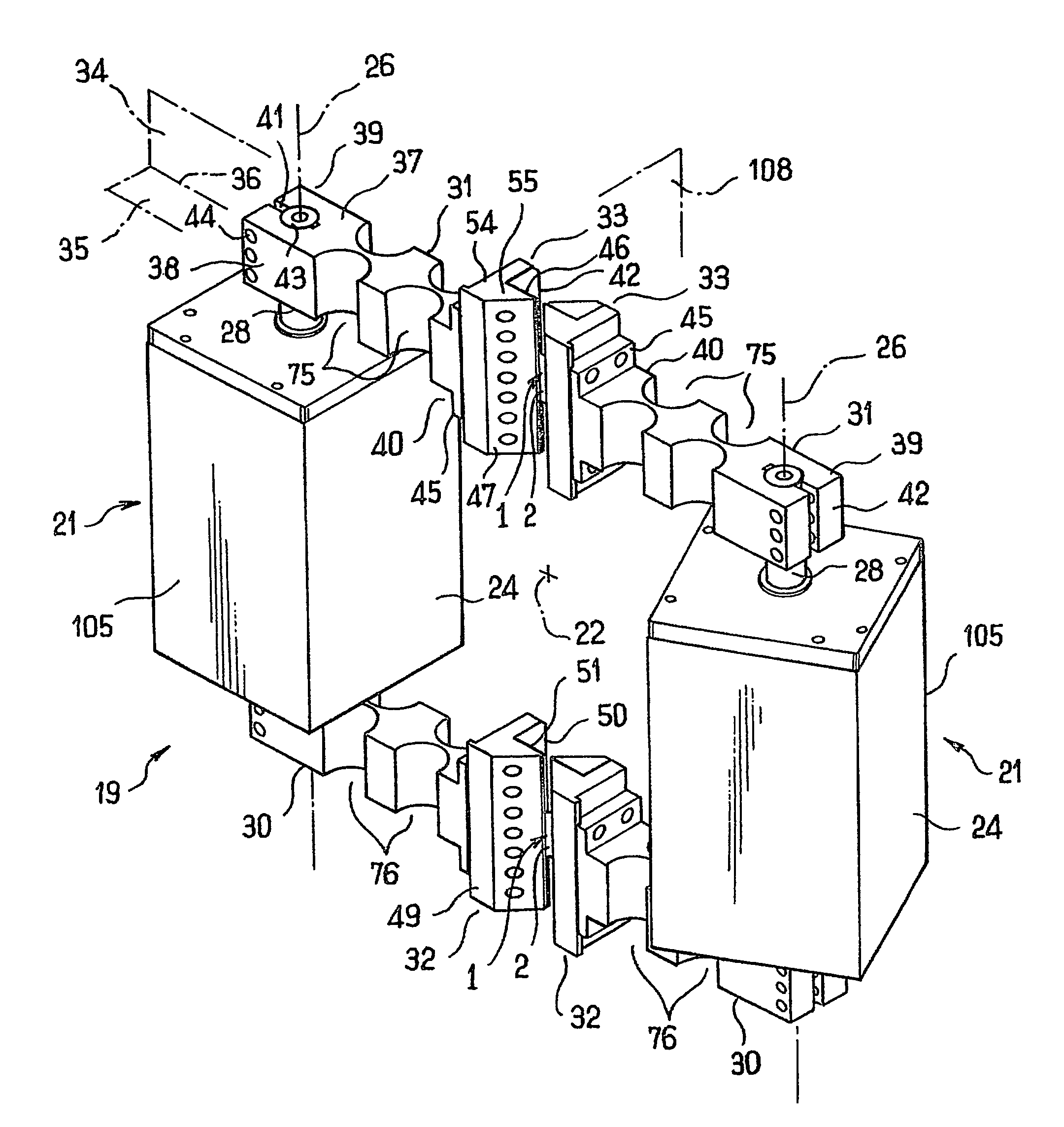

Material in-situ detection device and method under multi-load and multi-physical field coupled service conditions

ActiveUS20180180521A1Easy maintenanceReduce impactMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPhysical fieldMicroscopic observation

Provided are a material in-situ test device and method under multi-load and multi-physical field coupled service conditions. The device is composed of a precise six-degree-of-freedom composite load applying module, a precise torsion module, a precise indentation module, a clamp module and a control module which work together to complete a composite-load and multi-physical field coupled experiment, and is integrated with a digital speckle strain measurement and infrared thermal imaging module and a microscope observation module, so as to carry out in-situ observation and quantitative characterization on material deformation behaviours and damage mechanism phenomena in a composite-load and multi-physical field loading process. For example, loading methods of “cantilever type pure bending, cantilever type tension / compression-torsion, and cantilever type bending-torsion”, etc. can realize the loading of composite load. Silicon nitride ceramic heating sheets, Peltier tiles and current loading are used for achieving simulation of multiple physical fields such as cold / hot-electricity fields.

Owner:JILIN UNIV

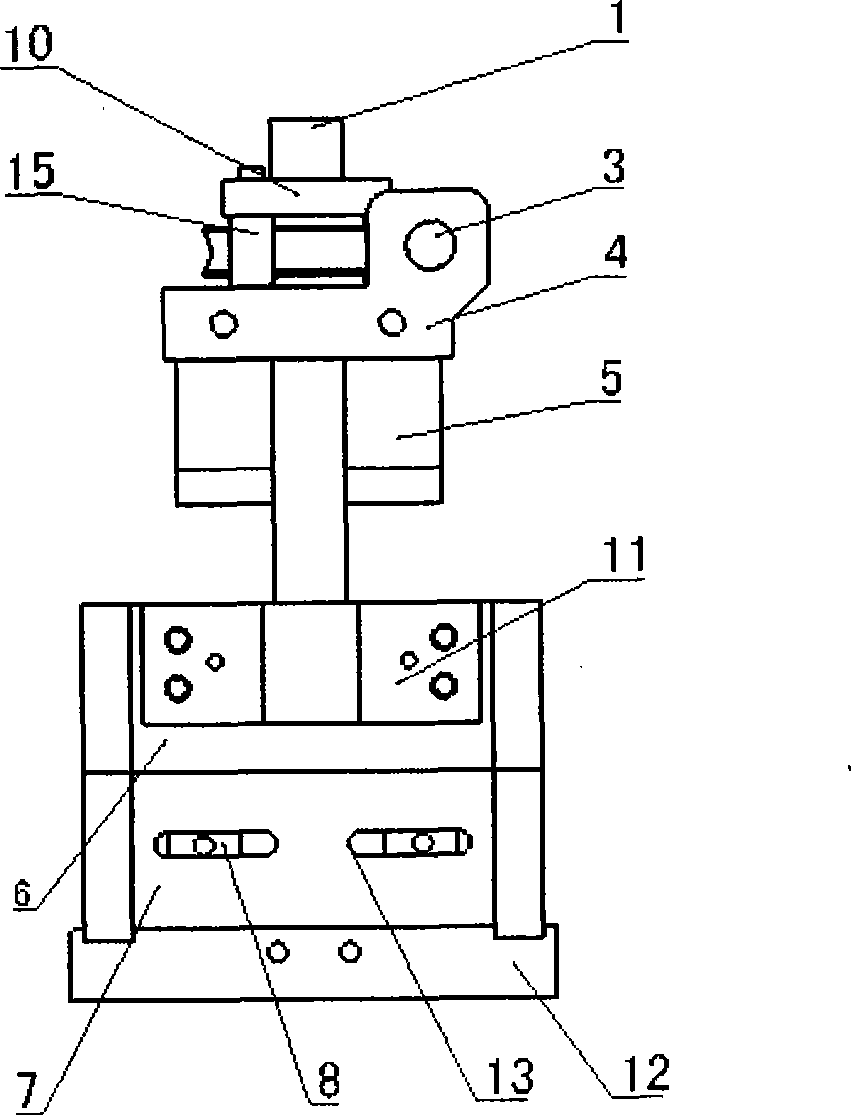

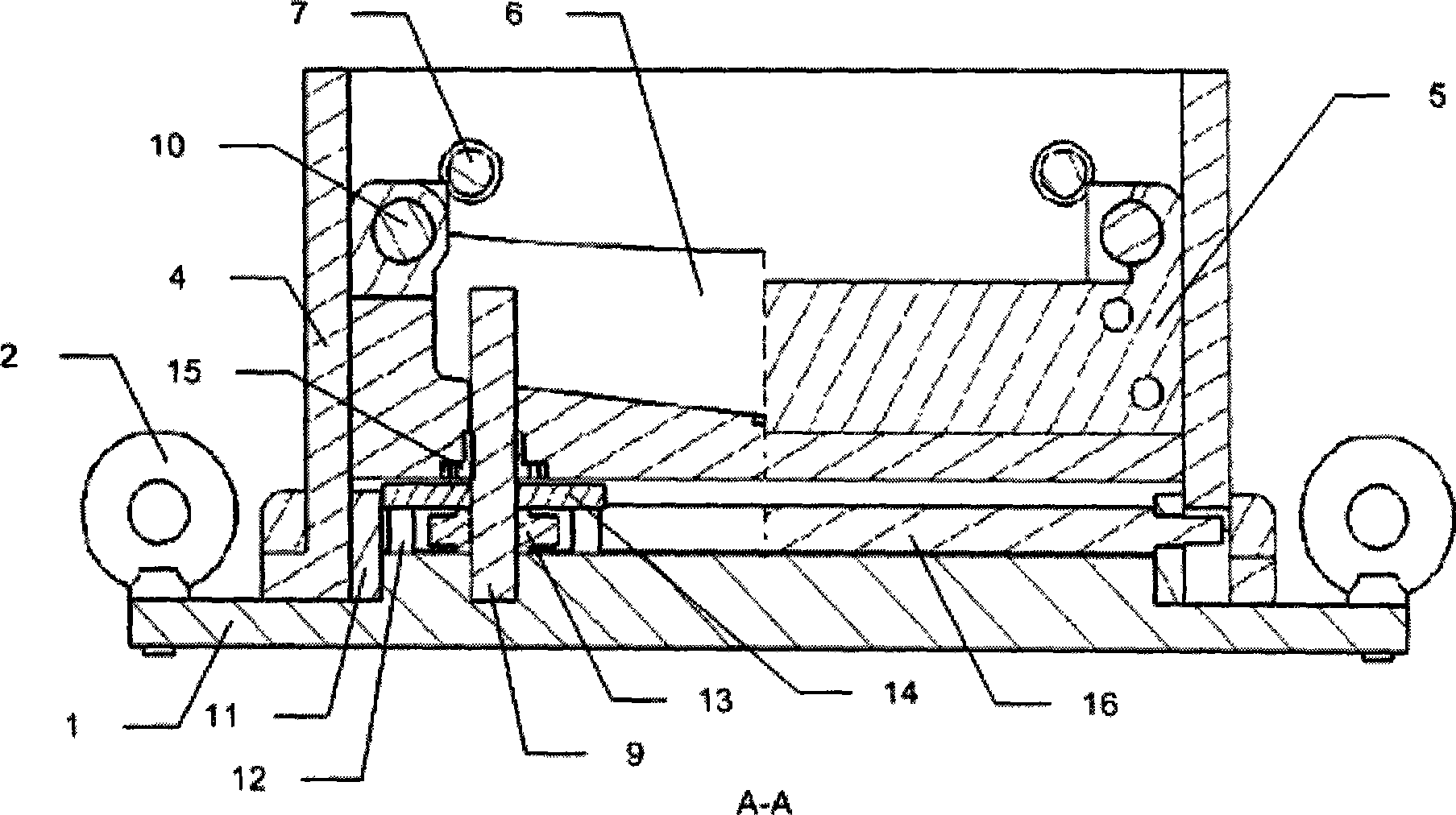

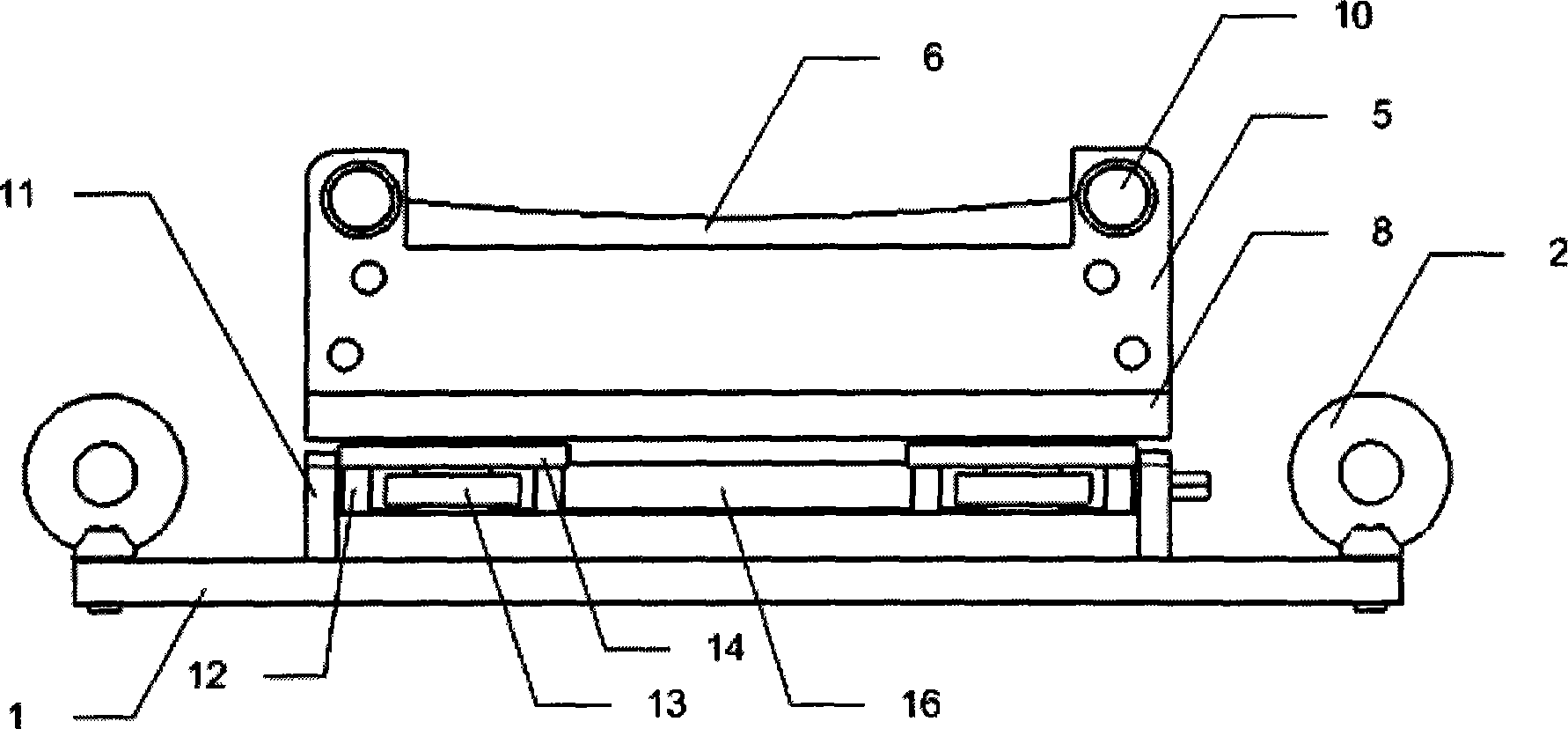

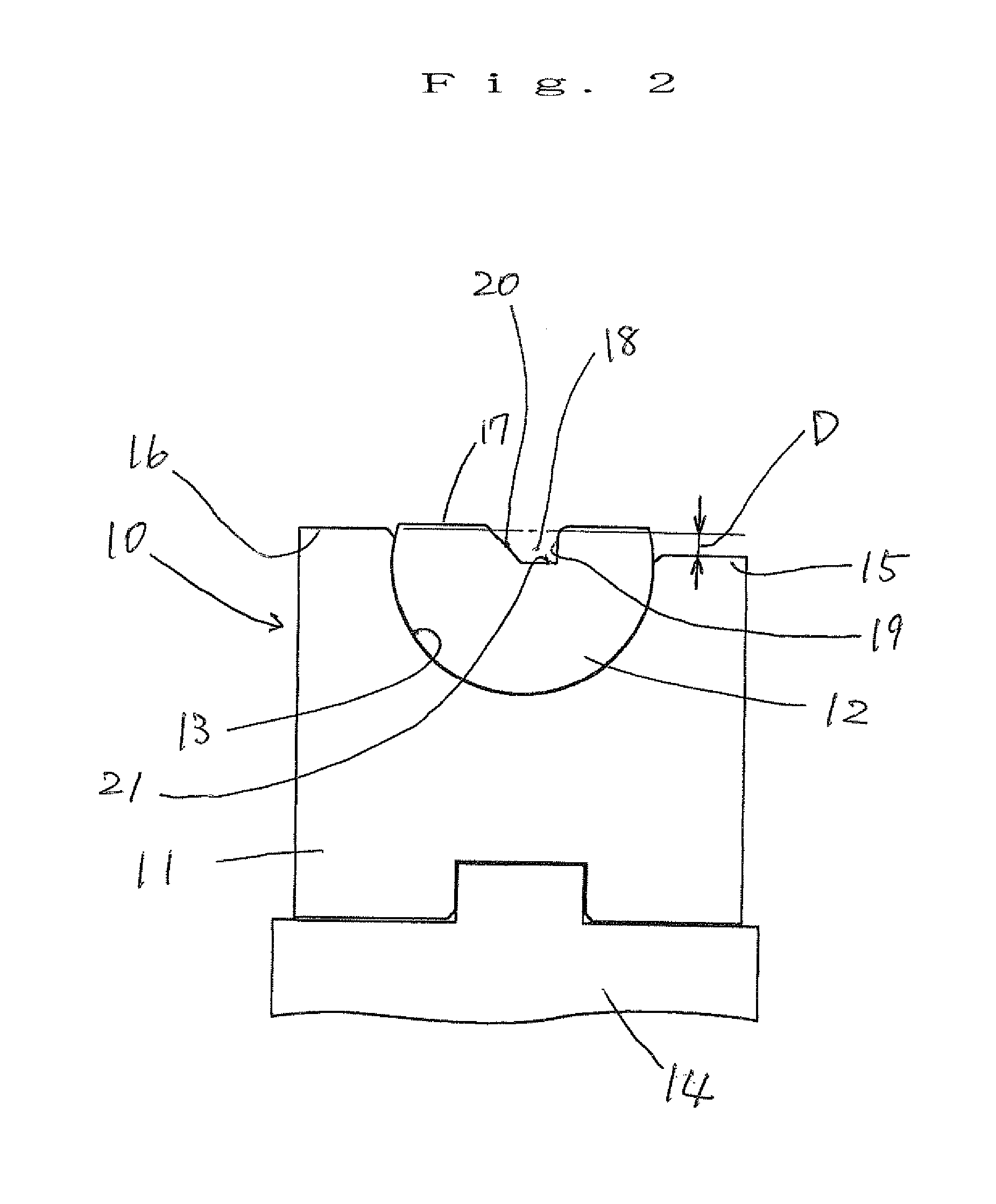

Pure bending age forming die

The invention discloses a pure bending age forming die, being a combination structure which combines four-point bending and a frame plate structure together and comprising a base plate (12), frame plates (6, 7), a pressing plate (2), a pressing block (5) and form plates (8); a lead screw seat (11) is fixed on an upper frame plate (6) at the two sides of a cavity; a worm (3) is installed on a supporting base (4); the two ends of the pressing plate (2) are provided with lead screw holes (17); a pair of pressing block slots (14) distributed symmetrically are arranged at the inner side of the lead screw holes and on the central line of the pressing plate; the pressing block (5) is fixed in the pressing block slots; a baffle supporting rod (15) is connected with the pressing plate (2); a turbine baffle (10) is fixedly connected with the baffle supporting rod (15); and two forming plates (8) are arranged in the cavity of the die, and the curvature of the upper surface thereof is determined according to the curvature requirement of a test piece. The invention uses a design way in which the distance between the forming plates is adjustable, is applicable to the pure bending load of the test piece, and has the advantages of simple structure and easy operation; in addition, the test piece still takes a round shape after rebounding.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

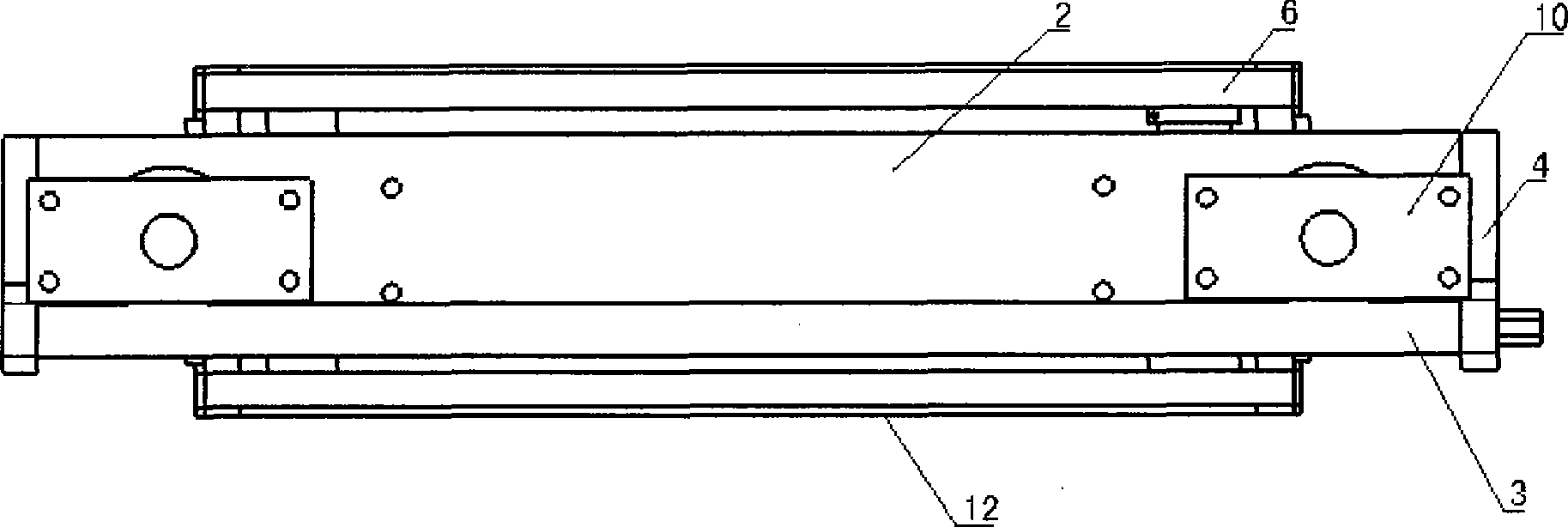

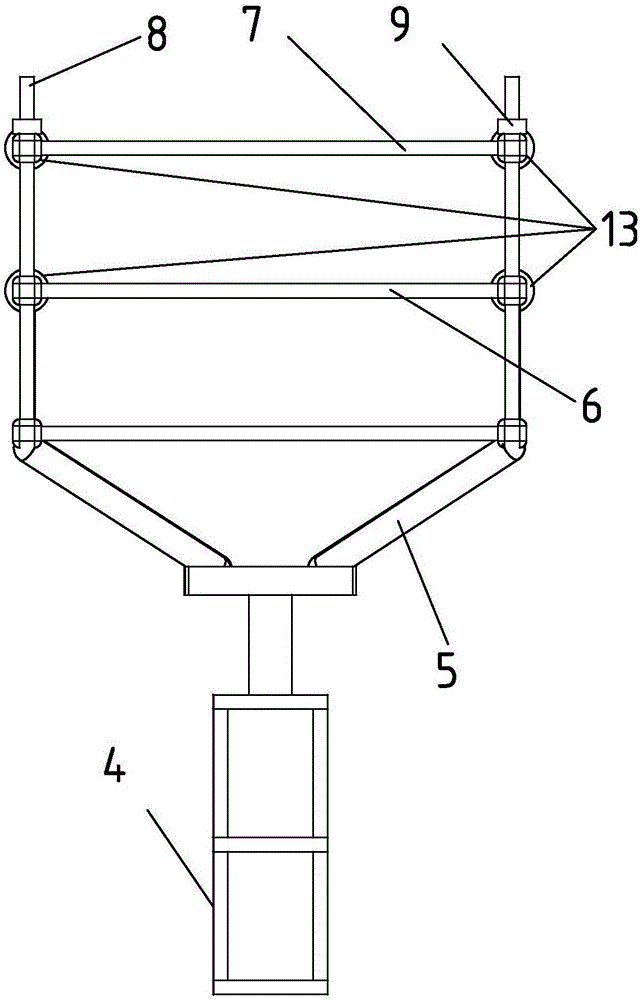

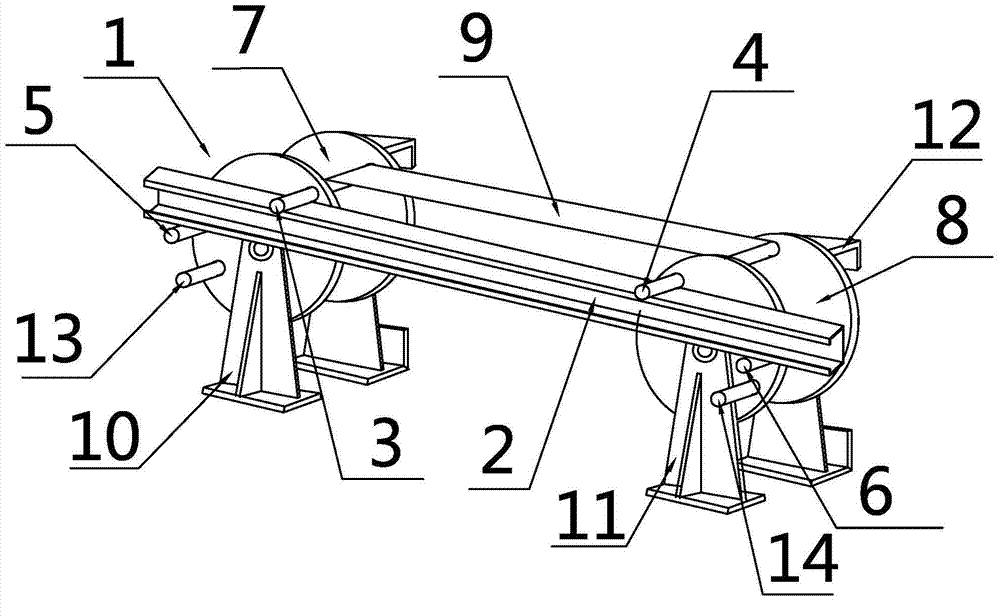

Oceanographic engineering flexible tube cable stretching bending combination experimental facility and experimental method

ActiveCN106442133AAccurately measure vertical displacementEasy to getMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesExperimental methodsPure bending

The invention discloses an oceanographic engineering flexible tube cable stretching bending combination experimental facility and an experimental method. The experimental facility comprises a fixing rotary joint, a four-point bending truss device and an axial tension device. The experimental facility fully combines respective advantages of the four-point bending and the axial tension experiment equipment so that the middle part of the tube cable merely bears pure bending loads and tensile loads, thus realizing stretching bending combination loads under an ideal sate. Besides, the experimental facility has multiple functions and detachability, can conduct a four-point bending experiment and an axial tension respectively without influencing each other, thus realizing a goal of 'one machine, three functions'.

