Bolt pure bending fatigue test tool and system

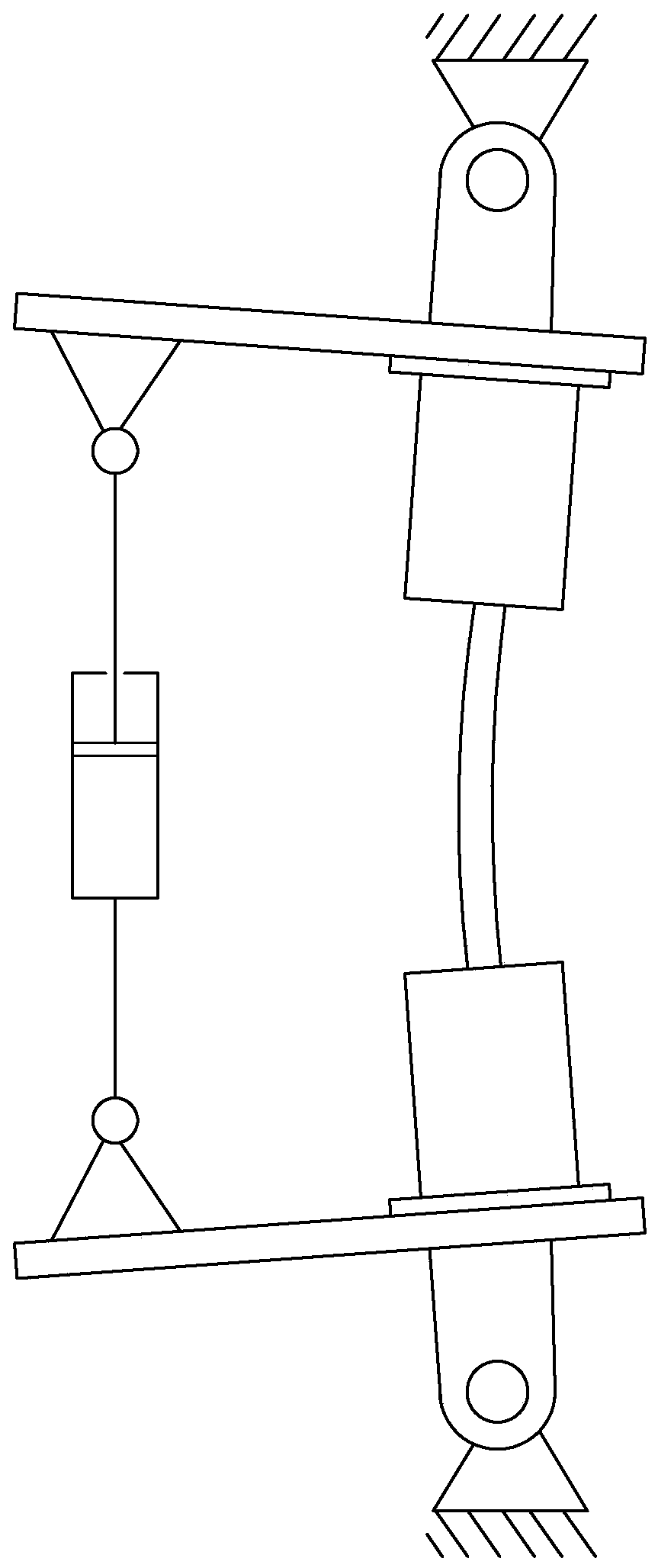

A fatigue test, pure bending technology, applied in the direction of using a stable bending force to test the strength of materials, measuring devices, and using repeated force/pulse force to test the strength of materials, etc., can solve the problem that the test structure is only suitable for specific test institutions and cannot be Pure bending loading and other problems, to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiment of the present invention will be illustrated in detail below in conjunction with the accompanying drawings, but the preferred embodiment cannot be used to limit the protection scope of the present invention.

