Patents

Literature

171results about How to "Promote warming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An engine cooling system and a cooling method

InactiveCN102733921AReduce fuel consumptionIncrease fuel consumptionLiquid coolingCoolant flow controlExpansion tankFriction loss

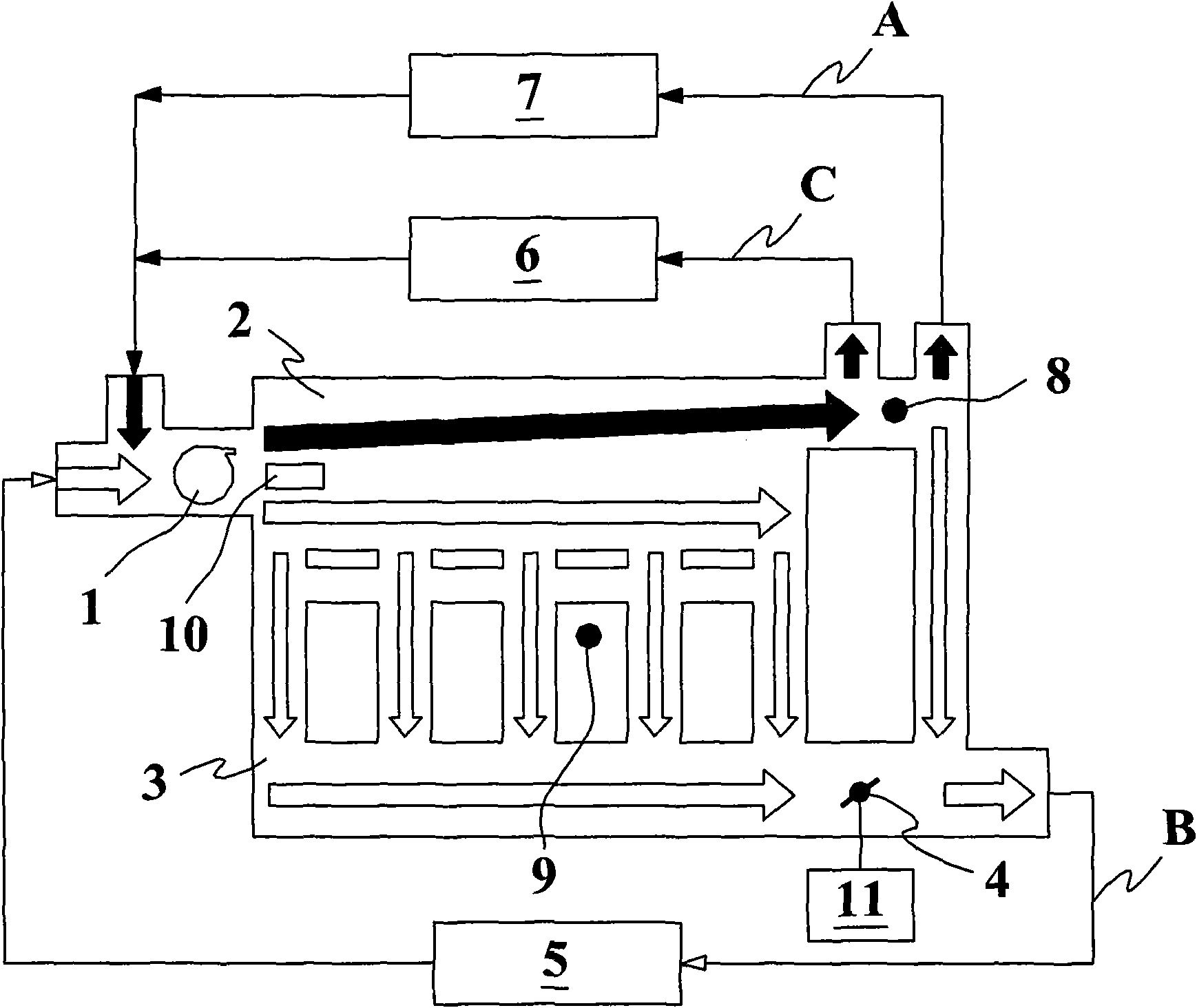

The invention relates to an engine cooling system, comprising a radiator, an expansion water tank, a pump unit, and a water jacket of a cylinder cover and a water jacket of a cylinder body that are communicated with each other. An outlet of the pump unit is communicated with an inlet of the water jacket of the cylinder cover to input cooling liquid; the input cooling liquid is arranged to be two flow paths for respectively cooling the cylinder cover and the cylinder body of the engine, wherein the first flow path is a loop where the cooling liquid outflows from an outlet arranged on the cylinder cover via the water jacket of the cylinder cover, and enters into an inlet of the pump unit after passing through the expansion water tank; the second flow path is a loop where the cooling liquid outflows from an outlet arranged on the cylinder body via the water jacket of the cylinder body, and enters into the inlet of the pump unit after passing through the radiator. The invention also relates to an engine cooling method. By utilizing the engine cooling system and the cooling method, temperatures of the cylinder cover and the cylinder body can be controlled and maintained in a more reasonable way, and therefore a temperature of lubricating oil can be notably improved, friction loss can be lowered, fuel consumption can be more efficient, and emission can be lowered.

Owner:SAIC GENERAL MOTORS +1

Rankine cycle device of internal combustion engine

InactiveUS6845618B2Wide temperature rangeMaintain performanceInternal combustion piston enginesExhaust apparatusMechanical energyInternal combustion engine

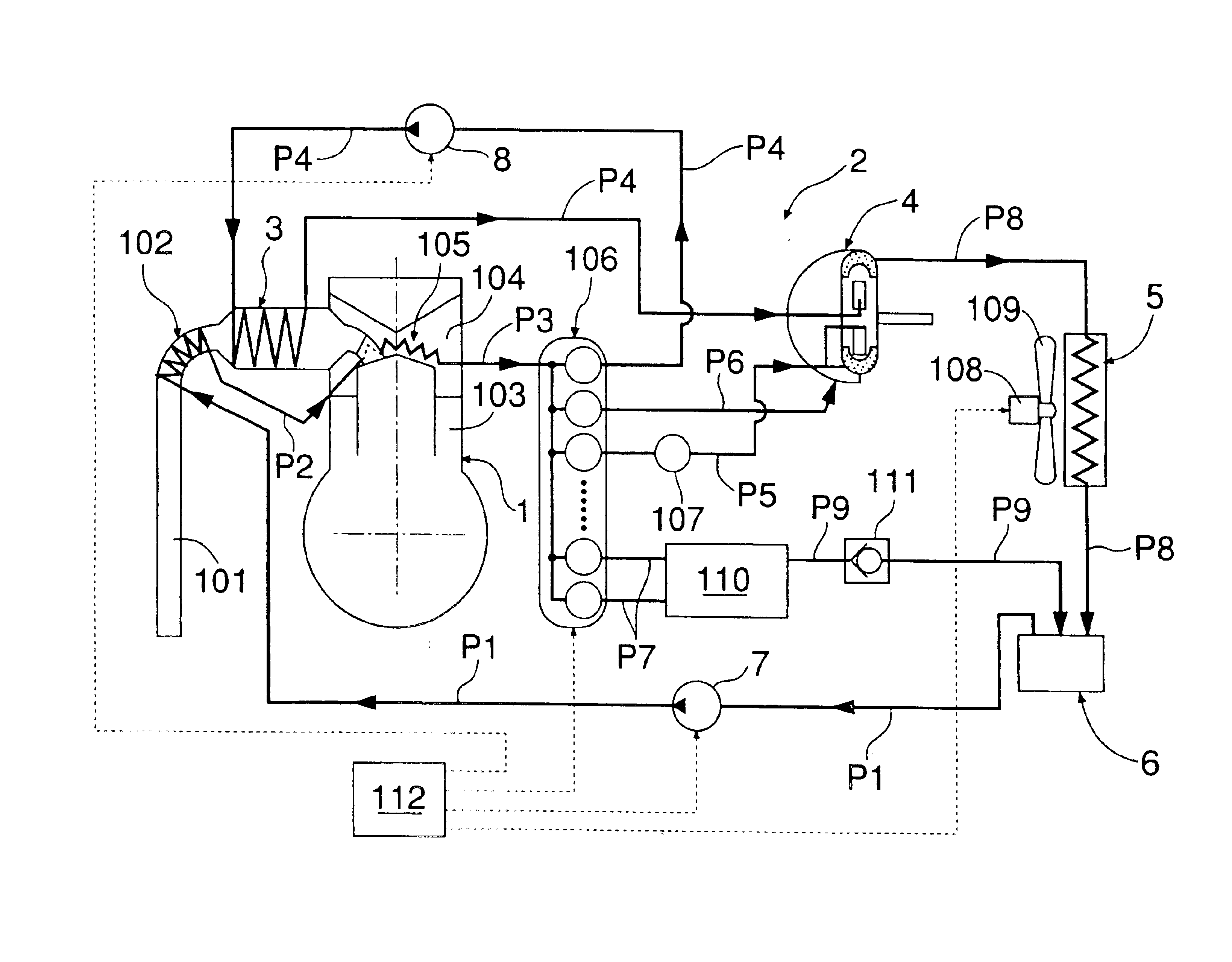

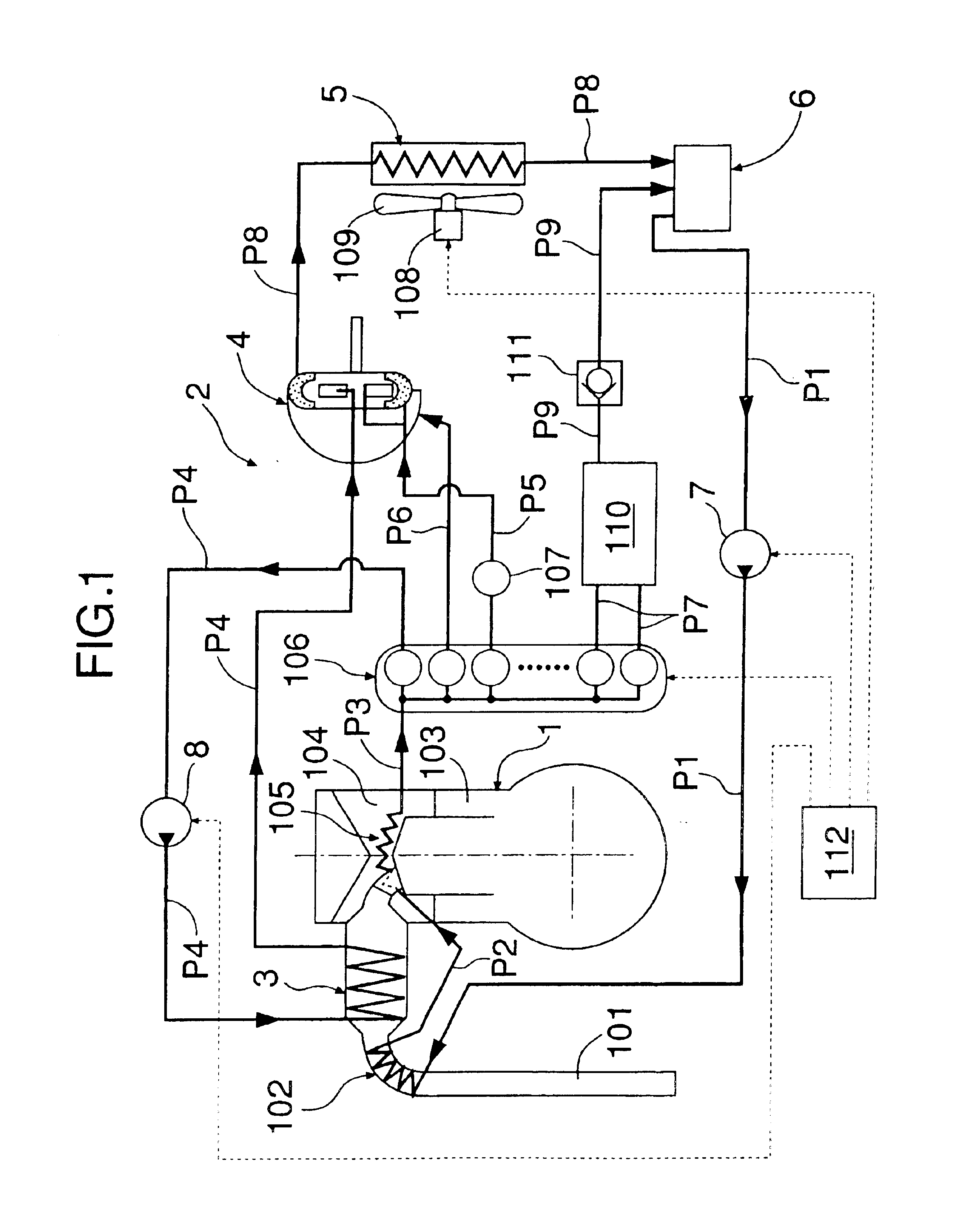

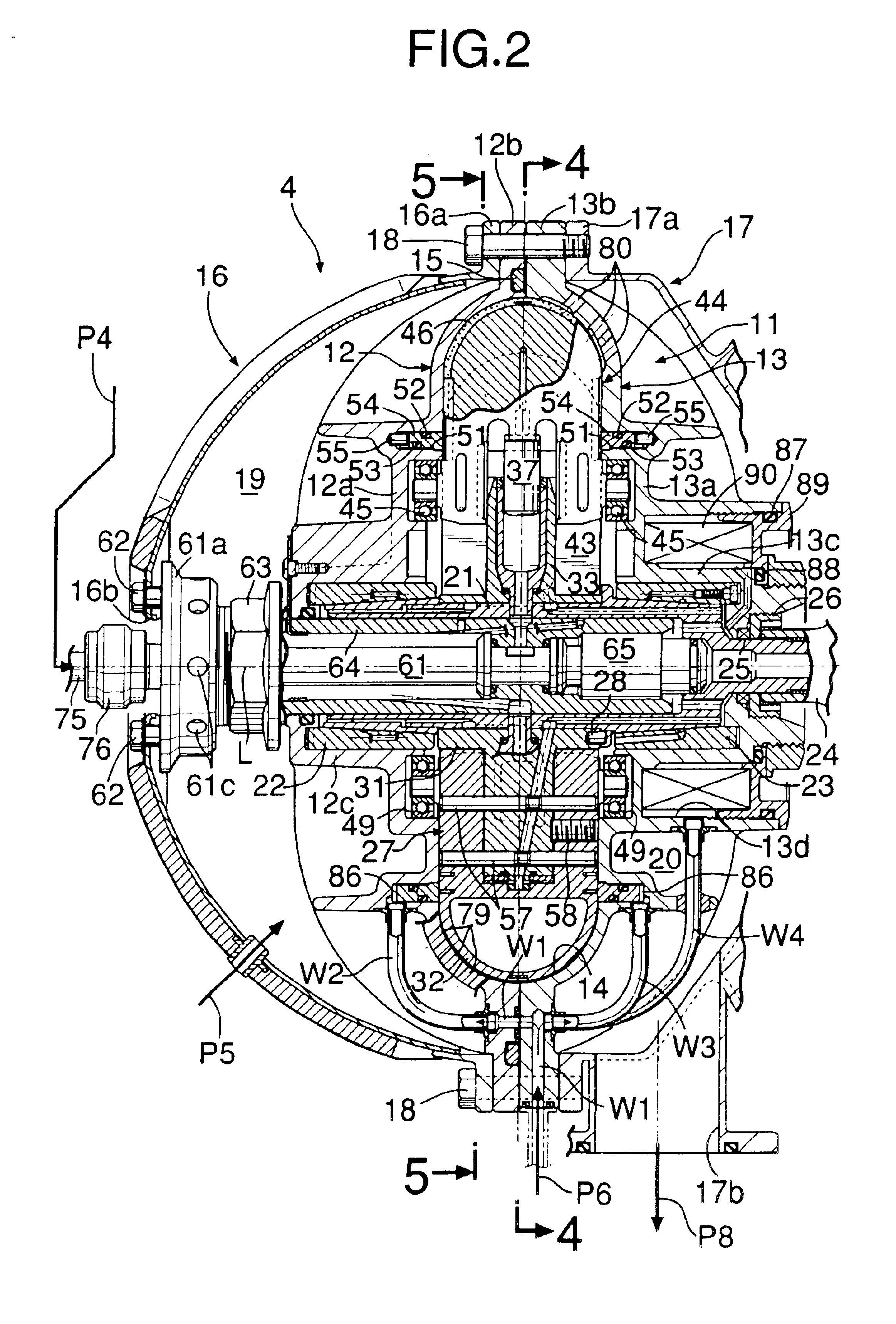

In a Rankine cycle system for an internal combustion engine, including an evaporator (3) for generating a vapor, an expander (4) for converting a heat energy of the vapor into a mechanical energy, a condenser (5) for cooling the vapor discharged from the expander (4) to restore it into water, a tank (6) for storage of the water from the condenser (5), and supply pumps (7, 8) for supplying the water in said tank (6) to the evaporator (3) in a pressurizing manner, the water in the tank (6) is supplied via a water jacket (105) of the internal combustion engine (1) to a dispensing valve (106) by the lower-pressure pump (7). A portion of the water dispensed by the dispensing valve (106) is further pressurized and supplied to the evaporator (3) by the higher-pressure pump (8), and another portion of the water dispensed by the dispensing valve (106) is discharged to the tank (6) after dissipating its heat in an auxiliary (110) such as a heater for heating a vehicle compartment and the like. Thus, it is possible to sufficiently cool heated portions of the internal combustion engine (1) by the water which is a liquid-phase working medium, while maintaining the performance of the Rankine cycle system, thereby aiming at the disuse of a radiator.