Owner:DALIAN UNIV OF TECH

Method for measuring static elasticity modulus of porous metal material

InactiveCN102998181AAccurate measurementGood repeatabilityMaterial strength using tensile/compressive forcesMechanical solid deformation measurementsMicrometerMetallic materials

The invention discloses a method for measuring static elasticity modulus of a porous metal material. The method comprises the following steps of: measuring the flexibility of a simply supported beam span in different loads by utilizing a simply supported beam four-point bending testing device and adopting static step-by-step loading; subsequently establishing a relationship curve between the flexibility in the span and the loads, and calculating according to a curve slope in equations so as to obtain a single time measurement value of the static elasticity modulus of the porous metal material; and measuring for multiple times within a linear elasticity range, and taking the average value so as to obtain the static elasticity modulus of the porous metal material. The method not only has the advantages of measurement result accuracy, good repeatability, high reliability, simple equipment, low testing cost, simpleness in sample preparation and the like, but also can realize repeated loading (unloading) and multiple measurements within the linear elasticity range; the method can be carried out on a conventional material mechanics pure bending testing table, no strain gages are necessary to be adhered, and only a dialgauge (micrometer gauge) is additionally arranged; and the method is simple and easy to operate and is applicable to popularization and application.

Owner:SHANGHAI UNIV OF ENG SCI +1

Method for adopting bend test to test tensile elasticity modulus of material

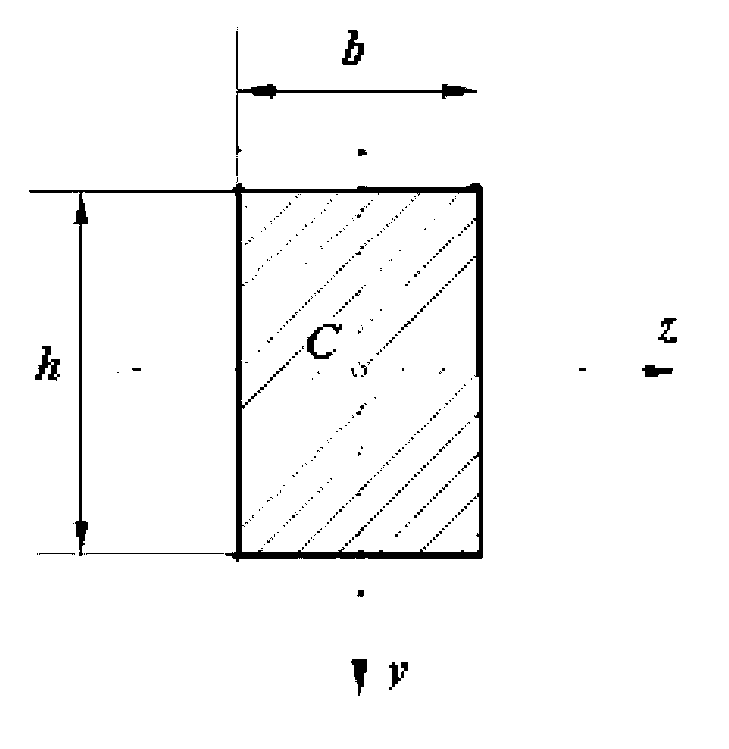

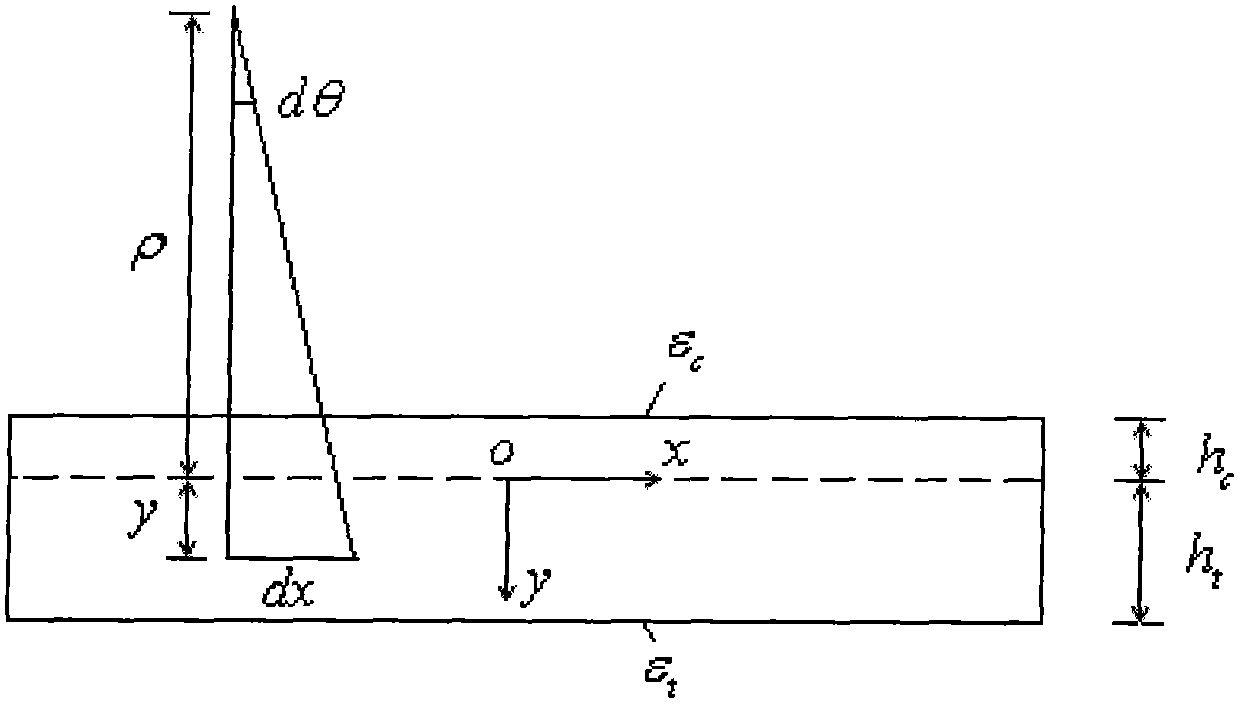

InactiveCN103018112ASolve test problemsReduce workloadMaterial strength using steady bending forcesEngineeringGreek letter epsilon

The invention discloses a method for adopting a bend test to test the tensile elasticity modulus of a material. A compressive elasticity modulus Ec of a material is supposed to be known, and the pure bending or transverse bending small transformation experiment is carried out in a linear elastic range of the material; axial strain values epsilon c and epsilon t of an optional position on upper and lower surfaces of the pure bending section of a sample or axial strain values epsilon c and epsilon t on the upper and lower edges of any cross section of the transverse bending section are measured in an experiment; a relation of the pressure-pulling elasticity modulus ratio and the pulling compressive strain ratio of the material is deduced through an equilibrium condition of a cross section, thereby determining the tensile elasticity modulus Et of the material according to the formulae shown in the specification. The method provided by the invention has the advantages that the theory is correct, a computing formula is concise, the parameter is easy to measure, and the tensile elasticity modulus of the material can be accurately measured.

Owner:SOUTHWEST JIAOTONG UNIV

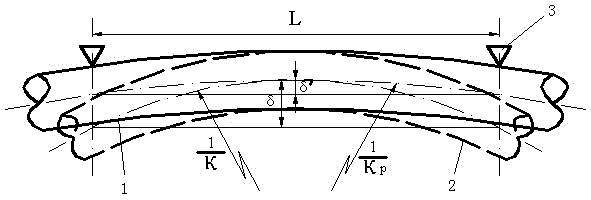

Model for predicting resilience of bar subjected to two roll straightening

ActiveCN104866641AAccurately reflectAccurately describe the stress-strain relationshipSpecial data processing applicationsStress distributionTension compression

The invention relates to a method for predicting resilience of a bar subjected to two roll straightening, and belongs to the technical field of two-roll straightening machines. The method comprises the followings steps: firstly, determining the offset of a stress neutral layer when the rod is subjected to straightening; then, determining a deformation-hardening coefficient and tension-compression stress distribution according to different straightening processes and deformation characteristics of rods in different specifications; finally, determining the model for predicting rebound bending moment and straightening rebound deflection by combining a pure bending and rebound theory, wherein the rebound deflection delta is related to the following variables of R, sigma<t>, lambda, xi, psi, kappa, I, E, L, B, n, R0, Rw, P and tau; R represents a rod radius; sigma<t> represents the yield limit; lambda represents a hardening coefficient; xi represents an elastic region ratio; psi represents a neutral layer offset radius ratio; k represents an anti-bend rate; I represents rod section moment of inertia; E represents modulus of elasticity; L represents the distance between the two end points in three-point bending; B represents a plastic coefficient; n represents a hardening index; R0 represents an initial bending radius; Rw represents an anti-bend radius; P represents straightening force; tau represents a correction coefficient. According to the method, a straightening and deformation process can be truly reflected, and the straightening theory can be perfected; resilience in the straightening process can be accurately predicted, and bases for the roll shape design and process parameter establishment are provided.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