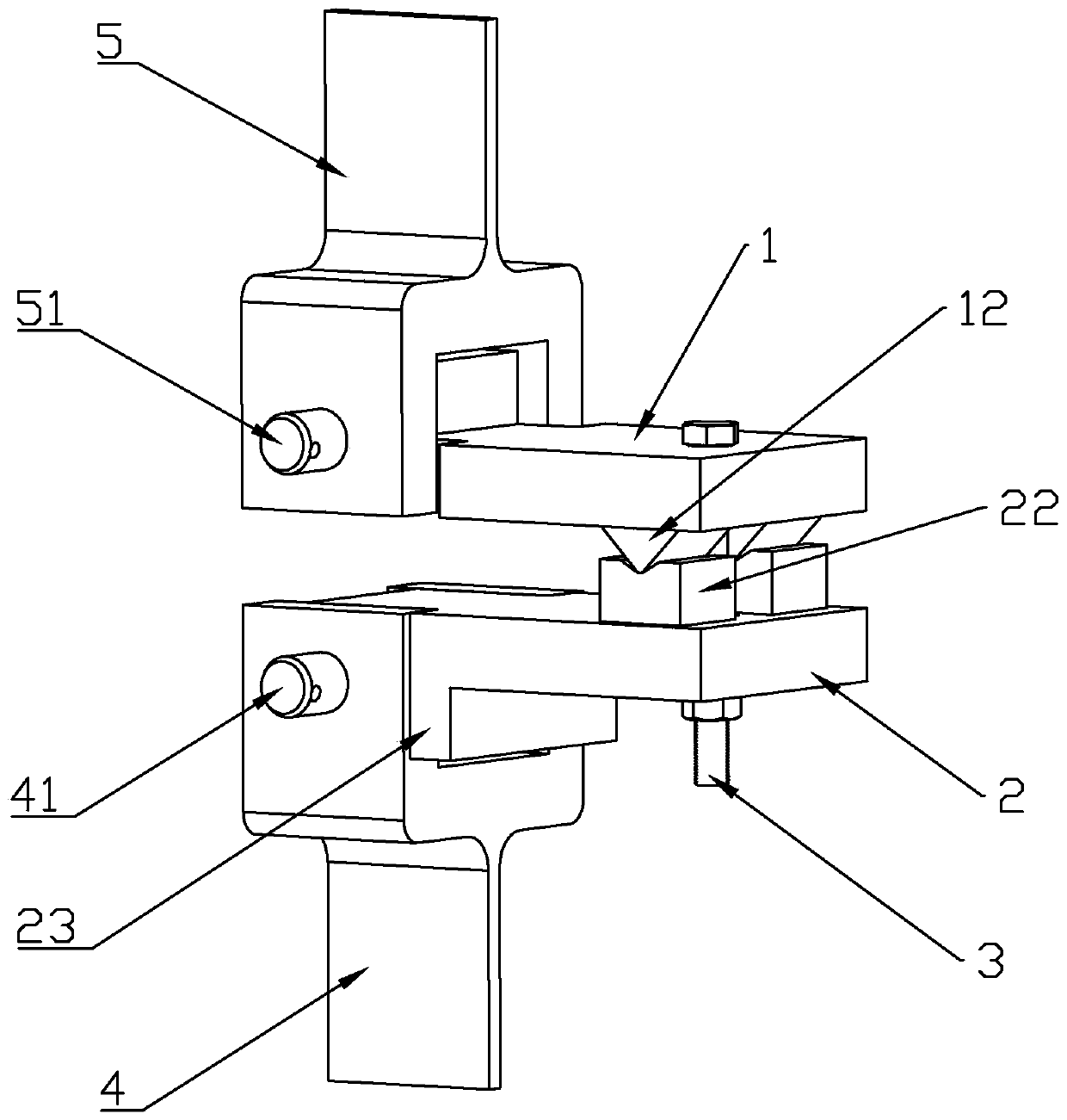

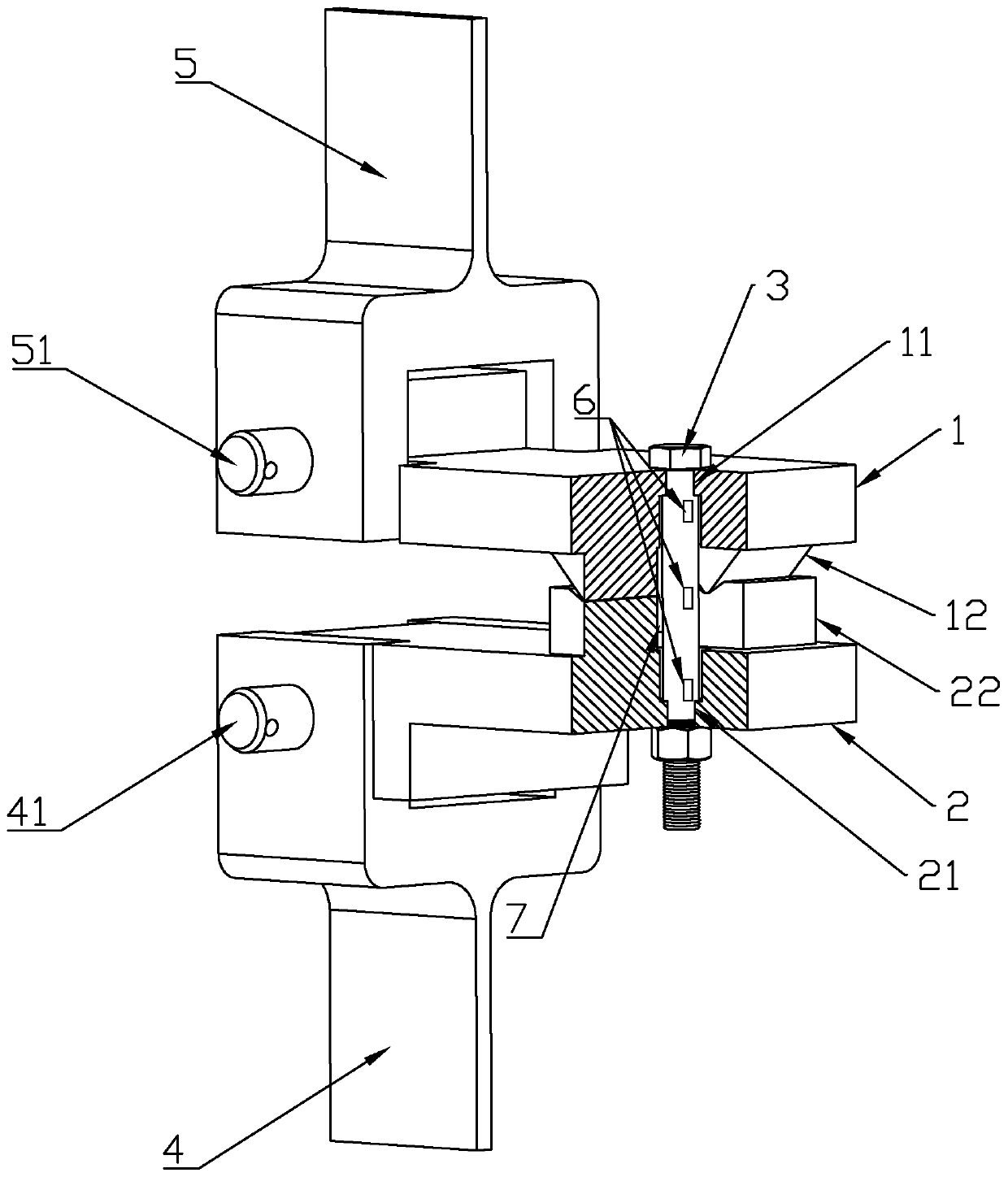

[0035] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention provides a kind of bolt pure bending fatigue test fixture, comprises:

[0036] The upper plate 1 and the lower plate 2 are parallel to each other, one end of the upper plate 1 is the positioning end, the other end is the pressure end, one end of the lower plate 2 is the positioning end, and the other end is the fixed end, the positioning end of the upper plate 1 is connected to the lower The positioning end of the plate 2 is respectively provided with an upper positioning hole 11 and a lower positioning hole 21 corresponding to the position, allowing the test bolt 3 to pass through and position;

[0037] Two groove blocks 22 with the same shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com