Injecting molding method of thermal plastic resin product and mold used thereof

A thermoplastic resin and injection molding technology, which is applied in the field of injection molding of thermoplastic resin products and the molds used, can solve the problems of complex mold structure, reduce mold production costs, etc., achieve easy molding process, realize molding time, and glossiness. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

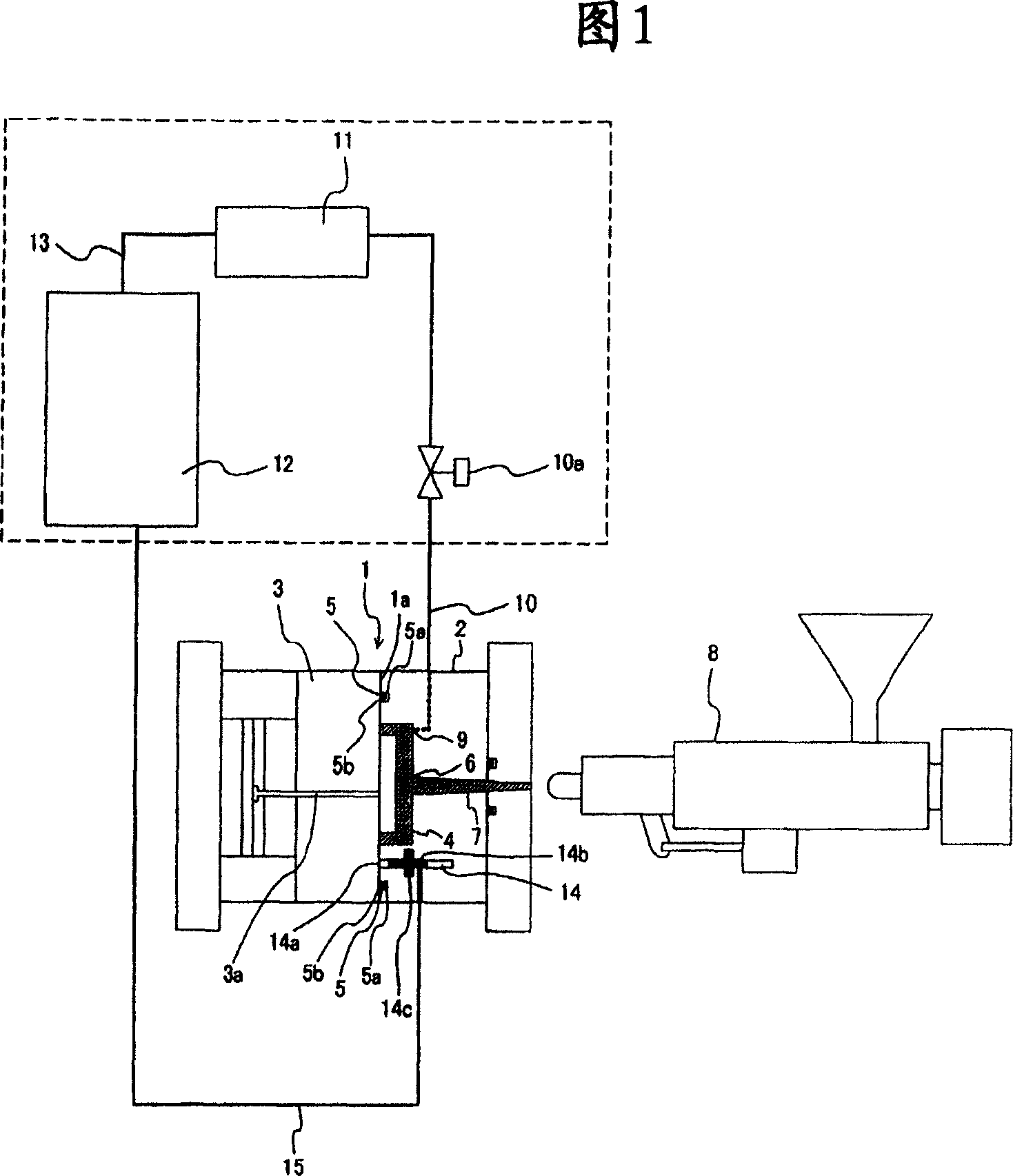

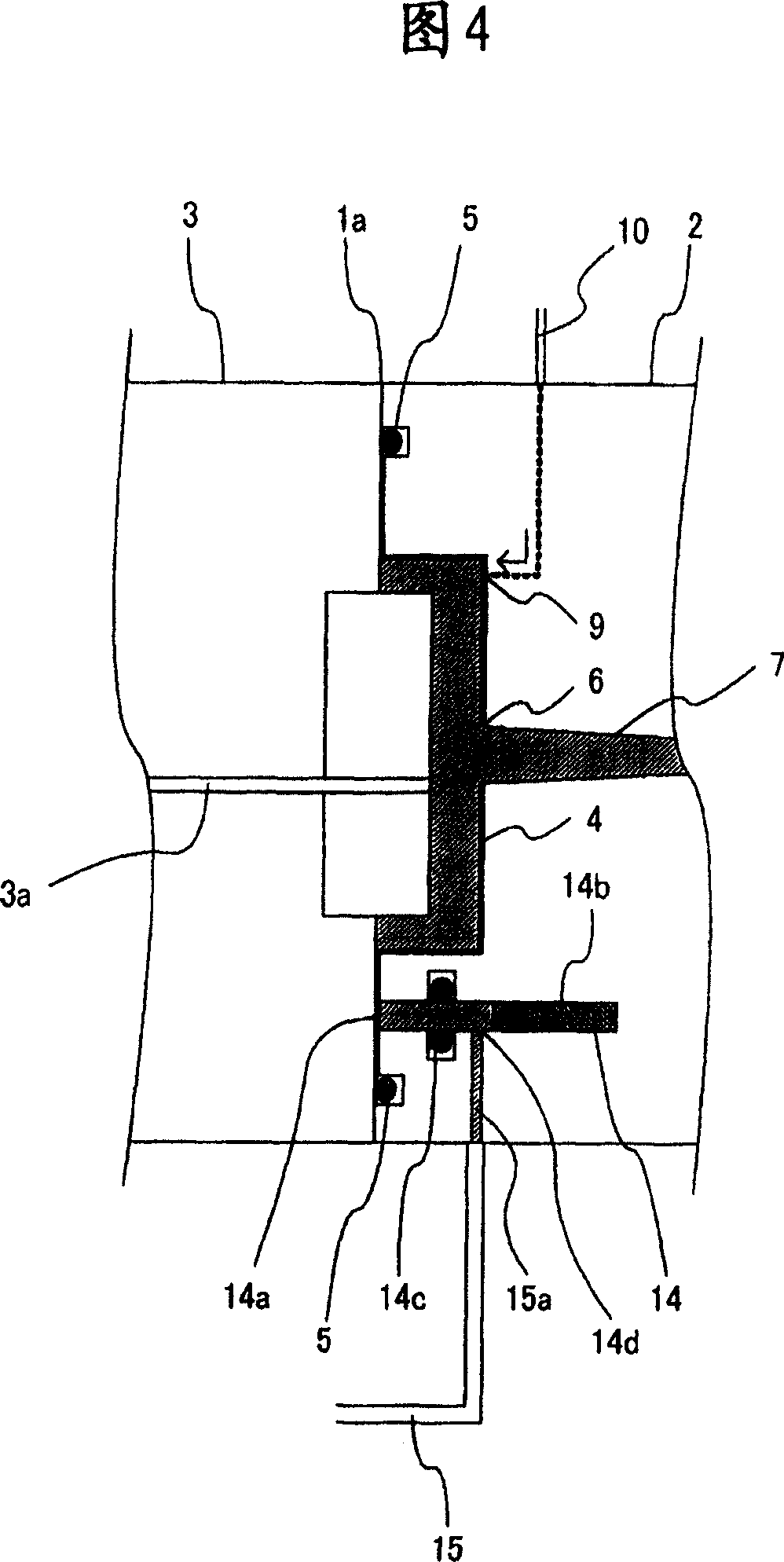

[0067] Figure 1 shows the molding method of the present invention for improving transferability and glossiness and its implementation in a mold. In this Fig. 1, 1 is a mold, and the mold 1 is composed of a fixed side mold 2 and a movable side mold 3, and a cavity 4 is formed when the molds are closed.

[0068] 5 is a sealing mechanism provided on the joint surface 1a to surround the above-mentioned cavity 4, the sealing mechanism 5 is composed of a sealing material mounting groove 5a formed on the fixed side mold 2, and a rubber sealing material 5b mounted in the mounting groove 5a. constitute.

[0069] 6 is the gate of the above-mentioned cavity 4, 7 is the runner connected to the gate 6, and 8 is a screw type resin filling machine for filling resin into the cavity 4 from the above-mentioned runner 7 through the gate 6.

[0070] 9 is a fluid injection port provided on the cavity surface of the fixed side mold 2 in the above-mentioned cavity 4, 10 is a fluid injection pipe co...

Embodiment 2

[0076] The structure of this embodiment 2 is: in order to prevent the air discharged from the cavity 4 from being hindered by the sealing mechanism 5 when filling the resin, the pressure in the cavity 4 and the pressure of the filled resin are higher than the specified pressure, as shown in Figure 5 The air groove 16 is formed in the fixed side mold 2, and the air discharged from the cavity 4 is temporarily accommodated in the air groove 16, so that the air can be discharged from the cavity 4 while preventing the resin pressure from increasing.

[0077] The above-mentioned Examples 1 and 2 are examples of improving the transferability and glossiness by using carbon dioxide. The operation examples when various fluids are used to modify the visible surface of the molded article can be carried out through the same process as the above-mentioned carbon dioxide injection method. forming.

Embodiment 3

[0081] The third embodiment is an example in which a sealing mechanism 5 is provided on the movable side mold 3 as shown in FIG. 6 and an example in which a sealing mechanism 5 is provided on the fixed side mold 2 as shown in FIG. 7 . In this way, any sealing mechanism 5 may be used, but it is preferable to install it on the non-movable fixed-side mold 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com