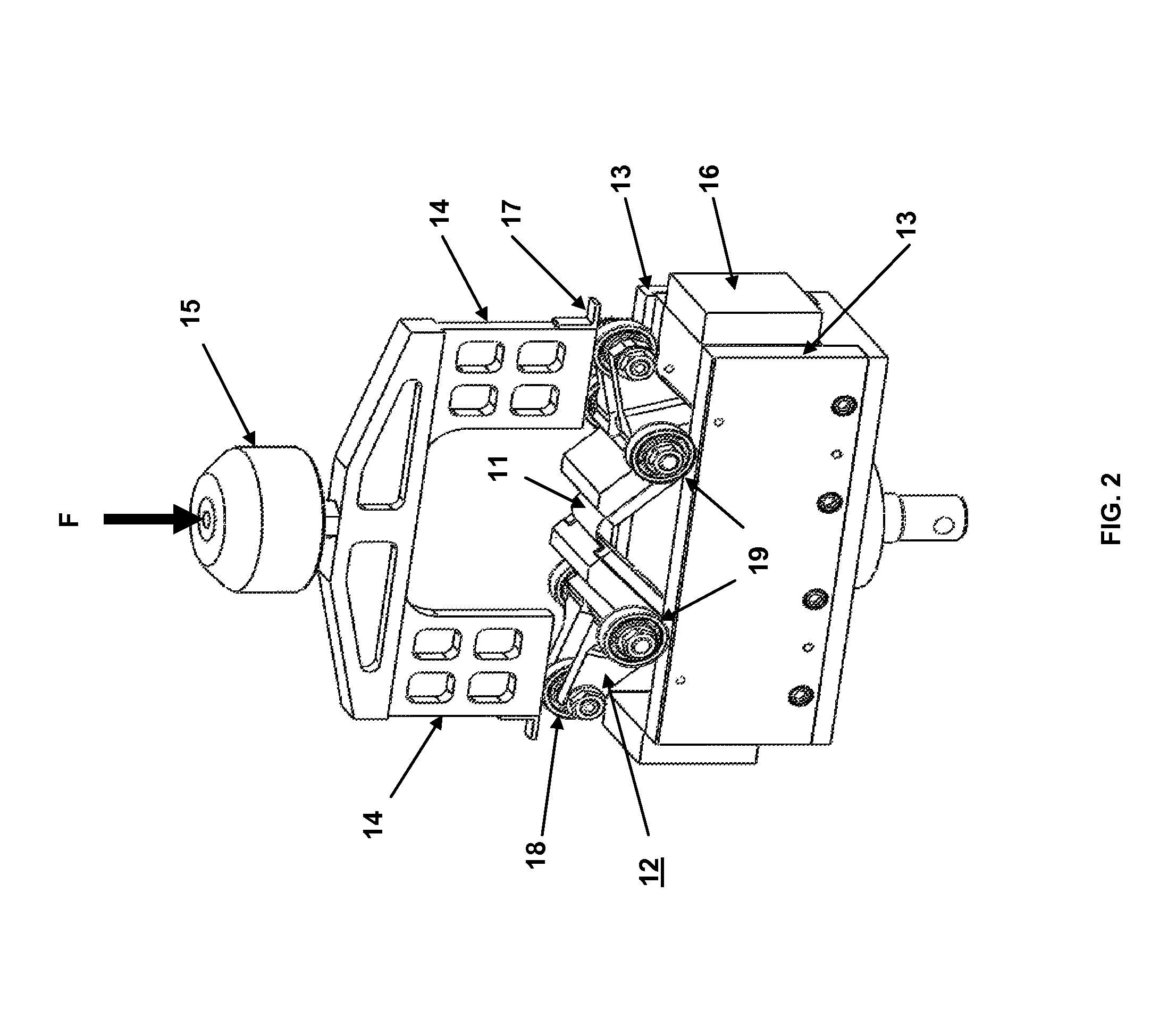

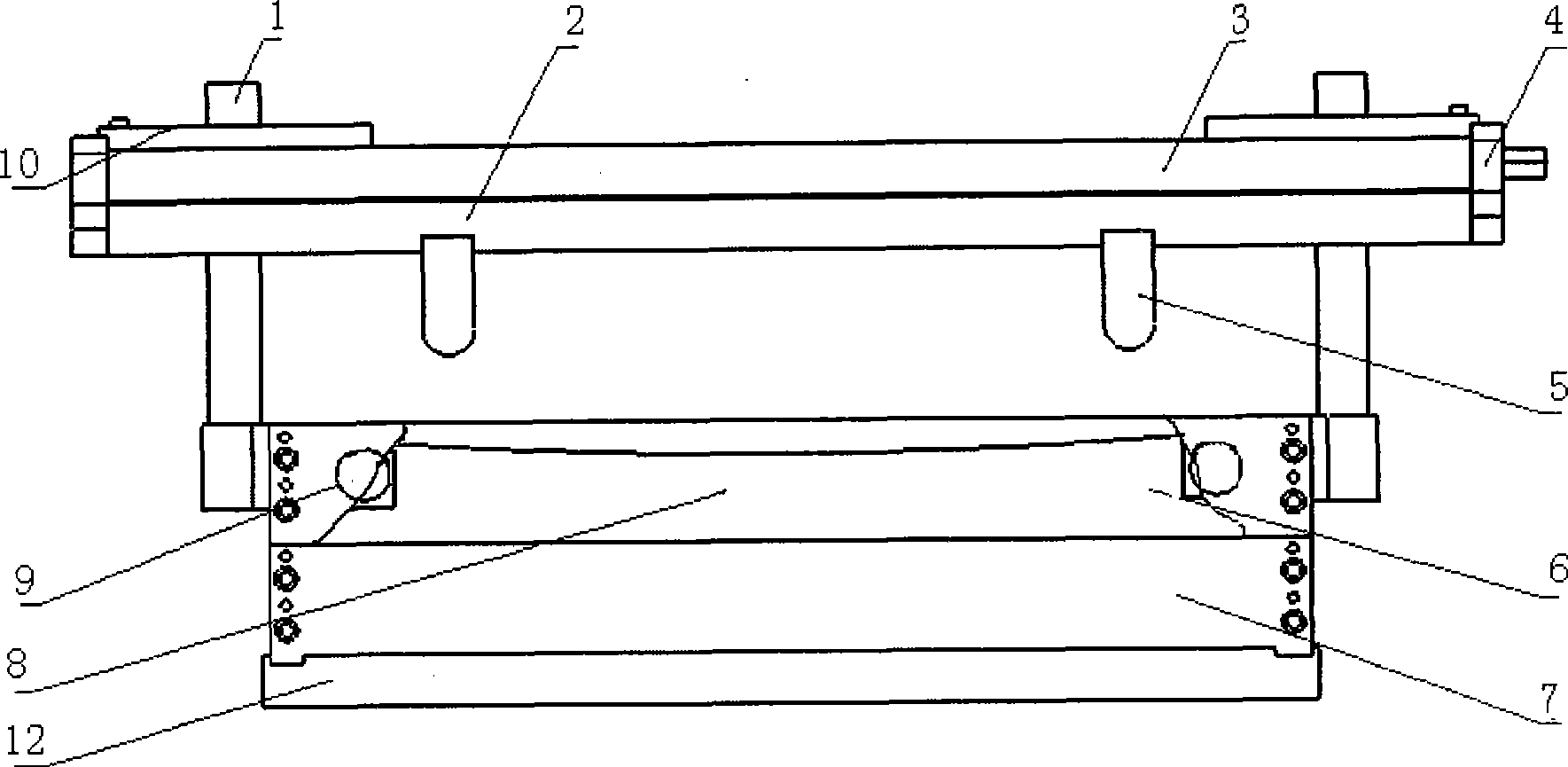

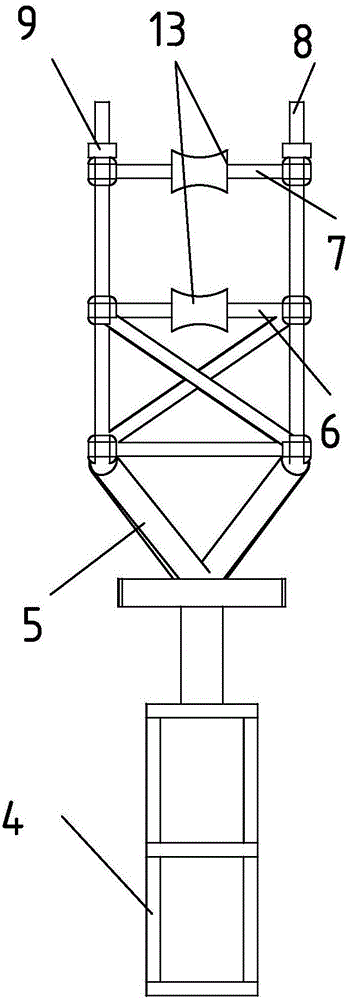

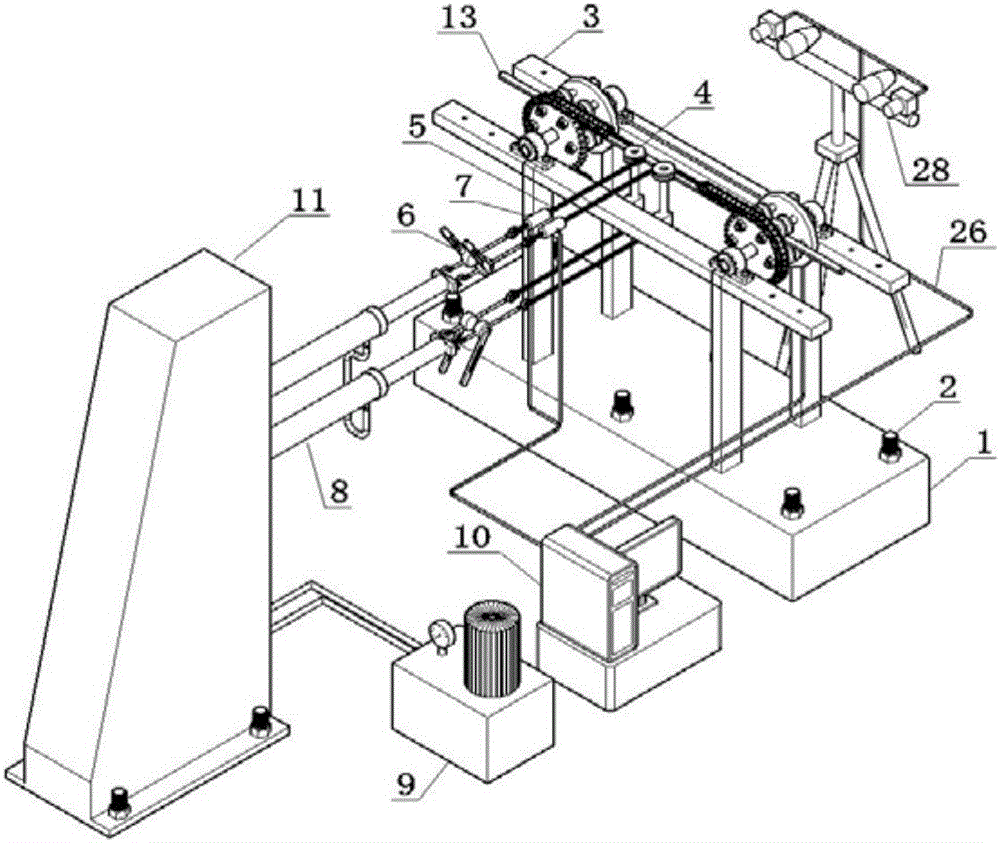

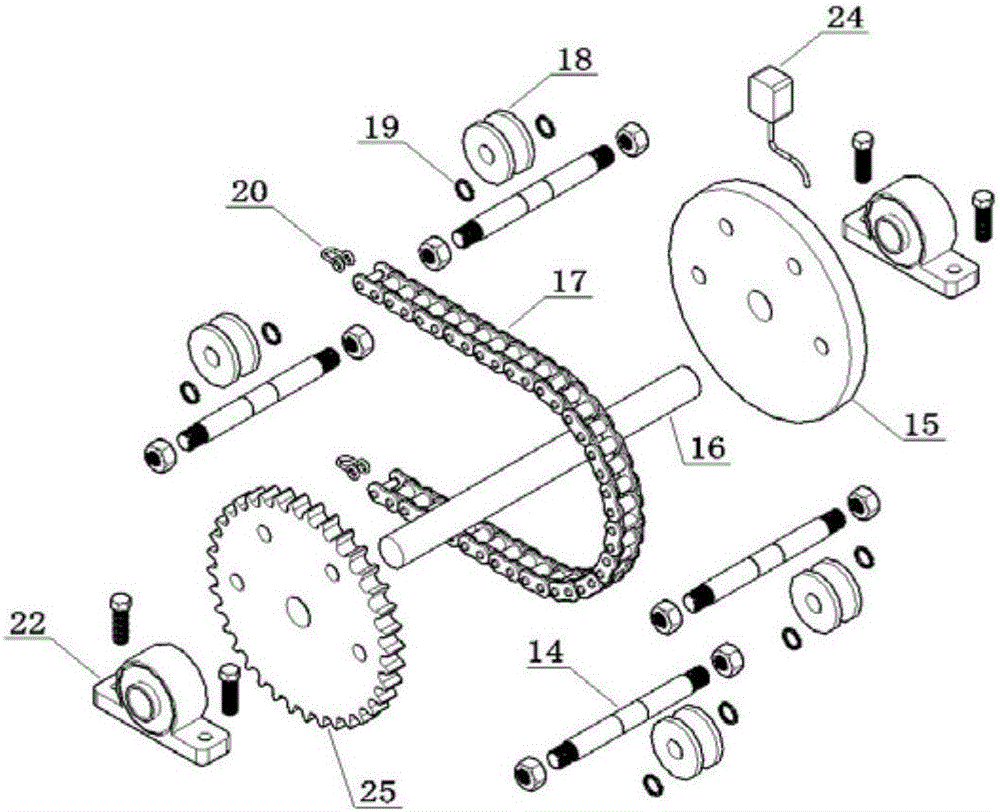

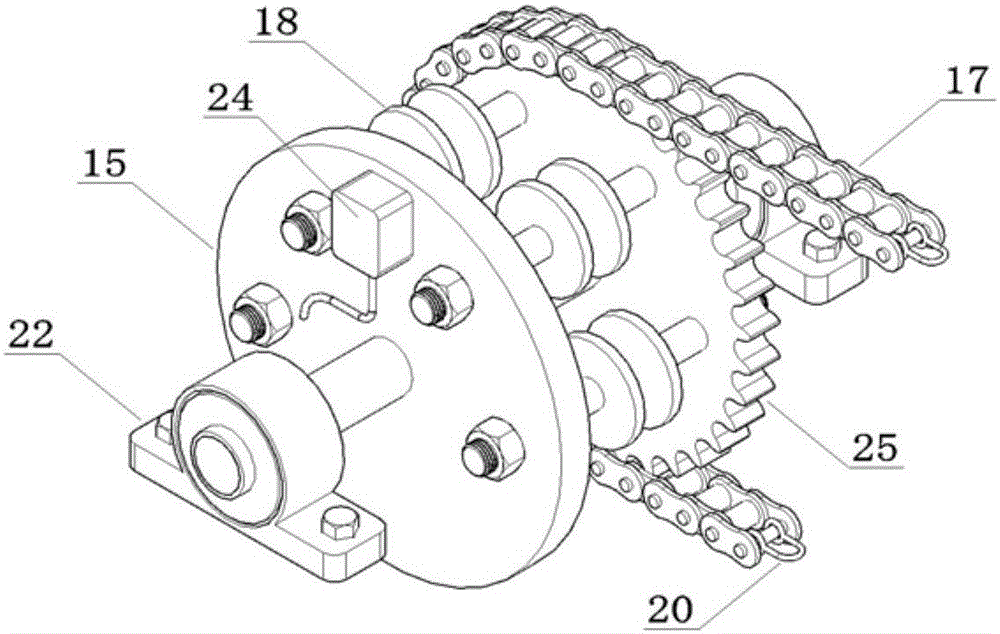

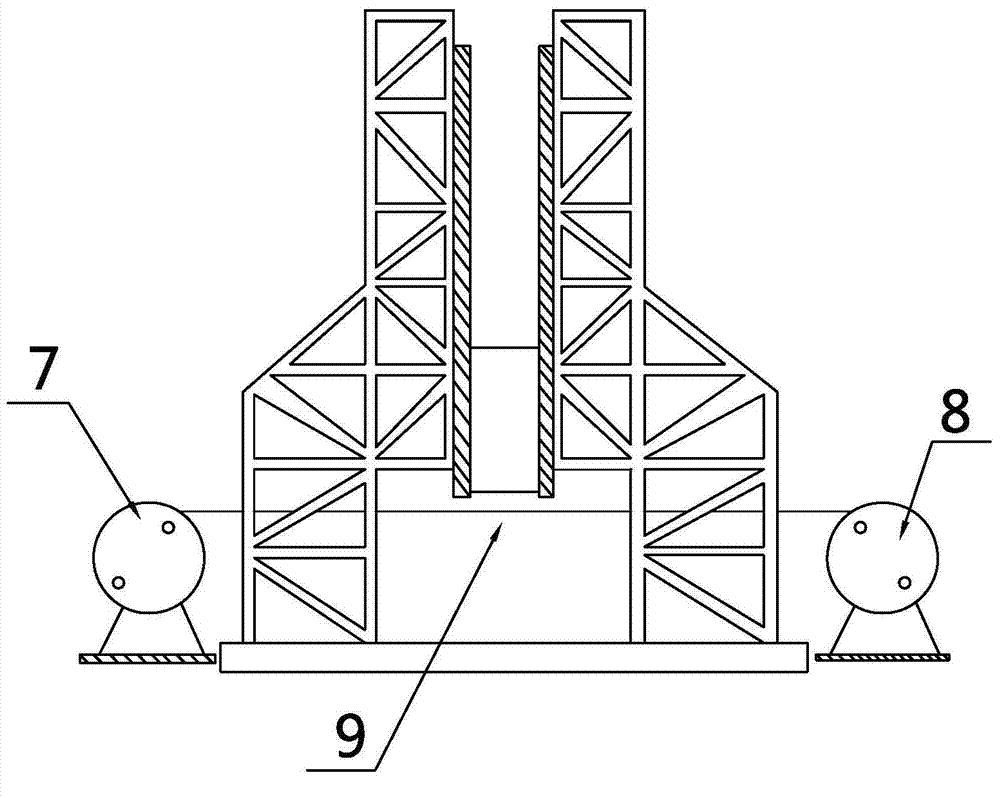

Metal pipe pure bending deformation test device and test method thereof

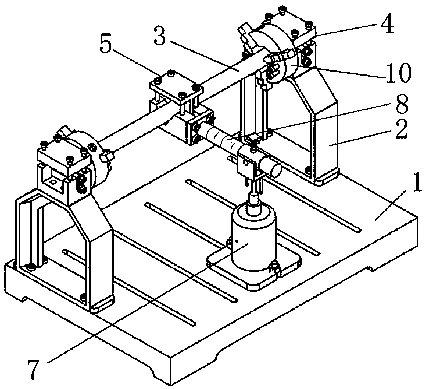

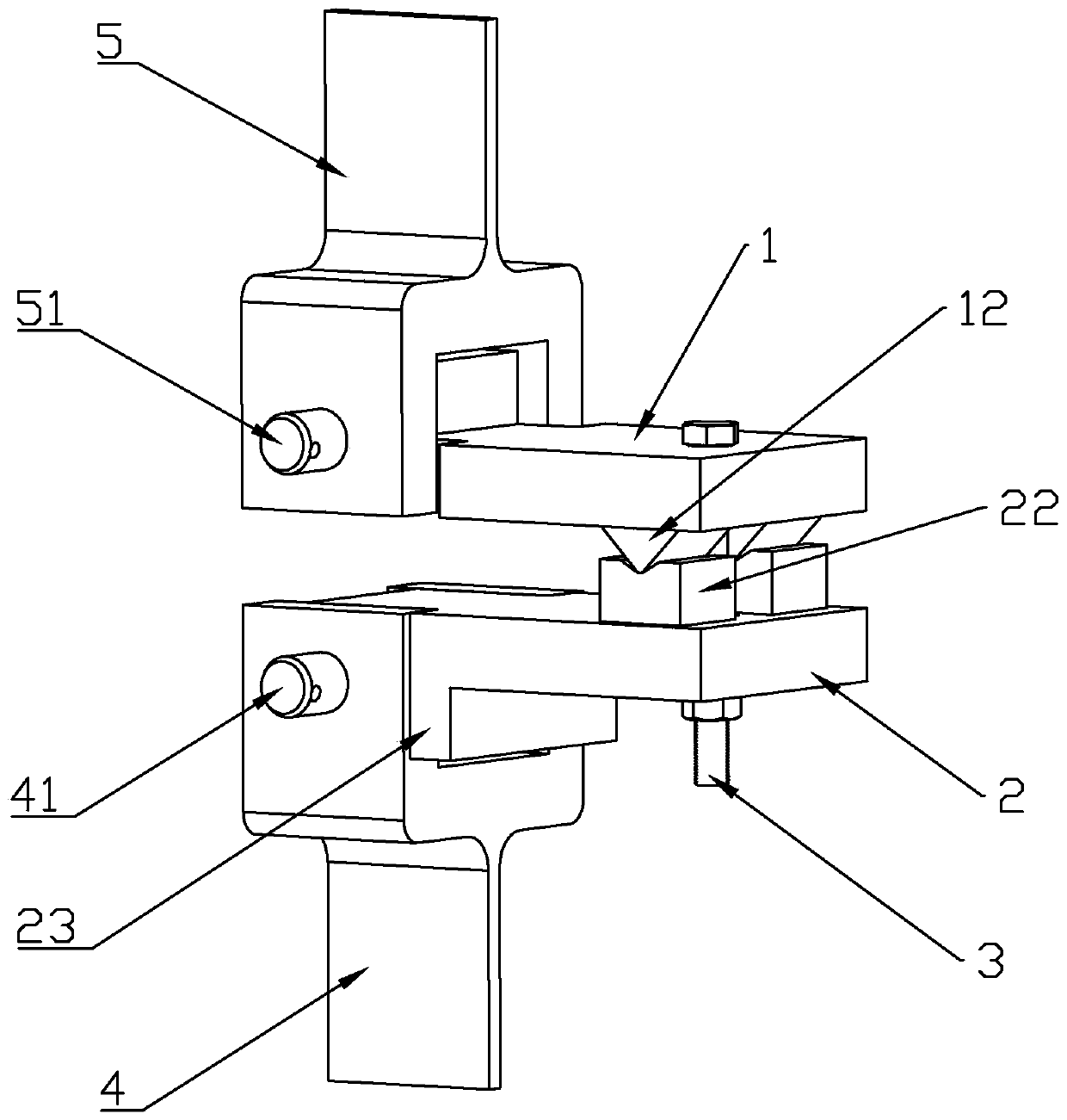

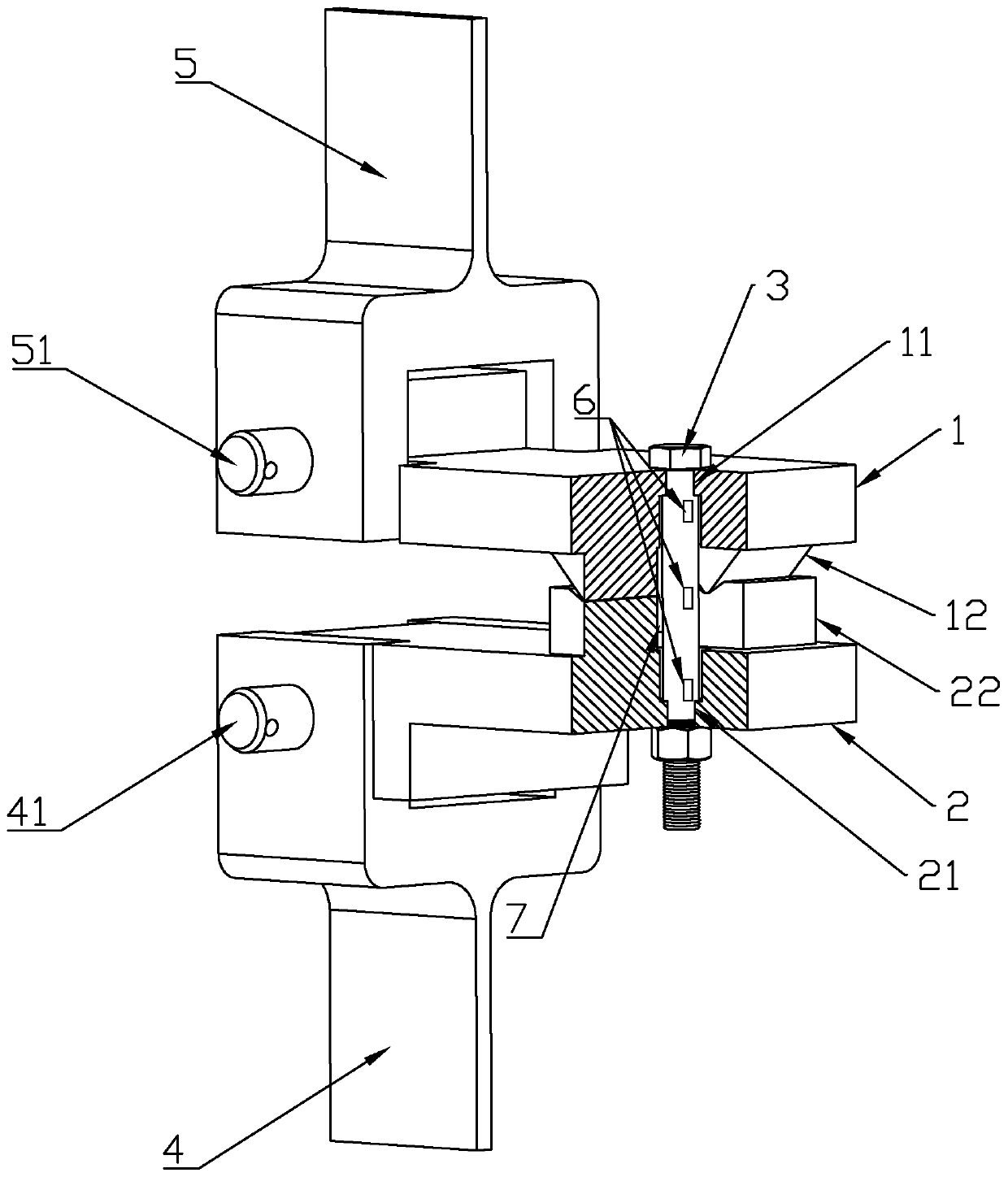

ActiveCN106596289AEliminate uneven forceAvoid failureMaterial strength using steady bending forcesDrive wheelData acquisition

The invention discloses a metal pipe pure bending deformation test device and a test method thereof. The metal pipe pure bending deformation test device comprises a reaction frame, a frame, a hydraulic type double-acting jack, a loading component, a hydraulic pressure station, a data acquisition component and a computer terminal. The metal pipe pure bending deformation test device is characterized in that a U-type groove bearing is assembled on each of connecting shafts of a chain wheel and a balance wheel in a driving wheel component of the loading component, and curvature radius of a groove arc of each U-type groove bearing is consistent with that of the wall surface of a metal pipe which is to be subjected to pure bending test. During test, two ends of the metal pipe are held by groove arc surfaces of the U-type groove bearings in a 360-degree fitting manner, non-radial external force borne by the metal pipe is small, bending deformation approaches to a pure bending state, and accordingly small system errors are achieved; a bending deformation link is automated, so that accidental errors are avoided. The metal pipe pure bending deformation test device is simple and compact in integral structure, and test operation is facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

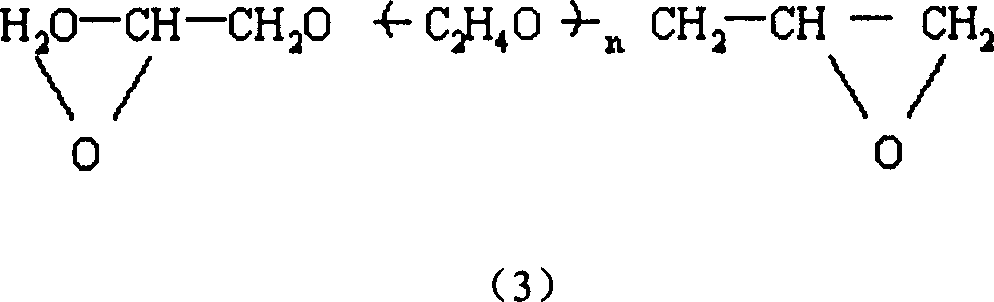

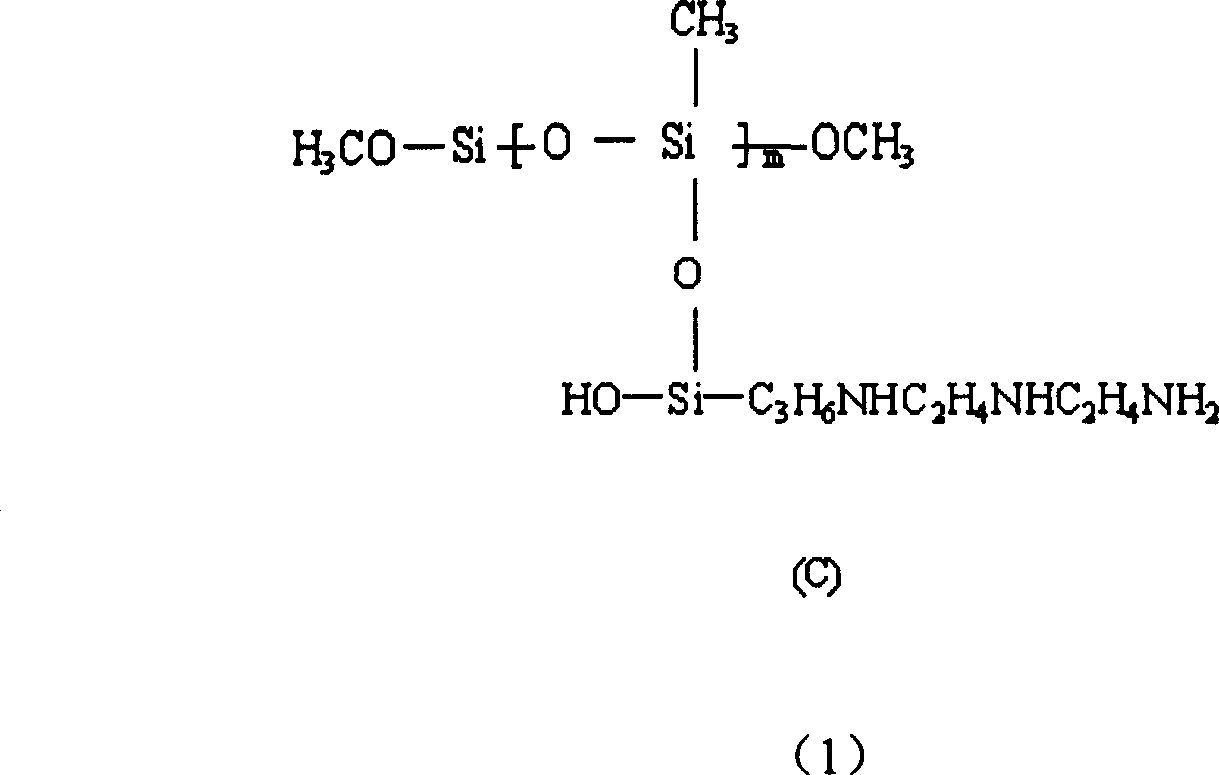

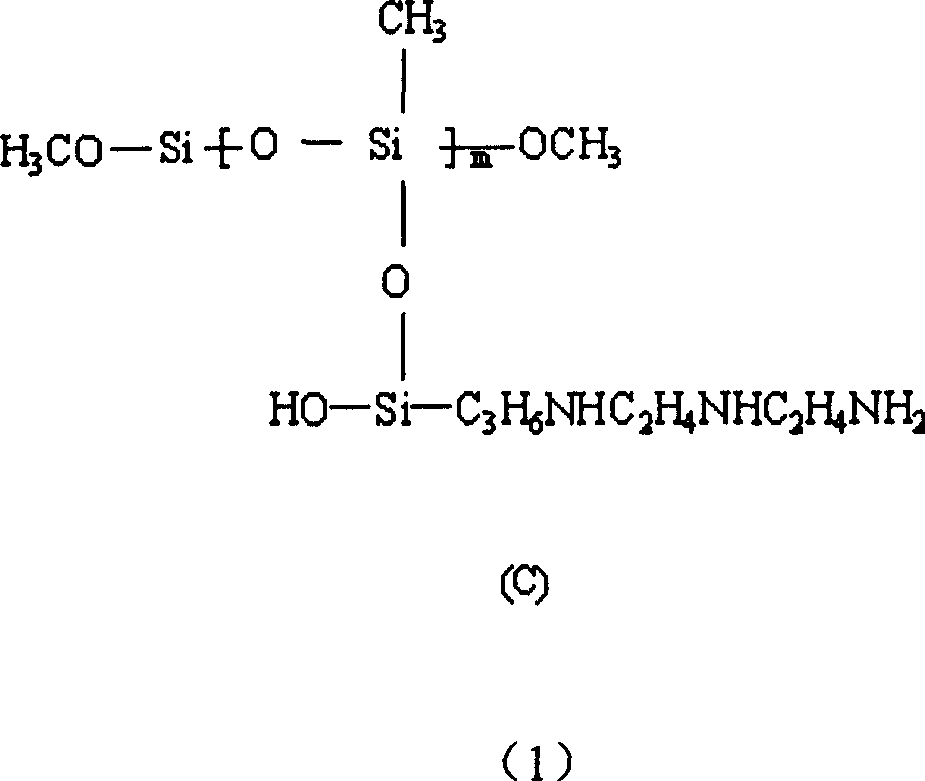

Wool fabric soft finish and application therefor

InactiveCN1970877AUniform crosslinkingGood color uniformity qualityFibre treatmentPerformance indexEngineering

The invention discloses a soft finishing agent for wood fabric and the application. The agent in the invention is suitable for softening finishing of wood fabric. Performance indexes of the wood fabric in the invention, such as softness (pure bending, shearing performance, drape coefficient), anti-pilling (pilling index), machine washing performance (total shrinkage and relaxed shrinkage) and so on, are superior to the related standard of international woodmark and nation. The invention is provided with good quality for color even degree in vision, good performance for anti-teasing and anti-pilling, good handle feeling and good softness degree. There is no international forbidden material in it and when finishing there is no poisonous gas with strong odor discharging. It is in favor of environmental protection.

