Patents

Literature

103results about How to "Soak evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

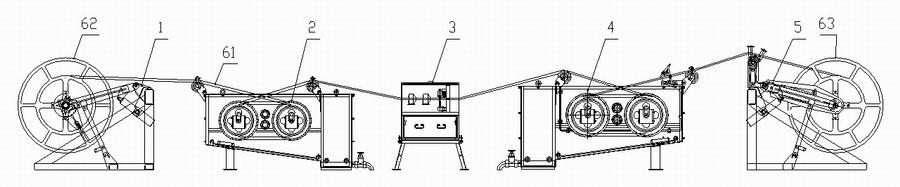

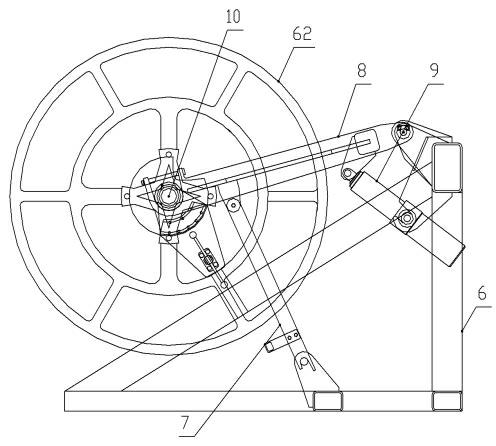

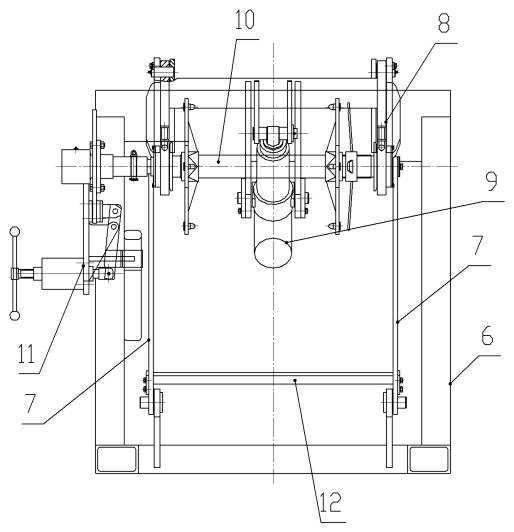

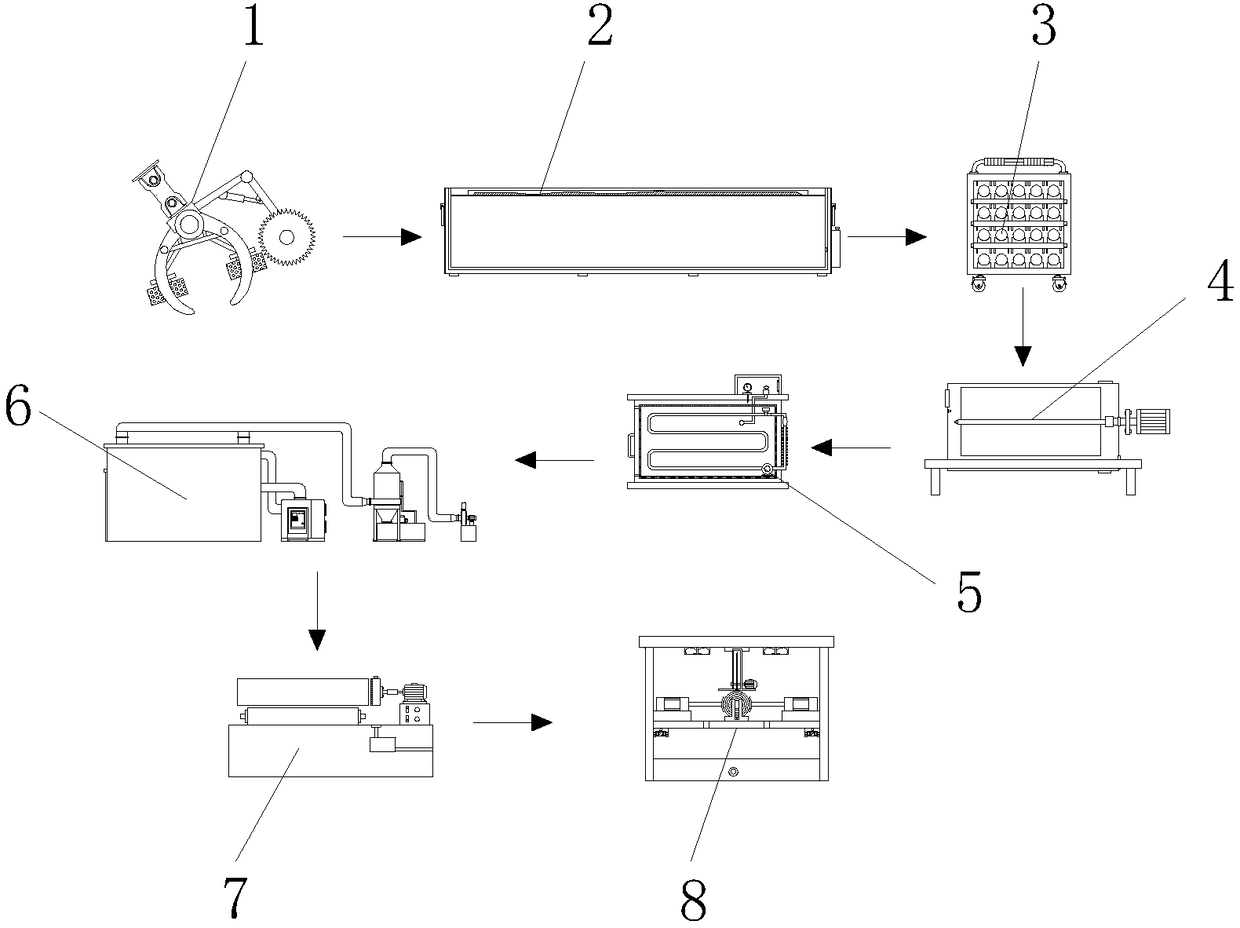

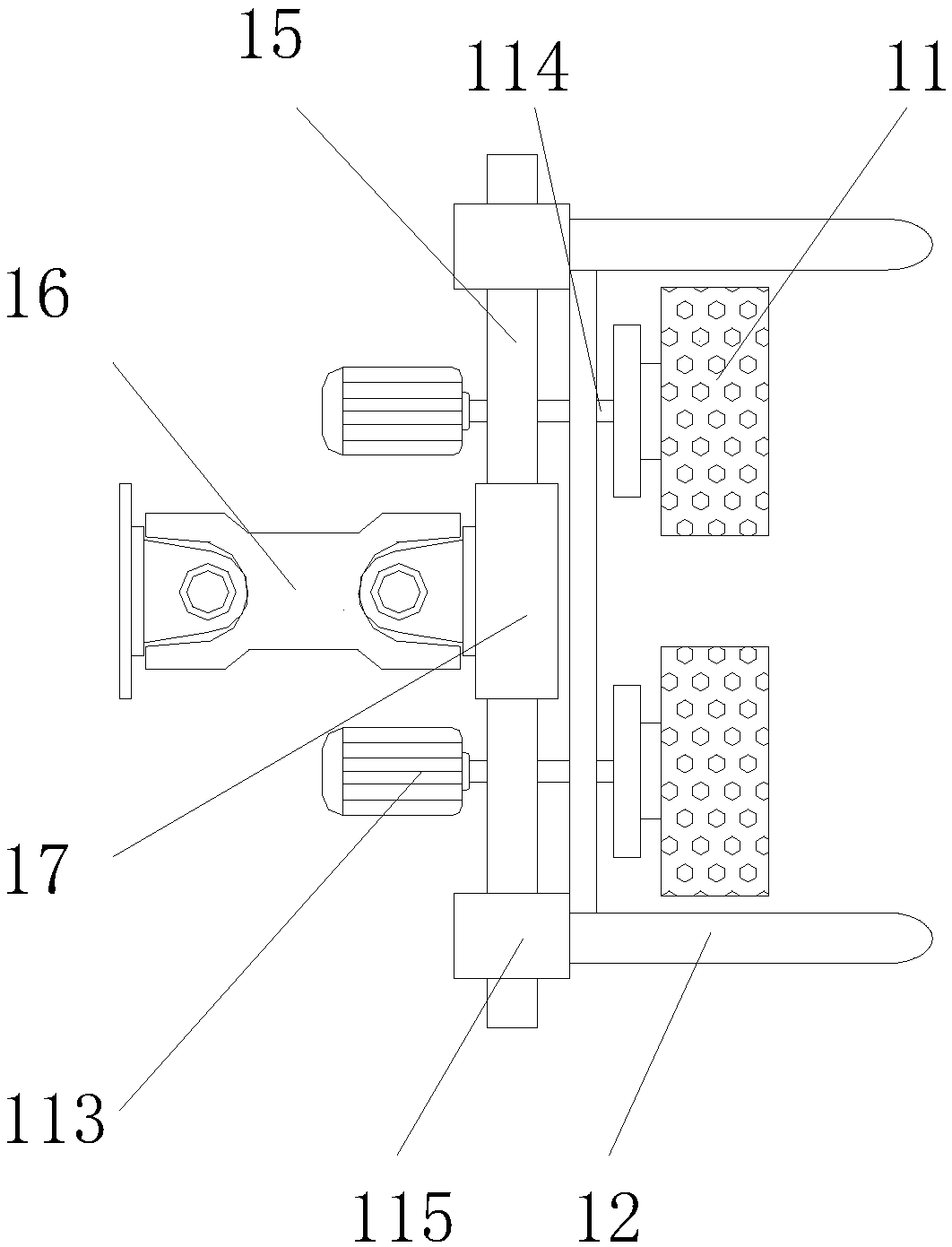

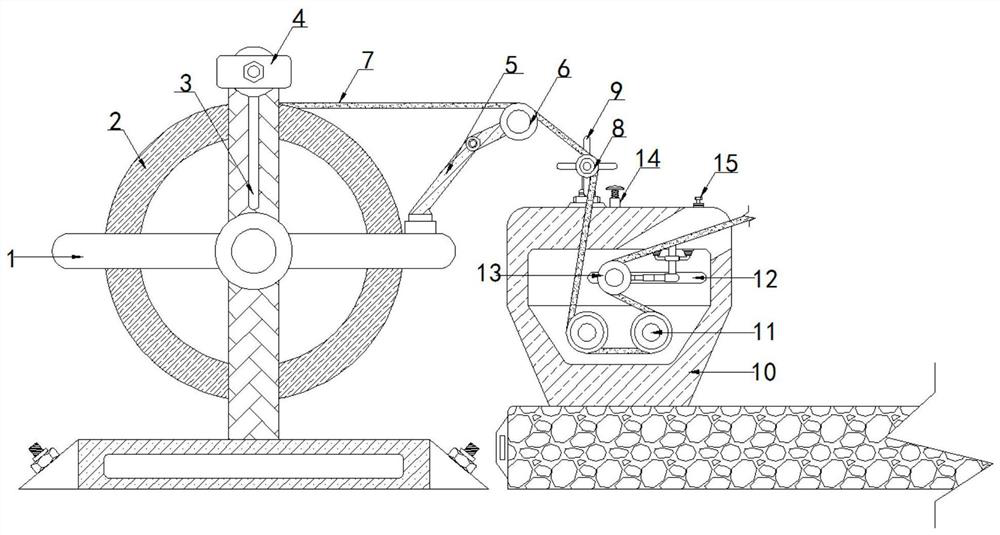

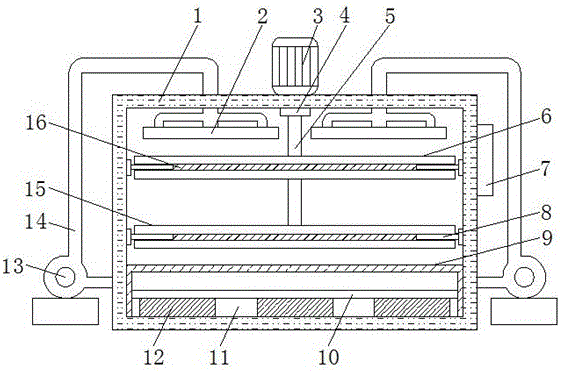

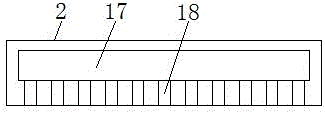

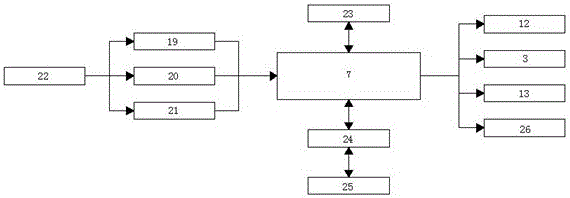

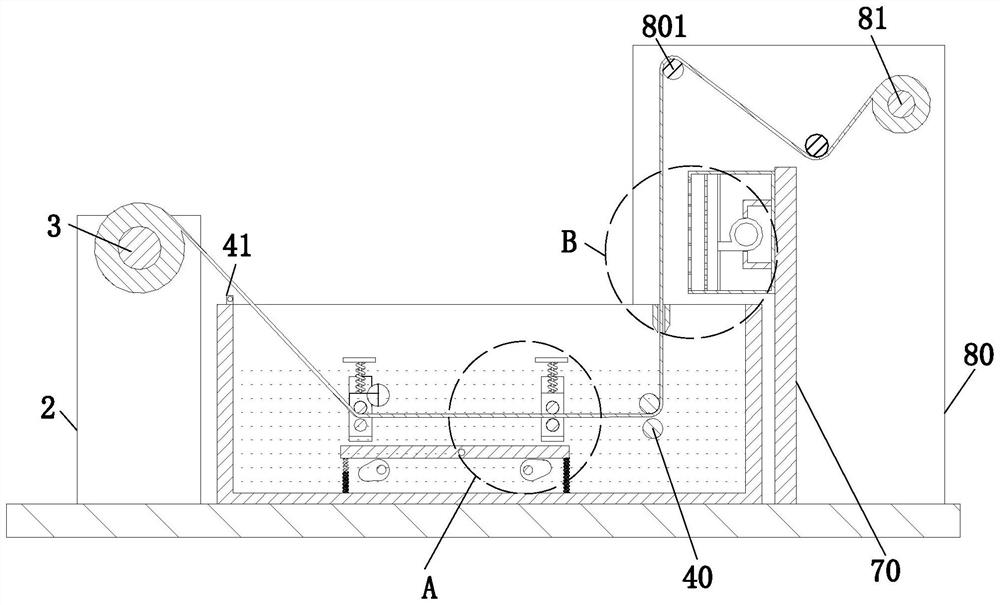

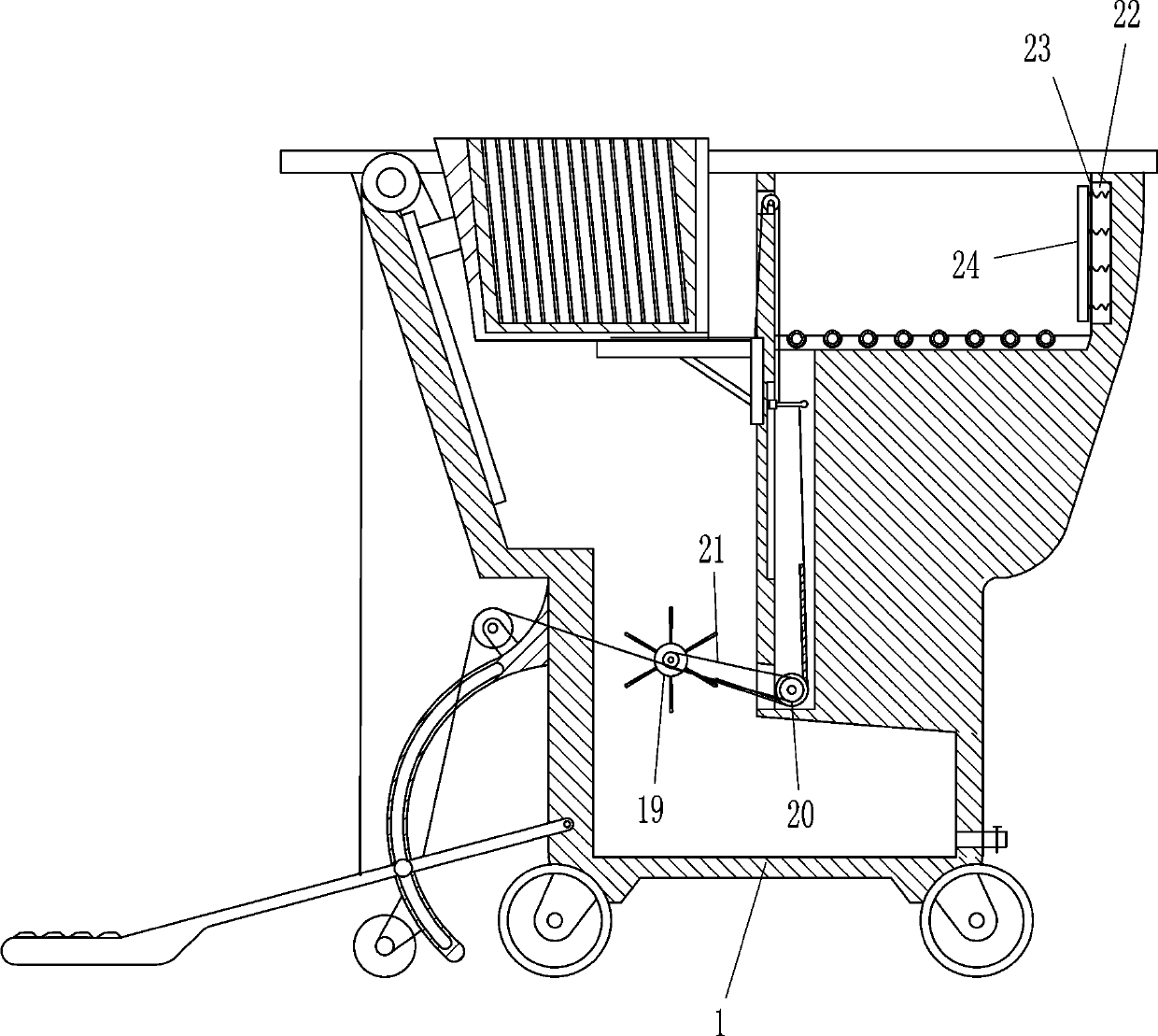

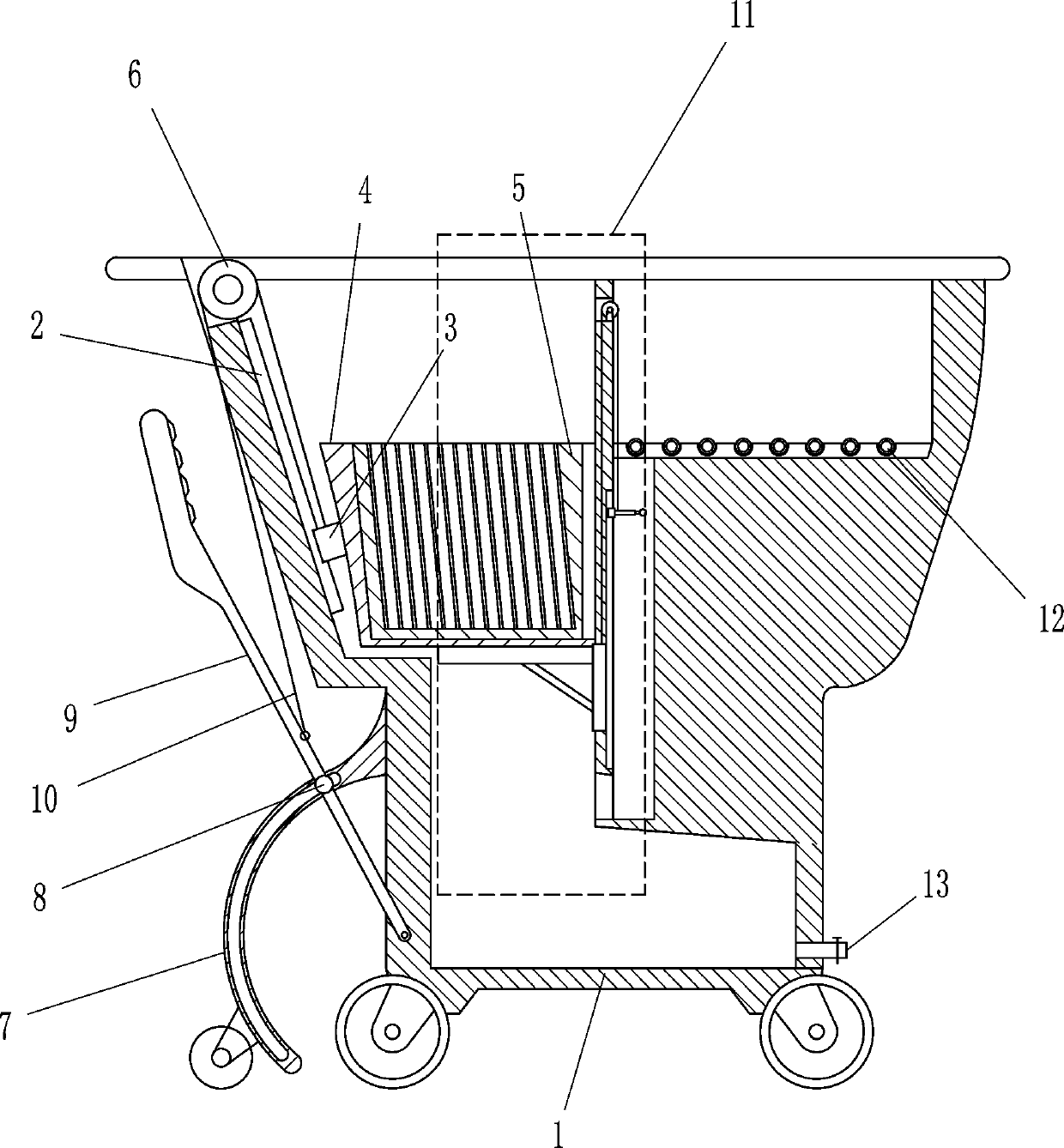

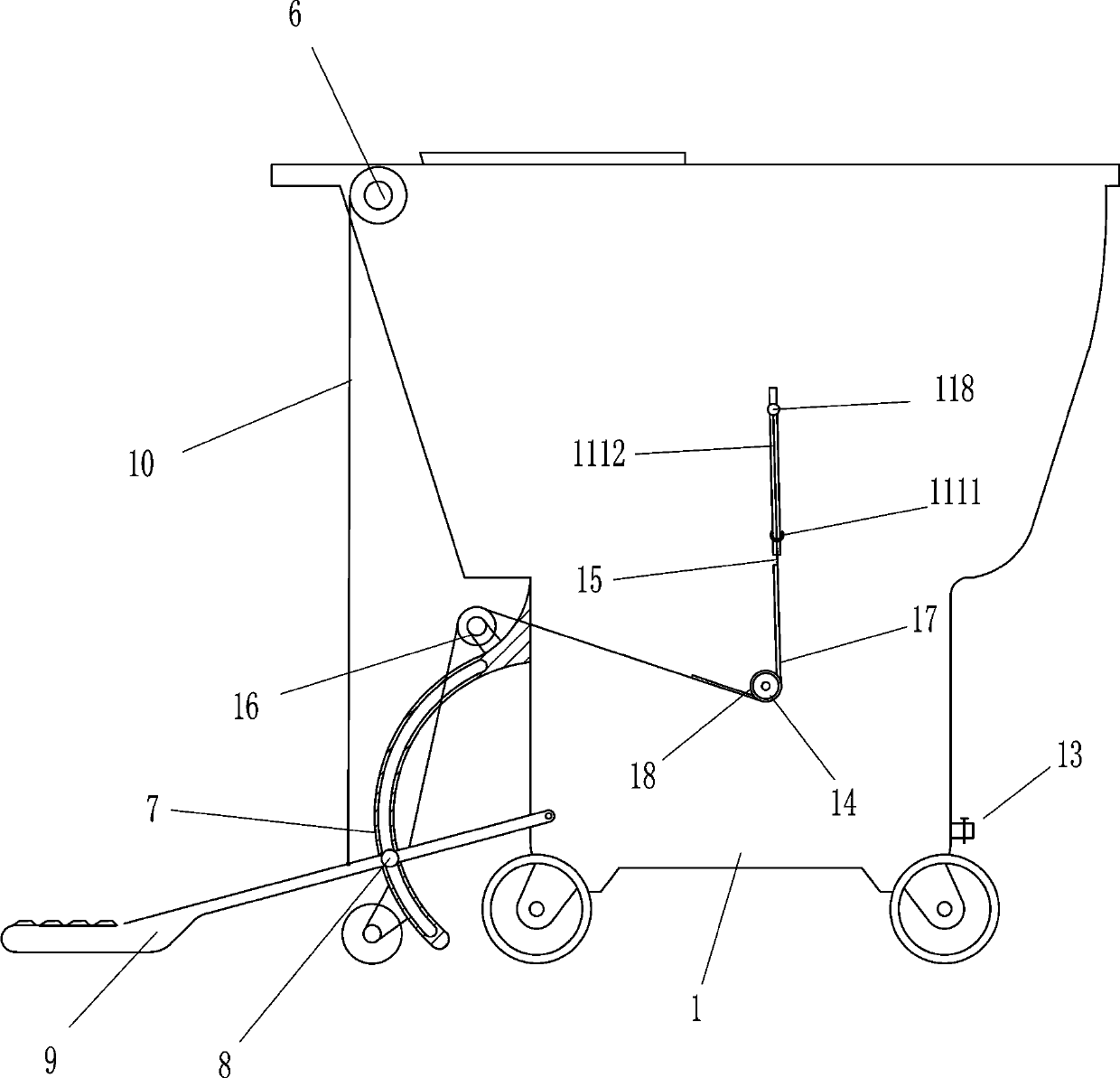

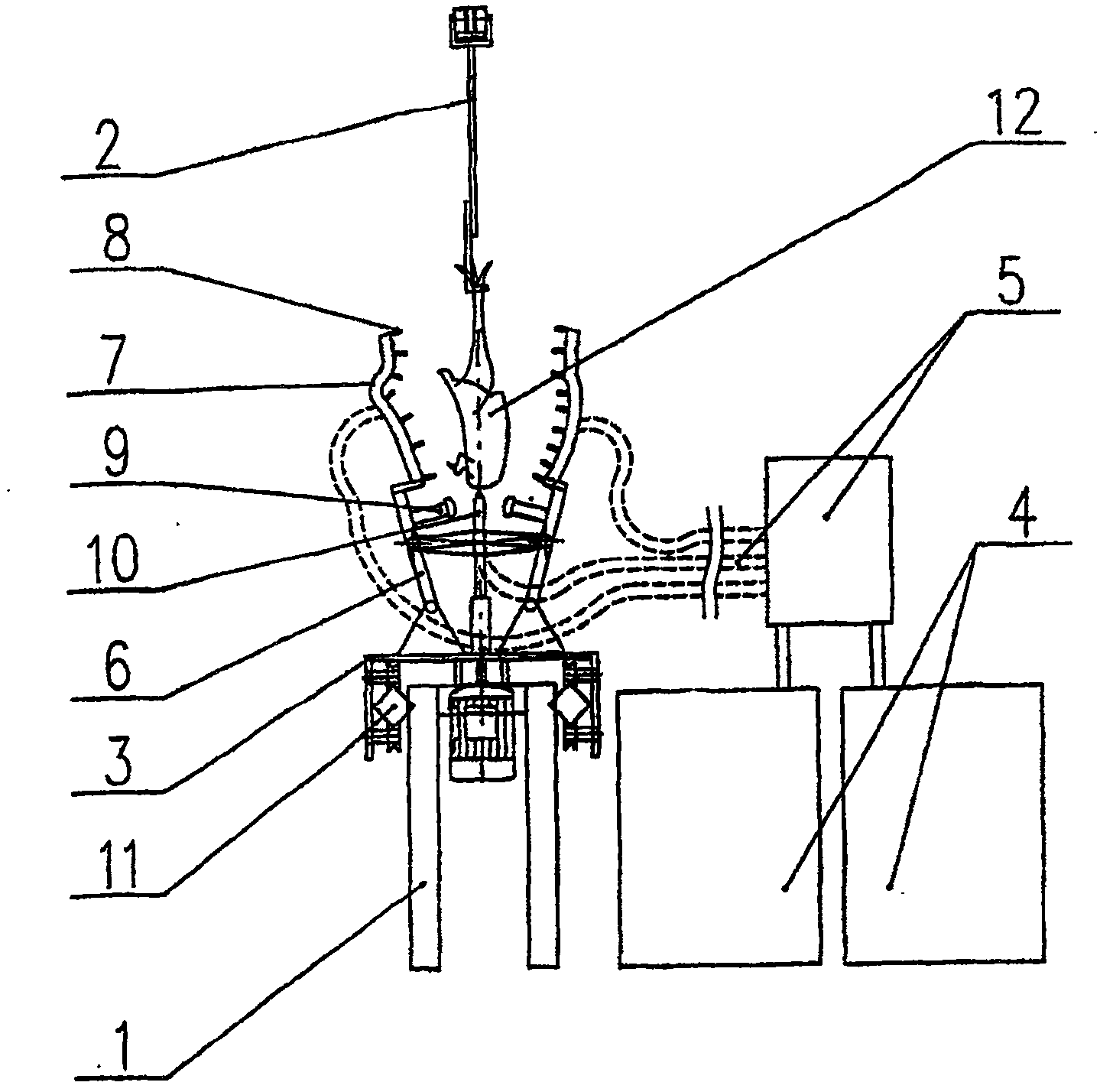

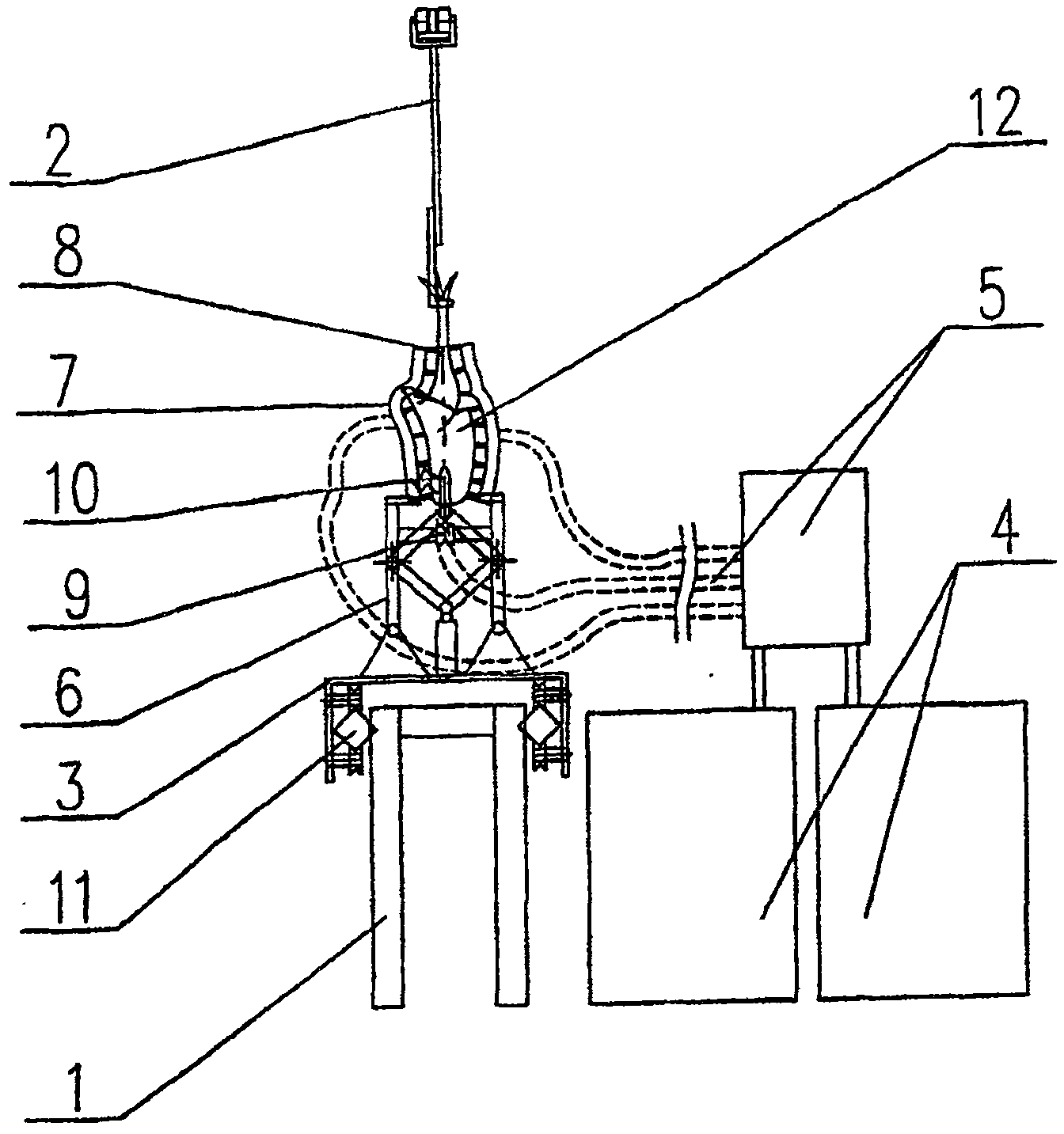

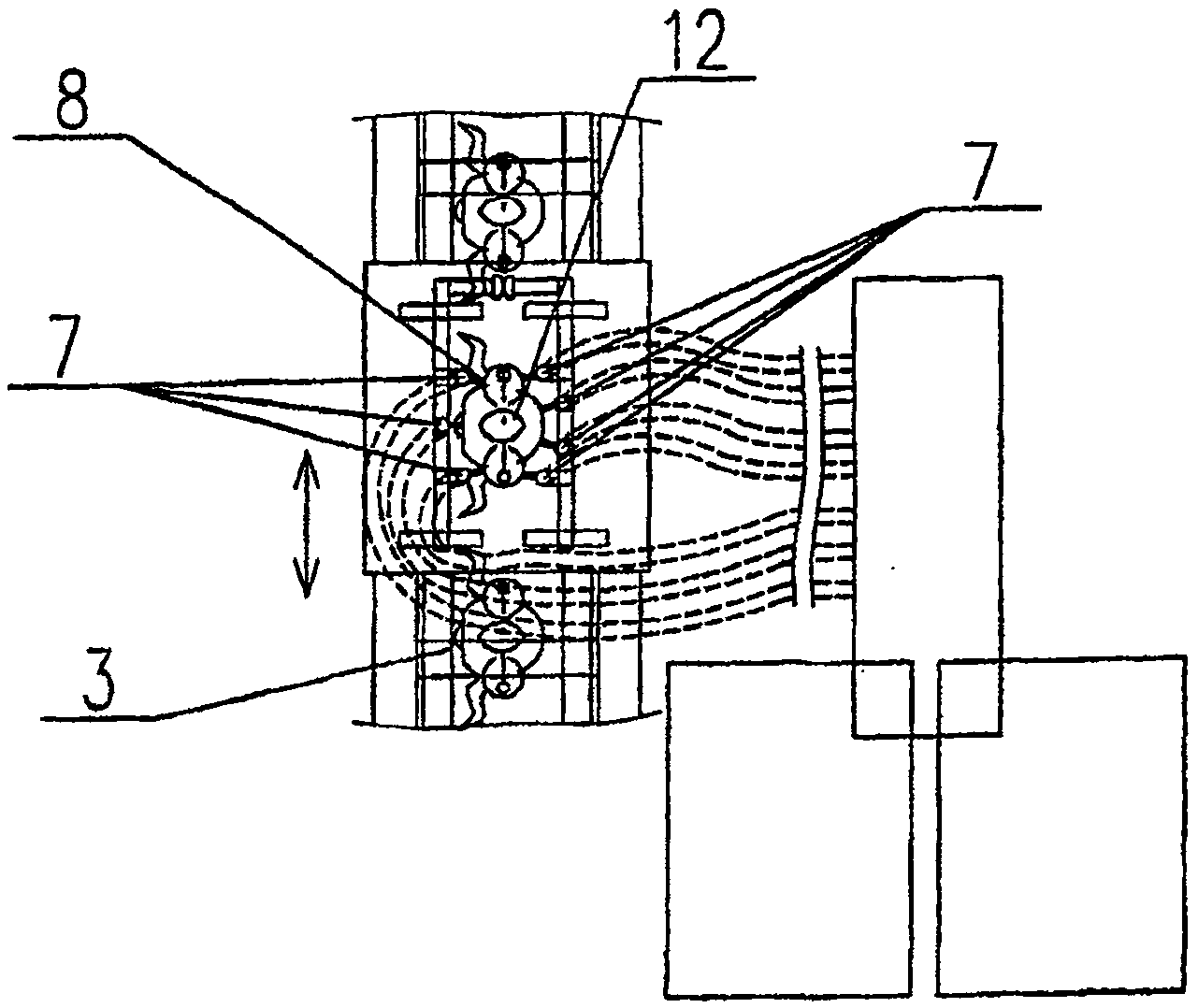

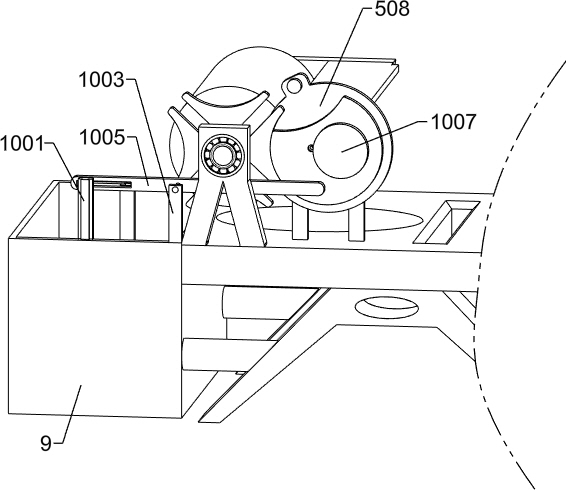

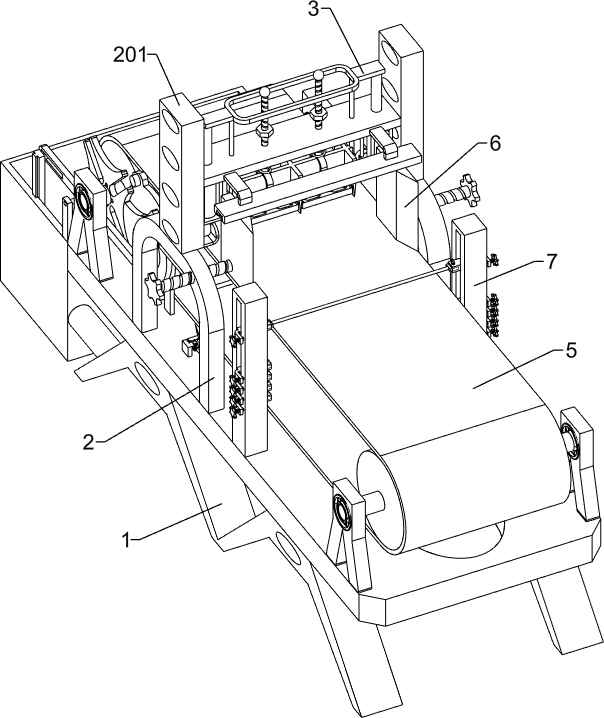

Environment-friendly cleaning and maintenance machine for steel wire rope

ActiveCN102247961AHeight adjustableSatisfy the requirements of pay-offCleaning processes and apparatusEngineeringUltimate tensile strength

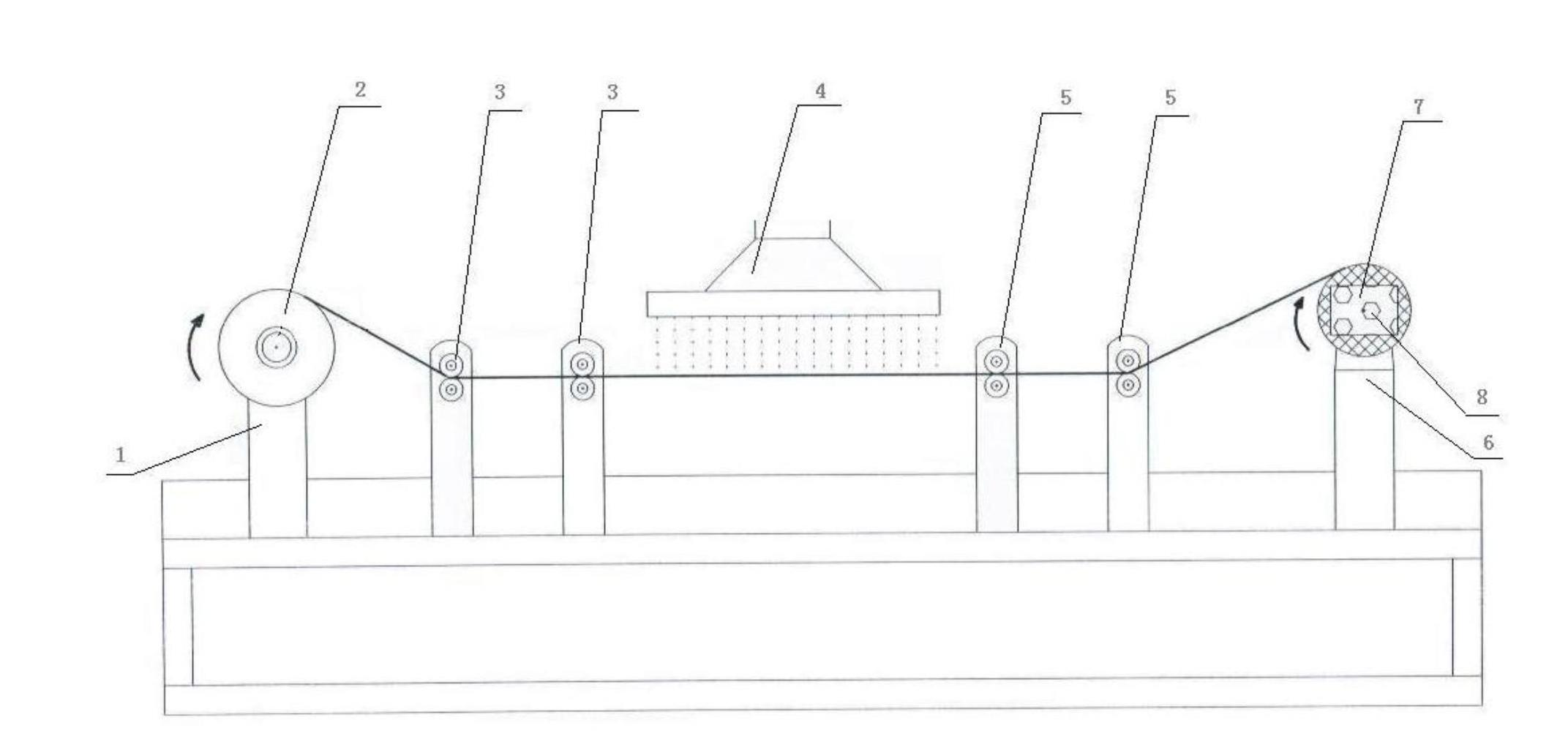

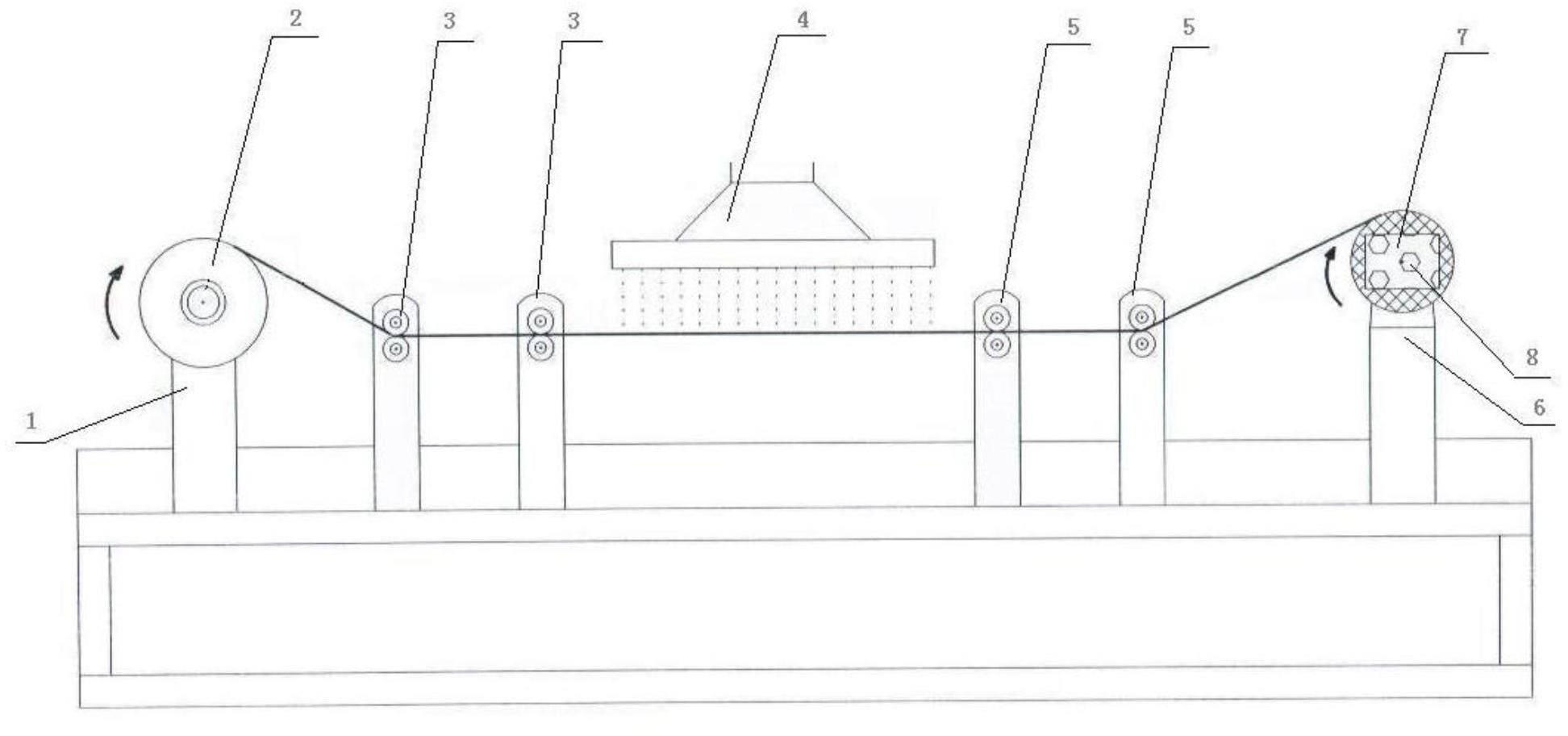

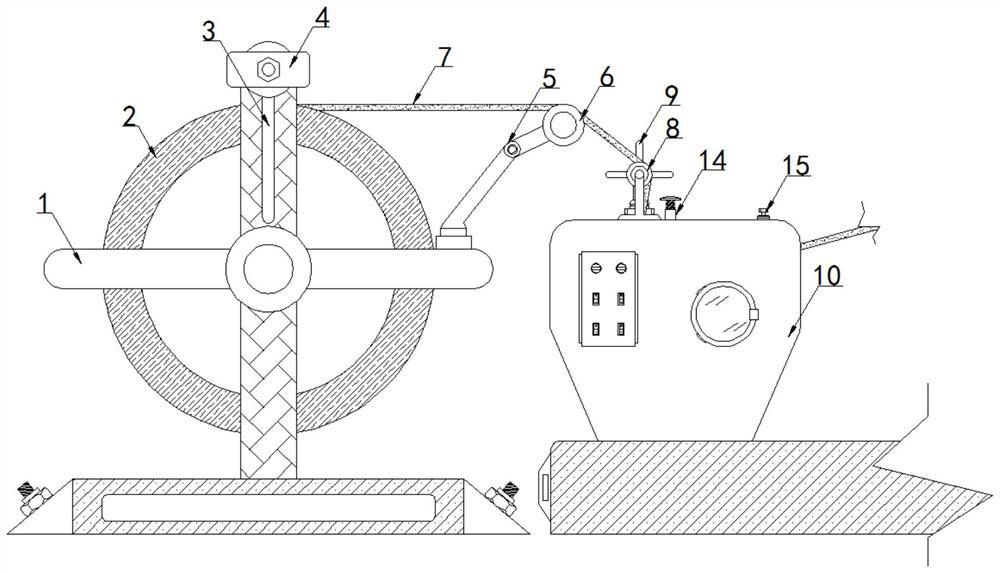

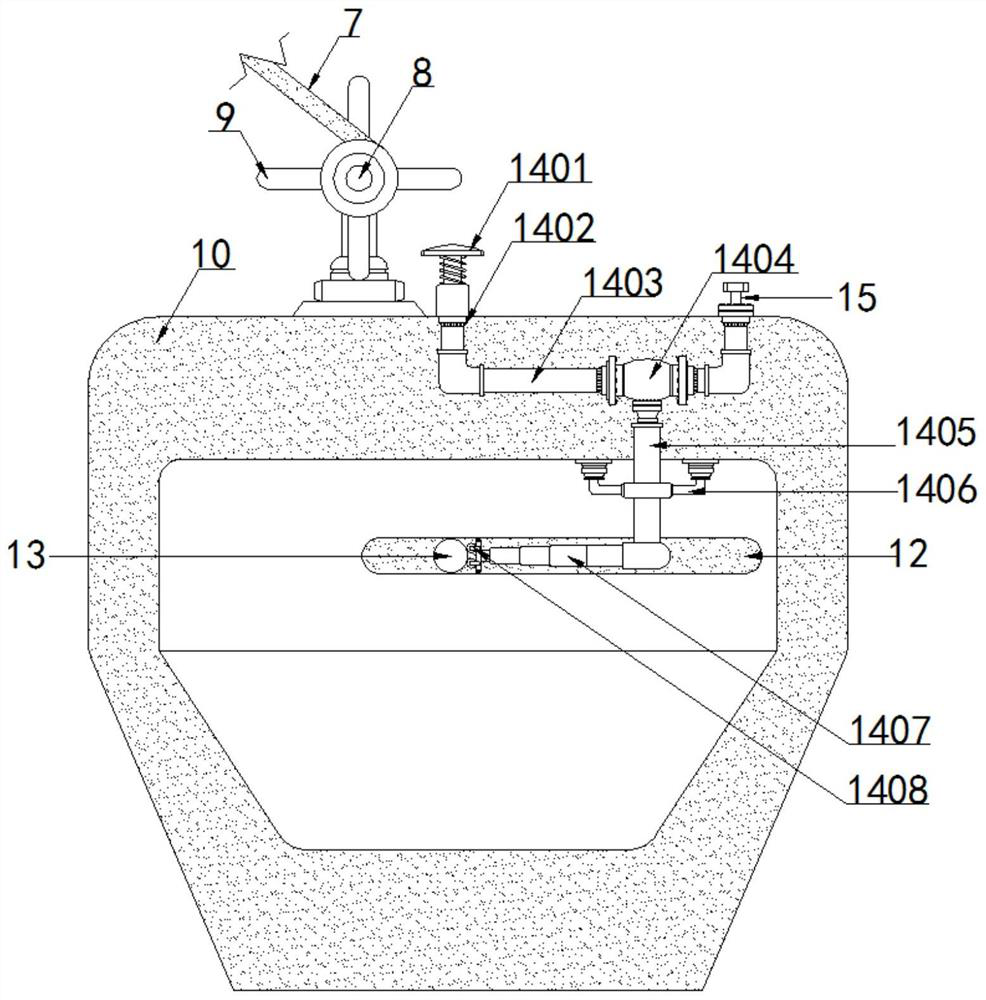

The invention discloses an environment-friendly cleaning and maintenance machine for a steel wire rope. The machine comprises a wire pay-off mechanism, a cleaning mechanism, a dirt-removing mechanism, a maintenance mechanism and a wire take-up mechanism, which are arranged in sequence, wherein the steel wire rope is cleaned and maintained by the wire pay-off mechanism, the cleaning mechanism, the dirt-removing mechanism, the maintenance mechanism and the wire take-up mechanism in sequence. By the adoption of the cleaning and maintenance machine disclosed by the invention, the problems of massive dirt accumulation, rust formation and damage happening during the use process of different types of steel wire ropes for constructions can be effectively avoided; and accidents of personal injury, traffic interruption and power failure, which are caused by the breakage of steel wire ropes during the construction process, can be effectively prevented by periodically cleaning and greasing steel wire ropes with the cleaning and maintenance machine every year. The cleaning and maintenance machine disclosed by the invention can be used for cleaning different types of steel wire ropes in a simple and highly-efficient method, has stable performances and good cleaning and maintenance effects. The cleaning and maintenance machine is easy to operate during the use process and has the beneficial effects of reducing the labor intensity, increasing the work efficiency, ensuring the service safety against twisting of steel wire ropes, prolonging the service life and the operating reliability of steel wire ropes and providing powerful guarantee for safety production.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

