Diffusion sheet and method of manufacturing the same, backlight, and liquid crystal display device

A diffusion sheet and structure technology, applied in optics, optical components, optical components, etc., can solve problems such as insufficient brightness, achieve the effects of improving brightness, good light-gathering function, and suppressing the generation of moiré fringes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0040] 1. First Embodiment (Example of Diffusion Sheet)

[0041] 2. Second Embodiment (Example of Applying a Diffusion Sheet to a Liquid Crystal Display Device)

[0042]

[0043] [1.1. Composition of diffuser]

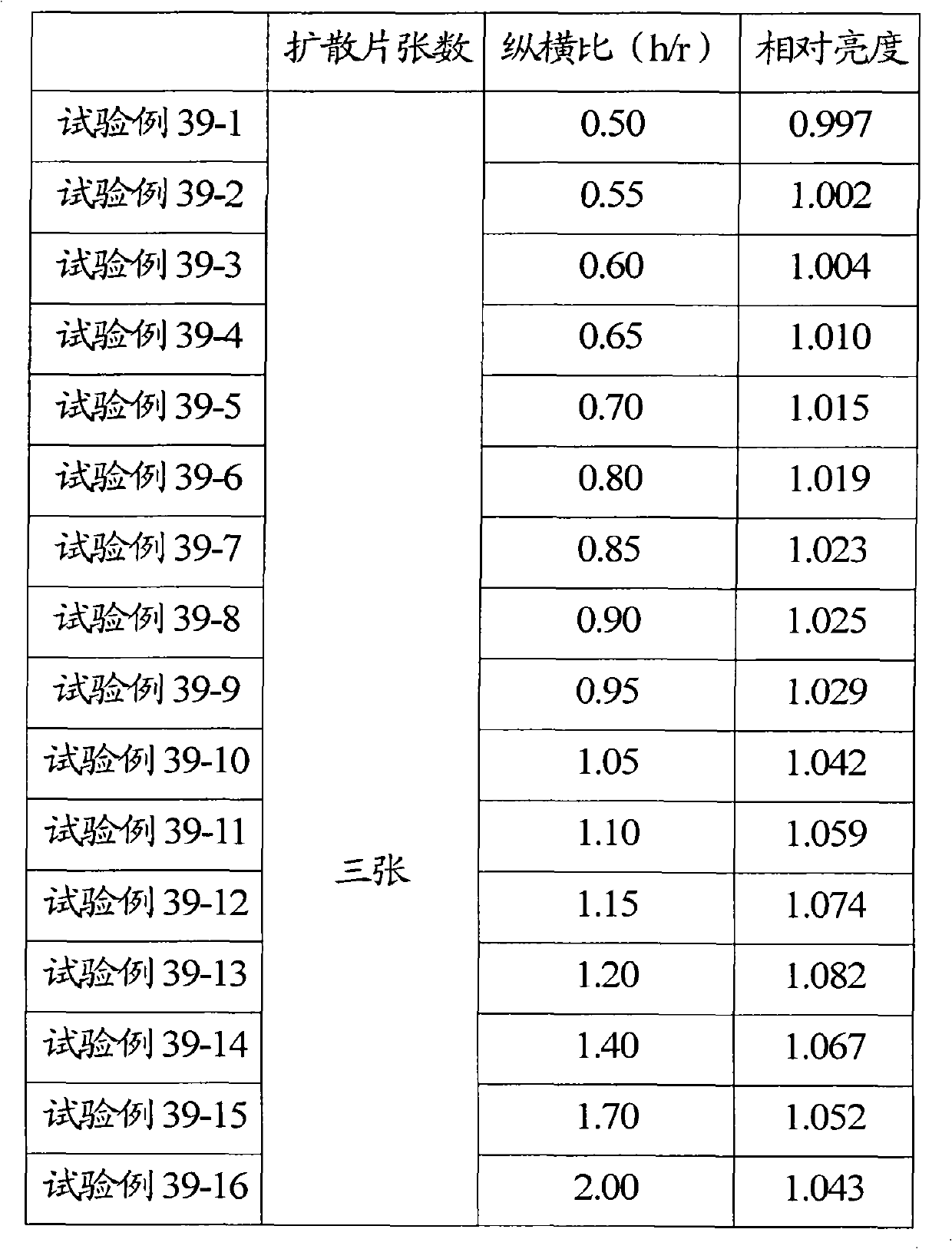

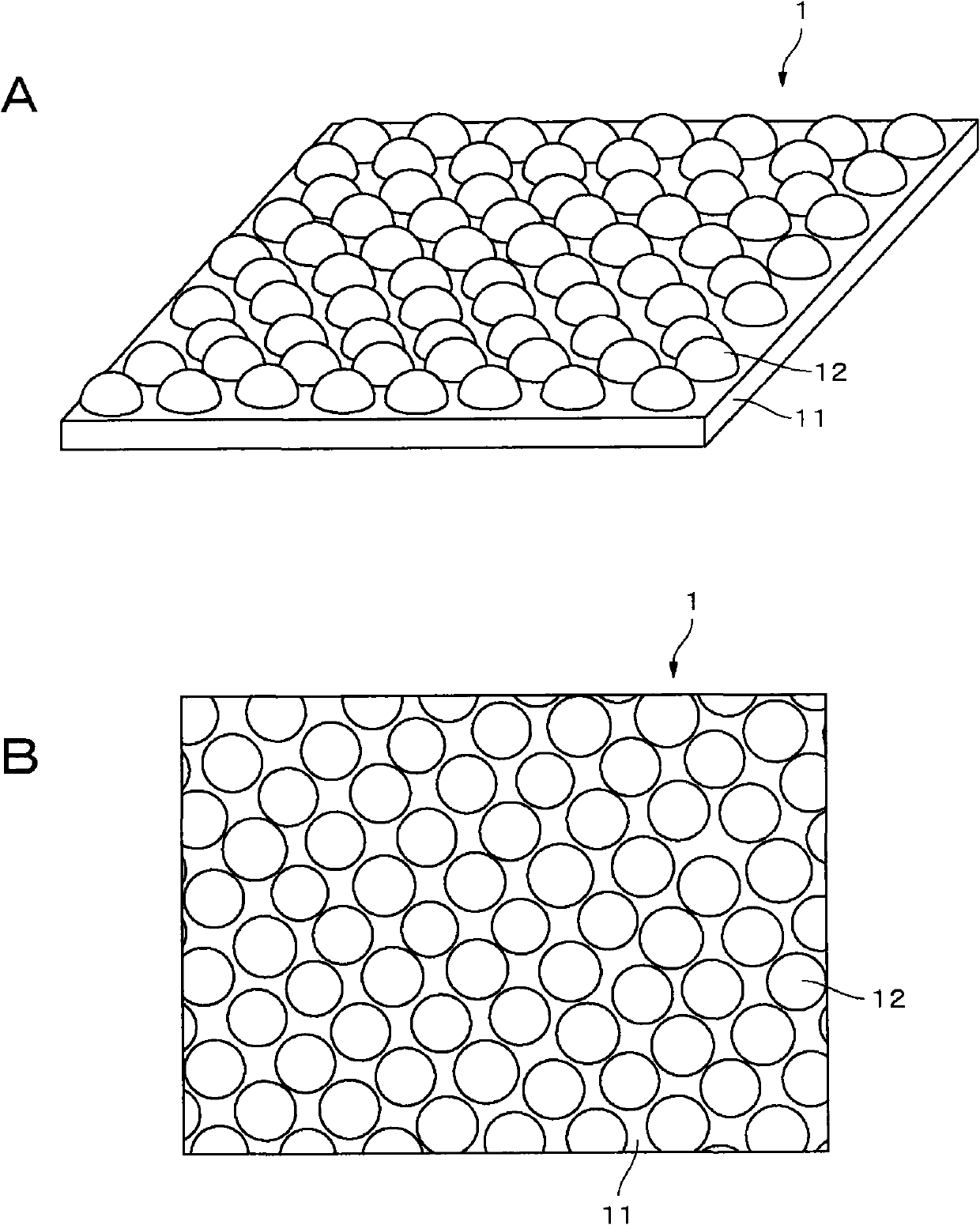

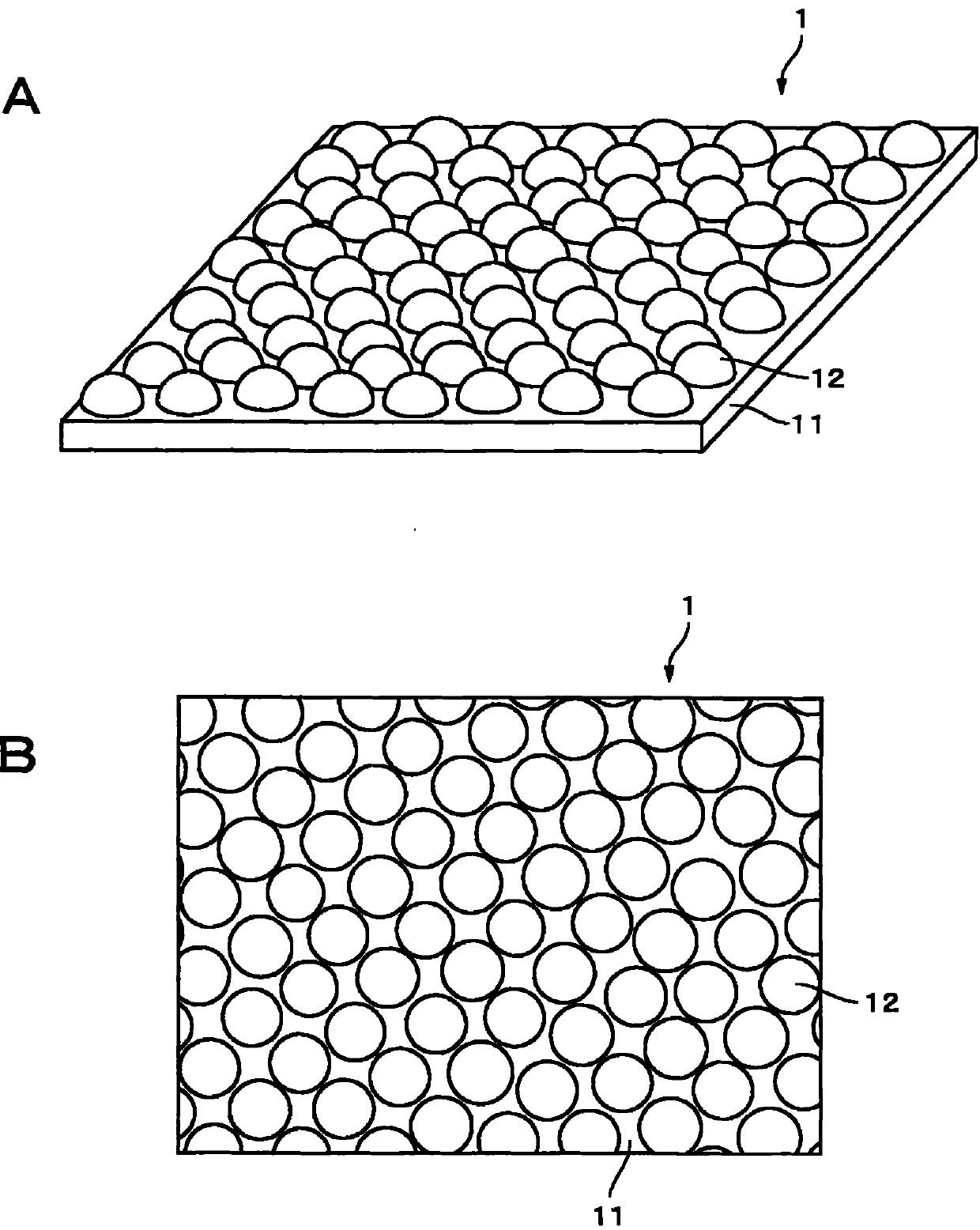

[0044] figure 1 A is an enlarged partial perspective view showing the diffusion sheet according to the first embodiment of the present invention. figure 1 B is an enlarged partial plan view showing the diffusion sheet according to the first embodiment of the present invention. Such as figure 1 A. figure 1 As shown in B, the diffusion sheet 1 includes a base 11 having two main surfaces (a first main surface and a second main