Owner:SHANGHAI SANMAO ENTERPRISE GROUP

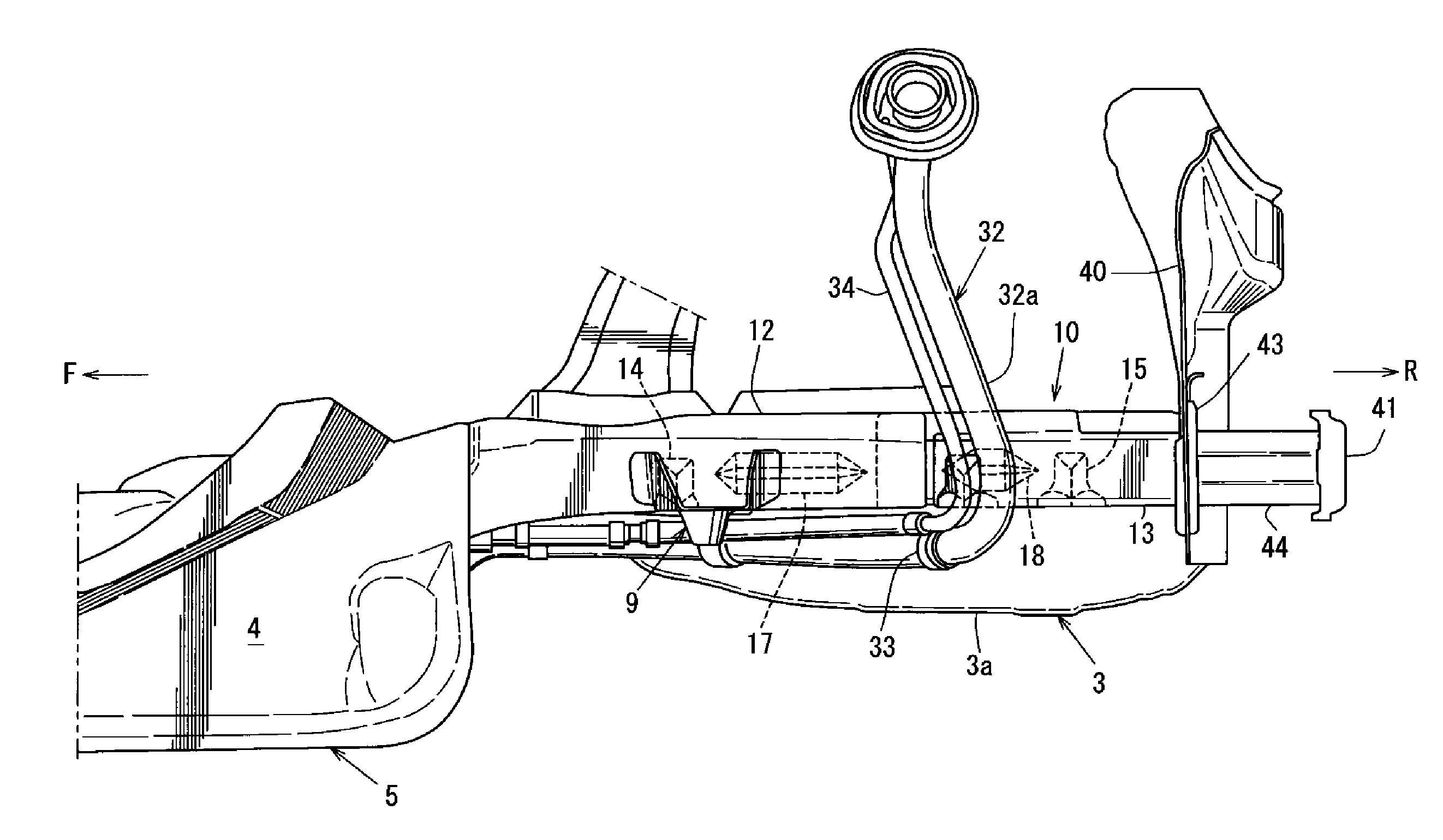

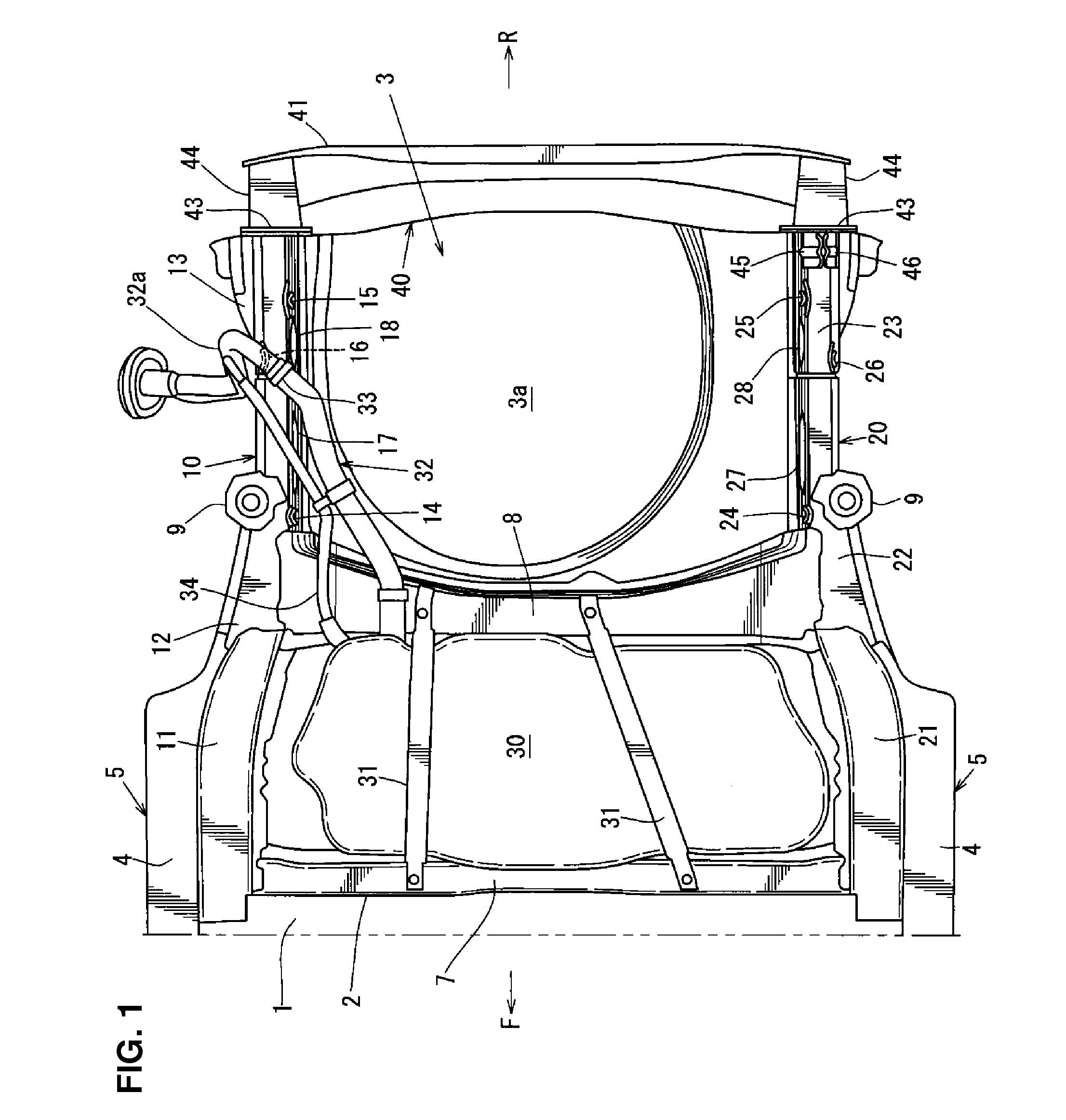

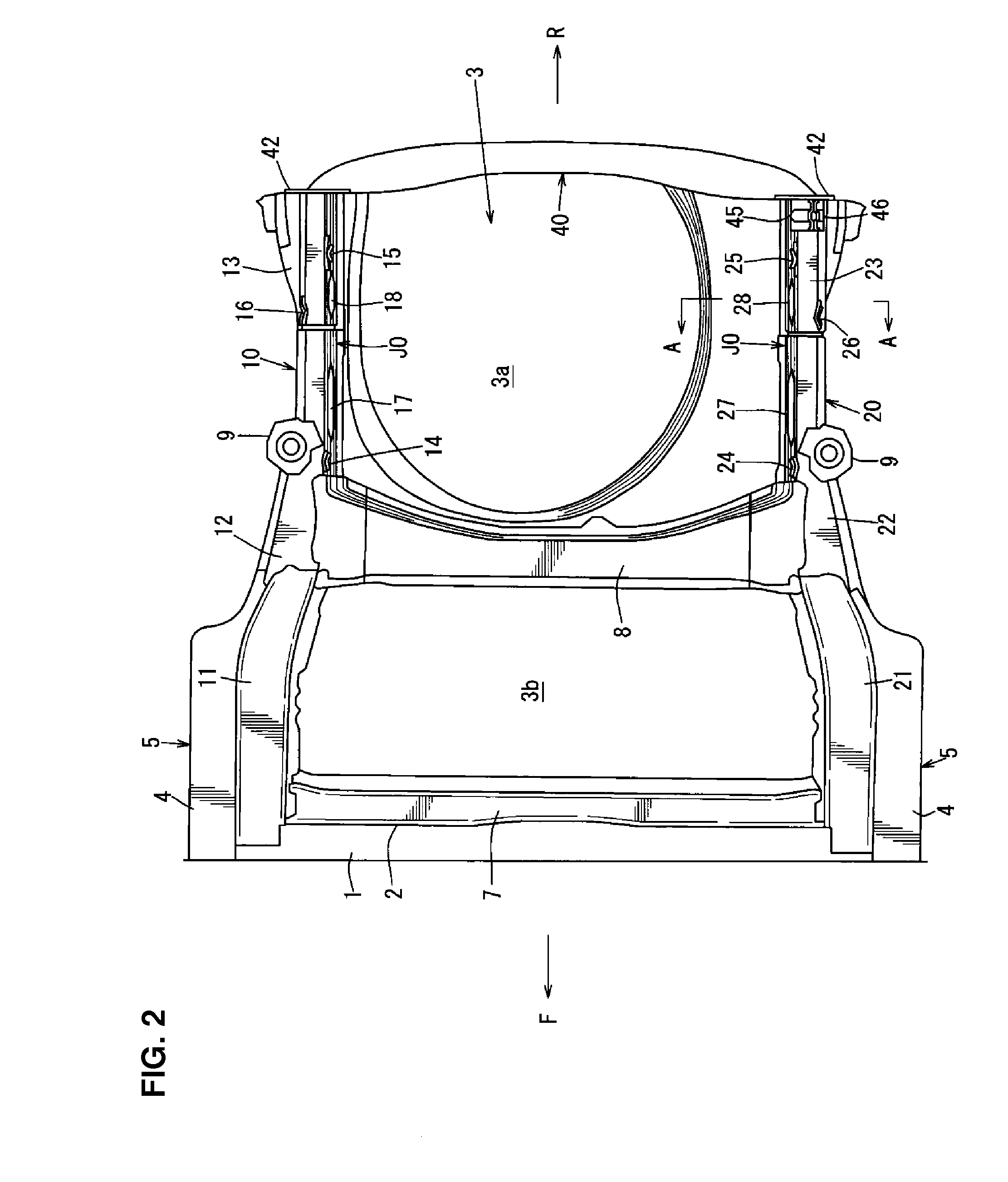

Rear vehicle-body structure of automotive vehicle

ActiveUS20160159400A1Precise absorptionDraw evenlyVehicle seatsUnderstructuresVehicle frameMotorized vehicle

Owner:MAZDA MOTOR CORP

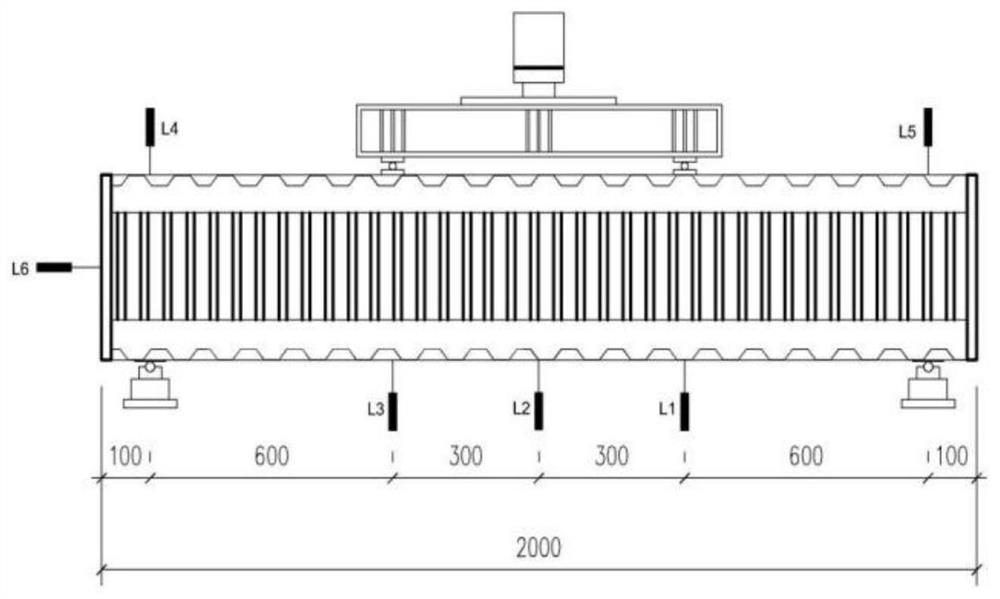

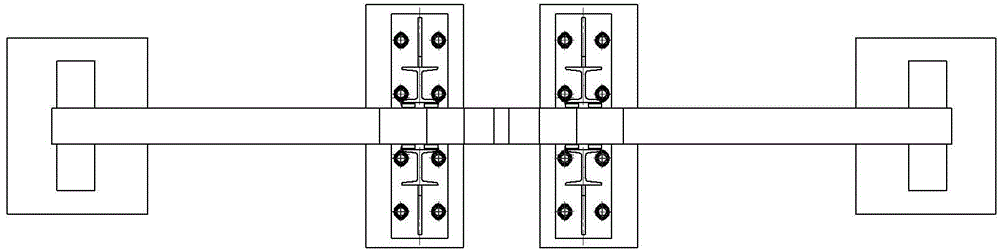

Static and dynamic four-point bending experimental device

ActiveCN103698202AAdjust pure bend distanceMaterial strength using steady bending forcesMaterial strength using single impulsive forceTest sampleBiochemical engineering

The invention discloses a static and dynamic four-point bending experimental device. The static and dynamic four-point bending experimental device comprises a device main body, a first loading part and a second loading part for loading a test sample, and a first support part and a second support part for supporting the test sample, wherein the device main body comprises a first runner and a second runner, the distance between the first runner and the second runner is adjustable, the first runner and the second runner are connected through a belt, the first loading part and the first support part are arranged on the first runner, the second loading part and the second support part are arranged on the second runner, and when the belt is subject to downward impact force, the belt drives the first runner and the second runner to rotate, the first loading part and the second loading part are simultaneously loaded on the upper surface of the test sample, and the first support part and the second support part are simultaneously supported on the lower surface of the test sample. The static and dynamic four-point bending experimental device has the advantage of being capable of adjusting the pure bending distance of the test sample, and is suitable for the test samples in various sizes.

Owner:NINGBO UNIV

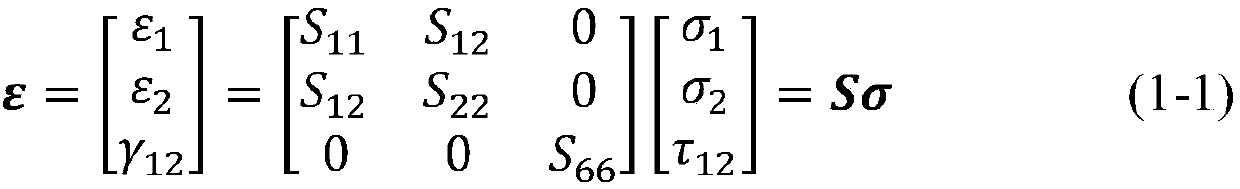

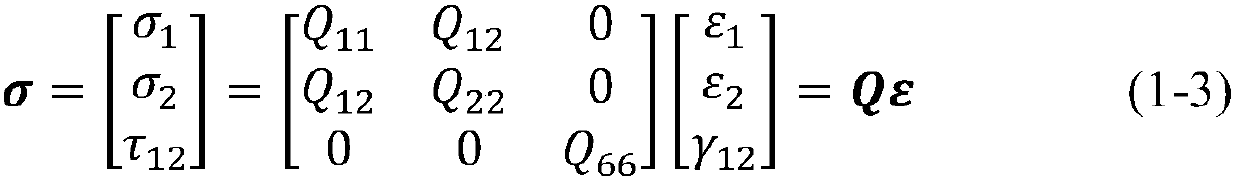

Calculation of equivalent modulus of composite laminates and strength verification under given load

ActiveCN108984841AFast resultsHigh precisionSustainable transportationDesign optimisation/simulationIn planeMaterial Design

The invention relates to the field of composite material design, in particular to calculation of equivalent modulus of composite laminates and strength verification under a given load. The invention comprises an information input module, an operation module and an information output module. Material property information, laminating information and load data information are input into the information input module. Three stiffness matrices A, D, B of composite laminates are calculated according to the input data by a computing program, and the equivalent modulus and stiffness matrices of composite laminates under pure in-plane load and pure bending-torsion load are calculated according to the matrix A and matrix D. At the same time, according to the stiffness matrix and load information, theoverall strain and deflection rate of the laminate can be calculated, and the stress and strain information of each single layer can be obtained. Through adoption of three composite failure criteria,whether the laminate meets the strength requirements under the specified load can be checked. The invention greatly improves the calculation speed, and the accurate numerical solution of stress and strain can be directly and quickly obtained for the analysis of the laminated plate under the simple stress condition, and the design efficiency is improved.

Owner:WEIHAI GUANGWEI COMPOSITES

Method for calculating flexural capacity of variable cross-section column

PendingCN111753351AAnti-bending capacity design formula, accurate calculationAccurate calculationGeometric CADDesign optimisation/simulationElement analysisClassical mechanics

The invention discloses a method for calculating the flexural capacity of a variable cross-section column. The method comprises the following steps: S1, calculating and determining a hoop coefficienttheta of a component; and S2, substituting the parameters into a formula to solve the ultimate flexural capacity. The influence of the corrugated plates, the area conversion of the irregular concretesection, the enhancement of the structural constraint effect and other factors are considered, the steel pipe, the corrugated plates and the concrete can be synergistically stressed under the pure bending load, the overall working performance of the combined column is good, and the deflection and cracks of the combined column can be effectively controlled; and the influence of the concrete strength grade on the flexural capacity of the component under the pure bending load is small. The mean value of the ratio of the crustacean column flexural capacity obtained through a calculation formula tothe ultimate bending moment obtained through finite element analysis is 0.999, the variance is 0.009, and the flexural capacity of the crustacean column can be accurately calculated.

Owner:JIANGNAN UNIV

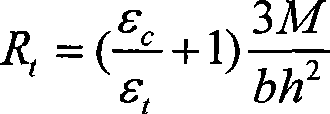

Improved method for testing tensile strength of material by bending test

InactiveCN102998187ASolving experimental measurement problemsDetermination of tensile strengthMaterial strength using steady bending forcesTension compressionTest sample

The invention provides an improved method for testing tensile strength of a material by a bending test, which particularly relates to an improved method for testing tensile strength of a material by a pure bending test or a transverse bending test. The conventional tensile strength calculation formula has the problem that a tension-compression elastic modular ratio of the material is inconveniently measured. Aiming at the problem, the improved method takes a strain ratio of corresponding positions on the upper surface and the lower surface of a beam to express tension-compression elastic modulus, thus obtaining an improvement on the method for testing the tensile strength of the material. The improved method comprises the following steps of: loading a beam test sample with a rectangular cross section; recording loads born by the test sample; and measuring axial strain values epsilon c and epsilon t in any position on the upper surface and the lower surface of a pure bending section or axial strain values epsilon c and epsilon t on the upper edge and the lower edge of any cross section of a transverse bending section when the test sample is subjected to linear elastic deformation. A calculation formula of the tensile strength Rt of the material can be derived from a theory of mechanics, and in the calculation formula, M is a maximum bending moment to the test sample which is subjected to critical failure; and b and h respectively are width and height of the cross section of the test sample. The improved method provided by the invention has the advantages of accurate principle, concise calculation formula and easiness of parameter measurement, and can be used for accurately measuring the tensile strength of the material.

Owner:SOUTHWEST JIAOTONG UNIV

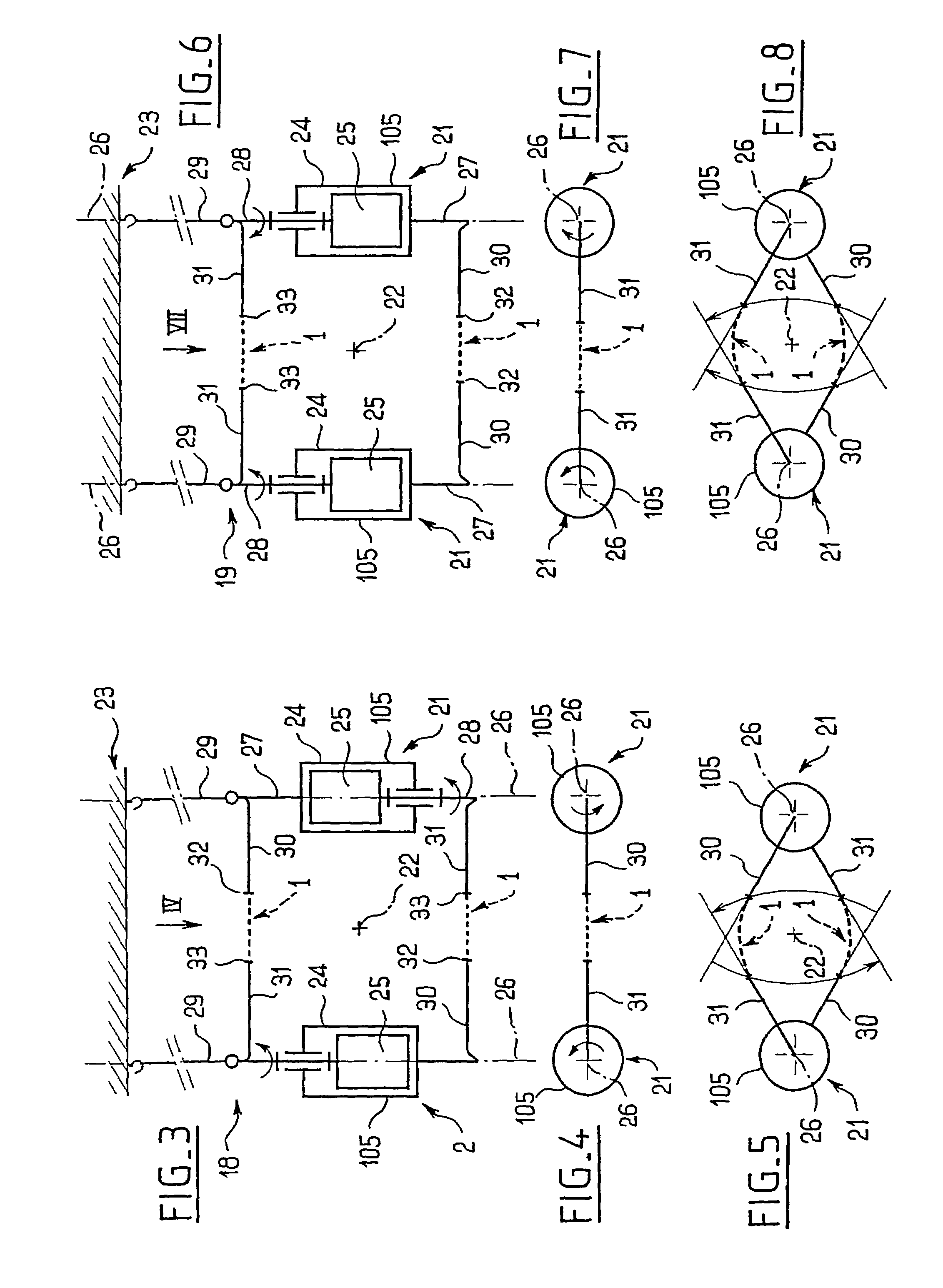

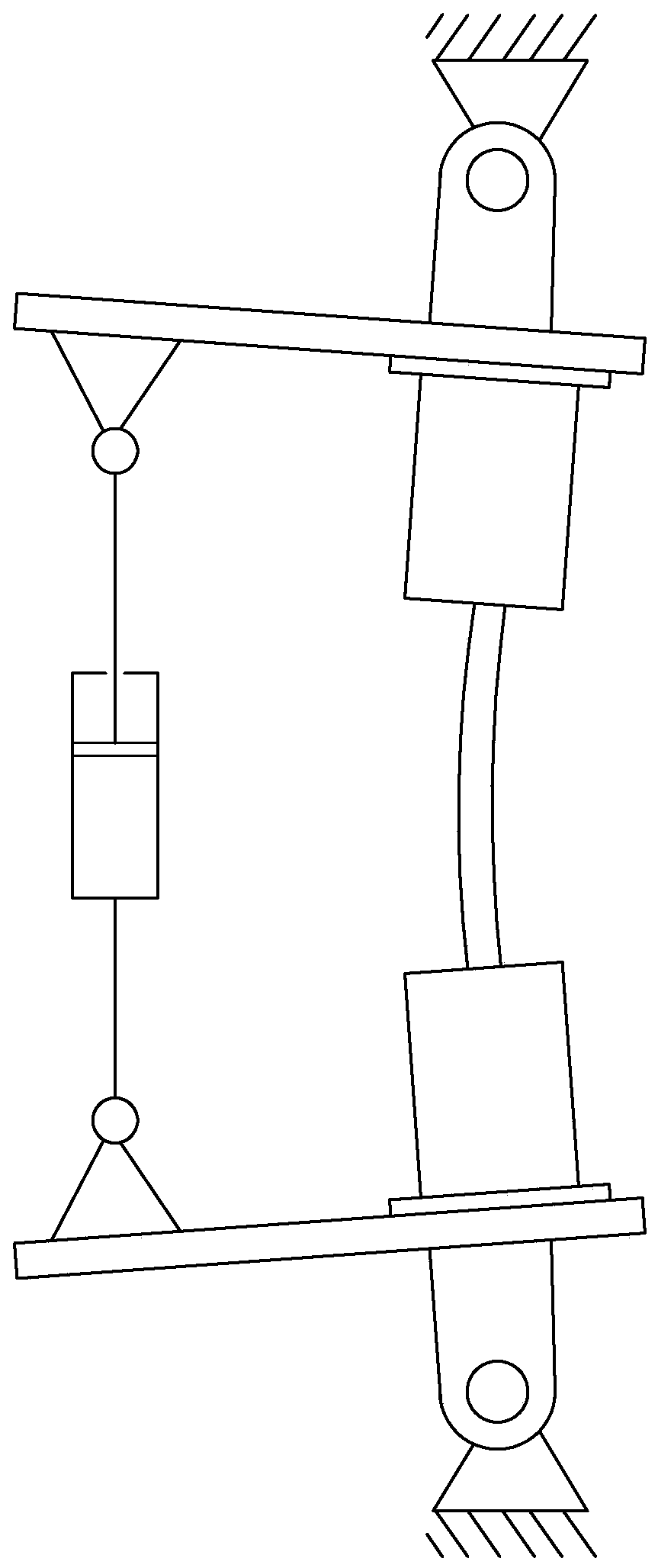

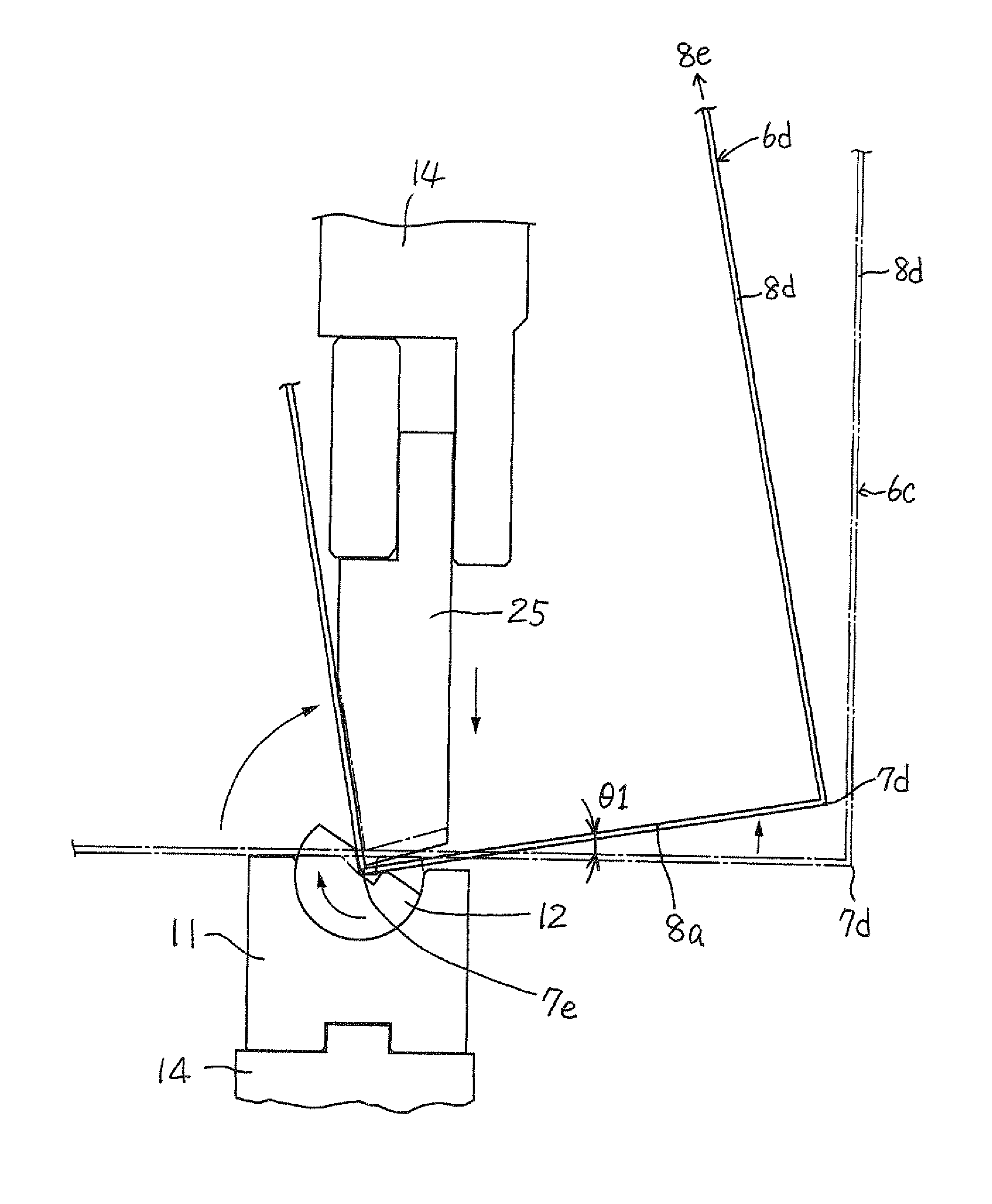

Method, device and machine for pure bending test optionally alternating

InactiveUS7017423B2Freedom of movementReduce riskMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesControl theoryPure bending

The present invention provides a method, apparatus, and a machine for testing in pure bending, optionally in alternating bending. Two mutually identical testpieces are subjected to optionally alternating opposing bending movements while conserving mutual symmetry about a point, under drive from two controlled motor assemblies that are free to move relative to each other. Interfering forces induced in the two testpieces during testing are minimized, and the performance of the testpieces in pure bending can be studied with increased accuracy.