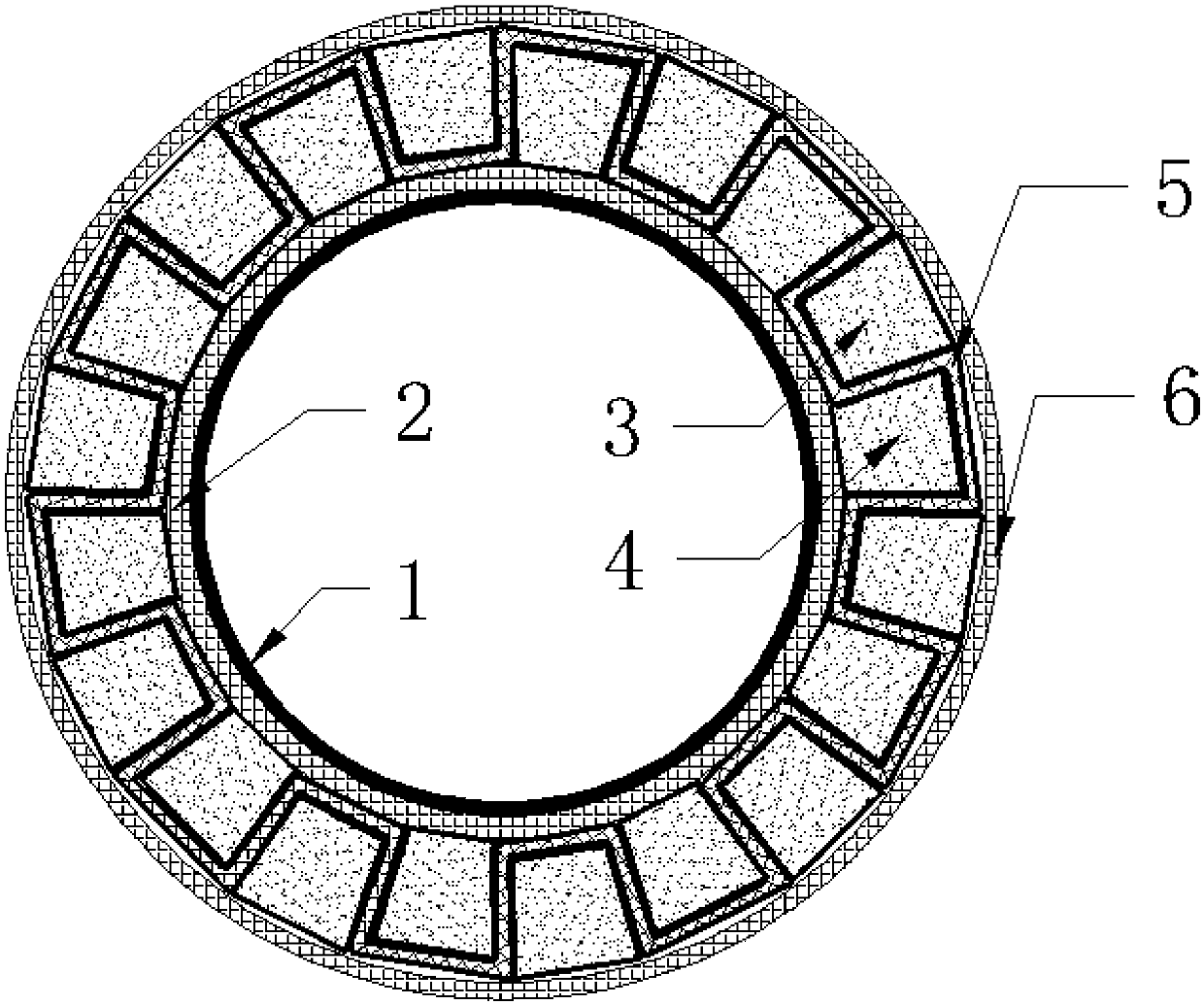

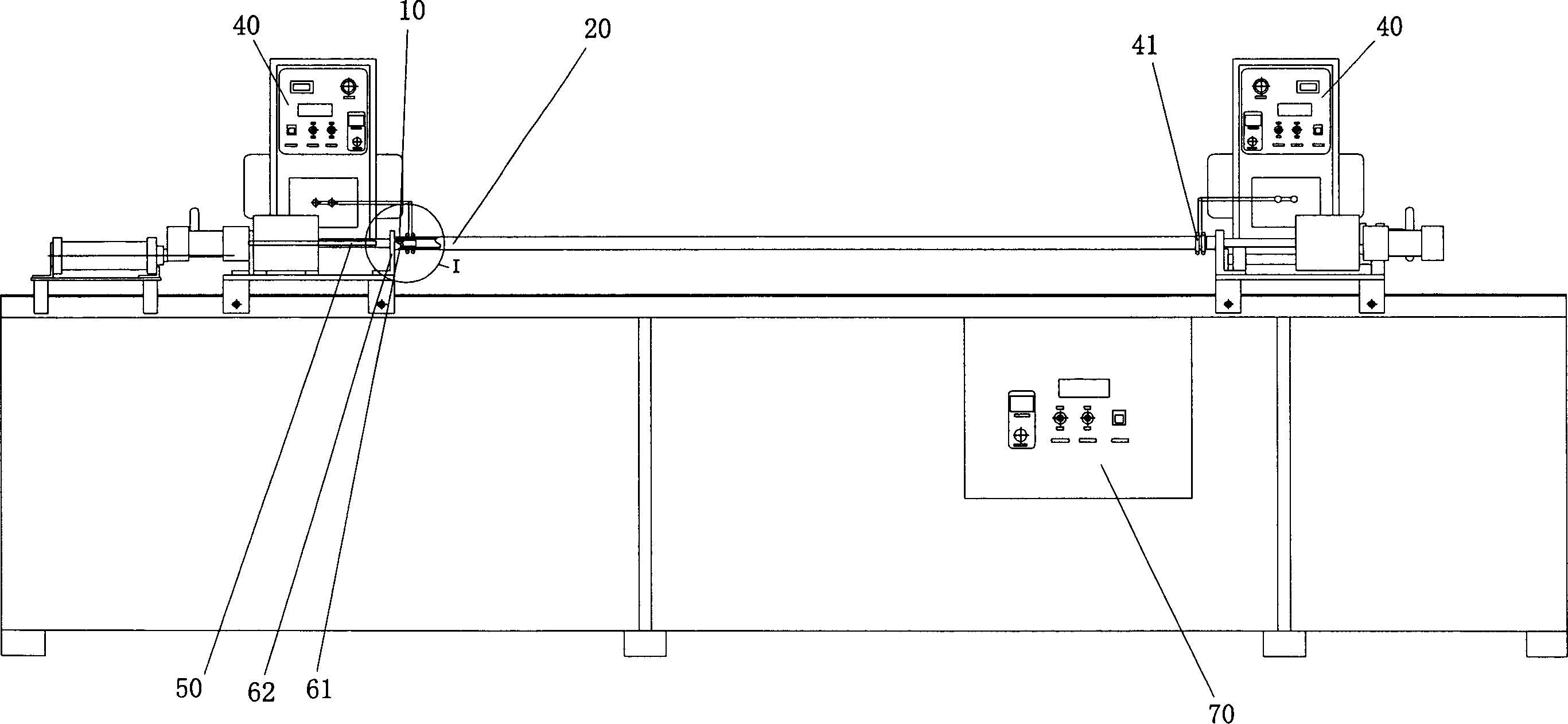

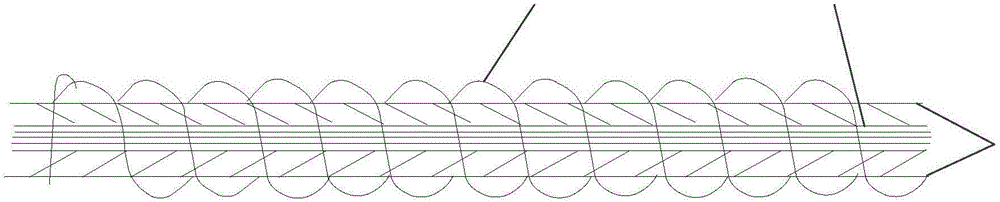

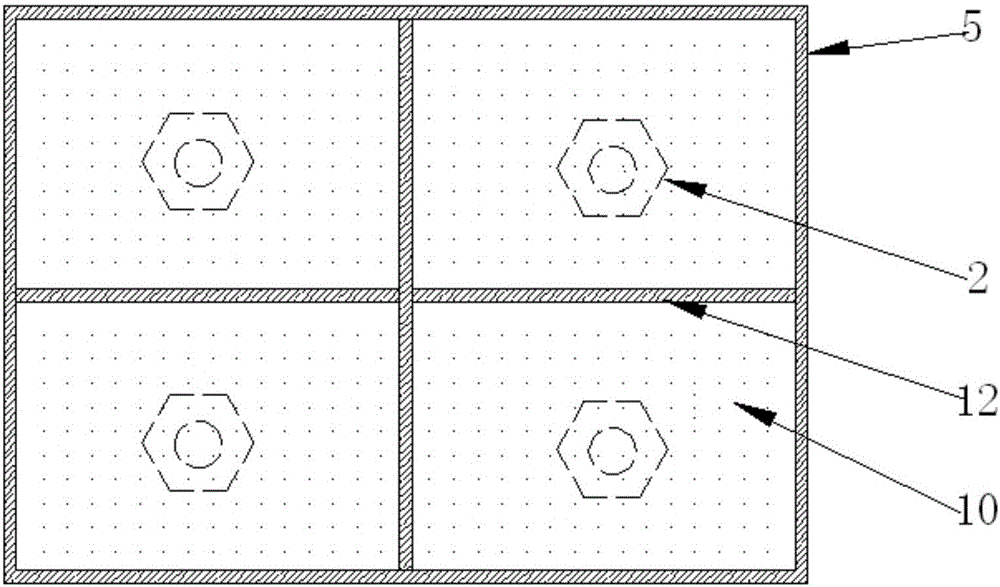

Composite dot-matrix interlayer double-skin cylindrical shell structure with metal liner for bearing inner pressure and preparation process thereof

ActiveCN107891634AHigh precisionReduce defectsSynthetic resin layered productsLaminationWinding machineFiber

The invention discloses a composite dot-matrix interlayer double-skin cylindrical shell structure with a metal liner for bearing inner pressure and a preparation process thereof, and relates to a preparation process of lightweight pressure bearing containers and pipelines with high automation level and large size. The preparation process of the structure aims at solving the problems that organic integration of high intensity, high rigidity and light weight cannot be well achieved on existing composite cylindrical shells, conventional preparation processes are complex, and batched production oflarge-scale structures is not achieved easily. The adopted preparation process includes the steps that the metal liner is wound with preset cellosilk on a winding machine to form an inner skin; a dot-matrix interlay core containing foam strips and corrugated ribs is laid; the outer wall of the dot-matrix interlayer core is wound with preset cellosilk to form the outer skin; the structure is placed in a solidifying stove for solidification to prepare the composite dot-matrix interlayer double-skin cylindrical shell structure with the metal liner.

Owner:NANJING UNIV OF TECH

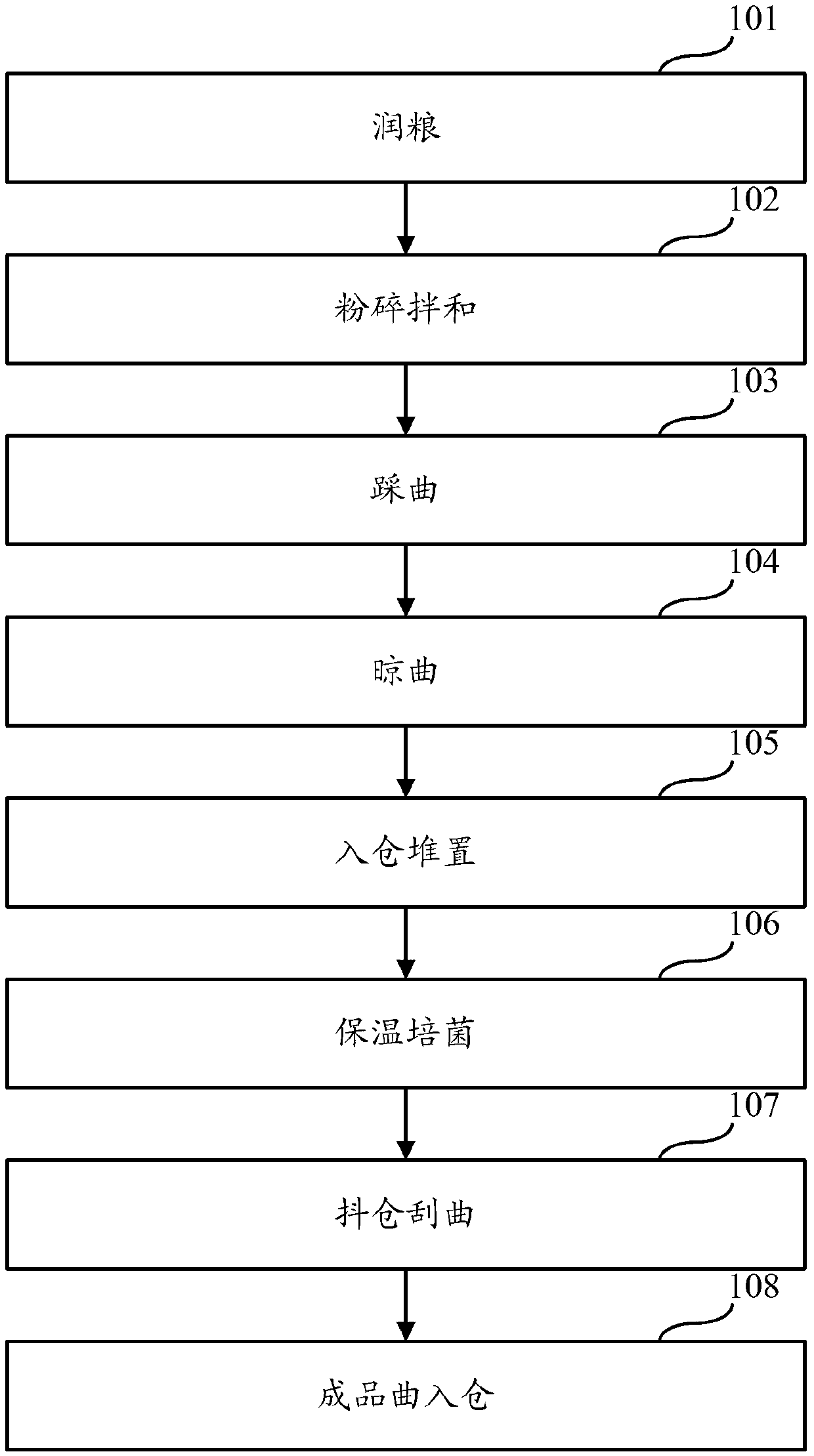

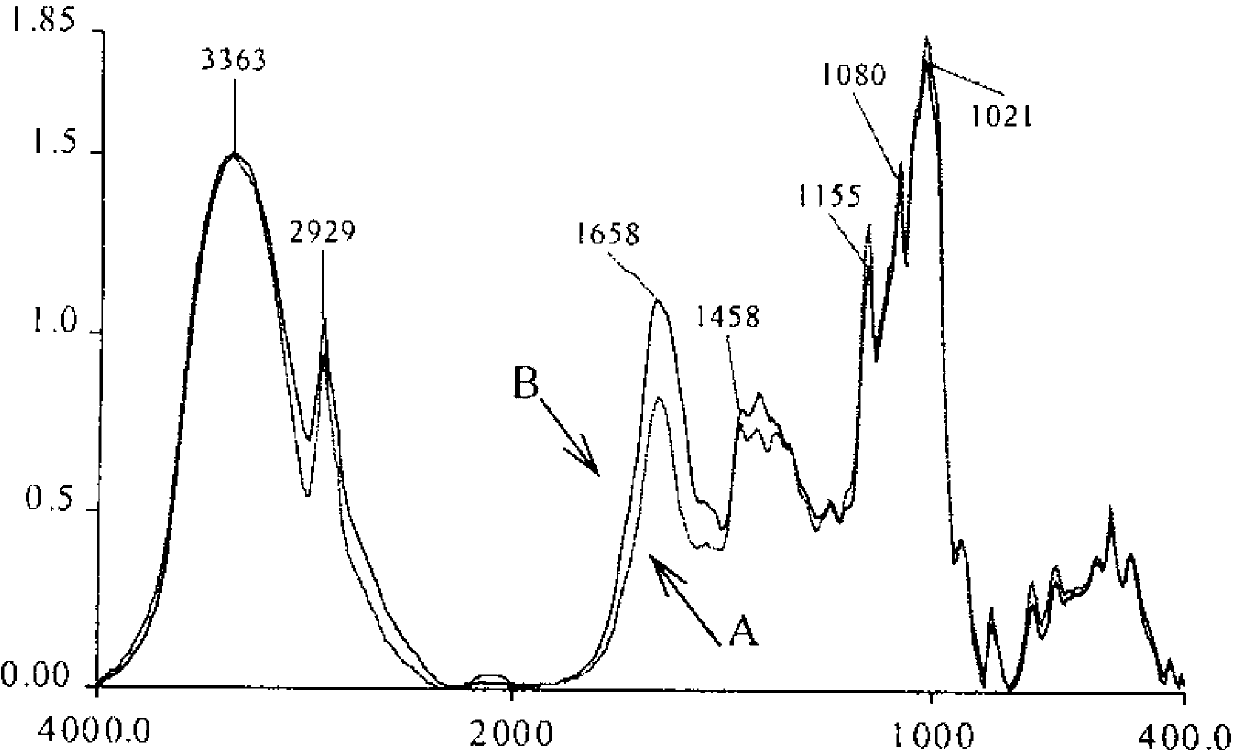

Preparation method of ultrahigh-temperature yeast for making hard liquor

InactiveCN103013764ASoak evenlyPromote fermentationAlcoholic beverage preparationNutritive valuesYeast

The invention discloses a preparation method of ultrahigh-temperature yeast for making hard liquor. The preparation method comprises the steps of moistening grains, crushing and blending, stamping yeast, drying yeast, warehousing for stacking, conducting heat-insulation cultivation and shaking bin and scraping yeast. The preparation method is characterized in that in the grain moistening step, water with the amount being 8-12% of the total weight of raw materials is added into the raw materials, the moistening time is 15-25 hours; and in the crushing and blending process, adding base yeast with the amount being 5-8% of the total weight of the raw materials into the moistened raw materials. The ultrahigh-temperature yeast prepared by the preparation method of the ultrahigh-temperature yeast, the yeast preparing temperature can exceed 65 DEG C to reach to 70 DEG C and even reach to 72 DEG C; more protease and microbial flora are contained, the final finished liquor prepared by the yeast for making hard liquor is high in nutritive value, soft in mouthfeel, and rich and dense in fragrance and taste.

Owner:SICHUAN LANGJIU GROUP

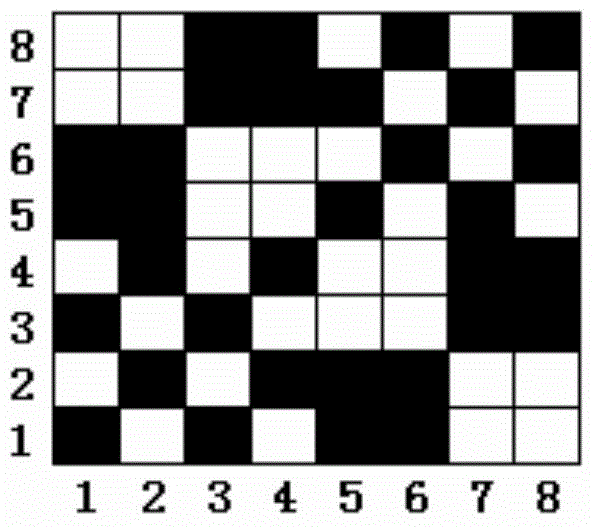

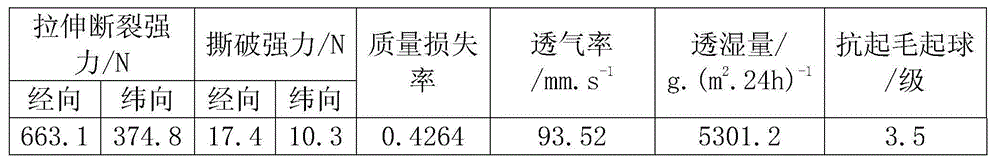

Production technology of mini-jacquard weft elastic yarn-dyed fabric made of aloe fiber

ActiveCN104947285AColors are bright without being flashyRaise the gradeSingeingSeaming textilesFiberYarn

The invention discloses a production technology of mini-jacquard weft elastic yarn-dyed fabric made of aloe fiber. The production technology comprises steps as follows: winding, warping, sizing, weaving and finishing, wherein the finishing comprises steps as follows: fabric inspection, fabric turning, sewing, singeing, desizing, setting, preshrinking and plaiting. The specification, the style and the dyed yarn arrangement of the mini-jacquard weft elastic yarn-dyed fabric made of the aloe fiber are designed, winding, warping, sizing, weaving and finishing processes are optimized, the production efficiency is up to 92%, and the rate of first-grade goods put in storage is up to 98%.

Owner:IANGSU COLLEGE OF ENG & TECH

High-frequency Welding method

A high-frequency weld method for welding copper pipe with jointer includes such steps as making slots on the external surface of jointer, winding the welding wire in the slot, coating flux, inserting part of jointer in said copper pipe, fixing said copper pipe by fixture, and high-frequency heating.

Owner:CHINA FANGDA GROUP CO LTD

Tea making combined utensil

The invention discloses a tea making combined utensil, which comprises a tea making seat and a tea making utensil, wherein an electric heater is arranged on the tea making seat, the top of the tea making seat is provided with a water outlet nozzle, the lower part of the tea making utensil is provided with a water inlet matched with the water outlet nozzle, and a check valve is arranged at the water inlet. According to the tea making combined utensil, the top of the tea making seat is provided with the water outlet nozzle, the lower part of the tea making utensil is provided with the water inlet, and the check valve is arranged at the water inlet, so that the boiled water enters the lower part of the tea making utensil from the water outlet nozzle through the water inlet and the check valve; because the tea leaves are put at the bottom of the tea making utensil and the boiled water enters from the lower part of the tea making utensil, the tea leaves are writhed all the time, the tea leaves are uniformly soaked, and the mouthfeel effect of the tea is improved; because the water outlet nozzle is short and is arranged on the top, the aesthetic feeling of the appearance is not affected, and the tea making combined utensil is suitable to be used in the fields of office table tops, dining tables and the like; and because the check valve is arranged at the water inlet of the tea making utensil, the boiled water enters from the check valve (the lower part of the utensil), namely the entering process of the boiled water is 'closed', the defect that scald is easily caused because the boiled water needs to enter from the top of the utensil (equivalently 'open water') in the past is overcome, and a child lock is not needed.

