Anchorage Connection Device for Precast Concrete Bridge Deck of Steel-Concrete Composite Beam

A technology of prefabricated concrete and connecting devices, which is applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of easy gaps at the joints, impact on bridge safety performance, and poor load-bearing effect, so as to improve the load-bearing effect, facilitate installation, The effect of enhancing the anti-stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

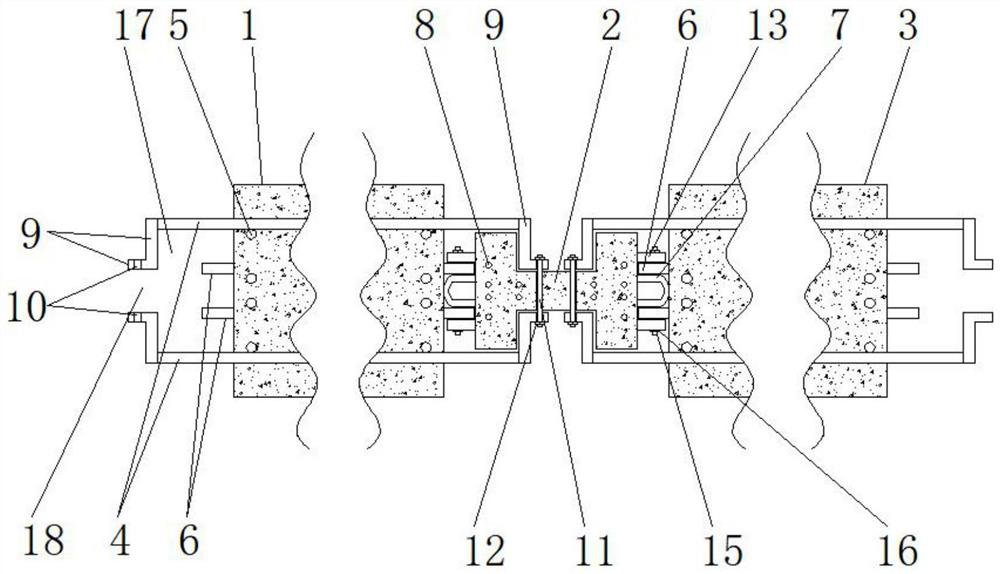

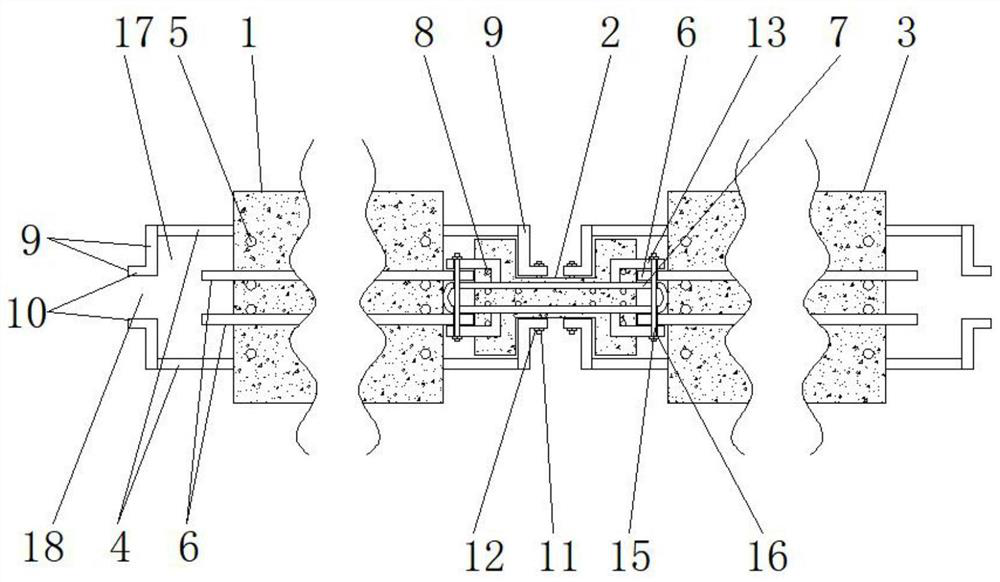

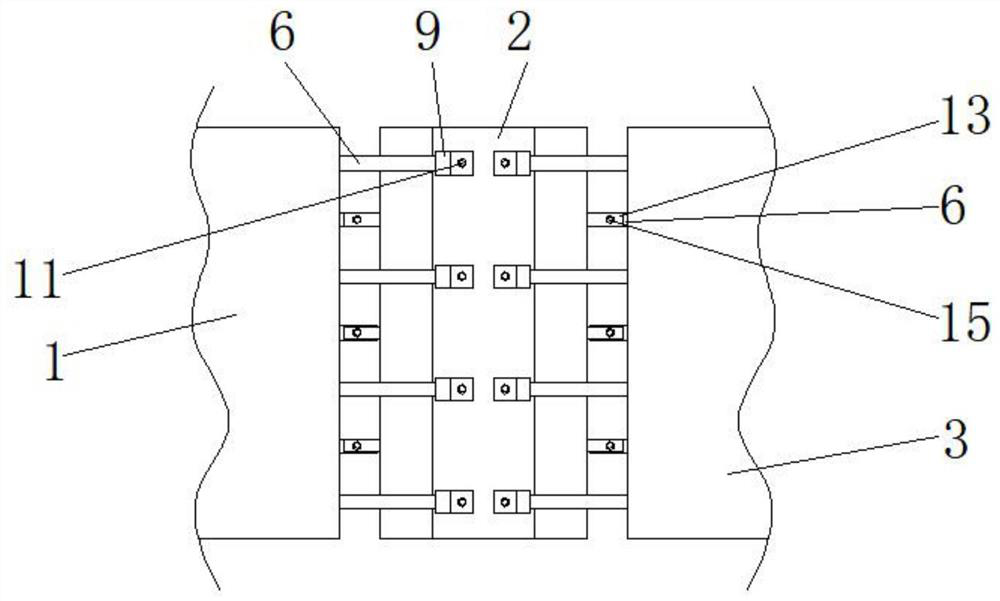

[0028] Such as Figure 1-7 The anchor connection device for the prefabricated concrete bridge deck of the steel-concrete composite beam shown includes a panel 1, one end of the panel 1 is connected to a panel 2 3 through a steel connector 2, and the inside of each panel is equidistantly provided with a first Transverse bar 4 and the longitudinal bar 5 perpendicular to the first transverse bar 4, and the longitudinal bar 5 and the transverse bar are all parallel to the panel two 3, the reinforcing bar connector 2 includes the first transverse bar 7, the longitudinal bar 8 perpendicular to the first transverse bar 7 and Concrete poured on the outside of the steel bar, and the first transverse steel bar 7 and the longitudinal steel bar 8 are parallel to the steel bar connector 2, the steel bar connector 2 has an H-shaped structure, and the first transverse bar 4 is arranged in two rows along the length direction of the panel, and Each row of first transverse ribs 4 is symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com