Owner:CENT NAT DE LA RECHERCHE SCI

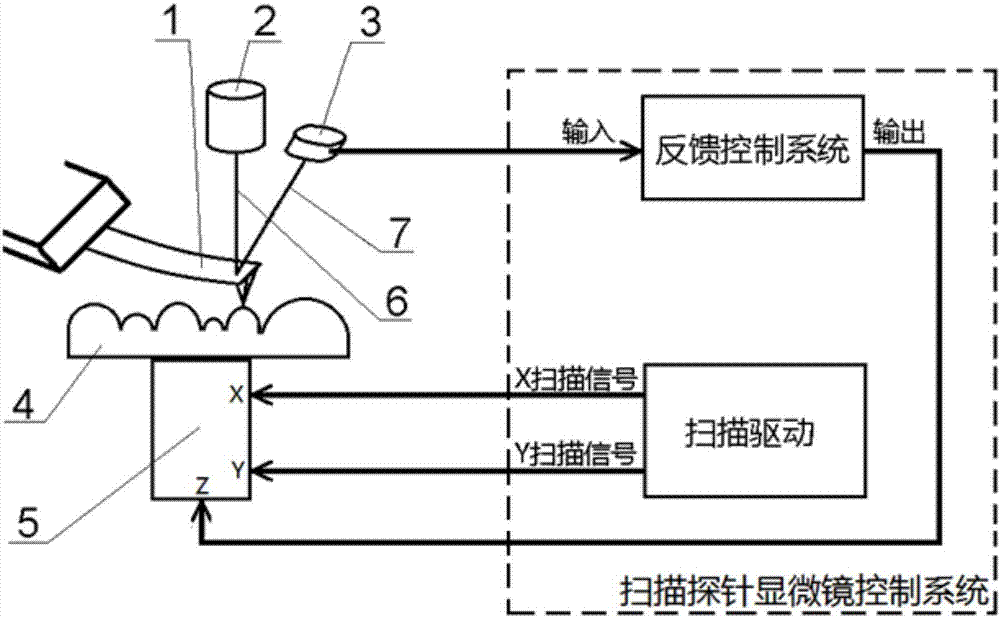

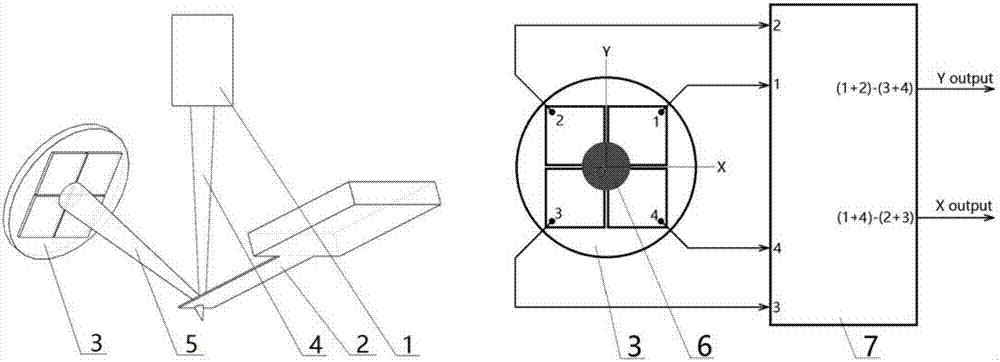

Novel scanning probe microscope detecting method and system

ActiveCN107085127AGuaranteed response frequencySimple structureScanning probe techniquesFour quadrantsResponse Frequency

The invention provides a novel scanning probe microscope detecting method and system. The system comprises a light source, a micro-cantilever probe, a four-quadrant receiver and a receiver signal processing module. The incident light emitted by the light source is reflected by the micro-cantilever probe to form reflected light. The reflected light is received by the four-quadrant receiver. The output end of the four-quadrant receiver is connected with the input end of the receiver signal processing module. The position where the light source and the four-quadrant receiver are adjusted and fixed can make the plane of the central axis of the incident light and the central axis of the reflected light perpendicular to the cantilever beam extension axis of the micro-cantilever probe. According to the invention, the plane of the central axis of the incident light and the central axis of the reflected light is perpendicular to the cantilever beam extension axis of the micro-cantilever probe; two kinds of motion modes such as probe bending and probe lift are fully decoupled on a detection signal; the structure is simple; the cost is low; and the micro-cantilever probe is used as the only load, which ensures the response frequency of a scanning drive. The novel scanning probe microscope detecting method and system can be widely applied to the technical field of microscopes.

Owner:BEING NANO INSTR LTD

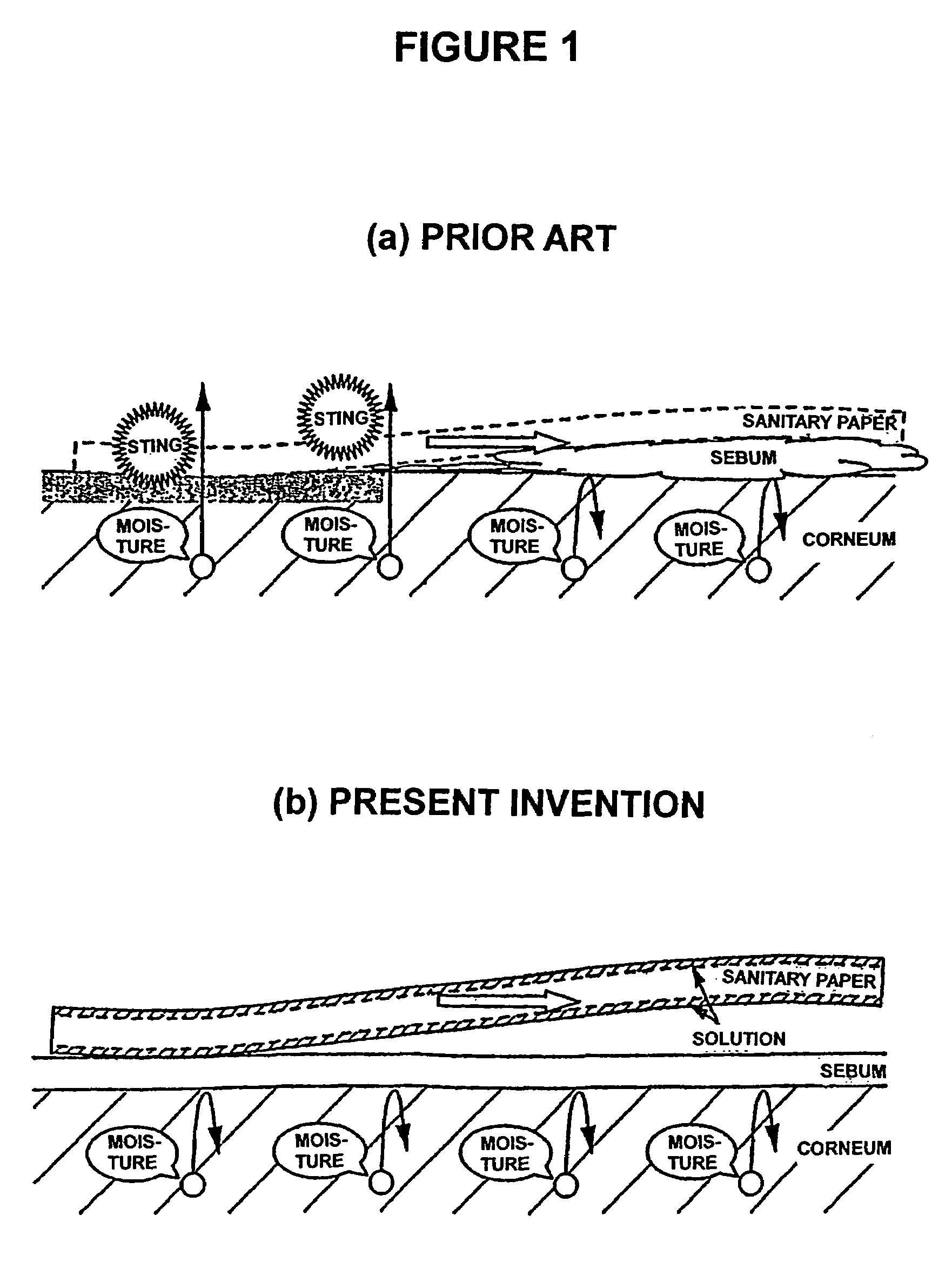

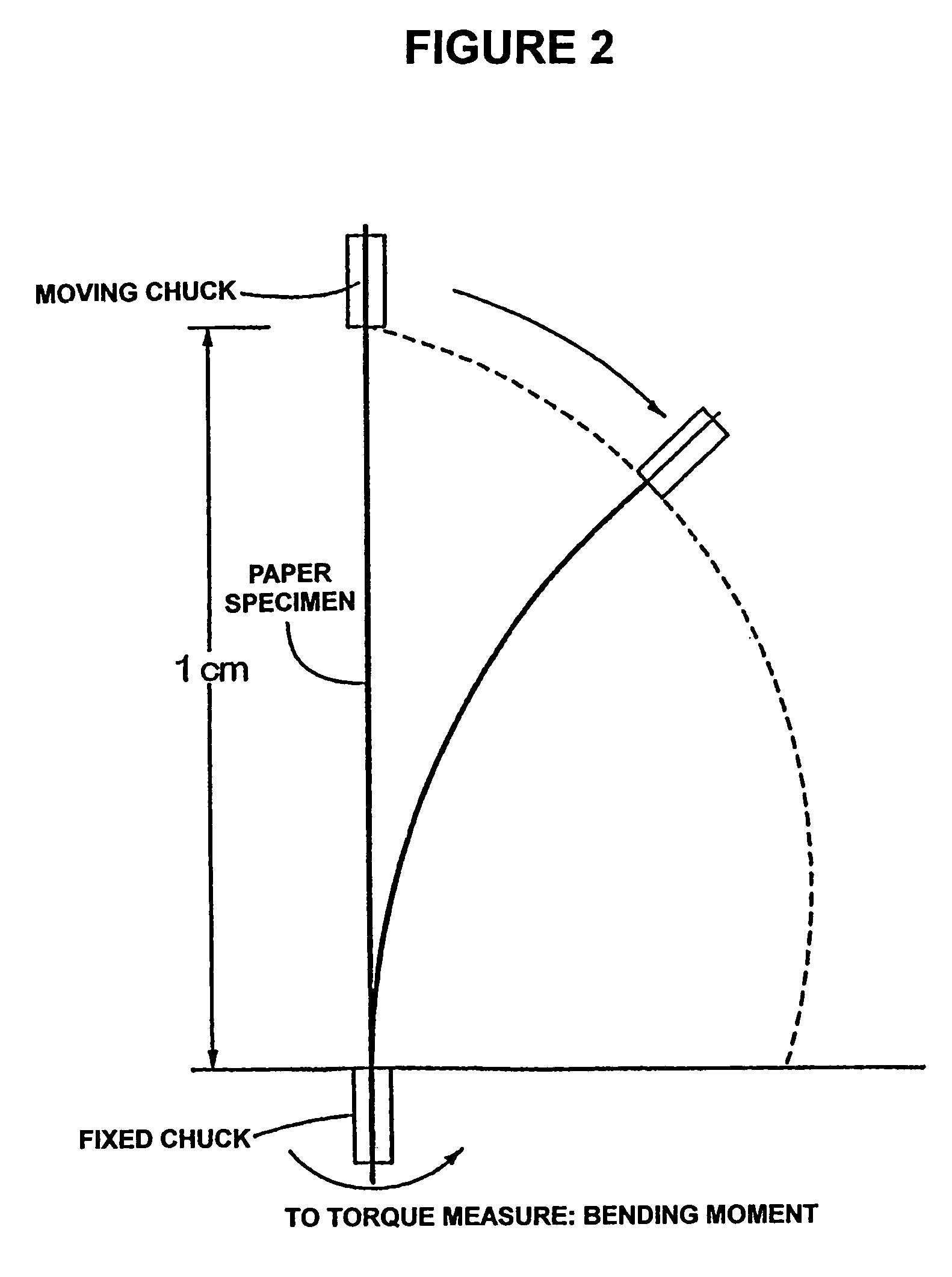

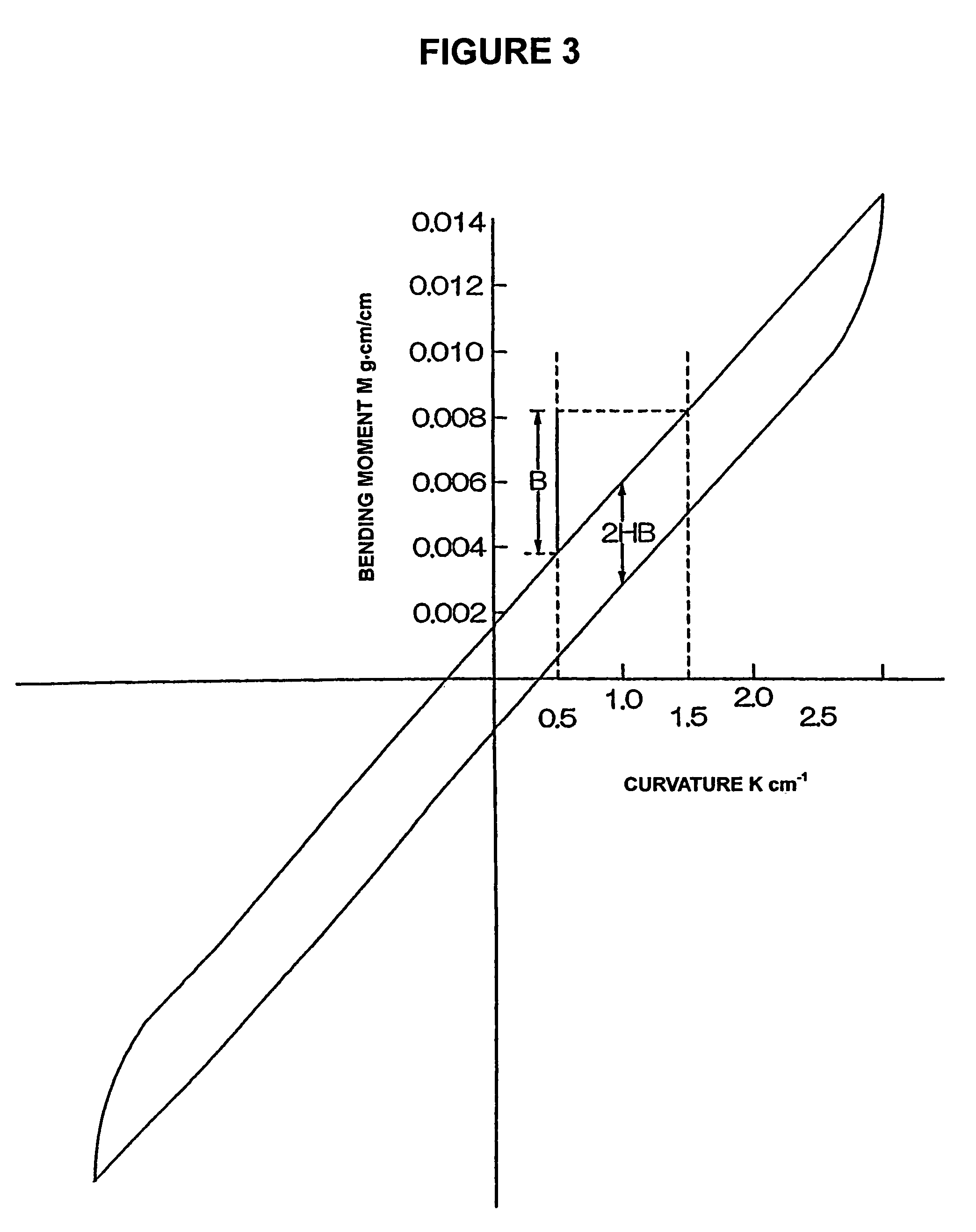

Sanitary paper

It is intended to provide sanitary paper which is excellent in texture such as moistness and softness and scarcely causes skin irritation or blushing even if it is brought into contact with the skin frequently. Namely, sanitary paper having an oil absorbance specified in JIS P8141 of 7 mm or less and a moisture content of from 9.50 to 15.00% (measured in accordance with JIS P8127 after conditioning in accordance with JIS P8111); carrying a solution, which contains a moistening agent, a softener, an antioxidant and so on, coated in a dose of 46.0 to 160.0 mg / cm3 of the paper base; and having a bending hardness B measured with the use of a pure bending machine of from 0.0040 to 0.0060 g·cm2 / cm.

Owner:DAIO PAPER CORP

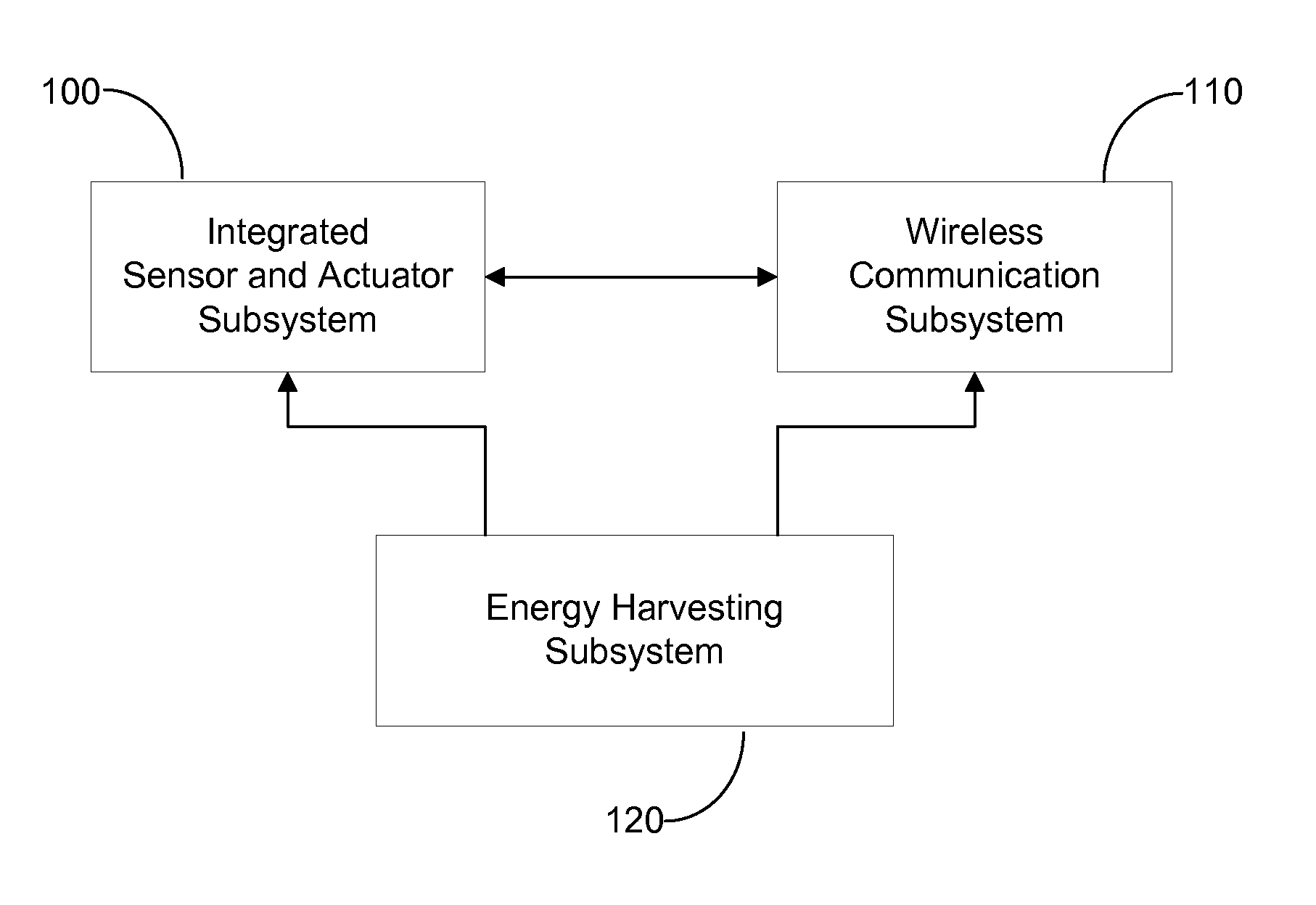

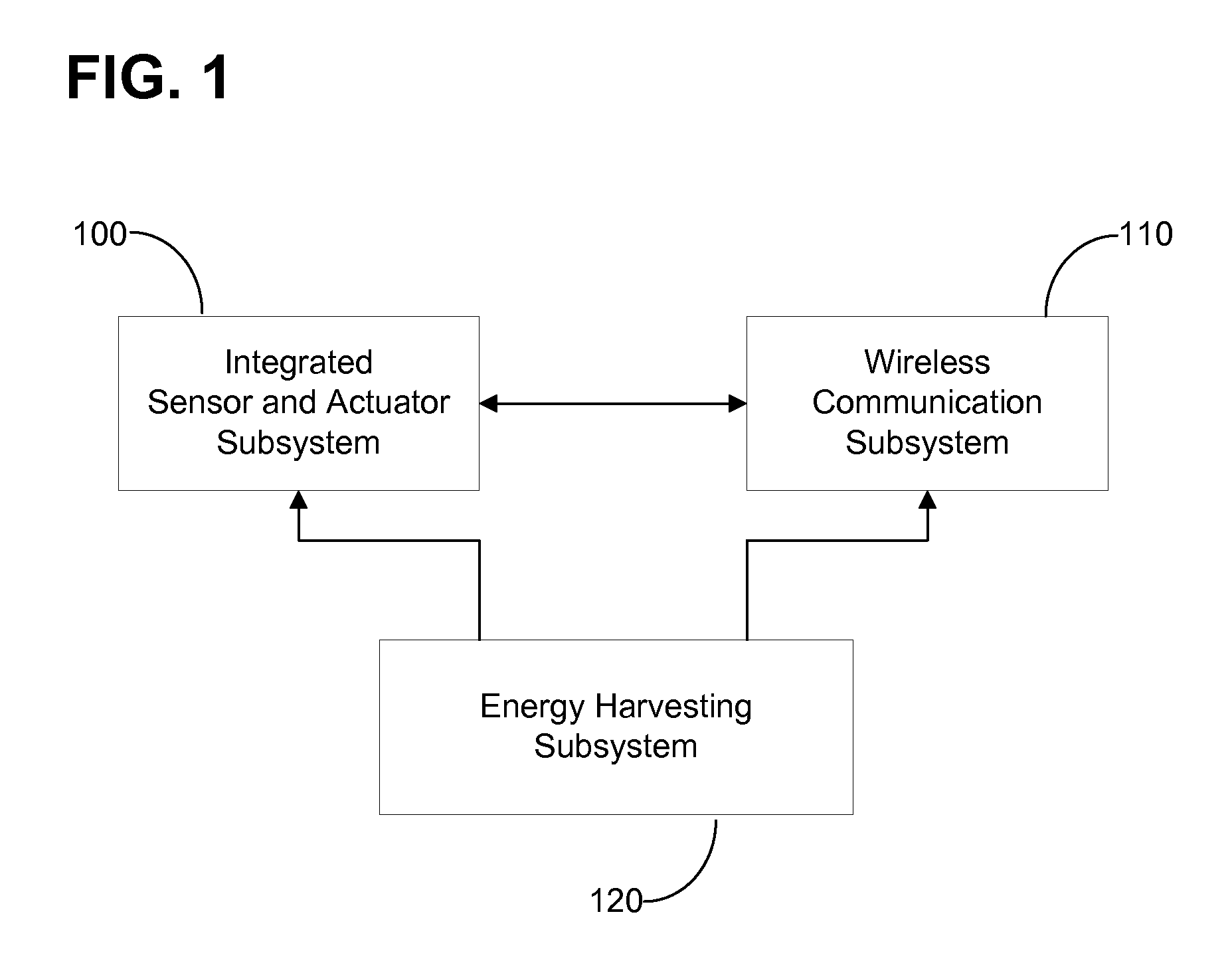

Wireless microelectromechanical systems (MEMS) pressure sensor with built-in calibration

ActiveUS7918138B2Fluid pressure measurement by electric/magnetic elementsForce measurementPressure senseEngineering

A wireless microelectromechanical system (MEMS) pressure sensor with built in calibration. An actuator is coupled with a pressure sensing device to enable the pressure to be calibrated against the known pressure exerted by the actuator. The sensing component is configured to flex under the application of force to a pure bending condition, i.e., the sensing component flexes with no or insignificant shear forces in the sensing component.