Owner:罗伟林

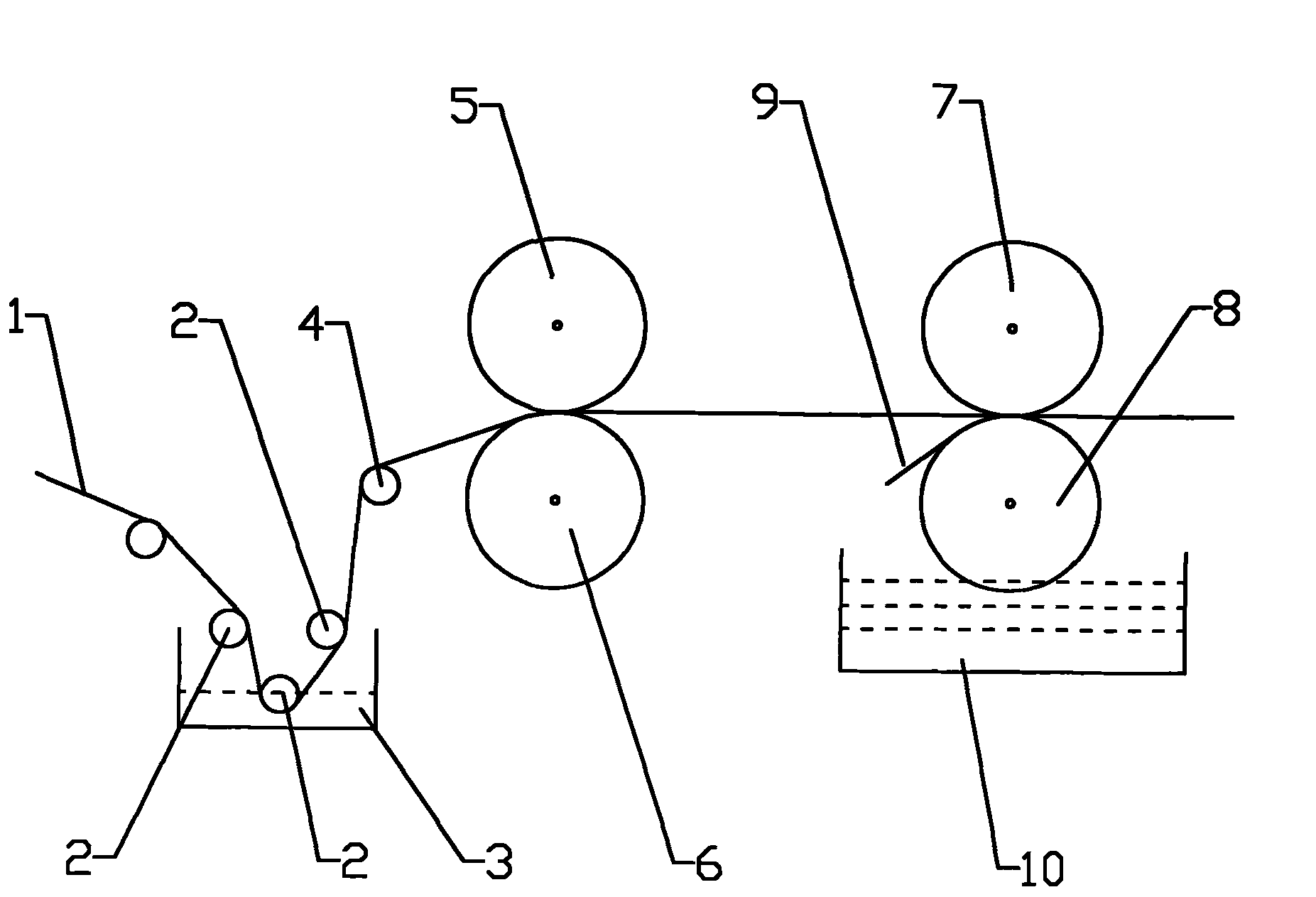

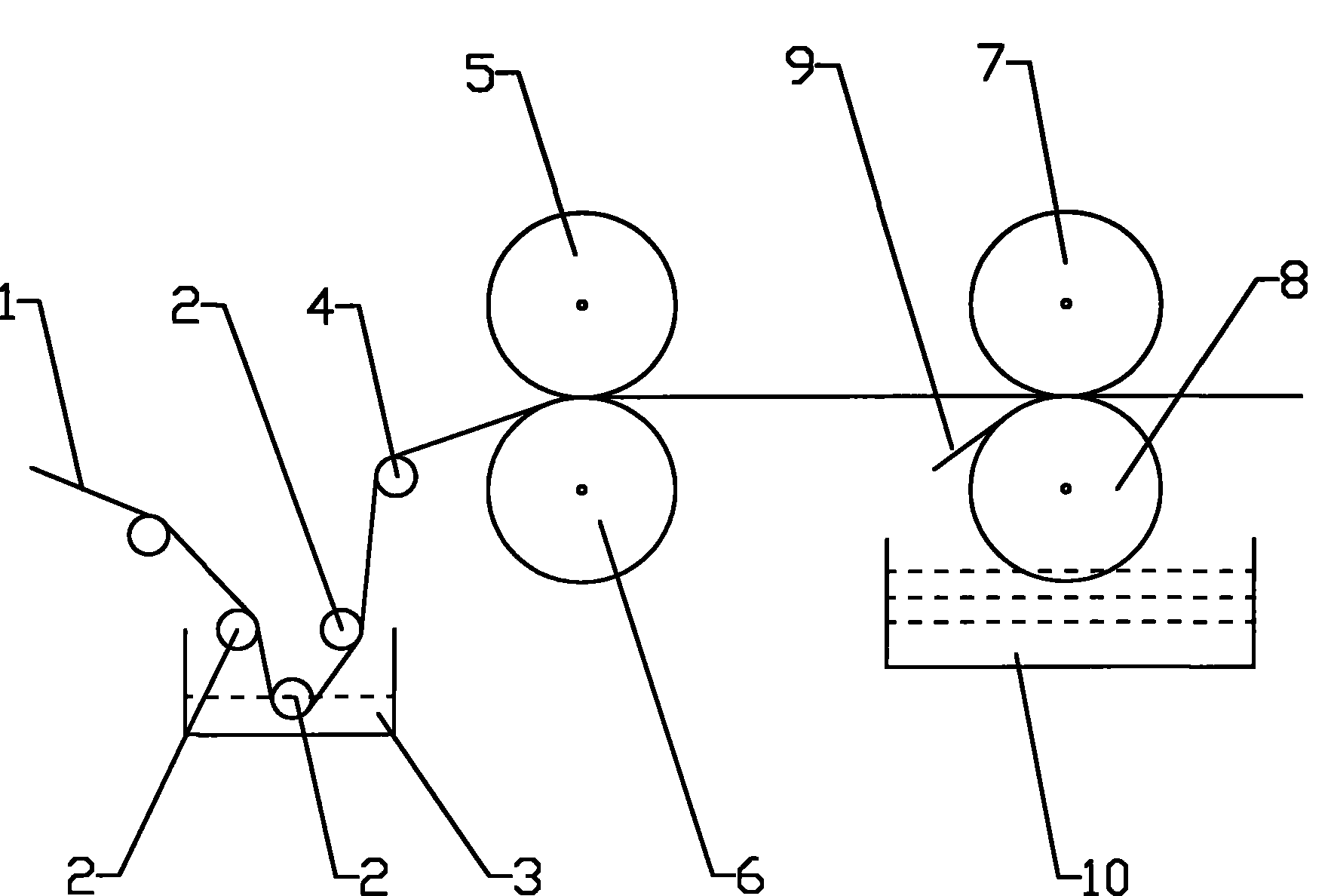

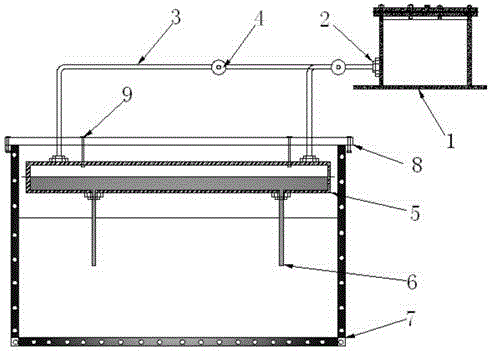

Continuous production method and equipment for composite type sleeper

The invention provides a continuous production method for a composite type sleeper. The continuous production method comprises the following four procedures: (1) spreading: enabling spread glass fiber woven fabric to pass through a supporting-spreading mechanism; (2) soaking: uniformly spraying polyurethane resin on the surface of the glass fiber woven fabric, and then enabling the glass fiber woven fabric to pass through pair rolls, thus forming a flat surface; (3) winding: winding the glass fiber woven fabric on the outer surface of a sleeper inner core, shearing off the glass fiber woven fabric and placing the sheared glass fiber woven fabric in a mold; and (4) molding: aging the polyurethane resin in the mold, removing the mold after the aging is ended, thus obtaining the composite type sleeper. The invention also provides continuous production equipment for the composite type sleeper. The interlayer shearing force of the sleeper produced by the method is cannot be damaged easily, the polyurethane resin in the outer surface of the sleeper produced by the method is distributed uniformly, and continuous and automatic production is realized by virtue of the method.

Owner:BEIJING PANTIAN NEW TECH

Wood processing treatment integrated system and treatment method thereof

ActiveCN108501124AAvoid damageHigh degree of automationWood treatment detailsProfiling/shaping machinesThermal insulationIntegrated systems

The invention discloses a wood processing treatment integrated system. The system comprises wood sectional acquisition equipment, wood thermal insulation and moisturizing transportation equipment, wood collision preventing storage equipment, automatic temperature-adjusting wood soaking equipment, layered freezing equipment, wood standing and drying equipment, end part oiling sealing equipment andwood section slitting equipment. The invention also discloses the wood processing treatment integrated system and a treatment method thereof. The automation degree is high, wood cannot be damaged, thesystem and the method have broad market competitiveness, the wood quality can be effectively guaranteed, atmosphere pollution is avoided, the production cost is saved, and the production environmentis effectively improved.

Owner:新沂市超华木业有限公司

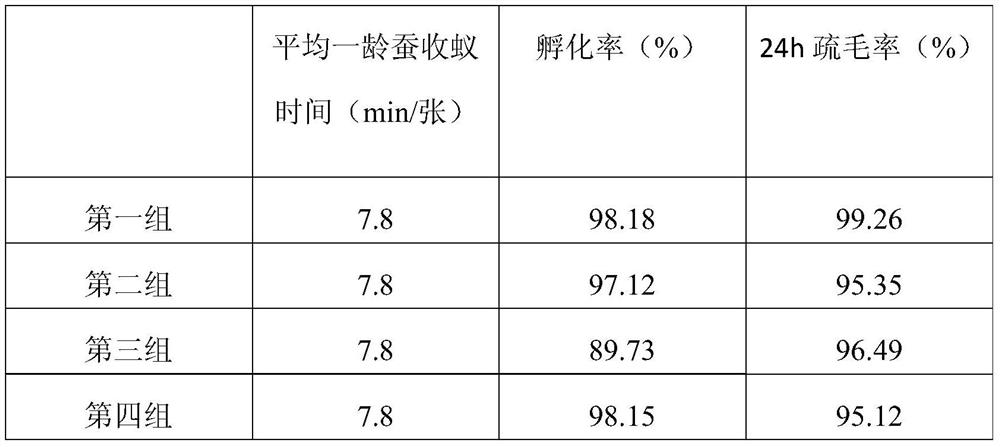

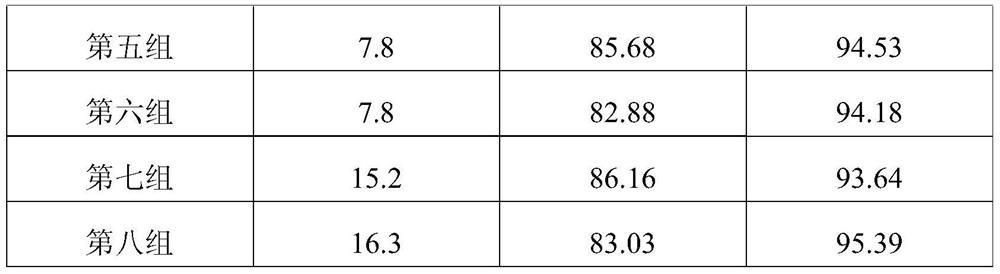

Simple newly-hatched silkworm brushing off method for silkworm artificial feed breeding

ActiveCN112273339AAnt fastAvoid damageAnimal feeding stuffAccessory food factorsAnimal scienceFishery

The invention relates to the technical field of home textiles, in particular to a simple newly-hatched silkworm brushing off method for silkworm artificial feed breeding. The simple newly-hatched silkworm brushing off method for silkworm artificial feed breeding comprises the following steps of (1) silkworm egg incubation; (2) silkworm egg scattering and disinfecting; (3) egg amount weighing and zoning; (4) feed treatment; (5), light sensing for newly-hatched silkworm brushing off; and (6) light supplementing and temperatuer rising. On the basis of feed breeding, starting from each technical link of newly-hatched silkworm brushing off according to physiological development characteristics of silkworms, by combining manners of optimizing temperature and humidity control, feed pretreatment,light supplement and temperature supplement in each stage of loose egg incubation, directly scattering loose eggs on the feed during artificial feed breeding, irradiating with an LED yellow warm lightlamp and the like, the method achieves the effects of one-time quick, labor-saving and efficient newly-hatched silkworm brushing off, is suitable for mechanical newly-hatched silkworm brushing off, and provides technical support for large-scale young silkworm artificial feed breeding.

Owner:来宾市农业科学院

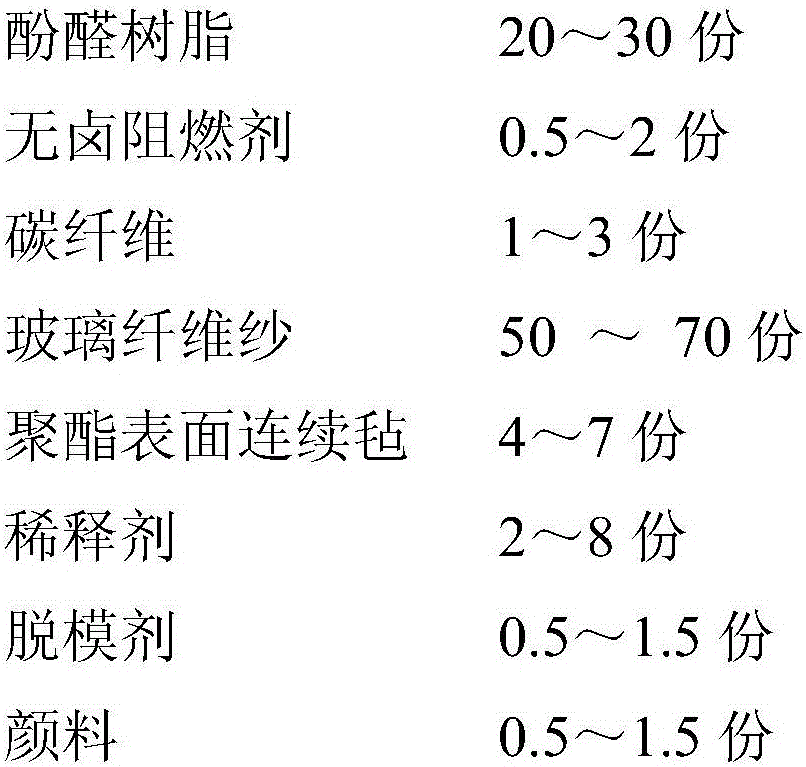

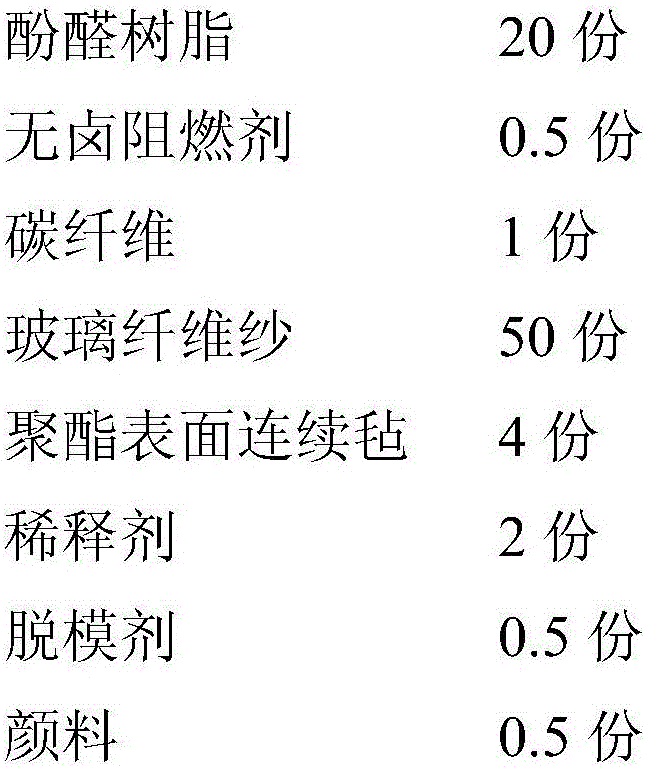

Bakelite corrugated board made of preliminarily woven components with flow guide layers and method for manufacturing bakelite corrugated board

The invention discloses a bakelite corrugated board made of preliminarily woven components with flow guide layers. Phenolic resin is used as matrix resin of the bakelite corrugated board. The preliminarily woven components with the flow guide layers comprise glass mats laid in a layered manner, fiber cloth for the flow guide layers and interlayer continuous fibers, the fiber cloth for the flow guide layers is positioned in middle layers of the glass mats laid in the layered manner, and the glass mats laid in the layered manner are sewn with the fiber cloth for the flow guide layers by the interlayer continuous fibers. The bakelite corrugated board has the advantages that A-grade fireproof nonmetal high-strength corrosion-resistant effects can be realized by the bakelite corrugated board, and the bakelite corrugated board can be widely applied to roofs or wall surfaces of steel structures.

Owner:SUZHOU ZHENRUICHANG MATERIAL TECH CO LTD

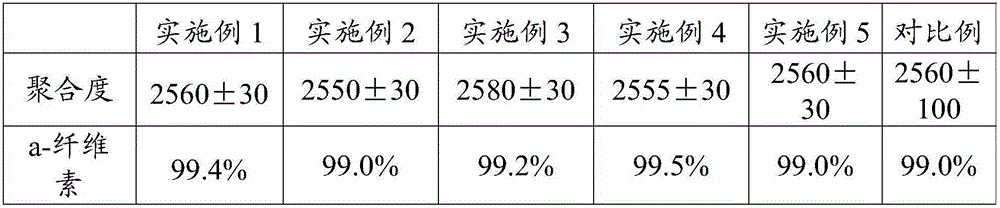

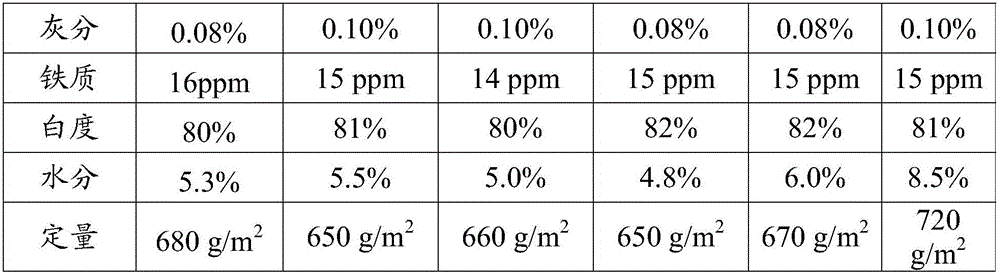

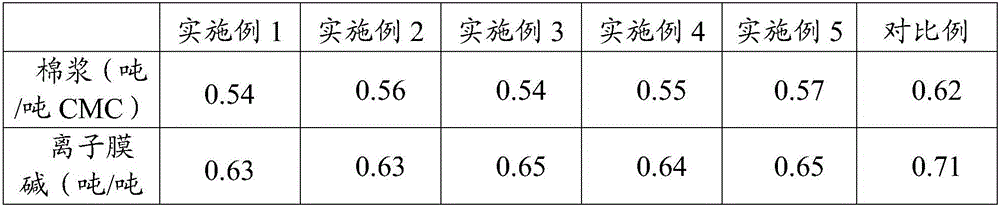

Cotton pulp and preparation method thereof, as well as carboxymethylcellulose and preparation method thereof

ActiveCN105821701AQuality improvementHigh reactivityPulping with inorganic basesNon-woody plant/crop pulpCarboxymethyl celluloseCotton fibre

The invention provides a preparation method of cotton pulp. The method comprises the following steps: mixing alkali liquor and cotton linters subjected to impurity removal, and performing continuous boiling, washing, pulping, degritting, primary concentration, chlorine alkalization, bleaching, acid treatment, water washing, degritting, secondary concentration and papermaking, so as to obtain the cotton pulp. The mass ratio of alkali in the alkali liquor to the absolute-dry cotton linters is (13 to 15): 100; the temperature for continuous boiling is 108 to 115 DEG C; the period for continuous boiling is 55 to 65min. According to the method, cotton pulp is prepared through a high alkali content, low temperature and short time continuous coiling mode, materials are uniformly heated in a tube, uniform permeation of alkali liquor is achieved, and the product polymerization degree is uniform; cotton fiber primary walls and secondary walls can be destroyed furthest, so that the degree of crystallinity of cotton pulp fiber is reduced, the amorphous region rises, and the reaction activity of the cotton pulp is improved. Through the adoption of the cotton pulp with high reaction activity, high-quality carboxymethylcellulose can be prepared.

Owner:ANHUI SNOW DRAGON FIBER TECH

Equipment for producing printed spunlaced non-woven fabric

The invention relates to equipment for producing a printed spunlaced non-woven fabric. The equipment comprises an immersing device, a squeezing machine and a printing device. The immersing device comprises an immersing tank and a guide roll, wherein the guide roll is arranged in the immersing tank; slurry is contained in the immersing tank; and the guide roll is immersed in the slurry. The squeezing machine comprises an upper squeezing roll and a lower squeezing roll, wherein the central axes of the upper squeezing roll and the lower squeezing roll are parallel and the peripheries of the upper squeezing roll and the lower squeezing roll are tangential to each other. The printing device comprises a rubber roll and a printing roll which are arranged up and down; the central axes of the rubber roll and the printing roll are parallel; the peripheries of the rubber roll and the printing roll are tangential to each other; patterns are carved on the periphery of the printing roll; a slurry tank is arranged below the printing roll; the slurry is contained in the slurry tank; and a part of the printing roll is immersed in the slurry. After flowing through the immersing device, excessive slurry is discharged; and through the squeezing machine, the two surfaces of the spunlaced non-woven fabric are printed. The conformity of the patterns on the two surfaces is improved and the malposition of the patterns is avoided.

