Soaking device for ceramic tiles for buildings

A technology for construction and ceramic tiles, which is applied in the direction of construction and building construction, which can solve the problems of inconvenient operation, low work efficiency, uneven soaking, etc., and achieve the effect of uniform soaking and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

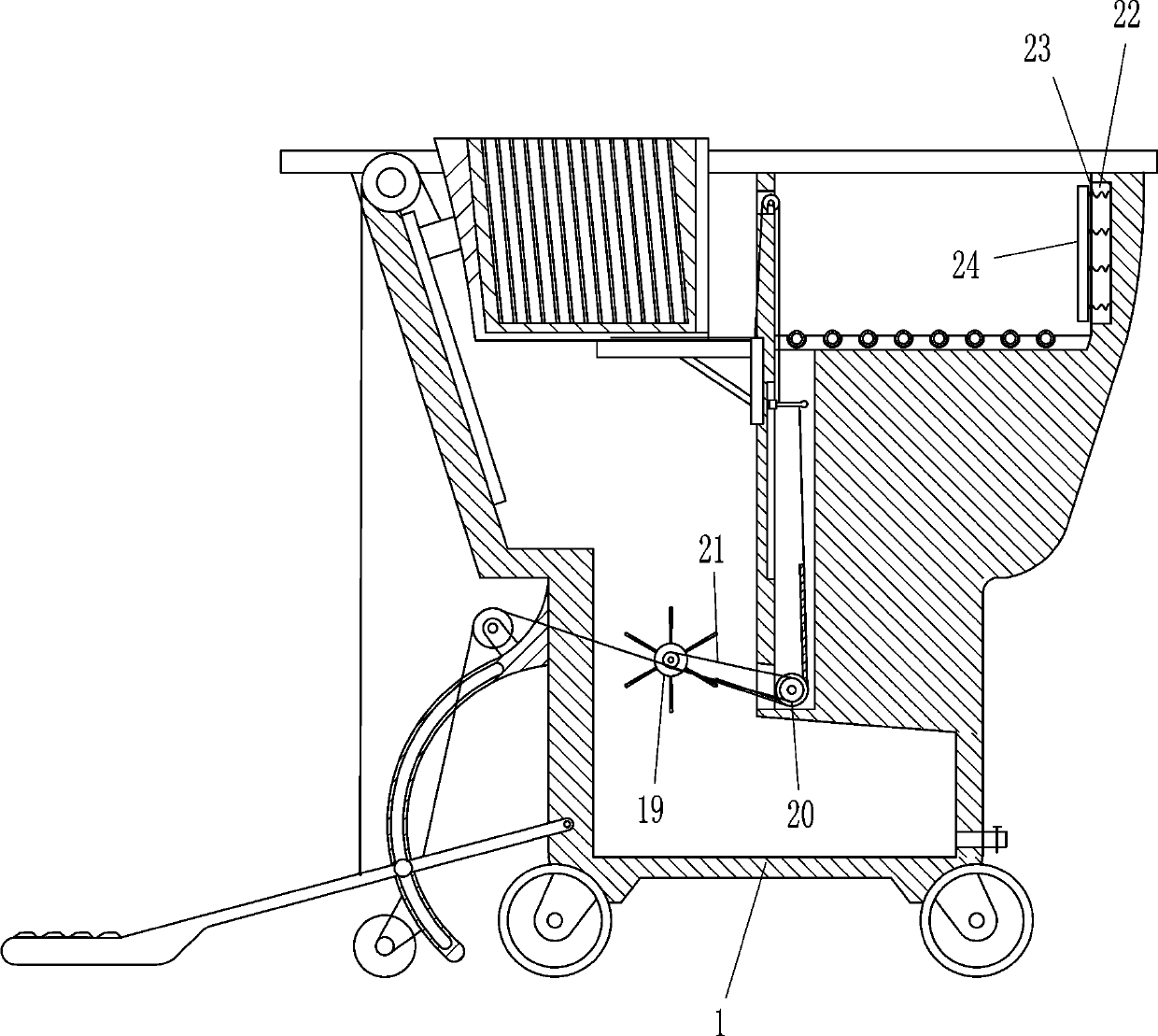

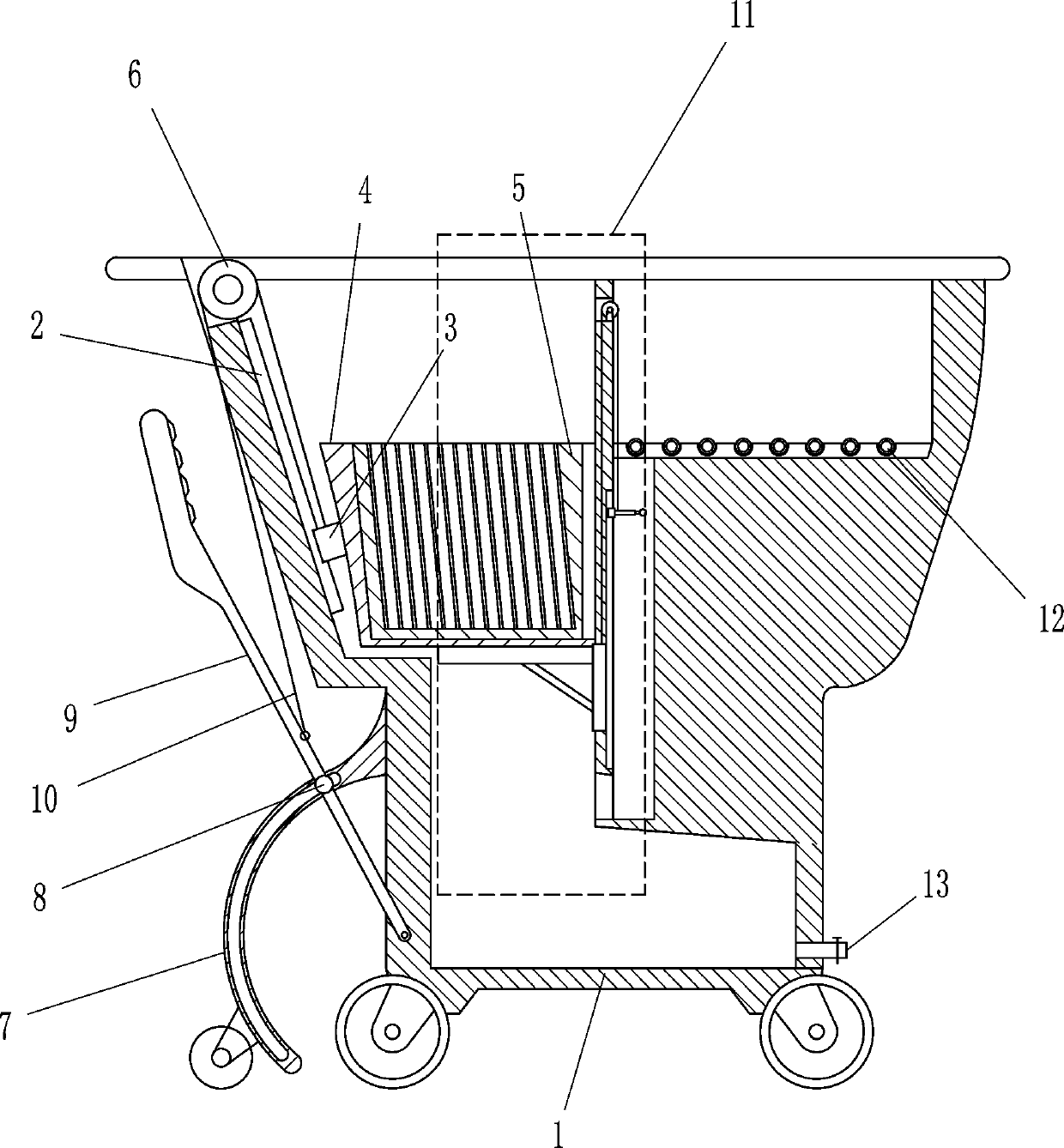

[0019] see figure 1 , figure 2 , image 3 and Figure 4 , a ceramic tile soaking device for construction, including a soaking box 1, a first slide rail 2, a first slide block 3, a placement box 4, a spacer box 5, a directional wheel 6, an arc-shaped slide rail 7, a slide shaft 8, and a pedal 9. The first pull rope 10, the guide device 11, the rolling wheel 12 and the water outlet pipe 13, the upper part of the inner wall of the soaking tank 1 is connected with the first slide rail 2 by means of bolt connection, and the first slide rail 2 is slidably provided with a first Slider 3, the first slider 3 is provided with a placement box 4, the placement box 4 is placed with a spacer box 5, the top of the soaking box 1 is provided with a directional wheel 6, and the left side wall of the soaking box 1 is symmetrically provided with curved slide rails. 7. Sliding shaft 8 is installed on the arc-shaped slide rail 7, pedal 9 is installed on the left side wall of soaking tank 1, and...