Owner:HONDA MOTOR CO LTD

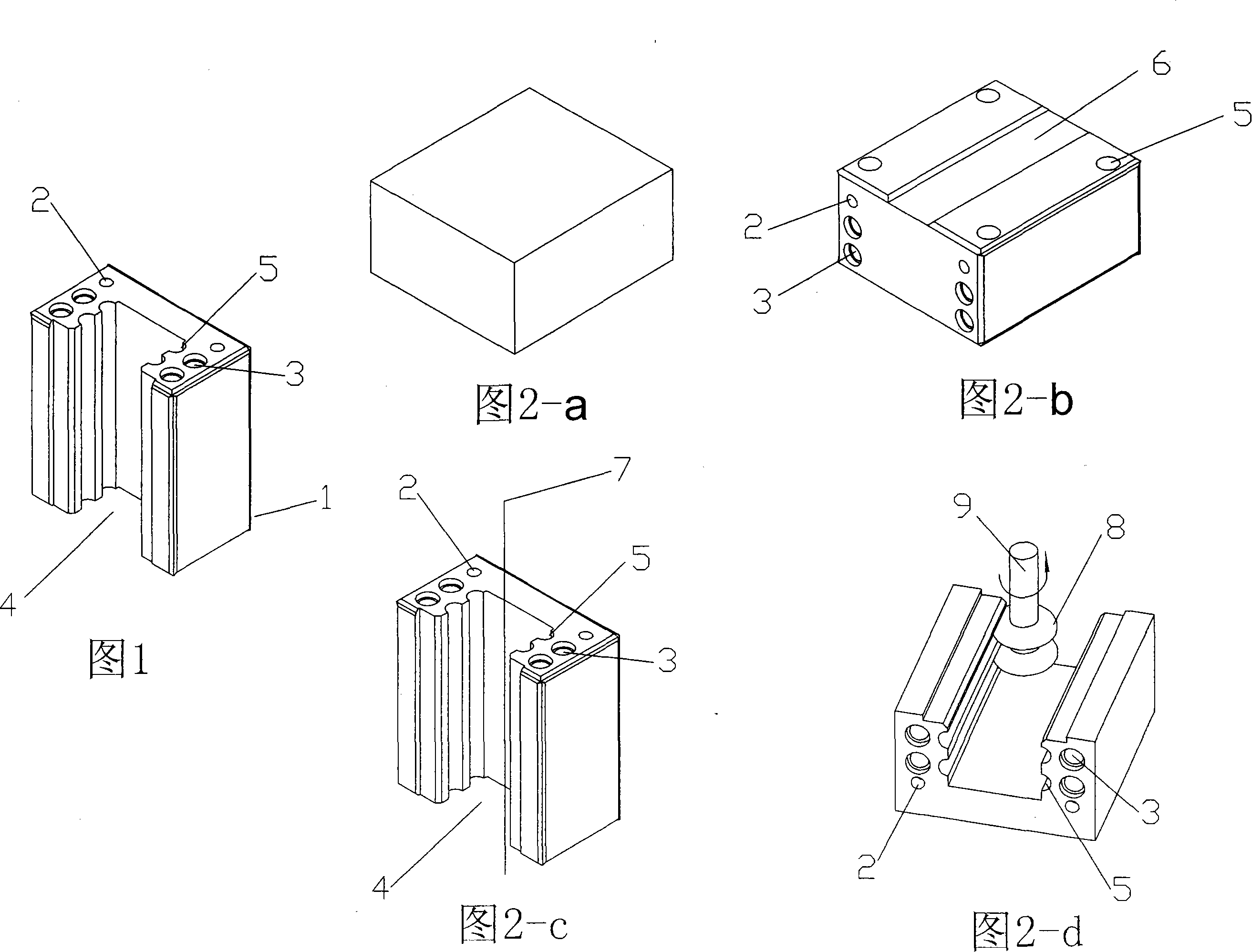

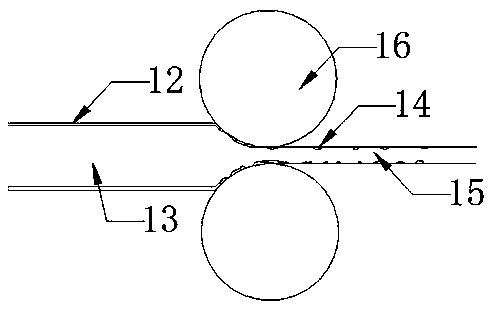

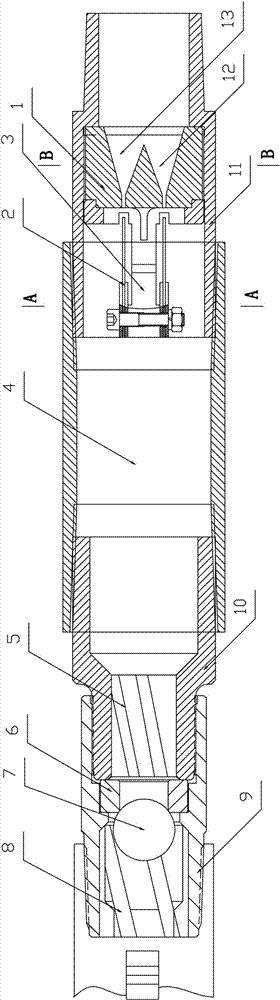

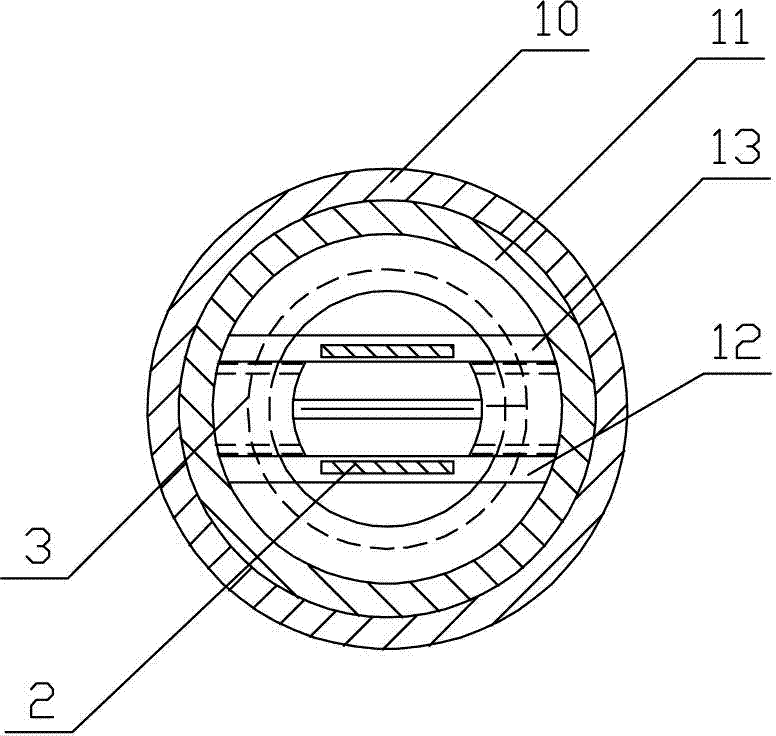

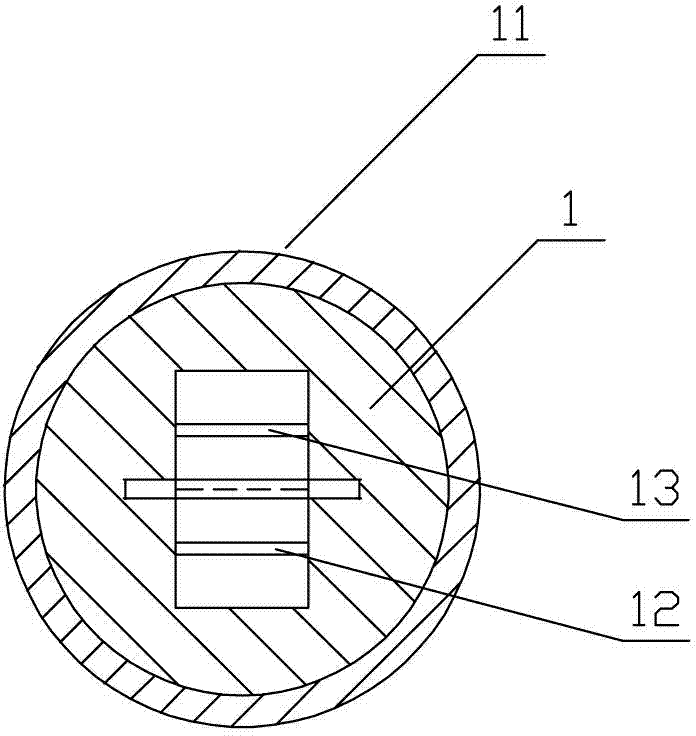

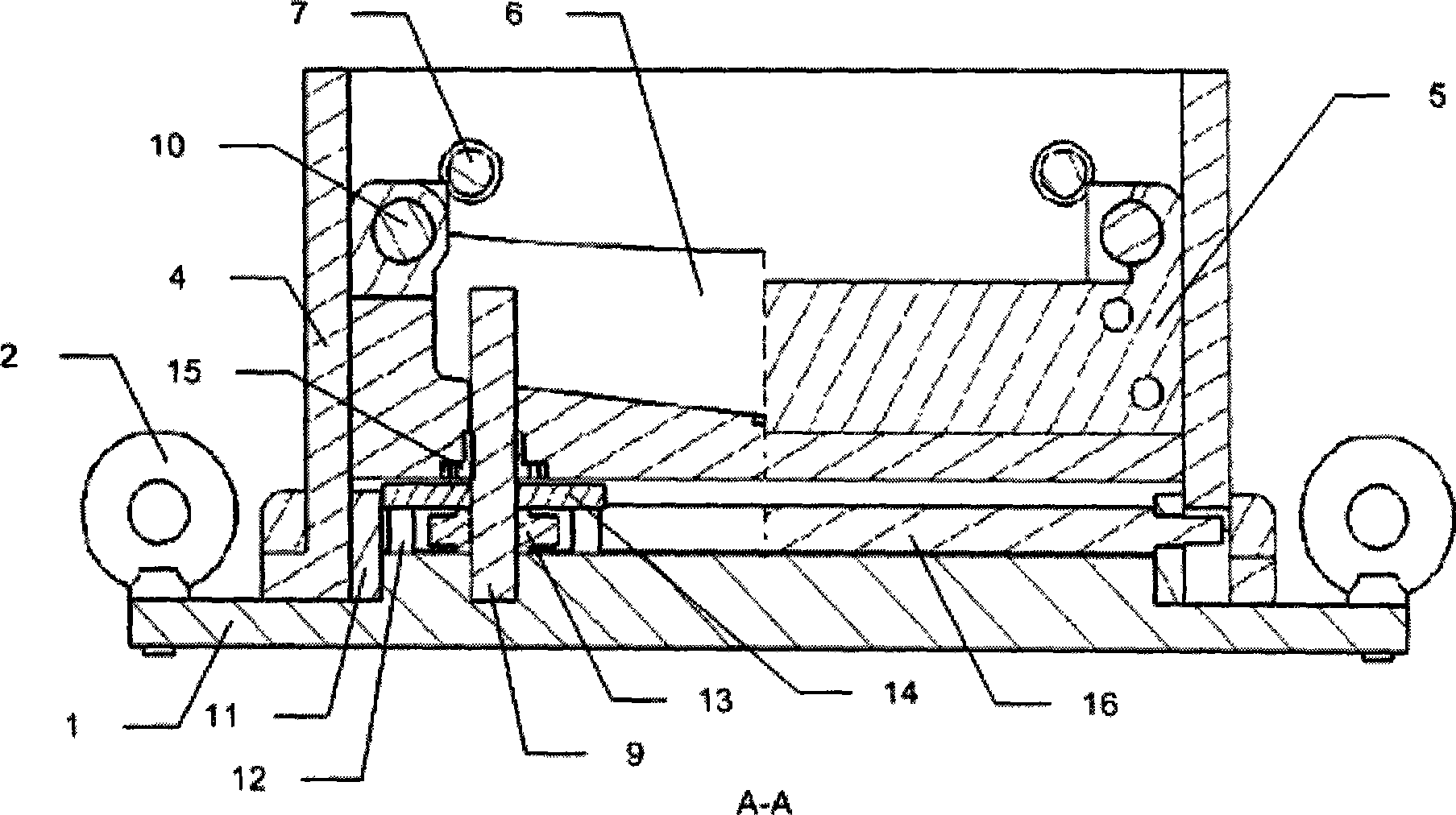

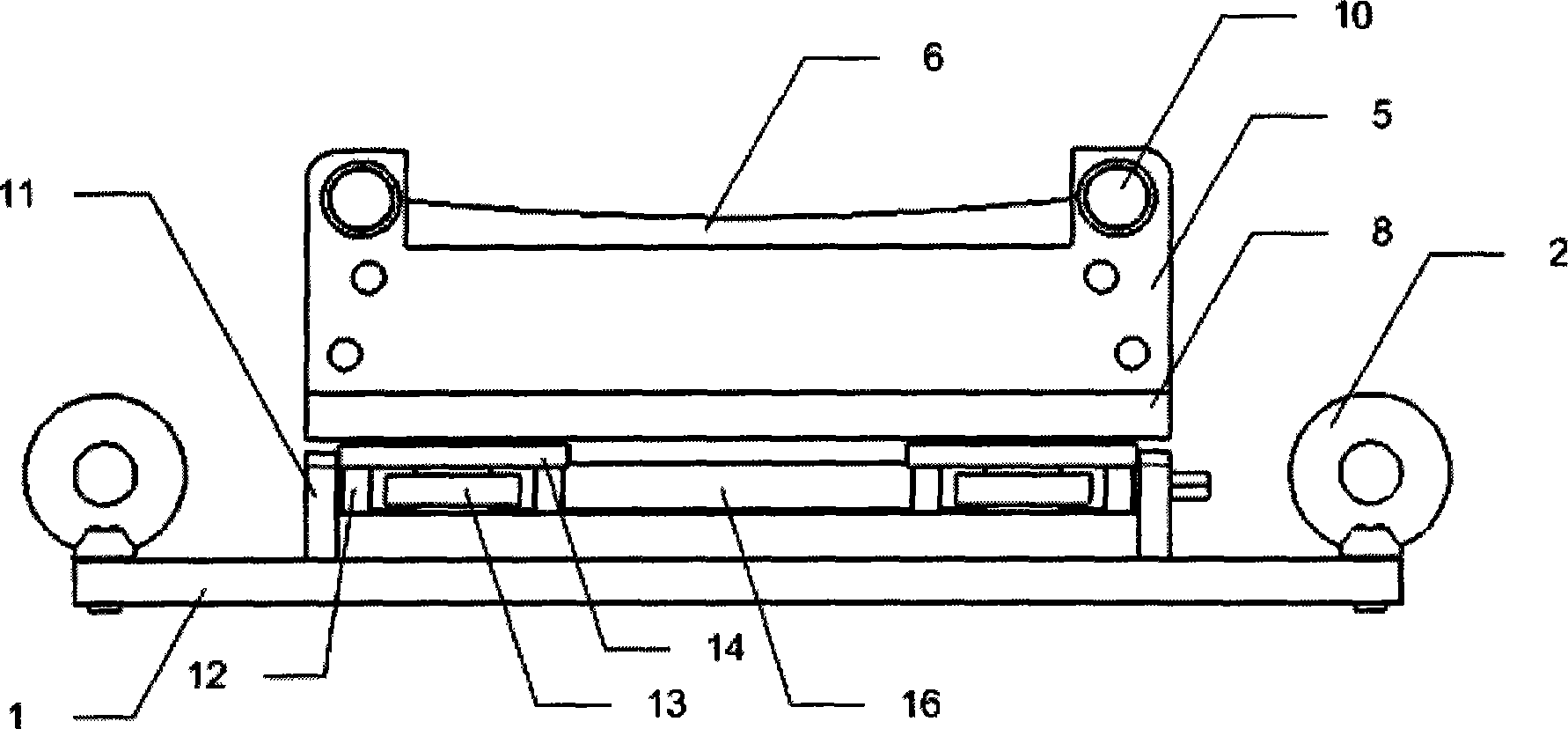

Straight-line rolling slipper block and method of manufacture

InactiveCN101235847AImprove compactnessStable and precise upper and lower contactLinear bearingsSEMI-CIRCLESteel bar

The invention relates to a linear rolling slider, which comprises a rolling steel ball which is arranged in the slider, an upper raceway groove and a lower raceway groove which are parallel are arranged on the inner walls of the two sides of an inner concave slider, and a raceway cavity which is reversely connected with the upper raceway groove and the lower raceway groove is horizontally arranged on the inner walls of the two sides of the inner concave slider. The method for preparation comprises that a round steel bar is thermally forged into a square green body, the square green body is milled and processed into cut angle end surfaces which are mutually vertical, and relative surfaces are hexahedron which are mutually parallel. The hexahedron is flatly ground and processed to achieve the required precision of parallelism and reference location, the hexahedron is cut and processed into a concave slider body by a wire electrical discharge, and an upper semi-circle raceway groove and a lower semi-circle raceway groove which are parallel and are arranged on the two sides of the inner concave slider are ground in high speed. A steel ball in the raceway groove not only operates in high speed not to block, but also is not bore in long time operation and not produces frictional heating. The friction coefficient is capable of being reduced to fiftieth of the original friction coefficient, the instantaneous speed is increased for 10 times, the linear rolling slider uses a double-row raceway groove, thereby being capable of greatly increasing carrier loads, achieving steady operation, and prolonging the service life.

Owner:宁波恒力汽配轴承有限公司

Honey processing process

InactiveCN103549250AHigh purityTargetedFood thermal treatmentMulti-step food processesHeating timeFiltration

The invention relates to a honey processing process. The honey processing process is characterized by comprising the following steps: (1) raw honey inspection; (2) (a) melting, wherein the heating temperature is 45-60 DEG C, and the heating time is 30-60 minutes or 4-8 hours according to the state of raw honey; (b) filtration, namely carrying out pressure filtration in a sealing device at the temperature higher than 40 DEG C so as to remove impurities and larger crystals; (3) vacuum concentration; (4) cooling. According to the honey processing process, the filtration step sequentially comprises rough filtration, fine filtration and refined filtration, wherein the temperature of the fine filtration is higher than that of the rough filtration, and the temperature of the refined filtration is higher than that of the fine filtration. The different processing time can be set according to different states of the raw honey, so that the pertinence is strong, not only can melting quality and the smooth operation of subsequent steps be guaranteed, but also the efficiency is increased, and the unnecessary time waste is reduced; besides, the filtration is performed three times, and the filtering temperatures are different, so that the efficiencies of each filtration process and the whole filtration are increased, and the purity of finished honey is improved.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

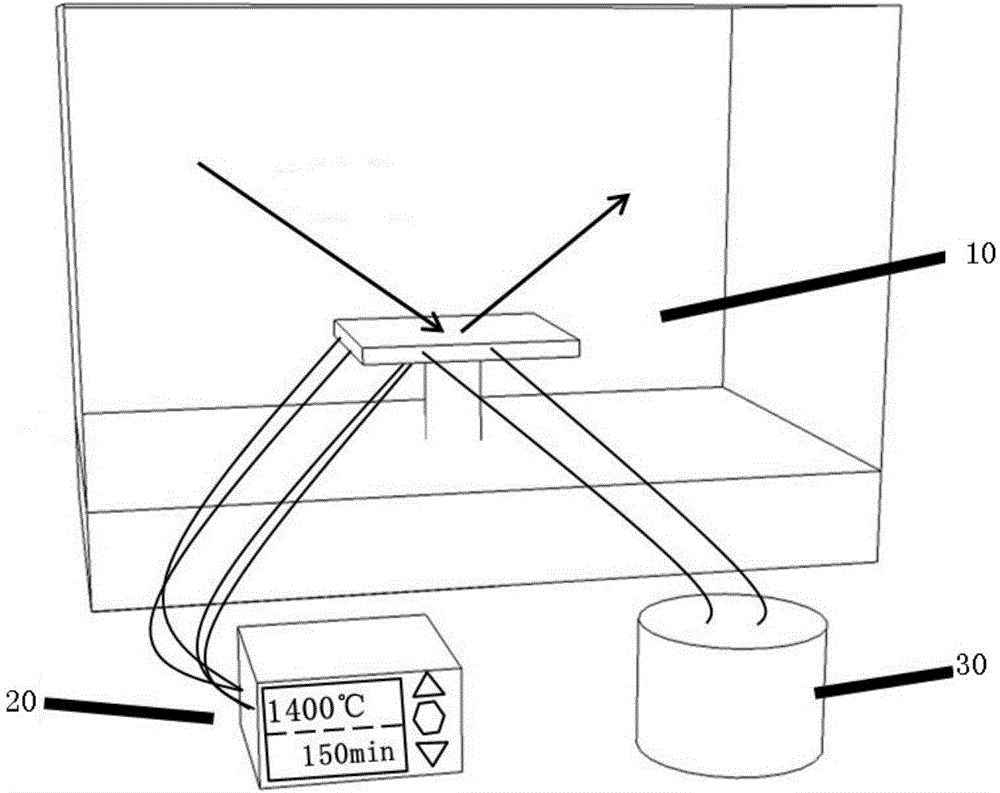

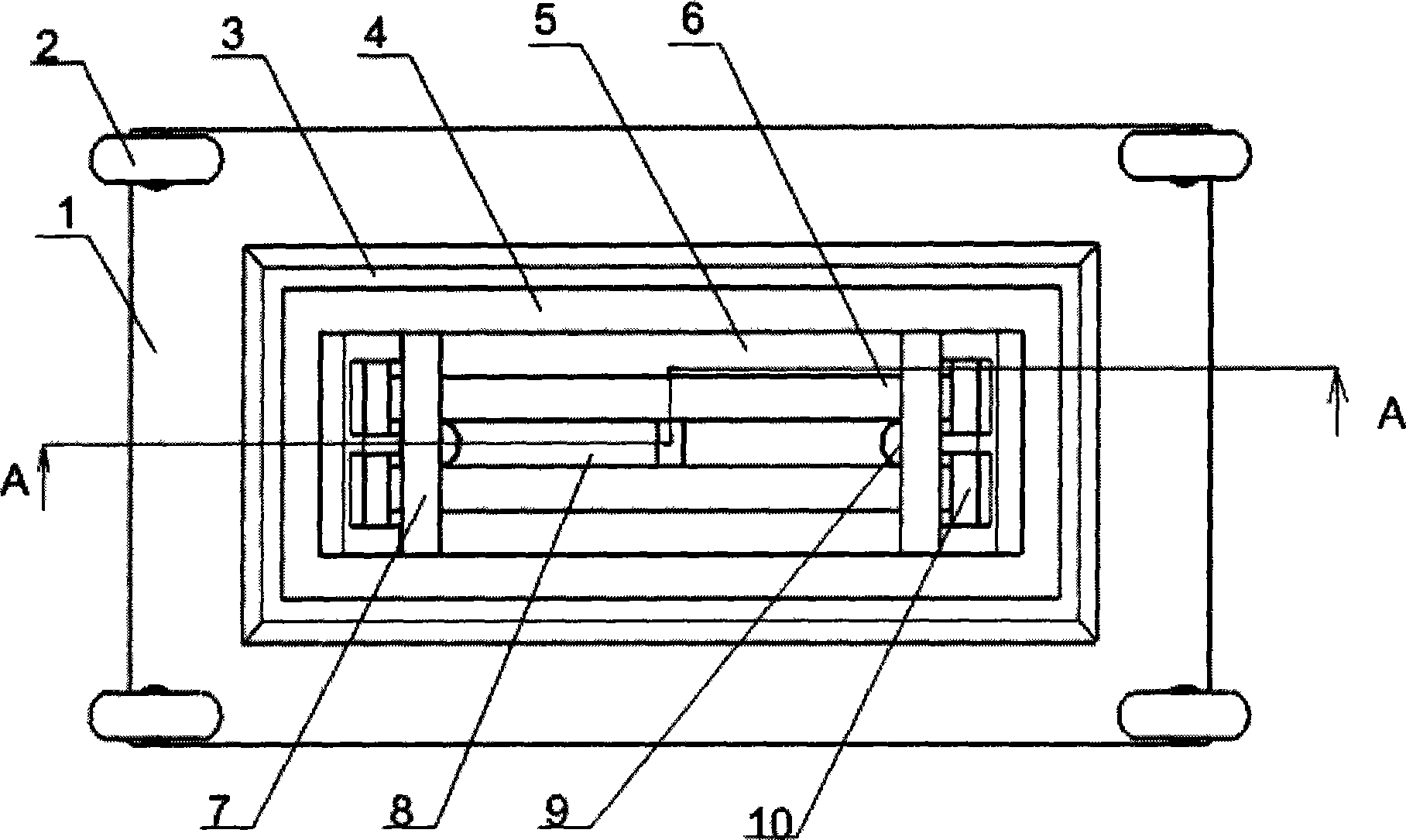

In-situ test sample platform

ActiveCN104458780AReasonable structureAccurate and controllable heating and cooling rateMaterial analysis using radiation diffractionElectric heatingTest sample

The invention provides an in-situ test sample platform. The in-situ test sample platform comprises a sample table, a sample table base, a ceramic heating plate, a heating plate supporting frame, a temperature control system and a circulating water cooling system, wherein the sample table base is installed on the lower surface of the sample table; the ceramic heating plate is used for carrying a sample, and an electric heating wire and a thermocouple are arranged inside the ceramic heating plate; the heating plate supporting frame supports the ceramic heating plate, so that the ceramic heating plate is suspended above the sample table; the temperature control system is connected to the electric heating wire and the thermocouple so as to control the temperature of the ceramic heating plate in real time; the circulating water cooling system is fixedly connected to the lower surface of the sample table so as to cool the sample table. By adopting the in-situ test sample platform, the in-situ test for the heating, high-temperature heat treatment and cooling process of the sample can be carried out in an online manner; moreover, the temperature control system and the circulating water cooling system do not affect each other, the temperature of the sample table is ensured not to be excessively high under the condition of guaranteeing the normal work of the circulating water cooling system, and the normal high-temperature work of the ceramic heating plate is not influenced.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