Owner:CHTC HELON

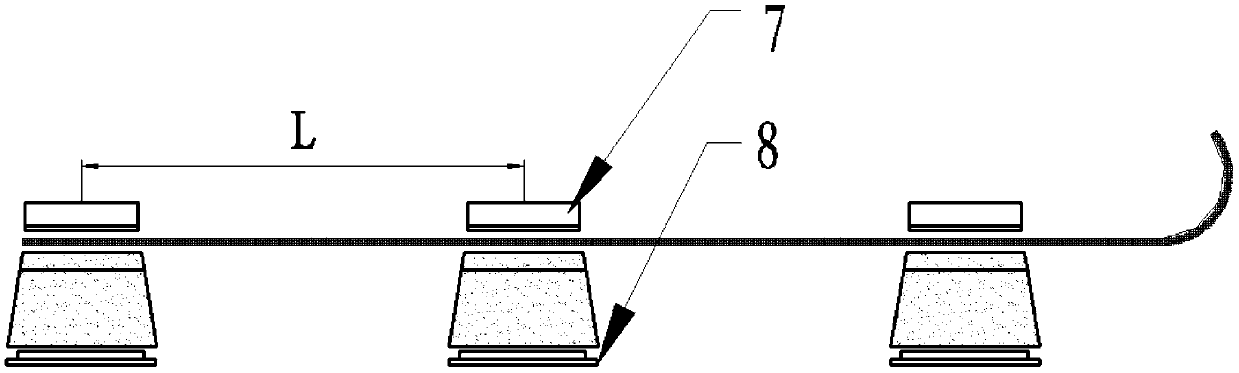

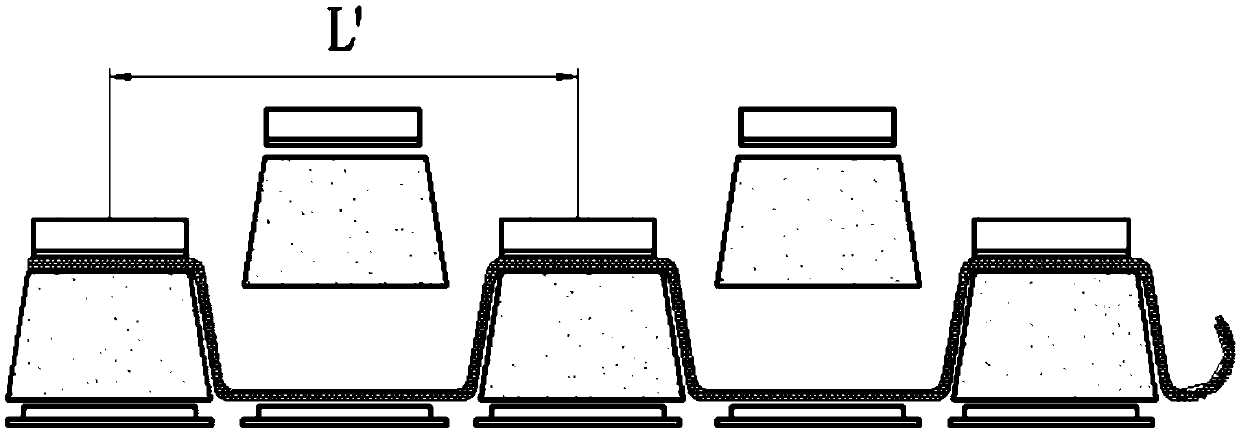

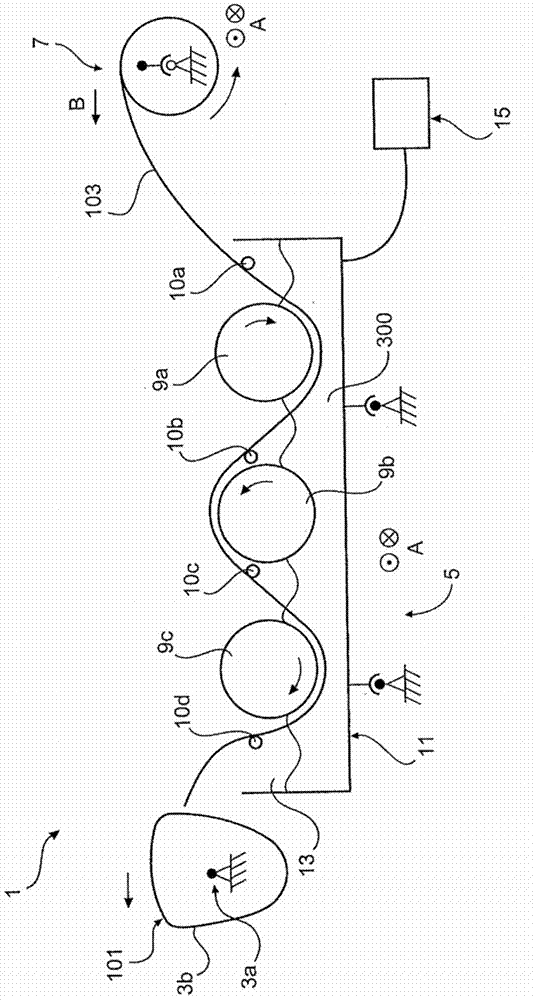

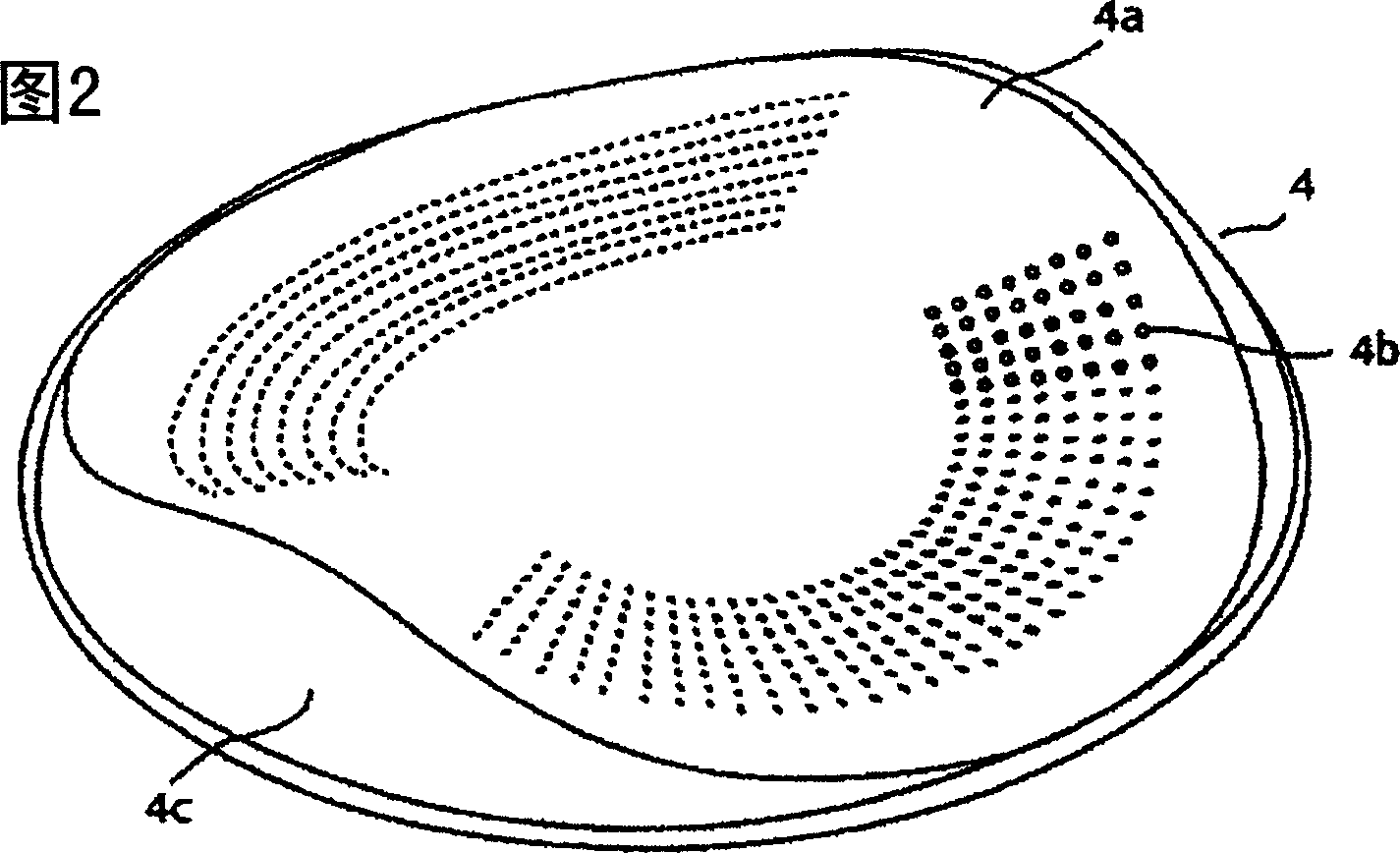

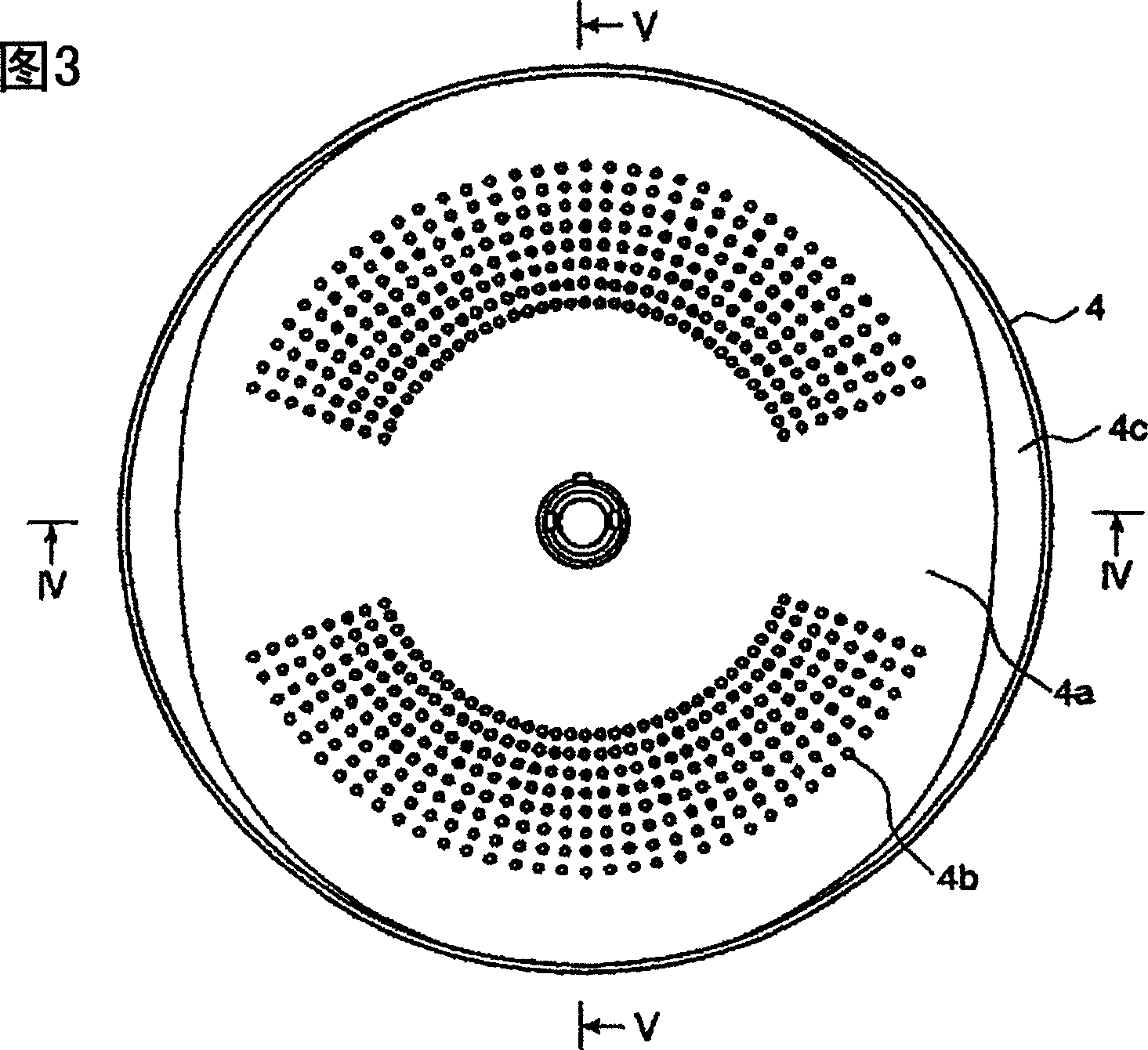

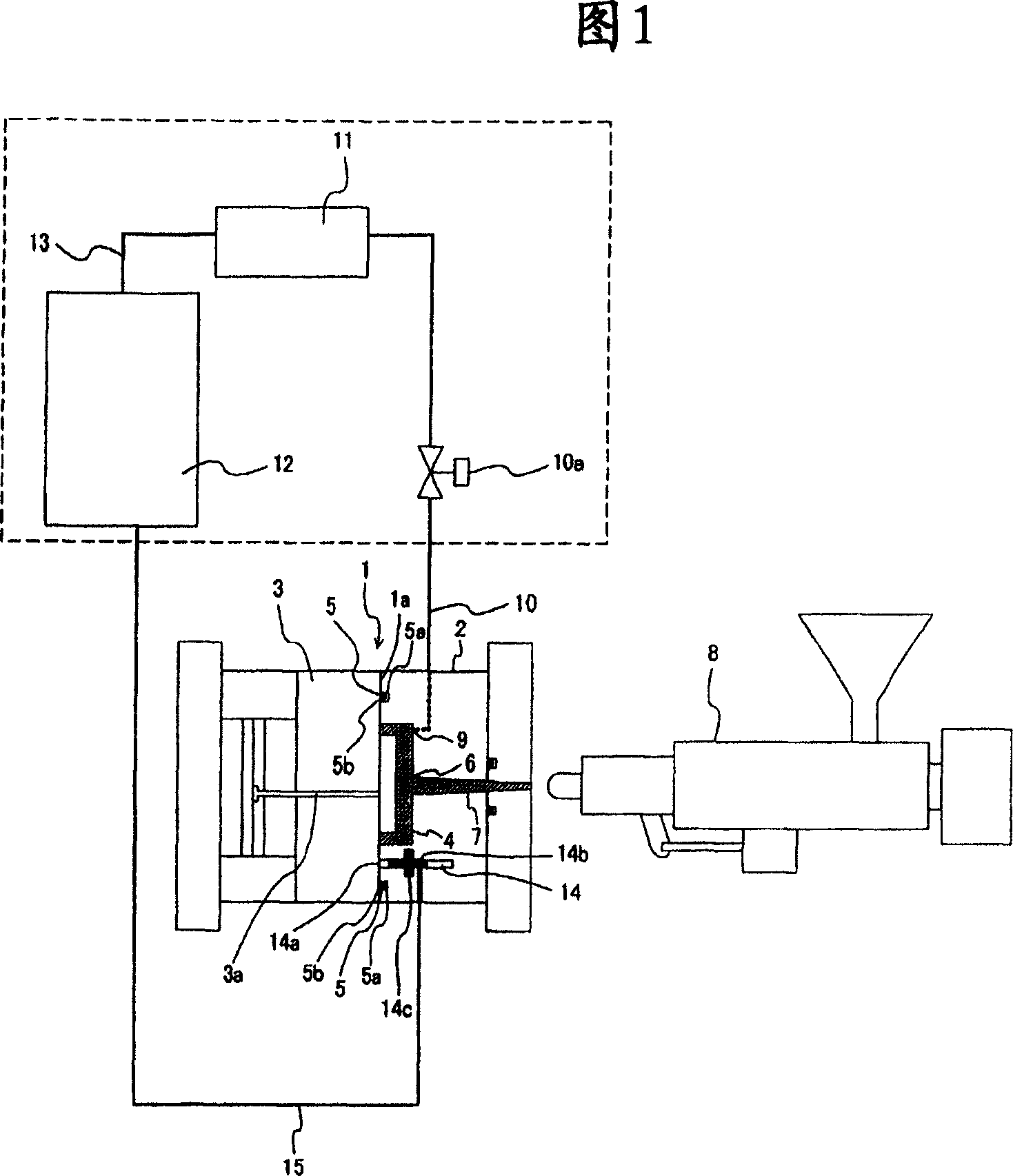

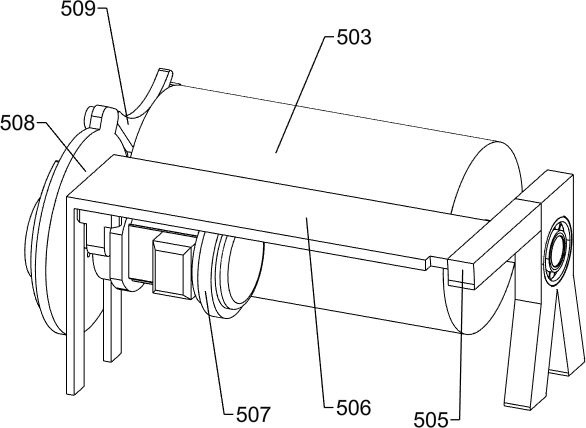

Device and method for producing semifinished products for wind power system rotor blades and rotor blade and wind energy system produced therewith

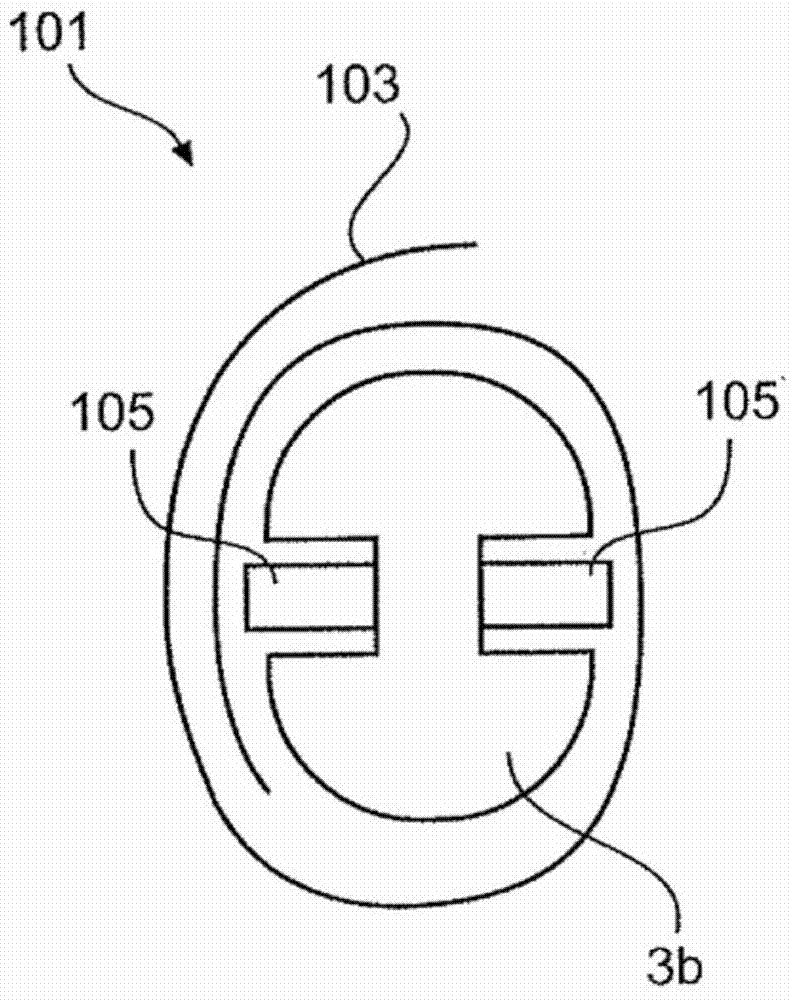

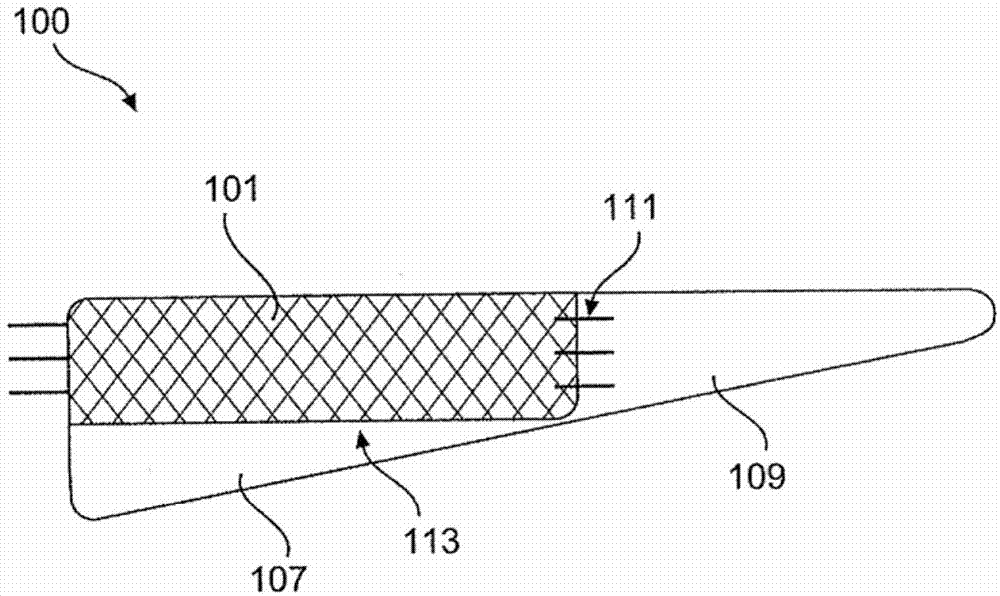

ActiveCN104812552ASoak evenlyFinal product manufactureFilament handlingWork in processWind power system

The invention relates to a device (1) for producing blade end semifinished products (101) for wind power system rotor blades (100), with a winding mandrel (3a), which can be rotated to wind up preferably strip-shaped, fibre composite material. According to the invention it is proposed that an impregnation system (5) which can be traversed along the winding mandrel for the impregnation of the fibre composite material before rewinding around the winding mandrel is a magazine device (7) for providing the fibre composite material which can be moved along the winding mandrel, preferably synchronously with the impregnation device.

Owner:WOBBEN PROPERTIES GMBH

Shrinkage setting machine for textile fabric production

ActiveCN112176615AReduce tensionThe effect of soaking the setting agent is goodHeating/cooling textile fabricsStretchingTextile technologyAir compression

The invention relates to the technical field of textile, and discloses a shrinkage setting machine for textile cloth production. The shrinkage setting machine comprises a first support, an air compression assembly and an exhaust assembly, the back surface of the first support is movably connected with a winding reel, the inner wall of the first support is provided with a first sliding groove, andthe inner wall of the first sliding groove is movably connected with a lower compression roller; and a second support is fixedly installed at the top end of the first support. According to the shrinkage setting machine for textile cloth production, through cooperative use of a second roller and a fourth roller, when cloth is conveyed in a third roller to be soaked in a setting agent, if the clothis loosened, the rotating speed of the second roller is increased, and the frequency of extruding a pressing plate by a rotating rod is increased, so that the amount of air entering an air conveying pipe is increased; and the air is increased, the exhaust rate of the air in an inner ring is constant, and redundant air enters a guide pipe, so that a telescopic pipe is stretched, the fourth roller is pushed to move leftwards, the tension degree of cloth is increased, and the effect of soaking the cloth in the setting agent is better.