Embodiment 2

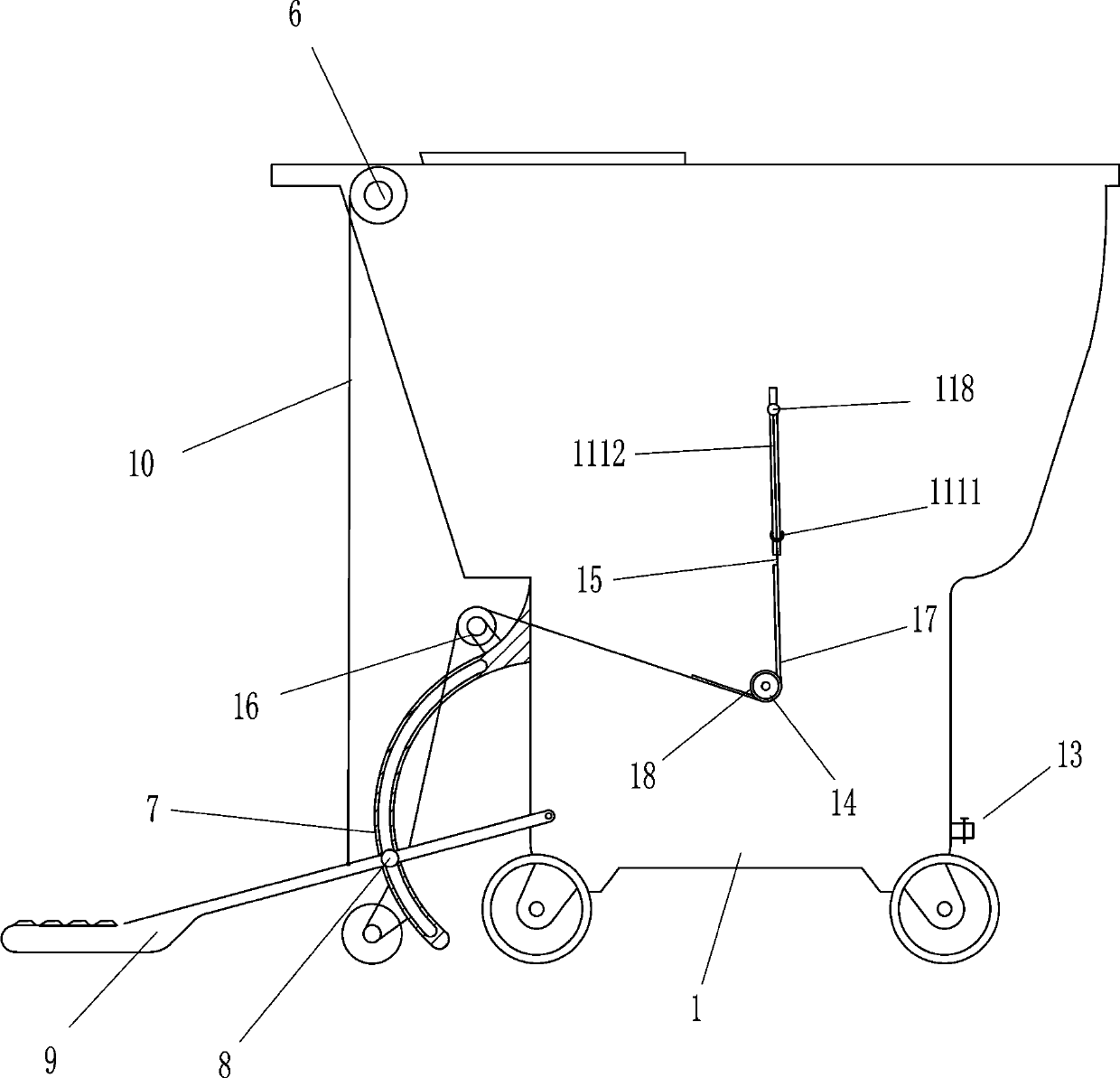

[0023] see figure 1 , figure 2 , image 3 and Figure 4 , on the basis of Embodiment 1, it also includes a first guide wheel 14, a rubber belt 15 and a second guide wheel 16, and the front and rear walls of the soaking tank 1 of the slot 1112 are provided with a first guide wheel through a connecting shaft rotation. Wheel 14, on the two curved slide rails 7, the second guide wheel 16 is connected by bolt connection, the sliding shaft 118 is provided with a rubber belt 15, and the rubber belt 15 walks around the first guide wheel on the same vertical surface 14 and the second guide wheel 16 are connected with pedal 9.

[0024] The working process of the present invention: when stepping on the pedal 9, the rubber belt 15 can drive the sliding shaft 118 to move downwards, and then drive the sliding plate 114 to move upwards, realizing linkage and convenient use.

[0025]Also comprise tooth bar 17, ring gear 18, water wheel 19, pulley 20 and flat belt 21, on the rubber belt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com