Static standard strain loading device based on simply-supported pure bending beam and method thereof

A standard strain and loading device technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as large errors, and achieve the effect of improving the accuracy of loading strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

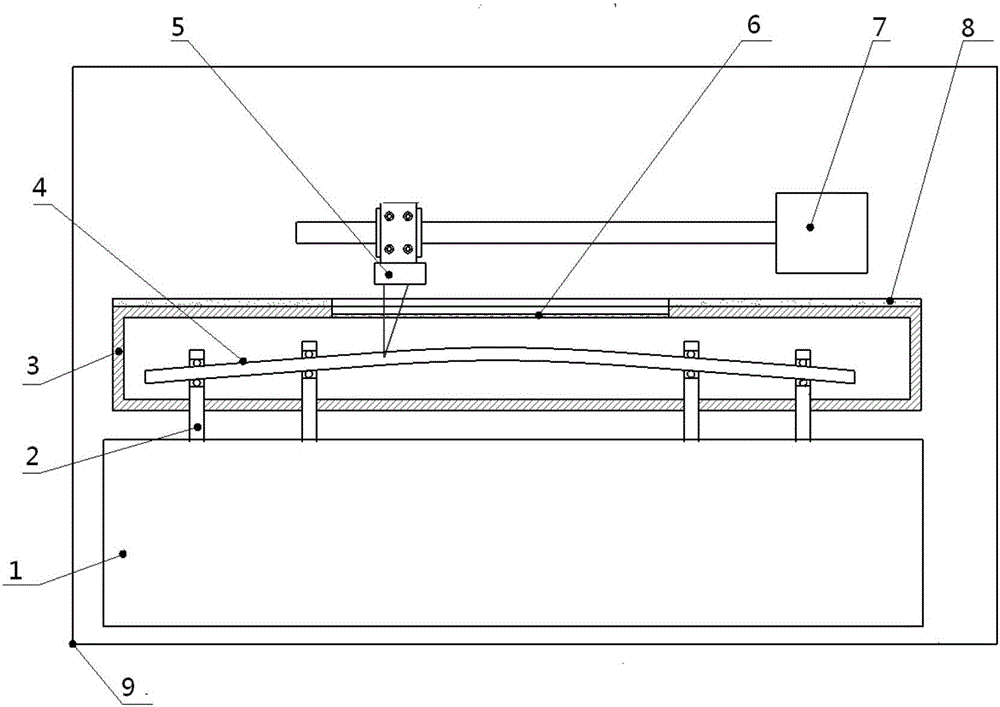

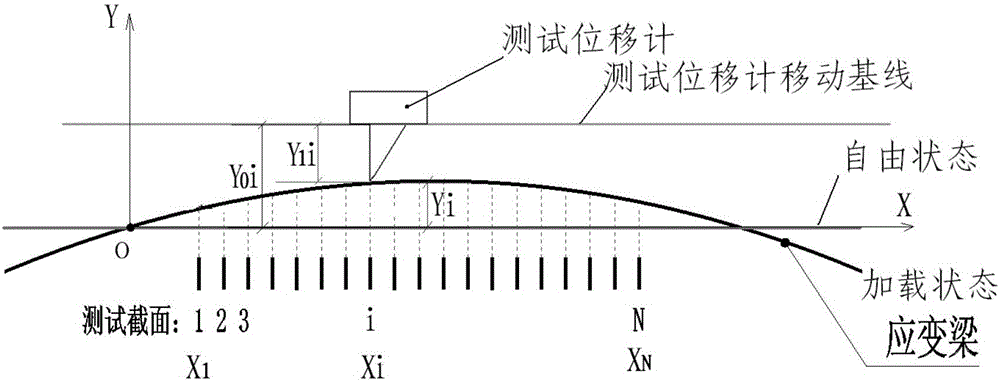

[0023] A static standard strain loading device based on a simply supported purely curved beam, characterized in that it includes a loading action module, a deformation measurement module, a strain beam 4,

[0024] The loading actuation module includes a loading actuator 1 and four loading rods 2 for bending the strain beam 4 for loading. The loading actuator 1 is fixed on a horizontal foundation platform 9 . The four loading rods 2 act on the strain beam 4 to form four loading points of the strain beam 4, and the distance between the two loading points on one side is the same as the distance between the two loading points on the other side. The loading actuator 1 can control the four loading rods 2 separately, so that each loading point moves along a straight line and can be stopped and fixed at a given position, and the four straight lines formed by the four loading points are parallel to each other and located in the same horizontal plane .

[0025] The deformation measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com