Owner:稷山县唐晋新材料科技有限公司

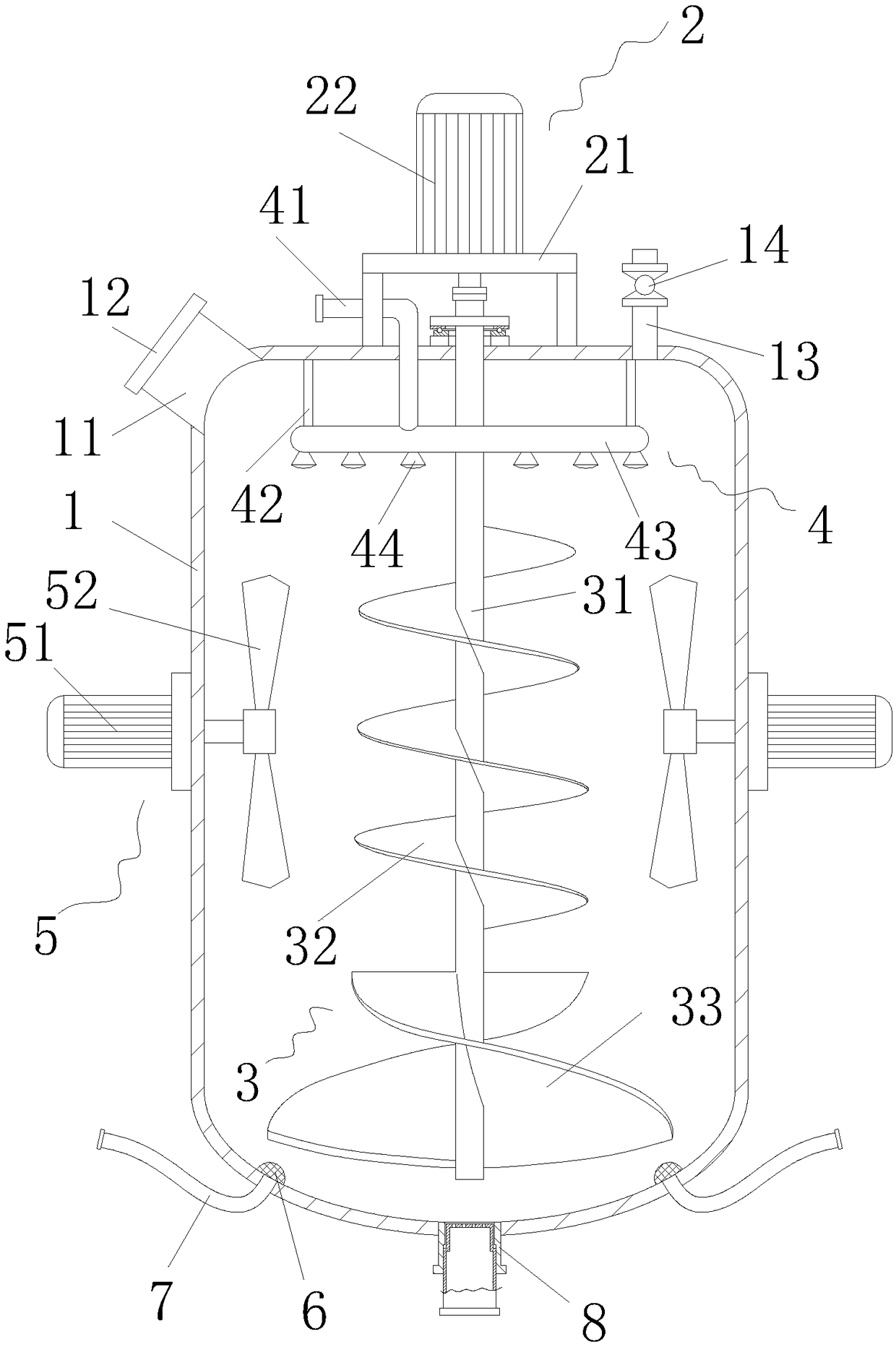

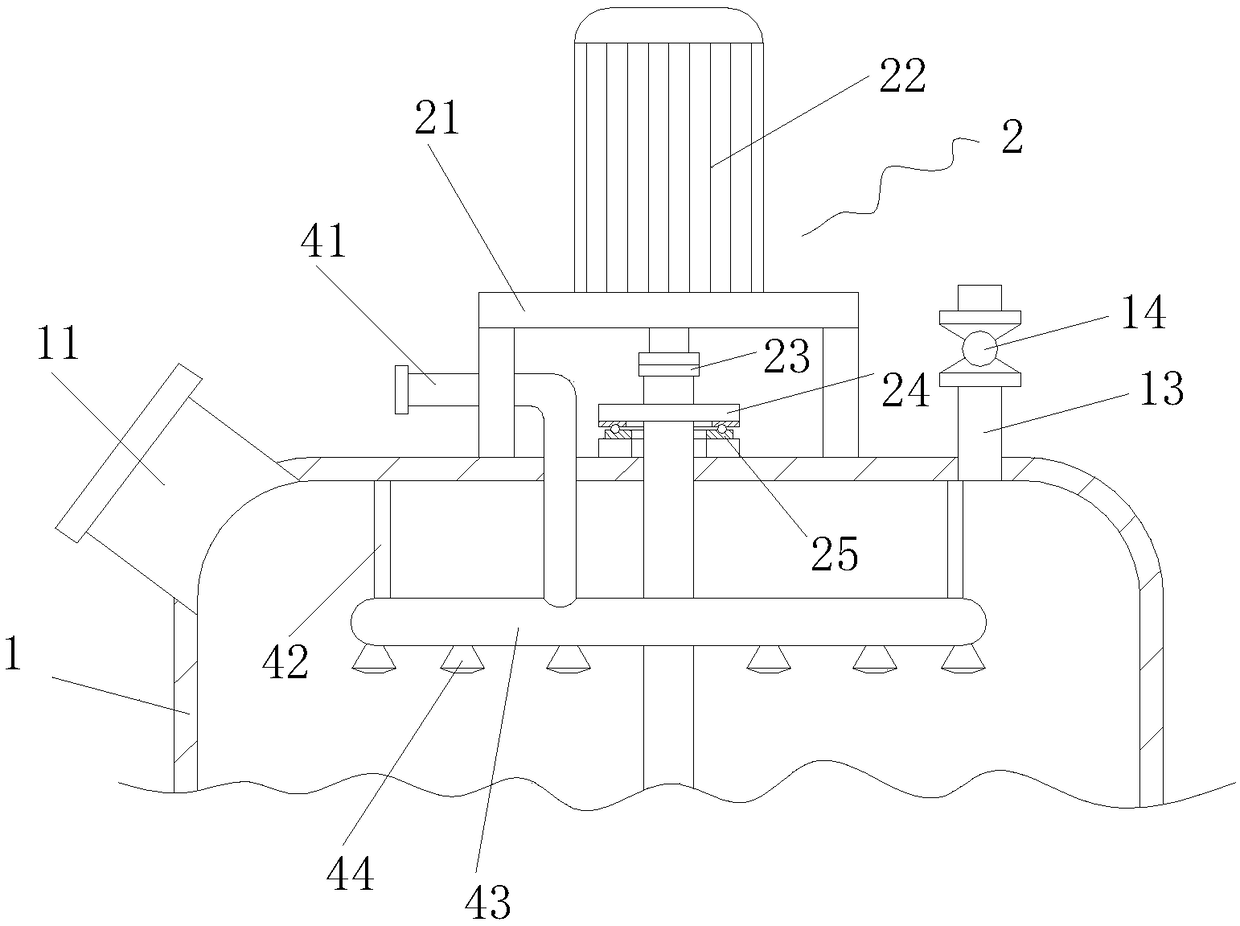

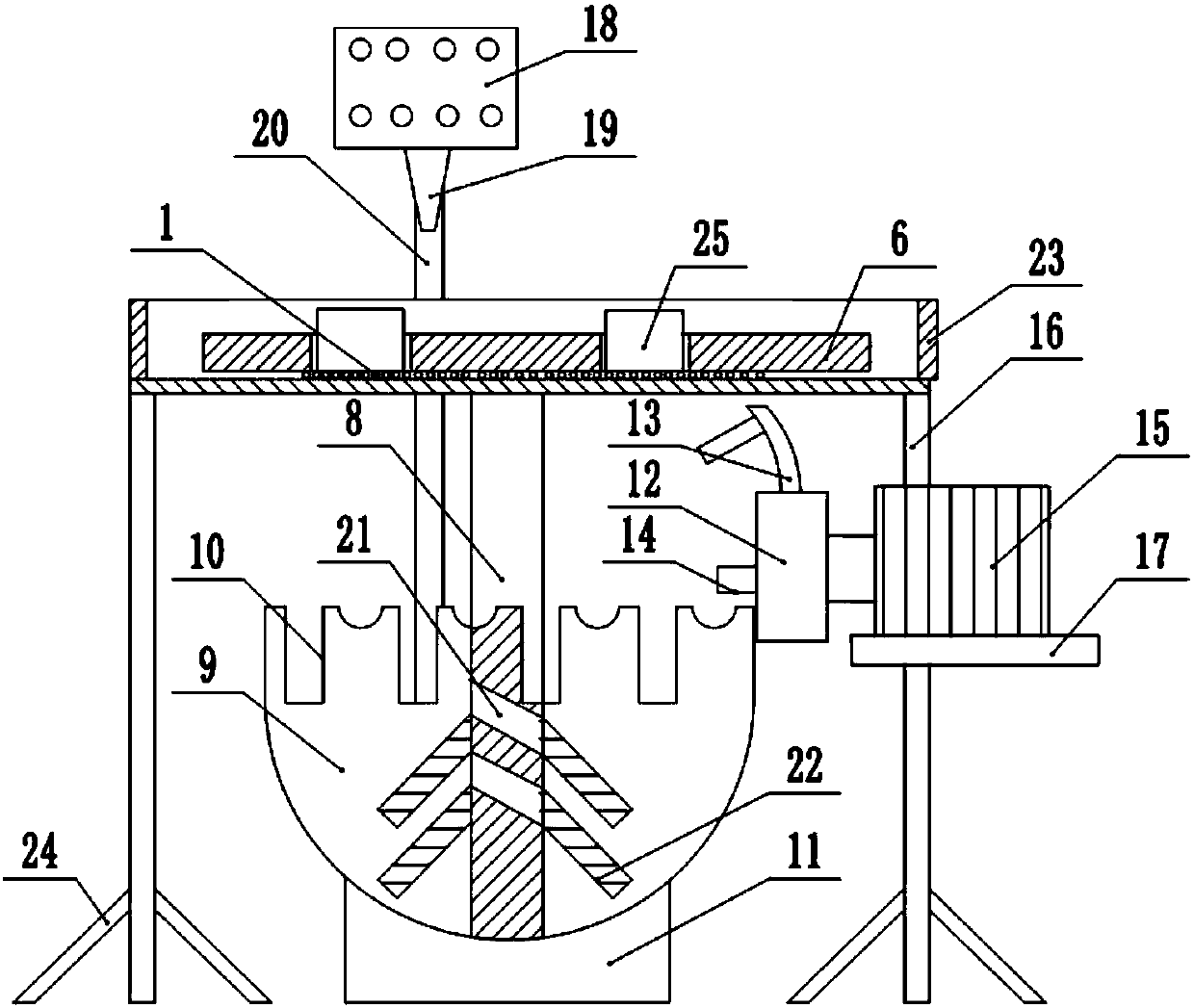

Raw material cooking apparatus for producing soy sauce

The invention discloses a raw material cooking apparatus for producing soy sauce. The raw material cooking apparatus comprises a cooking pot body, wherein a spiral stirring apparatus for stirring a raw material up and down is installed inside the cooking pot body, the top of the cooking pot body is provided with an overturning driving mechanism for driving the spiral stirring apparatus, the upperend of the cooking pot body is provided with a feeding pipe orifice and a pressure relief pipe, the feeding pipe orifice is provided with a feeding sealing cover, the pressure relief pipe is providedwith a safety valve, the inner lower end of the cooking pot body is circumferentially provided with a plurality of steam heads, the steam heads are connected with a steam conveying pipe extending outof the cooking pot body, the bottom of the cooking pot body is provided with an unloading pipe orifice, and the unloading pipe orifice is provided with a filtering apparatus for discharging the washing water and impurities. The raw material cooking apparatus is reasonable in structure layout, integrates the soaking and cooking, facilitates the reduction of treatment time of the raw material, and can improve the subsequent production efficiency of the soy sauce.

Owner:安徽朱隆记食品有限公司

Soybean immersing machine capable of conveniently adjusting temperature

InactiveCN106212259AGuaranteed temperatureAffect developmentAgriculture gas emission reductionCultivating equipmentsCouplingHeat conducting

The invention discloses a soybean immersing machine capable of conveniently adjusting temperature. The soybean immersing machine comprises a box body; a controller is arranged at one side of the box body; a motor is arranged at the top of the box body; an output shaft of the motor penetrates through a top plate of the box body and extends into the box body; the output shaft of the motor is connected with a control rod through a shaft coupler; a first placement plate is arranged at the middle of the control rod; a second placement plate is arranged at the bottom of the control rod; a water storage tank is arranged at the bottom of an inner cavity of the box body; a heat conducting plate is arranged in the water storage tank; a heating chamber is formed in a lower side of the heat conducting plate; electric heating plates are arranged in the heating chamber; water pumps are arranged at two sides of the box body. The soybean immersing machine can be used for simultaneously immersing soybeans with different types in time and the quality of bean sprouts is guaranteed; time can be saved and production benefits are improved; the soybeans can be at a moving state all the time and are prevented from being stacked together, so that the soybeans are immersed more uniformly, later-period development of the soybeans is facilitated and the utilization is more convenient.

Owner:WUXI SUYA FOOD CO LTD

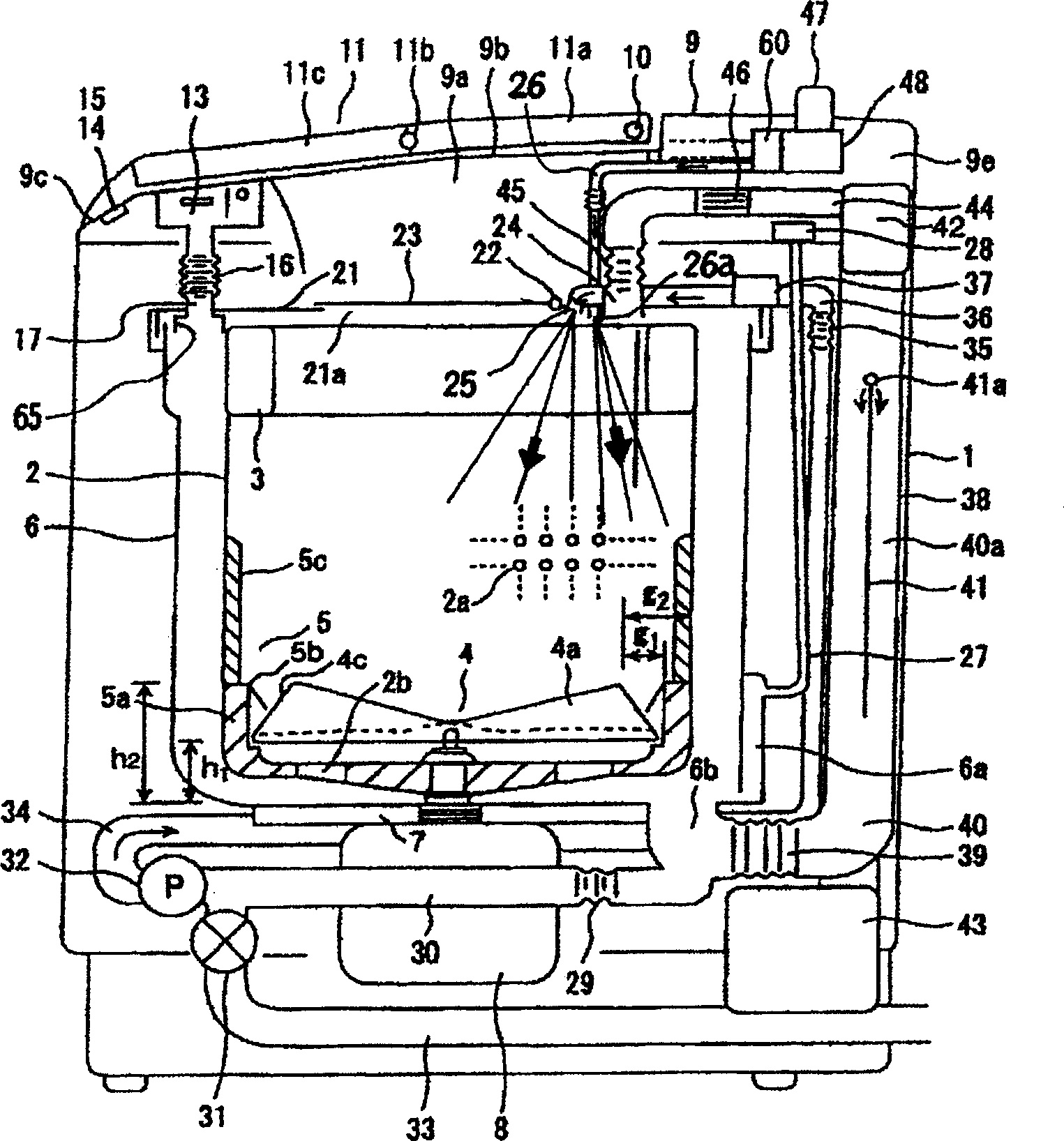

Washer and dryer

ActiveCN1880545AImprove chemical performanceIncrease temperatureControl devices for washing apparatusWashing machine with receptaclesWater savingImpeller

An object of the present invention is to provide a washing and drying machine capable of saving water and obtaining high cleaning power. It sprinkles the washing water with high detergent concentration in the inner cylinder (2), and while soaking the laundry, discharges the washing water from the bottom of the outer cylinder (6) to form a reliable air passage for the air circulation mechanism, while letting the pulsating impeller (4) Make forward and reverse rotation, while using the electric air blower (43) to suck the air in the outer cylinder, and blow the hot air heated by the PTC heater (46) into the inner cylinder to improve the washing and soaking. The temperature of the washing water in the laundry, and then supply water so that the water is accumulated at the bottom of the above-mentioned outer cylinder, and the washing water is kept at a water level not exceeding the above-mentioned pulsating impeller, and then, while allowing the washing water accumulated at the bottom of the above-mentioned outer cylinder The water is circulated, and it is sprinkled on the laundry on the above-mentioned pulsating impeller, while the above-mentioned pulsating impeller is rotated positively and negatively, to implement the washing that the upward force is repeatedly applied to the laundry by the pulsating impeller.

Owner:HITACHI HOME & LIFE SOLUTIONS INC

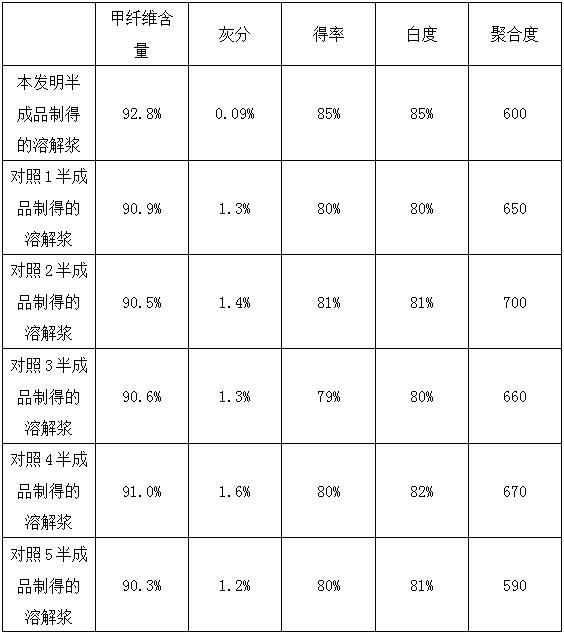

Material preparation process suitable for utilizing unbleached wood pulp to prepare dissolving pulp in modified mode

InactiveCN102677500AMonotonous performanceUniform shapePretreatment with alkaline reacting compoundsRaw material divisionFiberMaterials preparation

The invention discloses a material preparation process suitable for utilizing unbleached wood pulp to prepare dissolving pulp in a modified mode. The process comprises procedures of raw material preparation, dispersion, slicing, impregnation and the like. Specific to unbleached wood pulp raw materials, special process steps and process control parameters are utilized so that the purposes of improving quality of end products, energy saving and emission reduction can be achieved, armour fiber content, yield and whiteness of the end products can be improved, ash content of the end products is reduced, cost control of chemical liquid drug is facilitated, the curve of temperature rising in the follow-up cooking process is stable, poly reduction is even, prepared semi-finished products are suitable for various cooking modes, and the material preparation process has a wide application range.

Owner:YIBIN GRACE GROUP CO LTD

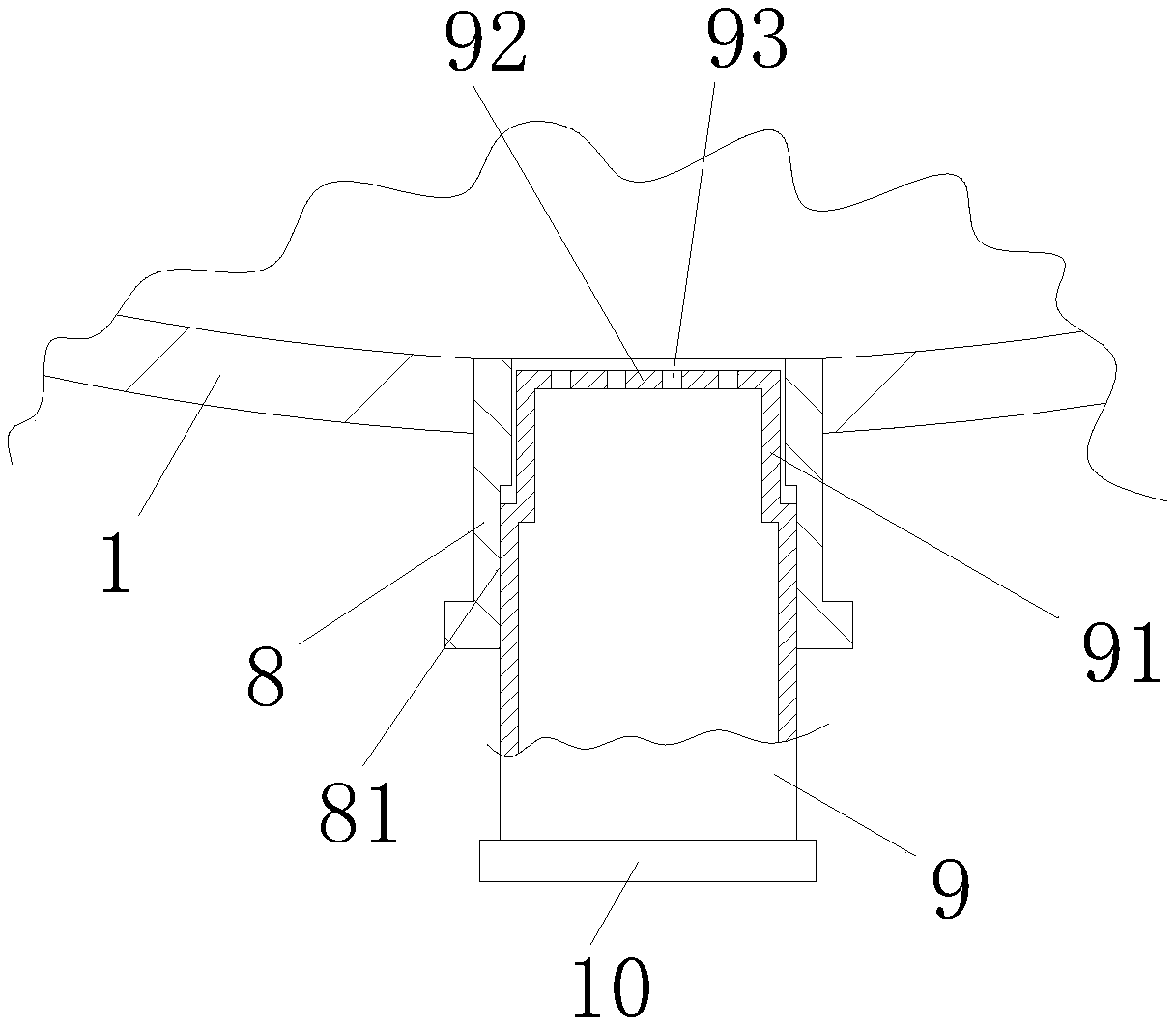

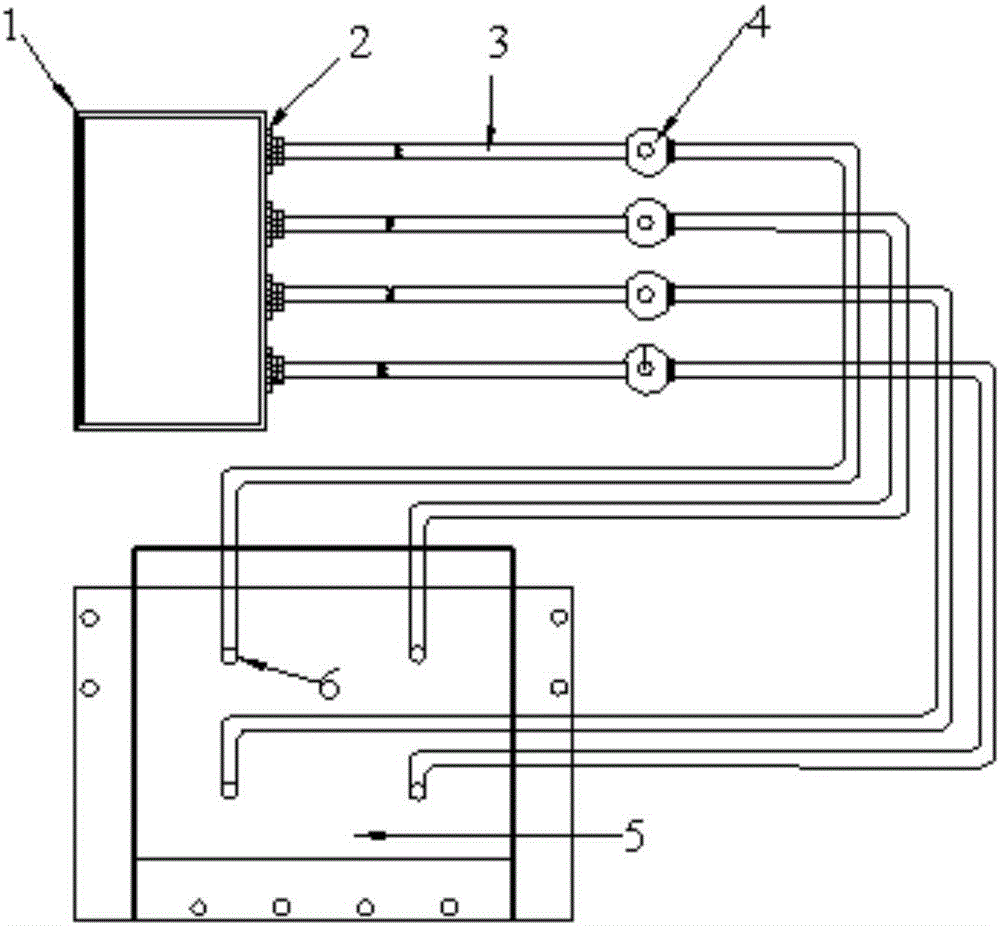

Water immersion system for centrifugal model test and test method

The invention discloses a water immersion system for a centrifugal model test and a test method. Requirements of different water immersion operating conditions in the centrifugal model test are met through setting a centrifugal field water immersion device, the water flow getting into a water immersion control water tank is controlled through an electromagnetic valve, the water immersion control water tank distributes inlet water to each compartments, and water in each compartment permeates into a test simulation material through a corresponding water immersion probe. The water immersion system disclosed by the invention is clear in structure and convenient to manufacture, and has high practical values.

Owner:CHANGAN UNIV

Mulberry branch separated bark and rods and their preparation method and use

ActiveCN108017722ASoak evenlyFull penetrationCultivating equipmentsOrganic fertilisersCuticleBast fibre

The invention discloses mulberry branch separated bark and rods and their preparation method and use. The preparation method comprises a, preparation of raw materials, b, two-step decoction, c, decoction concentration and drying, d, separation of bark and rods in the decoction, e, separation of skin, green skin and phloem of bark, f, preparation of a crude pectin product and phloem fibers from thephloem, and g, preparation of stem fibers from the rods. The preparation method realizes preparation of mulberry branch extract from the decoction, full separation of the bark and rods of mulberry branches, full separation of skin, green skin and phloem of bark, preparation of a crude pectin product and phloem fibers from the phloem and preparation of stem fibers from the separated rods, really realizes comprehensive and flow-line extraction of pectin, phloem fibers and stem fibers of mulberry branches, fully utilizes values of mulberry branches, improves the use rate and the use value of themulberry branches, realizes the comprehensive utilization of wastes and protects the environment.