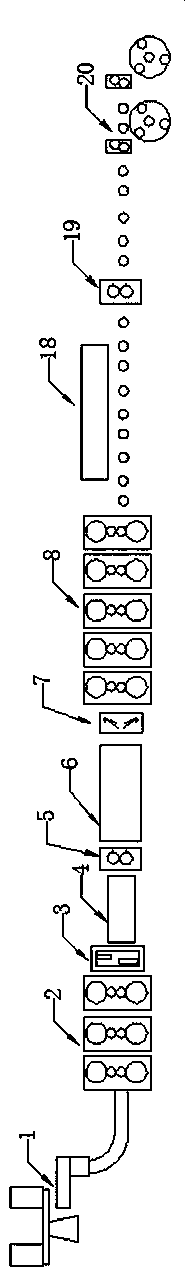

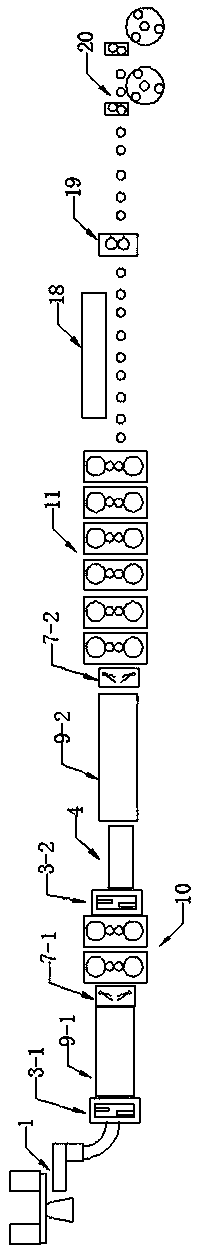

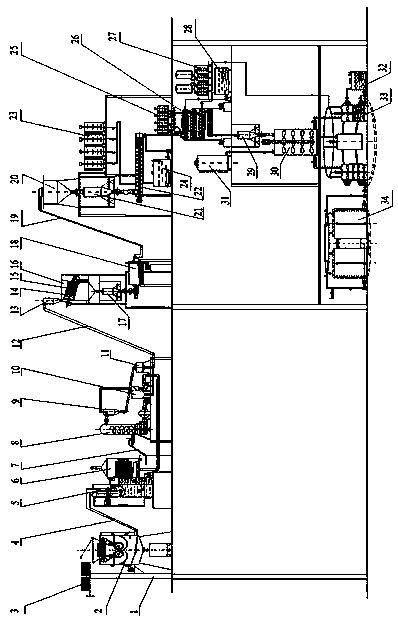

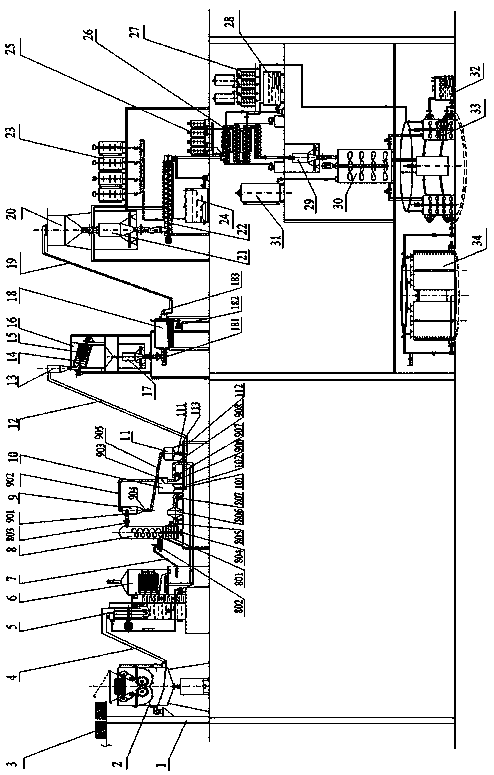

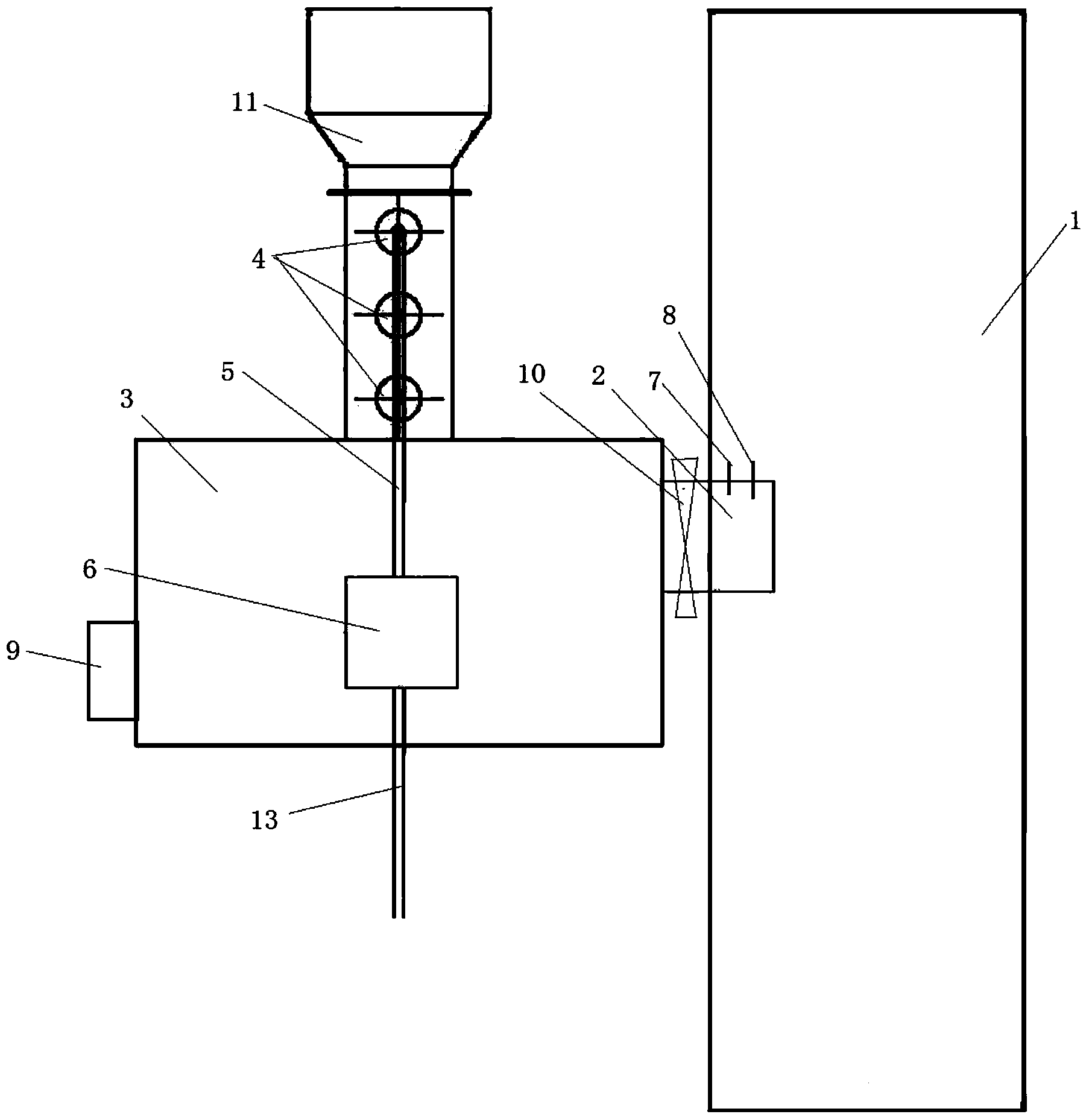

Sheet billet continuous casting and rolling production line and production process thereof

ActiveCN109013701AAvoid major production accidentsPromote warmingMetal rolling arrangementsProduction lineLaminar cooling

The invention relates to a sheet billet continuous casting and rolling production line and a production process thereof, and belongs to the technical field of sheet billet continuous casting and rolling. According to the technical scheme, the sheet billet continuous casting and rolling production line comprises a continuous casting machine (1), a 1#pendulum shear (3-1), a 1#tunnel type heating furnace (9-1), a 1#descaler (7-1), a roughing mill group (10), a 2#pendulum shear (3-2), a billet picking device (4), a 2#tunnel type heating furnace (9-2), a 2#descaler (7-2), a finishing mill group (11), a laminar cooling (18), a flying shear (19) and a reeling-up machine set (20) which are arranged in sequence according to a rolling sequence. When the continuous casting speed of the continuous casting machine (1) is less than 5m / min, single block rolling or semi-endless rolling is adopted; and when the continuous casting speed of the continuous casting machine (1) is greater than or equal to 5m / min, endless rolling is adopted. The sheet billet continuous casting and rolling production line and the production process thereof have the beneficial effects that the temperature uniformity and the surface quality of a casting blank can be ensured, and different rolling modes can be adopted according to the continuous casting speed of the continuous casting machine.

Owner:唐山全丰薄板有限公司

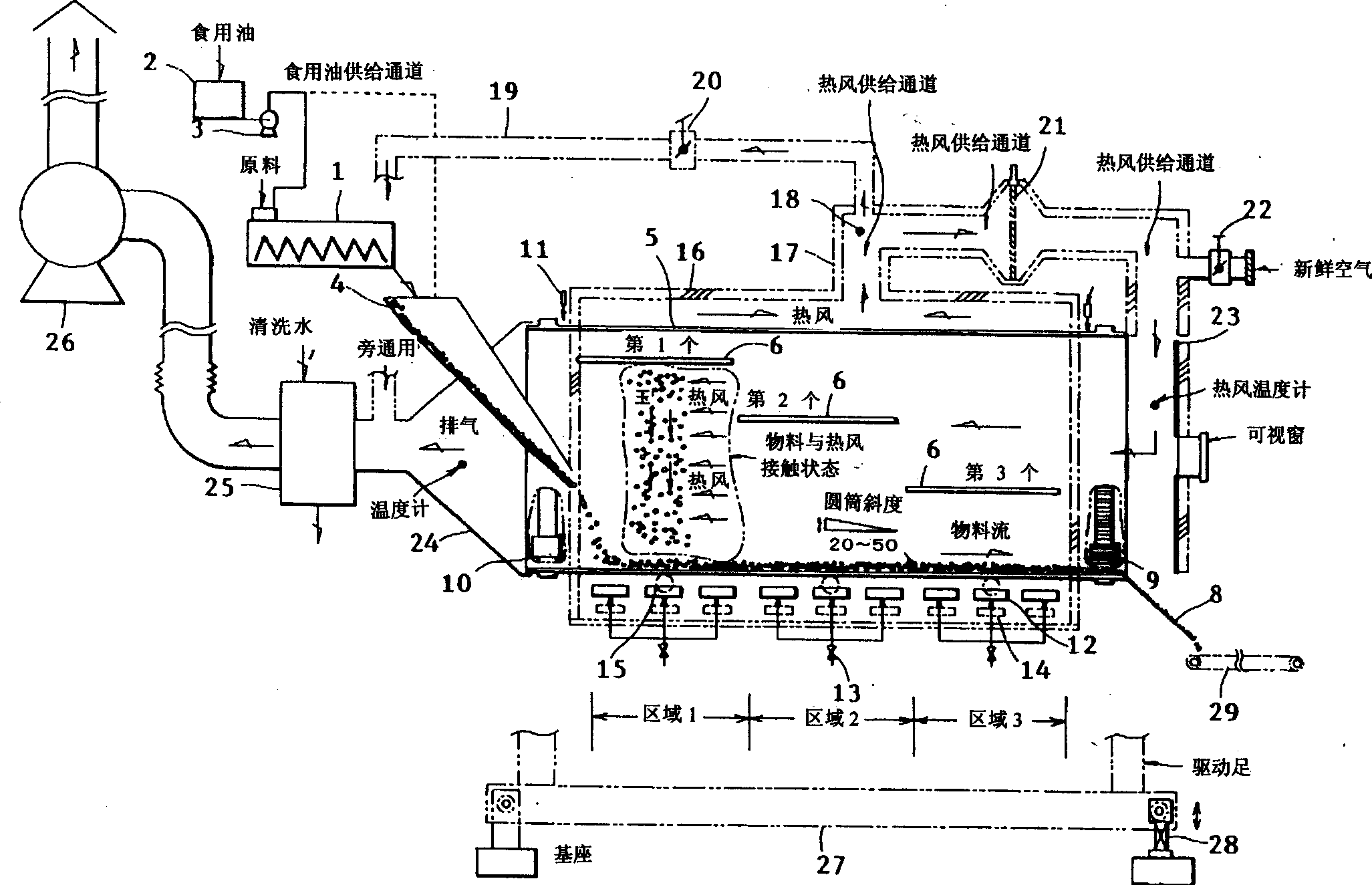

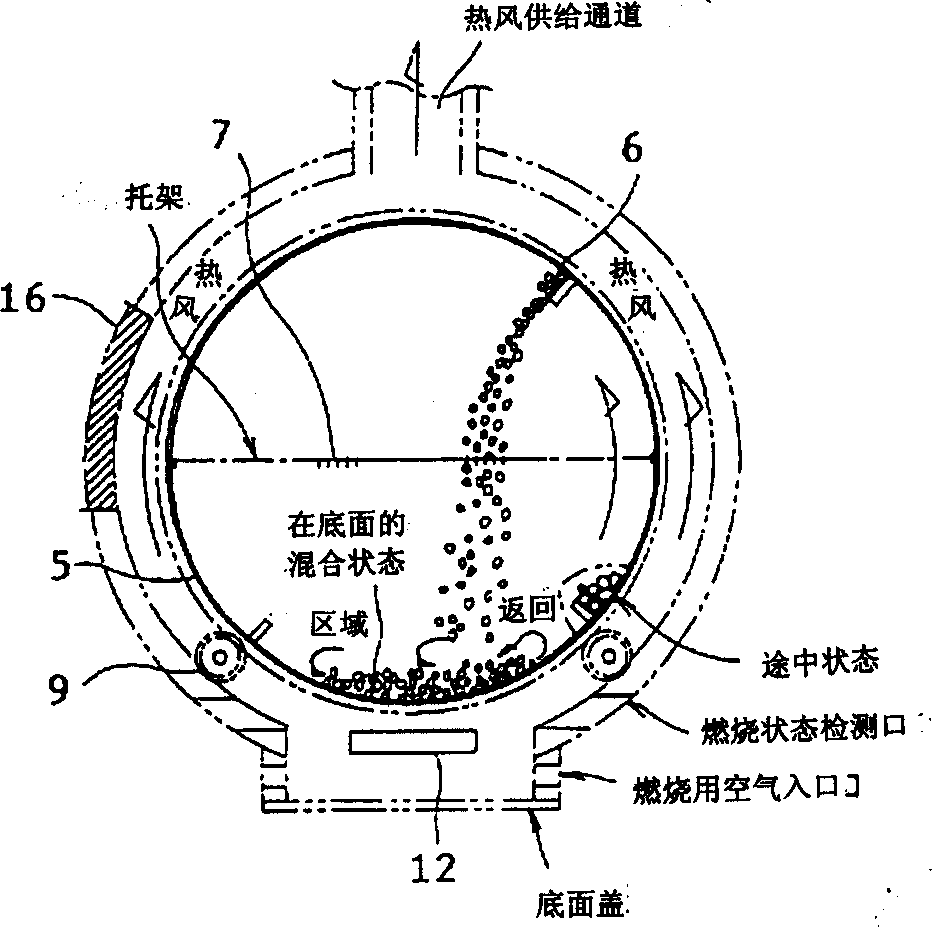

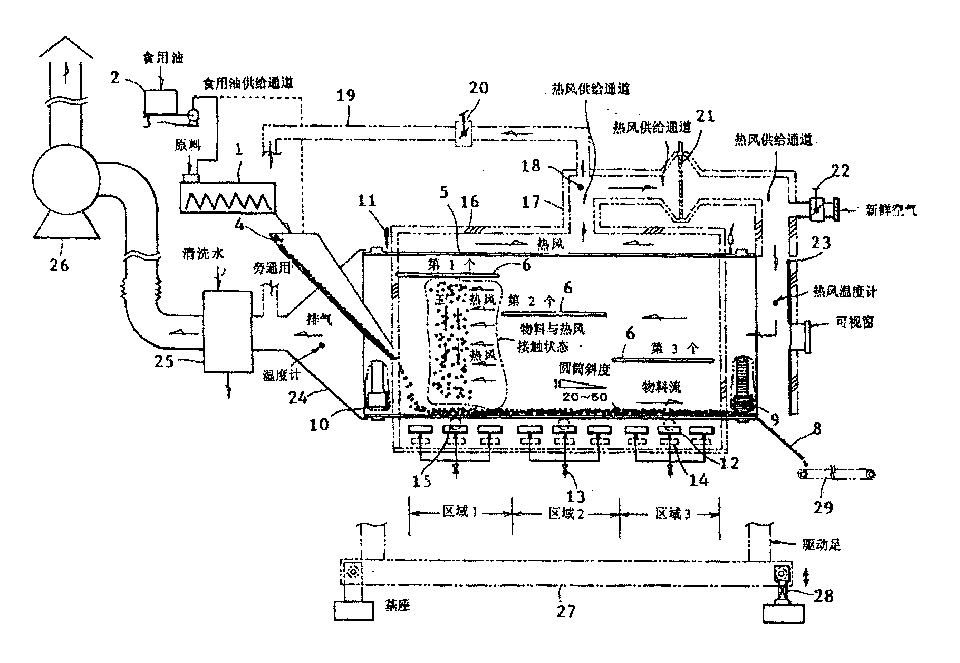

Lead-in hot air horizohntal rotary cylinder continuous frying apparatus

InactiveCN1347660APromotes warming and evaporationImprove processing powerBaking ovenCooking vesselsProduct gasEngineering

The invention provides a frying cooking device, which performs continuous processing, for improving problems that most of conventional frying devices are batch types which have low throughput, have problems on the aspect of a quality, require manpower, have low energy performance, require large installing spaces and have many other problems, and that a continuous frying machine transmits heat depending on only a direct contact with a cylindrical inner, which causes problems of throughput and scorching to an inner wall, etc. This horizontal rotary cylindrical type continuous frying device of an exhaust hot air introducing type is obtained by arranging an exhaust hot air feeding line for introducing the exhaust hot air of combustion gas used for heating the outer peripheral surface of a cylinder at a horizontal rotary cylindrical type continuous frying device.

