Cradle stand for electrolysis cell

A cradle frame and electrolytic cell technology, which is applied in the field of aluminum electrolytic cells, can solve the problems of arching and deformation at the bottom of the tank shell, and achieve the effects of reduced height, small deformation and reasonable stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

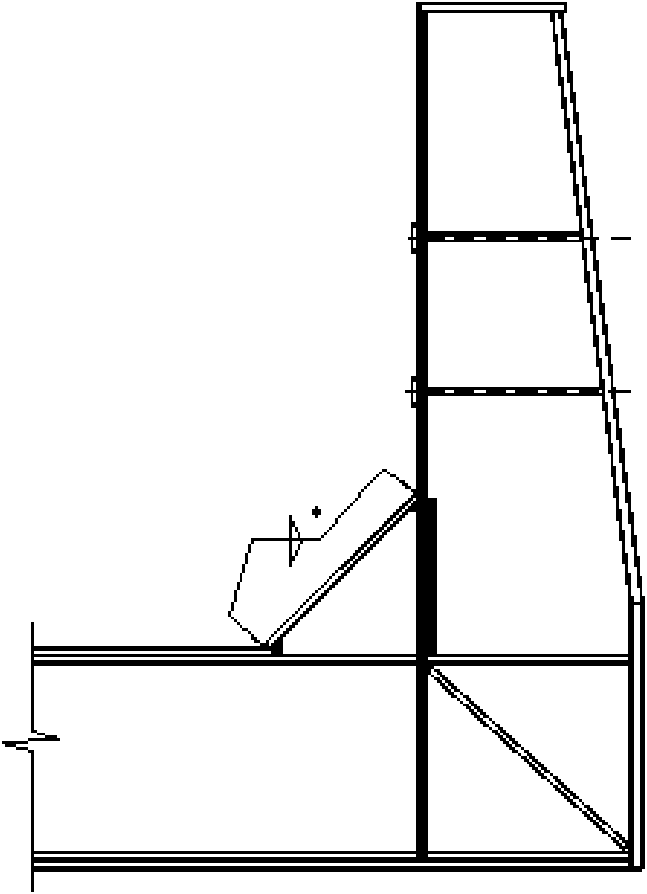

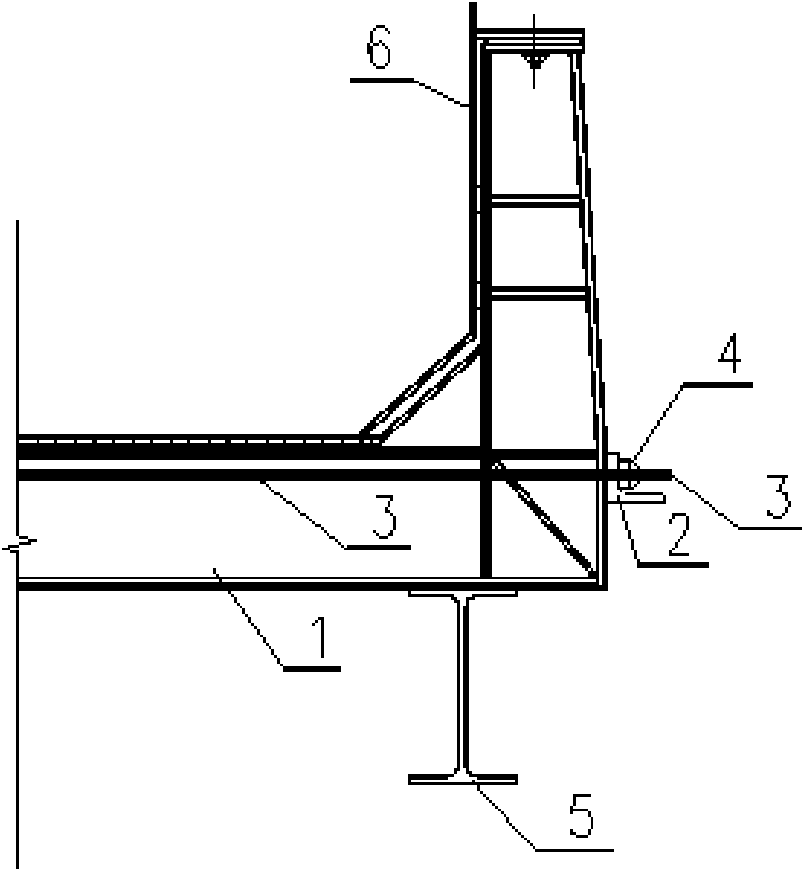

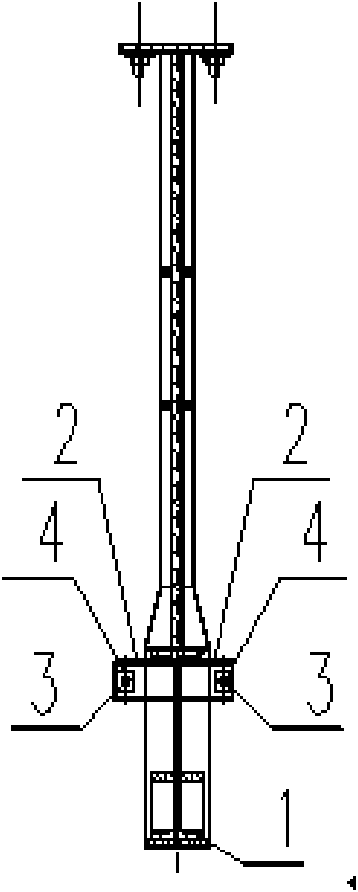

[0017] Embodiment 1 of the present invention: the electrolyzer cradle frame of the present invention is as figure 1 As shown (the cradle frame of the electrolytic cell is symmetrical on the left and right, and only half of it is shown in the figure), it supports the cell shell 6 of the electrolytic cell, which includes a bottom girder 1 located at the bottom of the cradle frame, and an electrolytic cell AB beam 5 is arranged below the bottom girder 1, Prestressed tie rods 3 are interspersed and fixed on the bottom girder 1 . There are two prestressed tie rods 3, which are respectively located on both sides of the bottom girder 1. The prestressed tie rods 3 are made of high-strength steel bars or steel strands, and both ends are provided with threads, which can be equipped with high-strength bolts. The left and right ends of the prestressed tie rods 3 are also provided with anchor ends 4 at the end of the prestressed tie rods, which are anchored together with the fulcrums 2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com