Owner:张明勋

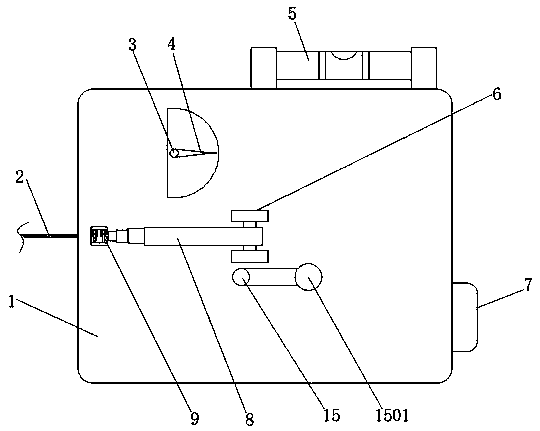

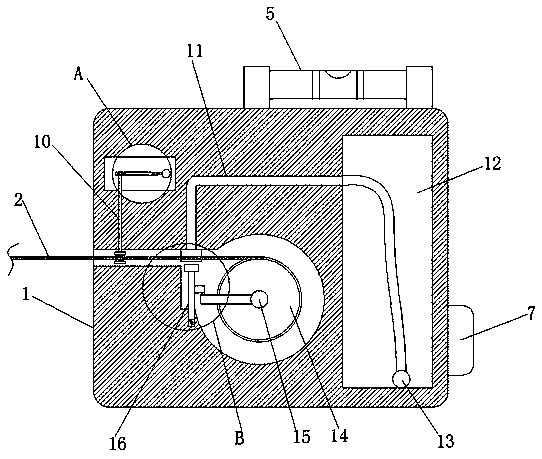

Ink fountain for building engineering

InactiveCN110480593AEasy to useSoak evenlyOther workshop equipmentArchitectural engineeringEngineering

The invention belongs to the technical field of building equipment, in particular relates to an ink fountain for building engineering. Aiming at the problem that ink on cotton threads will be obviously reduced after ink lines are used for a period of time and is not beneficial to the use of ink fountain, the following scheme is proposed. The ink fountain for building engineering comprises a main body, wherein one side of the main body is provided with an ink bin, the other side of the main body is provided with a first cavity, the main body is rotatably connected with a rotating shaft at the inner wall of one side of the first cavity, a pulley is welded at the middle of the rotating shaft, and ink lines are wound outside the pulley. According to the invention, the ink line drives the rotating rod to rotate around the rotating shaft, the rotating rod rotates for one circle to hit the moving block once, the push rod moves at the same time, the spring is stretched, the push rod drives themoving block to extrude sponge, the ink in the sponge is absorbed by the ink line, the rotating rod rotates continuously, the ink line continuously absorbs ink during the extraction process, and meanwhile, the ink line is evenly soaked by the ink through the water absorption of the ink line, so that the ink line can be used for a long time.

Owner:深圳市河图建设项目管理有限公司

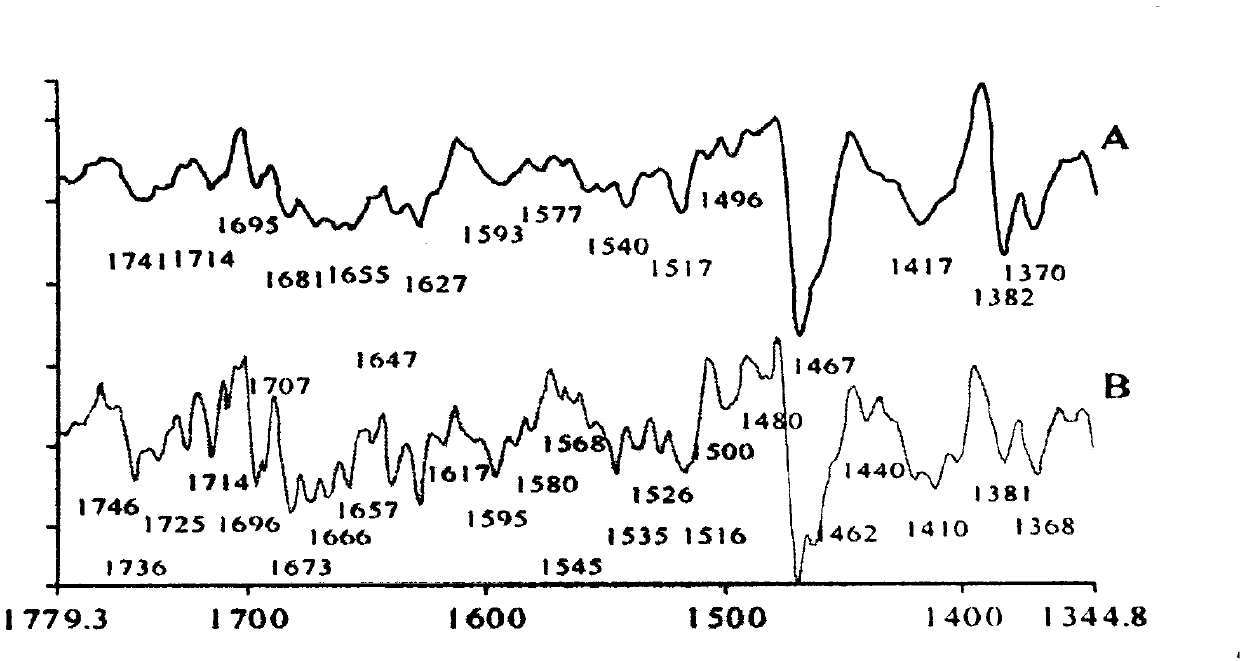

Interlamination reinforced fiber composite material with flow guiding layer and preparation method thereof

InactiveCN105711214ASoak evenlyImprove performanceSynthetic resin layered productsLaminationFibrous compositesMaterials science

The invention discloses an interlamination reinforced fiber composite material with a flow guiding layer . The interlamination improvement fiber composite material comprises an interlamination reinforced fiber pre-woven piece and basic body resin, the interlamination reinforced fiber pre-woven piece comprises glass felt laid layer by layer, flow guiding layer fiber cloth and interlamination continuous fibers, wherein the flow guiding layer fiber cloth is located at the position of a middle layer of the glass felt laid layer by layer, and the glass felt laid layer by layer and the flow guiding layer fiber cloth are sewn together through the interlamination continuous fibers. According to the interlamination reinforced fiber composite material, the interlamination shearing strength of the composite material can be improved while cost is reduced, and it can also be guaranteed that the fiber pre-woven piece can be uniformly soaked with resin.

Owner:SUZHOU ZHENRUICHANG MATERIAL TECH CO LTD

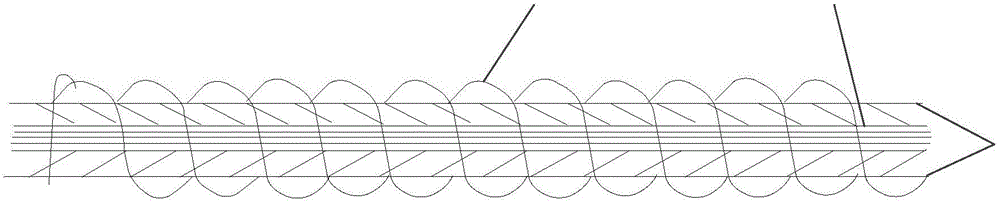

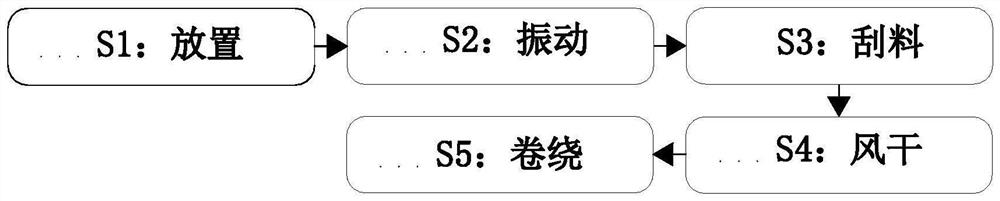

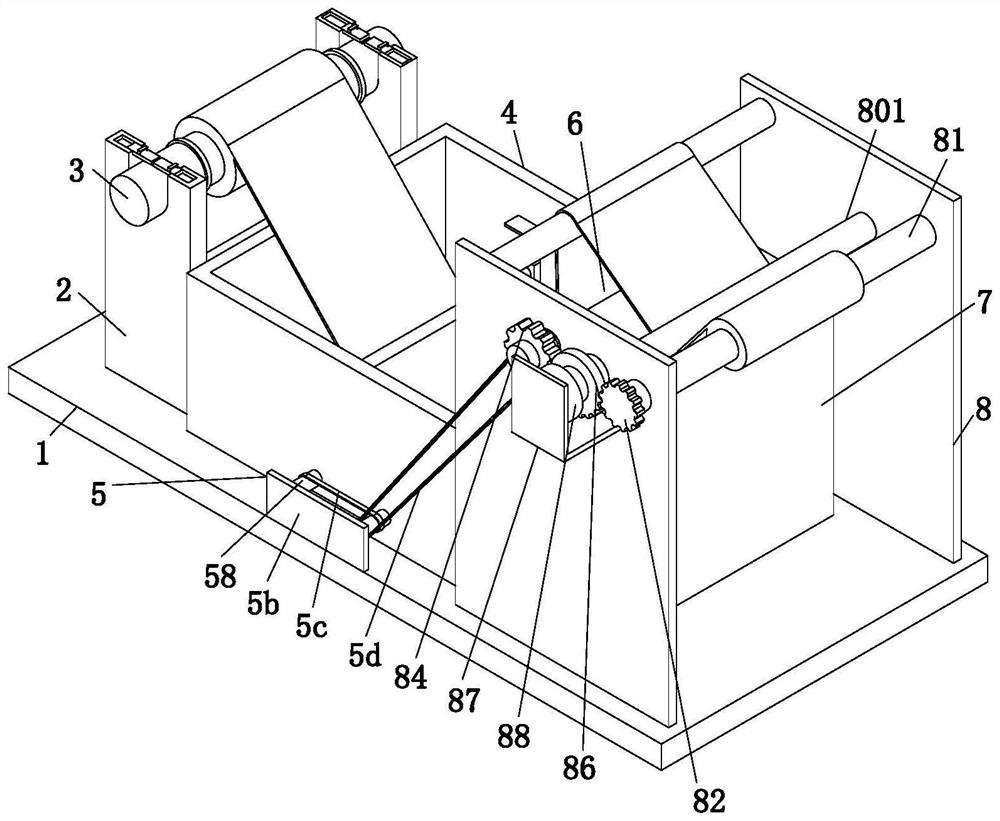

Glass fiber cloth production method

InactiveCN112796052ASoak evenlyConsistent thicknessLiquid/gas/vapor removal by scrapingTextile treatment carriersGlass fiberFiber

The invention relates to a glass fiber cloth production method which uses a glass fiber cloth production device. The glass fiber cloth production device comprises a workbench, a vertical plate, a placing shaft, a soaking pool, a vibration mechanism, a scraping plate, an air drying mechanism and a winding mechanism. According to the method, fiber gridding cloth is subjected to coating manufacturing in the mode that the fiber gridding cloth is soaked in the soaking pool filled with alkali-resistant emulsion, and the vibration mechanism drives the fiber gridding cloth to vibrate, so that the alkali-resistant emulsion enters meshes in an up-down vibration process of the fiber gridding cloth, and thus the fiber gridding cloth is soaked more uniformly; and the scraping plate is installed at the upper end of the soaking pool, and when the fiber gridding cloth coated with the alkali-resistant emulsion moves to the upper end of the soaking pool, the scraping plate scrapes off the redundant alkali-resistant emulsion on the fiber gridding cloth, so that the produced glass fiber cloth is consistent in thickness, and the uneven phenomenon is avoided.

Owner:李亚

Soaking device for ceramic tiles for buildings

The invention belongs to the technical field of building construction, and particularly relates to a soaking device for ceramic tiles for buildings. According to the technical problem, the ceramic tile soaking device for the buildings which is uniform in soaking, convenient to use and capable of conveniently assisting the paving of the wall surface is provided. The soaking device for ceramic tilesfor buildings comprises a soaking box, a first sliding rail, a first sliding block, a placing box, an interval box and the like; the upper part of the inner wall of the soaking box is provided with the first sliding rail, the first sliding block is slidably arranged on the first sliding rail, and the placing box is arranged on the first sliding block, and the interval box is placed on the placingbox. According to the ceramic tile soaking device, the effects that the soaking is uniform, the use is convenient, and assistance to the paving of the wall surface is facilitate are reached; when theceramic tile soaking device need to be used, the interval box filled with non-soaked ceramic tiles is put into the placing box, a pedal is loosened, the interval box and the placing box slide downwards under the action of gravity, and at the moment, water is injected into the interval box to soak the ceramic tiles.