Owner:AJINOMOTO CO INC

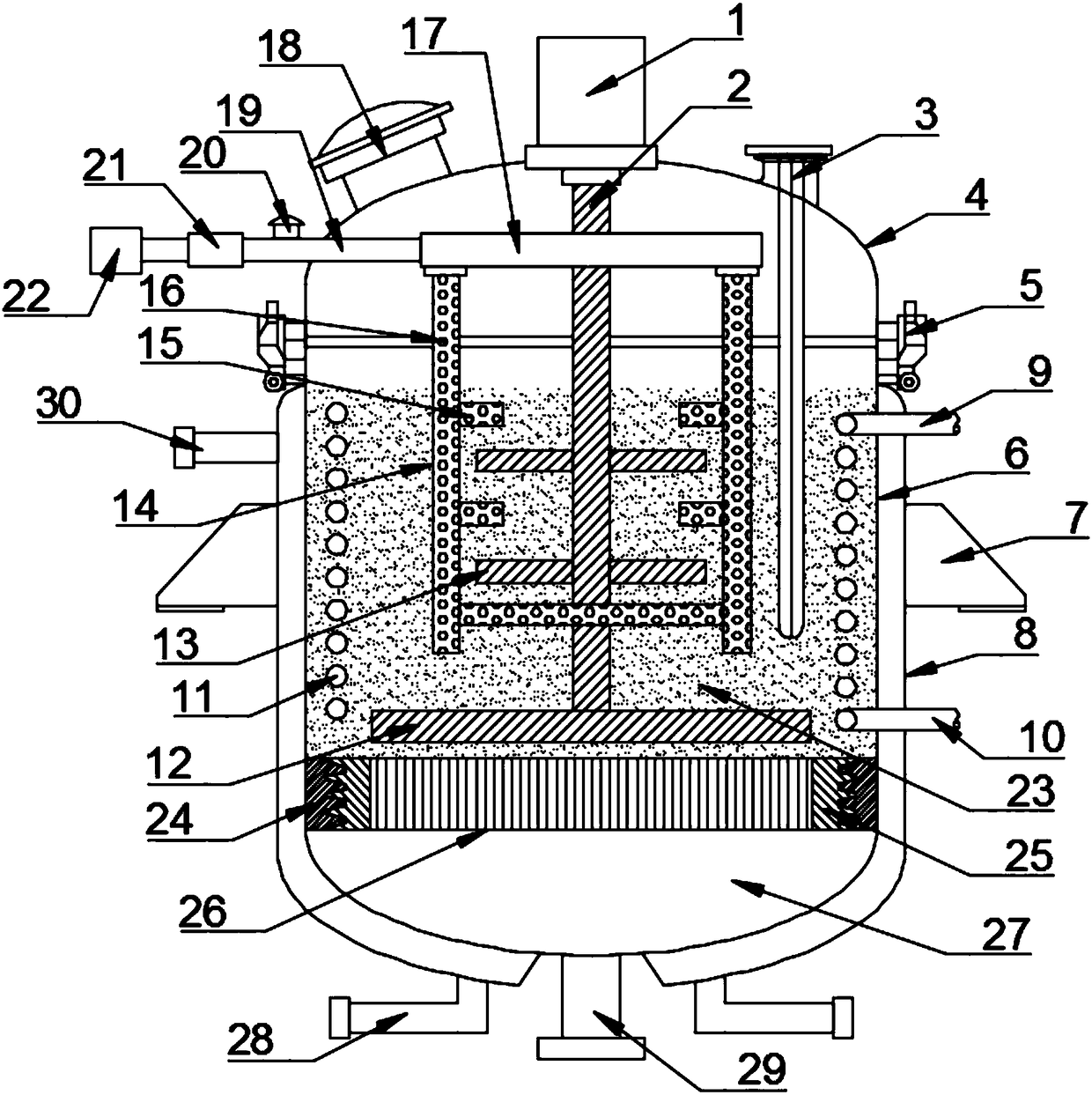

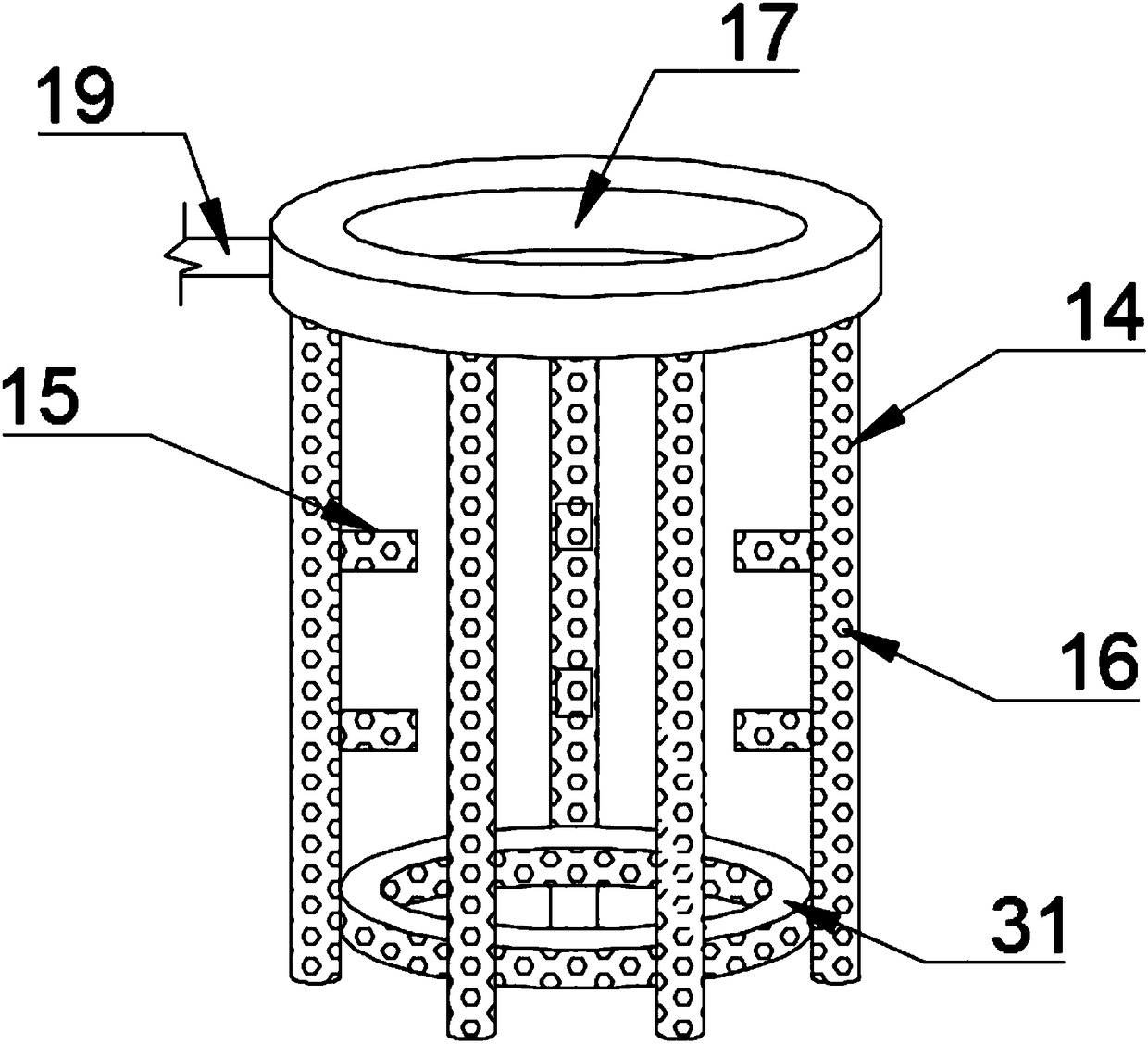

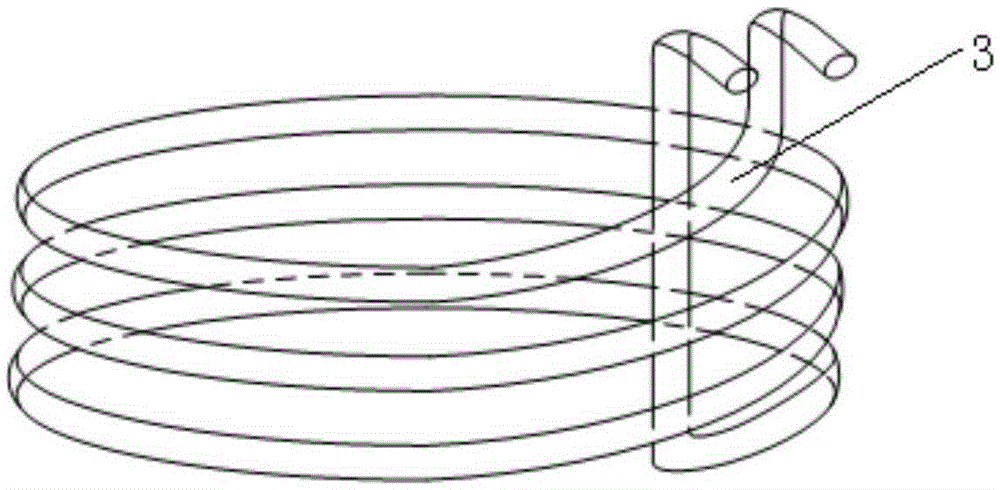

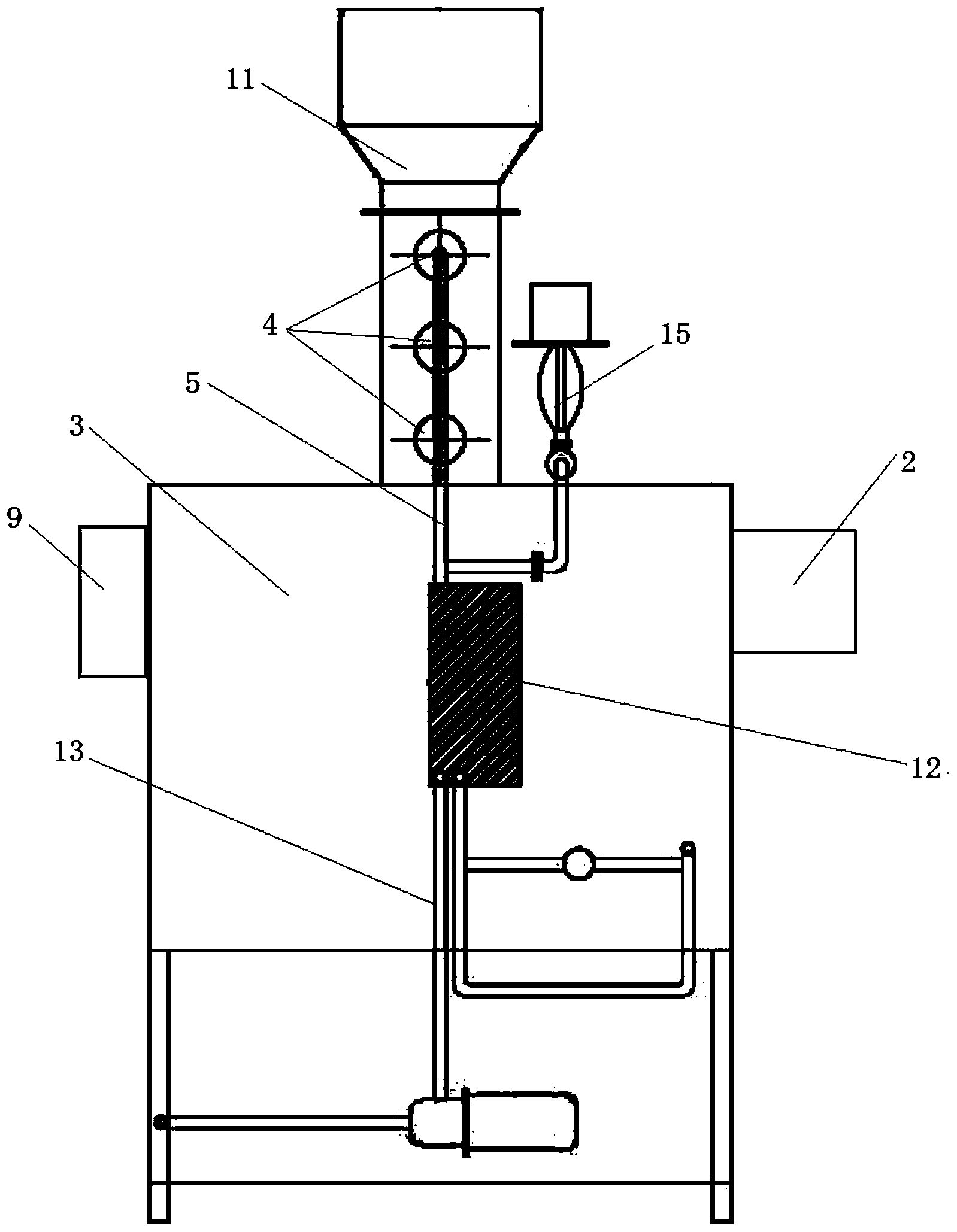

Anti-hardened biological fermentation reaction kettle with temperature adjustable

InactiveCN108192819AStable structureEasy to liftBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFlange

The invention discloses an anti-hardened biological fermentation reaction kettle with temperature adjustable. The reaction kettle comprises a rotating shaft, a tank body, an air intake circular pipe and a filter plate, wherein the top of the tank body is connected with a tank cover through a flange plate sealing part, the inner wall of the lower portion of the tank body is fixedly connected with an internal thread fixing ring, the internal thread fixing ring is in threaded connection with an external thread filter frame, the middle of the external thread filter frame is provided with the filter plate, the filter plate divides the inner portion of the tank body into a fermentation chamber and a liquid collection chamber, the inner portion of the fermentation chamber is provided with a spiral heating pipe, the outer portion of the tank body is provided with a cooling clamp cover, and an air inlet circular pipe is arranged in the fermentation chamber; hoisting assembly is convenient, thesealing effect is good, the heating and cooling operation of the fermentation chamber in the tank body can be conveniently adjusted through the cooling clamp cover and the spiral heating pipe; a gas distribution vertical pipe, a gas distribution transverse pipe and a gas distribution circular pipe are pre-buried in raw materials of the fermentation chamber, input gas is fully in contact with fungus in the raw materials conveniently; the effect that the hardening of the raw materials influences fermentation is prevented; a filter board filters out the fermented liquid to perform biomedical engineering conveniently.

Owner:山东新润知识产权有限公司

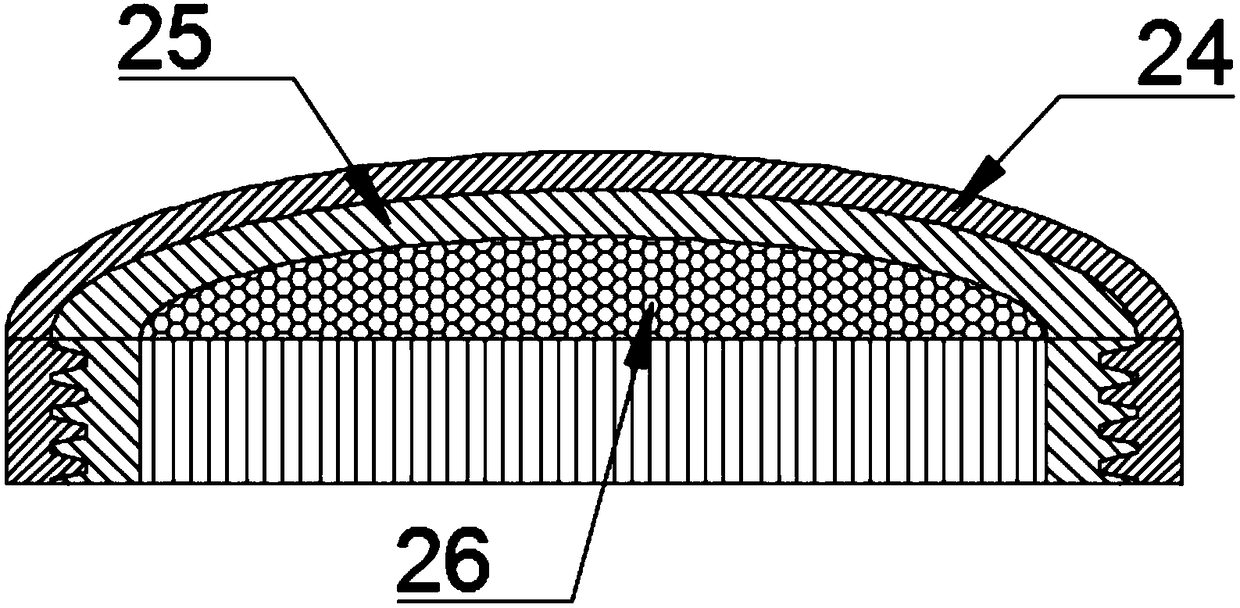

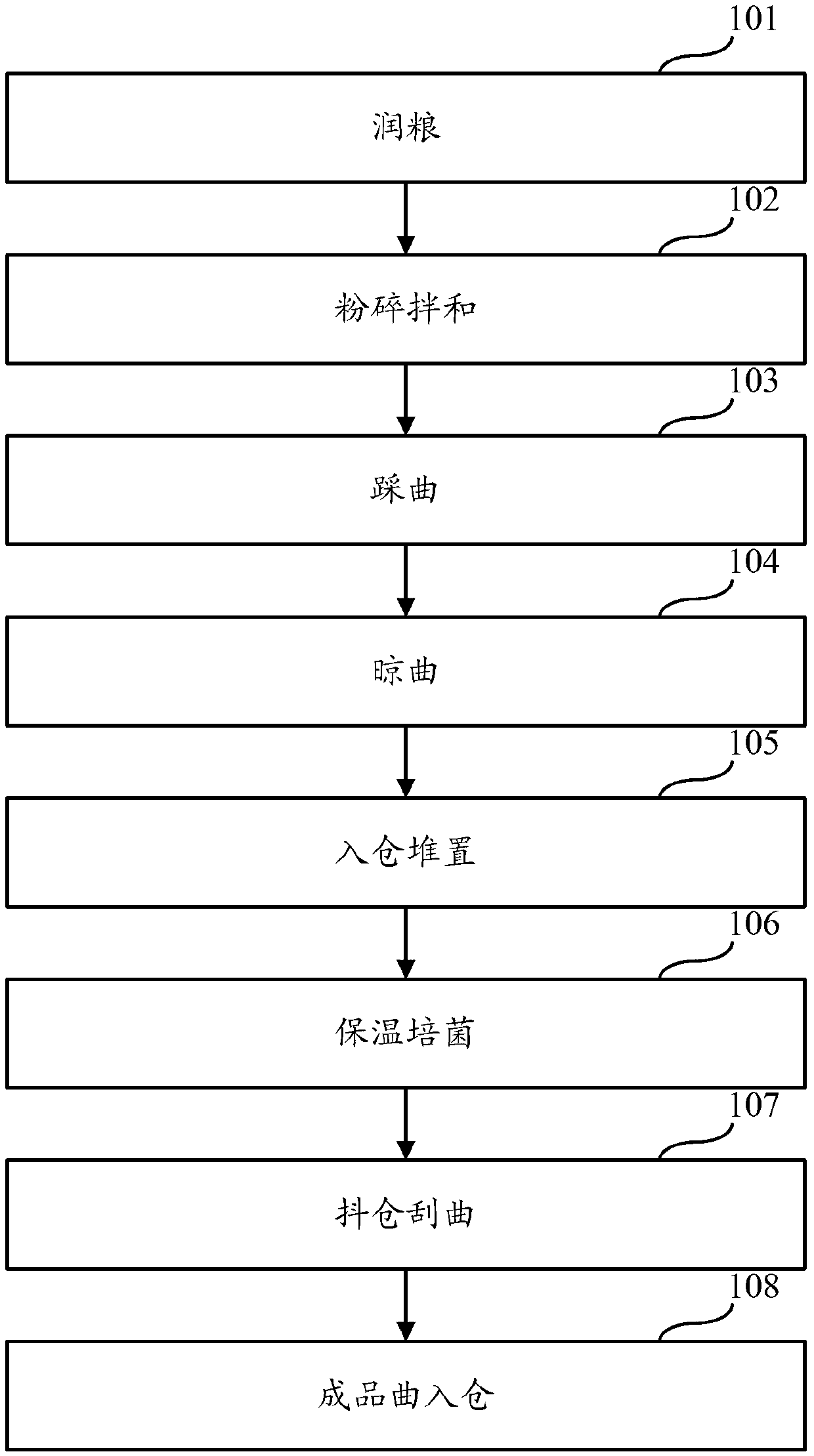

Preparation method of ultrahigh-temperature yeast for making hard liquor

InactiveCN103013764ASoak evenlyPromote fermentationAlcoholic beverage preparationNutritive valuesYeast

The invention discloses a preparation method of ultrahigh-temperature yeast for making hard liquor. The preparation method comprises the steps of moistening grains, crushing and blending, stamping yeast, drying yeast, warehousing for stacking, conducting heat-insulation cultivation and shaking bin and scraping yeast. The preparation method is characterized in that in the grain moistening step, water with the amount being 8-12% of the total weight of raw materials is added into the raw materials, the moistening time is 15-25 hours; and in the crushing and blending process, adding base yeast with the amount being 5-8% of the total weight of the raw materials into the moistened raw materials. The ultrahigh-temperature yeast prepared by the preparation method of the ultrahigh-temperature yeast, the yeast preparing temperature can exceed 65 DEG C to reach to 70 DEG C and even reach to 72 DEG C; more protease and microbial flora are contained, the final finished liquor prepared by the yeast for making hard liquor is high in nutritive value, soft in mouthfeel, and rich and dense in fragrance and taste.

Owner:SICHUAN LANGJIU GROUP

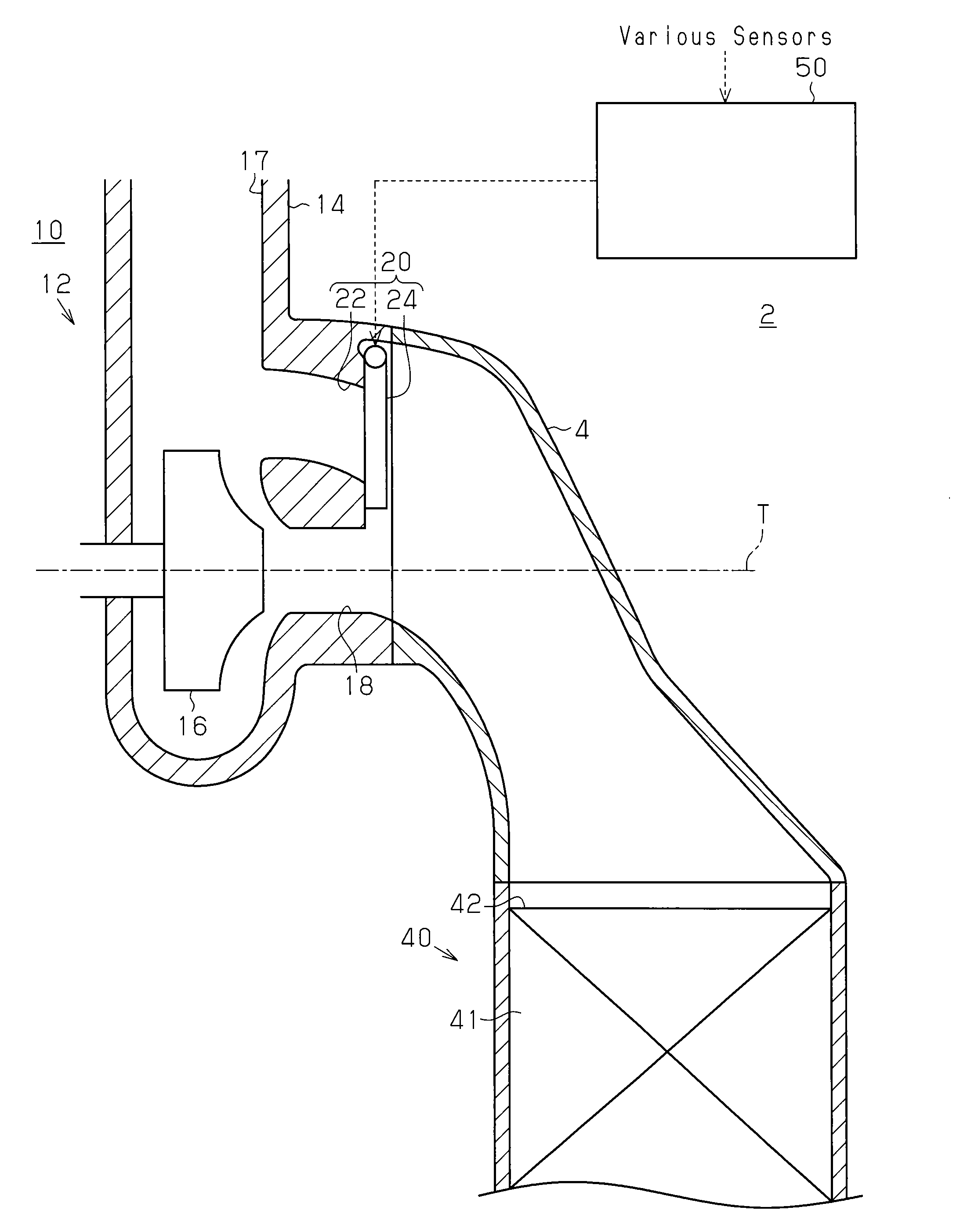

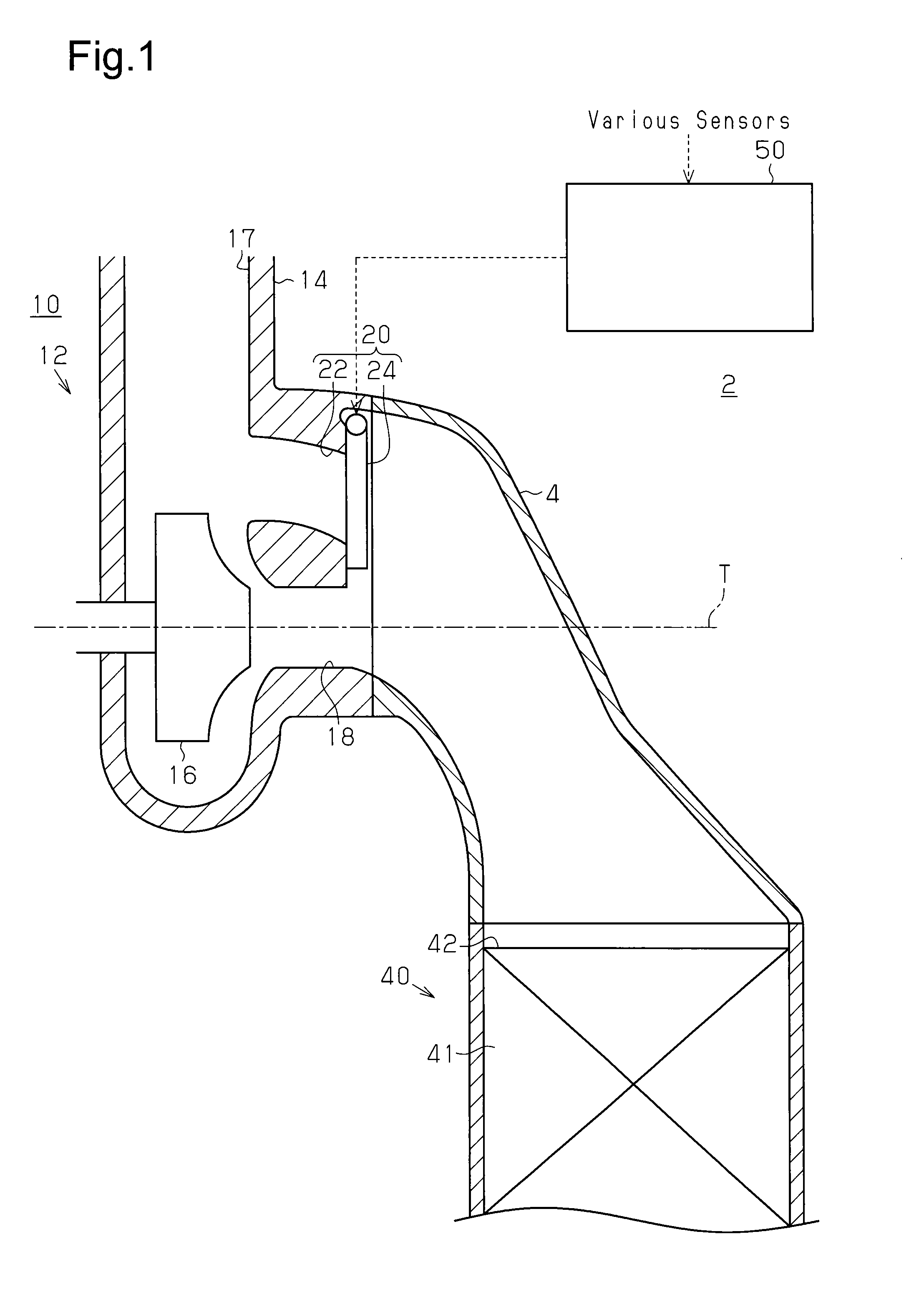

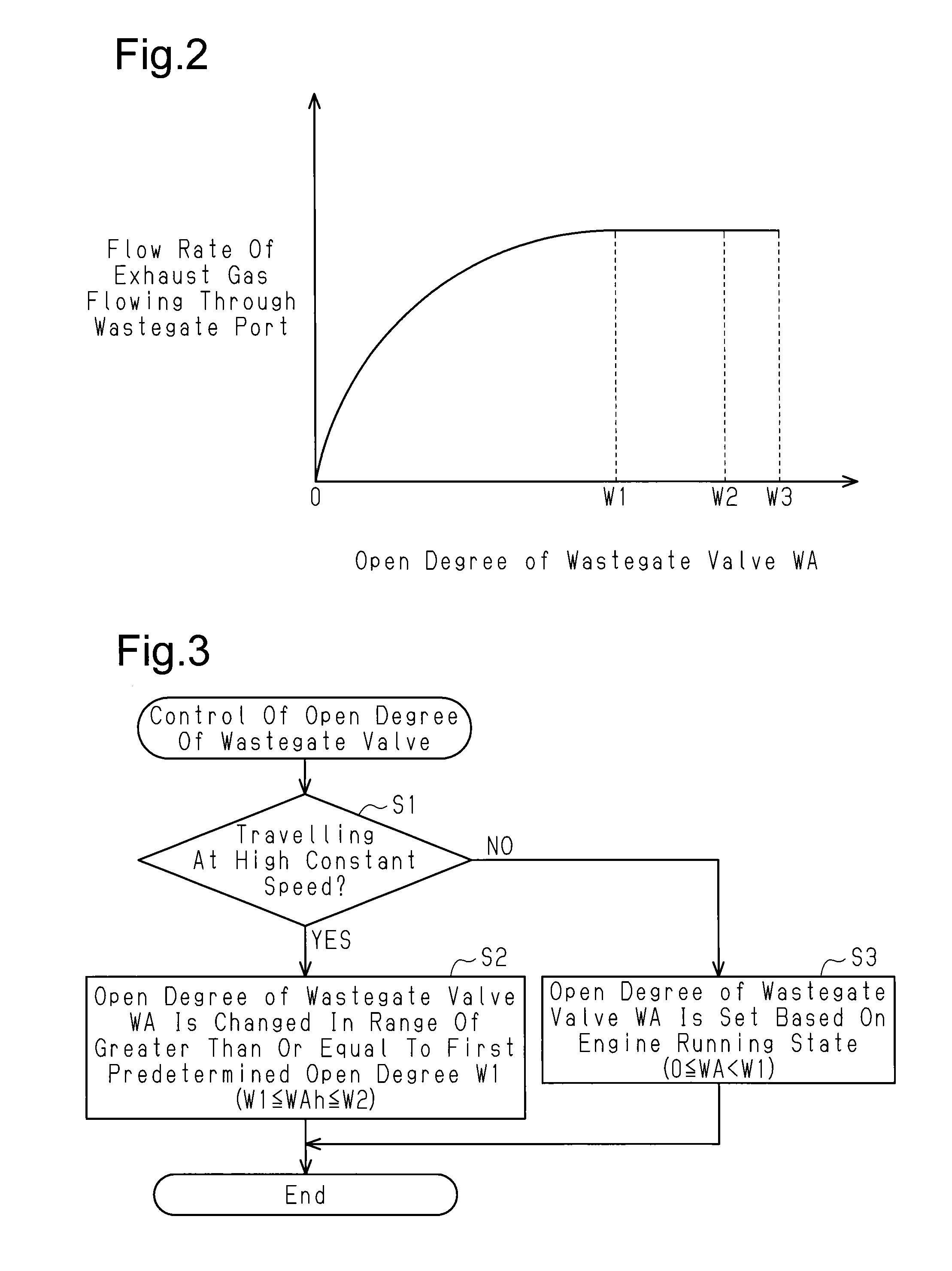

Control device for internal combustion engine

InactiveUS20150040561A1Accurately limits cloggingAvoid cloggingInternal combustion piston enginesExhaust apparatusWastegateEngineering

The minimum value for the degree of opening of a wastegate valve, wherein the flow volume of exhaust air flowing via a wastegate port when the degree of opening of the wastegate valve is changed toward the open side stops increasing, is defined as a first prescribed degree of opening An electronic control device controls the degree of opening of the wastegate valve on the basis of the engine operating state, and when the vehicle is running steadily at a high speed, that is, when the degree of opening of the wastegate valve which has been set on the basis of the engine operating state is equal to or greater than the first prescribed degree of opening, the degree of opening of the wastegate valve is varied between values equal to or greater than the first prescribed degree of opening.