surface) and a convex structure 12 formed on one of the two main surfaces of the base 11 . The diffusion sheet 1 is provided with a function of diffusing or concentrating light at the interface of the structure body 12 .

[0045] (substrate)

[0046] As the substrate 11, for example, a transparent sheet or the like can be used. Sheets are ...

no. 2 approach

[0092] [Structure of Liquid Crystal Display Device]

[0093] (first configuration example)

[0094] Figure 5 A is a schematic diagram illustrating a first configuration example of a liquid crystal display device according to a second embodiment of the present invention. Such as Figure 5 As shown in A, this liquid crystal display device has a backlight 6 that emits light, and a liquid crystal panel 7 that modulates the light emitted from the backlight 6 temporally and spatially to display an image.

[0095] Hereinafter, the backlight 6 and the liquid crystal panel 7 constituting the liquid crystal display device will be sequentially described.

[0096] (backlight)

[0097] As the backlight 6 , for example, a direct type backlight, an edge type backlight, or a planar light source type backlight can be used. Figure 5 A is an example in which the backlight 6 is a direct type backlight. The backlight 6 includes, for example, a reflection sheet 4 , a light source 5 , a diff...

Embodiment 1

[0131] First, a cylindrical master substrate made of a metal having good thermal conductivity is prepared. Then, a resist layer was formed on the outer peripheral surface of the cylindrical master substrate. A random pattern of circles with a diameter of 70 μm was then generated by computer. Next, based on the generated pattern, the resist layer formed on the outer peripheral surface of the master substrate is exposed with laser light, and the exposed resist layer is then developed. In this way, openings corresponding to the aforementioned generated patterns are formed on the resist layer. Then, using the resist layer in which the openings were formed as a mask, wet etching was performed on the outer peripheral surface of the substrate for mastering. In this way, a roll master in which structures having a partially spherical shape are randomly formed on the outer peripheral surface is obtained. Then, after mounting the roll master on a molding device, a polycarbonate sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com