Pure bending age forming die for autoclave

An aging forming and pure bending technology, which is applied in the field of sheet metal forming, can solve the problems of easily damaged vacuum bags, difficult wrapping of vacuum bags, complex shapes, etc., and achieve the effects of reduced damage, simple structure, and simple appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

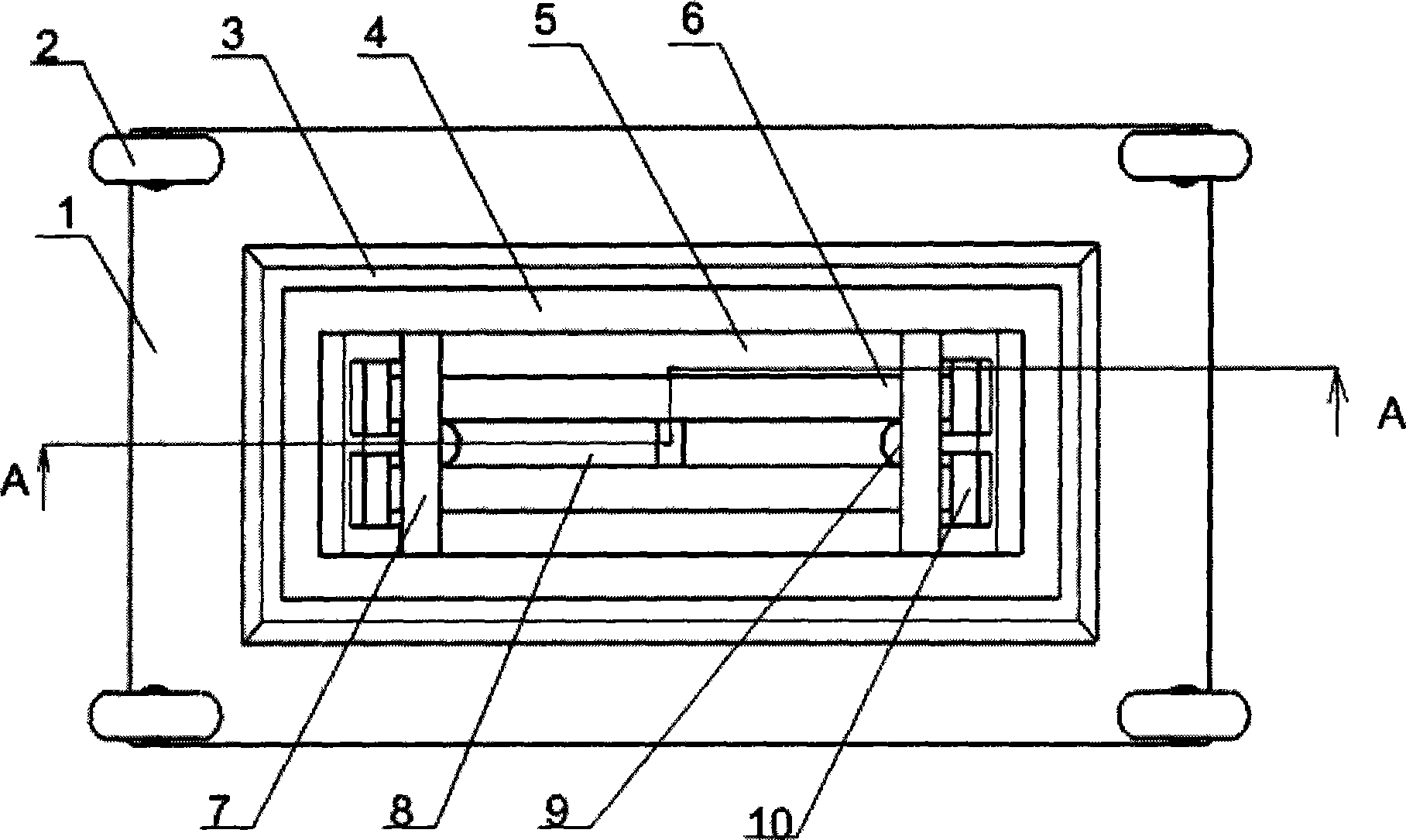

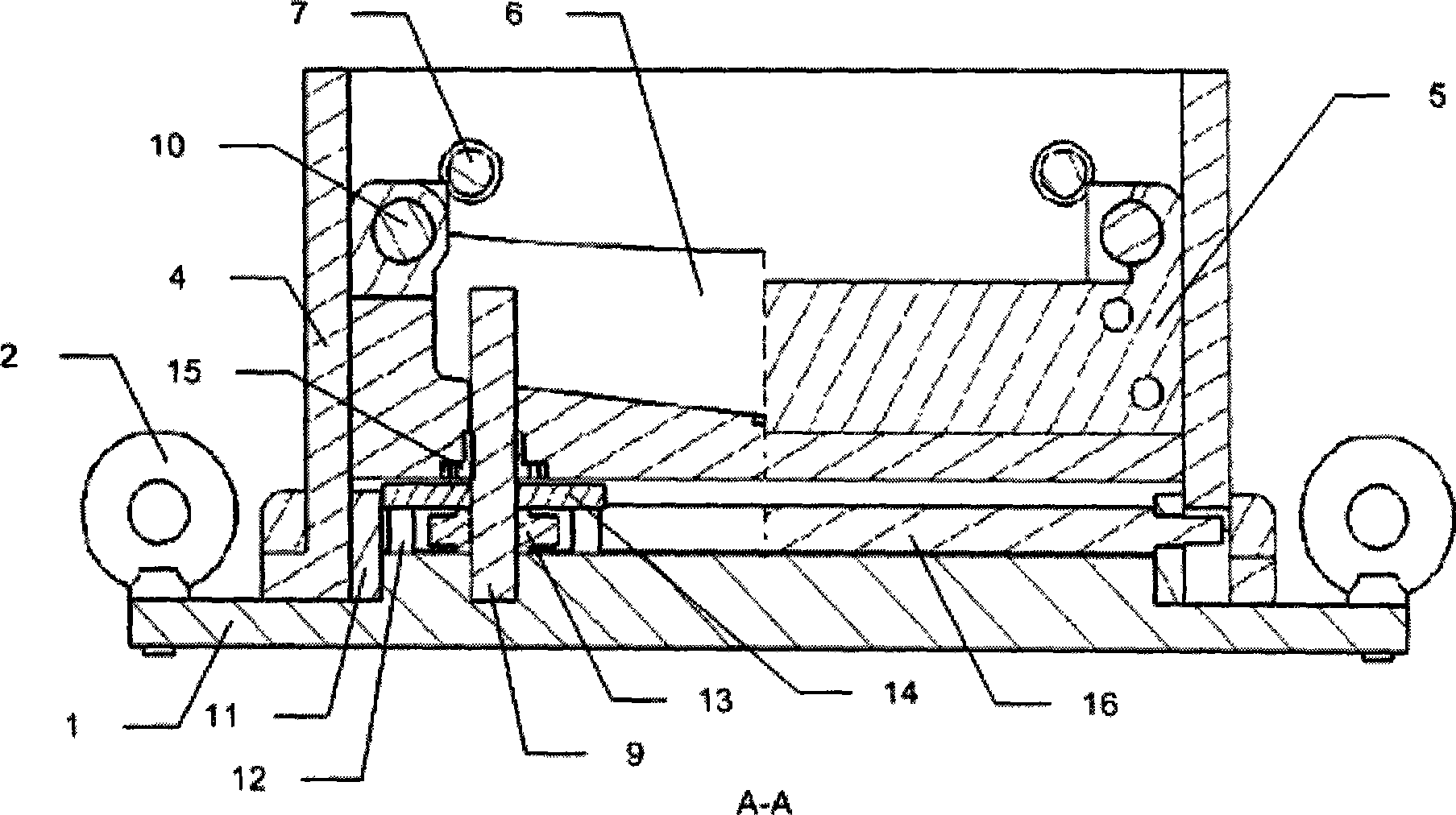

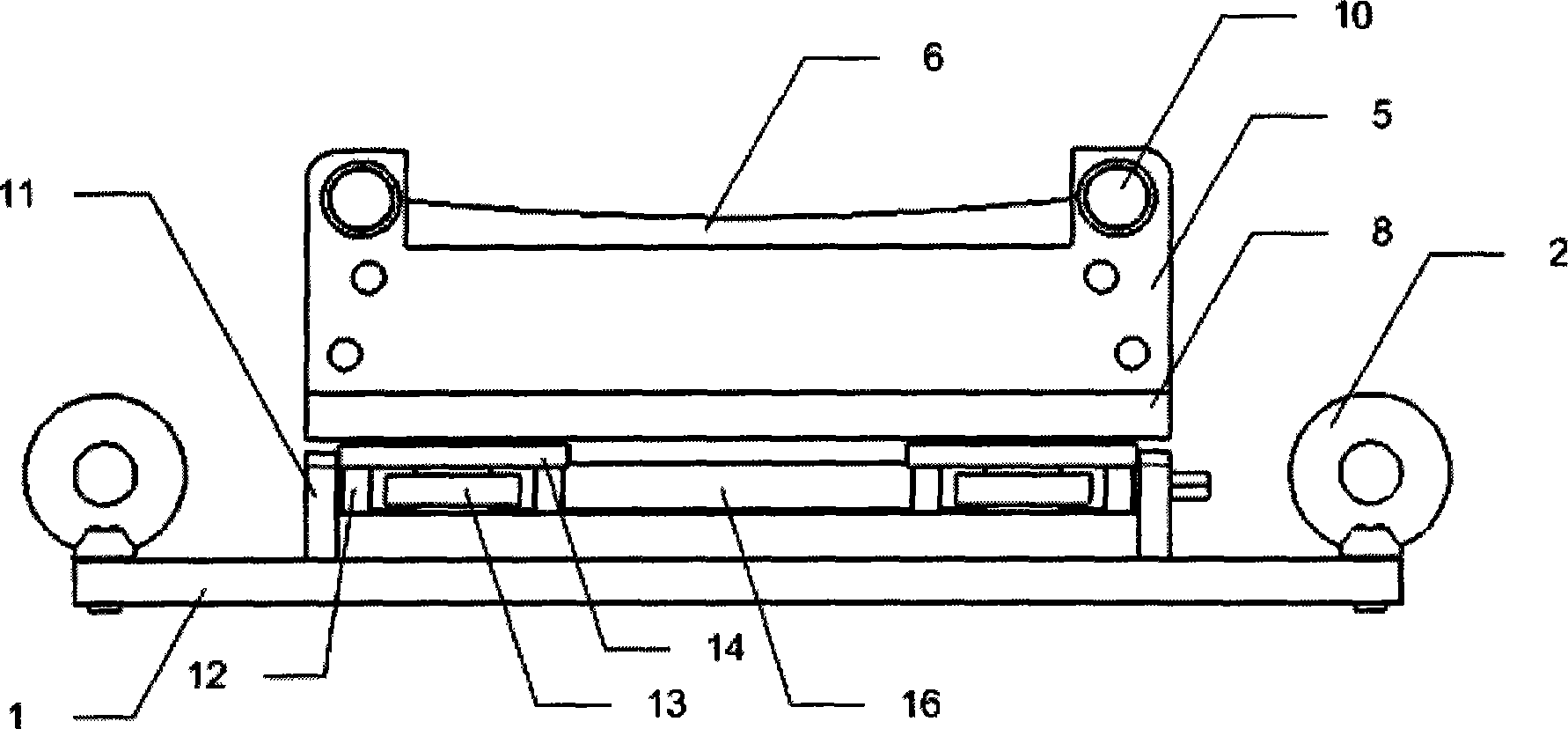

[0025] This embodiment is a pure bending aging forming mold for (500×50×5) mm thick flat plate autoclave (attached figure 1 To attach Figure 4 ), including base 1, lifting bolt 2, cover plate 3, box body 4, finale support 5, template 6, upper finale 7, pallet 8, lead screw 9, lower finale 10, worm support 11, double-ended screw 12 , worm gear 13, worm gear baffle plate 14 and lead screw nut 15, worm screw 16, wherein:

[0026] The base 1 is composed of a rectangular metal bottom plate and a rectangular boss in the middle of the upper surface of the bottom plate; the width of the boss is consistent with the width of the inner surface of the box body 4, and they cooperate with each other; there are worm brackets 11 on the bottom plate and the two ends of the boss, The sum of the length of the boss and the thickness of the two worm brackets 11 is equal to the length of the inner surface of the box body 4 . Four corners of the base 1 are respectively provided with threaded thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com