Owner:GOVERNMENT OF THE UNITED STATES THE AS REPRESENTED BY THE SEC OF THE NAVY +1

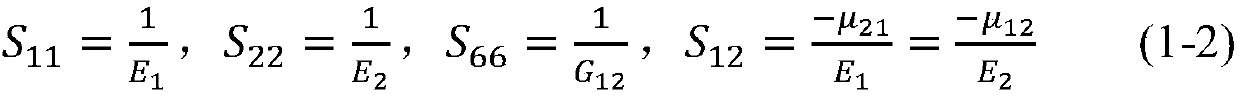

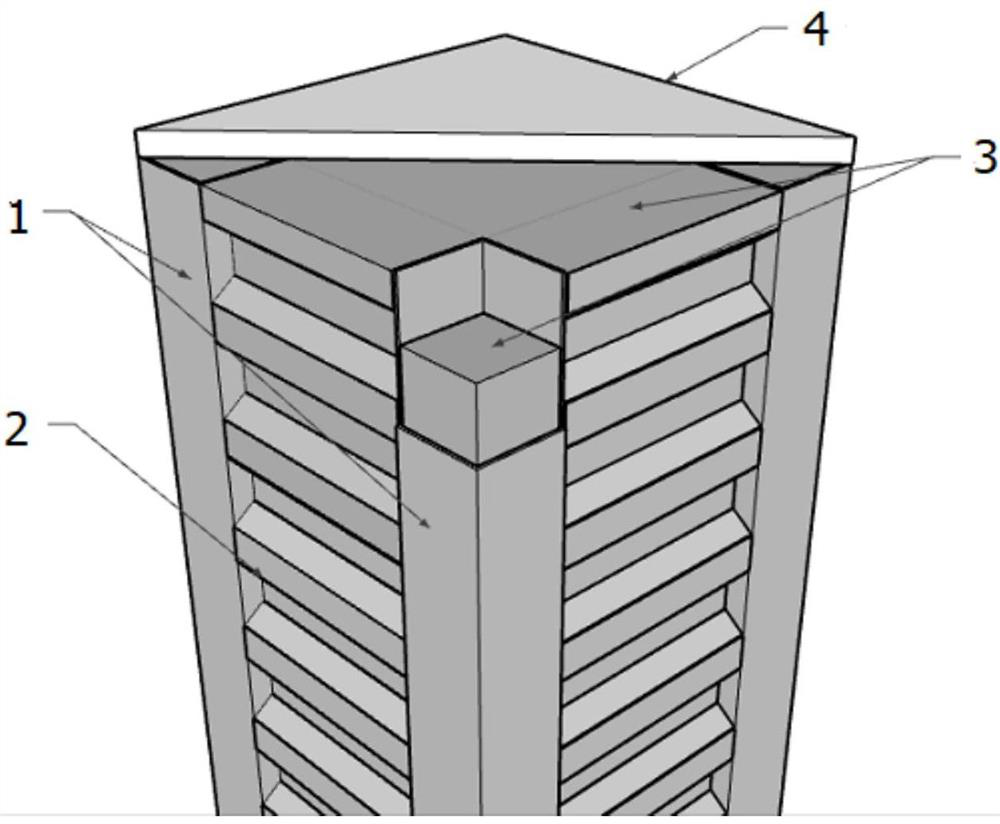

Pure bending age forming die for autoclave

The invention relates to a pure bending age forming die for an autoclave, which comprises a base, a cover plate, a box body, mould boards and a loading device. The loading device mainly comprising a worm, two worm wheels, two screw rods, press shafts, a press shaft bracket and a splint is arranged on the upper surface of the base; the splint is positioned at the center of the upper surface of the base; two mould boards are fixed on the upper surface of the splint; and the press shaft bracket is sleeved on the mould boards and is fixedly connected with the splint. The upper press shaft and the lower press shaft are arranged on the box body and the press shaft bracket respectively. When external force is transferred to the splint by the screw rods, screw nuts of the screw rods convert the rotation of the screw rods into the translation of the splint along the inner surface of the box body to push the mould boards and the lower press shaft to move upwards, therefore, the pure bending loading to test pieces is completed. The pure bending age forming die has concise appearance; the large circular bead transition is applied at the joint between the surfaces as much as possible; the positions for possibly causing the tension fracture of a vacuum bag are covered by the cover plate; the base is lager than the box body; and the pure bending age forming die has the characteristics of simple structure and convenient use.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

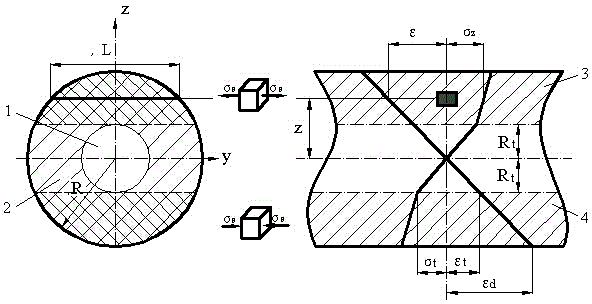

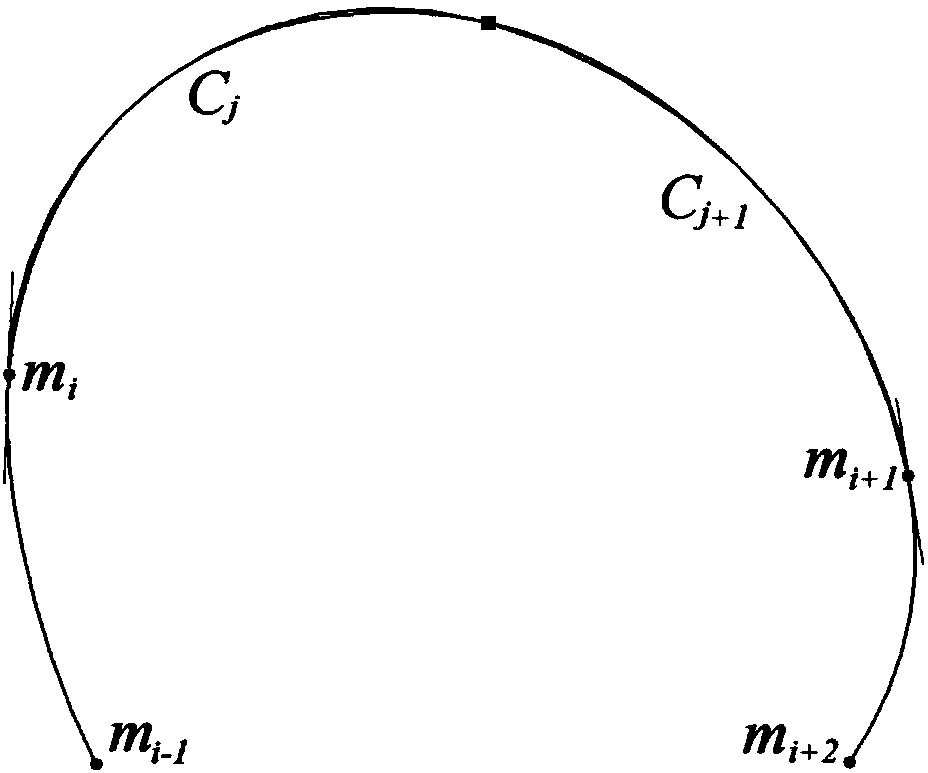

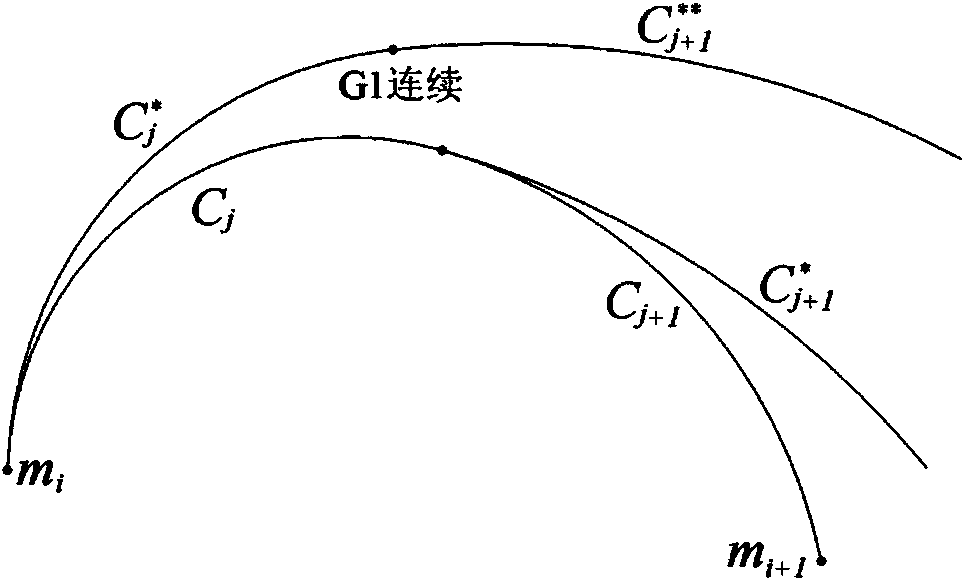

Method for predicting two-dimensional variable camber bending recovery of small-diameter thick-wall pipe

InactiveCN103439195ASimple stitchingMaterial strength using steady bending forcesEngineeringThick wall

The invention discloses a method for predicting two-dimensional variable camber bending recovery of a small-diameter thick-wall pipe, which is used for solving the technical problem of incapability of two-dimensional variable camber bending recovery of an existing small-diameter thick-wall pipe. According to the technical scheme, the method includes the steps of building a small-diameter thick-wall pipe bending recovery analytical model, performing discretization on the two-dimensional variable camber bent pipe along the axis, establishing a bending recovery radius relation expression by use of approximately pure bending recovery experiment, predicting the discrete bent pipe recovery, simply splicing the recovery predicted discrete bent pipe, and correcting the discrete bent pipe recovery splicing. The method can be used for predicting two-dimensional variable camber bending recovery of the small-diameter thick-wall pipe.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