Owner:吴昌泉

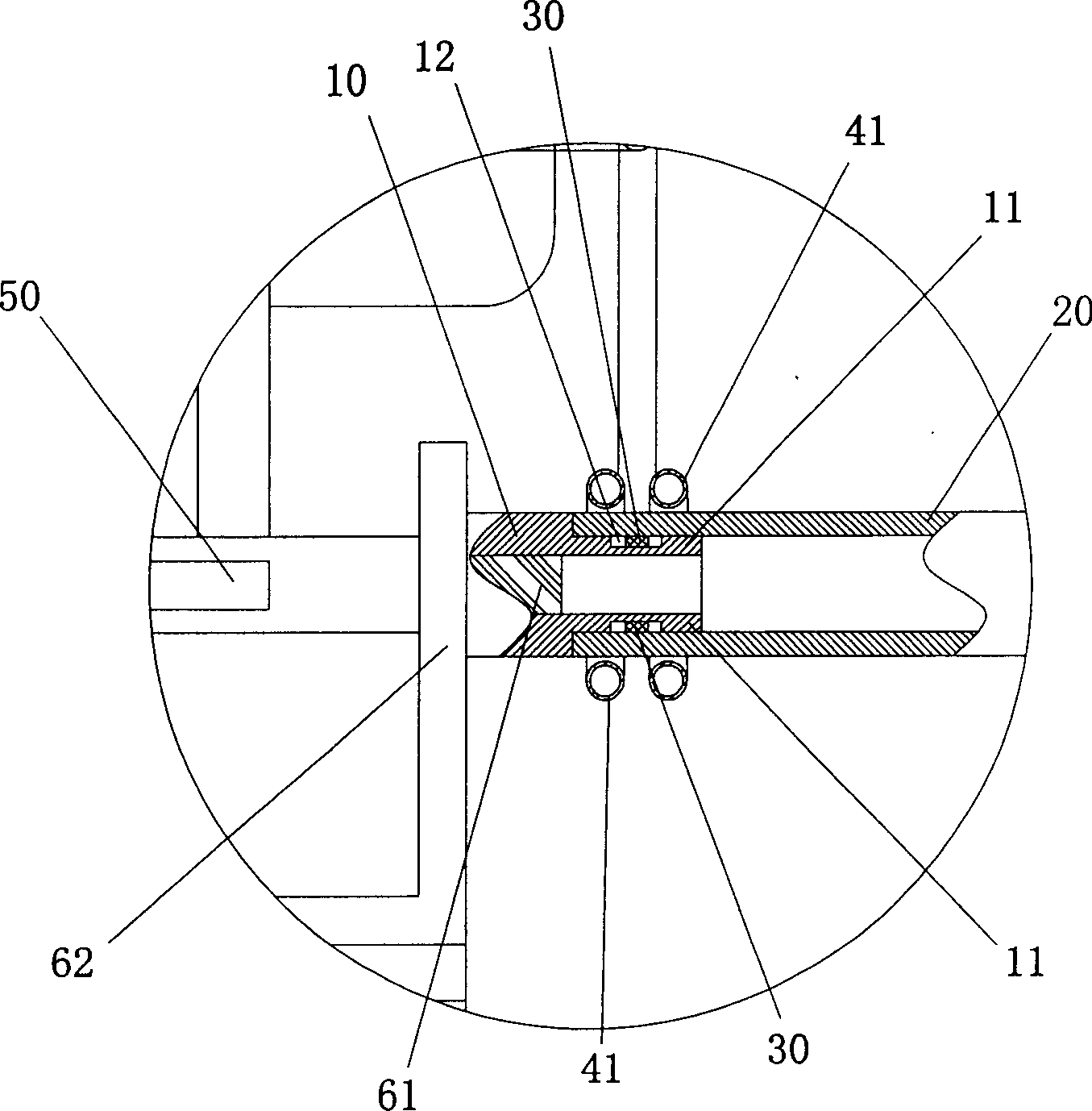

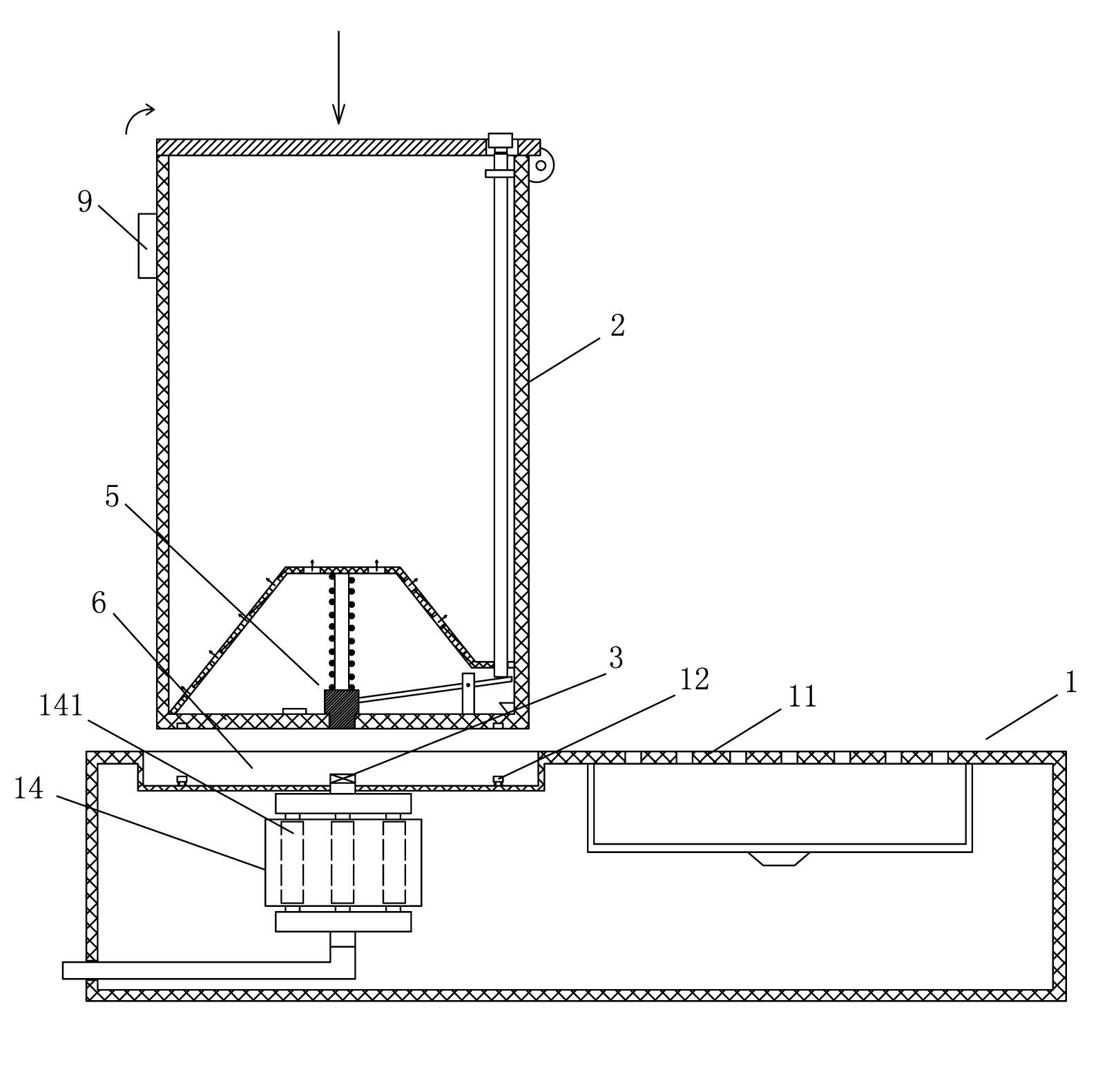

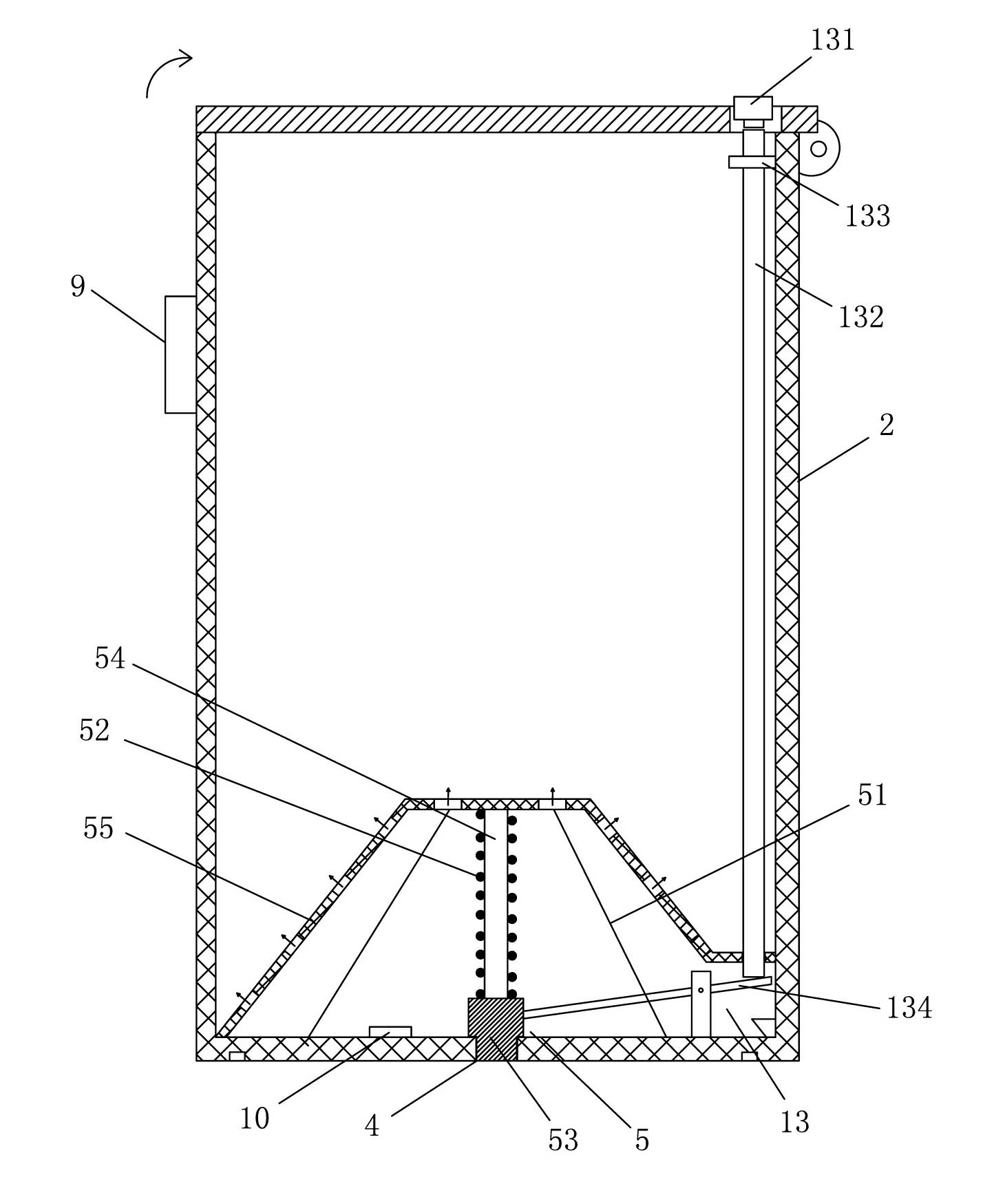

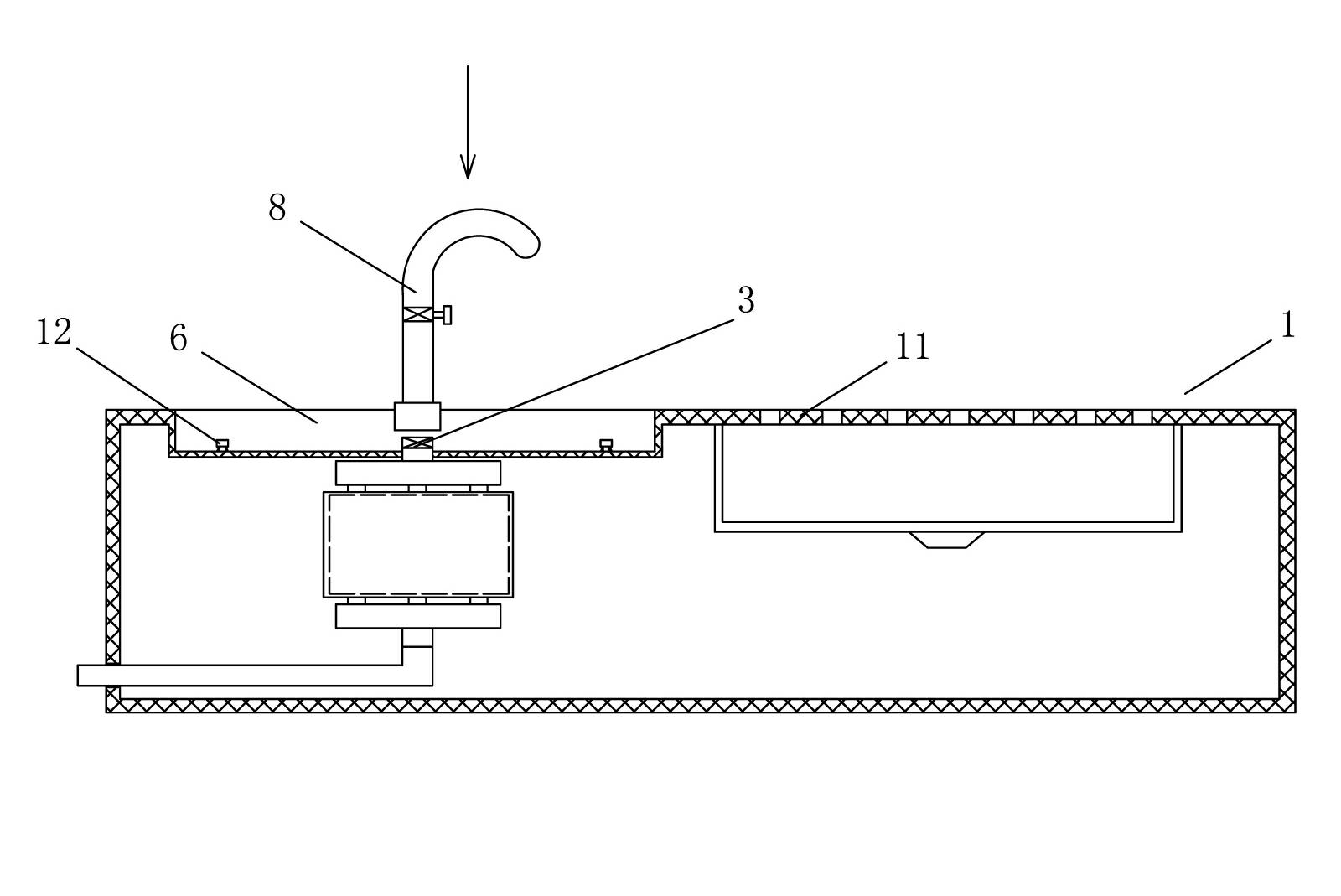

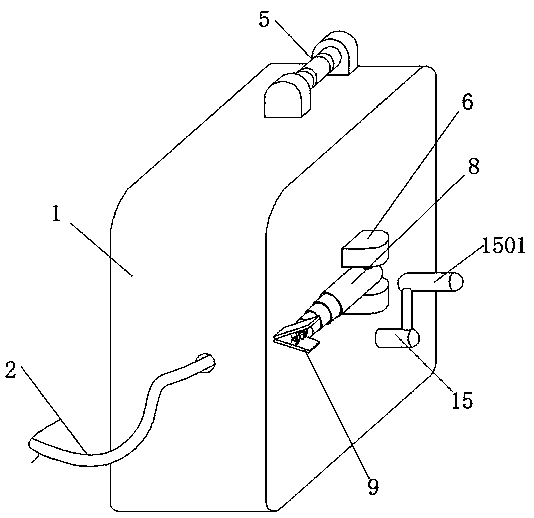

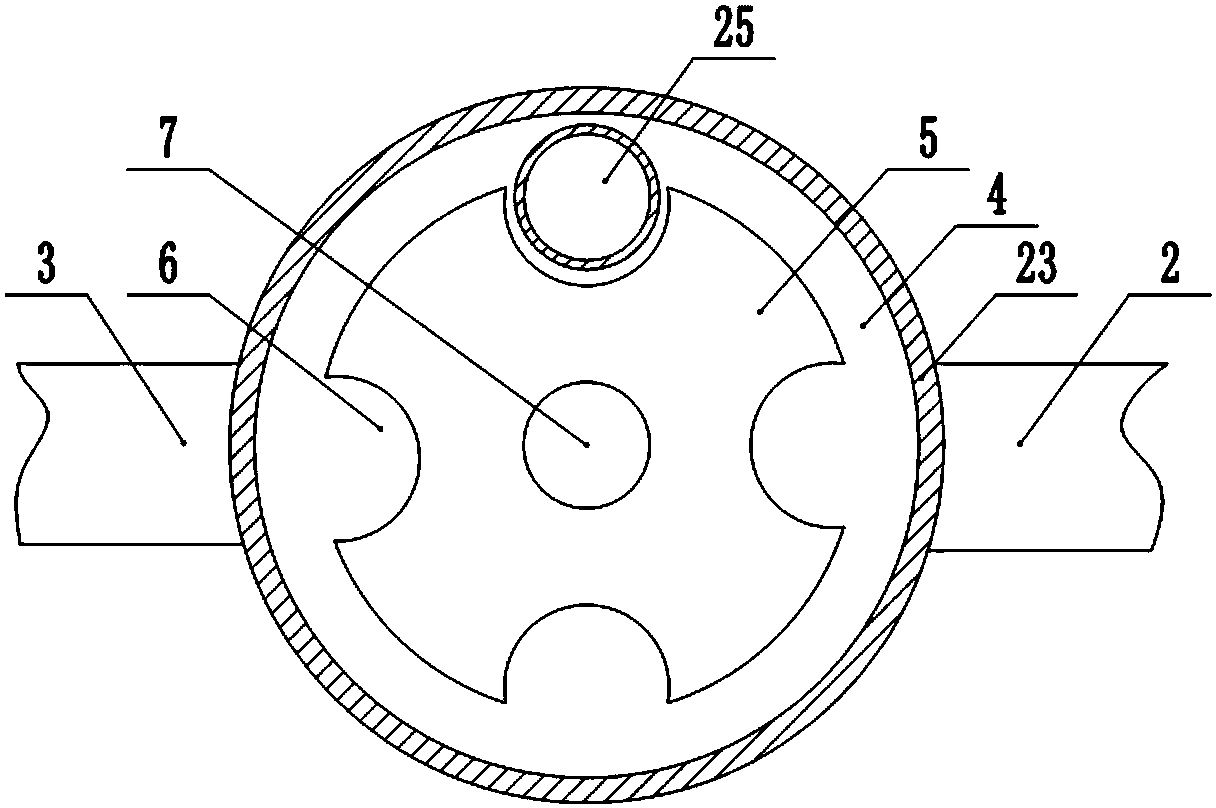

Device and method for introducing liquids into meat

InactiveCN1725955BGuaranteed relative speedHigh speedInjection based meat processingClimate change adaptationNeedle Free InjectionSpray nozzle

Disclosed is a device and a method for introducing liquids into meat containing bones and / or cartilage or connective tissue, e.g. in the slaughtered body of poultry as well as in legs and belly meat, in order to treat, season, and / or preserve said meat. The aim of the invention is to create a device and a method which make it possible to simultaneously introduce exactly defined, even very small quantities of water, brine, preservatives, seasoning liquids, and / or other liquids in a manner that is adapted to the anatomy of the body of the slaughtered animal, even into meat containing bones and / or cartilage or connective tissue, within a very short period of time on almost any conveying unit, even an existing one, and even on a slaughtering conveyor belt, without using any needle while beinghighly effective and highly reliable, having a robust structure, and providing minimal tolerance of the injected quantity. Said aim is achieved by a device for introducing liquids into meat, comprising a base frame (1). Said device is characterized by the fact that one or several machine frame / s (3) is / are arranged in a rigid manner or so as to be movable in a linear direction on the base frame (1) while one / several injection device / s (6) which is / are used for needle-free injection and is / are connected to one / several high pressure unit / s (4) via one / several liquid distribution system / s (5) is / are disposed on the machine frame / s (3), each injection device (6) comprising one or several nozzle pipe / s (7) on which one or several spray nozzle / s (8) is / are arranged and which is / are disposed on the machine frame (3) so as to be deliverable. The inventive method is characterized by the fact that each of the nozzle pipes (7) as well as one / several spray lance / s (6) can be separately impinged upon by an identical and / or different, precisely defined pressure that is applied to different liquids for identical and / or different, exactly defined periods of time.

Owner:FEINA

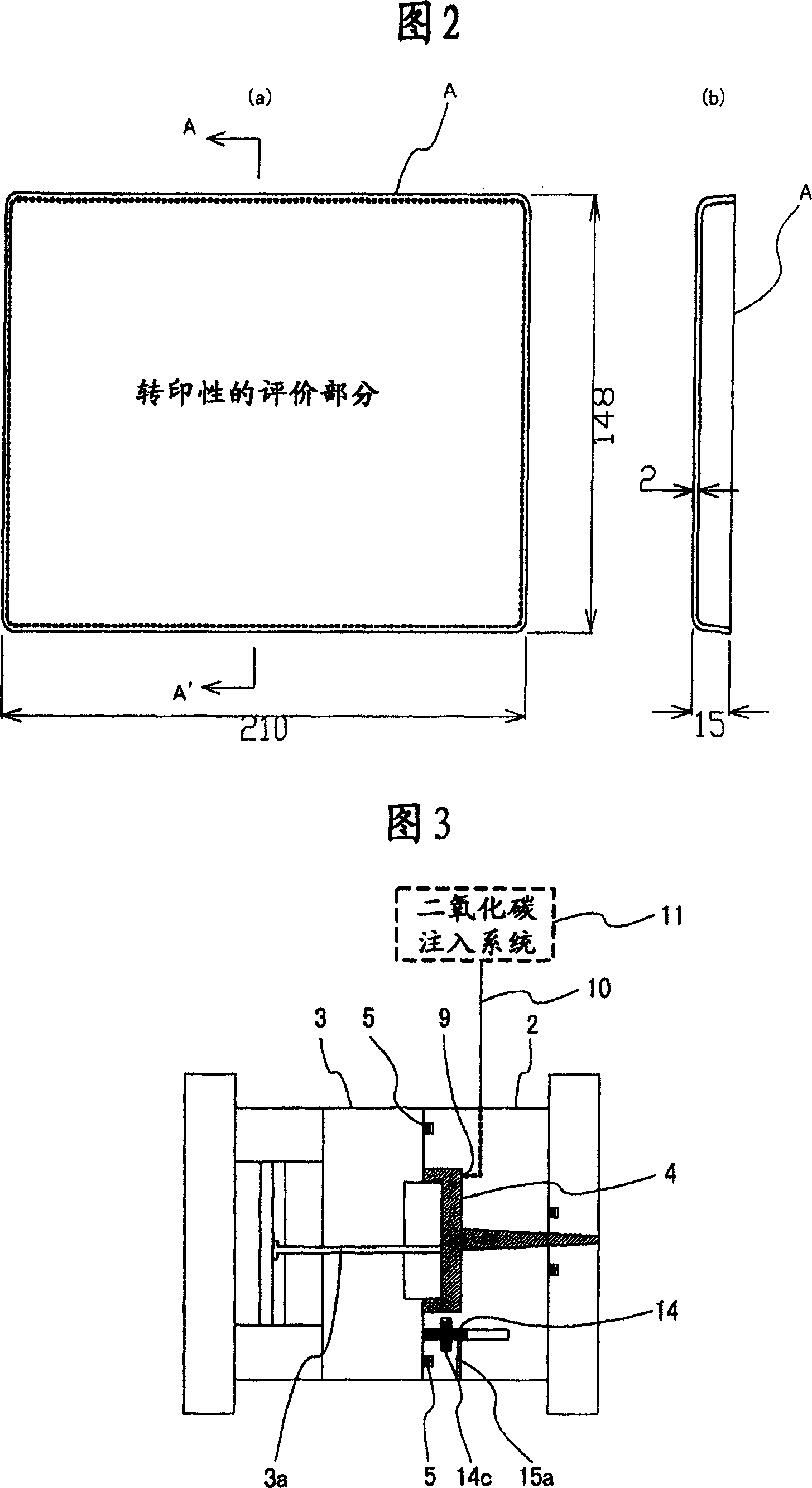

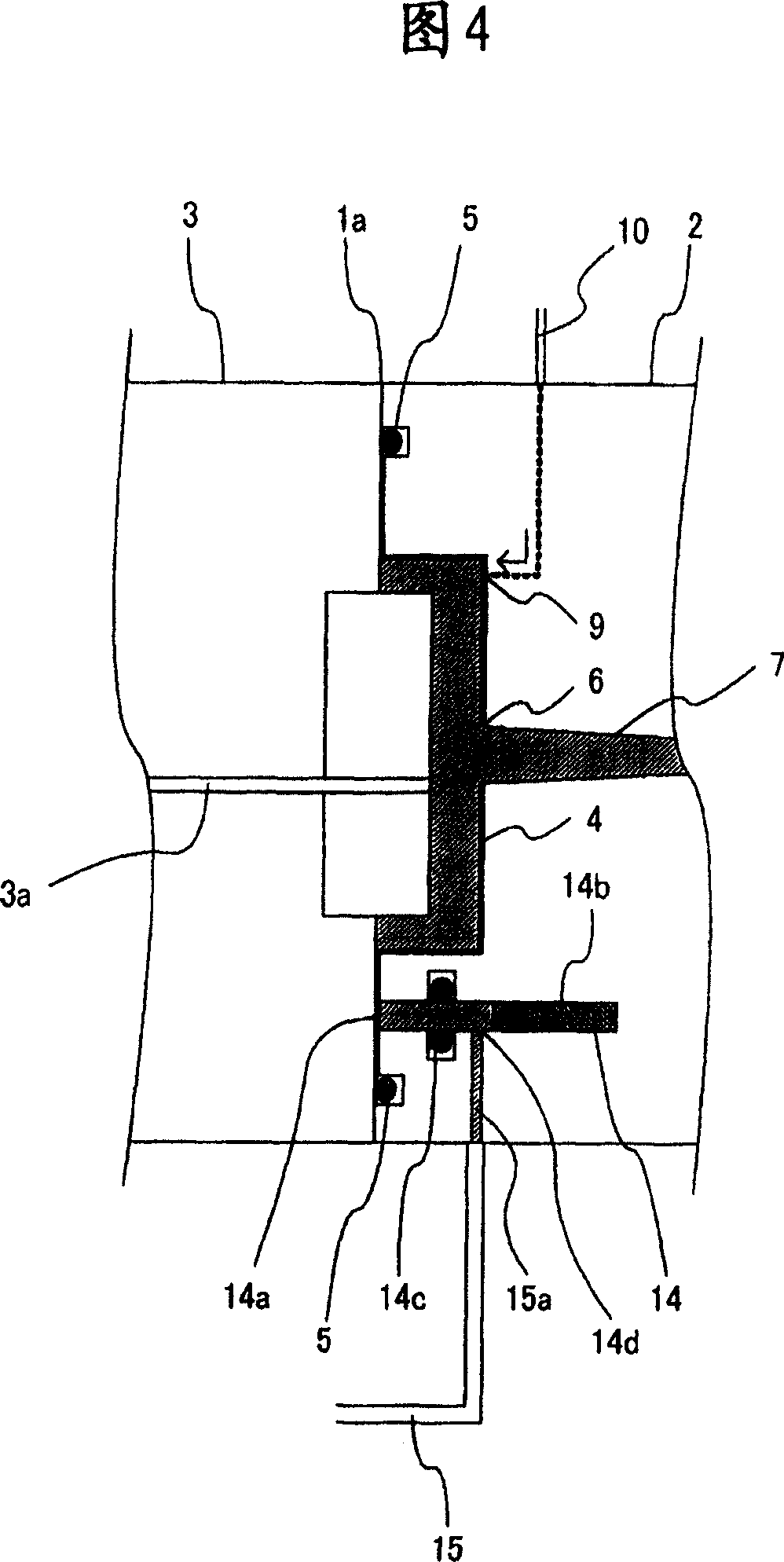

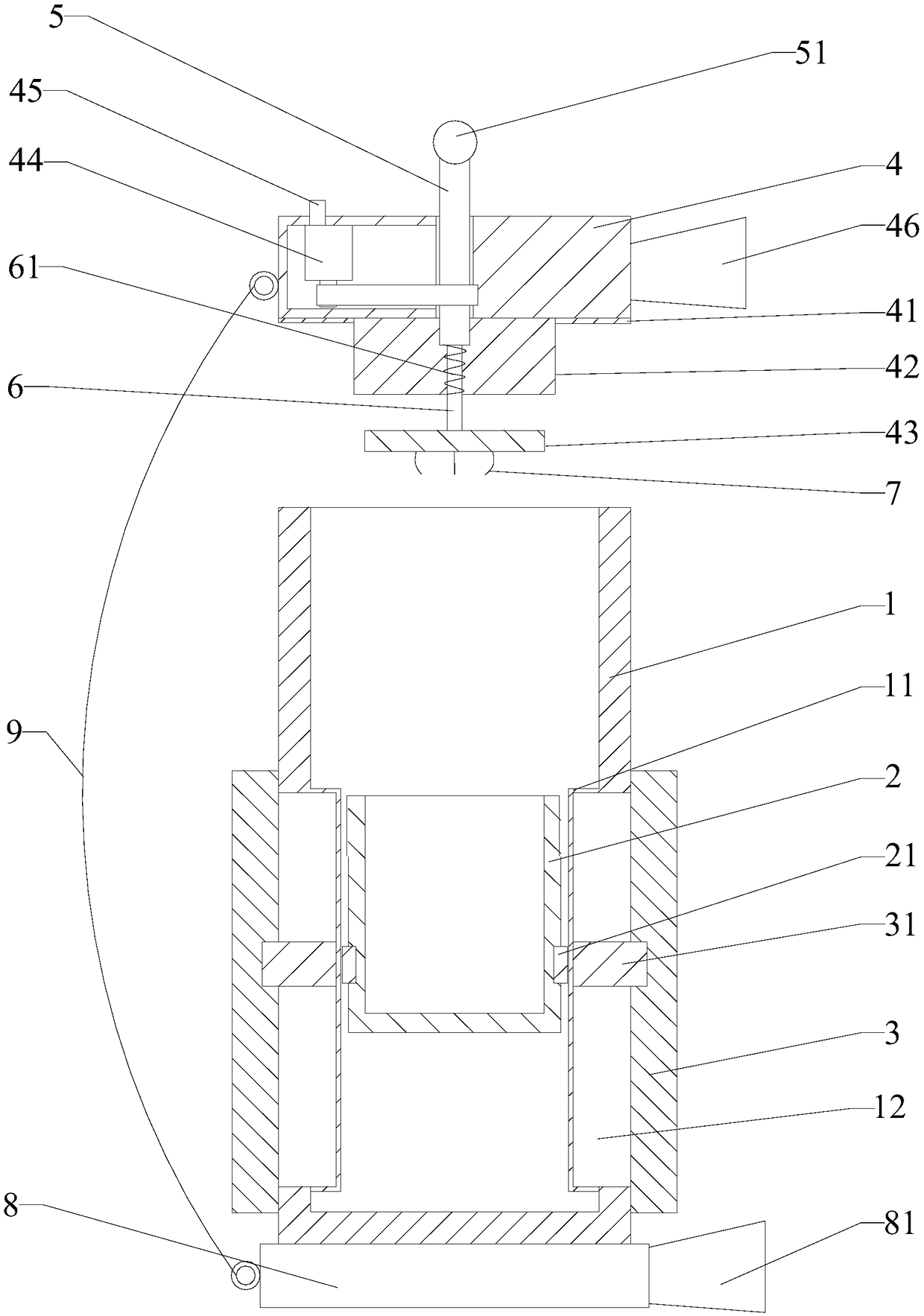

Injecting molding method of thermal plastic resin product and mold used thereof

In the injecting molding method of carbon dioxide and other fluids, the transfer printing performance and glossiness are excellent, it can save consumption of consumed fluid. The junction surface of fixing side die 2 surrounding the cavity 4 and the movable side die 3 is equipped with sealing device 5, the die of retracting device is installed between the sealing device 5 and the cavity 4 and the retracting device is used for recoveries the injecting fluid of cavity which flows out of said junction surface; first locking the die tightly, second filtering resin into cavity 4, then injecting fluid used for modifying the visible surface between the visible surface of product in cavity 4 and the cavity 4 surface contacting with the visible surface, such as carbon dioxide, and then increasing resin pressure to make the visible surface is closed with the cavity 4 surface, completing the injecting shaping after pressure maintaining and cooling. The recycling fluid can be used again.

Owner:宗形株式会社

Tea making device

InactiveCN109077568AImprove extrusion efficiencyAvoid wastingDomestic vesselsTeapotAgricultural engineeringMagnet

The invention relates to the technical field of tea making, in particular to a tea making device. The tea making device comprises a cup body, a tea leaf groove placed in the cup body, a heat insulation sleeve and a cup cover; the heat insulation sleeve sleeves the outer wall of the cup body; the tea leaf groove is made of magnetic materials, the inner surface of the heat insulation sleeve is connected with a first magnet, and the heat insulation sleeve slides up and down along the outer wall of the cup body to drive the tea leaf groove to slide up and down along the inner wall of the cup body;the cup cover comprises a cup cover body, a second magnet, a sleeve and a water squeezing disc, the second magnet is arranged on the inner surface of the cup cover body, and the sleeve is internallyprovided with a first vertical rod and a second vertical rod connected with the bottom of the first vertical rod; the extension end of the second vertical rod is connected with the water squeezing disc, and the part, not stretching out of the sleeve, of the second vertical rod is sleeved with a coil spring. According to the tea making device, through the heat insulation sleeve and the water squeezing disc which are opposite in movement direction, tea water left in the tea leaf groove is fully squeezed, the squeezing efficiency is high, and the waste of tea leaves is avoided; finally, the tea leaf groove is attracted by the cup cover body to be fixed and conveniently taken out.

Owner:大田县福韬体育用品有限公司

Bean curd dicing device with knife sticking prevention function for food processing

InactiveCN113400401ARealize automatic cuttingAvoid stickingMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of food processing, in particular to a bean curd dicing device with a knife sticking prevention function for food processing. Aiming at the defects in the prior art, the invention provides the bean curd dicing device with the knife sticking prevention function for food processing, which is used for preventing knife sticking and collecting bean curd blocks. According to the technical scheme, the bean curd dicing device with the knife sticking preventing function for food processing comprises a supporting table, first supports, first fixing plates, a dicing mechanism and a fixing mechanism, wherein the first supports are fixedly connected to the two sides of the top of the supporting table correspondingly, the first fixing plates are fixedly connected to the upper sides of the two first supports correspondingly, a dicing mechanism is fixedly connected between the two first fixing plates, and a fixing mechanism is arranged on the dicing mechanism in a sliding mode. Bean curd can be fixed through a limiting plate, and meanwhile the situation that the bean curd sticks to a cutter during processing, and consequently the surface of the bean curd is damaged is prevented.

Owner:钟满香

Pretreatment method of moringa seeds

The invention discloses a pretreatment method of moringa seeds, and belongs to the technical field of planting of moringa. The pretreatment method comprises the following steps: sorting seeds, treating the seeds under low temperature and high pressure, soaking, disinfecting and the like. According to the pretreatment method of the moringa seeds, through combination of microwave treatment under theaction of a soaking solution in the low-temperature and high-pressure treatment process and the soaking process, the activity of the seeds can be further improved; the activity of amylase is improved; meanwhile, the seeds can be more uniformly soaked in the soaking solution; the favorable condition basis is provided for germination of the seeds; the germination rate of the moringa seeds is increased; the survival rate of seedlings is increased.

Owner:DAXIN SCI & TECH INFORMATION RES INST

Chicken foot pickling equipment

The invention relates to chicken foot pickling equipment. The chicken foot pickling equipment comprises a machine frame, a first conveyor belt and a second conveyor belt, wherein a feeding disk is arranged between the first conveyor belt and the second conveyor belt, and comprises a bottom disk and a rotating disk; the bottom disk is fixed on the machine frame; a plurality of feeding grooves are formed in the rotating disk; a threaded hole is formed in the center of the rotating disk, and a threaded rod is connected to the threaded hole; a material storing groove is formed under the feeding disk; driving clamping grooves are formed in the upper part of the material storing groove; a base is arranged under the material storing groove; the bottom of the material storing groove is rotatably connected to the base; the bottom end of the threaded rod penetrates through the bottom disk and is fixedly connected with the bottom of the material storing groove; a driving shaft is arranged on theouter side of the material storing groove; clamping strips are arranged on the driving shaft; a driving motor is connected to the driving shaft; and a feeding mechanism is arranged on the feeding disk, and comprises a controller, a material injecting opening and a feeding pipe; a pressure pump is connected to the feeding pipe; and the bottom end of the feeding pipe is located in the material storing groove. Through the adoption of the chicken foot pickling equipment disclosed by the invention, the problems that the pickling of chicken feet is insufficient and pickled pepper water is liable tolayer and precipitate after being stored for a long time are solved.

Owner:ANQING YONGQIANG AGRI SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com