Owner:TOYOTA JIDOSHA KK

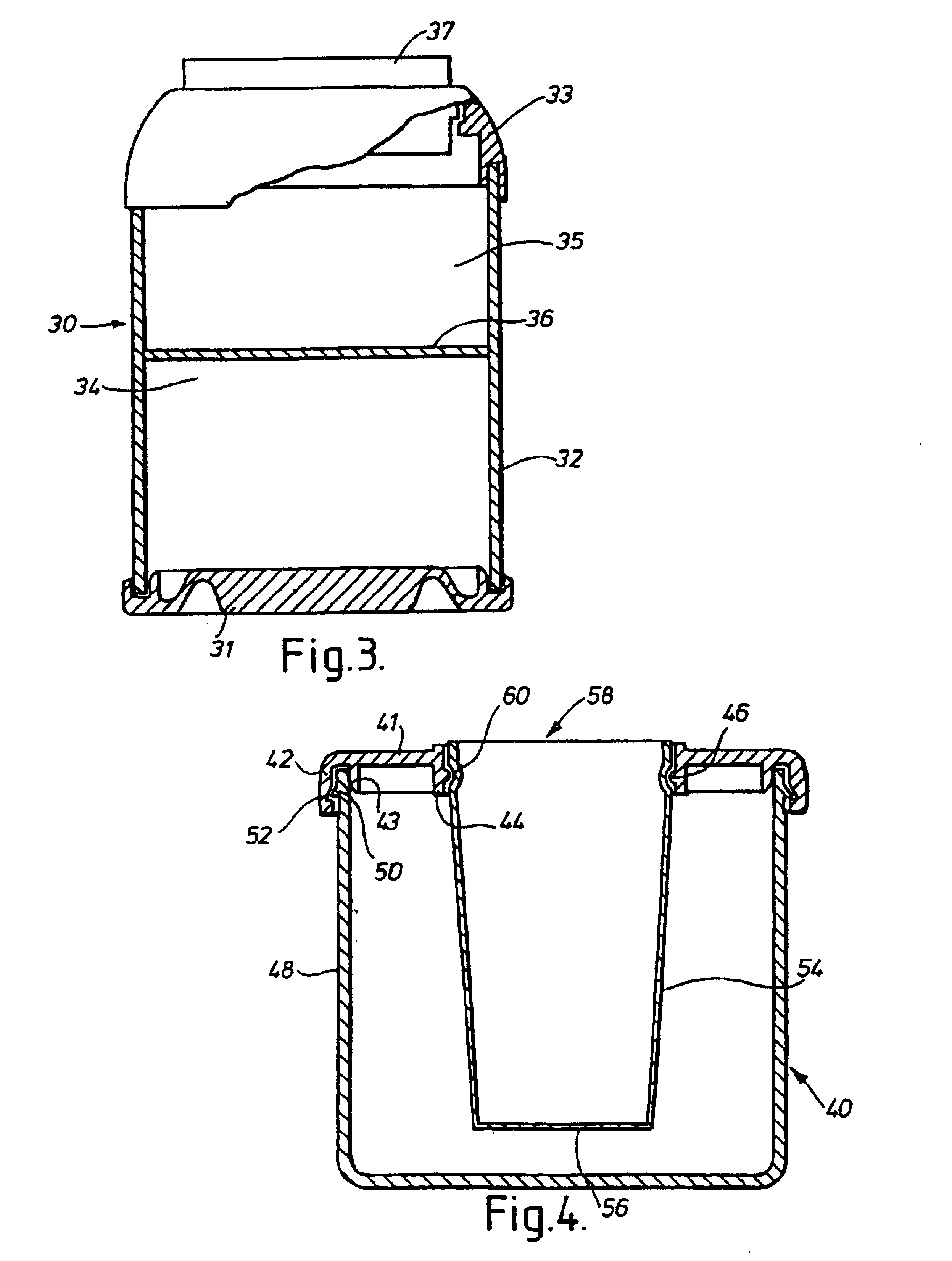

Open trench-concealed conduit combined water discharging and salt reducing method

InactiveCN106358479AThe effect of solving the salt content is not obviousSolve the poor effect of water savingSoil lifting machinesConstructionsAlkali soilWater discharge

The invention discloses an open trench-concealed conduit combined water discharging and salt reducing method, and belongs to the technical field of saline-alkali soil improvement. The method comprises the following steps of: selecting a field, digging a salt-controlling water discharging concealed conduit trench and a water collection conduit trench, laying a water-resisting layer, burying a salt-controlling water discharging concealed conduit and a water collection conduit, connecting the salt-controlling water discharging concealed conduit and the water collection conduit, backfilling the salt-controlling water discharging concealed conduit trench and the water collection conduit trench, reconditioning mounds, digging an open trench, perforating, applying soil fertility fertilizer, and managing the salt-controlling water discharging concealed conduit and the water collection conduit. By adopting the open trench-concealed conduit combined water discharging and salt reducing method, the water retention, fertility retention and temperature increase can be facilitated, the soluble salt ions can be rapidly leached below a plough layer, the salt ions leached to the soil deep layer are not moved to the surface soil along with the water, so that an effect of reducing the salt content in the surface soil can be realized; and by virtue of the method, the water drainage is facilitated, the leaching efficiency of the salt content in the plough layer is greatly increased, and the salt content in the soil is greatly reduced.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Liquid conductive cooling/heating device and method of use

InactiveUS7276046B1Easy to installHeat dissipation fastMedical devicesIntravenous devicesConductive materialsBiomedical engineering

Owner:LCR HALLCREST

Parallel-connection type double-sound-wave-vortex viscosity reducing and oil enhancing device

InactiveCN104763378AIncrease flow ratePrevent reaccumulationCleaning apparatusVibration devicesCavitationOil production

The invention relates to a petroleum production auxiliary device, and discloses a parallel-connection type double-sound-wave-vortex viscosity reducing and oil enhancing device for downhole oil pumping. The viscosity reducing and oil enhancing device is formed by connecting a jet flow ultrasonic vibrator with a vortex flow guide ejector in a butt joint mode. A cavitation cabin is arranged between the jet flow ultrasonic vibrator and the vortex flow guide ejector. The viscosity reducing and oil enhancing device is characterized in that the jet flow ultrasonic vibrator comprises a shell, a jet flow head is arranged in the shell, two parallel wedge-shaped through holes are formed in the jet flow head, the small opening ends of the two wedge-shaped through holes are opposite to the cavitation cabin and provided with an outwards-extending support, and the positions, corresponding to the two wedge-shaped through holes, of the support are each provided with a vibration elastic piece to form two parallel ultrasonic vibrators. By means of the viscosity reducing and oil enhancing device, the problems that the wax content is high, blockage is prone to happening, the viscosity of crude oil is high, and mobility is poor are better solved, especially the problem that other existing viscosity reducing devices can not adapt to low deep oil well oil pumping is solved, the oil pumping yield is greatly increased, and the viscosity reducing and oil enhancing device is widely applied to oil well oil production of different types, different wax contents and different water contents.

Owner:HUANGSHI KEWEI PETROLEUM EQUIP CO LTD

Cuttage reproducing method for cotton

InactiveCN1907001AKeep intactSolve the costAgriculture gas emission reductionCultivating equipmentsAgricultural scienceSprigging

The invention discloses a cuttage breeding method of cotton, which comprises the following steps: 1) grafting cotton bough in the culture medium of regenerated plant to breed root; or soaking cotton bough in the root-growing agent for 20-28h; plugging cotton in the soil-less base; 2) transplanting after the cotton bough grows root.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

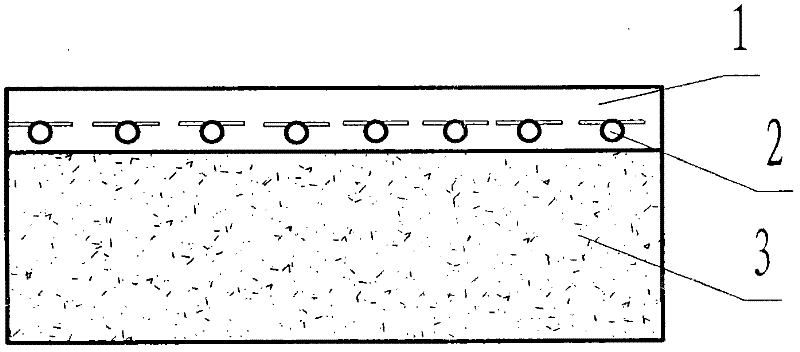

Airfield runway ice and snow melting device

The invention discloses an ice and snow melting device for an airport runway. It has an airport runway. The airport runway includes a runway base layer and a runway surface layer. A heat dissipation system is arranged between the runway base layer and the runway surface layer. The heat dissipation system and The heat source system is connected, and the heat source system includes a circulation pump and a heat source; the heat dissipation system is composed of a finned cooling pipe, an oil inlet main pipe, an oil return main pipe and a pipeline, and the outlet end of the oil return main pipe of the heat dissipation system is connected to the oil return port of the heat source. Connected, the pipe body of the oil return main pipe is respectively connected with the outlet ends of a plurality of fin heat dissipation pipes, the inlet end of the fin heat dissipation pipes is connected with the outlet end of the oil inlet main pipe, and the inlet end of the oil inlet main pipe is connected with the circulation The outlets of the pumps are connected, and the inlets of the circulating pumps are connected with the outlets of the heat source through pipes. The invention can overcome the problem that the normal flight of the aircraft is affected by ice and snow or freezing fog on the airport runway, saves energy, has the characteristics of simple equipment structure, fast ice and snow melting speed, long service life and the like.

Owner:高远新

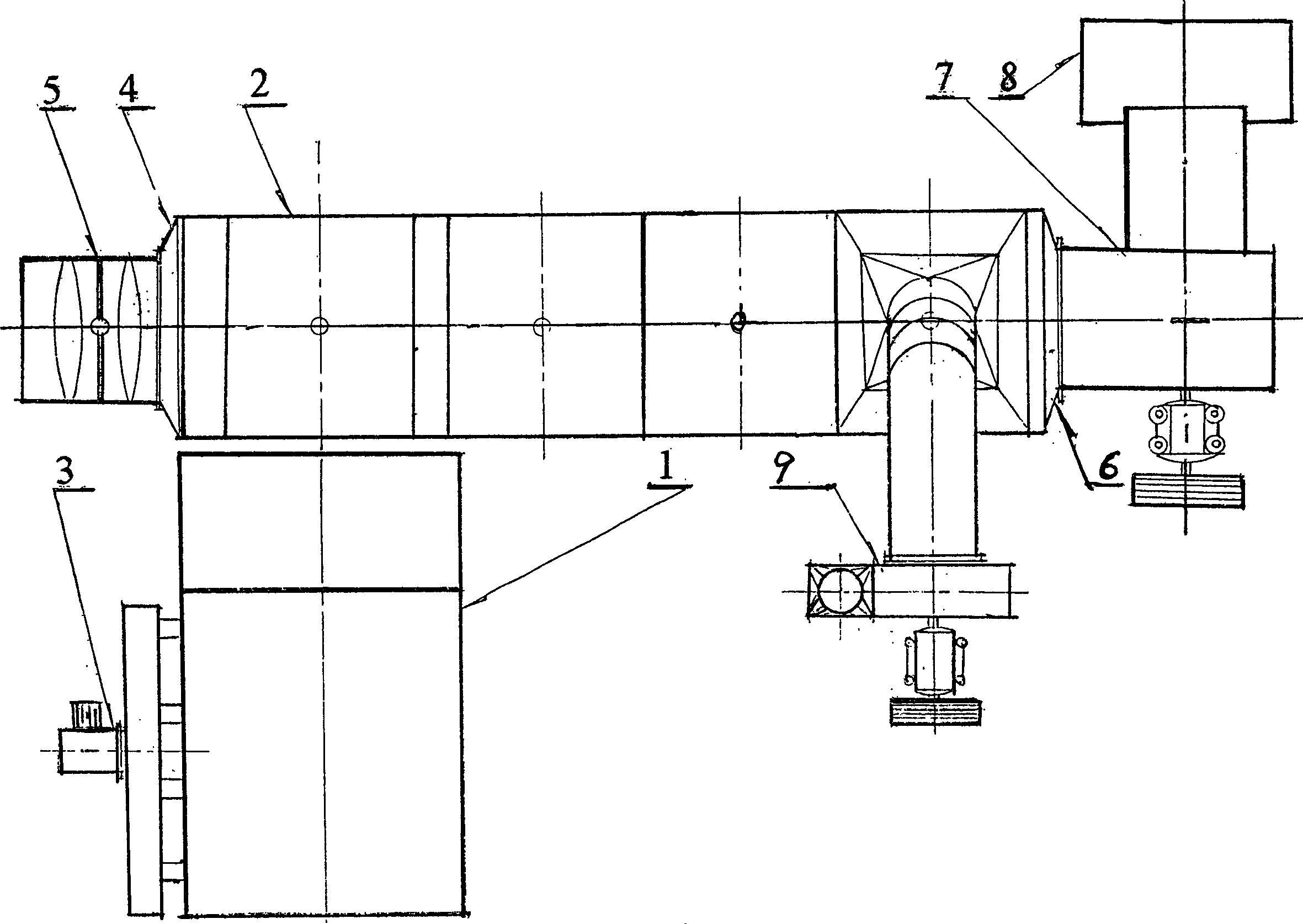

Hot-air furnace combined by combustion chamber and dustproof multi-stage heat exchanger with burning-resistant device

InactiveCN1800762AGuaranteed service lifeMake sure not to overheatDrying gas arrangementsHeating arrangementAutomatic controlCoal

The invention relates to a combined wind heater with an anti-burn device and the functions of multi-step heat exchange and de-dust, which is formed by a burning room and a heat exchange. The heat exchanger comprises a horizontal multi-step heat exchange, whose tubes are vertically downwards arranged, and the tube plane at the upper end of first heat exchanger has an anti-burn anti-corrosion device; a safety gate is arranged at the front of heat exchanger integration; the cold wind via the fan from the tail to first heat exchanger is transformed into horizontal hot wind; the high-temperature smoke via the first heat exchanger from up-to-down and via the multi-step heat exchanger pip is discharged via wind outlet. The invention can save 65% coal energy than steam boiler and save 30% coal energy than the heat conductive oil furnace, while it has lower maintenance cost, quick temperature increase, quick stop, and automatic control, while its temperature adjusting range is between 100-350Deg. C and the recycle rate of hot wind is between 85-95%.

Owner:南宁红枫王淀粉设备有限公司

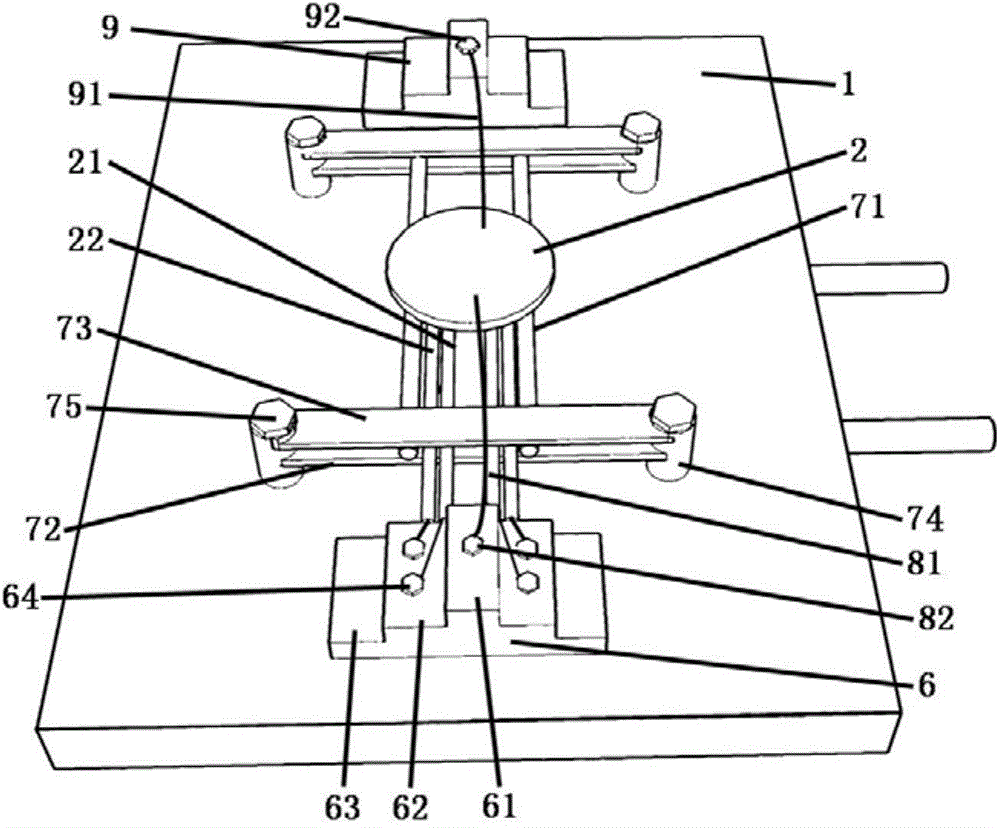

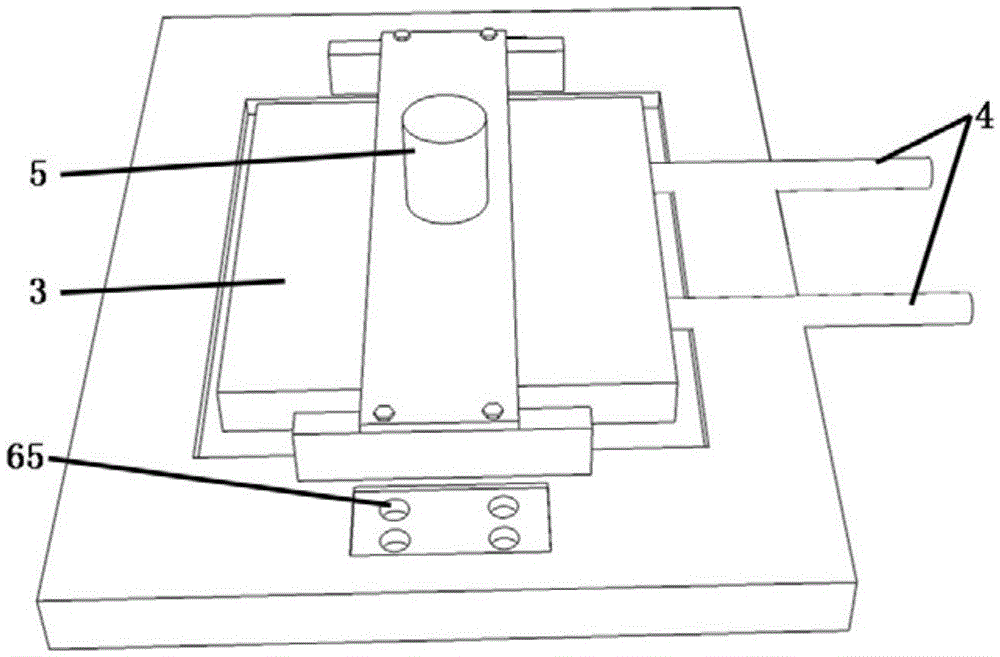

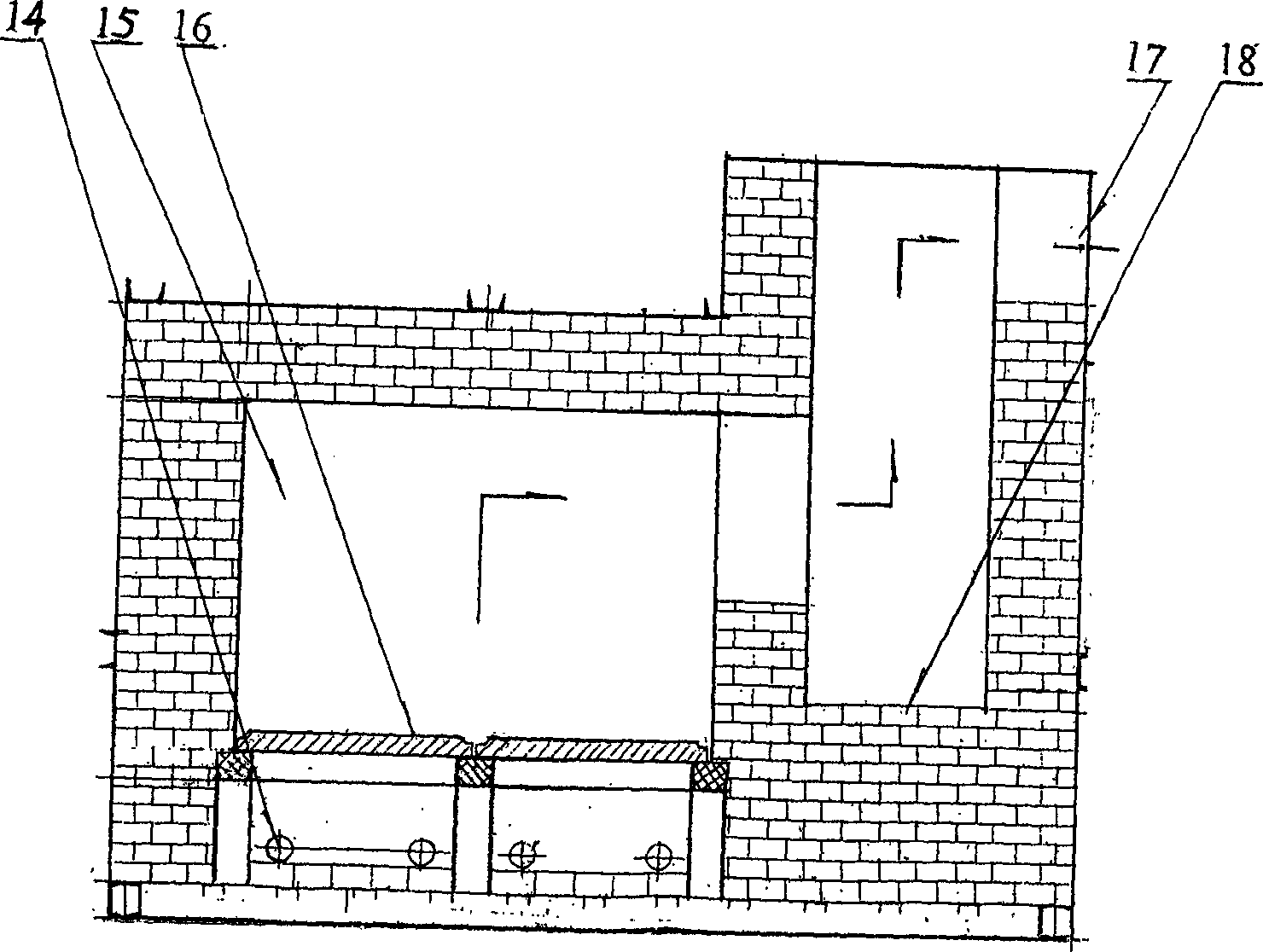

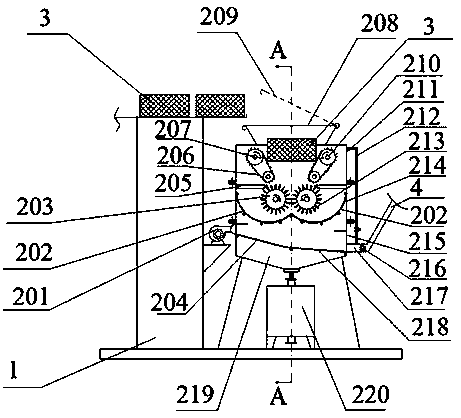

Pure bending age forming die for autoclave

The invention relates to a pure bending age forming die for an autoclave, which comprises a base, a cover plate, a box body, mould boards and a loading device. The loading device mainly comprising a worm, two worm wheels, two screw rods, press shafts, a press shaft bracket and a splint is arranged on the upper surface of the base; the splint is positioned at the center of the upper surface of the base; two mould boards are fixed on the upper surface of the splint; and the press shaft bracket is sleeved on the mould boards and is fixedly connected with the splint. The upper press shaft and the lower press shaft are arranged on the box body and the press shaft bracket respectively. When external force is transferred to the splint by the screw rods, screw nuts of the screw rods convert the rotation of the screw rods into the translation of the splint along the inner surface of the box body to push the mould boards and the lower press shaft to move upwards, therefore, the pure bending loading to test pieces is completed. The pure bending age forming die has concise appearance; the large circular bead transition is applied at the joint between the surfaces as much as possible; the positions for possibly causing the tension fracture of a vacuum bag are covered by the cover plate; the base is lager than the box body; and the pure bending age forming die has the characteristics of simple structure and convenient use.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method and application of ester ether sulfonated composite water reducing agent based on straw modification

The invention discloses a preparation method and application of an ester ether sulfonated composite water reducing agent based on straw modification. The water reducing agent is prepared from crop straw hydrolyzed powder through primary oxidation-sulfonation esterification modification, secondary oxidation-sulfonation esterification modification and primary methylolation-etherification modification of straw lignocellulose, wherein the straw hydrolyzed powder is obtained by performing primary crushing, washing, drying, fine crushing and micro crushing pretreatment on crop straw and then hydrolyzing straw powder. Crushing and hydrolyzing pretreatment are performed on a crop straw raw material, stepwise sulfonation modification is firstly performed on straw lignin and cellulose to form sulphonate, and then etherification modification is performed on the lignocellulose to obtain the straw-based ester ether sulfonated composite water reducing agent; the problem that the water reducing rateof the straw-based water reducing agent is 10-15% and is relatively low is solved; the obtained water reducing agent can be directly applied to the situation that the water reducing rate is about 25%and the delayed coagulation time is moderate; a technology is continuous, compact, easy to operate, low in cost, anti-settling and easy to industrialize.