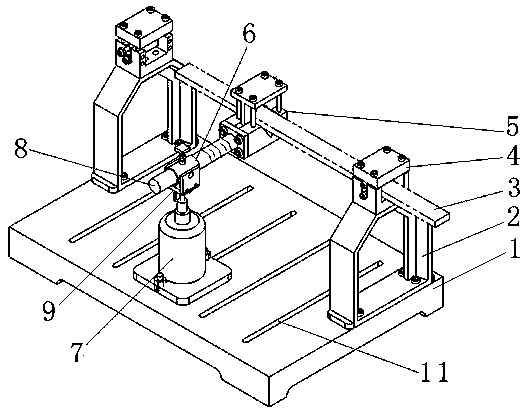

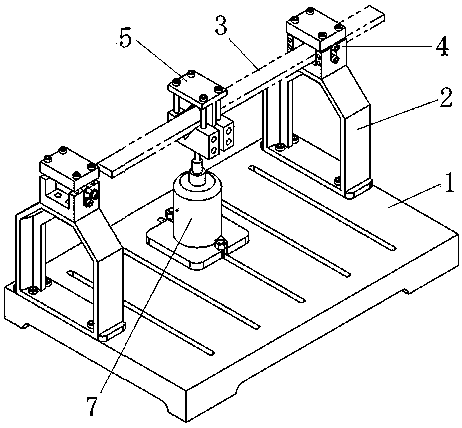

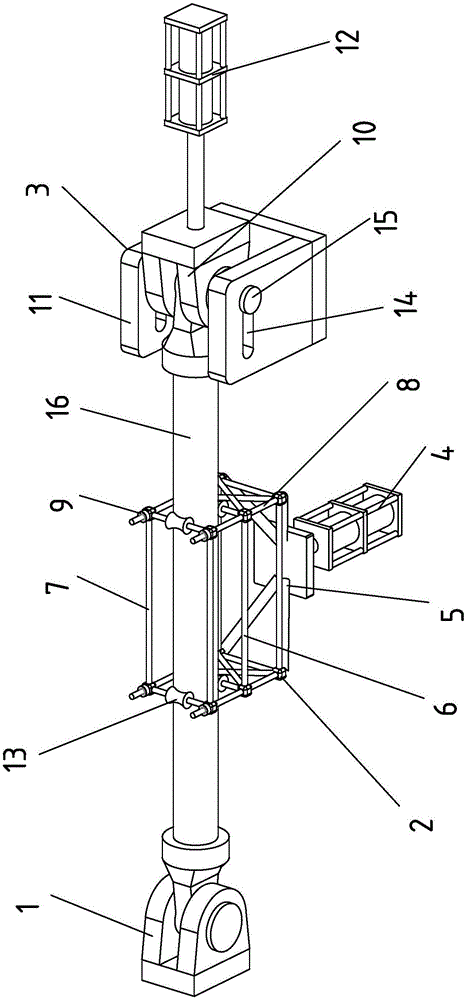

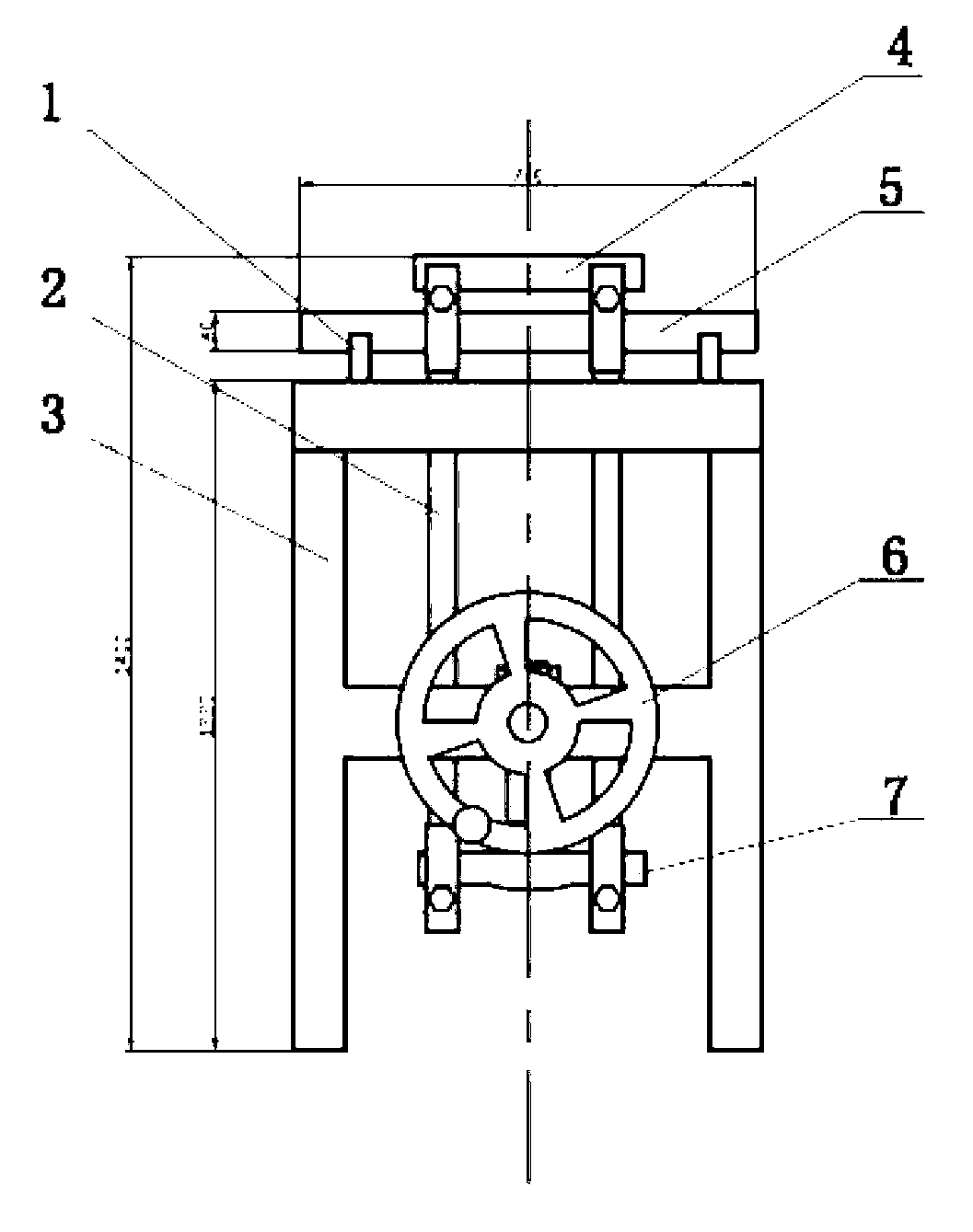

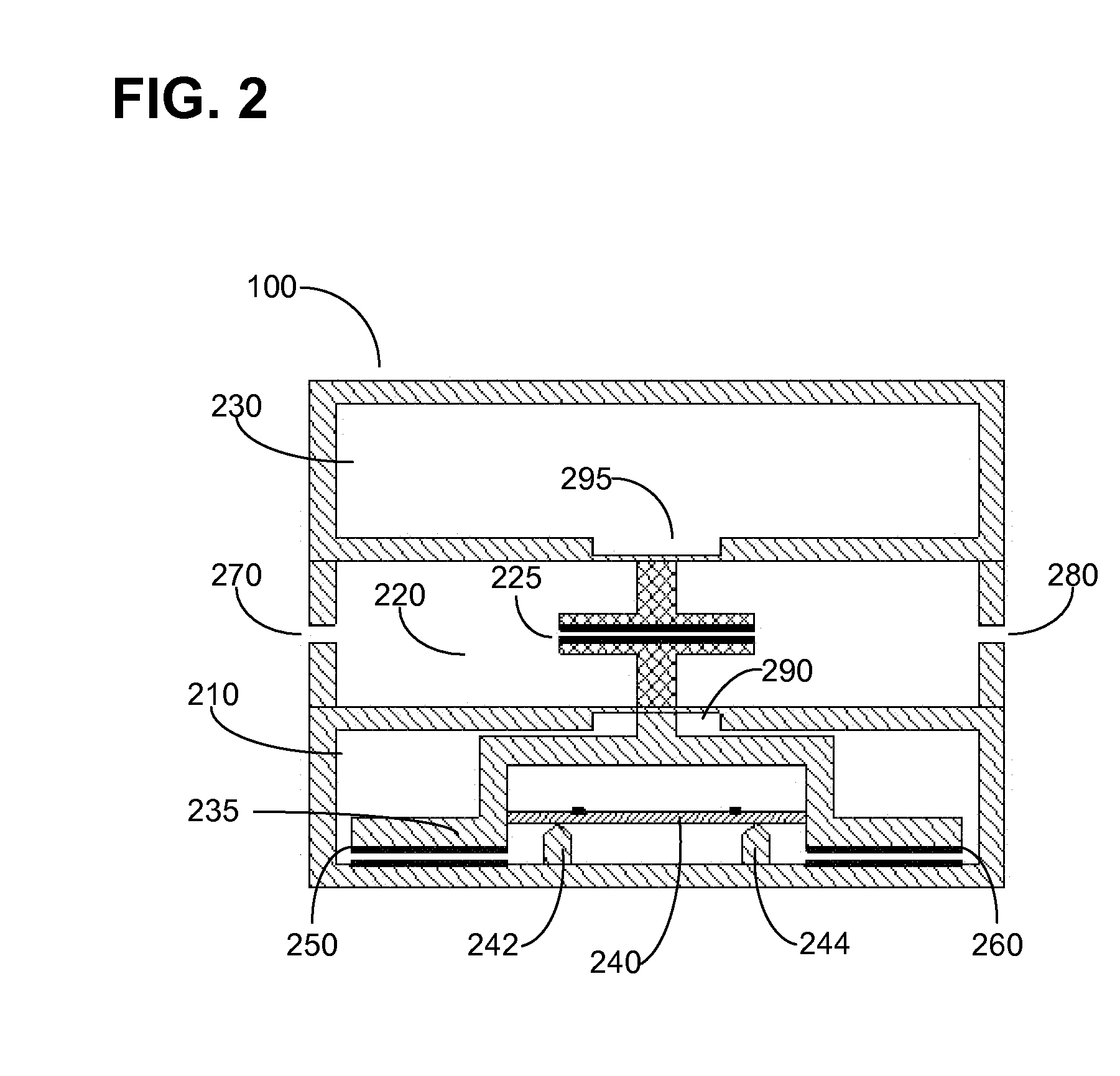

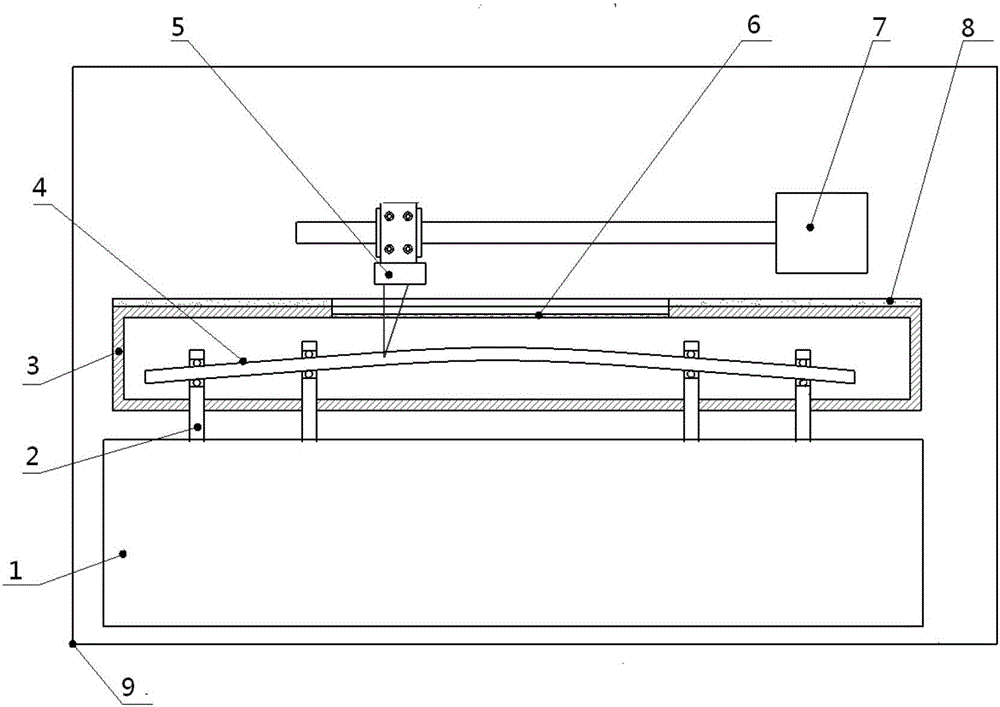

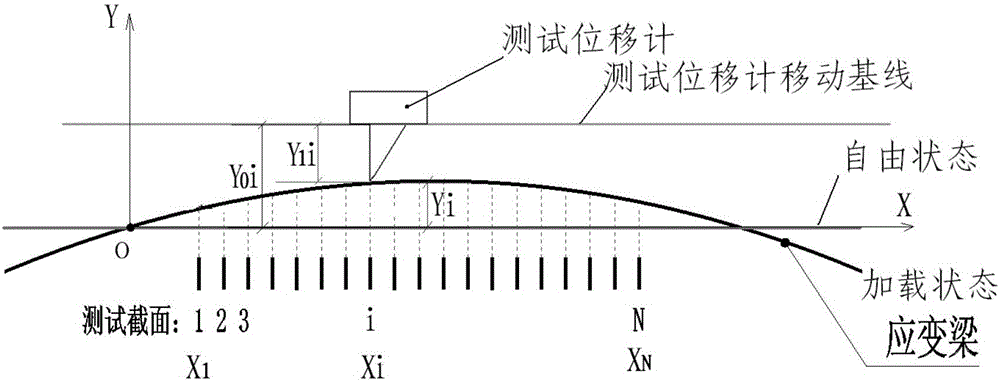

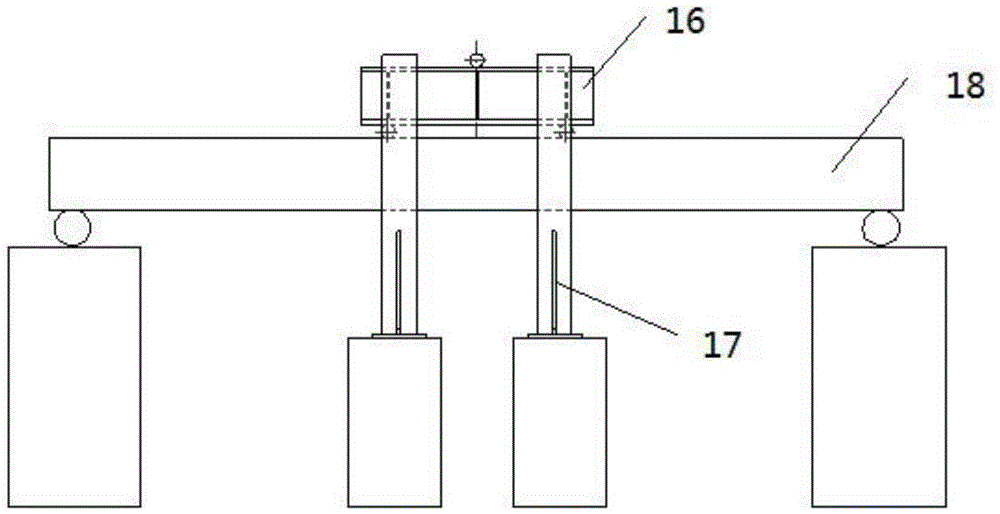

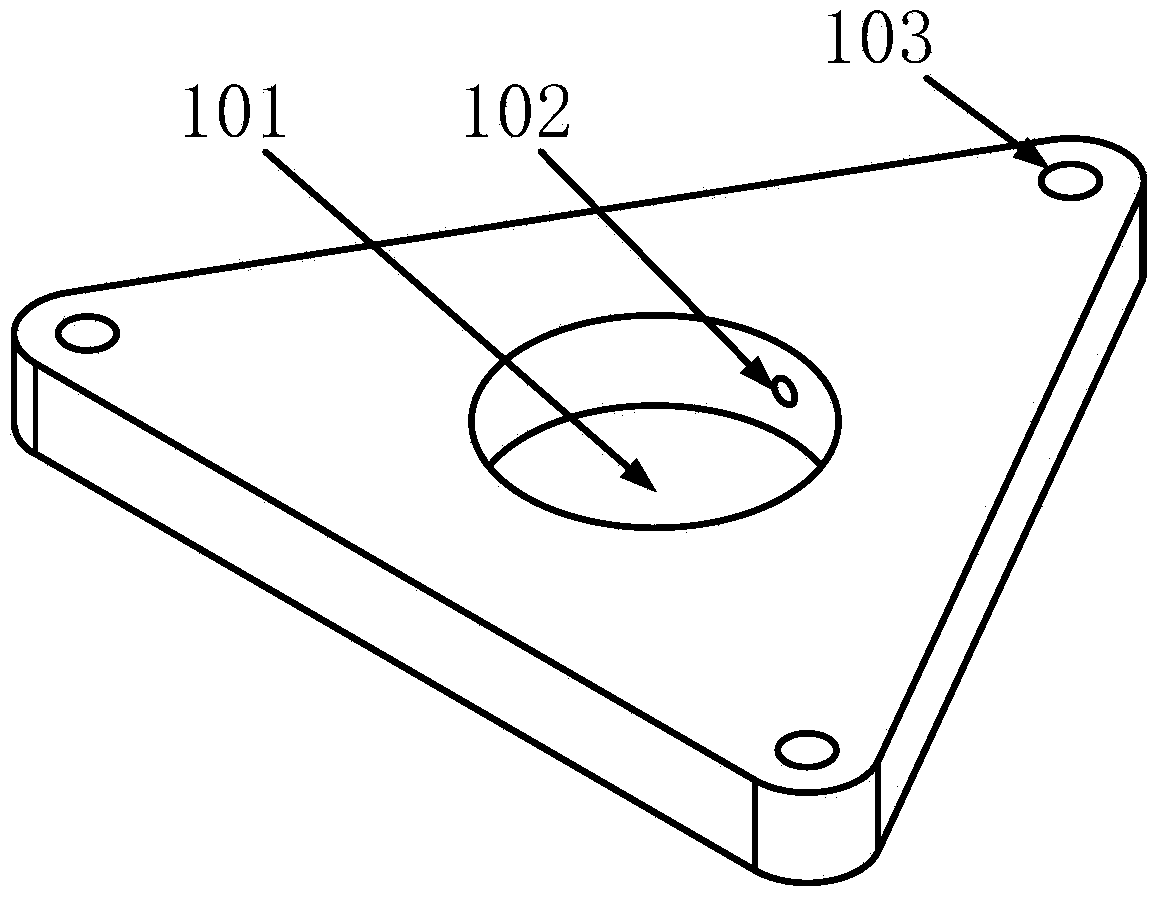

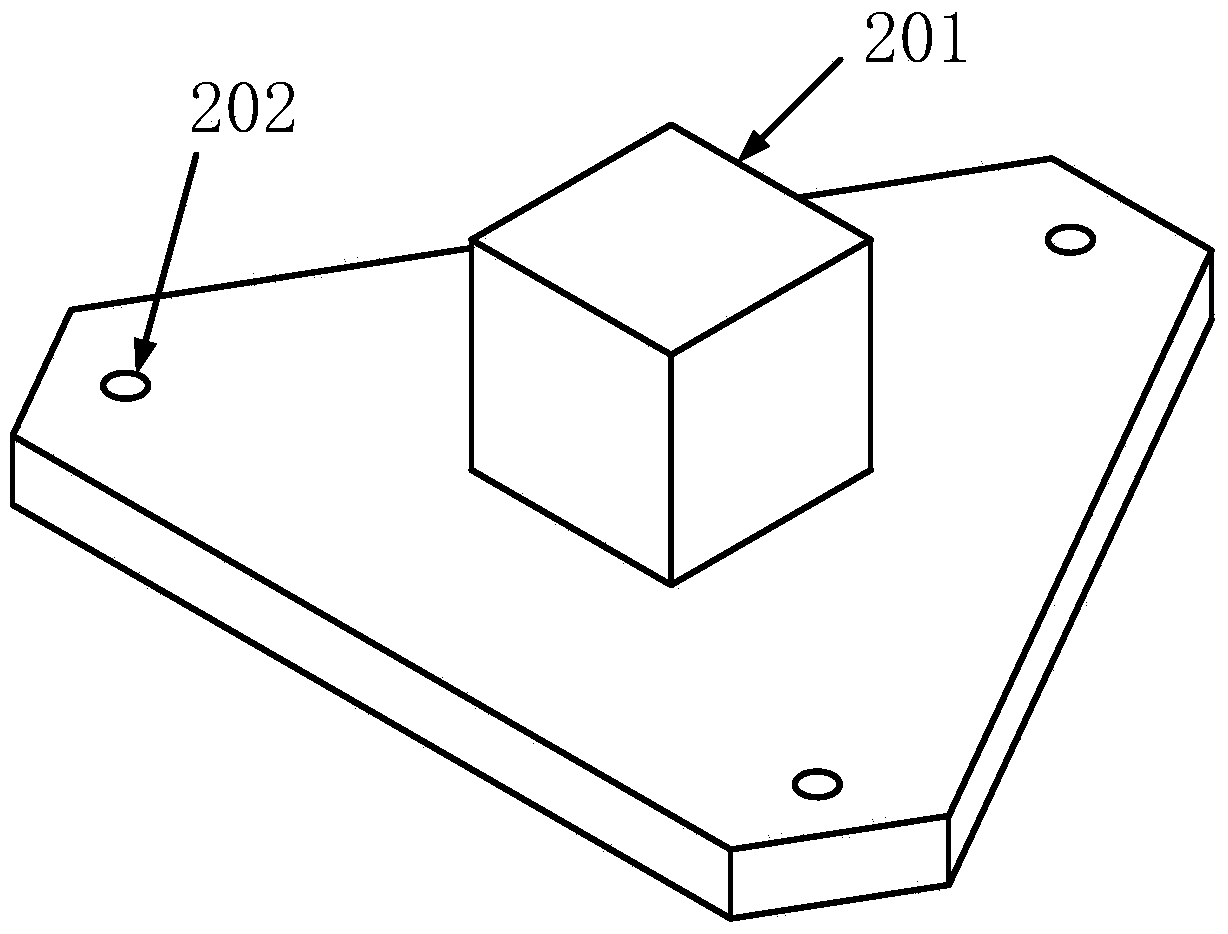

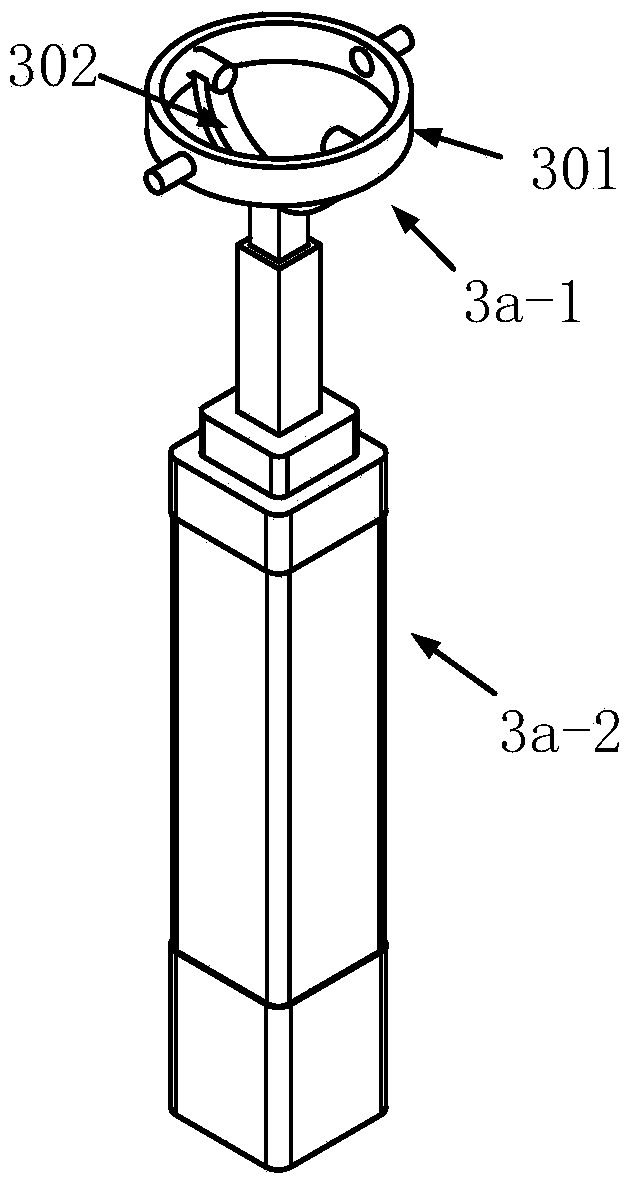

Static standard strain loading device based on simply-supported pure bending beam and method thereof

The invention relates to a static standard strain loading device based on a simply-supported pure bending beam and a method thereof, wherein the device and the method are used for static strain calibration. The device mainly comprises a loading actuation module, a deformation measurement module, a heating module and a strain beam. The loading actuation module comprises a loading actuator (1) and 4 loading rods (2). Through independently driving each loading rod (2), strain beam loading is performed so as to generate a standard strain. The deformation measurement module comprises a test displacement meter (5) and a slide platform (7) and deformation measurement is completed. The method comprises a strain beam loading method, a strain beam deformation deflection test method, a loading strain calculating method and a feedback control method, wherein the strain beam loading method is used to load and unload a strain beam and change a force condition; the strain beam deformation deflection test method is used to test a deformation deflection of the strain beam; the loading strain calculating method is used to calculate a strain loaded on the strain beam according to the measured deformation deflection; and the feedback control method is used to make the strain beam be in a pure bending state and adjust a loading strain size to be the standard strain. In the invention, a standard strain source with high precision can be provided under a normal temperature.

Owner:AECC SICHUAN GAS TURBINE RES INST

Bolt pure bending fatigue test tool and system

InactiveCN110108575ASimple and fast operationMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesEngineeringUltimate tensile strength

The invention provides a bolt pure bending fatigue test tool and system. The test tool comprises an upper plate and a lower plate which are parallel to each other, and two groove blocks and two protrusions which are engaged with each other, wherein the positioning end of the upper plate and the positioning end of the lower plate are provided with an upper positioning hole and a lower positioning hole with corresponding positions for enabling a test bolt to pass through and to be positioned; and the two groove blocks and the two protrusions are fixed or integrally formed on the lower plate andthe upper plate respectively and located at two sides of the upper positioning hole and the lower positioning hole, and thus, the connection line between two engaged points is vertical to the centralaxis of the test bolt. The system is formed when longitudinal test signals of an MTS testing machine are received at the other end of the upper plate. Through adopting the above structure, bolt bending fatigue strength test can be carried out on a general MTS fatigue testing machine.

Owner:BEIJING JIAOTONG UNIV

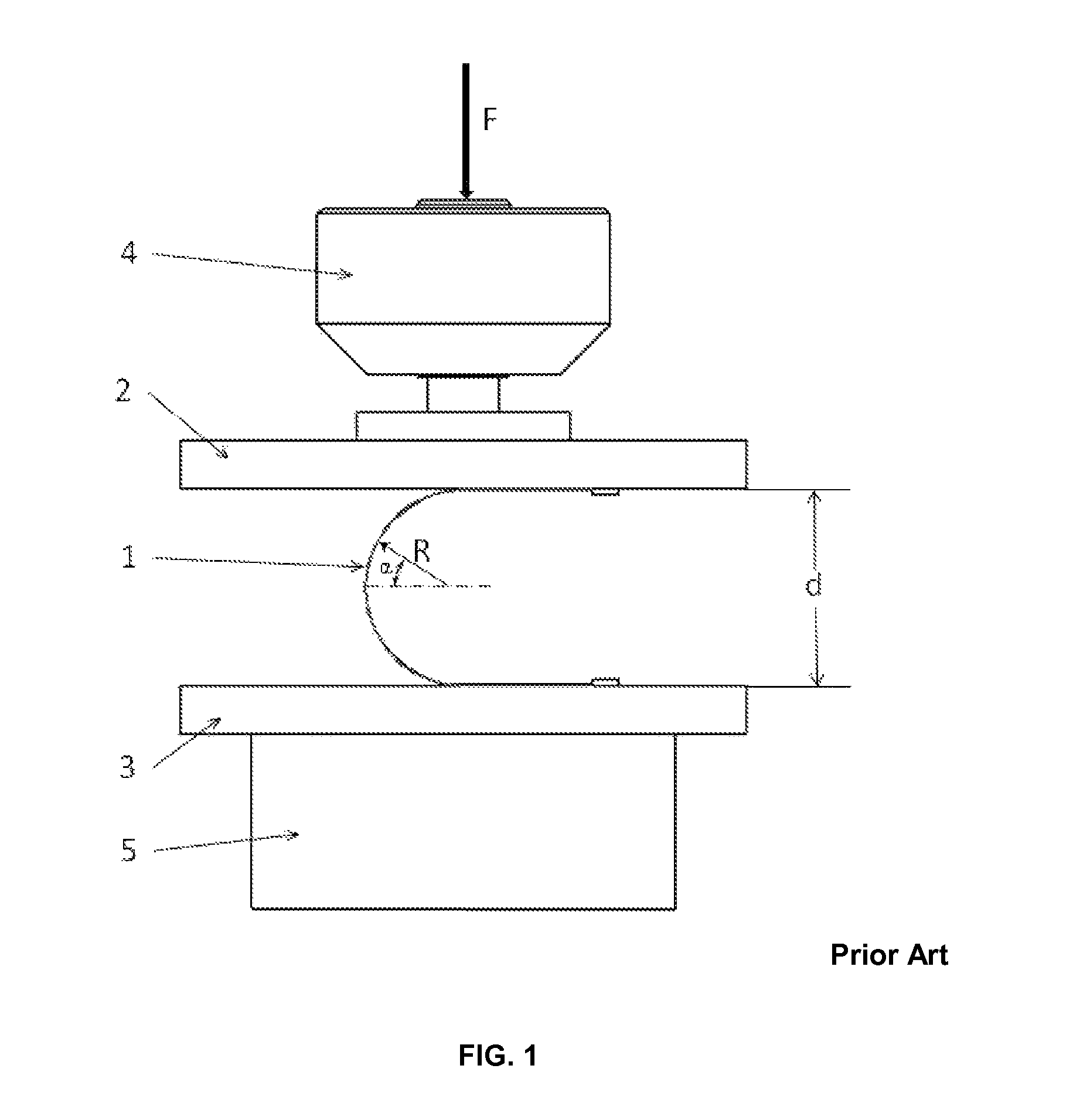

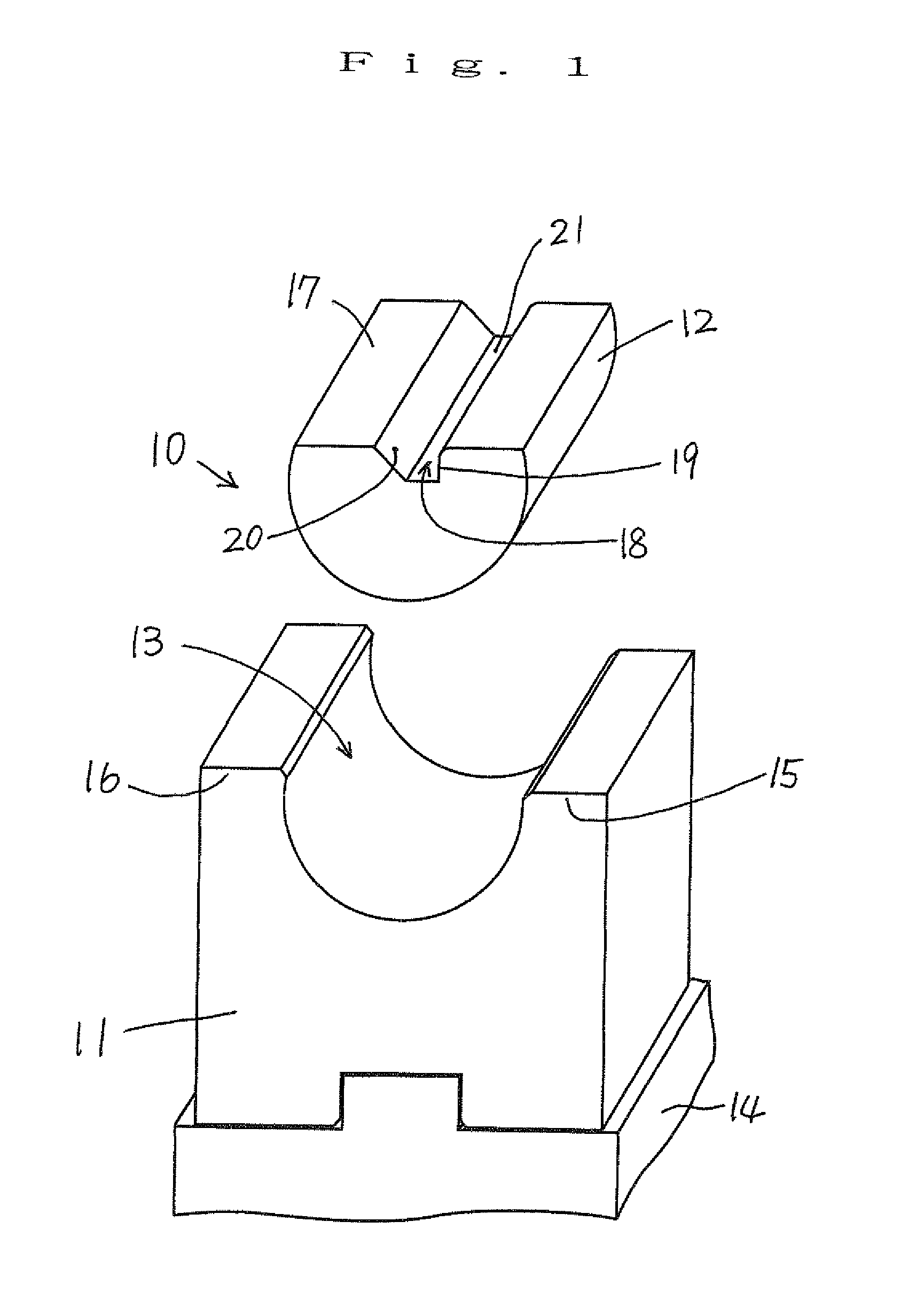

Lower die for press bending and tool using the same

InactiveUS20110030436A1Add depthShaping toolsForging/hammering/pressing machinesLeft directionMechanical engineering

In order to achieve a bending operation which provides a U-shaped metal piece of increased depth and to provide a bending operation safe to an operator involved in the bending operation, the invention is a lower die for press bending which includes: a block body which includes a groove on an upper surface thereof, the groove extending in a right and left direction, and the block body being fixed to a bending machine; and a rotating block which is received by the groove of the block body and is capable of oscillating about an axis of the groove, wherein a process groove is formed on an upper surface of the rotating block to receive a blade edge of an upper die. The block body includes a front shoulder and a rear shoulder at the front and rear sides of the groove. A level difference is defined between these shoulders such that the front shoulder is smaller in height than the rear shoulder.

Owner:MAKINO OSAMU

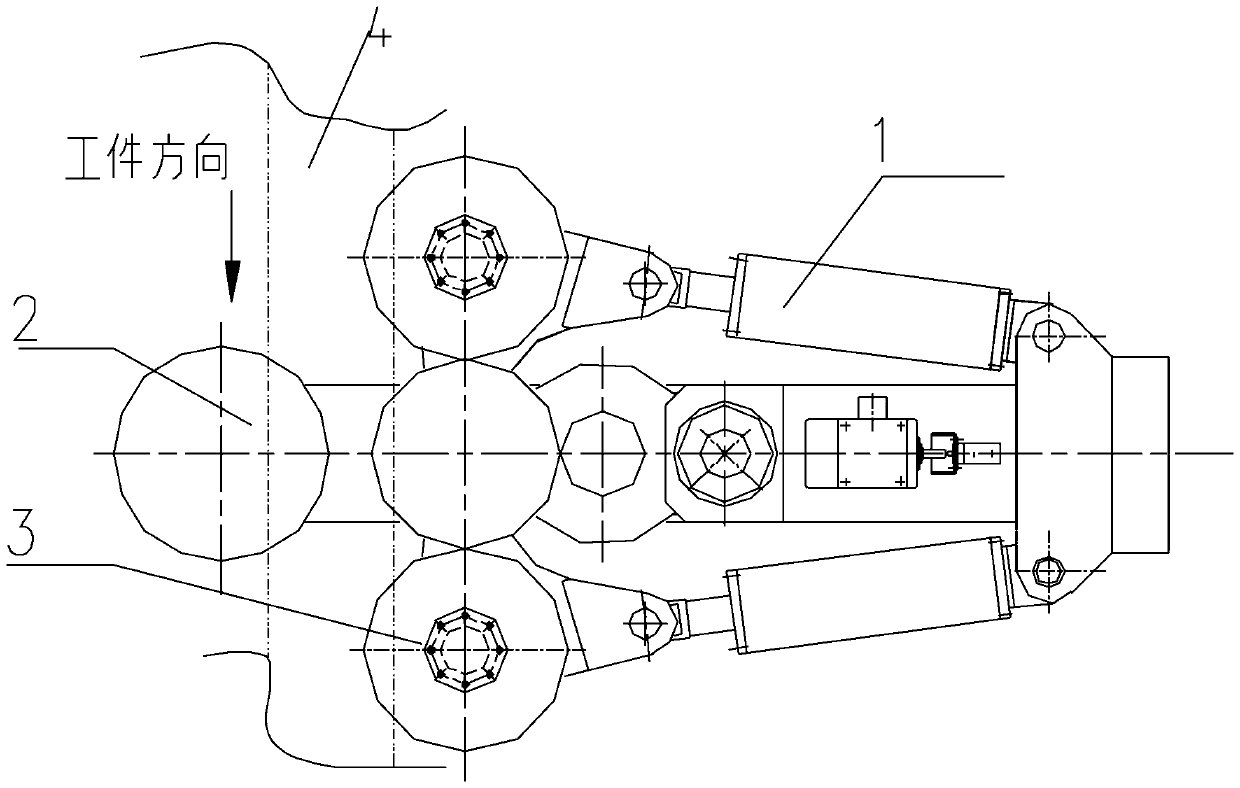

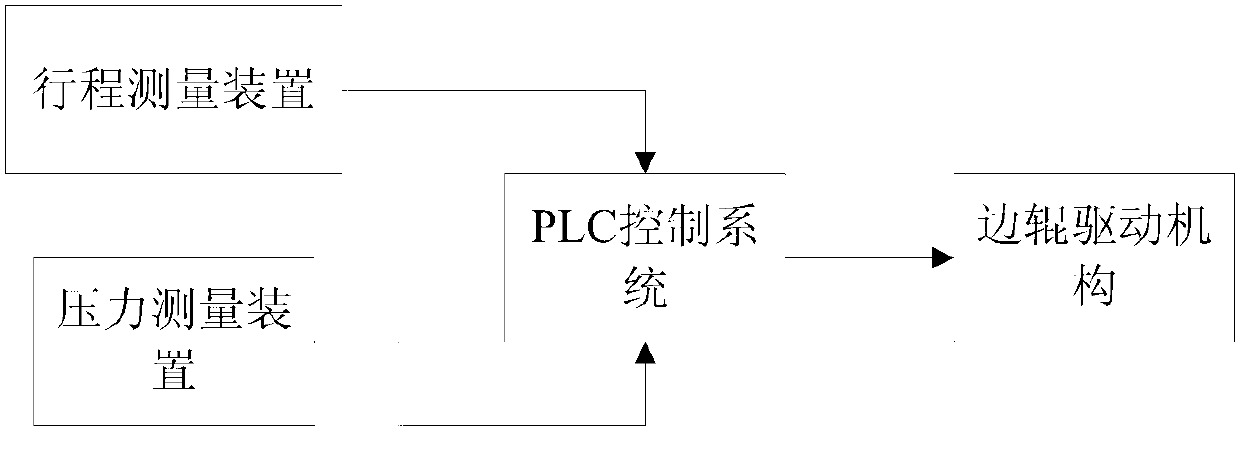

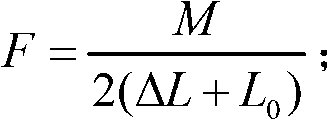

Pipe bender precision control method

The invention relates to a pipe bender precision control method. Because travel control switches for a left side roll and a right side roll, a bending pressure sensor, a PLC (programmable logic controller) control system and a display are added, the relative position coordinates and bending pressure data of the side rolls and a main roll in work are transmitted to the PLC control system, the PLC control system works out and then transmits the bending radius and radian of a workpiece to the display, and thereby pipe bending precision control is enhanced. The pipe bender precision control method can accurately work out the bending radius, reduce the labor of repeated pipe bending as the result of inaccurate artificial pipe radius prediction in pipe bending, save the pipe-bending time, increase the working efficiency of workers and decrease labor intensity.