Owner:TIANSHUI NORMAL UNIV

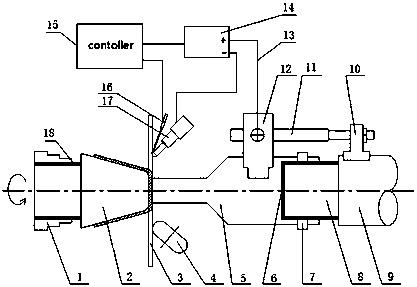

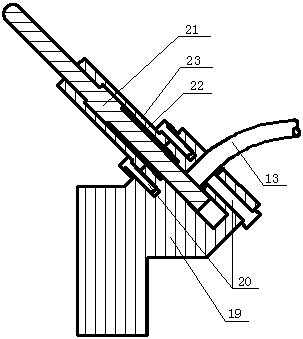

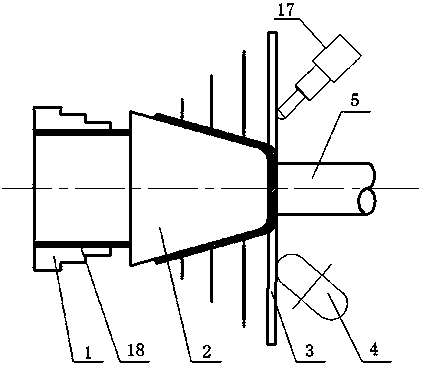

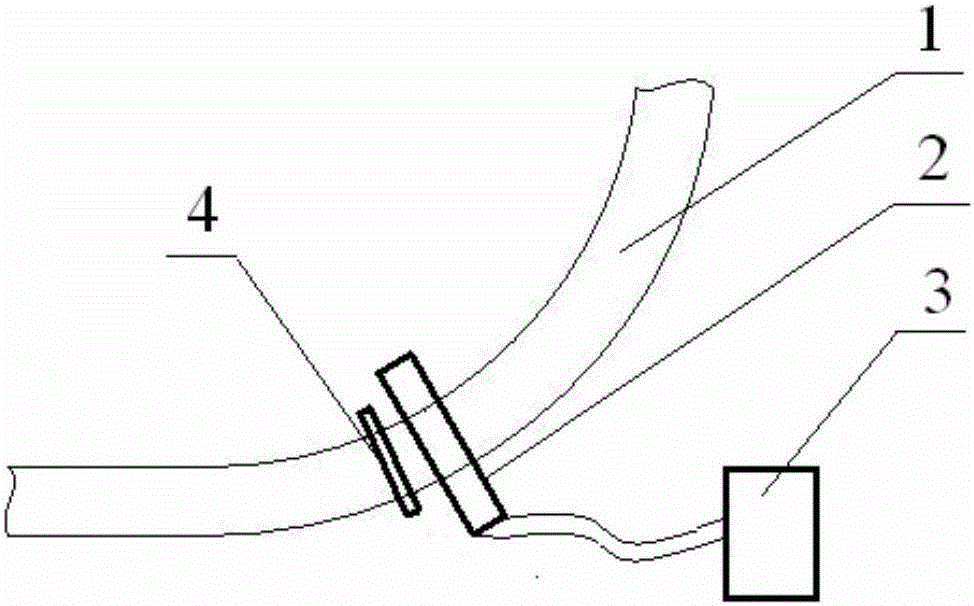

Synergistic self-resistance electric heating type plate auto-increment spinning forming device and method

The invention provides a synergistic self-resistance electric heating type plate auto-increment spinning forming device and method. The synergistic self-resistance electric heating type plate auto-increment spinning forming device comprises a spinning wheel, a high-frequency low-voltage power source, a high-temperature insulated spacer, a cable, a resistor rod, an infrared thermometer, a plate, acarbon brush and a fixing frame of the carbon brush. The spinning wheel and the resistor rod are located on the same arc surface of the plate and are symmetrically distributed (the spinning wheel andthe resistor rod are separated by 180 degrees), the spinning wheel and the resistor rod synergistically act to complete the heating and forming process. The synergistic self-resistance electric heating type plate auto-increment spinning forming device is compact in structure, the synergistic self-resistance electric heating type plate auto-increment spinning forming method is simple, the heating and formation problems of the material which is high in strength at normal temperature, large in forming force and difficult to deform are solved, and the synergistic self-resistance electric heating type plate auto-increment spinning forming method is suitable for auto-increment spinning formation of pure titanium plate materials, titanium alloy plate materials, magnesium alloy plate materials andthe like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

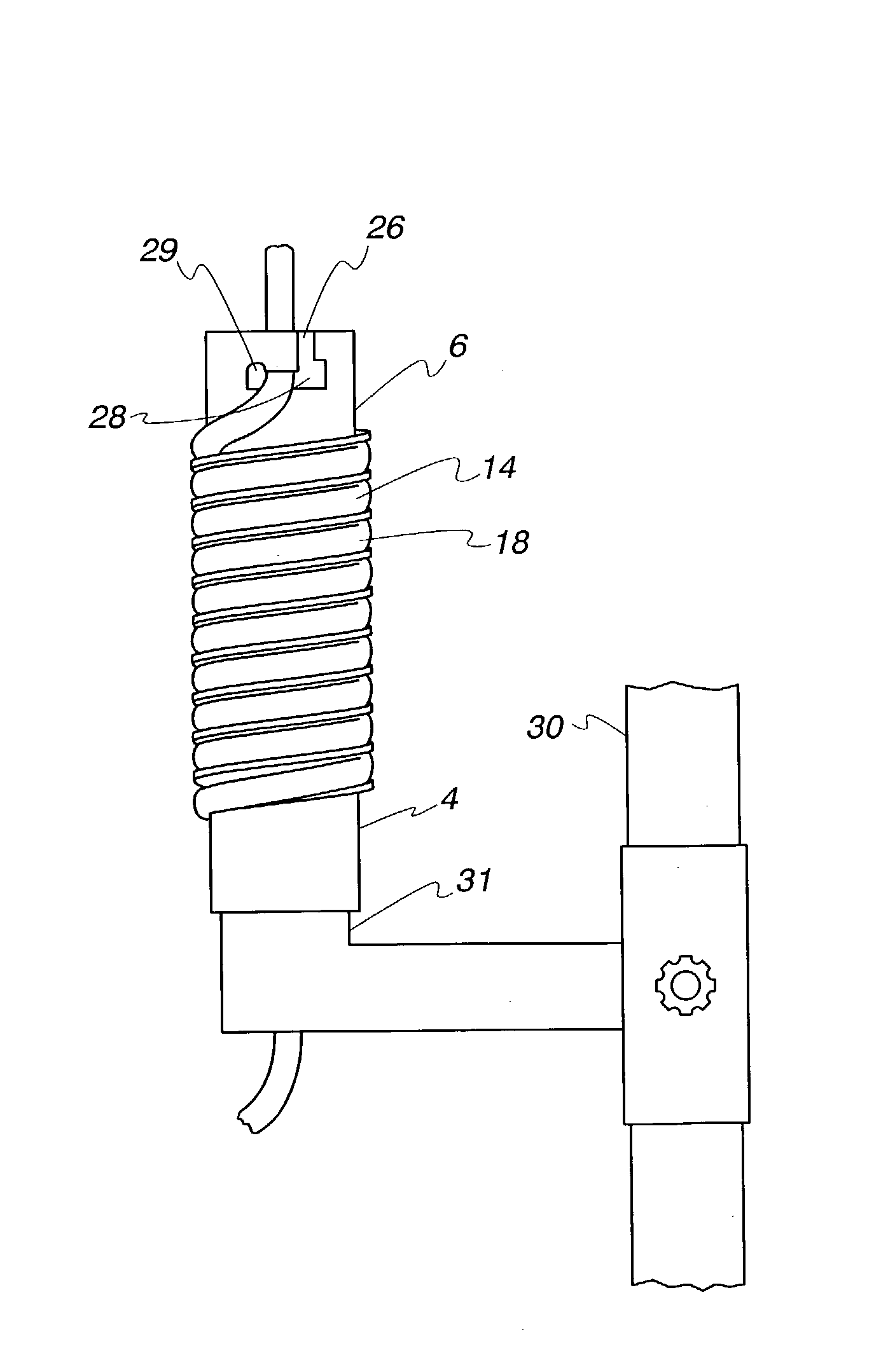

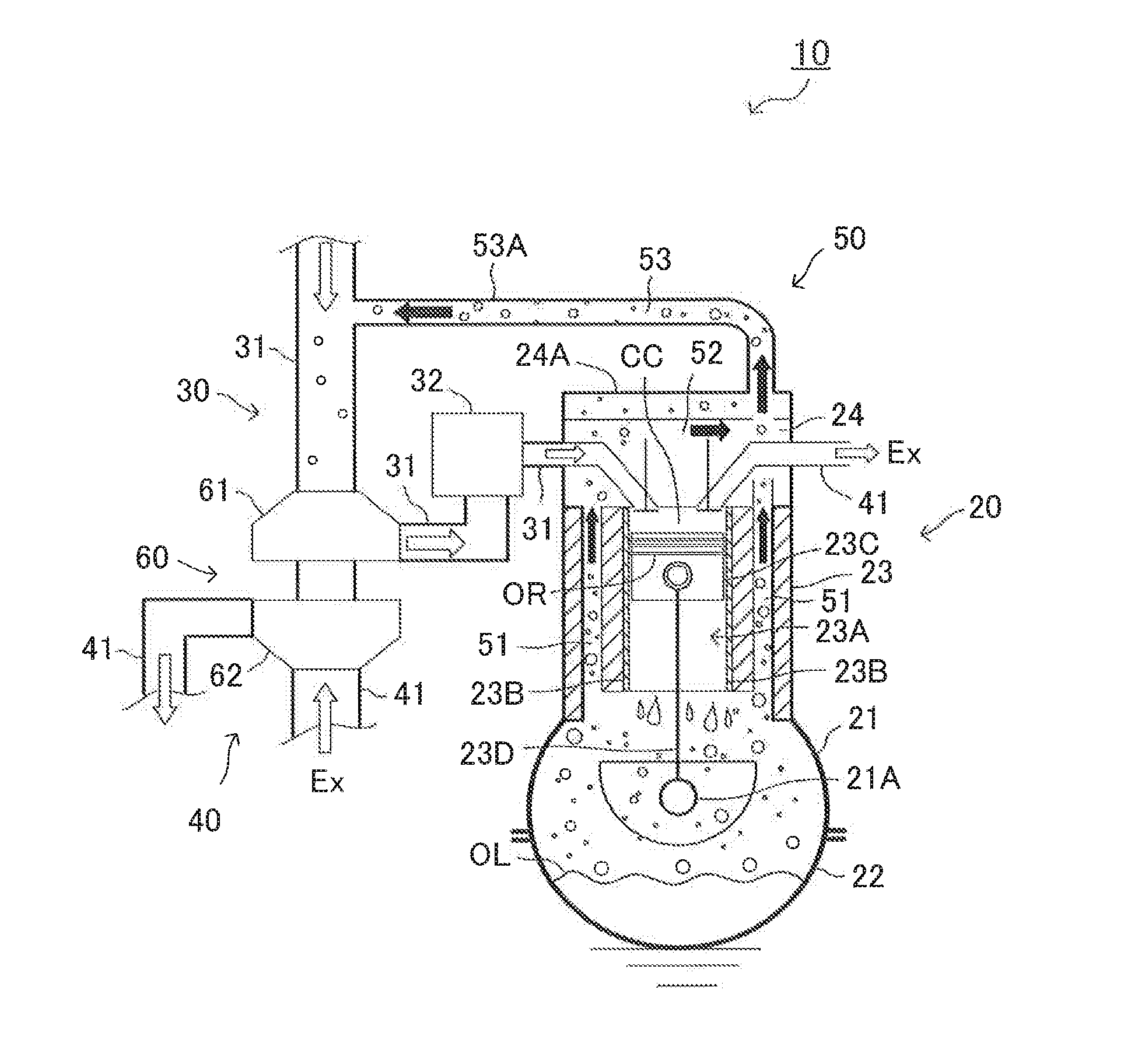

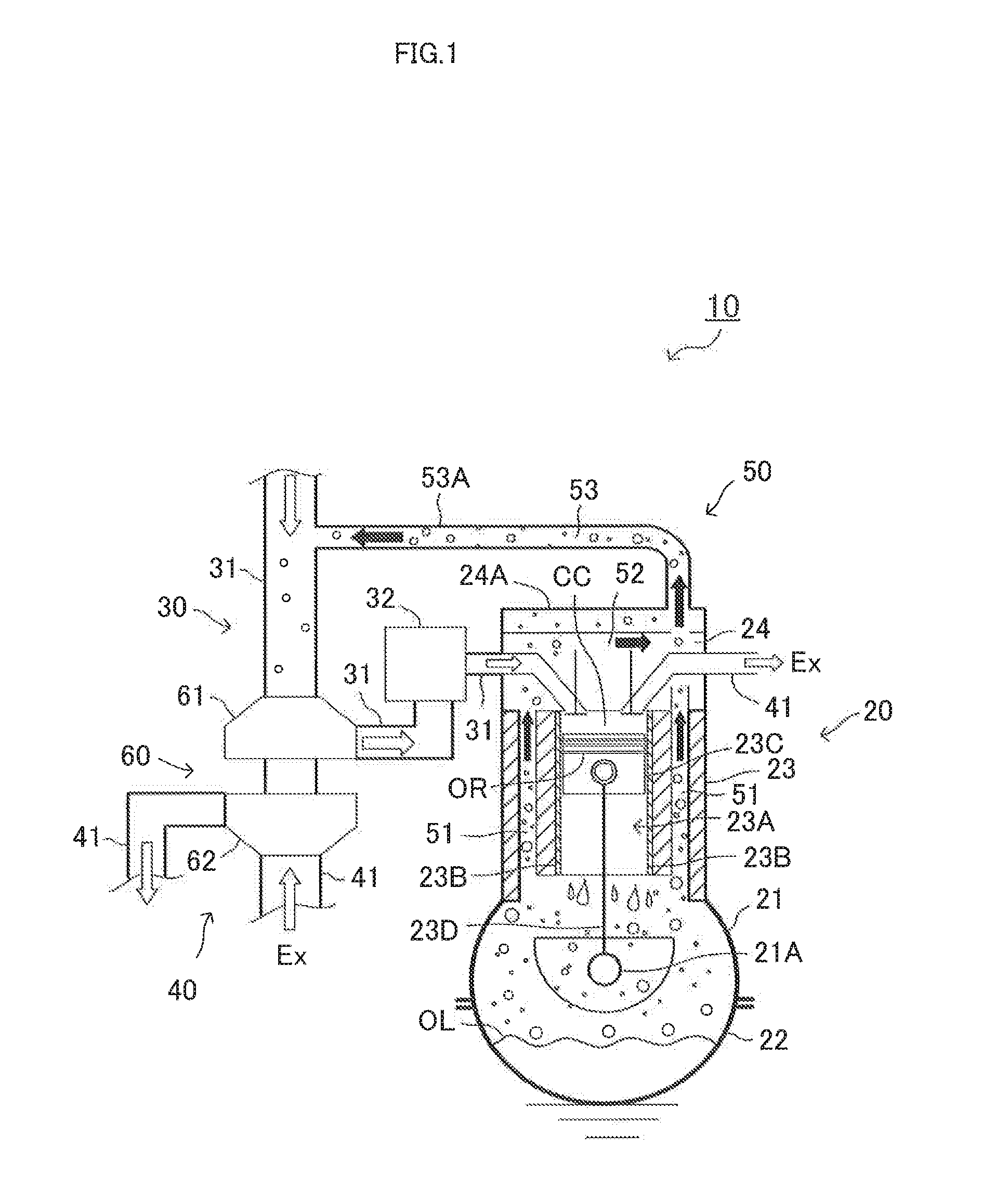

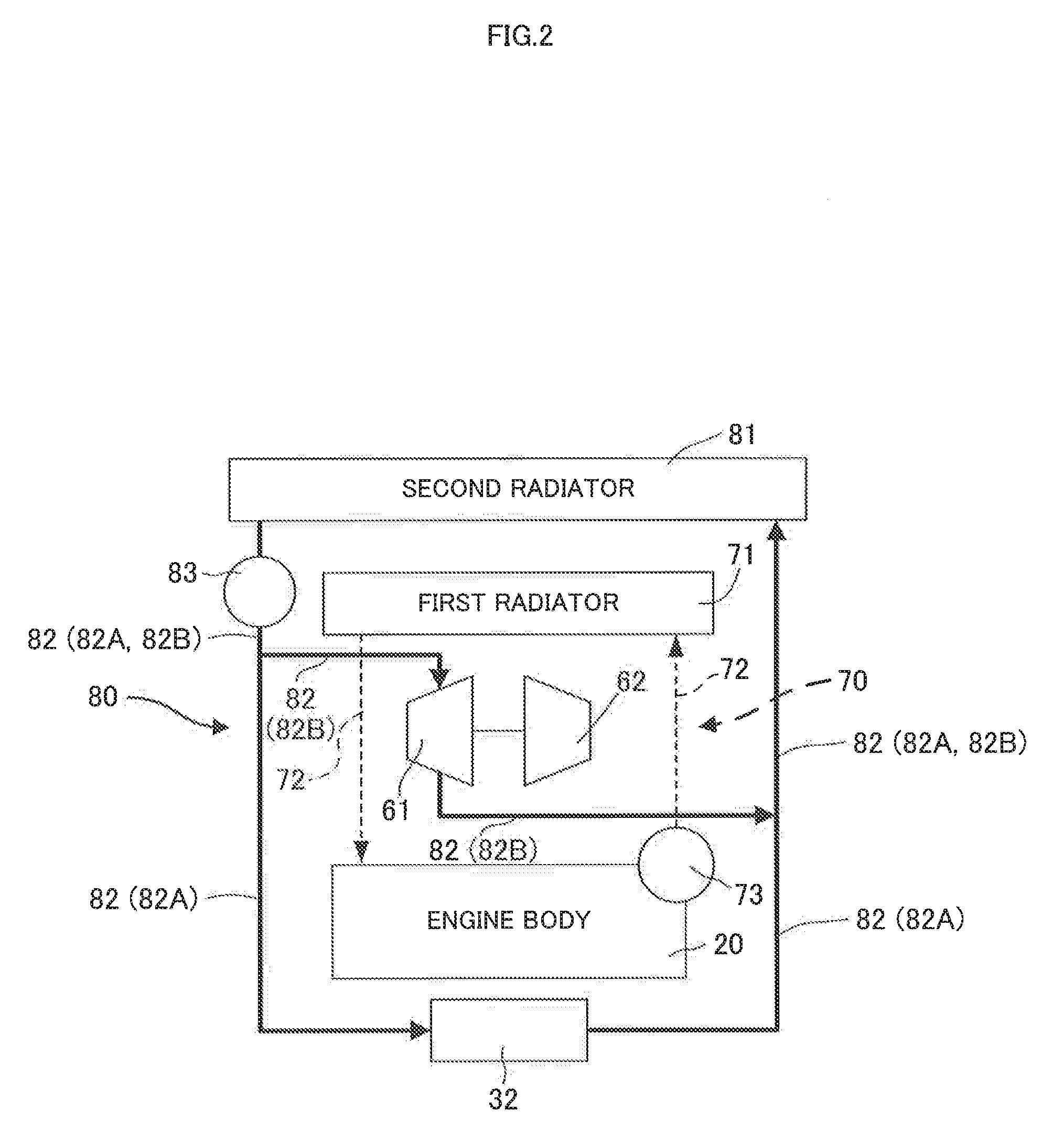

Cooling device for internal combustion engine provided with blowby gas recirculation device and turbocharger (as amended)

InactiveUS20160025048A1Suppress generationHigh temperatureInternal combustion piston enginesNon-fuel substance addition to fuelAerospace engineeringEngineering

The object of the invention is to provide a cooling device for accomplishing both of required engine and compressor cooling degrees. The invention relates to a cooling device for an engine provided with a blowby gas recirculation device (50) and a turbocharger (60), the blowby gas recirculation device recirculating a blowby gas to an intake passage upstream of a compressor of the turbocharger. The cooling device comprises a first cooling device (70) for cooling a body (20) of the engine and a second cooling device (80) for cooling an intake air, separately. The second cooling device cools the compressor (61).

Owner:TOYOTA JIDOSHA KK

Production method of waste-containing powdery emulsion explosive

The invention relates to a production method of waste-containing powdery emulsion explosive. The waste-containing powdery emulsion explosive comprises the following raw materials: ammonium nitrate, calcium nitrate, urea, waste powdery emulsion explosive, water, emulsifier and oil phase. The waste powdery emulsion explosive means the rock type powdery emulsion explosive which is in moisture-adsorption, demulsification and devitrification phenomenon, and out of detonator sensitivity and detonation ability. The specific production operation steps are as follows: heating and dissolving water phase component of the powdery emulsion explosive, dividing the powdery emulsion explosive into three parts, slowly adding the water phase for three times, dissolving and dispersing to form the water phase liquor; preparing compounded oil phase by melting the emulsifier and oil phase; and under the stirring state, adding the water phase liquor in the compounded oil phase, emulsifying to obtain powdery emulsion explosive matrix. The use rate of the waste powdery emulsion explosive is more than 50%, the processing problem of the waste explosive is solved, the operation is convenient, and the production process is safe.

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

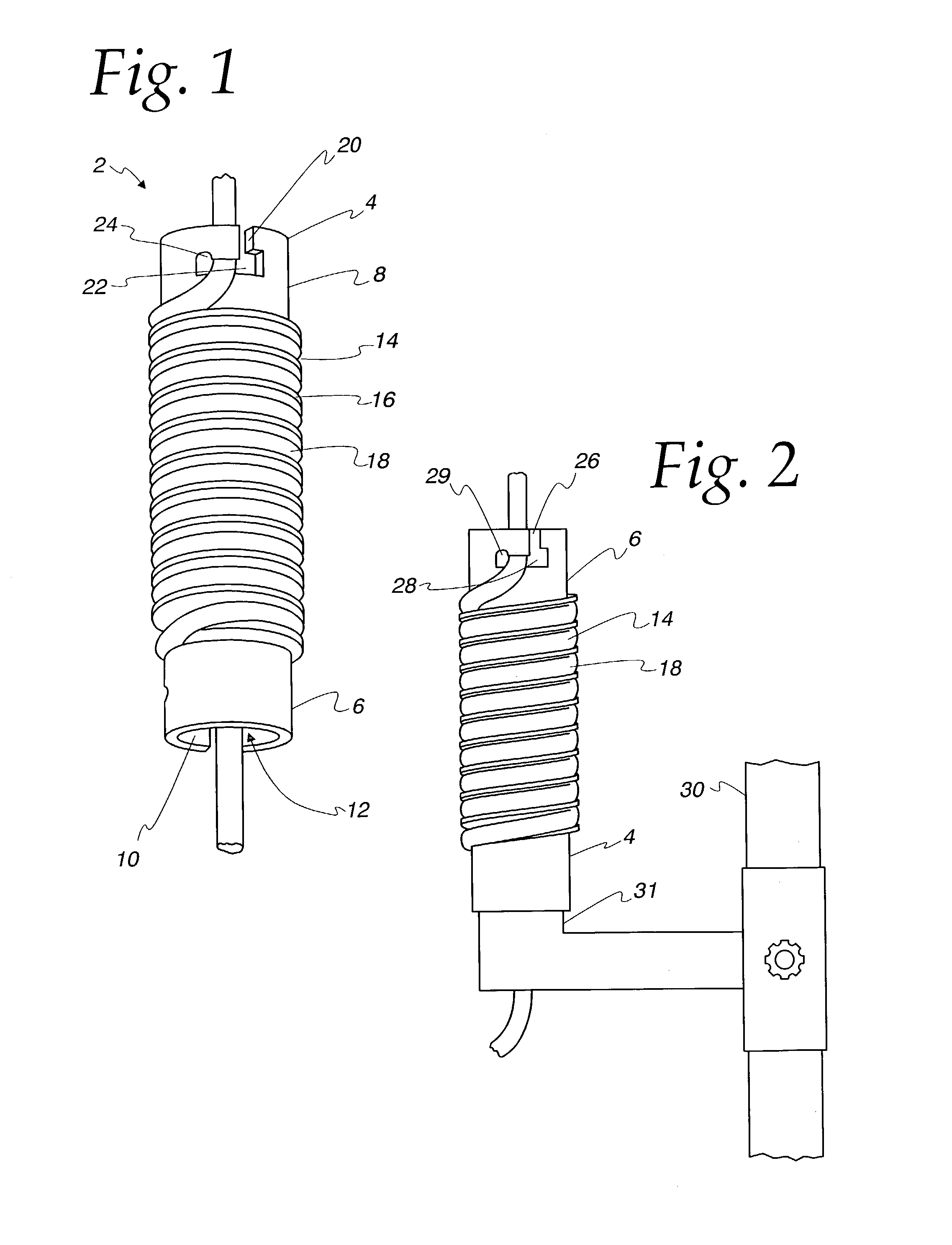

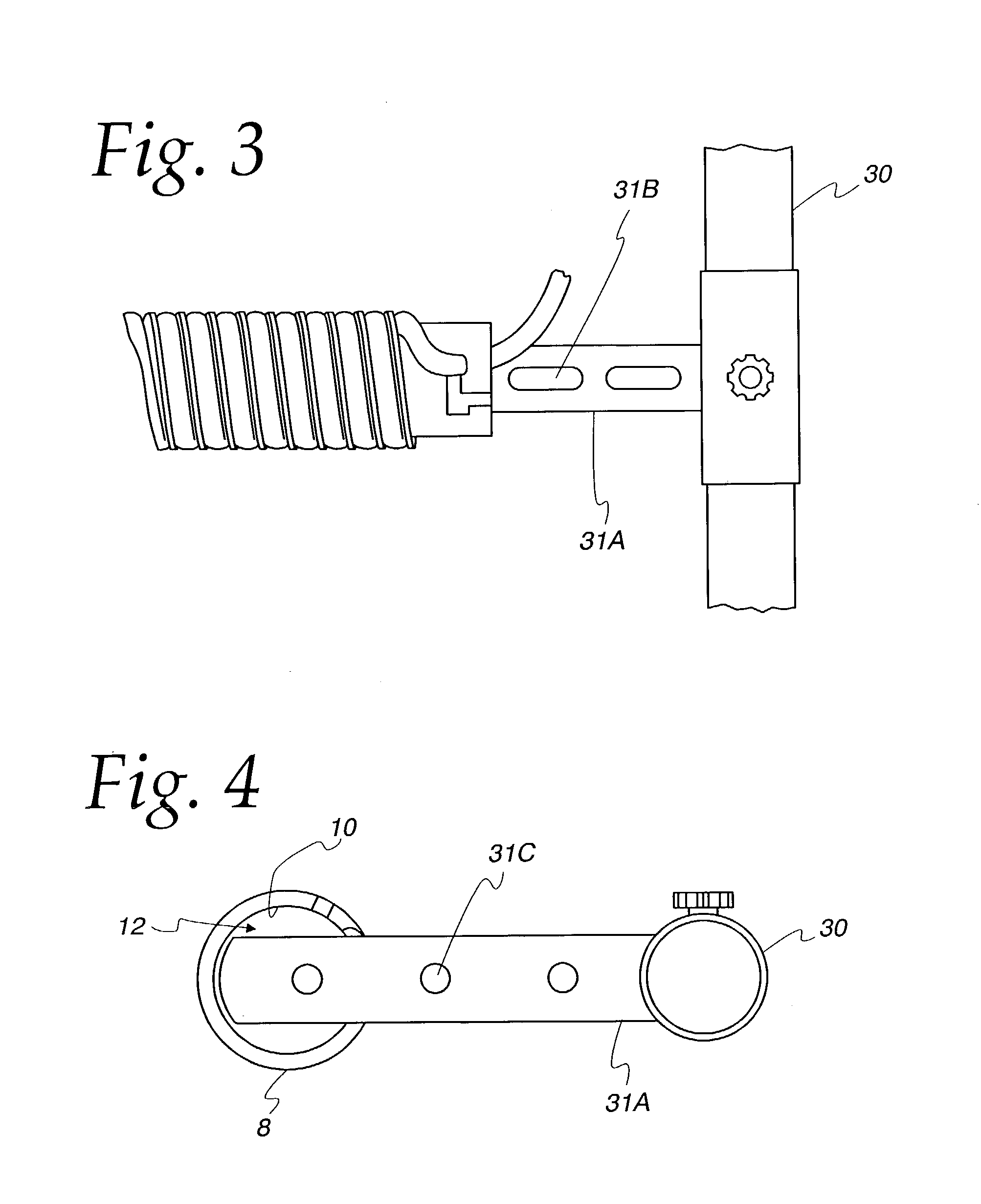

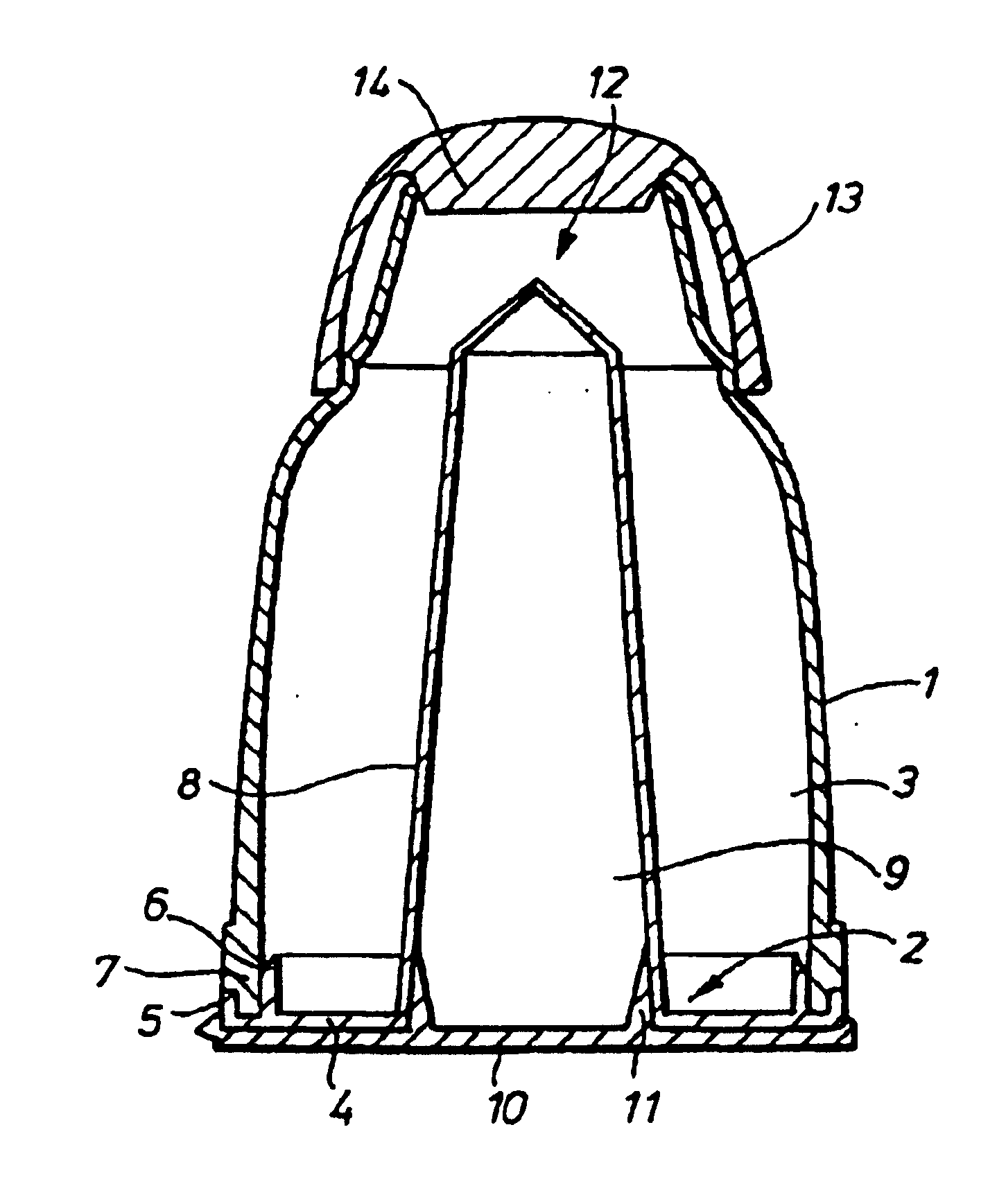

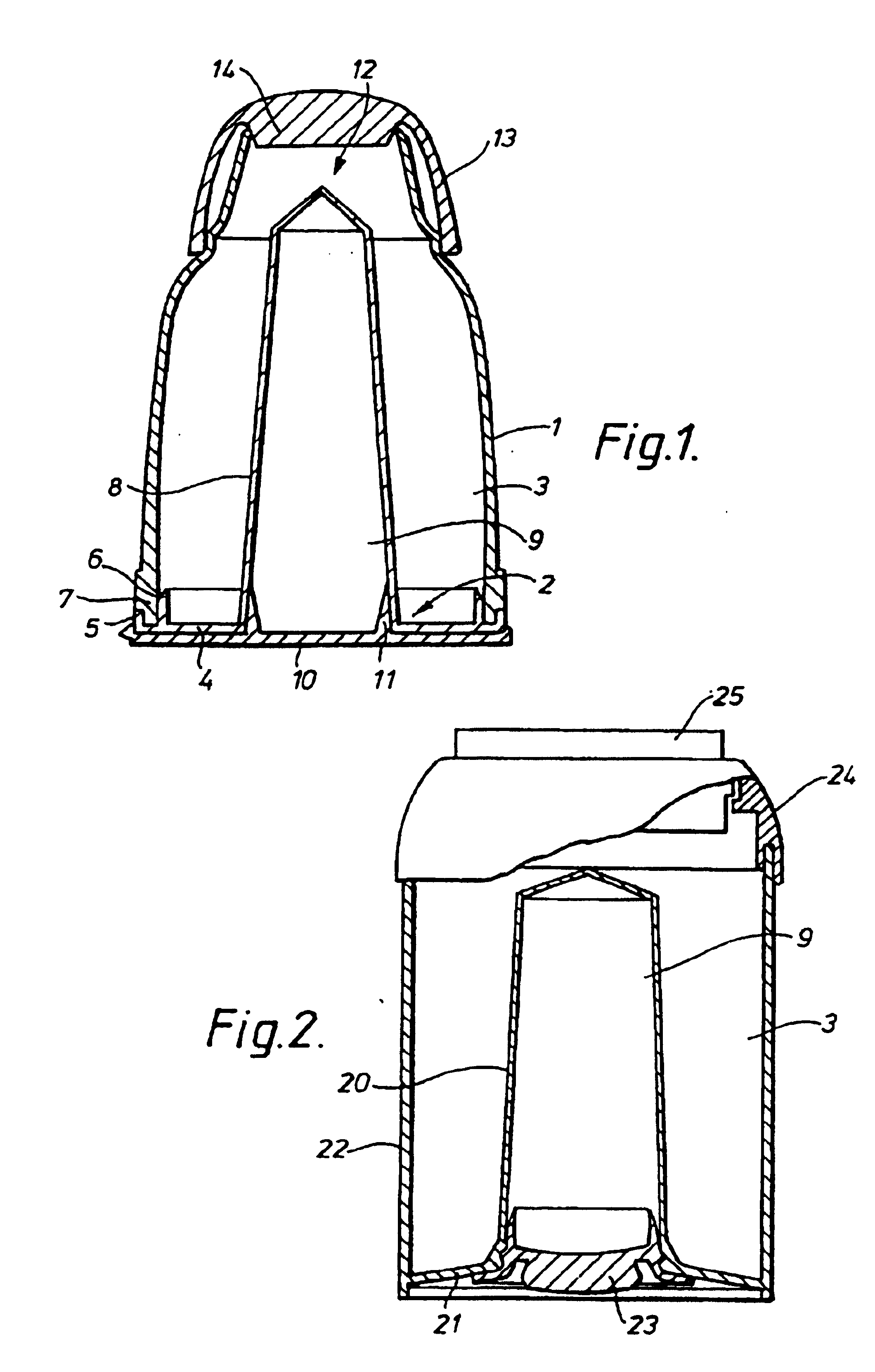

Container for dispensing a heated fluid

A container adapted to heat and dispense material comprises a container (1) which defines a first compartment (3) adapted, in use, to be filled with the material requiring heating, such as epilatory wax, and a second compartment (9) adjacent to the first compartment and separated therefrom by a dividing wall (8). The container (1) has an inlet to the second compartment (9) in the outer wall thereof which is closeable by a plug or stopper (10). In use, the second compartment (9) is filled with a heated liquid, such as warm water, to heat the material in the first compartment (3), so that it can be applied to a site through an applicator (12).

Owner:RECKITT BENCKISER FRANCE

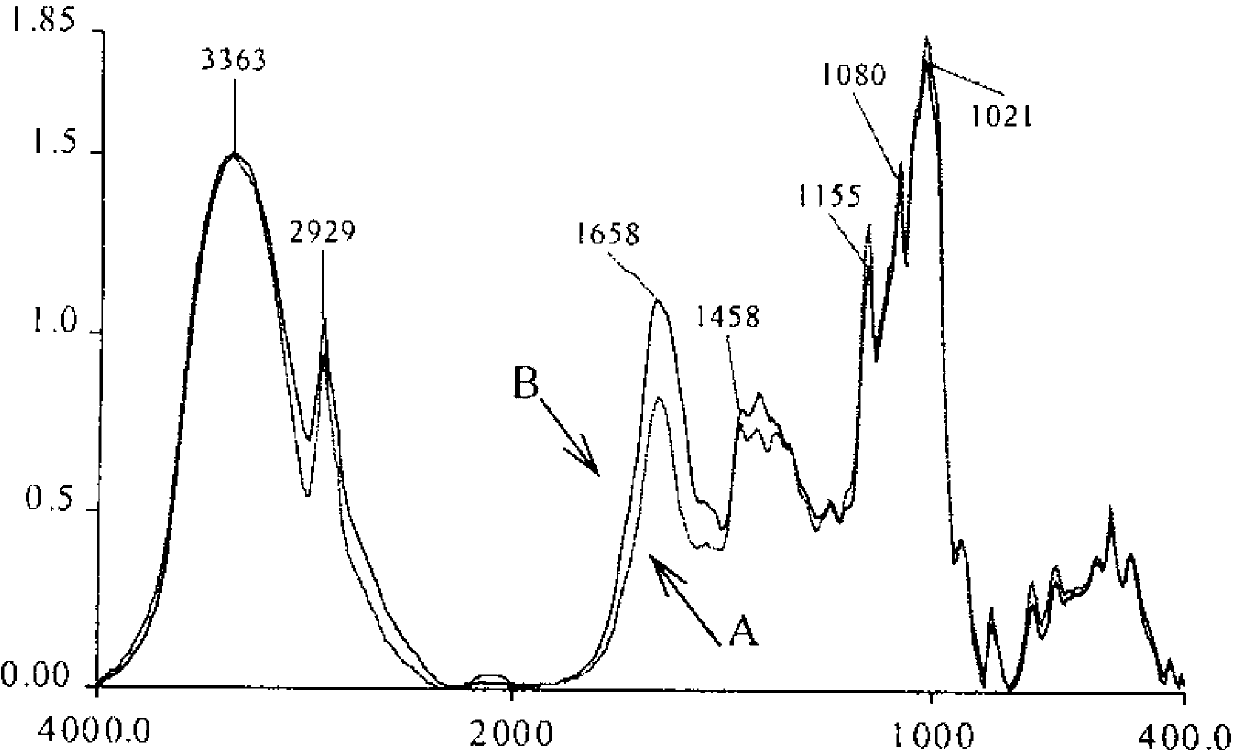

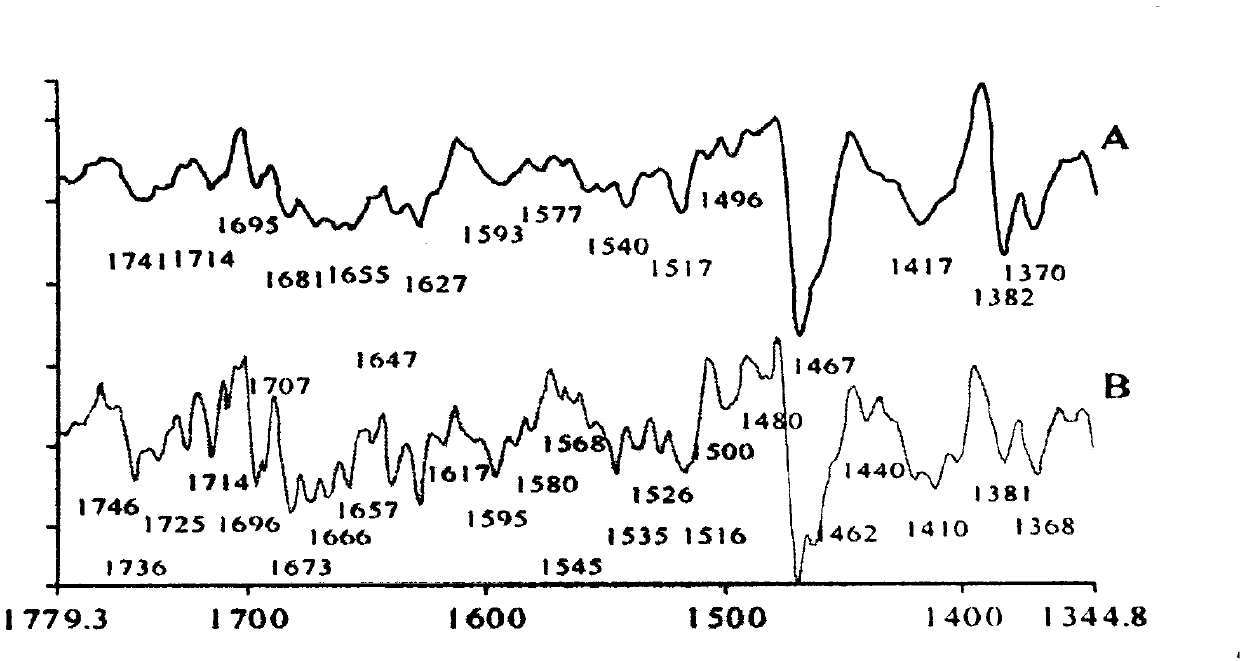

Sesame-flavor liquor and production process thereof

InactiveCN102978072AIncrease productionQuality improvementAlcoholic beverage preparationFlavorBiotechnology

The invention discloses sesame-flavor liquor and a production process thereof. The production process of the sesame-flavor liquor comprises the following steps of: adding 80-90 parts of sorghum, 10-20 parts of wheat and 4-6 parts of steamed rice husk to 40-50 parts of water for uniformly stirring, filling the mixture to a rice steamer and steaming; putting 80-100 parts of steamed unprocessed grain and 400-500 parts of distilled grains after last steaming to a packing bed for blasting and cooling; adding 5-10 parts of yeast and 20-25 parts of mouldy bran to the mixture for uniformly turning and stirring; packing and fermenting the fermented grain, which is uniformly turned and stirred, on the packing bed; cooling the packed and fermented grain, and then putting to a fermentation pit for fermenting; discharging the fermented grain out of the pit, adding 16-20 parts of steamed rice husk to the pit, and uniformly turning and stirring the mixture; and filling the mixture to the rice steamer for steaming, and removing the residues of the distilled liquor to obtain the sesame-flavor liquor. The production process has a liquor yield of 34-36%; and the obtained liquor has high yield, good quality, strong liquor flavor and outstanding sesame flavor, and is full and harmonious, and lasting in fine taste.