Owner:WISCODRI WUGANG ENG

Cradle stand for electrolysis cell

The invention discloses a cradle stand for an electrolysis cell. The cradle stand comprises a bottom girder (1) at the bottom of the cradle rack, wherein a pre-stress pull rod (3) passes through and is fixed on the bottom girder (1). By applying pre-stress to the bottom girder of the cradle stand of the electrolysis cell in advance, a component combining upper pure bending force with lower pure bending force of the bottom girder of the cradle stand is stressed instead of a lower pure bending part, so that the bottom girder of the cradle stand is prevented the over deforming because of bendingof the lower side of the bottom girder, stress of a high-strength material is sufficiently played, the structure receives the pre-pressure applied by the pre-stress pull rod before the structure is subject to a loading action, the loading formed pulling stress of the bottom girder of the cradle stand caused by bending of the lower side is reduced or counteracted, the thickness of bottom girder type steel webs, height of the bottom girder and usage of flange materials at two ends are effectively reduced, and the aims of reasonable stress and less deformation are achieved.

Owner:GUIYANG AL-MG DESIGN & RES INST

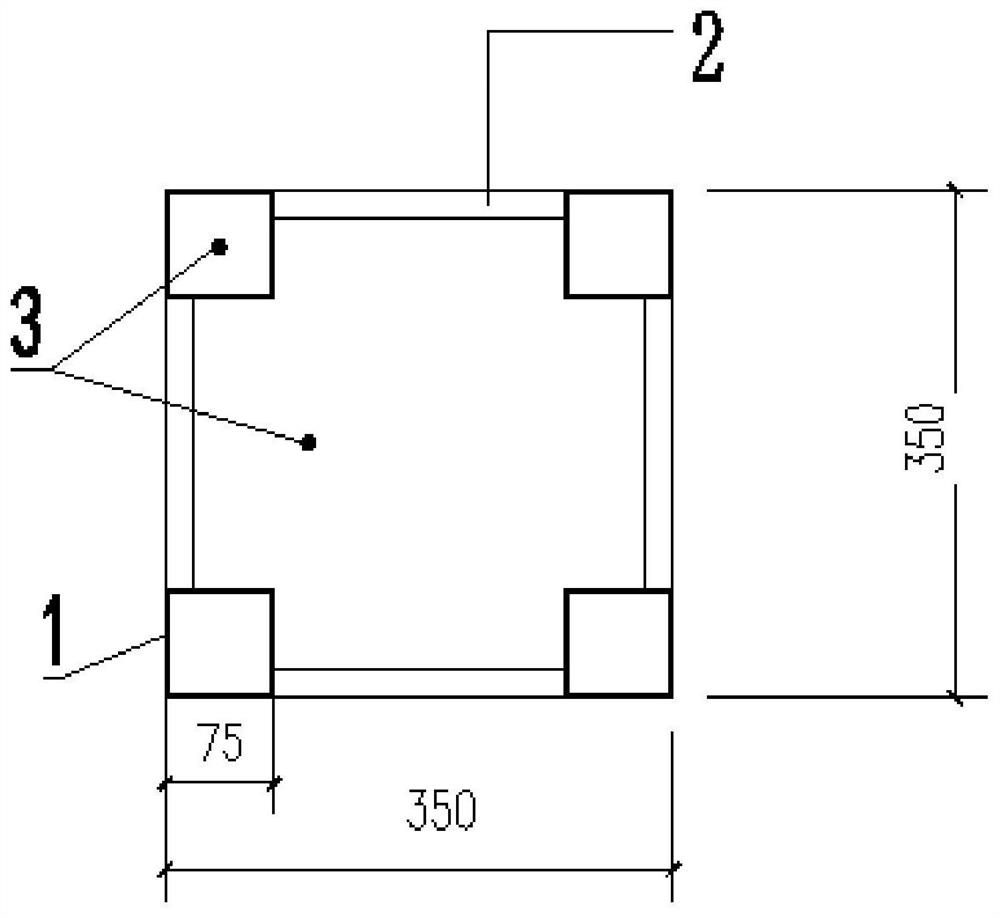

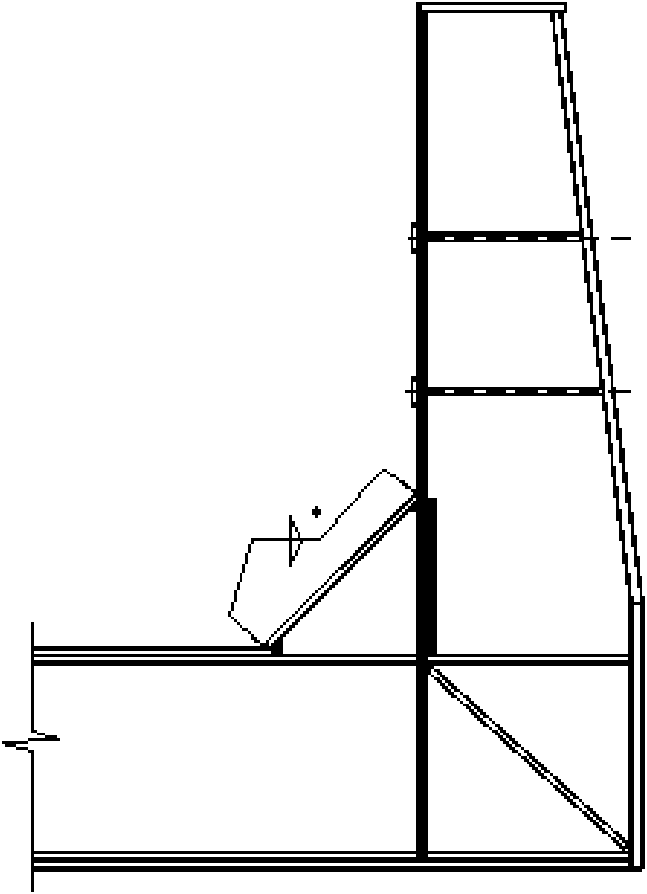

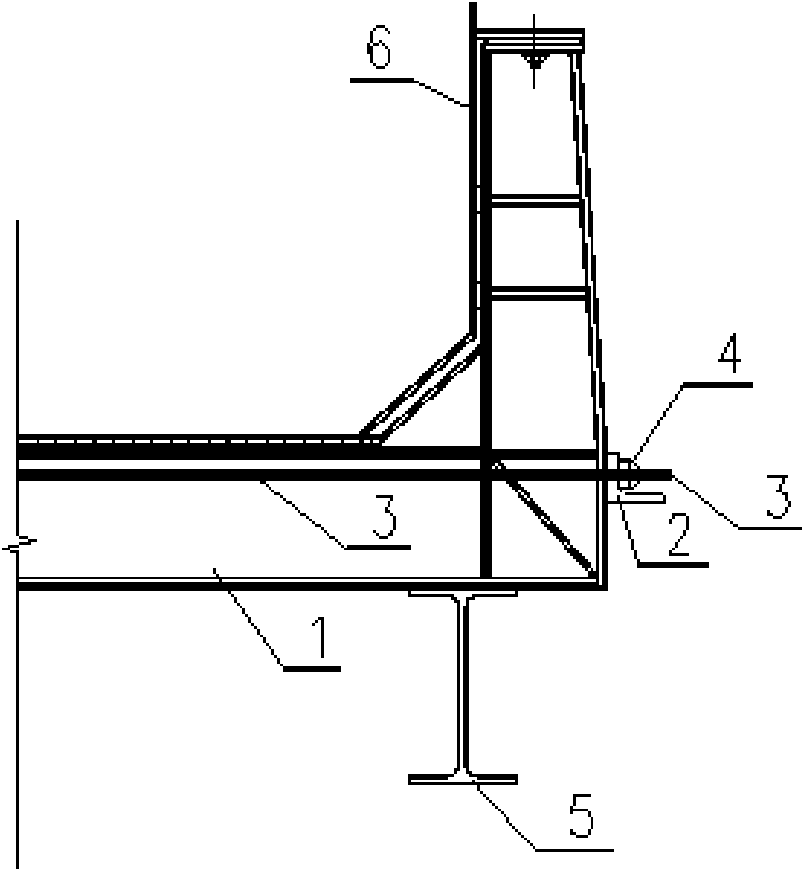

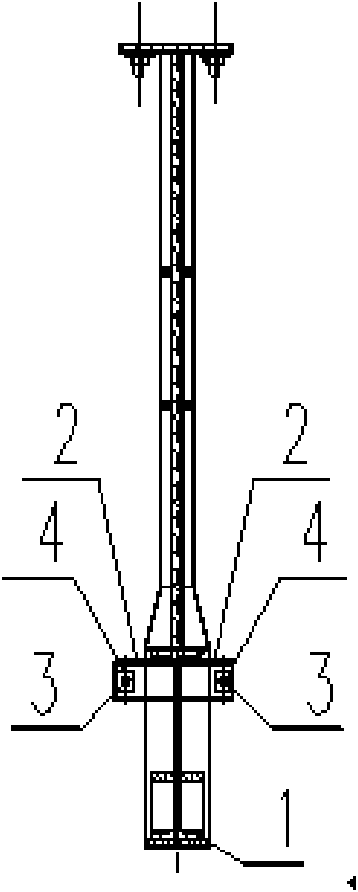

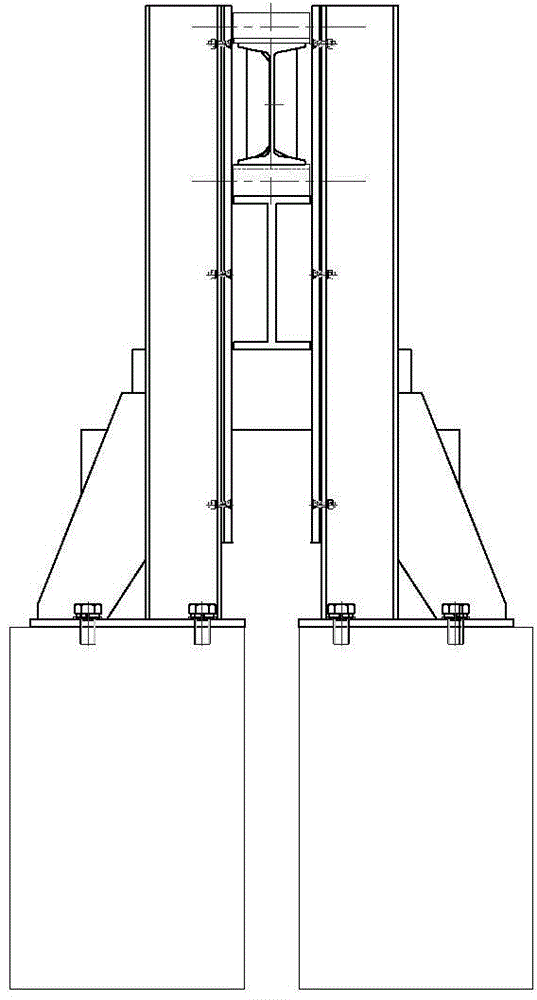

Device for testing pure bending performance of beam

InactiveCN104897482AImprove lateral deformationImprove torque performanceMaterial strength using steady bending forcesTest beamMechanical engineering

The invention relates to a structure testing device, in particular to a device for testing pure bending performance of a beam. The device comprises a loading beam and lateral limiting brackets, wherein the loading beam is arranged in the middle of the upper surface of a test beam; the lateral limiting brackets are arranged on two sides of the test beam and two sides of the loading beam; the loading beam comprises I-steel, round steel and a stiffening plate; each lateral limiting bracket comprises a vertically arranged lateral support, a horizontally arranged bottom plate, a diagonal bracing, connecting bolts, spring washers I, flat washers, rubber pads, plastic pads, countersunk bolts, spring washers II and nuts, one end of the diagonal bracing is connected onto the bottom plate, the other end of the diagonal bracing is connected onto the lateral support, the connecting bolts, the spring washers I and the flat washers are used for fixing the bottom plate, the rubber pads and the plastic pads cover one side surface of the lateral support, and the countersunk bolts, the spring washers II and the nuts are used for fixing the rubber pads and the plastic pads. The device is convenient to mount, and pure bending moment load is vertically applied; the positions of the lateral limiting brackets are easy to adjust, so that the device adapts to the test beams with different widths; and the effect of limiting lateral deformation and twisting of the test beam is good during testing.

Owner:中国人民解放军63983部队

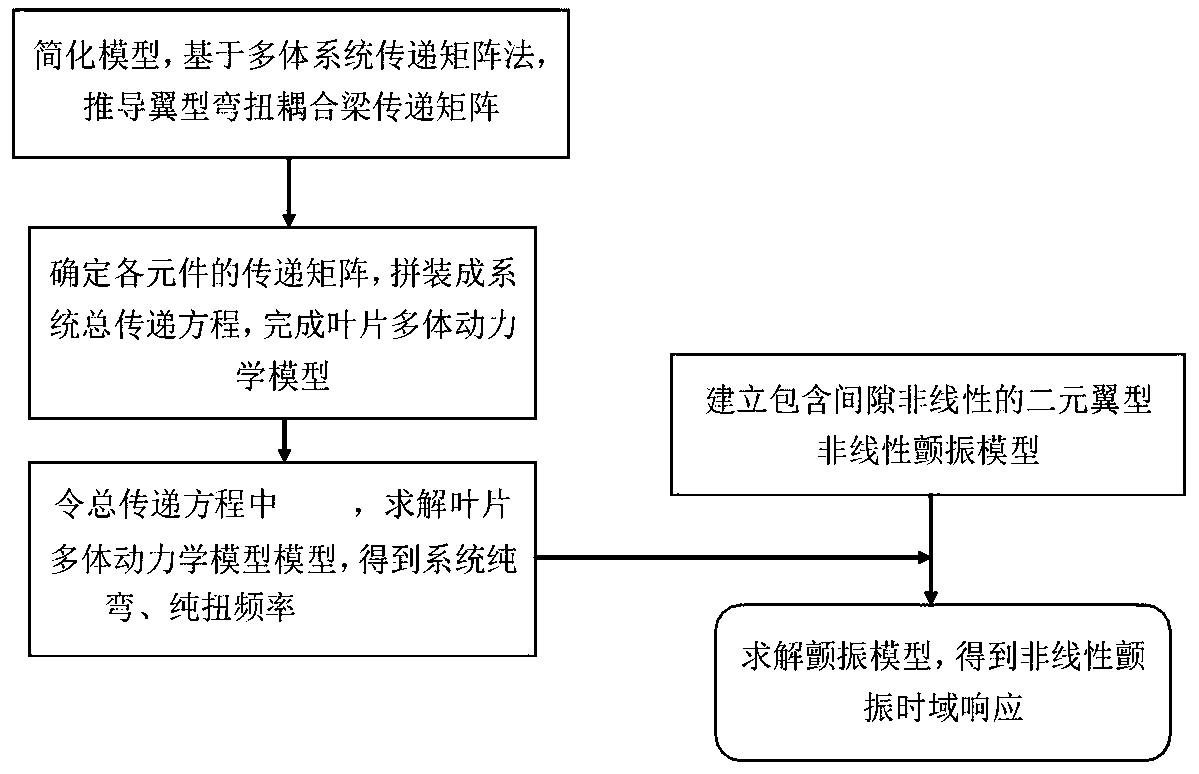

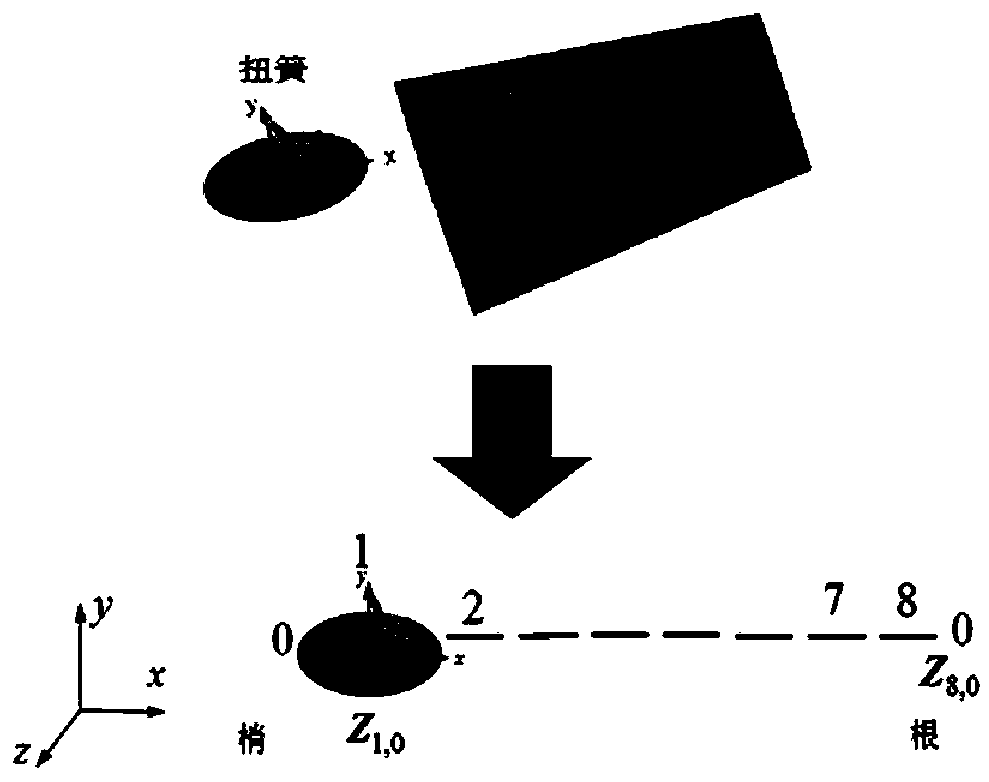

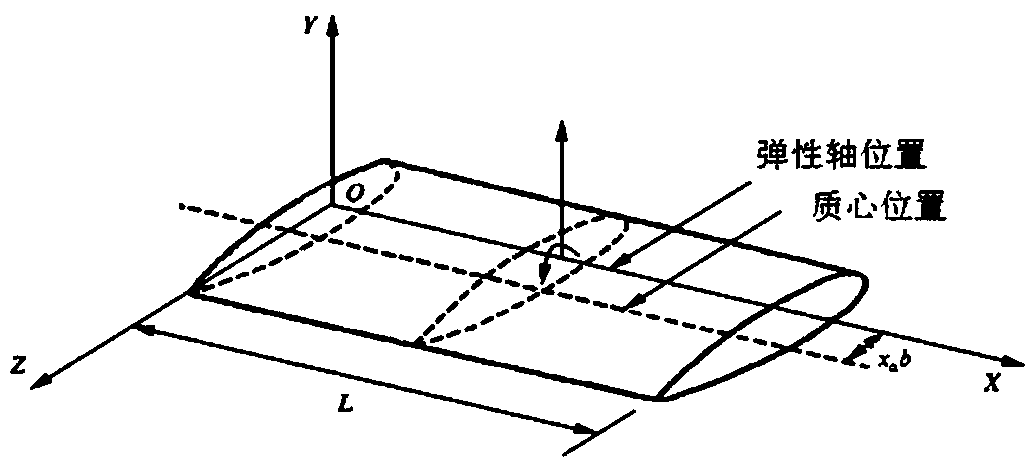

Modeling method of binary airfoil nonlinear flutter time domain model

The invention discloses a modeling method of a two-dimensional airfoil nonlinear flutter time domain model, which comprises the following steps of: simplifying a system by taking the system that a rudder blade is connected with a torsion spring as an object, and deducing a bending-torsion coupling beam transfer matrix based on MSTMM; determining a transfer matrix of each element, assembling the transfer matrixes into a total transfer matrix, and establishing a system overall dynamic model; superposing a rigid center and a mass center in the transfer matrix, and solving the kinetic model to obtain key parameters of a binary flutter model, namely rudder blade pure bending and pure torsion frequencies; taking a cross section of a 3 / 4 blade extension part, and establishing a binary airfoil nonlinear flutter model; solving the two-dimensional airfoil nonlinear flutter model, and solving the time domain response of the two-dimensional airfoil nonlinear flutter model. According to the method,key kinetic parameters, namely pure bending and pure torsion frequencies of the rudder system, required by the binary flutter model are calculated by adopting the MSTMM, a modeling thought of the binary airfoil flutter model considering gap nonlinearity and geometric nonlinearity is provided, and an effective technical approach is provided for nonlinear hydroelasticity research of the rudder system.

Owner:YANGZHOU UNIV

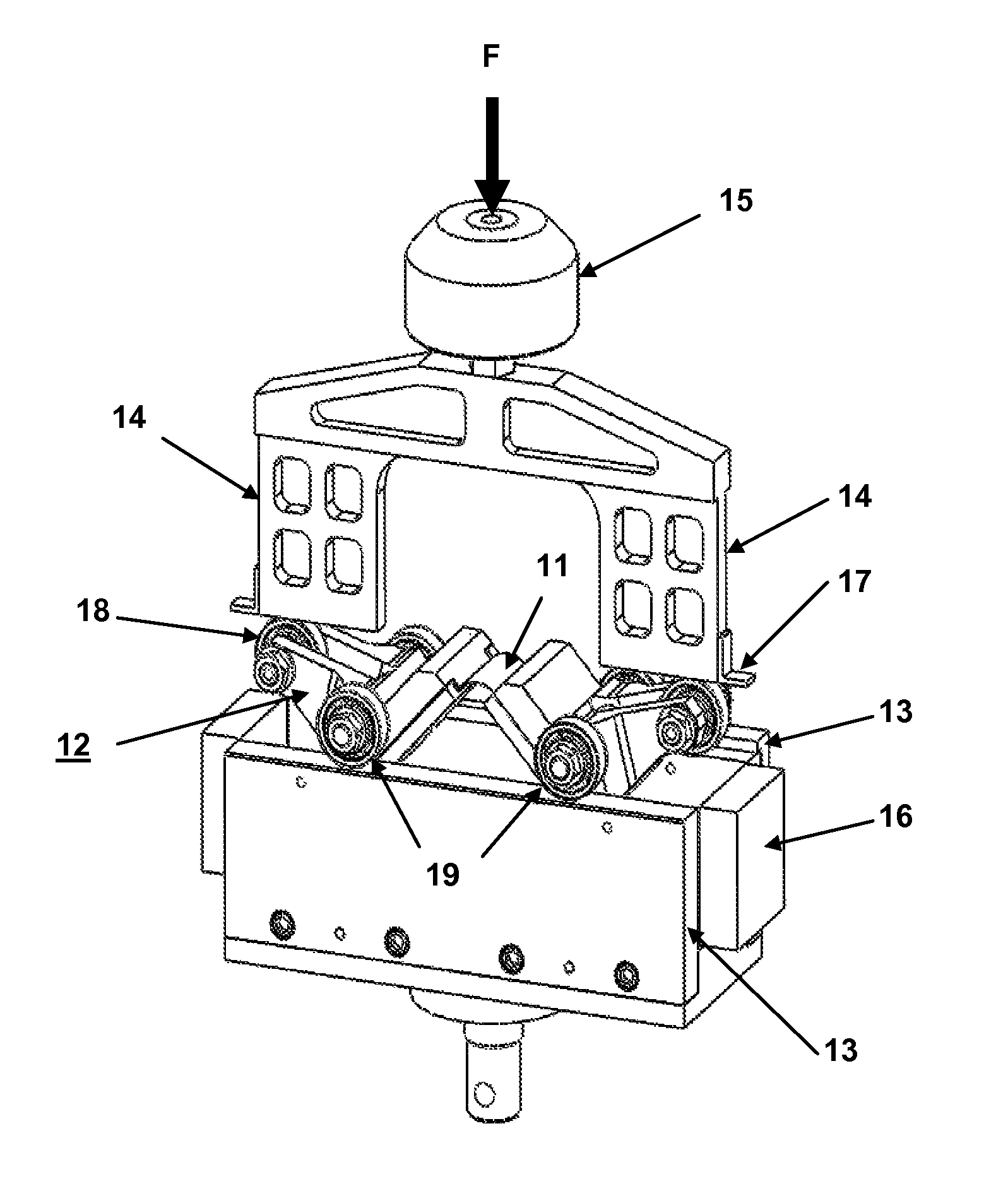

Composite load simulator for achieving multidimensional pure bending moment and tensile pressure

InactiveCN103884373ALarge working spaceWide range of stiffnessMeasurement devicesPure bendingBorn rigidity

The invention discloses a composite load simulator for achieving multidimensional pure bending moment and tensile pressure. The composite load simulator can achieve pure bending moment loading, tensile pressure loading and pure bending moment and tensile pressure composite loading in any direction. The simulator comprises a moving platform, a fixed base and moving branch chains. The moving platform is fixedly connected with a loaded test piece, and the moving branch chains comprise the central moving branch chain and the uniformly-distributed moving branch chains, wherein the uniformly-distributed moving branch chains are of six different structures. The uniformly-distributed moving branch chains of the different structures, the central moving branch chain, the fixed base and the moving platform can form six kinds of different bending moment-tensile pressure composite load simulator structures. The composite load simulator has the advantages that the composite load simulator can achieve multidimensional pure bending moment load output and can output composite loads of the bending moment and the tensile pressure; due to the fact that the branch chains exist, the structure has high bearing rigidity, decoupling can be achieved through output of the tensile pressure and the bending moment, and the composite load simulator is convenient to control, simple to manufacture and convenient to install.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com