Owner:SHANDONG JINGZHI WINE

Soil preparation method for improving production performance of soil in sandy soil matrix greenhouse

The invention relates to a soil preparation method for improving the production performance of soil in a sandy soil matrix greenhouse. According to the method, field soil is partially added in a pure sandy soil farming layer, the three-dimensional structure that sand is covered with soil, soil is coated with fertilizer and ridges are high is formed, and the pure sandy soil productivity is greatly improved. Based on the soil dressing principle, the good rooting performance, moisture and fertilizer retention performance, buffer performance, biological performance and nutrient performance of the field soil are kept, the pure sand layer is utilized for cutting off surface layer soil capillary force, the humidity in the greenhouse is lowered, and therefore diseases caused by high humidity in the greenhouse are greatly reduced. The soil temperature of the farming layer in winter is increased due to the fact that the ridges are high, and therefore the growth of vegetable root systems is promoted. Accordingly, the soil production performance and the vegetable output are greatly improved.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

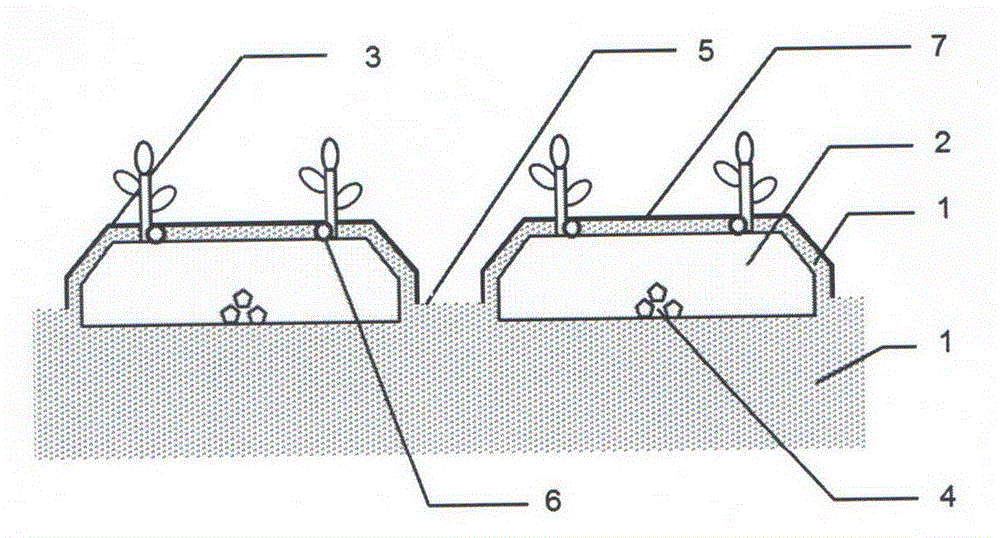

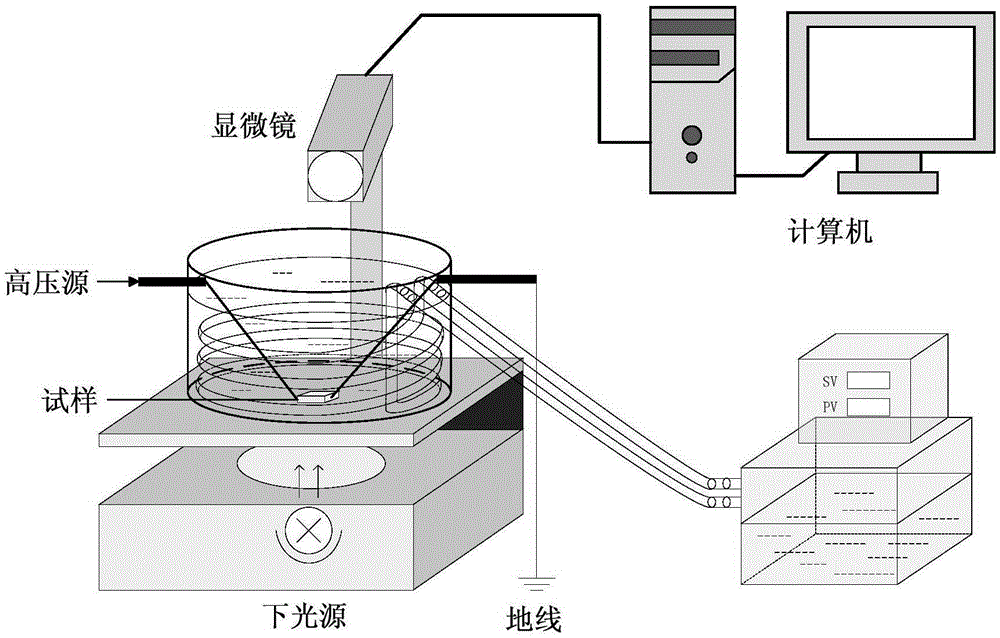

Solid insulation treeing type high temperature test system capable of realizing high efficiency temperature control

ActiveCN105425119AEfficient temperature controlImprove heat resistanceTesting vessel constructionLow voltageMicroscopic observation

The invention relates to a solid insulation treeing type high temperature test system capable of realizing high efficiency temperature control. The system comprises a test vessel formed by a container wall and a glass foundation, wherein the test vessel is internally filled with dimethicone, an annular glass tube surrounds an inner side of the test vessel in a spiral mode, the annular glass tube is connected with a high temperature heating source through a heat circulation tube, the high temperature heating source is internally filled with silicone oil, a sample is arranged at the bottom portion of the test vessel, one end of a high voltage leading wire is connected with an anode of the sample, the other end of the high voltage leading wire is connected with a high voltage power source, one end of a low voltage leading wire is connected with a cathode of the sample, and the other end of the low voltage leading wire is externally in grounding connection. The treeing type test on the solid insulation sample can be carried out under the action of external AC / DC voltages, microscopic observation on electrical tree initiation and growth characteristics can be realized, voltage stress and high temperature thermal stress can be simultaneously applied to the sample, treeing type test and measurement can be prevented from being influenced by a heating system, the system employs enclosed circulation, and the system further has advantages of small heat loss, high heat energy utilization efficiency, simple operation, reliable running, no noise and long service life.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Double-cropping-a-year peanut high-multiple cultivation method

ActiveCN103858656AEnsure temperatureEnsure humidityBiocidePlant growth regulatorsPlastic mulchEthephon

The invention relates to a double-cropping-a-year peanut high-multiple cultivation method. The method comprises the following steps that a field parcel is selected and deeply ploughed before winter, shallow ploughing is conducted before seed sowing next year, ridging is performed on the middle ten days of March, and the field parcel is covered with a mulching film after a weed killer is sprayed; seed sowing for first cropping is conducted when the temperature reaches over 15 DEG C one week after the field parcel is covered with the mulching film, holes are punched in the mulching film for seed sowing, and plastic arched sheds are built above seed sowing areas; all the arched sheds are removed when the outside air temperature stably ranges from 23 DEG C to 26 DEG C in mid-to-end May, and the first cropping is conducted on the last ten days of June; fresh seeds after the cropping are soaked with ethephon for 24 hours, seed sowing for second cropping is conducted, land leveling after the peanut cropping is conducted, ridging, mulching film coverage and seed sowing are conducted, and the second cropping is conducted in mid-to-end October. According to the double-cropping-a-year peanut high-multiple cultivation method, the double-cropping propagation coefficient can reach 150-210 times, the seed breeding process can be accelerated, seed breeding efficiency is improved, and seed breeding cost is lowered. The double-cropping-a-year peanut high-multiple cultivation method has the advantages of being easy and convenient to implement, low in cost, good in effect, high in success rate and the like, and provides a novel technique for large-area low-cost high-quality peanut seed breeding in the northern China.

Owner:HENAN ACAD OF AGRI SCI

Device for reducing cast slab corner cracks through flame heating and crack reduction method

The invention discloses a device for reducing cast slab corner cracks through flame heating and a crack reduction method. The device comprises a flame heater, a gas supply device and a temperature measuring device. The flame heater is composed of 4 to 8 flamethrowers. The flamethrowers are arranged on the corners of a cast slab. Each flamethrower can be individually adjusted and controlled. The gas supply device is connected with the flame heater for providing heating fuel for the flame heater. The temperature measuring device is arranged behind the flame heater, namely the slab drawing direction of the cast slab.

Owner:ANGANG STEEL CO LTD

Towel sterilizing device

InactiveCN105267998AEasy to sterilizeGood disinfection effectDomestic applicationsChemicalsThermal insulationInfrared

The invention relates to a towel sterilizing device. The towel sterilizing device comprises a cabinet, a cabinet door, a transverse rod, a handle, buttons, indicating lamps, a power line, an automatic timing switch, an ultraviolet tube, an infrared bulb, an ozone generator, a water tank and a thermal insulation layer, wherein the handle is mounted on the central part of the upper surface of the cabinet; the buttons, the indicating lamps and the switch are located on the panel of the cabinet door; the transverse rod is mounted between two opposite wall surfaces of the inner cavity of the cabinet; the water tank is located on the lower portion of the inner cavity of the cabinet; the ultraviolet tube and the infrared bulb are mounted on the upper wall surface of the inner cavity of the cabinet; the ozone generator is mounted on the lower surface of the inner cavity of the cabinet; the thermal insulation layer is located in the interlayer of the double-layer cabinet. The towel sterilizing device has the advantages that ultraviolet light and ozone can be used for sterilizing at the same time, the ozone has a good sterilizing effect on local dead angles where the ultraviolet light cannot irradiates, and the ultraviolet bulb can play a drying role and can remove odors; the towel sterilizing device is simple in structure, convenient to operate, easy to control, safe, good in sterilizing effect, wide in application range, widely applicable to institutions such as hotels, bathrooms and hospitals, and the like.

Owner:天津万广科技有限公司

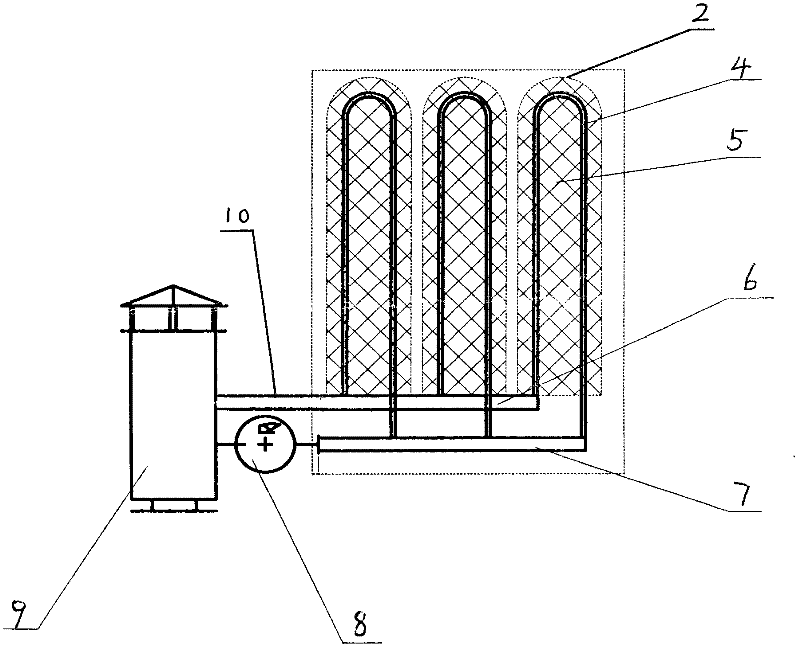

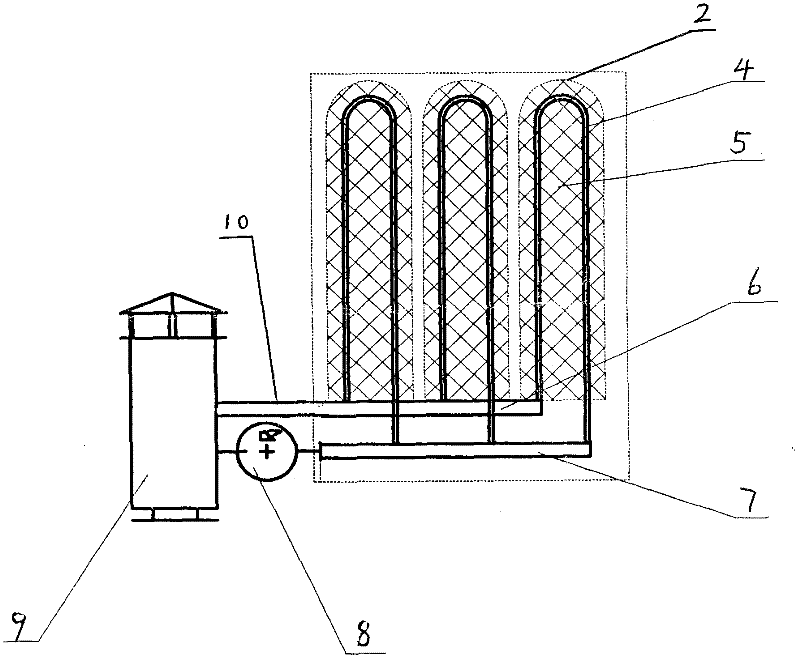

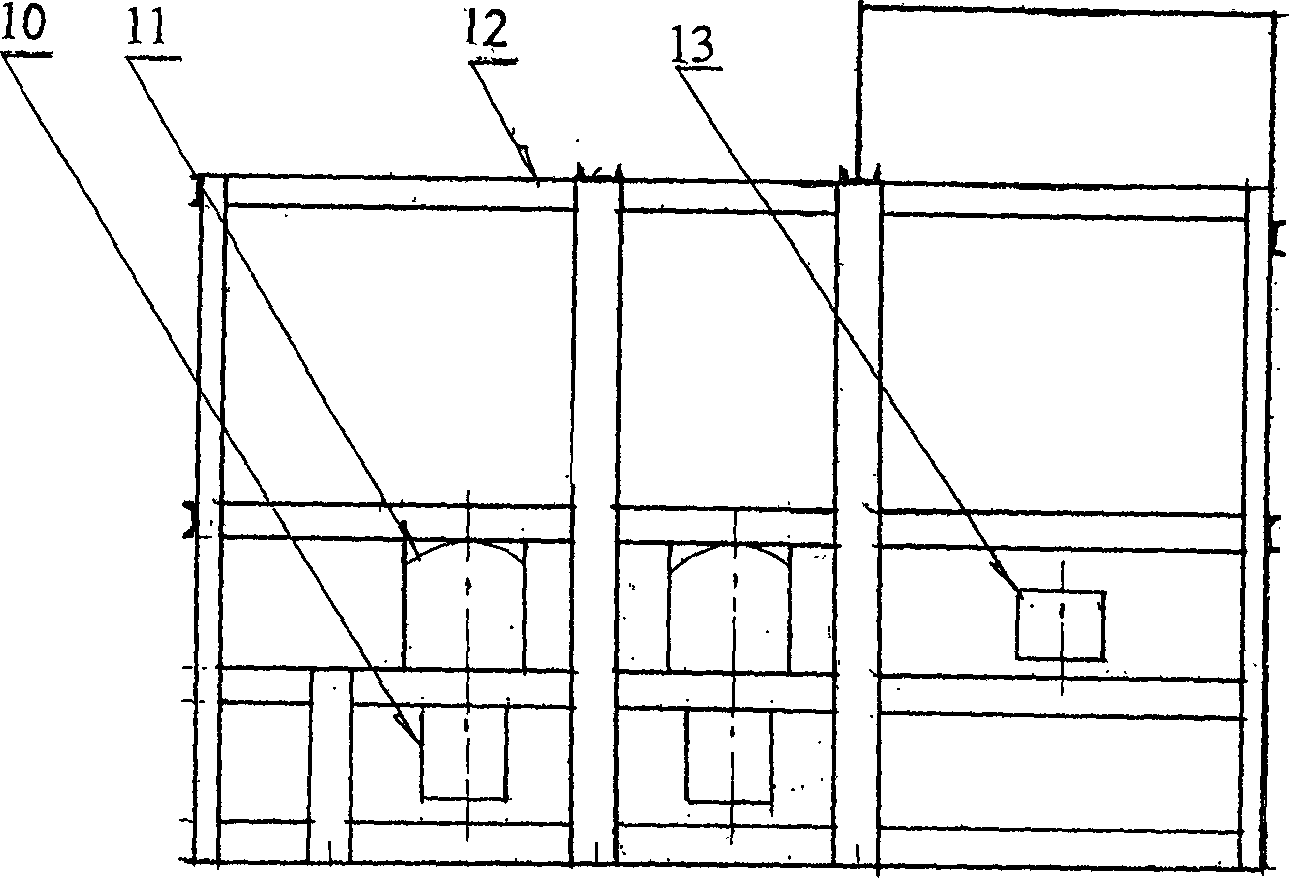

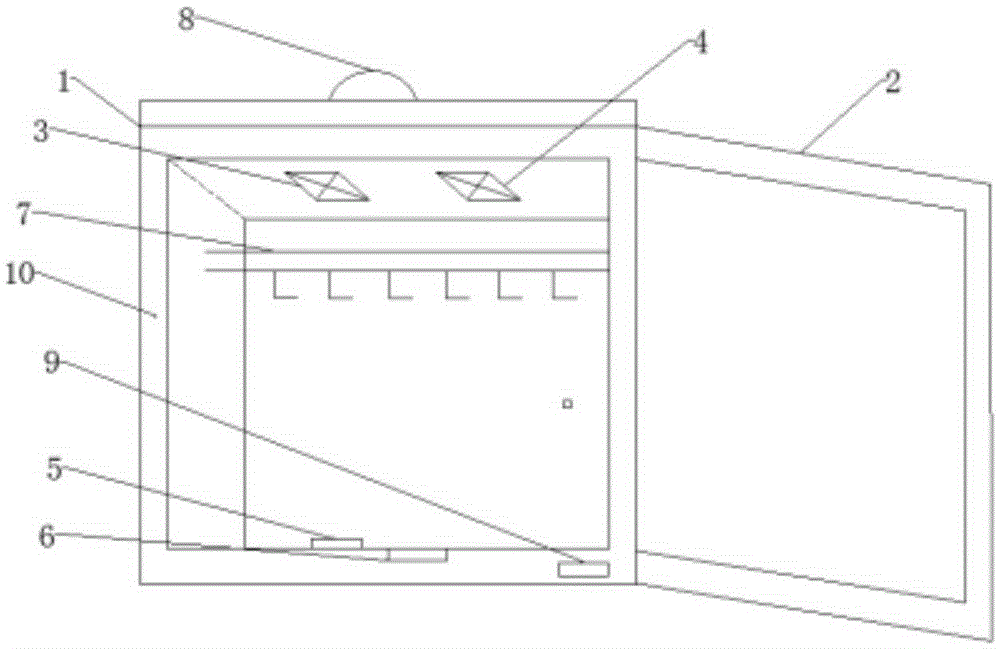

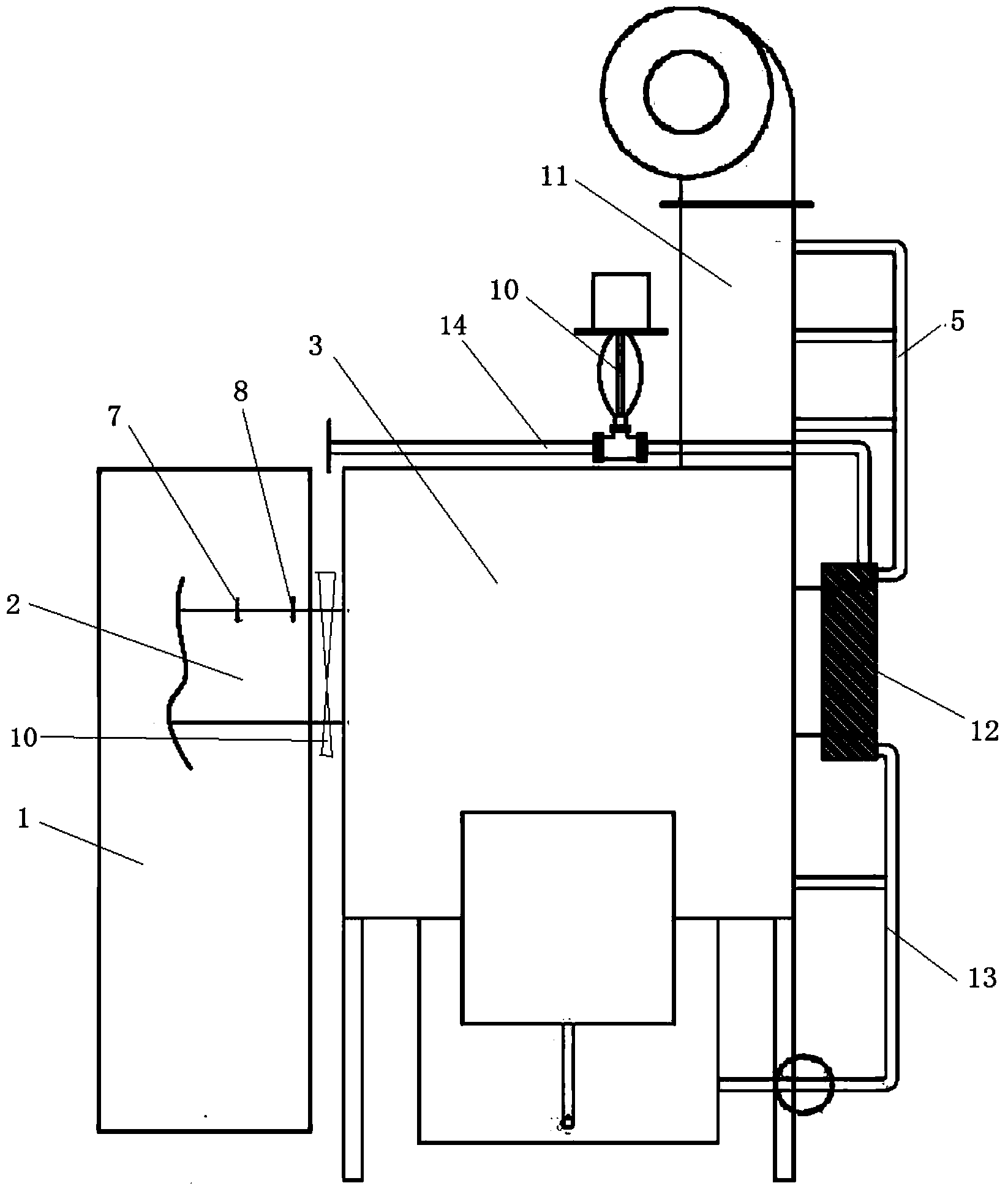

Black tea fermenting chamber

InactiveCN104286239APromote warmingImprove cooling effectPre-extraction tea treatmentBlack teaEngineering

The invention discloses a black tea fermenting chamber. The black tea fermenting chamber comprises an airtight fermenting chamber, wherein an air inlet is formed in the fermenting chamber; an atomizing cavity is also formed outside the fermenting chamber, the atomizing cavity is connected with the air inlet through a pipeline and is connected with a water pipe, atomizing spray heads are arranged at the tail end of the water pipe in the atomizing cavity, and a water temperature regulating device is also arranged at the inlet end of the water pipe; automatic steam regulating valves are arranged on the pipeline on which the atomizing cavity is connected with the air inlet; a temperature sensor and a humidity sensor are arranged in the fermenting chamber; a blower is also arranged above the atomizing cavity. Through the combined action of the atomizing spray heads and the blower, atomizing steam and oxygen which conform to temperature requirements are input at the same time, the requirements for the temperature, the humidity and the oxygen in the fermenting chamber are satisfied, and the fermenting chamber has the advantages of simple structure and low energy consumption. The method can be widely applied to the field of the black tea fermenting chambers.

Owner:谢裕大茶叶股份有限公司

Cutting planting technology for tamarix chinensis in dredger fill original soil area

InactiveCN104718834AReduce salt contentEasy to breatheFertilising methodsHorticultureEcological environmentCut and fill

The invention provides a cutting planting technology for tamarix chinensis in the dredger fill original soil area. The cutting planting technology aims to solve the greening difficult problem in the sea mud dredger fill heavy saline and alkaline area, changes the original high-invest and low-benefit greening mode, takes the ecological engineering science and the natural vegetation evolutionary changes as the guidance, and utilizes the principle of 'suitable land planted with suitable trees (plants), and suitable land with suitable method' and the salt-tolerance performance of the tamarix chinensis. The cutting planting technology adopts the method that localized amendment is conducted on the dredger fill artificially, that is, the local soil salinity is enabled to be reduced to below 2% through the permeable salt-leaching by the sand fertilizer column so that a local microenvironment suitable for root taking can be created for the cutting, and the ventilation, temperature increasing, water saving and the balance of water, air, fertilizer and the temperature can be benefited. After the growing requirement of the salt-tolerant plant like the tamarix chinensis is met, cutting is conducted. The tamarix chinensis are utilized to improve the soil after survival, reduce the soil salinity, attract the insects, birds and other animals and enable the ecological environment to be changed greatly. The cutting planting technology for the tramarix chinensis in the dredger fill original soil area is low in cost, fast in effect, sustainable and capable of providing strong technical support for the development and construction and the environmental improvement of the coastal areas.

Owner:天津港海湾园林绿化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com